Scotsman MXG Series, MXG 438 A/W, MXG 638 A/W, MXG 938 A/W, MXG 328 A/W Technical Service Training

...Page 1

TECHNICAL SERVICE TRAINING

Welcome to another Scotsman technical service presentation

This one will cover the electronic MXG series Ice Cube Machines

MXG SERIES

CUBERS

MXG SERIES

Page 2

MXG 328 A/W

Max. Ice Production = 150 Kg/24h*

* 10/10°C= Air & Water Inlet Temperature

NEW MXG SERIES

Page 3

MXG 428 A/W

Max. Ice Production = 195 Kg/24h*

* 10/10°C= Air & Water Inlet Temperature

NEW MXG SERIES

Page 4

MXG 438 A/W

Max. Ice Production = 195 Kg/24h

*10/10°C = Air & Water Inlet Temperature

NEW MXG SERIES

Page 5

MXG 638 A/W

Max. Ice Production = 340 Kg/24h

*10/10°C = Air & Water Inlet Temperature

NEW MXG SERIES

Page 6

MXG 938 A/W

Max. Ice Production = 400 Kg/24h

*10/10°C = Air & Water Inlet Temperature

NEW MXG SERIES

Page 7

TOPICS

On the next slides are shown the following steps by steps

procedures:

• UNPACKING

• INSTALLATION

• START UP AND OPERATIONAL CHECKS

• OPERATING PRINCIPLES and COMPONENTS

• MAINTENANCE

• SERVICE ANALYSIS

NEW MXG SERIES

Page 8

UNPACKING

NEW MXG SERIES

Page 9

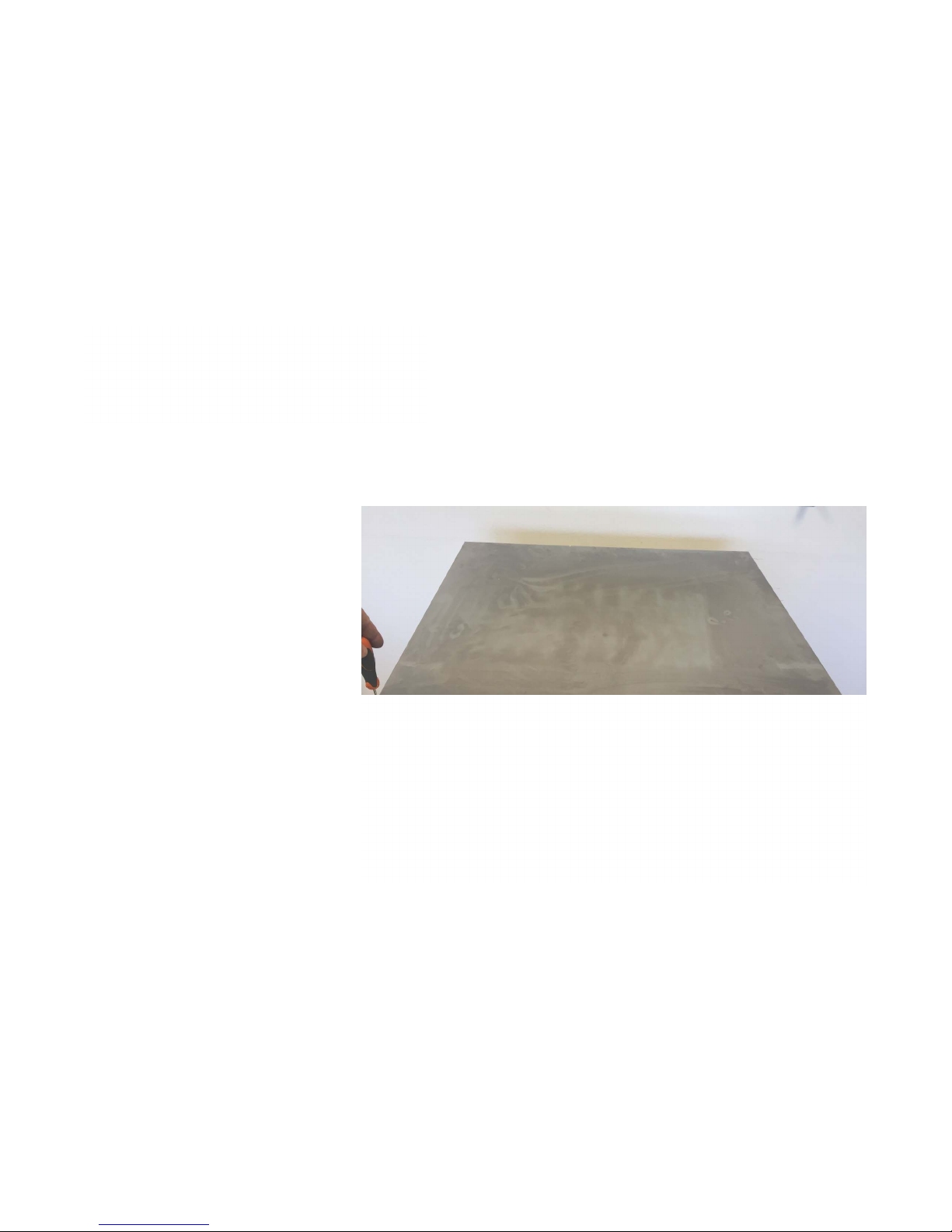

The machines are supplied

in a carton box secured by

two plastic strips to a

wooden base. Check first

the outside conditions of

carton box and wooden base

then cut the two plastic

strips, remove the tape and

then the carton box.

