Page 1

USER MANUAL

NU100/150/220/300

Part Number 99300403-01 Version: B

Page 2

Page 3

NUUndercounterIceMakerUserManual TableofContents

B1

Table of Contents Page

Preface, ice maker model and serial number introduction Page B2

Overview of the ice maker, electrical and plumbing requirements Page B3-B4

Ice maker size Page B5-B7

Installation of the ice maker Page B8

How the ice maker works Page B9

General operation of the ice maker Page B10

Scheduled maintenance Page B11-B12

Troubleshooting table Page B13-B14

Warranty card Page B15

Page 4

NUUndercounterIceMakerUserManual Preface

B2

Preface

Firstly, thank you for choosing our ice maker,

we sincerely wish you will use our ice maker for

a long time.

Our ice makers are designed by experts in the

industry following certain standards and

manufactured in a fully controlled process. We

believe that our innovative and high quality

products will not cause you any harm as long

as you install and use our machine according to

the manual correctly.

This manual will guide you on how to use our

ice maker correctly, how to avoid the machine

breakdowns and how to achieve its best

performance. Please do not reach into the

compressor or evaporator area with your hand

so you can avoid touching control and safety

devices.

Please read the manual thoroughly, especial

the warnings and notices, the machine model

and serial number need to be provided when

you contact any service provider.

Delivery

Please check the following items when the unit

is delivered:

Whether the packing and exterior of the ice

maker is intact.

Whether the ice maker model is the same

as your order.

Whether the components are in good

condition and whether the accessories and

documents in the storage bin are complete.

Whether the interior of the ice maker is

undamaged.

If there is serious damage or it lacks parts,

please inform your carrier and dealer

immediately. What is stated in the manual is

general; there could be a slight difference

between your unit and the machine supplied.

The copyright for the contents of the manual

belongs to the manufacturer; please don’t

duplicate the manual without the

manufacturer’s written approval. Scotsman will

improve the product continuously and reserves

the right to change the product without further

notice.

Transportation

Please use a forklift with a fork thickness of

less than 40mm to handle the ice maker.

Warranty

Scotsman Ice Systems (Shanghai) Co., Ltd. is

responsible for the warranty of the ice maker;

please refer to the warranty card for more

details.

If the machine is in need of replacement

components or parts, we require you to use

Scotsman Shanghai company exclusive parts,

otherwise the warranty becomes invalid.

