Page 1

Page 1

Page 1

SCOTSMAN EUROPE - FRIMONT SPA

Via Puccini, 22 - 20010 Pogliano M.se - Milano - Italy

Tel. +39-02-93960.1 (Aut. Sel.)- Telefax +39-02-93550500

Direct Line to Service & Parts:

Phone +39-02-93960350 - Fax +39-02-93540449

Website: www.scotsman-ice.com

E-Mail: scotsman.europe@frimont.it

ISO 9001 - Cert. n. 0080

SERVICE MANUAL

MVP 456

MVP 606

MVP 806

MVP 1006

REV. 10/2008

Page 2

Page 2

Page 2

TABLE OF

CONTENTS

Page

Specifications 3 ÷10

Water 11

General Installation - Air or Water Cooled 11

Adjustments 13

Water purge setting 13

Prodigy Cuber System Information 14

Controller Information 14

How It Works 15

Electrical Sequence - Air or Water Cooled. 15

Electrical Component Details 16

Refrigeration 18

Water System 18

Control Operation 19

Control Safeties 19

Restarts 19

Control Button Use (from standby) 20

Service Specification 21

Diagnostics – Air Cooled 22-23

Test Procedures - Sensors 24

Ice Thickness Sensor 24

Water Level Sensor 24

Temperature Sensors 25

Test Procedures - Loads 25-28

Controller Differences 28

Wiring diagrams 29-30

Repair Procedures 31

Cleaning, sanitation and maintenance 32-33

INTRODUCTION

This technical manual covers the New Prodigy MVP line.

All models are shipped with an Installation and User’s manual, which can be referred to separately.

General installation information is included in this manual.

Page 3

Page 3

Page 3

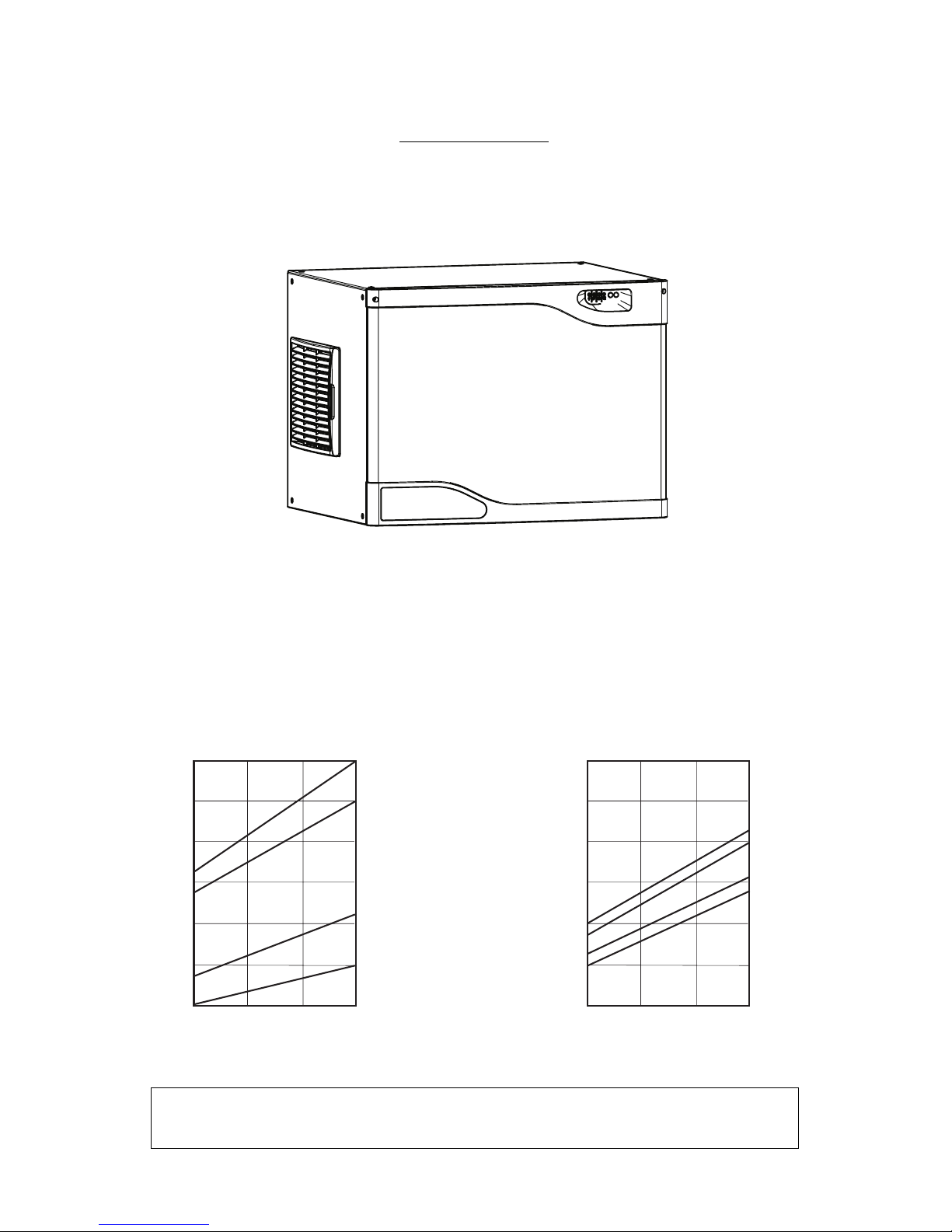

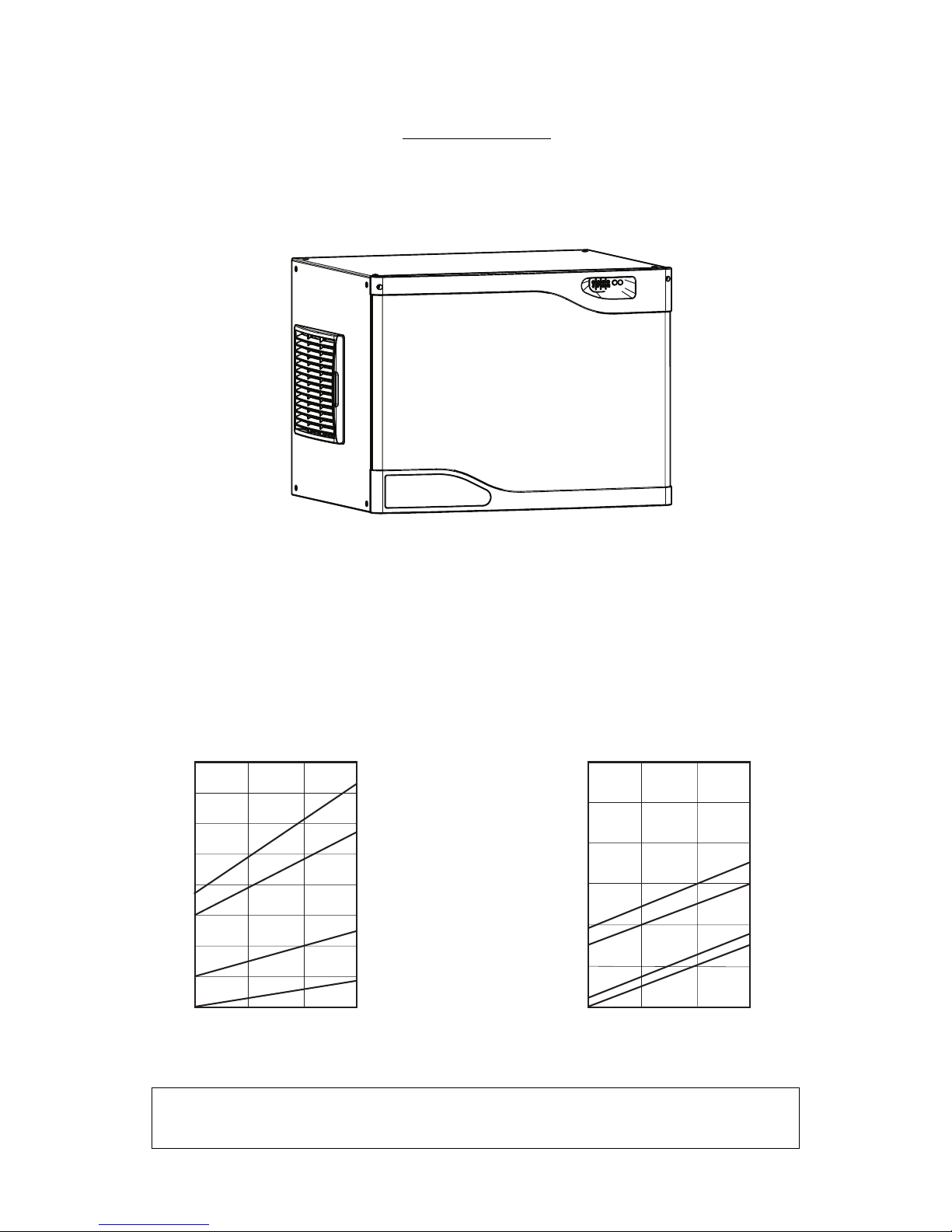

SPECIFICATIONS

MODULAR CUBER MVP 456

NOTE. To keep your Modular cuber performing at its maximum capacity, it is necessary to perform

periodic maintenance as outlined on last pages of this manual.

ice making capacity

ICE PRODUCED PER 24 HRS

Kg.

32

°C

15

10

AIR COOLED MODELS

WATER TEMPERATURE

AMBIENT TEMPERA TURE

°C

10

21

32

38

WATER COOLED MODELS

21

240

220

200

180

160

140

120

ICE PRODUCED PER 24 HRS

Kg.