UNPACKING

NEW MXG SERIES

Page 10

Slip away – remove

plastic strip

UNPACKING

NEW MXG SERIES

Page 11

Remove front panel

air filter (AC version

only)

UNPACKING

NEW MXG SERIES

Page 12

Remove front panel

screws and the

panel

UNPACKING

NEW MXG SERIES

Page 13

Remove top panel

screws and the

panel

UNPACKING

NEW MXG SERIES

Page 14

Remove I/R bracket

installation

instruction and

water inlet and

outlet hoses

UNPACKING

NEW MXG SERIES

Page 15

Remove side

panels screws and

the panels

UNPACKING

NEW MXG SERIES

Page 16

UNPACKING

NEW MXG SERIES

…..unscrew

the unit

frame from

the wooden

base….

Page 17

The Modular Cuber machines

require for the installation the

use of a companion storage

bin to store the ice produced.

Perfect “matching” storage

been are:

SB 193 – 322 for MXG 328-428

SB 393 – 530 for MXG 438-638-938

UNPACKING

NEW MXG SERIES

Page 18

Due to design reason MXG

series can not be stacked:

• Ice chutes not aligned

• Not enough space for

Service over the bottom unit

top evaporator

• Not possible to remove

bottom unit front panel

UNPACKING

NEW MXG SERIES

Page 19

INSTALLATION

NEW MXG SERIES

Page 20

After having installed the

ice maker on top of chosen

bin, remove polystyrene

block form ice chute top

and remove the ice chute.