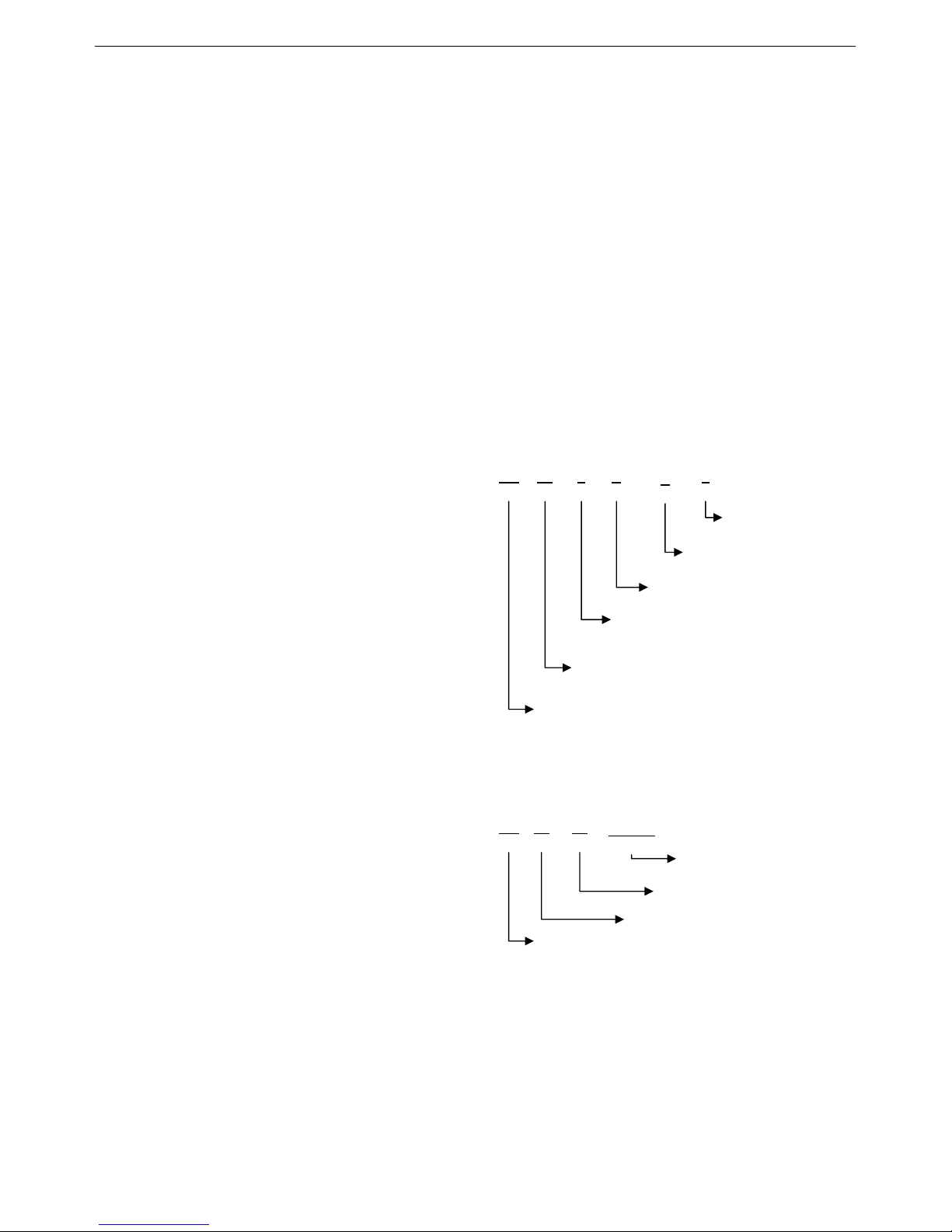

Ice maker model and serial number

Ice maker model

Example:NU150HA2

Serial number

The serial number includes 12 digits; the first

two letters are the series name, the next two

numbers refer to the year the machine was

manufactured, then the two digit month codes,

the final six digits are the serial identifier.

NU 14 06

000001

Serial identifier

Month

Year

Series name

NU 15 0 H

A

2

Design change number

A=Air Cooled

W=Water Cooled

H=Half Cube; F=Full Cube

Power

0 = 220V 50Hz;

24h Ice Capacity

(21

℃

Air/10 ℃ Water)

*

=

Series Name

Page 5

NUUndercounterIceMakerUserManual Summary

B3

Summary

The NU100/150/220/300 commercial ice maker

in this manual is electronically controlled; it is

equipped with an advanced and unique

electronic control system, which can control the

operation of the ice maker automatically. When

the storage bin is full of ice, the ice maker will

stop working automatically and restart working

again when the bin is no longer full.