32

°C

15

10

AMBIENT TEMPERA TURE

°C

10

21

32

38

21

255

235

215

195

175

155

135

WATER TEMPERATURE

Page 4

Page 4

Page 4

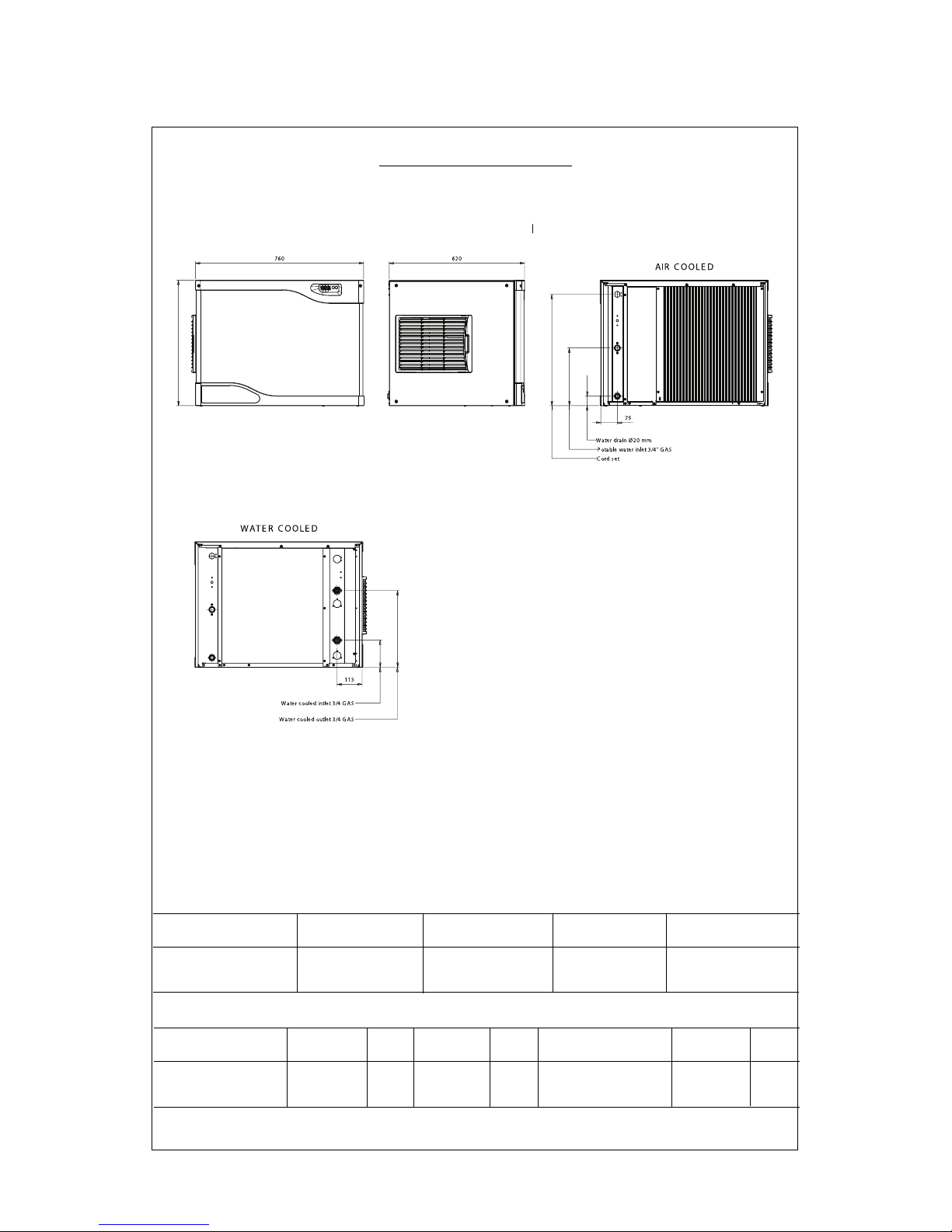

SPECIFICATIONS (CONT'D)

Model Cond. unit Finish Comp. HP

MVP 456 - MACHINE SPECIFICATIONS

Water req.

lt/24 HR

Model

Basic

electr.

amps

Start

amps

watts

Electric power cons.

Kwhx24 HR.

N. of wires

Amps

Fuse

220-240/50/1

MVP 456 - AS

MVP 456 - WS

3x1,5 mm

2

16

Cubes per harvest: 234 Full - 468 Half

* With water at 15°C

Stainless Steel 7/8

4.5

4.0

29

1000

850

23

19.5

Dimensions:

HEIGHT 575 mm. (22" 1/2)

WIDTH 760 mm. (30")

DEPTH 620 mm. (24" 1/2)

WEIGHT 77 Kgs.

MVP 456 - AS Air 410*

MVP 456 - WS Water 2400*

Page 5

Page 5

Page 5

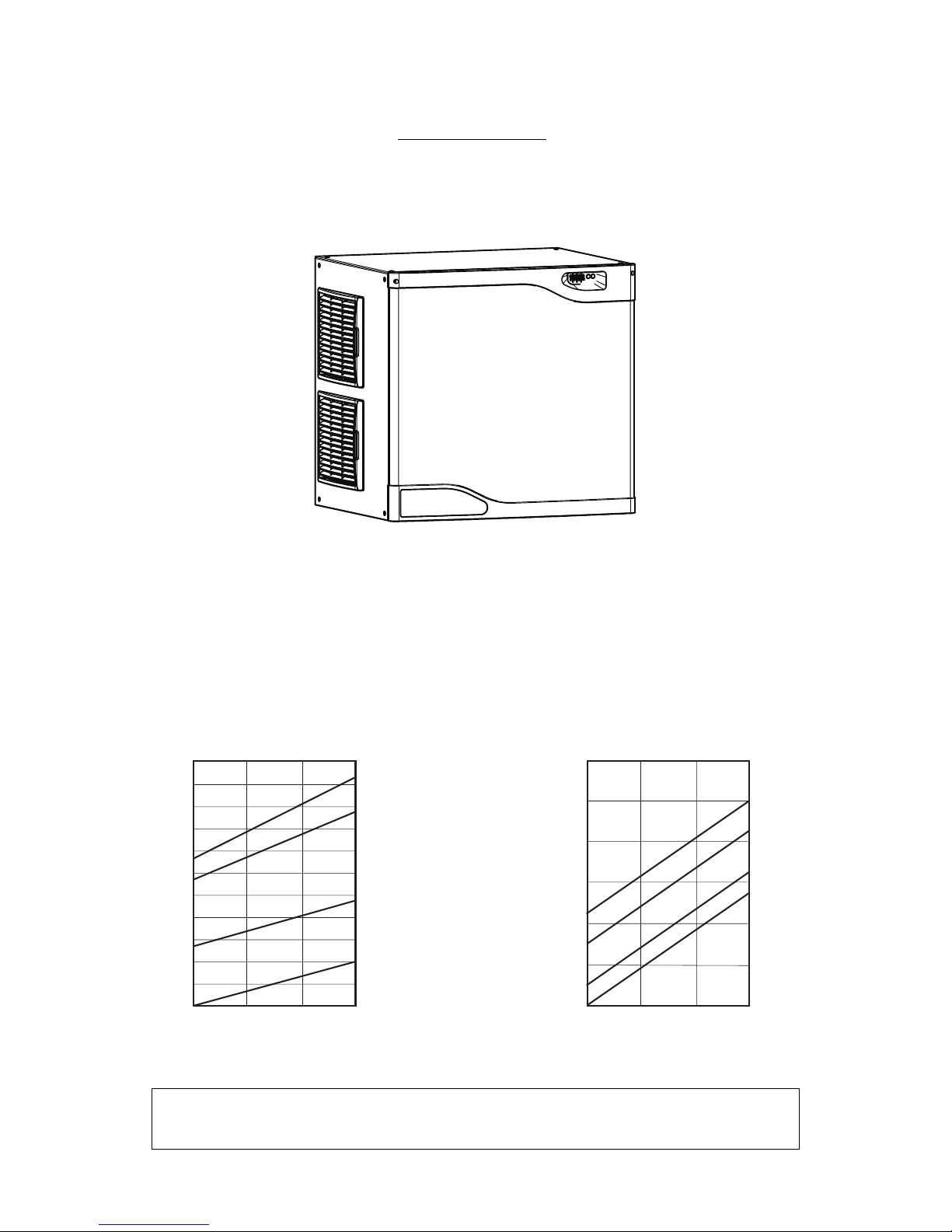

SPECIFICATIONS

MODULAR CUBER MVP 606

NOTE. To keep your Modular cuber performing at its maximum capacity, it is necessary to perform

periodic maintenance as outlined on last pages of this manual.

ice making capacity

Kg.

32

°C

15

10

°C

10

21

32

38

21

335

315

295

275

255

235

215

195

175

Kg.

32

°C

15

10

°C

10

21

32

38

21

335

315

295

275

255

235

215

ICE PRODUCED PER 24 HRS

AIR COOLED MODELS

WATER TEMPERATURE

AMBIENT TEMPERA TURE

WATER COOLED MODELS

ICE PRODUCED PER 24 HRS

AMBIENT TEMPERA TURE

WATER TEMPERATURE

Page 6

Page 6

Page 6

SPECIFICATIONS (CONT'D)

Model Cond. unit Finish Comp. HP

MVP 606 - MACHINE SPECIFICATIONS

Water req.

lt/24 HR

Model

Basic

electr.

amps

Start

amps

watts

Electric power cons.

Kwhx24 HR.

N. of wires

Amps

Fuse

220-240/50/1

MVP 606 - AS

MVP 606 - WS

3x1,5 mm

2

16

Cubes per harvest: 234 Full - 468 Half

* With water at 15°C

Stainless Steel 1 3/8 1 1/2

6,2

5,2

32

1300

1050

28

23

Dimensions:

HEIGHT 575 mm. (22" 1/2)

WIDTH 760 mm. (30")

DEPTH 620 mm. (24" 1/2)

WEIGHT 77 Kgs.