locate I/R and its bracket,

release the same from

clamps

INSTALLATION

NEW MXG SERIES

Page 21

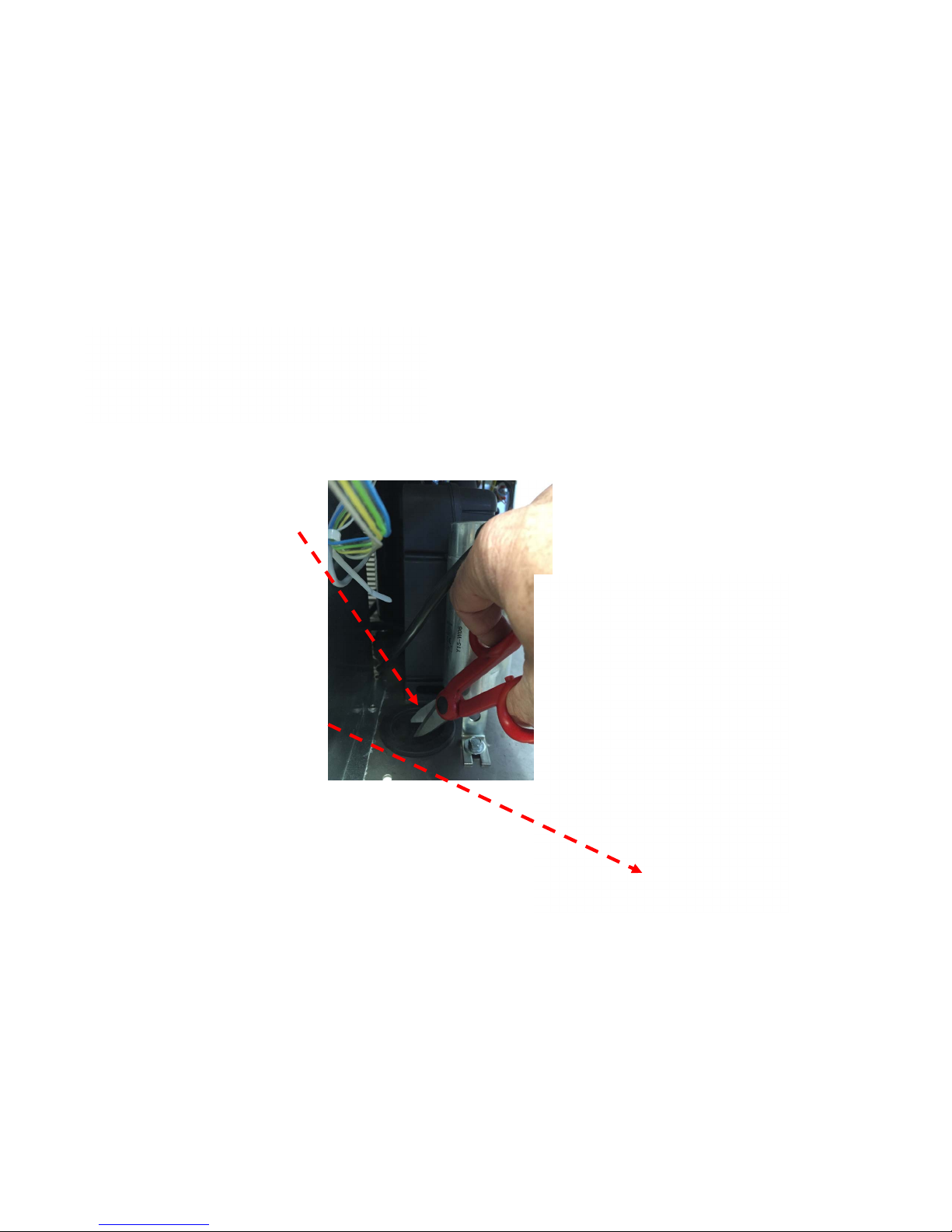

Cut the unit base

gasket , pass the

I/R sensor through

the same reaching

the inner bin area.

INSTALLATION

NEW MXG SERIES

Page 22

Fix the IR

by

supplied

screws to

related

bracket

INSTALLATION

NEW MXG SERIES

Page 23

Fix IR bracket at

ice chute

discharge area by

stainless steel

screw

INSTALLATION

NEW MXG SERIES

Page 24

Once installed optical level

sensor, re-install ice chute

previously removed paying

attention to hang the same

to its hook rim point.

INSTALLATION

NEW MXG SERIES

Page 25

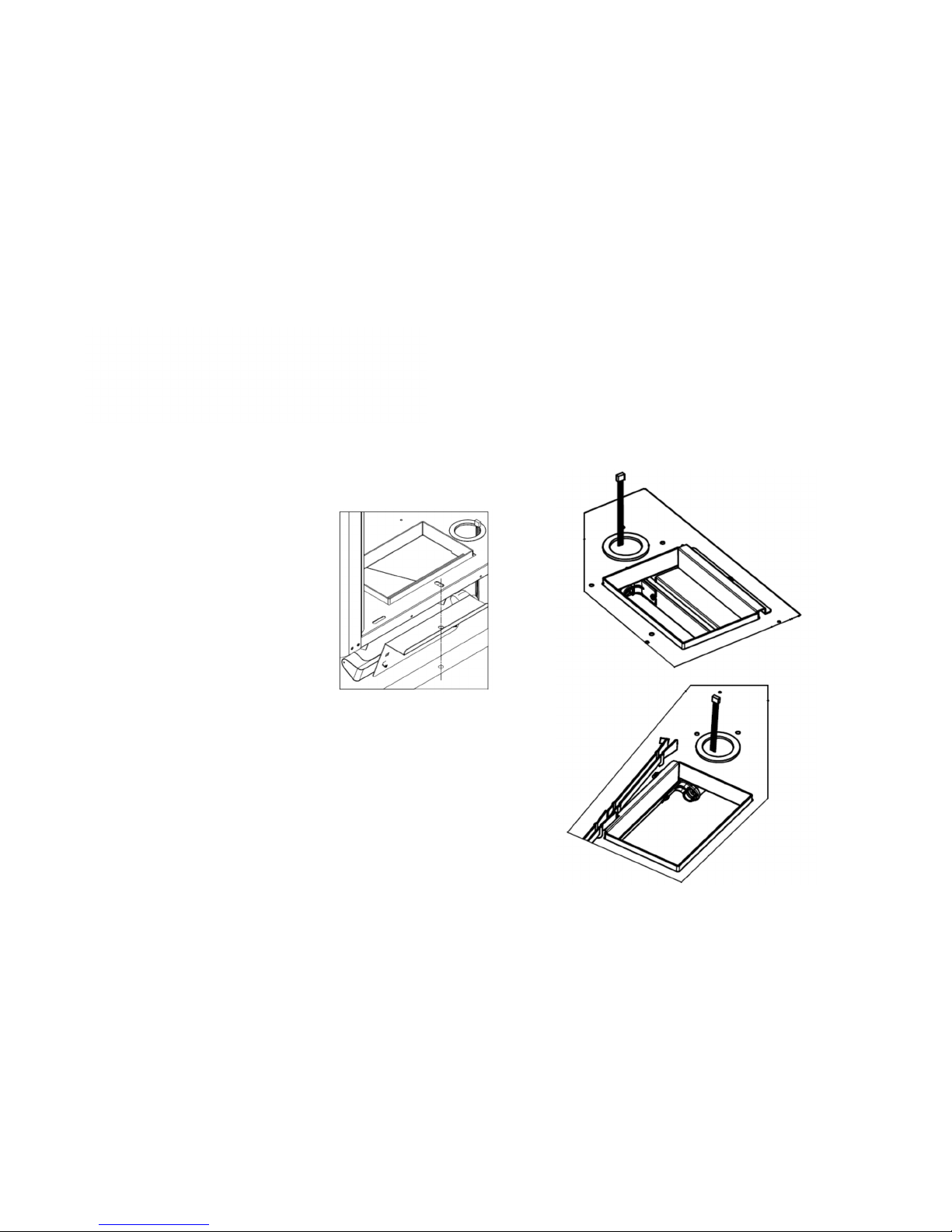

Note different

location

according to

MXG models

INSTALLATION

NEW MXG SERIES

MXG 328-428-438-938

MXG 638

Page 26

Check the data plate

of the machine

located on the rear

panel for correct

voltage as well as

for the proper

wiring/fuse size.

