Scotsman MXG Series,MXG 438 A/W,MXG 638 A/W,MXG 938 A/W,MXG 328 A/W,MXG 428 A/W Technical Service Training

TECHNICAL SERVICE TRAINING

Welcome to another Scotsman technical service presentation

This one will cover the electronic MXG series Ice Cube Machines

MXG SERIES

CUBERS

MXG SERIES

MXG 328 A/W

Max. Ice Production = 150 Kg/24h*

* 10/10°C= Air & Water Inlet Temperature

NEW MXG SERIES

MXG 428 A/W

Max. Ice Production = 195 Kg/24h*

* 10/10°C= Air & Water Inlet Temperature

NEW MXG SERIES

MXG 438 A/W

Max. Ice Production = 195 Kg/24h

*10/10°C = Air & Water Inlet Temperature

NEW MXG SERIES

MXG 638 A/W

Max. Ice Production = 340 Kg/24h

*10/10°C = Air & Water Inlet Temperature

NEW MXG SERIES

MXG 938 A/W

Max. Ice Production = 400 Kg/24h

*10/10°C = Air & Water Inlet Temperature

NEW MXG SERIES

TOPICS

On the next slides are shown the following steps by steps

procedures:

• UNPACKING

• INSTALLATION

• START UP AND OPERATIONAL CHECKS

• OPERATING PRINCIPLES and COMPONENTS

• MAINTENANCE

• SERVICE ANALYSIS

NEW MXG SERIES

UNPACKING

NEW MXG SERIES

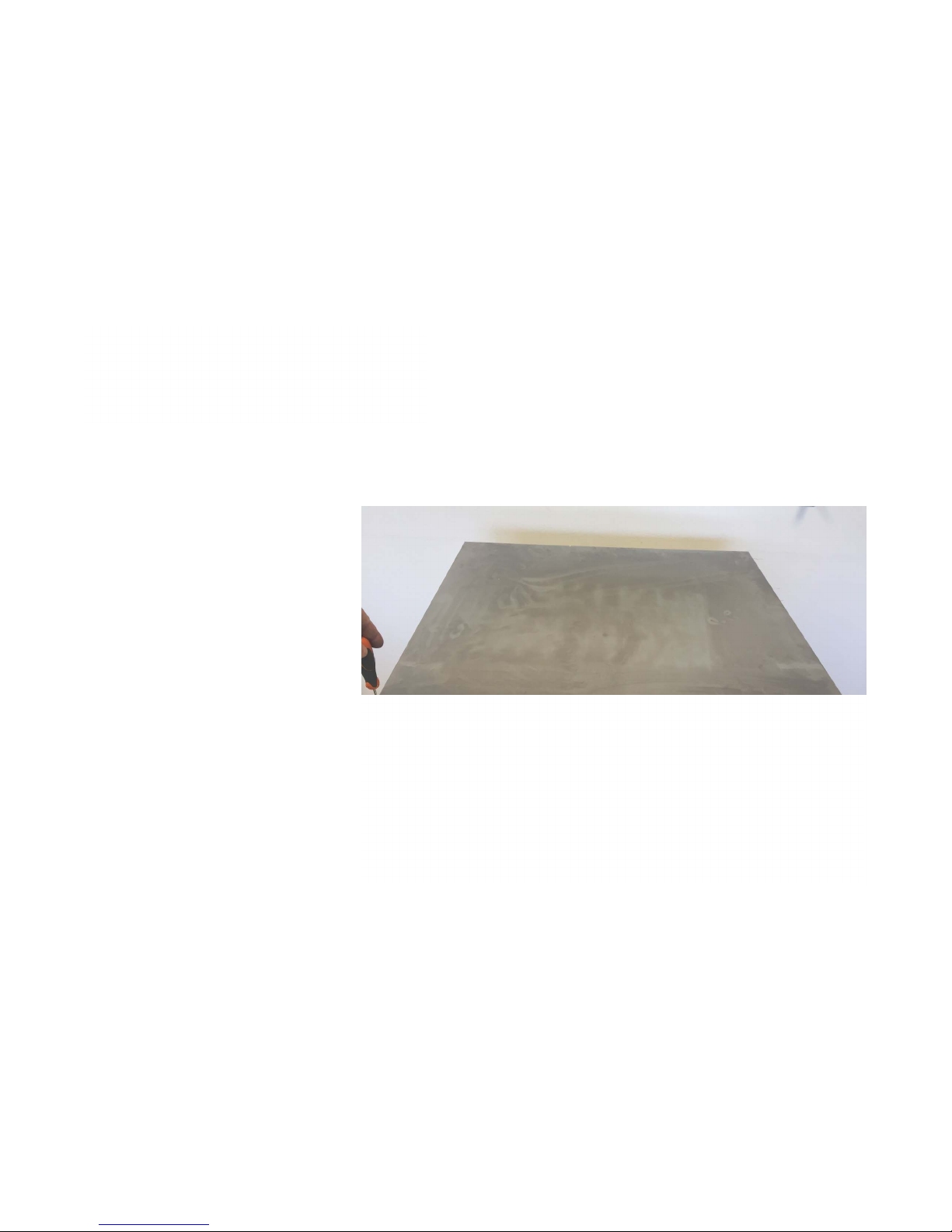

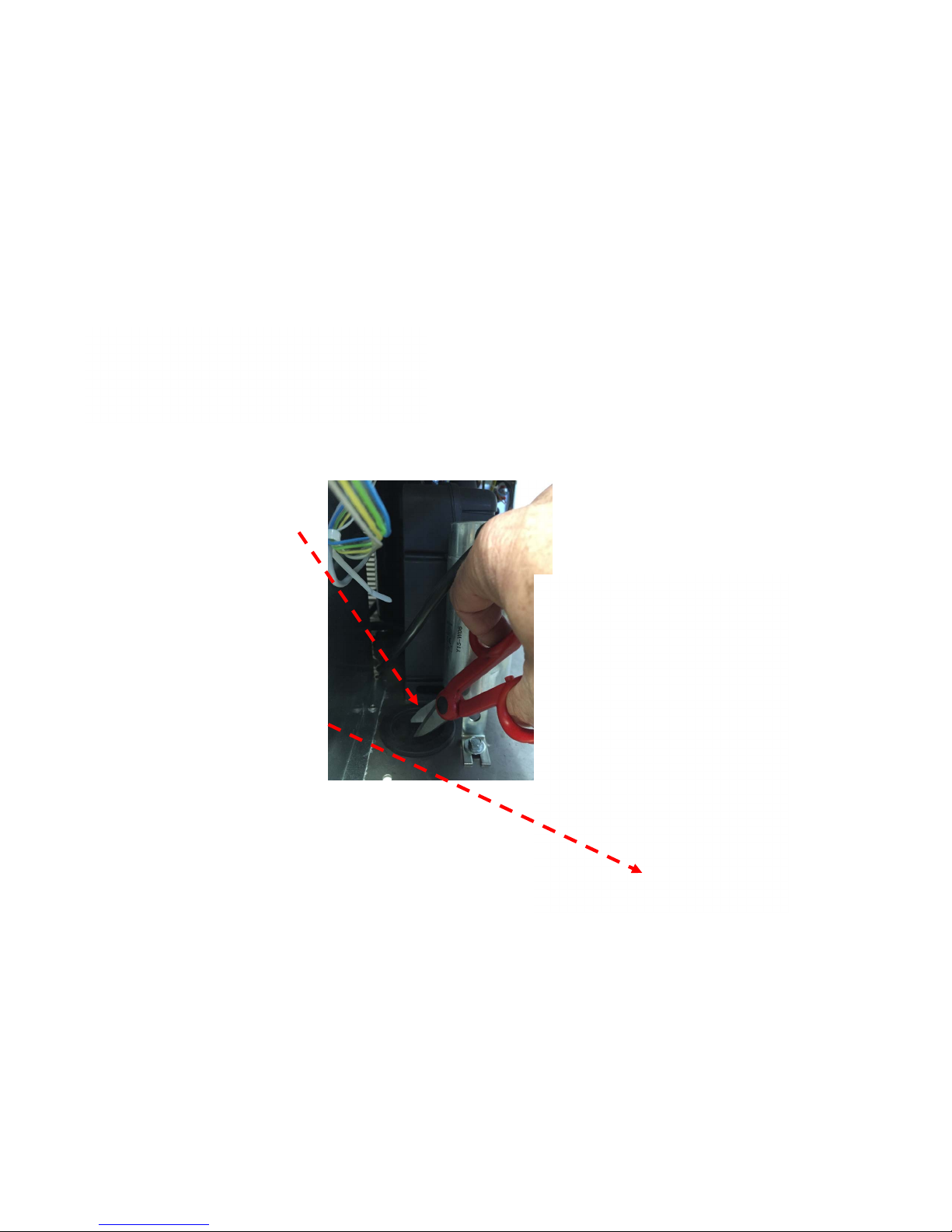

The machines are supplied

in a carton box secured by

two plastic strips to a

wooden base. Check first

the outside conditions of

carton box and wooden base

then cut the two plastic

strips, remove the tape and

then the carton box.

UNPACKING

NEW MXG SERIES

Slip away – remove

plastic strip

UNPACKING

NEW MXG SERIES

Remove front panel

air filter (AC version

only)

UNPACKING

NEW MXG SERIES

Remove front panel

screws and the

panel

UNPACKING

NEW MXG SERIES

Remove top panel

screws and the

panel

UNPACKING

NEW MXG SERIES

Remove I/R bracket

installation

instruction and

water inlet and

outlet hoses

UNPACKING

NEW MXG SERIES

Remove side

panels screws and

the panels

UNPACKING

NEW MXG SERIES

UNPACKING

NEW MXG SERIES

…..unscrew

the unit

frame from

the wooden

base….

The Modular Cuber machines

require for the installation the

use of a companion storage

bin to store the ice produced.

Perfect “matching” storage

been are:

SB 193 – 322 for MXG 328-428

SB 393 – 530 for MXG 438-638-938

UNPACKING

NEW MXG SERIES

Due to design reason MXG

series can not be stacked:

• Ice chutes not aligned

• Not enough space for

Service over the bottom unit

top evaporator

• Not possible to remove

bottom unit front panel

UNPACKING

NEW MXG SERIES

INSTALLATION

NEW MXG SERIES

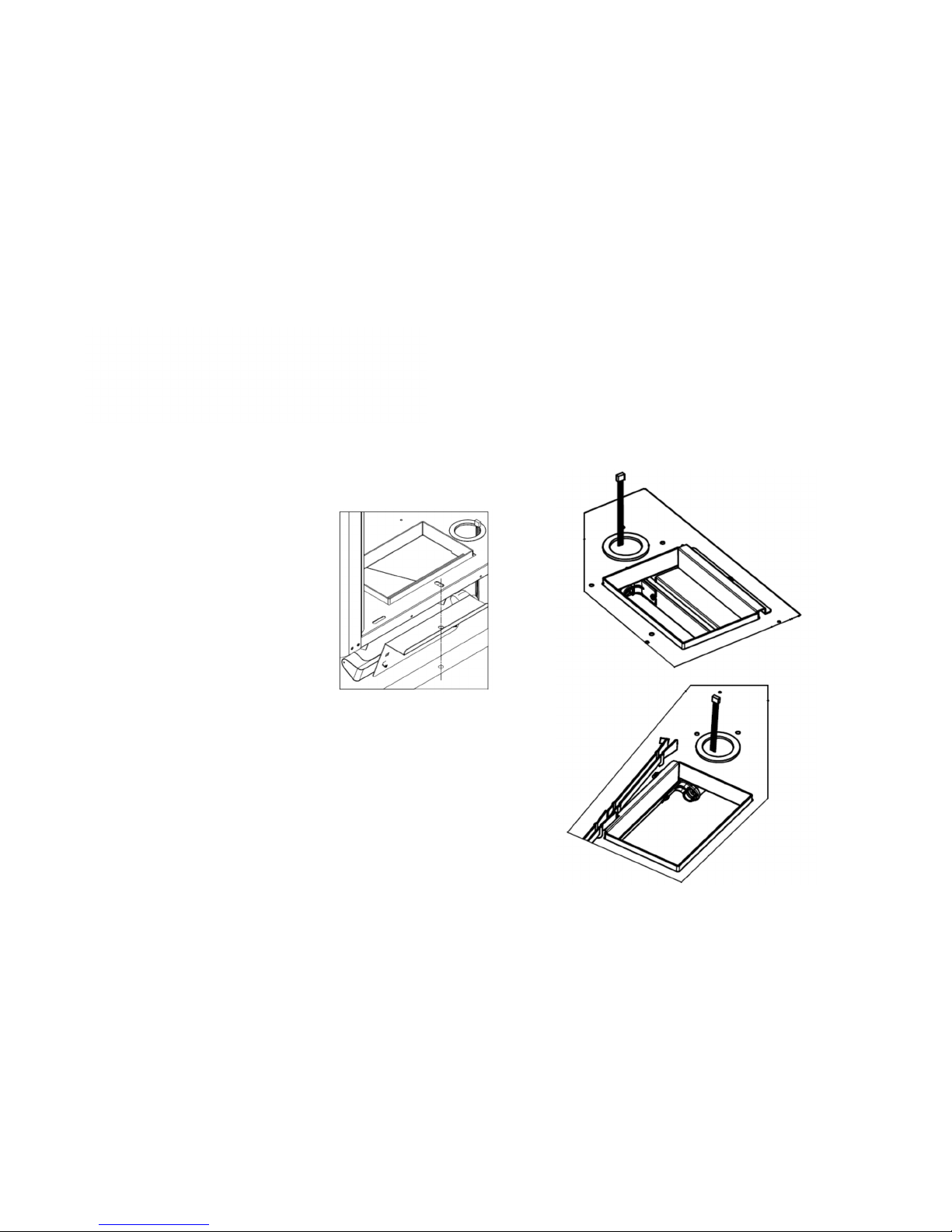

After having installed the

ice maker on top of chosen

bin, remove polystyrene

block form ice chute top

and remove the ice chute.

locate I/R and its bracket,

release the same from

clamps

INSTALLATION

NEW MXG SERIES

Cut the unit base

gasket , pass the

I/R sensor through

the same reaching

the inner bin area.

INSTALLATION

NEW MXG SERIES

Fix the IR

by

supplied

screws to

related

bracket

INSTALLATION

NEW MXG SERIES

Fix IR bracket at

ice chute

discharge area by

stainless steel

screw

INSTALLATION

NEW MXG SERIES

Once installed optical level

sensor, re-install ice chute

previously removed paying

attention to hang the same

to its hook rim point.

INSTALLATION

NEW MXG SERIES

Note different

location

according to

MXG models

INSTALLATION

NEW MXG SERIES

MXG 328-428-438-938

MXG 638

Check the data plate

of the machine

located on the rear

panel for correct

voltage as well as

for the proper

wiring/fuse size.

Remember that all

machines require a

solid earth wire.

INSTALLATION

NEW MXG SERIES

Check for the correct water and ambient conditions that

should be:

• Min. ambient temperature 10ºC (50F)

• Max. ambient temperature 40ºC (100F)

• Min. water temperature 5ºC (40F)

• Max. water temperature 35ºC (90F)

• Min. water pressure 1 bar (14 PSI)

• Max. water pressure 5 bar (70 PSI)

INSTALLATION

NEW MXG SERIES

Adequate space must

be left for proper water

and electrical

connections on the rear

side of the machine. A

minimum clearance of

15 cm on both sides for

best routing air.