MVP 606 - AS Air 440*

MVP 606 - WS Water 2750*

Page 7

Page 7

Page 7

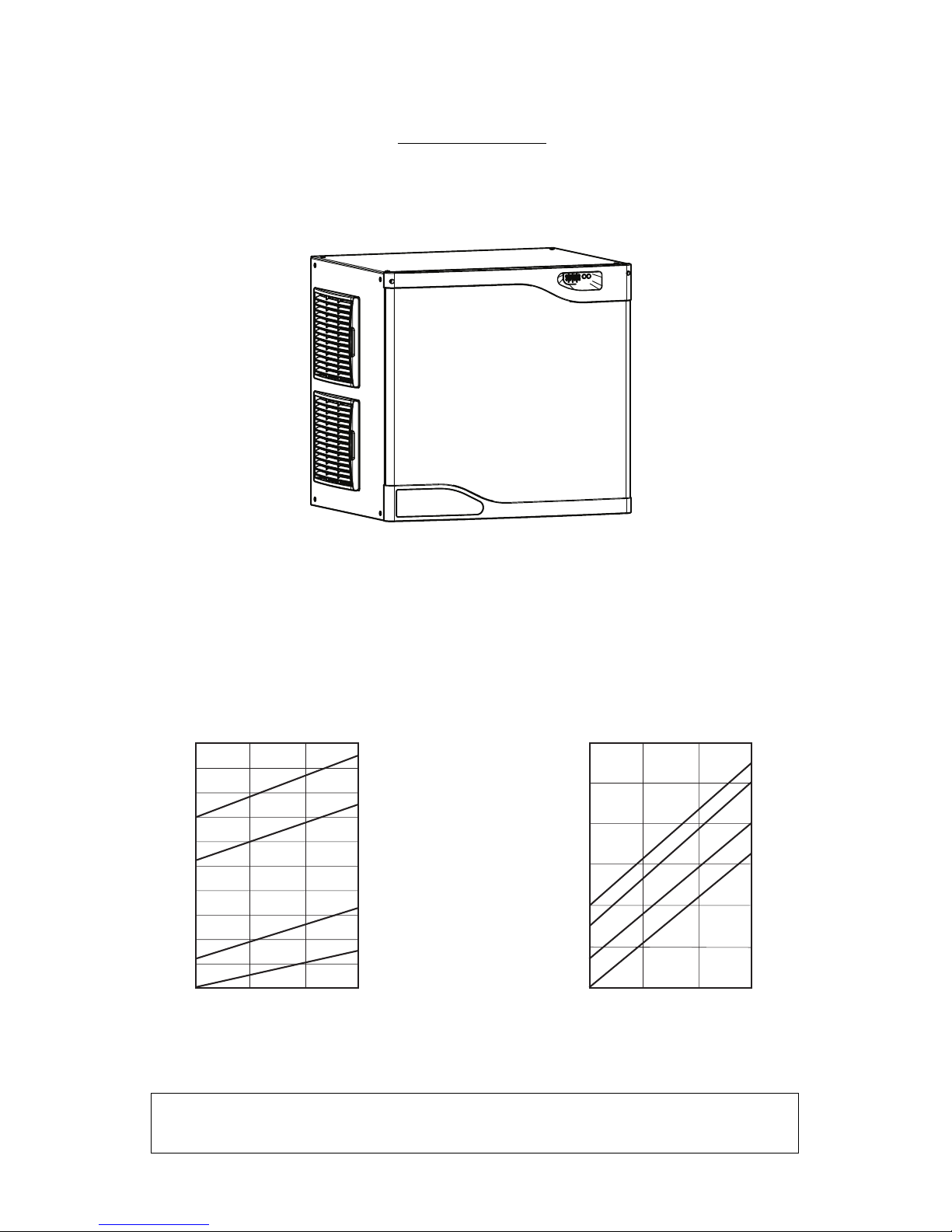

SPECIFICATIONS

MODULAR CUBER MVP 806

NOTE. To keep your Modular cuber performing at its maximum capacity, it is necessary to perform

periodic maintenance as outlined on the last pages of this manual.

ice making capacity

Kg.

32

°C

15

10

°C

10

21

32

38

21

445

425

405

385

365

345

325

305

285

265

245

225

Kg.

32

°C

15

10

°C

10

21

32

38

21

390

370

350

330

310

290

270

ICE PRODUCED PER 24 HRS

AIR COOLED MODELS

WATER TEMPERATURE

AMBIENT TEMPERA TURE

WATER COOLED MODELS

ICE PRODUCED PER 24 HRS

AMBIENT TEMPERA TURE

WATER TEMPERATURE

Page 8

Page 8

Page 8

MVP 806 - AS Air 580*

MVP 806 - WS Water 3900*

SPECIFICATIONS (CONT'D)

Model Cond. unit Finish Comp. HP

MVP 806 - MACHINE SPECIFICATIONS

Water req.

lt/24 HR

Model

Basic

electr.

amps

Start

amps

watts

Electric power cons.

Kwhx24 HR.

N. of wires

Amps

Fuse

MVP 806 - AS

MVP 806 - WS

3x1,5 mm

2

16

Cubes per harvest: 342 Full - 684 Half

* With water at 15°C

Stainless Steel 1 5/8 2.5

231

1850

1450

40

33.4

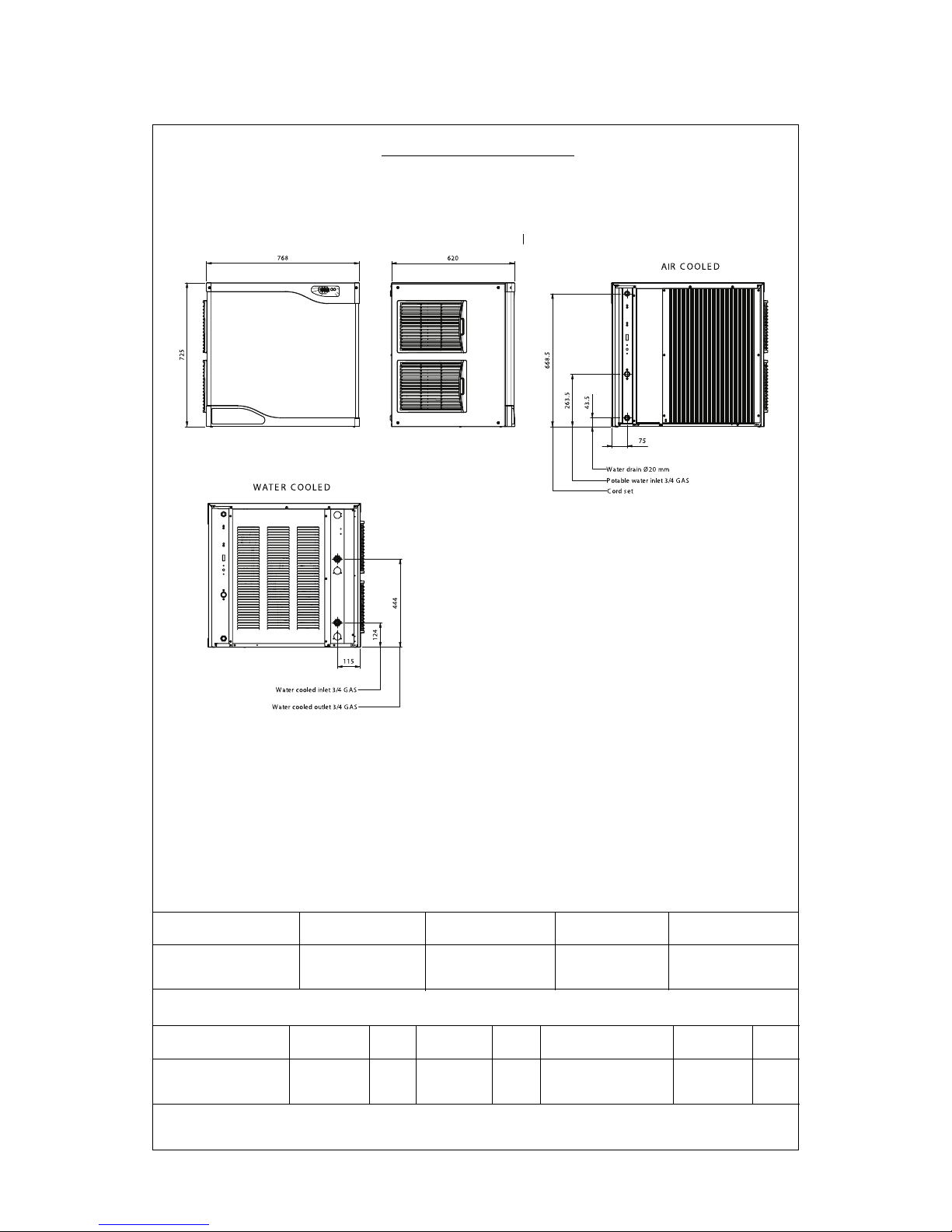

Dimensions:

HEIGHT 725 mm. (28" 1/2)

WIDTH 760 mm. (30")

DEPTH 620 mm. (24" 1/2)

WEIGHT 97 Kgs.

220-240/50/1

9.0

8.0

Page 9

Page 9

Page 9

SPECIFICATIONS

MODULAR CUBER MVP 1006

NOTE. To keep your Modular cuber performing at its maximum capacity, it is necessary to perform

periodic maintenance as outlined on the last pages of this manual.

ice making capacity

Kg.

32

°C

15

10

°C

10

21

32

38

21

475

455

435

415

395

375

355

335

315

295

275

Kg.

32

°C

15

10

°C

10

21

32

38

21

425

405

385

365

345

325

305

ICE PRODUCED PER 24 HRS

AIR COOLED MODELS

WATER TEMPERATURE

AMBIENT TEMPERA TURE

WATER COOLED MODELS

ICE PRODUCED PER 24 HRS

AMBIENT TEMPERA TURE

WATER TEMPERATURE

Page 10

Page 10

Page 10

MVP 1006 - AS Air 600*

MVP 1006 - WS Water 3800*

SPECIFICATIONS (CONT'D)

Model Cond. unit Finish Comp. HP

MVP 1006 - MACHINE SPECIFICATIONS

Water req.

lt/24 HR

Model

Basic

electr.

amps

Start

amps

watts

Electric power cons.

Kwhx24 HR.

N. of wires

Amps

Fuse

MVP 1006 - AS

MVP 1006 - WS

5x1,5 mm

2

10

Cubes per harvest: 342 Full - 684 Half

* With water at 15°C

224

1900

1600

41.3

37

Dimensions:

HEIGHT 725 mm. (28" 1/2)

WIDTH 760 mm. (30")

DEPTH 620 mm. (24" 1/2)

WEIGHT 104 Kgs.

380-400/50/3

Stainless Steel

2

3.5

3.3

Page 11

Page 11

Page 11

GENERAL INSTALLATION

Air or Water Cooled

Location Limitations:

The product is designed to be installed indoors,

in a controlled environment. Air cooled models

discharge very warm air into the room out the

back. Space must be allowed at the left side and

back for air intake and discharge. Water cooled

models discharge warm water into the building’s

drain. Space needs to be provided on both

sides and above for service access.

Space Limitations

Note: Although the machine will function, ice

capacity of air cooled machines will be

significantly reduced with minimal clearance

at the sides, back and top. Some space is

recommended for service and maintenance

purposes on all models.

15 cm (6") of space at the sides and back are

required for adequate operation. To get the most

capacity, locate the machine away from heat

producing appliances and heating ducts.

Airflow is in the left side, out the back (as viewed

from the front).

Environmental Limitations

Minimum Maximum

Air temperature 10°C (50F) 40°C (100F)

Water temperature 5°C (40F) 40°C (100F)

Water pressure 1 bar (14 psi) 5 bar (70 psi)

Power supply - acceptable voltage ranges

Minimum Maximum

115 104 126

230 207 253

Warranty Information

The warranty statement for this product is provided

separately from this manual. Refer to it for

applicable coverage. In general warranty covers

defects in material or workmanship. It does not

cover maintenance, corrections to installations,

or situations when the machine is operated in

circumstances that exceed the limitations printed

above.

Plumbing Requirements

All models require connection to cold, potable

water. A hand actuated valve within site of the

machine is required. Air cooled models have a

single 3/4" male inlet water connection.

Water cooled models have the same inlet fitting

plus an additional 3/4" male condenser inlet

water connection.

WATER

The quality of the water supplied to the ice

machine will have an impact on the time between

cleanings and ultimately on the life of the product.