Remember that all

machines require a

solid earth wire.

INSTALLATION

NEW MXG SERIES

Page 27

Check for the correct water and ambient conditions that

should be:

• Min. ambient temperature 10ºC (50F)

• Max. ambient temperature 40ºC (100F)

• Min. water temperature 5ºC (40F)

• Max. water temperature 35ºC (90F)

• Min. water pressure 1 bar (14 PSI)

• Max. water pressure 5 bar (70 PSI)

INSTALLATION

NEW MXG SERIES

Page 28

Adequate space must

be left for proper water

and electrical

connections on the rear

side of the machine. A

minimum clearance of

15 cm on both sides for

best routing air.

INSTALLATION

NEW MXG SERIES

Min. space 15 cm

Page 29

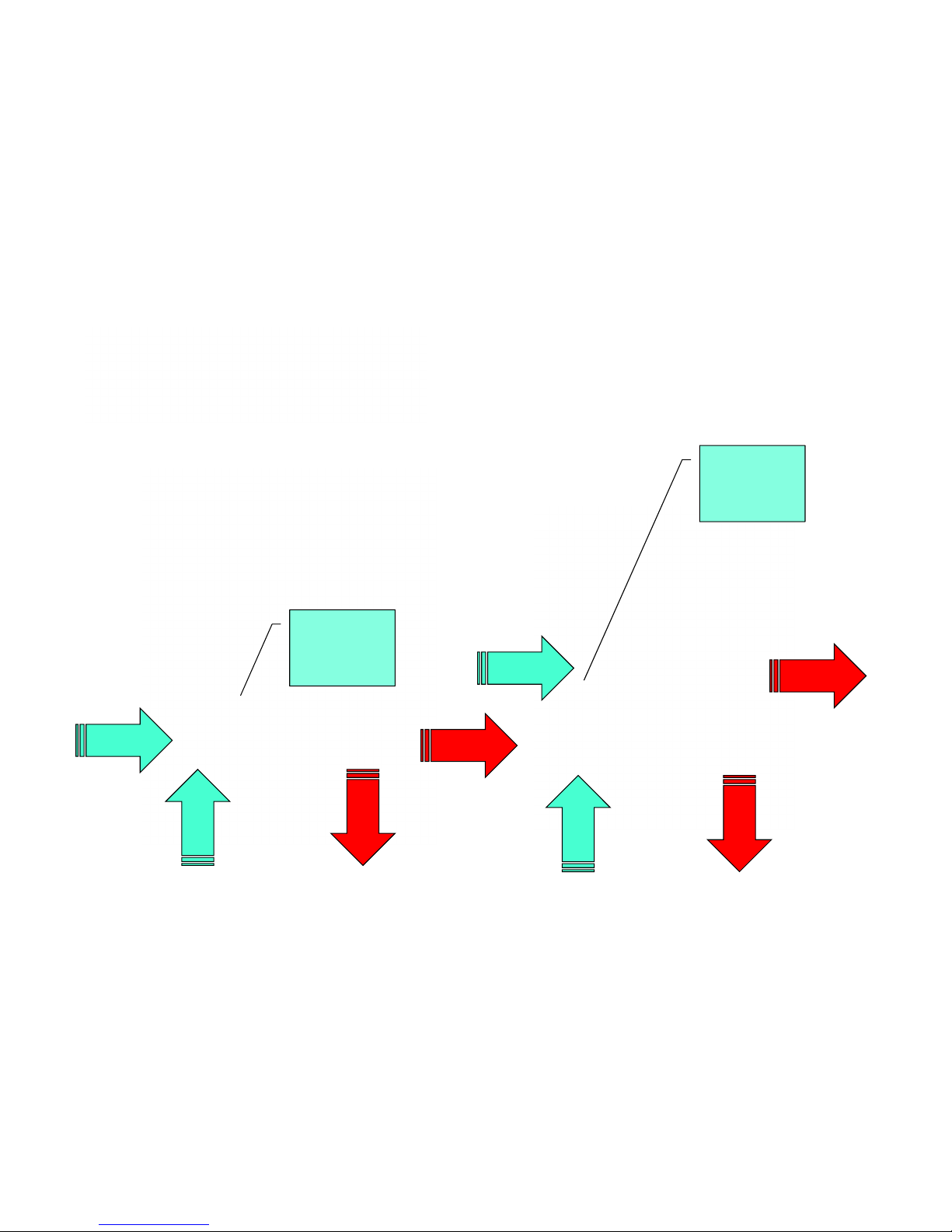

NEW MXG SERIES

Air

filter

Air

filter

INSTALLATION

328 – 428 - 438 air flow

Page 30

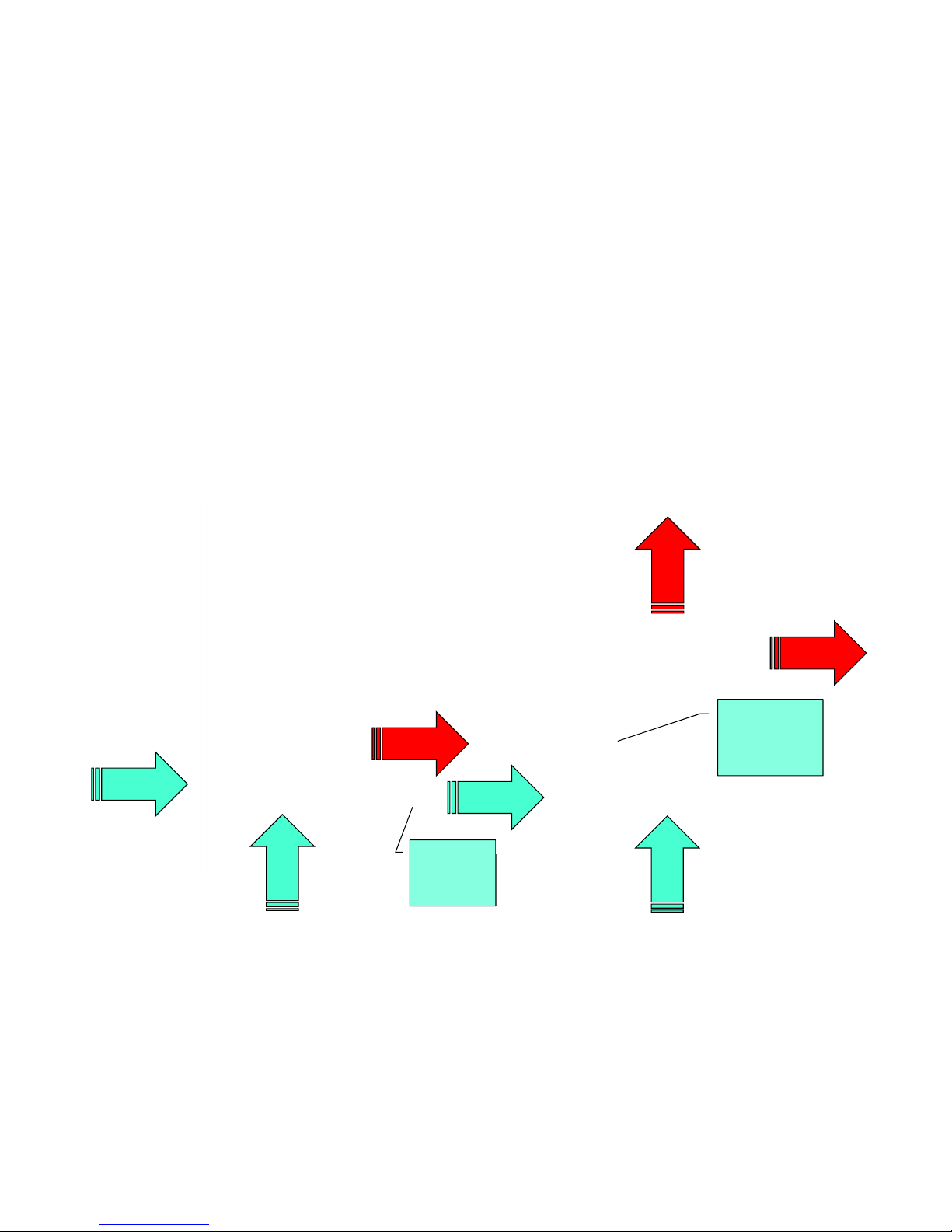

NEW MXG SERIES

Air

filter

INSTALLATION

638 air flow

Air

filter

Page 31

NEW MXG SERIES

Air

filter

Air

filter

INSTALLATION

938 air flow

Page 32

Level the unit on

both directions front

to rear and right to

left side using the

adjustable legs.

STACKING INSTALLATION

NEW MXG SERIES

Page 33

Install, on the cable

supply with the

machine, an

adequate electrical

plug according to

the local standards

and regulations.

Maximum voltage

variation should be

±10%.

Machine must be

individually fuse

protected.

INSTALLATION - ELECTRICAL

NEW MXG SERIES

Page 34

Connect the water inlet 3/4” male

threat of the water inlet solenoid valve

to the water supply line by means of

the rubber hose provided with

machine.Install on water supply line

closed to the machine a water valve

(tap).

Connect the 20 mm O.D. fitting of the

water drain with the flexible hose

supply with the machine securing it by

proper

INSTALLATION – WATER PIPING

NEW MXG SERIES

Page 35

AIR COOLED VERSION

TYPICAL INSTALLATION

NEW MXG SERIES

POWER

WATER INLET

WATER DRAIN

HAND DISCONNECT

SWITCH

WATER

FILTER

WATER

VALVE

WATER DRAIN

Page 36

On the water

cooled version

there are two

separate 3/4”

male thread

water inlet

fittings…..