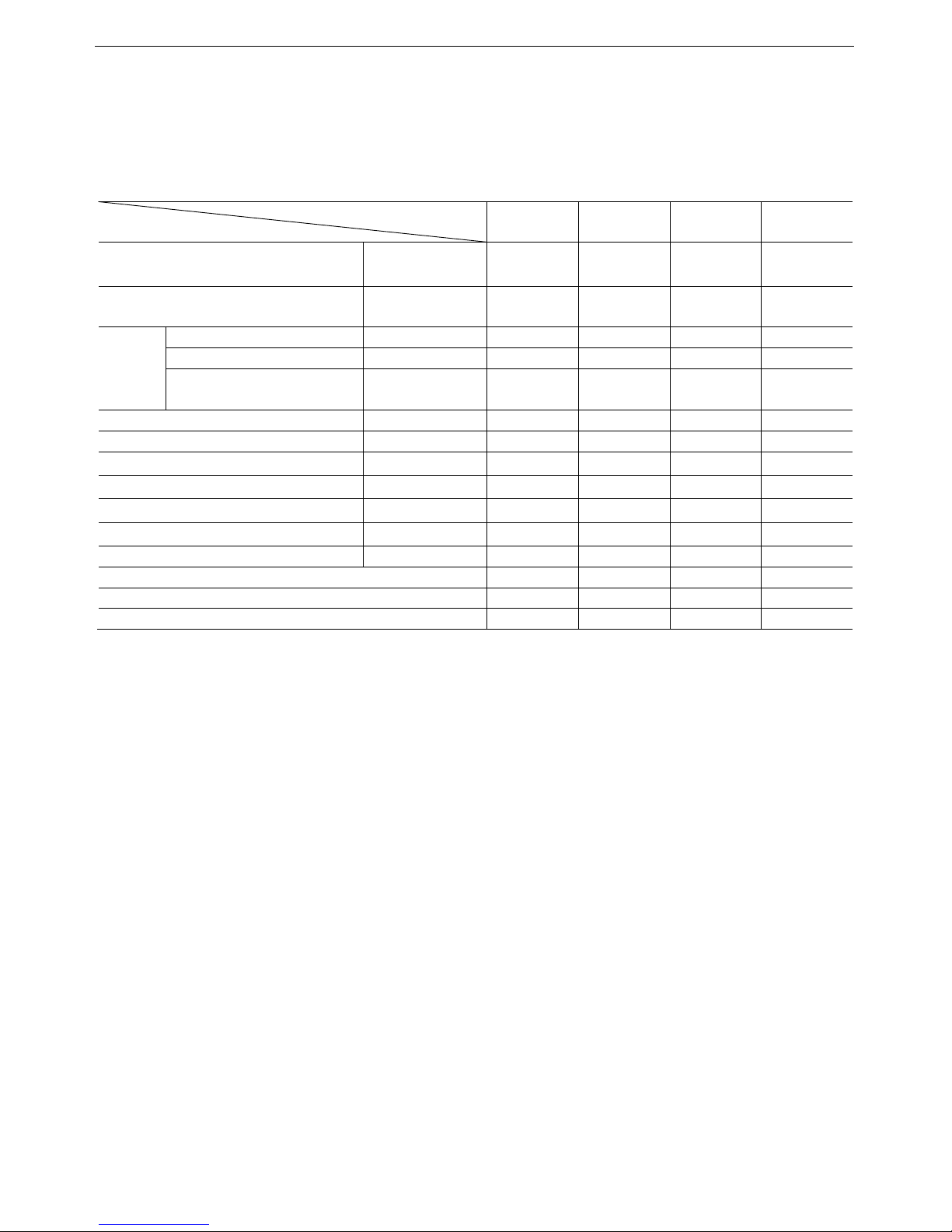

Model

Item

NU100 NU150 NU220 NU300

Capacity

(24 hours) ①

[kg]

45 68 100 132

Power

[V/Hz/

ph]

220/50/

1

220/50/1

220/50/1 220/50/1

(Size)

(width) mm

600 600 650 650

(depth) mm

610 610 690 690

(height with short foot)

(height with high foot)

mm

770

875

770

875

870

976

898

1004

Power cord [Ø mm2]

1.5 1.5 1.5 1.5

Power input # [W]

900 1000 1200 1500

Power consumption ①

[KWh/100lbs]

8 5.6 5.9 6.5

Power consumption ②

[KWh/100lbs]

12.6 8.5 8.5 9

Water consumption ①

[Gal/100lbs]

32 20 19 20

Water consumption ②

[Gal/100lbs]

32 20 19 20

Net weight [kg]

50 50 62 65

Cooling type

Air Air

Air Air

Refrigerant

R404a R404a R404a R404a

Charge

320 g 320 g 360 g 420g

# Maximum working condition

① At 21℃ (70℉) ambient temperature/10℃

(50℉) water temperature

② At 32℃ (90℉) ambient temperature/21℃

(70℉) water temperature

Notes: The manufacture reserves the right to

change the model or specifications of the

product without further notice.