There are two ways water can contain impurities:

in suspension or in solution. Suspended solids

can be filtered out. In solution or dissolved

solids cannot be filtered, they must be diluted or

treated. Water filters are recommended to

remove suspended solids. Some filters have

treatment in them for suspended solids. Check

with a water treatment service for a

recommendation.

RO water. This machine can be supplied with

Reverse Osmosis water, but the water

conductivity must be no less than 10

microSiemens/cm.

Potential for Airborne Contamination

Installing an ice machine near a source of yeast

or similar material can result in the need for

more frequent sanitation cleanings due to the

tendency of these materials to contaminate the

machine. Most water filters remove chlorine

from the water supply to the machine which

contributes to this situation. Testing has shown

that using a filter that does not remove chlorine

will greatly improve this situation, while the ice

making process itself will remove the chlorine

from the ice, resulting in no taste or odor impact.

Additionally, devices intended to enhance ice

machine sanitation can be placed in the machine

to keep it cleaner between manual cleanings.

Water Purge

Cube ice machines use more water than what

ends up in the bin as ice. While most water is

used during ice making, a portion is designed to

be drained out every cycle to reduce the amount

of hard water scale in the machine. That’s

known as water purge, and an effective purge

can increase the time between needed water

system cleaning.

In addition, this product has the capability to

automatically vary the amount of water purgeed

based on the purity of the water supplied to it.

The water purge rate can also be set manually.

Adjustments of purge due to local water

conditions are not covered by warranty.

Page 12

Page 12

Page 12

Water Filters

If connecting to water filtration, filter only the

water to the reservoir, not to the condenser.

Install a new cartridge if the filters were used with

a prior machine.

All models require drain tubing to be attached to

them. Air cooled models have a single 21mm

O.D. male drain fitting in the back of the cabinet.

Water cooled models have the same fitting plus

an additional 3/4" male drain fitting in the back of

the cabinet.

Note: This NSF listed model has a 1" antiback flow air gap between the water inlet

tube end and the highest possible reservoir

water level, no back flow device is required

for the potable water inlet.

Drain Tubing:

Use rigid drain tube supplied with machine and

route them separately - do not Tee into the bin’s drain.

Horizontal runs of drain tubing need a 1/4" fall per

foot of run for proper draining.

Follow all applicable codes.

Electrical

See the spec sheet or User’s Manual for Wire

Size and Maximum Fuse Size ratings.

The machine is supplied with a 1,5 meter length

power cord.

Install the electrical plug accordingly to the local

standard needed.

The dataplate on the back of the cabinet details

the power requirements, including voltage,

phase, minimum circuit ampacity and maximum

fuse size. Extension cords are not permitted. Use

of a licensed electrician is recommended.

Follow all applicable local, state and national

codes.

Page 13

Page 13

Page 13

ADJUSTMENTS

Ice Bridge Thickness

Caution: Do not make the bridge too thin or

the machine will not harvest properly. Bridge

thickness adjustments are not covered by

warranty.

Shut machine off.

Access the ice thickness sensor.

Check gap between metal tip and evaporator

grid. Small cube standard gap is 5 mm (3/16"),

medium cube standard gap is 5,5 mm (7/32"). To

set, place a 5 mm - 3/16" (small cube) or 5,5 mm

- 7/32" (medium cube) drill bit between sensor tip

and evaporator to check. Adjust gap using

adjustment screw.

Restart unit and check ice bridge. Repeat as

needed.

WATER PURGE SETTING

The water purge is factory set to the Automatic setting. The setting can be changed to one of 5 manual

settings or placed on automatic. The purge setting shows in the Code Display.

To set:

Switch the machine OFF by holding the Off

button in until a number or the letter A shows on

the display.

Press and release the On button repeatedly until

the number on the display corresponds to the

desired setting.

Press and release the Off switch again to return

to the normal control state.

(very soft

≤ 4°f)

Soft

water

(5 ≤ °f ≤ 9)

(10 ≤ °f ≤ 16)

Hard

water

(17 ≤ °f ≤ 22)

Very hard

water

(

°f ≥ 23)

Page 14

Page 14

Page 14

PRODIGY CUBER SYSTEM

INFORMATION

Overall System Type:

• Refrigeration: Mechanical, either air cooled,

water cooled.

• Water System: Inlet water solenoid valve fills

reservoir once per cycle. Purge solenoid valve

opens to discharge some reservoir water once

per cycle.

• Control System: Electronic

• Harvest cycle sensor: Conductivity probe

• Water full/empty sensor: Conductivity probe

• Bin Control: Curtain Switch

• Ice type: Unified

• Harvest system: Hot gas defrost with mechanical

assist

Electrical Components:

• Compressor

• Contactor

• Water Pump

• Inlet Water Solenoid Valve

• Purge or purge Valve

• Fan Motor(s)

• Fan motor pressure control

• High pressure cut out

• Harvest Assist Solenoid

• Hot Gas Valve

• Controller

• Transformer - 12v AC for the controller only

• Water Level Sensor

• Ice Thickness Sensor

• Curtain Switch

CONTROLLER INFORMATION

Machine Indicator Lights

• Power

• Status

• Water

• Clean

Code Display

Main codes - automatically displayed

F Freeze Cycle

F flashes Freeze Cycle is Pending

H Harvest Cycle

H flashes Manual Harvest

b Binis Full

C Clean Cycle

L Board Locked

d Test Mode

O Off

E Self Test Failed

1 flashes Max Freeze - Retrying

1 Max Freeze Time Shut Down

2 flashes Max Harvest - Retrying

2 Max Harvest Time Shut Down

3 Slow Water Fill

4 High Discharge Temp

5 Sump Temp Sensor Failure

7 Discharge Temp Sensor Failure

8 flashes Short Freeze - Retrying

8 Short Freeze - Thin ice

Setting Codes - requires push button sequence for access

Water Purge Settings

A, 1, 2, 3, 4, 5

De-scale Interval Settings

6, 5, 3, 3

CONTROLLER INFORMATION

Component Indicator Lights

• Condenser Fan

• Water Pump

• Purge Valve

• Water Solenoid

• Hot Gas

• Compressor

• Ready to Harvest

• Sump Empty

• Sump Full

• Curtain SW1

• Curtain SW2 (not used)

Page 15

Page 15

Page 15

HOW IT WORKS - AIR COOLED

Freeze Cycle. At start up the controller drains

and refills the reservoir. The reservoir refills

when the mid length water level sensor probe is

uncovered and continues to fill until the top probe

is in contact with water. When the reservoir has

filled, the compressor and water pump start.

After the discharge pressure has increased past

the cut in point of the fan pressure control, the fan

motor(s) will begin to operate and warm air will be

discharged out the back of the cabinet. The fan

motor will switch on and off as the discharge

pressure rises and falls. Water flows over the

evaporator as the refrigeration system begins to

remove heat. When the water temperature falls

to a preset point, as measured by the water

temperature sensor, the controller shuts off the

water pump for 30 seconds. The freeze cycle

resumes when the pump restarts and ice begins

to form on the evaporator. As it forms, the water

flowing over the ice moves closer and closer to

the metal tip of the ice thickness sensor. When it

comes into contact with the sensor for a few

continuous seconds, that signals the controller

that the freeze cycle is complete.

The controller may shut the air cooled fan motor

off for a variable period of time to build up heat for

harvest. This is dependant upon the temperature

of the discharge line sensor.

Harvest Cycle. When the harvest cycle begins,

the controller shuts off the fan motor, switches on

the hot gas valve, and through a parallel circuit,

the harvest assist solenoid. After a few seconds

the purge valve opens and water is drained from

the reservoir. Based on either the automatic

purge or manual purge setting, the pump and

purge valve will be switched off at a time

determined to have drained enough water for

that setting. The inlet water valve will open to fill

the reservoir anytime the mid length probe is

uncovered, which occurs during the reservoir

drain cycle. Harvest continues as the hot

discharge gas flows into the evaporator

serpentine, heating up the evaporator. At the

same time the harvest assist solenoid is pushing

against the back of the ice slab. When the ice

releases from the evaporator, it harvests as a

unit, and the harvest assist probe provides some

additional force to push it off. When the ice falls

off it will force the curtain open. An open curtain

during the harvest cycle signals the controller

that the evaporator has released its ice terminating

harvest. If the curtain remains open, the controller

will shut the machine at bin full. Anytime harvest

is complete the hot gas valve and harvest assist

solenoid are shut off. The harvest assist solenoid

pin returns to its normal position by spring

pressure.

If the curtain re-close after harvest, the freeze

cycle will restart.

HOW IT WORKS - WATER COOLED

Freeze Cycle. At start up the controller drains

and refills the reservoir. The reservoir refills

when the mid length water level sensor probe is

uncovered and continues to fill until the top

probe is in contact with water. When the reservoir

has filled, the compressor and water pump start.

After the discharge pressure has increased past

the set point of the water regulating valve, the

water regulating valve will open and warm water

will be discharged out the condenser drain. The

water regulating valve will modulate to maintain

a relatively constant discharge pressure. Water

flows over the evaporator as the refrigeration

system begins to remove heat. When the water

temperature falls to a preset point, as measured

by the water temperature sensor, the controller

shuts off the water pump for 30 seconds. The

freeze cycle resumes when the pump restarts

and ice begins to form on the evaporator. As it

forms, the water flowing over the ice moves

closer and closer to the metal tip of the ice

thickness sensor.

When it comes into contact with the sensor for a

few continuous seconds, that signals the

controller that the freeze cycle is complete.

Harvest Cycle. When the harvest cycle begins,

the controller switches on the hot gas valve, and

through a parallel circuit, the harvest assist

solenoid. After a few seconds the purge valve

opens and water is drained from the reservoir.

Based on either the automatic purge or manual

purge setting, the pump and purge valve will be

switched off at a time determined to have drained

enough water for that setting. The inlet water

valve will open to fill the reservoir anytime the

mid length probe is uncovered, which occurs

during the reservoir drain cycle. Harvest

continues as the hot discharge gas flows into the

evaporator serpentine, heating up the evaporator.

At the same time the harvest assist solenoid is

pushing against the back of the ice slab. When

the ice releases from the evaporator, it harvests

as a unit, and the harvest assist probe provides

some additional force to push it off. When the ice

falls off it will force the curtain open. An open

curtain during the harvest cycle signals the

controller that the evaporator has released its ice

terminating harvest. If the curtain remains open,

the controller will shut the machine at bin full.

Anytime harvest is complete the hot gas valve

and harvest assist solenoid are shut off.

The harvest assist solenoid pin returns to its

normal position by spring pressure.

If the curtain re-close after harvest, the freeze

cycle will restart.

ELECTRICAL SEQUENCE

Air or Water Cooled

Power connected, unit previously switched Off.