INSTALLATION

NEW MXG SERIES

Page 37

…..a second separate

drain hose must be

connected to the outlet

3/4” male fitting located

on the upper side of the

water regulating valve.

INSTALLATION

NEW MXG SERIES

Page 38

WATER COOLED VERSION

TYPICAL INSTALLATION

NEW MXG SERIES

POWER

WATER INLET

WATER DRAIN

HAND DISCONNECT

SWITCH

WATER

FILTER

WATER

VALVE

WATER DRAIN

Page 39

START UP AND

OPERATIONAL

CHECKS

NEW MXG SERIES

Page 40

Open the water tap/valve and Switch ON the power on the

electrical supply line.

START UP AND OPERATIONAL CHECKS

NEW MXG SERIES

Page 41

Green Lighted

Master Push

Switch located in

the front panel.

By pushing it is

possible to Switch

ON and OFF the

machine.

NEW MXG SERIES

START UP AND OPERATIONAL CHECKS

Page 42

Push the Green

Push Button

Switch to Start

Up the machine

START UP AND OPERATIONAL CHECKS

NEW MXG SERIES

Page 43

A start-up delay is

factory set at 60’ on the

models MXG 638 - 938

with the Yellow LED

blinking.

This delay can be set

up with the Jumper n.3

Jump IN = 0’

Jump OUT = 60’

FREEZING CYCLE

BIN FULL

POWER

TOO HI EVAP TEMP

TOO HI COND TEMP

PUSH

START UP AND OPERATIONAL CHECKS

NEW MXG SERIES

Page 44

START UP AND OPERATIONAL CHECKS

NEW MXG SERIES

Once the start delay is elapsed the Ice Machine will start up automatically

through the 5 minutes of “Water Filling Phase”.

Page 45

The components energized

during this period are:

• PC Board

START UP AND OPERATIONAL CHECKS

NEW MXG SERIES

Page 46

• Water Inlet Solenoid Valve

START UP AND OPERATIONAL CHECKS

NEW MXG SERIES

Page 47

• W ater drain

valve

START UP AND OPERATIONAL CHECKS

NEW MXG SERIES

Page 48

• Hot Gas

Solenoid

Valve

START UP AND OPERATIONAL CHECKS

NEW MXG SERIES

Page 49

During the first 5’ the water

goes through the Water Inlet

Valve then…

….flows into the small

orifice of the “Flow Control”

located on the outlet port of

the same.

START UP AND OPERATIONAL CHECKS

NEW MXG SERIES

Page 50

Following the plastic inlet

hose the incoming water

arrive on the upper side of

the evaporator….

.... where it flows onto the

plastic evaporator platen

dribbling down through the

holes located on the corners.

START UP AND OPERATIONAL CHECKS

NEW MXG SERIES

Page 51

Dribbled water is

collected down into

the water sump

where is located

the overflow that

assures the proper

water level and

quantity for the next

freezing cycle.

START UP AND OPERATIONAL CHECKS

NEW MXG SERIES

Page 52

START UP AND OPERATIONAL CHECKS

NEW MXGSERIES

Once the start delay is elapsed the Ice Machine will start up automatically

through the 5 minutes of “Water Filling Phase”.

Page 53

After the first 5’ of water filling

phase the machine start up

automatically on freezing cycle

with the following electrical

components in operation:

• Compressor

START UP AND OPERATIONAL CHECKS

NEW MXG SERIES

Page 54

• Water Pump

START UP AND OPERATIONAL CHECKS

NEW MXG SERIES

Page 55

• Fan Motor (on air cooled

version only)

START UP AND OPERATIONAL CHECKS

NEW MXG SERIES

Page 56

• Contactor

START UP AND OPERATIONAL CHECKS

NEW MXG SERIES

Page 57

The operation of the

fan motor is controlled

by a condenser

temperature sensor

located within the fins

of condenser that

transmit a signal to

the PC Board to

activate in ON-OFF

mode the fan motor

so to keep between

two pre-set values the

condenser

temperature and

pressure.

START UP AND OPERATIONAL CHECKS

NEW MXG SERIES

Page 58

On PC Board the LED energized are:

• Power

FREEZING CYCLE

BIN FULL

POWER

TOO HI EVAP TEMP

TOO HI COND TEMP

PUSH

START UP AND OPERATIONAL CHECKS

NEW MXG SERIES

Page 59

On PC Board the LED energized are:

• Power

• Freezing

FREEZING CYCLE

BIN FULL

POWER

TOO HI EVAP TEMP

TOO HI COND TEMP

PUSH

START UP AND OPERATIONAL CHECKS

NEW MXG SERIES

Page 60

Water is

circulating by

the water pump

into the

inverted tin

plated copper

molds of the

evaporator….

START UP AND OPERATIONAL CHECKS

NEW MXG SERIES

Page 61

….while the

refrigerant is

flowing into the

serpentine

welded on the

upper side of

the tin plated

copper molds.