INSTALLATION

NEW MXG SERIES

Min. space 15 cm

NEW MXG SERIES

Air

filter

Air

filter

INSTALLATION

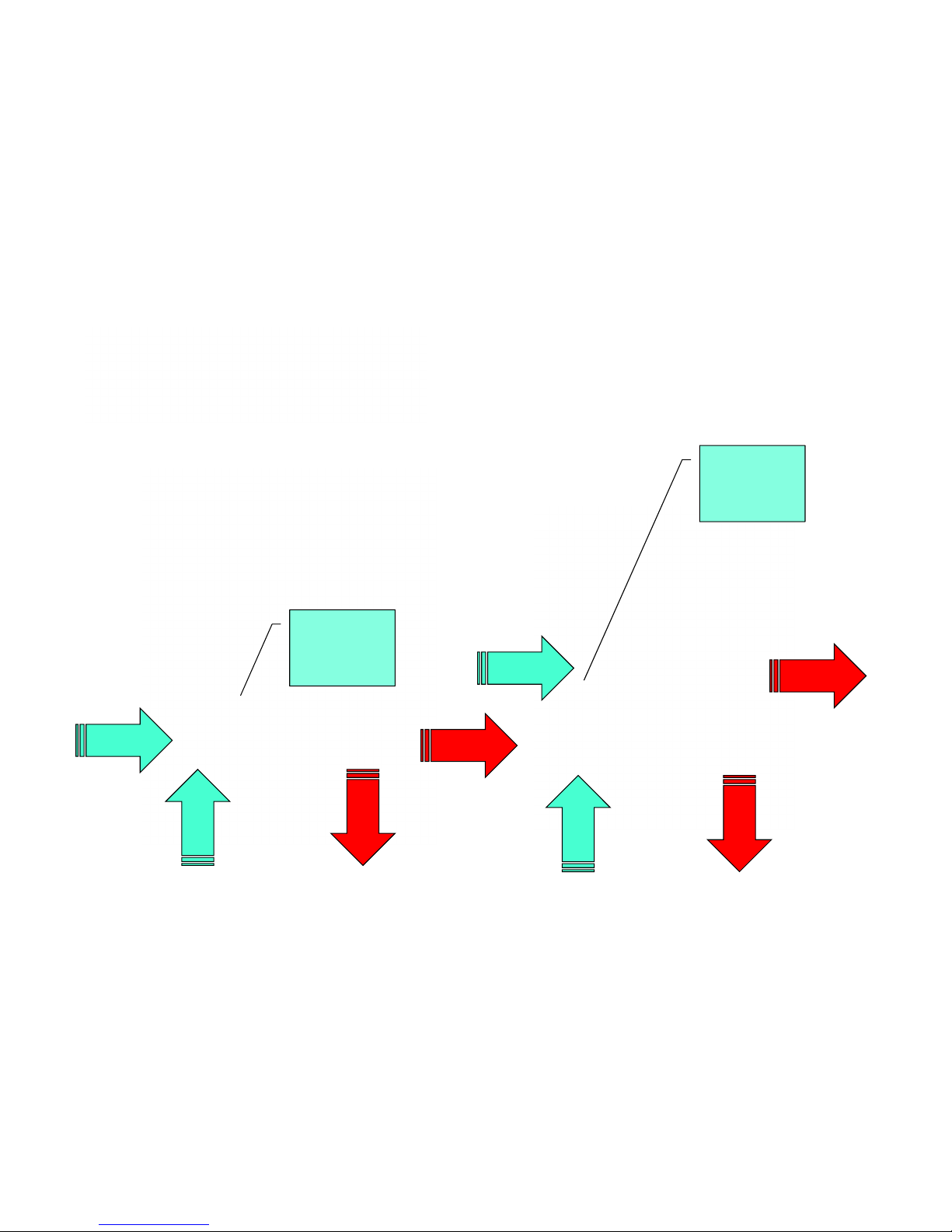