Page 6

NUUndercounterIceMakerUserManual Summary

B4

Safety instruction

In order to ensure the machine works normally

for a long time, before installation, please read

the manual carefully and follow it strictly. The

manufacturer is not responsible for any

damage or bodily injury due to ignoring the

safety instructions. If there is any doubt, please

contact the local dealer.

Installation requirements

Please consider the following items in

determining the installation location:

Power source: the power switch for the ice

maker should be easily reachable, be sure

that the power supply is reliably grounded.

Water supply: the water supply switch

should be easily reachable.

Water drain: be sure that the drain pipe

extending from the unit has a minimum 3

cm drop per meter.

In order to reach its high performance and

ensure durability, please pay attention to the

following items:

The water temperature should be between

5℃ to 35℃.

The water pressure should be between 1

bar to 5 bar.

The power supply should be accordance

with the requirements on the nameplate.

The fuse of the power supply switch should

be a bipolar fuse. The gap between the

bipolar should be more than 3mm.

The working ambient temperature should

be between 10℃ to 40℃.

For the required ventilation, the distance

between the machine and the wall on the

sides and back should be more than 150

mm.

Be sure the machine is leveled correctly.

Don’t hang curtains or pile goods around

the machine to avoid overheating caused

by bad ventilation, be sure there is no heat

source (such as a stove, oven, etc.) around

the machine and the working environment

of the ice maker should not be overly humid。

Note:

In order to avoid any hygiene and health safety issues,

the water for making ice should be potable. If needed,

please install a water filter or water processor.

Page 7

NUUndercounterIceMakerUserManual Size

B5

NU100/150 Size

With Short Foot With High Foot

Page 8

NUUndercounterIceMakerUserManual Size

B6

NU220 Size

Page 9

NUUndercounterIceMakerUserManual Size

B7

NU300 Size

Page 10

NUUndercounterIceMakerUserManual Installation

B8

Installation

Installation steps:

Be sure the ice maker is level (level the

machine with the supplied legs in the

storage bin)

Connect the water supply with the supplied

pipe.

Set the supplied water drain pipe on the

drain outlet; be sure there is a minimum 3

cm drop per meter.

Turn on the water supply switch.

Plug the power source plug into the socket.

Press the power switch button to ‘on’

position.

(Installation chart)

Air Outlet

Air Inlet

10~40 ℃

Important:

The ice maker should be installed by an authorized

maintenance personnel.

Page 11

NUUndercounterIceMakerUserManual HowtheIceMakerWorks

B9

How the ice maker works

For the NU100/150/220/300 ice maker, the

water for making ice is pumped into the spray

bar by a water pump. After flowing out of the

holes of the spray bar, then it will flow over the

surface of the evaporator plate with a constant

and even speed. On the evaporator plate,

some of the water will turn into ice; the

remaining water will flow into to the water

trough by gravity and will be re-circulated by

the water pump.

Freezing Cycle

The refrigerant gas discharged from the

compressor goes into the condenser, where it

is cooled and condensed into a liquid. The

liquid will flow into the drier filter and then it will

pass through the expansion valve. After that,

the pressure and temperature of the refrigerant

liquid will get much lower.

The refrigerant starts evaporating when it gets

into the serpentine pipes on the back of the

evaporator plate and cools the water flowing

over the front of the evaporator plate.

The refrigerant evaporates in the evaporator;

finally, the liquid changes into vapor and then it

will be pumped into the compressor where the

cycle starts again.

The 30 seconds before the freezing cycle starts

is the pre-cooling period, in this period, the

compressor is working, water pump is not, the

fan is working (controlled by the temperature

sensor on the condenser) and water inlet valve

is working (controlled by the water-level sensor

in the water trough).

The freezing cycle is controlled by the ice

thickness sensor, as long as the sensor

touches the ice for 30 consecutive seconds, the

ice thickness has reached the set point. Then,

the freezing cycle ends. The total length of

freezing cycle depends on the ambient

temperature and ice thickness setting.

Defrosting cycle

As soon as the controller detects the ice

thickness has reached the set point, the

machine will go into the defrosting cycle.