START UP AND OPERATIONAL CHECKS

NEW MXG SERIES

Page 62

• EVAPORATOR

SENSOR

NEW MXG SERIES

Page 63

After

approximately 5

minutes since the

start up of the

freezing cycle, the

temperature of

the evaporator

serpentine drops

down to 0ºC….

START UP AND OPERATIONAL CHECKS

NEW MXG SERIES

0ºC

Page 64

….with the blinking of the small RED LED located in the center

of PC Board.

START UP AND OPERATIONAL CHECKS

NEW MXG SERIES

Page 65

After

approximately 10

minutes from the

start up of the

freezing cycle, the

temperature of

the evaporator

serpentine drops

down to - 15ºC….

START UP AND OPERATIONAL CHECKS

NEW MXG SERIES

-15ºC

Page 66

….with the light ON steady of the small RED LED located in the

center of PC Board.

START UP AND OPERATIONAL CHECKS

NEW MXG SERIES

Page 67

The machine

remains in the

freezing cycle till its

completion for an

additional time

according to the

set up of the first

four DIP SWITCH

of the PC Board.

START UP AND OPERATIONAL CHECKS

NEW MXG SERIES

Page 68

START UP AND OPERATIONAL CHECKS

NEW MXG SERIES

Page 69

Once completed the freezing

cycle the machine enters into

the defrost or harvest cycle

with the following electrical

components in operation:

• Compressor

START UP AND OPERATIONAL CHECKS

NEW MXG SERIES

Page 70

• Water Inlet Solenoid valve

START UP AND OPERATIONAL CHECKS

NEW MXG SERIES

Page 71

• Water Drain

Solenoid Valve

START UP AND OPERATIONAL CHECKS

NEW MXG SERIES

Page 72

• Hot Gas Valve

START UP AND OPERATIONAL CHECKS

NEW MXG SERIES

Page 73

The length of the defrost or

harvest cycle is controlled

by the PC Board according

to the setting of the DIP

SWITCH 5 and 6 and it is

related to the time that the

machine takes to drop the

evaporating temperature

from 0ºC to -15ºC (time T2)

as shown on the table.

A

SWITCH 5 AND 6

D

BC

START UP AND OPERATIONAL CHECKS

NEW MXG SERIES

LENGTH OF HARVEST CYCLE ACCORDING TO THE TIME TO DROP THE

EVAP. TEMPERATURE FROM 0ºC TO -13ºC

LENGTH PROGRAMS

HARVEST

CYCLE A B C D

180” Up to 6’ *** Up to 9’ ***

165” 6’-7’ Up to 3’ 9’-10’ ***

150” 7’-8’ 3’-3’15’ 10’-11’ ***

135” 8’-9’ 3’15”-3’30” 11’-12’ ***

120” 9’-10’ 3’30”-4’30” 12’-13’ Up to 3’

105” 10’-12’ 430”-6’ 13’-15’ 3-4’

90” >12’ >6’ >15’ >4’

Page 74

It’s possible to extend the length of the defrost cycle by

means of the DIP SWITCH 7 and 8 as per below chart.

ADDITIONAL DEF ROST TIME

78

ON ON 0

OFF ON 30"

ON OFF 60"

OFF OFF 90"

D I P SWITCH

START UP AND OPERATIONAL CHECKS

WATER PUMP OFF

NEW MXG SERIES

Page 75

During the defrost or

harvest cycle the

combined action of

refrigerant in Hot Gas

state and incoming

Water are going to

partially melt the ice

cubes in contact with

the tin plated copper

molts with the

dropping down of the

same through the

curtain.

START UP AND OPERATIONAL CHECKS

NEW MXG SERIES

Page 76

Ice maker turns OFF just when

bin is full by ice and cubes cut

the I/R beam.

It is possible to test I/R

operation by keeping some ice

cubes between lenses during

a defrost ……...

START UP AND OPERATIONAL CHECKS

NEW MXG SERIES

Page 77

The Bin Full YELLOW LED starts to blink slow.

