Page 1

Installation and User Manual for

Model UF424 and UN324

Page 2

UF424 / UN324 Installation and User Manual

To the owner or user: the service manual is intended

to provide you and the maintenance or service

technician with the information needed to install,

startup, clean, maintain and repair this product.

Observe any caution or warning notices. They are

important and provide notice of potential hazards.

Keep this manual for future reference.

If additional technical information is needed, go to

Scotsman’s website, www.scotsman-ice.com to

download a service manual.

Note: This is a commercial product. If service is

needed on a unit in a residence, warranty may be

limited. Use a commercial service company. Locate

one from the Scotsman website: www.Scotsman-ice.

com

Table of Contents

Specications ....................................................................................................................3

Cabinet Drawing ................................................................................................................4

Placement..........................................................................................................................5

Installation: Water and Drain ............................................................................................6

Initial Start up.....................................................................................................................7

Maintenance and Cleaning ................................................................................................8

Basic Troubleshooting .................................................................................................... 10

July 2018

2

Page 3

UF424 / UN324 Installation and User Manual

Specications

This ice maker is designed to be installed indoors, in a controlled environment. Although

it can operate in a wide range of air and water

temperatures, it will provide the best performance

if not subject to extremes.

Air Temperature Limitations

o

• Maximum: 100

F or 38o C

• Minimum: 50o F or 10o C

Water Temperature Limitations

• Maximum: 100o F or 38o C

• Minimum: 40o F or 4.4o C

Water Pressure, Potable

• Maximum: 80 PSI or 5.5 BAR

• Minimum: 20 PSI or 1.3 BAR

Water Pressure, Condenser inlet

• Maximum: 145 PSI or 10 BAR

• Minimum: 20 PSI or 1.3 BAR; can be as low

as 5 PSI or 0.3 BAR if clean and supplied

with 45o F water.

Condenser GPM

• 70oF or 21oC water: 0.25 GPM or 0.95 LPM

• 50o F or 10oC water: 0.15 GPM or 0.57 LPM

Voltage

115 volt models

• Maximum 126 VAC

• Minimum 104 VAC

230 volt models

• Maximum 207 VAC

• Minimum 253 VAC

Water Conductivity:

Minimum:10 micro Siemens/CM

RO water may be supplied to the potable water

system, but if it has less than the above conductivity, the water level sensor will not detect water

and the unit will not make ice.

Deionized water is not recommended due to

it’s potential corrosive nature and any damage

caused by DI water will not be covered by warranty.

Operating the machine outside of any of the

above limitations is considered abuse and any

resulting damage is not covered by warranty and

could cause a complete loss of warranty coverage.

Warranty Information

The warranty statement for this product is provided separately from this manual. Refer to it for

applicable coverage. In general warranty covers

defects in material or workmanship. It does not

cover maintenance, corrections to installations,

or situations when the machine is operated in

circumstances that exceed the limitations printed

above.

Product Information:

The UF424 produces aked ice and the UN324

produces nugget ice. The ice is stored in an

insulated bin with ice level automatically maintained by the control system.

• A back ow preventer may be required by

local plumbing codes.

• Has a 5.5 ft. power cord with NEMA 5-15P

plug.

• Air cooled models ows in the right front and

out the left front and include a cleanable air

lter.

• Legs are provided, thread size is 5/8-11.

• Machine may be installed without legs.

• For available options and kits, see sales

literature.

Electrical

Model

(Volts/Hz/Phase)

UF424A-1A / UN324A-1A 115/60/1 Air 15A

UF424W-1A / UN324W-1A 115/60/1 Water 15A

Condenser

Maximum Fuse Size

October 2017

3

or Breaker

(Amps)