Hot refrigerant gas discharged from the

compressor directly flows into the serpentine

pipes of the evaporator, which bypasses the

defrost valve.

The refrigerant circulating in the serpentine

pipes heats the evaporator plate, which will

cause the ice cubes to melt. The ice cubes will

separate from the evaporator plate, then fall off

and go into the ice chute by gravity, finally

going into the storage bin.

When the ice has been harvested, the defrost

cycle will end. Then, the hot gas valve and

drain valve close (according to the PC board

setting); and the unit goes into its new ice

making cycle.

Page 12

NUUndercounterIceMakerUserManual GeneralOperatingInstruction

B10

General Operating Instruction

Turn on the machine

After the power is switched on, with the three

minute water cleaning procedure ends, the ice

maker will enter into the ice making cycle

automatically; after 20 to 25 minutes, the first

batch of ice will fall into the storage bin.

Before the first ice making cycle, be sure to

sanitize the interior of the storage bin with

sanitizer, then rinse it with clean water.

Stop the machine

There are two buttons on the NU front panel,

the switch on right side is the power switch with

which can switch off the power after you press

the button.

Power Switch Panel

Or you can stop the ice maker by cutting off the

circuit breaker.

Ice thickness adjustment

The ice thickness has been adjusted to the

optimal level before it was shipped out, if you

find that the ice is irregular in your use, you can

check whether the ice thickness sensor is too

close or too far from the evaporator plate, if

needed, adjusts the screw on the sensor

properly to achieve the suitable thickness.

Ice thickness sensor

The buttons on the front panel

(see Fig. Power Switch Panel)

There are two switches on the NU front panel:

the right green switch is the power switch, the

red switch is the cleaning switch.

The lamps on the control box

BMLX—Ice full ZBLX—Freezing

TBLX—Defrosting SWLX—Water Supply

R1LX—Water Shortage

Alarm

R2LX—High Temperature

Alarm

CLLX—Cleaning CLEAN—Clean button

MODE—Mode Button

Control Box Panel

Buttons Instruction

Mode Button Functions

Press the button one time in order, then the

machine enters the next step:

Power on - Water Supply – Pre-Cooling –

Freezing - Defrosting - Ice Bin Full Detecting

The function of the cleaning button

When the power switch is on, the clean button

only activates in the first minute. Hold the clean

button for five seconds, the ice maker will enter

into the cleaning procedure automatically. With

Scotsman special cleanser and sanitizer, the

ice maker can be better cleaned and sanitized.

Alarm lamps failure description:

lamps State Failure Description

BMLX + R1LX On Ice chute failure

ZBLX + R1LX On Ice making delayed more

than five times in a row

R1LX + R2LX On Condenser sensor failure

BMLX + R2LX On Ice thickness sensor

failure

SWLX + R2LX On Water level sensor failure

R1LX On Shortage of water

R2LX On High temperature alarm

R1LX + R2LX Blinks High pressure alarm

TBLX Blinks Ice harvest delayed more

than three times in a row

SWLX Slowly

Blinks

Water temperature sensor

failure

Warning:

Only authorized maintenance people are allowed to

press the MODE button.

Note:

The machine running noise should be under 70dB.

Notes:

If the room temperature is below 15 ℃, the ice making

cycle is shorter (about 10 to 15 minutes).

If the room temperature is over 30 ℃, the ice making

cycle is longer (about 15 to 30 minutes).

Page 13

NUUndercounterIceMakerUserManual ScheduledMaintenance

B11

Scheduled Maintenance

In order to prevent bacteria on the ice, please

pay attention to the following items:

Don’t store any goods in the storage bin.

Keep the ice scoop clean.

There is an ice scoop holder designed for

holding ice scoop which is located on the

right side of the bin.

Ice Scoop Holder

Keep the storage bin door closed.

When cleaning the floor around the ice

maker. Be sure to prevent the fan motor

from sucking in dust.

In order to avoid any damage to the machine,

please pay attention to the following items:

Don’t cut off the water supply when the

machine is running.

Open or close the door of the storage bin

gently, slamming or hitting the door is

prohibited.