Control board does a self check. If the self check

fails, the unit displays an E and no further action

will occur.

If the self check passes, the controller will display

a 0, the curtain light will be ON and the Power

and Sump Empty lights will be ON.

Pushing and releasing the On button will start

the ice making process.

Page 16

Page 16

Page 16

The display will begin to blink F. The component

indicator lights will switch on and off to match

the following process:

The purge valve opens and the water pump

starts to empty the reservoir. This is done to

discharge any excess water from ice melting into

the reservoir.

The hot gas valve and the harvest assist solenoid

are energized.

The inlet water valve will open to fill the reservoir.

The water valve can open any time the water

level is low.

After a few seconds the purge valve closes and

the pump shuts off.

When the reservoir is full the inlet water valve

stops and the compressor switches on. Five

seconds after the compressor starts the hot gas

valve and the harvest assist solenoid are deenergized.

Light Information: The display shows a nonblinking F. The Power and Status Lights will be

Green. The compressor, fan motor, water

pump, sump full and the curtain switch lights

will be ON.

The air cooled model’s fan motor will start to turn

when the discharge pressure has built up to the

fan pressure control’s cut in point. This is about

15 seconds after the compressor starts.

The Freeze cycle continues. The compressor,

water pump, fan motor and curtain indicator

lights will be ON. When the reservoir water

temperature falls to a certain preset point, the

water pump will shut off for 30 seconds. This is

the anti-slush period. At this time the controller

checks the conductivity of the water in the

reservoir for the auto-purge feature. After the

water pump restarts the Sump Full light will go

out and neither sump lights will be on for the rest

of the freeze cycle.

When the ice has built up enough so that the

water flowing over the evaporator comes into

continuous contact with the ice level sensor, the

Ready to Harvest light will begin to blink on and

off. When it has been On continuously for 3

seconds, the controller will switch the machine

into a Harvest cycle.

ELECTRICAL SEQUENCE

Air or Water Cooled

Indicator Information: The display shows a

non-blinking H. The Power and Status Lights

will be Green. The compressor, hot gas valve

and one curtain switch lights will be ON. After

a few seconds the water pump, purge valve

and inlet water valve lights will come on.

The fan motor(s) shut off and remain off

throughout the harvest cycle.

The harvest assist solenoid is connected in

parallel with the hot gas valve. Although it is

energized throughout the harvest cycle, its piston

does not move until the ice has become partially

loosened from the evaporator plate by the action

of the hot refrigerant gas passing through the

evaporator serpentine.

The water pump and purge valve will shut off

when the purge level setting time has been

reached, either the manual time or the automatic

time. The inlet water valve will remain on until it

fills the reservoir. The Ready to Harvest light will

switch Off when the ice falls from the evaporator.

Harvest continues until the ice slab is ejected

from the evaporator and falls, opening the curtain.

When the curtain opens, the magnetic reed curtain

switch opens, breaking the circuit to the controller.

If the curtain re-closes within 30 seconds, the

controller switches the machine back into another

freeze cycle. If the curtain switch remains open,

the controller shuts the machine down at bin full.

ELECTRICAL COMPONENT DETAIL

Compressor

• Operated by the compressor contactor. Single

or three phase.

Contactor

• Operated by the controller and the high pressure

cut out switch. Line voltage coil. When energized

the Compressor indicator light will be ON.

Water Pump

• Operated by the controller. When energized,

the Water Pump indicator light will be ON.

Inlet Water Solenoid Valve

• Operated by the controller. Line voltage coil.

When energized, the Water Solenoid indicator

light will be ON.

Purge Valve

• Operated by the controller. Line voltage coil.

When energized, the Purge Valve indicator

light will be ON. Energized for a time during

harvest.

Fan Motor(s)

• Operated by the controller and the fan pressure

control. Can cycle on and off in the freeze cycle,

always off during harvest. When the controller

has energized it, the indicator light will be ON

but the fan will not turn unless the discharge

pressure is high enough to close the high

pressure control.

• Fan(s) may shut off near the end of the freeze

cycle to build up heat for harvest. Time of shut

off depends upon available heat, as measured

by the discharge temperature.

High pressure cut out

• Some air cooled and all remote and all water

cooled models have a high pressure cut out

switch that shuts the power off to the compressor

contactor if the discharge pressure is too high.

It is an automatic reset.

Page 17

Page 17

Page 17

Harvest Assist Solenoid

• Operated by the controller in parallel with the

hot gas valve. Cycles on and off at the beginning

of a restart. Energized throughout the harvest

cycle. Line voltage coil.

Hot Gas Valve

• Operated by the controller in parallel with the

harvest assist solenoid. Cycles on and off at

the beginning of a restart. Energized throughout

the harvest cycle. Line voltage coil.

Controller

• Senses ice thickness, water level, water temperature, discharge temperature. Controls

compressor contactor, fan motor, water pump,

inlet water valve, hot gas valve, purge valve,

harvest assist solenoid. Indicates status and

component operation. 12 volt.

Transformer

• 12 volt secondary, supplies power to controller

only.

Water Level Sensor

• Three probe conductivity sensor. Bottom probe

is common, mid probe is refill sump, top probe

is full sump. Refill can occur at any time.

Ice Thickness Sensor

• Single wire conductivity sensor. Circuit made

from controller to ground to controller when

water contacts a probe suspended over ice

plate. Signals ready for harvest.

Curtain Switch

• Magnetic reed switch. Normally open, switch is

closed when magnet is nearby and can be

connected to either J8 or J7 of controller.

Curtains may be removed in the freeze cycle

without affecting controller operation. A curtain

removed during harvest will cause the controller

to terminate harvest and shut the unit off. If it

remains open for 30 seconds that signals the

controller to shut the unit off at bin full.

Water temperature sensor.

• Thermistor inserted into the water pump

discharge hose. Reported temperature used

by the controller to determine anti-slush cycle

start time.

Discharge temperature sensor.

• Thermistor attached to the discharge line near

the compressor. Reported temperature used

by the controller to determine end-of-cyclefan-off-delay time. If discharge temperature

exceeds a preset maximum, controller will shut

the machine off.

Note: Controller will operate machine in a

default mode with thermistors disconnected

from the controller. Diagnostic code #3 will be

displayed during that time.

Component Indicator Light Table

SYSTEM INDICATOR LIGHT ON

Condenser Fan or Liquid Line Valve Fan Motor Powered or LLV open

Water Pump Pump Motor Powered

Purge Valve Purge Valve Opens

Inlet Water Solenoid Valve Inlet Water Valve Opens

Hot Gas Hot Gas Valve Opens

Compressor Contactor Contactor Closes

Ready to Harvest Water contacting ice thickness sensor probe

Sump Empty Open between mid sensor and common

Sump Full Closed between top probe and mid probe

Curtain Switch Curtain open

Page 18

Page 18

Page 18

REFRIGERATION

Refrigerant: R-404A

Compressors: Copeland or Tecumseh hermetic

by model

Expansion valves: Non adjustable, internally

equalized.

Hot gas valve: Pilot operated, line voltage coils.

Condensers: Forced draft air, counterflow water.

All air cooled models have left side air inlet.

All air cooled models exhaust air out the back.

Air filters: Surface mounted to left side panel.

Filter media removable without removing panel.

Fan blades: Reduced vibration blades in most

air cooled models.

Fan pressure control. All AC. Controls fan

motor operation in the freeze cycle.

High pressure cut out. WC, AC.

Evaporator: Unified cell plate. Nickel plated

copper. Two heights: 12" and 18". Small cube =

half dice, medium cube = full dice.

Small cube: 22 mm high x 22 mm deep x 9,5 mm

high (7/8" high x 7/8" deep x 3/8" high).

Medium cube: 22 mm high x 22 mm deep x

22 mm high (7/8" high x 7/8" deep x 7/8" high).

WATER SYSTEM

Batch type. Water reservoir contains full water

charge for each ice making cycle.

Water valve: Solenoid type. Opens to fill reservoir

when mid sensor probe no longer makes a circuit

to the bottom probe. Closes when reservoir is full

and top probe makes circuit to mid probe.

Pump: Unsealed pedestal type, S.S. side

mounting bracket

Water purge valve: Solenoid type. Opens to

purge water during harvest cycle.

Water Level Sensor: Three probe conductivity.

Distributor: ABS plastic. Evenly distributes water

over the evaporator surface. Slides off the

evaporator top. Removable cover for ease of

cleaning.

Page 19

Page 19

Page 19

CONTROL OPERATION

Standard control:

• Electronic controller operating from a 12 AC volt

power supply. Will operate within a voltage

range between 10 and 15.5.

• User’s Indicator lights, four front visible: Power,

Status, Water, De-scale/Sanitize.

• Accessible On switch.

• Accessible Off switch.

• Code Display: Displays letters and numbers to

indicate cycles and diagnostic codes.

• Manual Harvest switch: Use to trigger harvest at

any time.

• Clean switch: Use to initiate and finish the descale or sanitizing cycles.

• Component Operation Indicator Lights: Indicate the status of certain components; water

level; ready for harvest; curtain switch position.

• Power Light: On when power is being supplied

to the controller.

• Status Light: Green when machine is in ice

making mode and is operating correctly. Blinks

red when a machine malfunction has been

detected.

• Water Light: Blinks red when reservoir does not

fill with allowed time period.

• De-scale / sanitize: Yellow when the controller

has determined it is time to de-scale and sanitize

the machine. Use clean process to reset light.

Time is determined by power up time and

controller’s setting. Standard setting is 6

months. See adjustment process

Controller Connections:

• J1 - Ground and Power Supply

• J2 - High voltage power harness to loads

• J3 - Factory use

• J4 - Optional board connector

• J5 - Communications port

• J6 - Thermistor connection

• J7 - Curtain switch

• J8 - Curtain switch

• J9 - Water level sensor

• J10 - Ice thickness sensor

• J11 - Bin thermostat. Use with NO thermostat

(closes on temperature fall) & specified harness.

CONTROL SAFETIES

Max freeze time - 45 minutes

When exceeded, control shuts the unit off for 50

minutes and will attempt a restart. If the condition

is exceeded again the next cycle, the control will

shut the unit off for 50 minutes and attempt a

restart. If it fails a third consecutive time the

controller will shut the machine down and must

be manually reset.

Min freeze time - 6 minutes

If the controller switches the machine into harvest

within 20 seconds of the minimum freeze time,

the controller will harvest for a preset time and

does not stop if the curtain switch opens.

If this occurs again in the next three cycles, the

machine will shut down and must be manually

reset.

Max harvest time - 3 minutes

If the harvest cycle has continued for 3 minutes

without the curtain opening, the controller will

shut the machine off for 50 minutes and then

restart. If there is another the machine will shut

the machine off for another 50 minutes and then

restart. If it fails a third consecutive time the

controller will shut the machine down and must

be manually reset.