328 – 428 - 438 air flow

NEW MXG SERIES

Air

filter

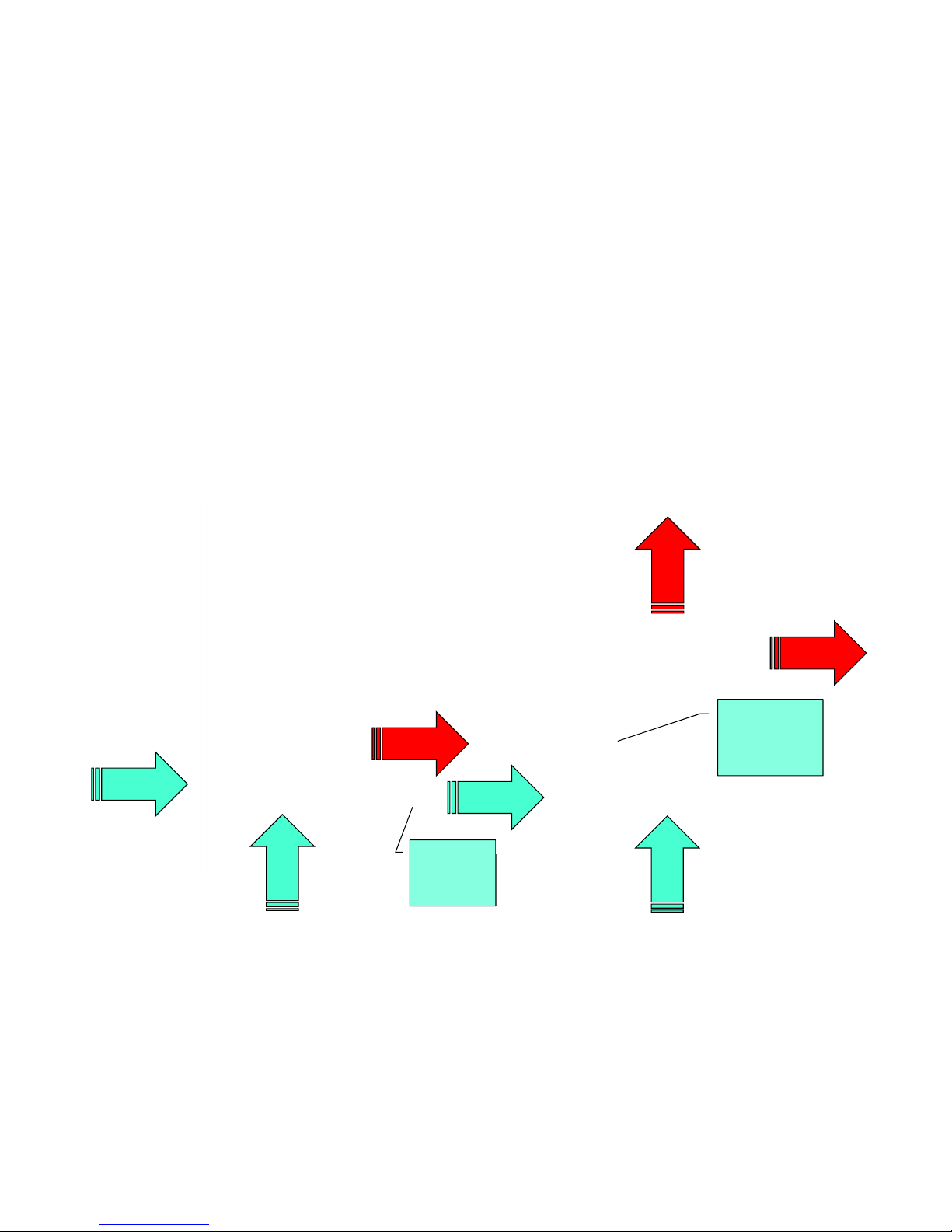

INSTALLATION

638 air flow

Air

filter

Loading...

Loading...