In order to avoid bad ventilation or

worsening the sanitation, please don’t pile

any goods on the top or around the

machine.

Clean and maintenance

Clean or replace the air filter

The NU series air cooled ice makers are

equipped with an air inlet filter. As the ice maker

runs, dust will be sucked into the machine

through the filter, thus excessive dust cuts

down the air volume to be sucked in as well as

the efficiency of the ice maker.

In order to enable the ice maker to work

efficiently, be sure to clean the air filter monthly.

If the filter is damaged, call the Scotsman

service agent to replace it.

Air filter

Monthly inspection

If the ice cubes are abnormal, please take the

spray bar down from over the evaporator; put it

in warm water diluted with a neutral de-scaling

solvent to wash its surface and spiracles, and

then rinse it with clean water.

For ensuring that the ice maker is clean, please

wipe the interior of the storage bin with a

cleanser diluted in the lightly warm water, then

sterilize it with liquid sanitizer, finally rinse it

with clean water.

Use a soft cloth and cleanser specially made

for stainless steel to clean the panels of the ice

maker.

Cleaning and sanitizing the water system

The sanitation of the water system is very

important; it needs to be washed at least twice

a year, call an authorized service agent to do it.

We suggest you use the cleanser/sanitizer

made specially for ice makers to deal with scale

and mineral sediments

Automatically clean/rinse:

In the first minute after the power is turned on, press

the ‘clean’ button on front panel and hold it for five

seconds, then the ice maker enters into the

‘wash/rinse’ procedure automatically (the whole

process will take about 40 minutes). During the

process, the ‘CLLX’ light blinks quickly, at the end of

the process, the ‘CLLX’ light blinks slowly, restart

power or press the ‘MODE’ button and hold for more

than five seconds, then the ice maker will enter into

the normal ice making cycle.

Notes:

Don’t disassemble any fastened panels.

Call the authorized service agent to maintain and

clean your ice maker.

Be sure to lift the ice maker when you move the ice

maker to avoid damage to the supporting legs.

Don’t push or pull the ice maker.

Warning:

Be sure to cut off the power and water supply

before cleaning or servicing the ice maker.

Keep your hands completely dry.

Page 14

NUUndercounterIceMakerUserManual ScheduledMaintenance

B12

Troubleshooting analysis (inspection items to

do before calling the service provider)

Ice maker out of work (all the lamps are not

on)

Whether the manual switch is ‘on’?

Whether the fuse in the fuse box has

blown?

Whether the power plug is plugged in?

Whether the power switch on the front

panel is “on”?

Low ice capacity or low efficiency

Whether the water supply switch has been

switched on?

Whether the water temperature or ambient

temperature is too high?

Whether there is heat source near the

machine or bad ventilation around the

machine?

Ice cube shape is poor

Whether the water supply is sufficient?

Whether the air filter is blocked?

Whether some spiracles on the spray bar

are blocked?

Important:

The machine should be maintained by authorized

maintenance people.

If a wire is damaged, in order to avoid danger, call

authorized maintenance people to replace it.

Page 15

NUUndercounterIceMakerUserManual TroubleshootingTable

B13

Symptom Possible Cause Suggested Correction

Unit does not

run

Abnormal power supply Check the power supply voltage, if no voltage,

check the power line

Check the power supply voltage, if it is low, contact

the power company

The fuse on the PC board

blew

Replace the fuse. If the fuse is breaks again, check

the cause.

The machine stopped

abnormally (such as high

temperature protection)

Press the MODE key on the PC board to reset, the

machine starts or starts automatically two hours

later or unplug the power plug and plug it again

three minutes later, the machine starts.