• Time between resets - 50 minutes

• Number of automatic resets - 2

• Max water fill time - 5 minutes. Machine will

attempt a restart every 20 minutes.

• Max discharge temp - 120°C (250 degrees F).

• Time interval between cleanings - 6 months

power on time - adjustable in one month

increments, can be set at 6, 5, 4 or 3 months of

power up time.

• Manual harvest time - 3 minutes

• Minimum compressor off time - 4 minutes

• Continuous Run Time Maximum Cycles - 25

RESTARTS

Power Interruption

The controller will automatically restart the ice

machine after adequate voltage has been

restored.

• H blinks on code display

• Status indicator light blinks

• Reservoir is drained and refilled

• Default harvest is initiated. The curtain switch

does not have to open to terminate harvest,

harvest will continue until either the curtain’s

switch opens or the default harvest time expires.

Default harvest time is 2 and half minutes. The

machine will then return to a normal freeze

cycle.

Water Interruption

• The controller will attempt to fill the reservoir

every twenty minutes until it is successful.

On-Off Switch Access

All models ship with the On and Off switches front

accessible.

Page 20

Page 20

Page 20

CONTROL BUTTON USE

(from standby)

Set purge level, 1-5 (1 is minimum, 5 is maximum)

or Automatic:

• Hold off button in till a number or the letter A

shows on display and green STATUS led

ON. . Release.

• Press and release the On button to cycle through

and select one of the five purge settings (1->5)

or to use the Automatic setting (A).

Recall diagnostic code:

• Hold off button in till a number or the letter A

shows on display and green STATUS led

ON. . Release.

• Press and release the Harvest button to cycle

through each of the last 10 error codes from

most recent to oldest.

Clear diagnostic code:

• Hold Clean and Harvest buttons in for 3 seconds

to clear all prior codes.

Reset control:

• Depress and release Off, then depress

andrelease On.

Start Test Mode:

• Hold off button in till a number or the letter A

shows on display and green STATUS led

ON. . Release.

• Hold Clean button in till letter d shows on

display. Release.

Lock / Unlock control:

• Hold On button in for 3 seconds, keep holding

then press and release Off twice.

Empty reservoir:

• Hold Clean button in till dash (-) shows on

display. Release. Pump and purge valve will be

ON for 30 seconds. Repeat as needed.

Test Mode: See next page for Air and Water

Cooled mode.

• Hold off button in till a number or the letter A

shows on display and green STATUS led ON,

release. Then depress Clean for 3 seconds till

letter d shows on display.

• The sump will fill the first 30 seconds of the test.

If the sump is full it will overflow into the bin. At

30 seconds the WIV will shut off and the WP will

turn on. You will be able to see and hear the

water running over the plate. After 10 seconds

the PV and HGV will turn on. Water will be

purging from the machine. After 10 more

seconds the compressor will start. 5 seconds

later the HGV will close. The compressor will

run for a total of 20 seconds. After which

everything will turn off for 5 seconds. After that

time the HGV will open and you’ll be able to

hear the hissing as the pressure is equalized.

10 seconds later the fan will turn on (if air

cooled). After 10 seconds all will be off and the

output test will be complete.

Change De-Scale Notification Interval

Like the others, this feature is accessible only

from standby (Status Light Off).

• Press and hold harvest button till a number

shows on display.

• This will allow control to enter Time to Clean

Adjustment State.

• Display current time to clean months on 7

segment display.

• Pressing clean button repeatedly will cycle

through one of 4 possible settings:

6 months (4380 hours) (default)

5 months (3650 hrs)

4 months (2920 hrs)

3 months (2190 hrs)

Time (seconds) On Off

0 WIV -30 seconds WP, HGV, Comp, Fan, PV

30 WP -10 seconds WIV, HGV, Comp, Fan, PV

40 WP, PV, HGV -10 seconds WIV, Comp, Fan

50 HGV, Comp -5 seconds WIV, WP, Fan, PV

55 Comp -15 seconds WIV, HGV, WP, Fan, PV

70 None -5 seconds All

75 HGV -10 seconds WIV, WP, Comp, Fan, PV

85 Fan -10 seconds WIV, HGV, WP, Comp, PV

95 None All - Test Complete

Test Mode Sequence Table - Air or Water Cooled

Page 21

Page 21

Page 21

Disch. Disch. Hi Suction Suction Amps Amps

Pressure Pressure Pressure Pressure Pressure

Compressor Compressor

Freeze max Freeze min CUT OUT Beginning end Freeze Beginning end

bar bar bar Freeze bar bar Freeze Freeze

MVP 456 A - 230/50/1

17,5 15,5 33 3,5 2,0 15 4,7 3,6

MVP 456 W - 230/50/1

16,5 16,5 33 3,5 2,2 16 4,2 3,4

MVP 606 A - 230/50/1

18 16 33 2,7 1,5 13 6,2 4,8

MVP 606 W - 230/50/1

16,5 16,5 33 3,2 1,7 13 5,8 4,5

MVP 806 A - 230/50/1

18,5 16,5 33 2,0 1,8 12,5 8,6 6,4

MVP 806 W - 230/50/1

16,5 16,5 33 3,5 1,9 14,5 9,0 6,7

MVP 1006 A - 400/50/3

16 14 33 2,9 1,6 12 3,7 3,0

MVP 1006 W - 400/50/3

16,5 16,5 33 3,2 1,8 13,5 3,6 2,8

Cycle time

minutes

MODEL

Refrigerant charge R 404 A - gr.

MODEL MVP 456 MVP 606 MVP 806 MVP 1006

Air cooled 700 850 1300 1600

Water cooled 500 550 650 1200

Refrigerant metering device

Thermostatic expansion valve.

SERVICE SPECIFICATION

In servicing a machine, it is often, useful to

compare that individual units operating

characteristics to those of a normally operating

machine. The data that follows gives those

characteristics; however, be aware that these

values are for NEW, CLEAN machine operating

at 21 °C ambient and 15 °C water. USE THESE

NUMBERS AS A GUIDELINE ONLY.

OPERATING CHARACTERISTICS

On air-cooled models during the freezing cycle,

the discharge pressure is maintained between

two preset values by means of fan control

(condenser sensor); and at the same time, the

suction pressure will also decline reaching it’s

lowest point just before harvest. Compressor

amps experience a similar drop.

On water-cooled, the discharge pressure is

constantly, maintained during the freeze cycle by

the water regulating valve. However, suction

pressure and compressor amps, will still decline

as the machine freezes ice.

NOTE: Always check nameplate on individual

icemachine for special refrigerant charge

before charging the refrigeration system.

Such refrigerant charge is the average charge

for the MVP Modular Cubers. However it is

important to check nameplate for each

machine.

Page 22

Page 22

Page 22

DIAGNOSIS

No ice

Problem Likely Cause Probable Solution

No power to unit Power disconnected Check breaker or fuse. Reset or

replace, restart and check

No power to controller Transformer open Replace transformer

Shut down on maximum Water shut off Restore water supply

water fill time

Shut down on maximum Water leak Check purge valve, curtain,

freeze time sump, pump hose

Air filters clogged Clean air filters

Dirty condenser Clean condenser

Restricted location, intake air too hot

Have machine moved

Ice thickness sensor dirty or Check ice thickness sensor probe

disconnected

Water distributor dirty Remove and clean water distributor

Inlet water valve leaks through Check inlet water valve

during freeze

Connected to hot water Check for bleed thru from / missing

check valve in building water supply

Incomplete harvest Check harvest system

High pressure cut out opened Check fan motor pressure control,

check fan motor, check controller

using test mode

Fan motor pressure control open Check fan pressure control

Fan motor not turning Check fan motor, check fan blade,

check controller using test mode

Water pump not pumping Check pump motor, check controller

using test mode

Shut down on maximum Pump hose disconnected Check hose

freeze time

Check compressor contactor,

check controller using test mode

Compressor not operating Check compressor start components

Check compressor voltage

Check compressor windings

Low refrigerant charge Add some refrigerant and restart unit.

If cycle time improves, look for leak.

Hot gas valve leaks through during Check hot gas valve for hot

freeze outlet during freeze

Thermostatic expansion valve Check bulb

bulb loose

Thermostatic expansion valve Check evaporator superheat,

producing very low or very high change TXV if incorrect

superheat

Compressor inefficient

Check compressor amp draw, if low and

all else is correct, change compressor

Page 23

Page 23

Page 23

Problem Likely Cause Probable Solution

Shut down on maximum Ice bridge thickness too small, Check and adjust if needed

harvest time not enough ice to open curtain

Ice bridge thickness too large, Check and adjust if needed

ice frozen to evaporator frame

Purge valve does not open, water Check purge valve

melts ice bridge, not enough ice to

open curtain

Incomplete ice formation Check water distributor for partially

plugged holes

Curtain out of position Check curtain for swing restriction

Curtain switch does not open when Check switch with ohmmeter

curtain does

Machine in very cold ambient Move machine to a warmer location

Hot gas valve does not open Check hot gas valve, check controller

using test mode

Harvest assist probe out of position -

Check harvest assist mechanism ejector pin not retracted spring should retract pin

Damaged evaporator Check evaporator surface

Fan motor stays on during harvest Check controller using test mode

Shut down on minimum Grounded ice thickness sensor Check sensor for dirt and position.

freeze time

Clean and check gap to evaporator surface.

Long freeze cycle Dirty air filters Clean filters

Dirty condenser Clean condenser

Hot ambient Reduce room air temperature

Water leak Check purge valve, check curtain

Water inlet valve leaks through Check inlet valve

Low on refrigerant Add refrigerant, if cycle time drops,

check for leak

Incorrect superheat Check evaporator superheat, if

significantly low or high, replace TXV

Fan(s) cycle on and off Check pressures fans cycle at.

Replace fan pressure switch if too low

Long Harvest Cycle Dirty evaporator De-scale water system

No harvest assist Check harvest assist solenoid

Bridge thickness too big Check and adjust bridge thickness

Machine in very cool ambient Increase room temperature

False bin full signal

Ice jammed in between curtain and sump

Clear ice away

Curtain does not close correctly Check curtain for proper swing

Fan blade vibrates Blade is bent Replace fan blade

Fan motor mount is broken Replace motor mount

Compressor vibrates Mounting bolts loose Tighten bolts

Water pump vibrates Pump bearings worn Replace pump

Panels vibrate Mounting screws loose Tighten screws

DIAGNOSIS

Page 24

Page 24

Page 24

TEST PROCEDURES

All electrical components in this ice machine can

be diagnosed with a volt-ohmmeter.