Page 4

UF424 / UN324 Installation and User Manual

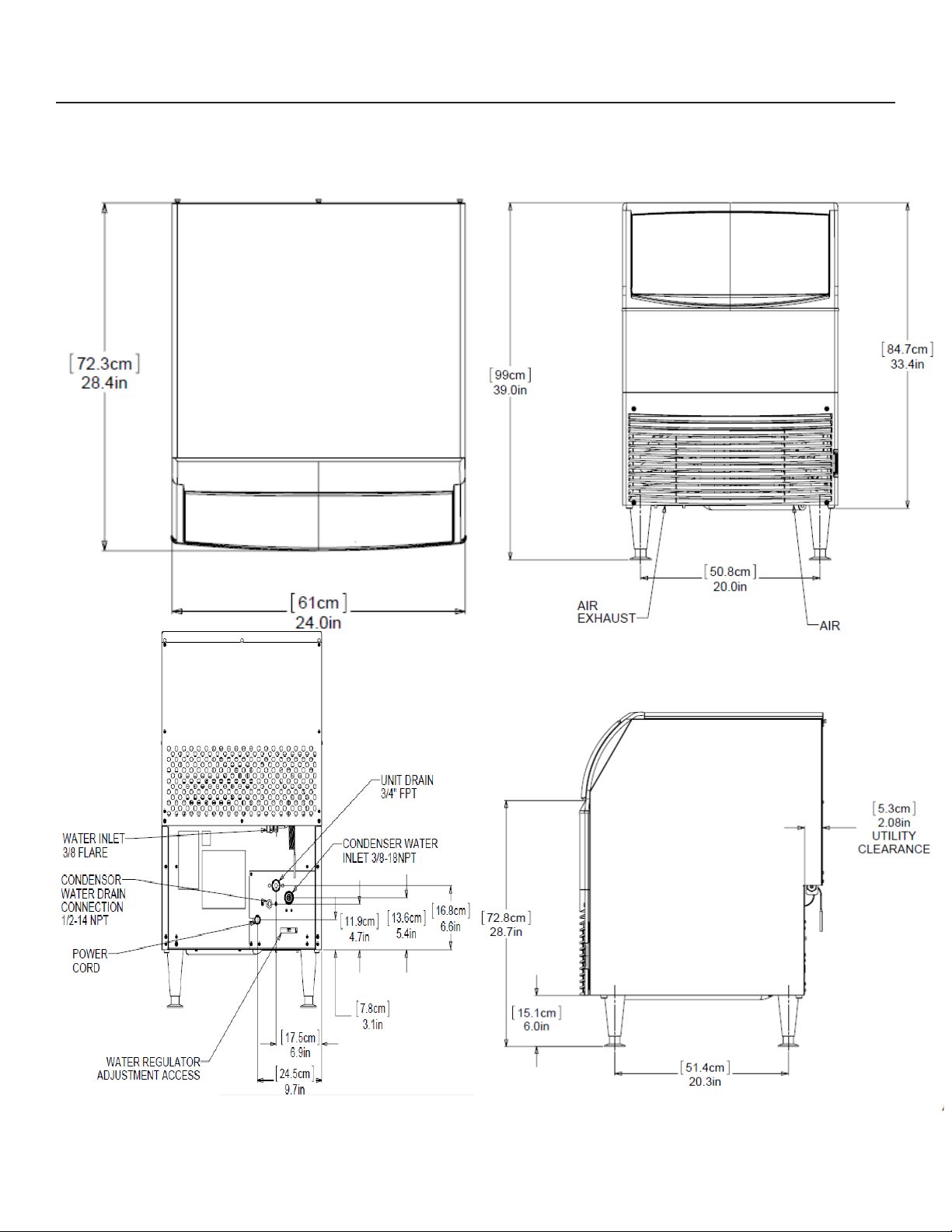

Cabinet Drawing

Scotsman Ice Systems are designed and manufactured with the highest regard for safety and perfor-

mance. They meet or exceed UL563, veried by Intertek, ETL.

August 2017

4

Page 5

UF424 / UN324 Installation and User Manual

Placement

The location of the equipment should be selected

with care. Consideration should be given to allow

adequate space for air cooled models to breathe.

The ice machine is not designed for outdoor

use. It must be installed indoors, in a controlled

environment. The air and water temperatures

must not exceed rated limits.

Scotsman assumes no liability or responsibility of

any kind from products manufactured by Scotsman that have been altered in any way, including

the use of any part and/or other components not

specically approved by Scotsman.

Scotsman reserves the right to make design

changes and/or improvements at any time.

Specications and design are subject to change

without notice.

Airow on air cooled models:

Intake from the right grill

Exhaust from the left grill

Do not install where this air ow is blocked.

3. Remove bolts holding machine to pallet.

4. Install the legs. The legs are to be screwed

into the same holes the shipping bolts were

removed.

5. Remove the protective plastic covering the

panels. The longer it is left on the panel, the

more difcult it will be to remove it.