FREEZING CYCLE

BIN FULL

POWER

TOO HI EVAP TEMP

TOO HI COND TEMP

PUSH

START UP AND OPERATIONAL CHECKS

NEW MXG SERIES

Page 78

..till defrost cycle is elapsed thus to release all ice cubes from

inverted mold cups; after that the machine will stop at bin full

condition with the yellow LED steady ON

FREEZING CYCLE

BIN FULL

POWER

TOO HI EVAP TEMP

TOO HI COND TEMP

PUSH

START UP AND OPERATIONAL CHECKS

NEW MXG SERIES

Page 79

As soon as the ice is removed between transmitter and received

the infrared beam is resumed immediately with fast a blinking of

the Yellow LED, then the machine restart with 45” of recharging

water

FREEZING CYCLE

BIN FULL

POWER

TOO HI EVAP TEMP

TOO HI COND TEMP

PUSH

START UP AND OPERATIONAL CHECKS

NEW MXG SERIES

Page 80

OPERATING

PRINCIPLES

and

COMPONENTS

NEW MXG SERIES

Page 81

Compressor

Evaporator

Air cooled

condenser

Hot

gas

valve

OPERATING PRINCIPLES - FREEZE

NEW MXG SERIES

Page 82

Compressor

Evaporator

Air cooled

condenser

Hot

gas

valve

OPERATING PRINCIPLES - HARVEST

NEW MXG SERIES

Page 83

OPERATING PRINCIPLES 938

NEW MXG SERIES

Liquid valves

Liquid valves

hot gas valves

Page 84

TXV

valves

factory

setting,

full

opening

(countercl

ockwise

then 1 turn

clockwise

OPERATING PRINCIPLES 938

NEW MXG SERIES

Page 85

OPERATING PRINCIPLES 938

NEW MXG SERIES

Evaporator

sensor location

Page 86

OPERATING PRINCIPLES 938

NEW MXG SERIES

Condenser

sensor

location

air cooled

version

Page 87

OPERATING PRINCIPLES 938 - FREEZE

NEW MXG SERIES

Condenser

sensor

location

water

cooled

version

SWEP

water

cooled

condenser

Page 88

OPERATING PRINCIPLES 938

NEW MXG SERIES

DANFOS

S water

regulating

valve set

at 17 bar

Page 89

WATER SYSTEM – FREEZING CYCLE

NEW MXG SERIES

Page 90

WATER SYSTEM – HARVEST CYCLE

FIRST PORTION 30”

NEW MXG SERIES

Page 91

WATER SYSTEM – HARVEST CYCLE

SECOND PORTION

NEW MXG SERIES

Page 92

OPERATING PRINCIPLES – PC BOARD

NEW MXG SERIES

Page 93

SWITCH 9

OPERATING TIME

OF WATER PUMP

DURING HARVEST

OFF = 15”

ON = 30”

SWITCH 7 AND 8

EXTENTION TIME OF

HARVEST CYCLE BY 0”, 30”,

60” OR WATER PUMP OFF

SWITCH 5 AND 6

LENGTH OF THE

HARVEST CYCLE

ACCORDING TO THE

TIME T

2

SWITCH 1, 2, 3 AND 4

SETTING OF THE

TIMED PORTION OF

FREEZING CYCLE

SWITCH 10

CONDENSER

SAFETY CUT OUT

TEMPERATURE

(60ºC WATER -

OFFAND 70ºC AIR

- ON)

OPERATING PRINCIPLES – DIP SWITCHES

NEW MXG SERIES

Page 94

OPERATING PRINCIPLES – JUMPERS

NEW MXG SERIES

Page 95

Time T

1

From start

up of

freezing

cycle till

the blinking

of 0°C Red

LED

OPERATING PRINCIPLES – PC BOARD

NEW MXG SERIES

Page 96

Time T

2

From

blinking of

Red LED

till the light

ON steady

of -15°C

Red LED

OPERATING PRINCIPLES – PC BOARD

NEW MXG SERIES

Page 97

Time T

a

Added time controlled

by the PC Board

according to the setting

of the DIP SWITCH

1, 2, 3 and 4.

LENGTH OF TIMED PORTION OF FREEZING

CYCLE – FIRST 4 SWITCHES

25’

13’

19’

11’

17’

3’

9’

15’

21’23’

7’ 5’

OPERATING PRINCIPLES – PC BOARD

NEW MXG SERIES

Page 98

Time T

s

Harvest Time TSis

controlled by the PC

Board and it is inversely

proportional to the Time

T2of the Freeze Cycle

(from 0ºC to -13ºC) as

per the combination A

of the Table.

Time TSis NOT

adjustable.

LENGTH OF HARVEST CYCLE ACCORDING TO THE TIME

TO DROP THE EVAP. TEMPERATURE FROM 0ºC TO -13ºC

LENGTH PROGRAMS

HARVEST

CYCLE A B C D

180” Up to 6’ *** Up to9’ ***

165” 6’-7’ Upto 3’ 9’-10’ ***

150” 7’-8’ 3’-3’15’ 10’-11’ ***

135” 8’-9’ 3’15”-3’30” 11’-12’ ***

120” 9’-10’ 3’30”-4’30” 12’-13’ Up to 3’

105” 10’-12’ 430”-6’ 13’-15’ 3-4’

90” >12’ >6’ >15’ >4’

OPERATING PRINCIPLES – PC BOARD

NEW MXG SERIES

Page 99

It’s possible to extend the length of the harvest cycle (Te)

by means of the DIP SWITCH 7 and 8 as per below chart.

ADDITIONAL DEF ROST TIME

78

ON ON 0

OFF ON 30"

ON OFF 60"

OFF OFF 90"

D I P SWITCH

OPERATING PRINCIPLES – PC BOARD

WATER PUMP OFF

NEW MXG SERIES

Page 100

Time T

a

Time T1+T

2

Time

T

s

Freezing = T1+ T2+ T

a

Defrost/Harvest = Ts + T

e

0°C

-15°C

T

e

OPERATING PRINCIPLES – PC BOARD

NEW MXG SERIES

Loading...

Loading...