Curtain Switch:

1. Test using the controller’s indicator lights.

Observe SW1 or SW2. Open and close the

curtain in question. When the curtain is opened,

the SW light will be ON. When the curtain gets to

within a half inch of closing (at the switch) the SW

light will go OUT.

Note. As the Prodigy MVP series is equipped

with just one Curtain Switch, it’s normal to

have one SW led always ON.

2. Test with an ohmmeter. Disconnect electrical

power. Open the control box cover. Unplug the

curtain switch lead from the controller. Connect

an ohmmeter to the leads of the switch. Open

and close the curtain. When the curtain is closed,

the switch is closed and there will be continuity.

When the curtain is open, the switch is open and

the circuit will be open.

3. Test the controller’s curtain switch circuit by

jumping the connectors on J1 or J2 together.

Reconnect electrical power. When jumped, the

matching SW light will go out. When unplugged

or open, the SW light will be ON.

ICE THICKNESS SENSOR

1. Test using the controller’s indicator light.

Observe the Ready To Harvest light. Shut the

machine off. Use a wire to connect the metal part

of the Ice Thickness sensor to the evaporator or

simply remove the Ice Thickness Sensor and

touch its metal surface to the metal control box

wall. The Ready for Harvest light should go ON.

2. Test with an Ohmmeter. Disconnect electrical

power. Open the control box cover. Unplug the

ice thickness sensor lead from the controller.

Connect an ohmmeter lead to the ice thickness

sensor lead, touch the other ohmmeter lead to

the ice machine chassis. There must be an open

circuit. If there is continuity, the sensor must be

replaced. If there is no continuity, touch the

ohmmeter lead to the metal part of the ice

thickness sensor. There should be continuity. If

open, check the ice thickness sensor for scale

build up. Clean and recheck. If still open, replace

the ice thickness sensor.

3. Test the controller’s ice thickness sensor

circuit by connecting a wire from J10 to ground.

Reconnect electrical power. The Ready for

Harvest light should go ON

WATER LEVEL SENSOR

1. Test using the controller’s indicator lights

(sump empty and sump full). Unit must be powered

up and there must be water in the sump. Add

some manually if needed. Locate water level

sensor. Release from sump cover and slowly lift

up until the mid-length probe is out of the water.

The sump empty light should come on, and if the

unit is on the inlet water solenoid valve will open

to fill the reservoir. Return the water level sensor

to its normal position. If the unit is on and calling

for ice the water will fill until the top probe is in

contact with it, at that time the sump full light will

switch ON.

2. Test with an ohmmeter. Disconnect electrical

power. Open the control box cover. Unplug the

connector at J9. Locate water level sensor and

Page 25

Page 25

Page 25

remove it from the sump cover. Test 1: Place one

lead of the ohmmeter on the longest probe and

the other on the controller end of the red wire,

there should be continuity. Test 2: Place one lead

on the controller end of the white wire and the

other on the mid-length probe, there should be

continuity. Test 3: Place on lead on the controller

end of the black wire and the other on the

shortest probe, there should be continuity.

If not, clean the probes and recheck.

3. Test the controller’s water level sensor circuit.

Reconnect electrical power. Unplug harness from

water level sensor, the sump empty light should

be ON. Jump harness wires white and black. The

sump full light should be ON. Jump harness

wires black and red, the sump full and sump

empty lights will be OFF. Check harness wire by

wire for continuity if there is no reaction from the

controller during this test.

TEMPERATURE SENSOR

1. Check controller. If the sensor calibration is

completely out of range, the code display will

read either 5 or 7.

2. Check with an ohmmeter. Open control box

cover, unplug sensor from J6. Water temperature probe: Measure the temperature of the water.

Push and release the clean button. Wait one

minute. Measure the resistance of the water

probe (two leads next to the open socket) and

compare to the resistance in the chart for that

WATER

TEMP.

SET

DISCHARGE

TEMP.

SET

temperature. Any reading within 1000 ohms is

acceptable. Discharge sensor: Measure the temperature of the discharge line as close to the

sensor as possible. Measure the resistance of

the discharge temperature sensor (two leads

farthest away from the open socket on the harness

connector) and compare to the resistance in the

chart for that temperature. Any reading within

1000 ohms is acceptable.

3. Alternate procedure: Remove both water

and discharge sensors from their places on the

ice machine. Put both into a container of ice

water. Put a thermometer in the water. When the

thermometer is at 0°C (32 degrees F), check the

resistance of each sensor. The resistance should

be 32650 ohms

°C Ohms

0 32650

10 19000

15 15715

20 12495

25 10000

30 8055

35 6530

Compressor

Failure to start.

Single phase models. All have resistance start,

capacitor run type motors. Check voltage to

compressor at the contactor. Compare the idle

voltage (compressor off) to the active voltage

(compressor starting). The supply voltage must

not be less than the lowest rated voltage for the

ice machine. If the voltage is correct, proceed to

the next step.

Page 26

Page 26

Page 26

Check starting components.

Potential relay. If the compressor will not start,

check the amp draw of the starting circuit. If very

low, the potential relay contacts or start capacitor

may be open. Measure the resistance of the

potential relay contacts and the start capacitor. If

either is open it should be replaced. If the

compressor starts but draws very high amps

from the starting circuit, the potential relay may

not switch off. In that case the relay should be

replaced.

Measure resistance from Common to ground. It

should be infinite. Measure resistance from

Common to Run - compare to the chart. Measure

resistance from Common to Start - compare to

the chart.

Compressor check for high amp draw. Measure

amp draw of starting circuit. If it does not drop off

immediately after start up, the starting relay

should be replaced.

If the compressor is drawing excessive amps but

is operating, the run capacitor may be open.

Disconnect electrical power, discharge the

capacitor and measure its resistance. If open,

replace it. If shorted to ground, replace it.

Any time the compressor is replaced, the potential

relay, start capacitor and run capacitor should be

replaced with the compressor.

Fan motor

1. Test using the controller’s indicator lights.

Note: Fan pressure control connection must

be jumped to perform this test.

Put the controller into test mode (depress Off for

3 seconds then depress Clean for 3 seconds).

At the end of the test cycle, the fan motor will be

powered and the Condenser Fan motor indicator

light will be on. The fan motor should start and run

at that time. If it does not, repeat the test but

check the voltage to the fan motor, it must receive

full voltage at the fan motor lead connection at

the end of the test. If there is voltage and the

motor does not operate, replace the motor. If

there is no voltage, check the controller high

voltage harness connection.

The fan motor lead is the top wire. Check voltage

from it to ground, at the end of the test, when the

fan motor indicator light is On, there must be

voltage from this pin to ground. Note: high voltage

power is supplied to the bottom pin from the

contactor line. Refer to the machine wiring

diagram as needed.

2. Test using an ohmmeter. Disconnect

electrical power. Unplug fan motor from harness.

Measure fan motor winding resistance. If open,

replace the fan motor.

Water Pump

1. Test using the controller’s indicator lights.

Check the indicator light during the freeze cycle.

The light will be On for all but the 30 second antislush period, so observe the light for one minute.

When it is On, check the water pump, it should be

operating. If not, check voltage to the pump. If low

check the voltage from the controller to ground.

The water pump pin is number 6. If there is

voltage at that pin to ground, but very low voltage

at the pump motor, there must be a broken wire

in the harness. If the voltage is low at pin 6, the

controller should be replaced.

2. Test using an ohmmeter. Disconnect

electrical power. Unplug the water pump motor

leads from the harness. Measure the resistance

of the motor windings. If open, replace the pump.

Measure resistance to ground. If there is any,

replace the pump.

Purge valve

1. Test using the controller’s indicator lights. Shut

unit off by holding the Off button for 3 seconds.

Wait four minutes. Push and release the On

button, observe the Purge Valve indicator light.

As the unit drains the reservoir, the purge valve

will be powered. When it gets power, the indicator

light will be ON. If the purge valve does not open

to drain the reservoir when its indicator light is on,

do a voltage check. Shut the unit down by holding

the Off button in for 3 seconds. Unplug the

harness connection from the purge valve. Wait

Page 27

Page 27

Page 27

four minutes. Push and release the On button to

restart the machine. As the unit drains the

reservoir, the purge valve connection should

receive full voltage. If it does, the purge valve

should be replaced. If there is no voltage, check

voltage from the controller to ground. The purge

valve pin is 3 (dump valve on wiring diagram). If

there is voltage from that pin to ground, but low

voltage at the valve harness connection, the

harness has a broken wire or poor connection

and must be replaced.

If the voltage to ground is low, the controller

should be replaced.

Note: The coil of this valve is internally rectified,

and will normally show infinite resistance when

tested with an ohmmeter.

Compressor contactor

1. Test using the controller’s indicator lights.

When the unit is in ice making mode the

compressor contactor will have power. Check

the Compressor indicator light, when it is on the

compressor contactor will have pulled in. If it is

not, do a voltage check. Place voltmeter leads on

the coil of the contactor. There should be full

voltage . If there is full voltage present and the

contactor has not pulled in, replace the contactor.

If there is no voltage check if the high pressure

cut out is open. If the high pressure cut out is

closed, check for voltage from the controller to

ground. The contactor pin is 4. Check from 4 to

ground when the compressor indicator light is

on. There should be voltage. If not, replace the

controller. If there is voltage at the controller but

not at the contactor coil, the harness wires or

connectors are damaged and must be replaced.

2. Test using an ohmmeter. Test the coil of the

contactor for continuity or shorts to ground.

Replace if open or shorted.

3. Check connections and contacts. Be sure

connections are tight and that the contacts are

not burnt. Replace any contactor with burnt

contacts.

Pressure switches

There are two pressure switches: Fan and High

Pressure cut out.

Fan. The fan pressure switch will open to shut the

fan motor off at a certain pressure and re-close at

a preset higher pressure.

High pressure cut out. The high pressure cut out

switch will open at a preset pressure, shutting off

power to the compressor contactor. After the

pressure has fallen to another preset level, the

switch will re-close and the contactor coil will be

engergized.

To Test Fan Pressure Switch:

A. Attach refrigeration gauge set to high side port.

B. Unplug both wires from fan pressure control.

Be SURE the wire’s terminals are wrapped

in electrical tape to prevent short circuits

to ground during the test.

C. Connect ohmmeter to terminals of fan pressure

control.

D. Switch ice machine on, observe pressure that

the pressure control closes at, compare to

spec. Switch unit off, allow system to equalize,

observe pressure the pressure control opens

at, compare to spec.

To Test High Pressure Switch:

A. Attach refrigeration gauge set to high side port.

B. Unplug fan motor or shut water off if water

cooled.

C. Measure voltage between contactor side

terminal of high pressure control and ground.

D. Switch ice machine on, observe pressure that

the pressure control opens at, compare to spec.

Allow system to equalize, observe the pressure

that the pressure control closes at, compare to

spec.