Spacing:

No additional spacing is required at the top or

sides. However, suggested minimum side clearance for the installation is 1/8’’ or 3.2 mm and

suggested minimum top clearance is 1/4” or 6.4

mm.

The machine may be installed with 0 clearance at

the back. Do not block louvers at the front of the

cabinet.

Pre Installation:

Water supplied to the ice machine should be

ltered. Install a lter system that lters out

suspended solids. It may be necessary to add a

coarse pre-lter ahead of the ne lter.

The power outlet should be located within the

length of the supplied power cord. If legs will be

used, allow space for the total cabinet height.

Air cooled models in a small room will require

ventilation to exhaust heat from the condenser.

The condenser fan and motor will generate some

noise while the machine is running. Noise sensitive areas should consider water cooled equipment or locate the machine where the noise from

ice making will not objectionable.

Unpack

1. Separate the carton from the shipping

pallet

2. Inspect for any hidden shipping damage. If

any is found, retain carton and notify carrier

for potential claim. Shipping damage is not

covered by warranty.

Caution: Tip Over hazard to prevent injury or

damage to the machine please use caution when

lifting the unit. It will easily tips to the rear.

August 2017

Inspect the place where the ice machine is to be

installed. Check for:

• Space for the cabinet

• Water Supply

• Drain Availability

• Electrical Power Supply

DO NOT USE EXTENSION CORDS.

The building drain inlet must be lower than the

drain outlets at the back of the ice machine.

The water supply must have a hand shut off valve

accessible when the unit is installed.

5

Page 6

UF424 / UN324 Installation and User Manual

Installation: Water and Drain

For the Plumber

1. Connect cold potable water to the 3/8’’

male are behind the lower back panel.

A water lter is recommended. Flush the

water line prior to connecting to the ice

machine.

A loop of copper tubing may be used between the

ice machine and the water supply. This will allow

the ice machine to be pulled out from its installed

location without disconnecting water. No back

ow preventer is required in the potable water

line. This is provided by the reservoir seat, which

is above the reservoir water level and cannot be

siphoned

2. Connect a drain tube to the drain tting.

Drain tubes for a water cooled machine

should be run separately. The bin drain

tting is 3/4’’ FPT. And it is plastic. Do not

overheat.

• Drain tube material must be rigid and

meet local code.

• Traps in the bin drain line without vents

ahead of them will cause poor draining

• The bin drain must be vented if there

is a long horizontal run 5 feet or more.

All drains are gravity and must have a

minimum fall of 1/4’’ per foot of horizontal run.

• Maintain the air gap required by local

code between the end of the drain to,

and the building drain receptacle.

• Drain tubing should be insulated to

prevent condensation from forming on

the tubing.

For the Electrician

This is a cord-connected unit and must be on a

separate single phase power supply. Check the

name plate for the correct voltage. The maximum fuse size for this circuit should be 15 A, per

the nameplate use fuses or HACR circuit breaker.

Follow all local codes. This unit must be

grounded. Do not use extension cords and

do not disable or bypass the ground pin on

electrical plug.

After utility connections

1. Level the cabinet, use the leg levelers

on the end of the legs to adjust to cabinet

height. Legs should have been installed

when the unit was unpacked.

2. Wash the bin and hood. If desired, the

interior of the bin could be sanitized.

3. Locate the scoop, wash it and have it

available for use when needed.

3. Water cooled models have a separate 3/8”

FPT tting for condenser water inlet. DO

NOT FILTER water to this connection. The

condenser drain is1/2’’ FPT and does not

need a vent.

August 2017

6

Page 7

UF424 / UN324 Installation and User Manual

Initial Start up

Final check list:

Ice machine is installed indoors with air

and water temperature controlled within

the limitations detailed in this manual

Ice machine is level in its nal position

Electrical disconnect (switch or plug as

required) is within sight of the installed

machine

Electrical circuit is dedicated to this ice

maker

Voltage has been conrmed within the

specications in this manual and the

name plate on the ice maker

Plumbing connections are complete

and tested for leaks

Ice maker is installed with proper clear-

ance, allowing for service and utility

connections

Water shut off valve installed near the

ice maker

cooled models will discharge warm (about

1200F/480C) water out of the condenser

drain. In a few minutes, ice will begin to

fall into the bin.