Bin full Adjust the position of the ice cubes in the storage

bin to let the ice chute reset and then start the

machine

Abnormal water supply See the processing method for water-shortage

Compressor

cycles

intermittently

Low voltage Check circuit for overloading

Non-condensable gas in

system

Check the power supply voltage, if it is low, contact

the power company

Purge the system and re-charge

Compressor starting device

has loose wires

Check for loose wires in the starting device

Mechanical problem Replace compressor

Cubes too

small

Ice making cycle too short Check the distance between the ice thickness

sensor and the evaporator plate

Expansion valve partially

blocked

Check the expansion valve, if damaged, replace

it

Moisture in the system Purge the system and re-charge

Shortage of water See the processing method for water-shortage

Shortage of refrigerant

Check for leaks in the refrigeration system and

recharge

Cloudy ice

Shortage of water See the processing method for water- shortage

Dirty water supply Use water softener or a water filter

Accumulated impurities Cleaning according to the procedure

Water temperature sensor

failure

Replace the water temperature sensor

Shortage of

water

Water spilling out through ice

chute

Tighten the screws on the clamping plate of the

PVC pipe to reduce the water flow

Water inlet solenoid valve not

opening

Check, if damaged, replace it

Water leak in water tank

Check for the leaking points and repair them.

If necessary, replace it.

Water inlet valve blocked Replace the water inlet valve

Water drain valve leaking Check, if damaged, replace it

Page 16

NUUndercounterIceMakerUserManual TroubleshootingTable

B14

Symptom Possible Cause Suggested Correction

Irregular cube

sizes and some

cloudy cubes

Spray bar blocked Clean the spray bar

Shortage of water

See the processing method for

water-shortage

Machine not level Level the machine as required

Water temperature sensor failure Replace the water temperature sensor

Decreased ice

capacity

Inefficient compressor Replace the compressor

Water valve leak Check, if damaged, replace it

Spray pipe blocked Check, if blocked, clean it.

Non-condensable gas in system Vacuum and re-charge

Bad ventilation Improve ventilation or put the machine

in a good ventilation place

Too much dust on air filter Clean the air filter, if needed, replace it.

Expansion valve partially blocked Check, if damaged, replace it

Defrost valve leaking Change charged volume, release

slowly

Refrigerant over charge

Shortage of refrigerant

Vacuum and re-charge according to the

nameplate

Discharge pressure too high or

too low

Check for the cause of the incorrect

discharge pressure

Defrost valve blocked or not

open

Check, if damaged, replace it

Unit doesn’t defrost

or no ice

PC board failure

Check, if damaged, replace it

Defrost valve not opening Check, if damaged, replace it

Water inlet solenoid valve not

opening

Check, if damaged, replace it

Incorrect discharge

pressure

Inoperative condenser sensor Check, if damaged, replace it

Too much or too little refrigerant,

or non-refrigerant gas was

charged

Check whether the refrigeration system

is leaking

Vacuum and re-charge according to the

nameplate and the requirements from

Scotsman

Inoperative PC board Check, if damaged, replace it

Excessive water at

unit base

Water system leak

Check for leaking points and repair

them. If necessary, replace it.

Page 17

B15

WARRANTY CARD

Brand Model Serial No.

Name Dealer

Address Date of Purchase

Notes:

Please keep this card for warranty protection of your system.

WARRANTY CARD (DUPLICATE)

Brand Model Serial No.

Name Dealer

Address Date of Purchase

Notes:

Please return this card to factory for warranty protection.

Customer Signature:

Page 18

Notes:

Page 19

Page 20

EUROPE, MIDDLE EAST & AFRICA ASIA PACIFIC

Scotsman Ice Systems (Shanghai) Co., Ltd.

Scotsman Ice s.r.l.

Via Lainate 31

20020 Pogliano Milanese (MI) – ITALY

www.scotsman-ice.it - info@scotsman-ice.it

Tel. +39 02 93960350 - Fax +39 02 93540449

Address:

Room 2505, Building 2, No 20 Xuhong Middle Rd,

Shanghai, China. 200235

Phone:0086-21-61313200

Fax:0086-21-61313330

Hotline:0086-4006300076

E-Mail: sales@scotsman-china.com

Website:www.scotsman-china.com

Scotsman Industries Singapore Pte Ltd

140 Paya Lebar Road Singapore 409015

www.scotsman-ice.it

scotsman@scotsman.com.sg

Tel. +65 6738 5393 - Fax +65 6738 1959

Loading...

Loading...