6. Push the on/off button to switch the machine off. Scoop out any ice in the bin.

7. Create a solution of sanitizer. Mix

4oz/118ml of NuCalgon IMS III and

2.5gal/9.5L of (900F/320C to 1100F/430C)

potable water to create a 200 ppm solution.

8. Sanitize bin by wiping all surface areas

with the sanitizer solution. Allow to air dry.

9. Turn the ice maker on by pressing the on

button.

10. Replace inner panel, front cover and louvered panel.

11. Give the owner/user this manual, instruct

him/her in the operation and maintenance

requirements of the unit. Make sure they

know who to call for service.

Fill out the Customer Evaluation and Warranty

Registration form, and mail it in to Scotsman

or register the unit at Scotsman’s website

(www.scotsman-ice.com).

Start up:

1. Remove louvered front panel.

2. Open bin door and remove the inner panel,

held in place by 4 thumb screws.

3. Open the water valve. Observe that water

enters the water reservoir, lls and then

shuts off. Check for leaks. Repair any leaks

before going further.

4. Switch electrical supply on. Lights on con-

troller will ash and then the power light will

remain on. The code display will show O.

5. Push and release the On/Off button. The

machine will start the ice making process. The code display will show F. Air

cooled models will discharge warm air

out the left side of the front panel. Water

Once started, the ice machine will automatically

make ice until the bin level sensors are blocked.

This will happen once the ice pile up to the sensors. The typical ice level when the machine is off

will be several inches below the door. When ice

level drops from use or meltage, the ice machine

will resume making ice.

Tip: To maximize ice storage scoop the ice to the

sides of the bin.

Noise:

This is a commercial ice machine. It contains a

powerful compressor, heavy duty gear reducer and, if air cooled, a fan motor. It will produce

some noise when it is making ice. Every effort

was made during its design to minimize the

sound level but some is unavoidable.

August 2017

7

Page 8

UF424 / UN324 Installation and User Manual

Maintenance and Cleaning

There are 4 areas of maintenance

1. Ice making system

2. Photo eye ice level control system

3. Bin

4. Air cooled condenser and lters

Ice making System:

Remove Scale

1. Remove front panel.

2. Turn the machine off by pressing the on /

off button.

3. Empty the ice from the storage bin

4. Remove the inner panel using the 4 thumb

screws.

5. Remove the top cover from the reservoir.

6. Shut water supply off at the reservoir by

turning the knob counterclockwise.

7. Locate the evaporator drain in the ice

machine compartment. Unplug it and drain

the evaporator.

8. Replug the drain.

9. Mix a solution of 1.5qt/1.4L of warm water

(900F/320C to 1100F/430C) and 4 ounces

of Scotsman Clear 1 Ice Machine Scale

Remover.

10. Pour the cleaning solution into the reser-

voir until it is full (a squirt bottle may be

necessary to ll reservoir with cleaning

solution).

11. Push the clean button. the machine will

operate the auger motor for approximately

20 minutes. Then it will start making ice

with the cleaning solution.

12. Add remaining cleaning solution to the

reservoir as ice is being made for the next

20 minutes. After the full 40 minutes (steps

11 & 12) the unit turn off.

13. Drain the solution from the reservoir by

removing the plug. Once drained, replace

the plug.

14. Pour clean water into the bin to melt any

ice produced during the cleaning cycle.

15. Mix a solution of 4oz/118ml of Scotsman

Clear 1 ice machine scale remover and

16oz/473ml of potable water. Use this

scale remover solution for the water reservoir cover, ice discharge chutes, the stor-

age bin and the inner front cover.

Sanitize Water System

16. Create a solution of sanitizer. Mix

4oz/118ml of NuCalgon IMS III and

2.5gal/9.5L of (900F/320C to 1100F/430C )

potable water to create a 200 ppm solution.

17. Pour the sanitizing solution into the reservoir until it is full and wait 2 minutes.

18. Turn on the water supply and press the

ON /Off button to turn the ice machine on

19. Operate the machine for at least 15 minutes.

20. Drain the solution from the system by pulling the reservoir plug from the drain hose.

Return plug when drained.

Photo Eye ice level control

1. Mix solution of 4 ounces of Clear 1 Ice

Machine Scale Remover and 1.5qt/1.4L of

900F/320C to 1100F/430C water.

2. Remove sensors from inner cover by removing the white c-clip .

3. Use cotton swab and cleaning solution to

thoroughly clean photo sensors.

4. Rinse sensors with clean water.

5. Reinstall sensors in inner panel.

Ice machine cleaner contains

acids. Acids can cause burns.

If concentrated cleaner comes

in contact with skin, ush with

water. If swallowed, do NOT

induce vomiting. Give large

amounts of water or milk. Call

physician immediately. Keep

out of the reach of children.

August 2017

8

Page 9

UF424 / UN324 Installation and User Manual

Bin

1. Use the same cleaning mixture to thoroughly clean bin surfaces.

2. Rinse with clean water.

3. Use sanitizer mix on all bin surface areas

and areas that may contact the ice.

4. Rinse with clean water.

Filters and Air Cooled Condenser

The air lter located on the lower front grill will

capture airborne dust during operation. As the

dirt builds up, it begins to restrict air ow and

causes the refrigeration system to work less efciently. Clean the air lter regularly.

1. Remove the lter by sliding it to the right

until it is clear of the ice machine.

2. Remove dust and dirt by washing the lter

in a utility sink.

3. Reinstall lter in the ice machine.

Condenser

The condenser ns require semi annual cleaning.

Use caution to prevent damage to the condenser

ns.

1. Lightly brush dust from the condenser.

2. Use a vacuum to thoroughly clean the

condenser.

August 2017

9

Page 10

UF424 / UN324 Installation and User Manual

Basic Troubleshooting

Troubleshooting

Symptom Possible Cause Probable Correction

No ice in bin Unit in off mode or off on

error code.

No Power to unit Check for the power light on the controller. If not

Auger motor not operating Open windings. Check motor windings and replace

Compressor not operating Contactor coil is open, check and replace if needed.

Compressor operating,

auger turning, no ice is

made

Excessive noise Tubing contact Check for tubes rattling and panels not tight

Fan blade out of balance Replace fan blade

Compressor noisy Replace compressor

Moaning noise when

making ice

Slow or Low production Condenser is dirty Check and clean condenser

Water seal being

compressed

Room and/or Water

Temperature too high

Restricted air ow to unit Check and remove air ow restrictions

Remove front panel and check controller code

display. Push ON/OFF button to reset

illuminated restore power.

if open.

Gear reducer seized, replace gear reducer.

Auger bearings seized, replace bearings and seal

No power to auger motor, Auger light is ON.

Replace controller.

Code 2 in controller. Check that sensor rotates with

motor and isn’t loose. Tighten screw if loose.

Code 1 in controller, replace auger motor.

Compressor hot and overheated, check start relay

and start capacitor

No power to compressor or contactor coil.

Compressor light is ON. Replace controller.

Compressor at room temperature, will not start.

Check windings. If open, replace compressor. If not

open, check/replace start relay and start capacitor.

Check refrigeration system, TXV may be set to too

much superheat or the system is low on refrigerant.

Gear reducer bearing failure, replace gear reducer

Maximum production will be achieved at 70°F / 21°C

air and 50° / 10°C water

August 2017

10

Page 11

UF424 / UN324 Installation and User Manual

Controller Diagnostics

Code or Light Action Probable Cause Suggested Action

O

F

b

E

C

d

1

2

3

4

Status light is on Unit is in ice making mode Normal, may not be making ice if

Time to Clean light is on Unit has not been cleaned for at

Unit manually switched off If desired, switch unit on.

Freeze mode None, unit is making ice.

Bin sensors sense bin full Check if bin is full.

Corrupted memory Replace controller

Clean mode Continue clean mode

Test mode None, allow unit to nish test

mode.

Auger motor rotated auger

backwards.

Auger motor stalled or operating

slowly

No water in reservoir Restore water. If there is water,

High pressure cut out open Check fan motor on air cooled or

least 6 months

Replace auger motor. Check water

seal area for leaks, replace seal if

leaking.

Clean ice making system and retry.

If unit shuts off again right after a

reset, magnet rotor on motor shaft

may be loose.

is it too pure? Are sensor wires

connected?

water supply on water cooled.

bin is full

Clean unit

Auger light is on Auger motor is active Normal when making ice

Compressor light is on Compressor is active Normal when making ice

August 2017

11

Page 12

SCOTSMAN ICE SYSTEMS

101 Corporate Woods Parkway

Vernon Hills, IL 60061

800-726-8762

17-3627-01 Rev.A

Last Revised July 2018

Loading...

Loading...