Transformer

Check secondary voltage, it must be between 10

and 15.5 AC volts. Replace if no voltage is output

or if above or below the acceptable voltage.

Controller

The controller’s software operation is confirmed

if it is functioning. Execute the test to confirm its

operation of the loads. Illumination of a diagnostic

code (other than E) is not an indication of controller

failure. Each code requires its own diagnosis.

Inlet Water Solenoid Valve

1. Test using the controller’s indicator lights.

Shut unit off by holding the Off button for 3

seconds. Wait four minutes. Push and release

the On button, observe the Water Solenoid

indicator light. After the unit drains the reservoir,

the inlet water valve will be powered to refill the

reservoir. When it gets power, the indicator light

Page 28

Page 28

Page 28

will be ON. If the water valve does not open to fill

the reservoir when its indicator light is on, do a

voltage check. Shut the unit down by holding the

Off button in for 3 seconds. Unplug the harness

connection from the inlet water valve. Wait four

minutes. Push and release the On button to

restart the machine. After the unit drains the

reservoir, the inlet water valve connection should

receive full voltage. If it does, the inlet water valve

should be replaced. If there is no voltage, check

voltage from the controller to ground. The inlet

water solenoid valve pin is 7. If there is voltage

from that pin to ground, but low voltage at the

valve harness connection, the harness has a

broken wire or poor connection and must be

replaced. If the voltage to ground is low, the

controller should be replaced.

2. Test using an ohmmeter. Disconnect

electrical power. Unplug coil from harness.

Measure coil resistance. If open, replace the inlet

water solenoid.

Harvest assist solenoid

1. Test using the controller’s indicator lights.

Push and release the Harvest button. The Hot

Gas indicator light will be on. At the same time the

Harvest Assist Solenoid will be powered. If the

ice on the evaporator is thin, the solenoid will

extend. If the ice is nearly full sized, the solenoid

will press against the ice until it releases from the

evaporator, then the solenoid probe will extend.

If the probe extends, the solenoid is good. If not,

do a voltage check. Unplug the high voltage

harness from the harvest assist solenoid. Attach

a voltmeter to the harness connector. Push and

release the Harvest button. There should be full

voltage at the connector.

If there is and the solenoid does not extend,

replace the solenoid. If full voltage is not present,

check voltage at the controller. If there is no

voltage, check voltage from the controller to

ground. The hot gas / harvest assist pin is 5. If

there is voltage from that pin to ground, but low

voltage at the solenoid harness connection, the

harness has a broken wire or poor connection

and must be replaced. If the voltage to ground is

low, the controller should be replaced.

Note: The coil of this valve is internally rectified,

will normally show infinite resistance when

tested with an ohmmeter.

Hot Gas Valve

1. Test using the controller’s indicator lights. If

the unit is running, or has been off for more than

4 minutes, push and release the Harvest button.

The Hot Gas indicator light will be on and the hot

gas valve will be energized. The compressor will

force discharge gas into the evaporator inlet,

warming it. If the evaporator inlet does not warm

up, do a voltage check. Shut the unit off by

holding the Off button in for 3 seconds. Unplug

the high voltage harness from the hot gas

solenoid. Attach a voltmeter to the harness

connector. Wait 4 minutes. Push and release the

Harvest button. There should be full voltage at

the connector. If there is and the solenoid does

not open, replace the solenoid coil. If full voltage

is not present, check voltage at the controller. If

there is no voltage, check voltage from the

controller to ground. The hot gas pin is 5. If there

is voltage from that pin to ground, but low voltage

at the solenoid harness connection, the harness

has a broken wire or poor connection and must

be replaced. If the voltage to ground is low, the

controller should be replaced.

2. Test with an ohmmeter. Disconnect electrical

power. Unplug high voltage harness from hot gas

or vapor valve. Measure resistance of hot gas or

vapor valve coil. If open, replace the coil.

CONTROLLER DIFFERENCES

The controllers are programmed at the factory for

the model they are installed on, they cannot be

moved from one model to another due to

differences in:

• Water purge time per setting

• Maximum harvest time

• Number of evaporator plates

The service controller has a selector switch that

allows it to be used as a replacement part in any

of the Prodigy models in production at the time

the controller was manufactured. As new Prodigy

models are introduced, those models will be

added to the list of models new service controllers

will work with.

The Service Controller includes a selector switch.

The switch must be set to the model the controller

is being installed on. As new models are

introduced, their setting will be added to service

controllers produced after that point.

Page 29

Page 29

Page 29

MVP 456/606/806/1006 - WIRING DIAGRAM

220 V. 50 Hz. 1 ph.

A - Input terminal board

B - Compressor remote control switch

C - Compressor

D - Ice sensor

E - End defrosting switch

F - Water level sensor

G1 - Condenser temperature probe

G2 - Water temperature probe

H - Led card

I - Electronic card

J - Max pressure switch

m = brown

bc = light blue

gv = yellow green

b = white

n = black

r = red

a = orange

v = viola

123J9

12

3

4

J11

J10

12345678

J2

12

12

J6

J1

J8

J7

F

D

1234

E

G1

G2

L

v

bc

m

bc

m

m

a

a

mrvnabm

gvnr

b

n

r

bcm

bcm

gv

gv

gv

gv

M

bc

r

N

bc

b

O

bc

n

SP

bc

n

P2

m

bc

gv

P1

A

K - Automatic reset switch

L - Water pump

M - Water inlet valve

N - Water discharge valve

O - Hot gas valve

SP - Solenoid harv assist

P1 - Fan motor 1 (only AIR cooled unit)

P2 - Fan motor 2 (only AIR cooled unit)

RC - Compressor relay

CS - Start condenser

CM - Run condenser

Page 30

Page 30

Page 30

MV 1006 - WIRING DIAGRAM

400 V. 50 Hz. 3 ph.

A - Input terminal board

B - Compressor remote control switch

C - Compressor

D - Ice sensor

E - End defrosting switch

F - Water level sensor

G1 - Condenser temperature probe

G2 - Water temperature probe

H - Led card

I - Electronic card

J - Max pressure switch

S - Fan pressure switch

K - Automatic reset switch

L - Water pump

M - Water inlet valve

N - Water discharge valve

O - Hot gas valve

SP - Solenoid harv assist

P1 - Fan Motor 1 (only AIR cooled unit)

P2 - Fan Motor 2 (only AIR cooled unit)

RC - Compressor relay

CS - Start condenser

CM - Run condenser

R - Run condenser

m = brown

bc = light blue

gv = yellow green

b = white

n = black

r = red

a = orange

v = viola

123J9

1234

J11

J10

12345678

J2

12

12

J6

J1

J8

J7

F

D

1234

E

G1

G2

L

v

bc

m

bc

m

m

a

a

mrvnabm

gvnr

b

n

r

m

gv

gv

gv

M

bc

r

N

bc

b

O

bc

n

SP

bc

n

P1

m

bc

gv

P2

n n

Page 31

Page 31

Page 31

REPAIR PROCEDURES

Ice thickness sensor

1 Push and release the Off switch.

2 Remove front and top panels.

3 Push and release the Harvest switch

4 Disconnect electrical power.

5 Open the control box.

6 Remove curtain.

7 Locate sensor, squeeze mounting legs

together to release it from the mounting

bracket.

8 Remove sensor, follow wire back to control

box.

9 Disconnect from controller connection J10.

10 Remove sensor from machine.

11 Reverse to reassemble.

12 Set initial probe-to-evaporator-surface gap

using a 5,5 mm drill bit as a gauge.

Controller

1 Disconnect electrical power.

2 Remove front panel.

3 Open control box door.

4 Unplug all wires from controller.

5 Remove screws holding controller to door

6 Push controller snaps down and pull controller

from mounting bracket.

7 Before touching new controller, discharge

any static electricity by touching the metal

surface of the ice machine cabinet.

8 Rotate selector switch to the proper model

number for the machine the controller is

being installed on.

9 Install new controller on mounting bracket,

secure with original screws.

10 Attach all wires removed.

11 Shut control box cover.

12 Switch on the electrical power.

Curtain

1 Push and hold the Off button to shut the

machine off.

2 Remove front panel.

3 Remove evaporator cover.

4 Push inside tab in to release front curtain pin

from holder.

5 Pull curtain from machine.

6 Reverse to reassemble.

7 Push and release the ON button to restart the

machine.

Curtain switch

1 Push and hold the Off button to shut the

machine off.

2 Disconnect electrical power

3 Remove front panel.

4 Open control box.

5 Locate curtain switch on evaporator mounting

bracket. Pull switch from its snaps.

6 Dismount wires from sump cover and remove

from J7 or J8 connector on control board.

7 Reverse to reassemble. Be sure wires are

re-mounted to sump cover edge.

Water level sensor

1 Push and hold the Off button until the machine

shuts off.

2 Remove the front panel.

3 Squeeze the locking tabs together and pull

the sensor up and out of the sump.

4 Unplug the electrical connection from the

sensor.

5 Reverse to reassemble.

Page 32

Page 32

Page 32

CLEANING, SANITATION AND

MAINTENANCE

This ice system requires three types of

maintenance:

• Remove the build up of mineral scale from the

ice machine’s water system and sensors.

• Sanitize the ice machine’s water system and

the ice storage bin or dispenser.

• Clean or replace the air filter and clean the air

cooled condenser (air cooled models only).

It is the User’s responsibility to keep the ice

machine and ice storage bin in a sanitary

condition. Without human intervention, sanitation

will not be maintained. Ice machines also require

occasional cleaning of their water systems with a

specifically designed chemical. This chemical

dissolves mineral build up that forms during the

ice making process.

Sanitize the ice storage bin as frequently as local

health codes require, and every time the ice

machine is cleaned and sanitized.

The ice machine’s water system should be

cleaned and sanitized a minimum of twice per

year.

1. Remove the front panel.

2. Remove the evaporator cover.

3. If the machine is operating, push and release

the Harvest button. When the machine completes

the Harvest cycle it will stop. If the bin is full (

b

shows in display) push and release the Off button.

4. Remove all ice from the storage bin or

dispenser.

5. Push and release the Clean button. The

yellow Clean light will blink and the display will

show C. The machine will drain the reservoir and

refill it. Go onto the next step when the reservoir

has filled.

6. Pour 8 ounces of Scotsman Cleaner 1 ice

machine scale remover into the reservoir.

7. Allow the ice machine scale remover to

circulate in the water system for at least 10

minutes.

Ice machine cleaner contains acids. Acids

can cause burns. If concentrated cleaner

comes in contact with skin, flush with water.

If swallowed, do NOT induce vomiting. Give

large amounts of water or milk. Call

Physician immediately. Keep out of the

reach of children.

8. Push and release the Clean button again. The

yellow Clean light will be on continuously and the

machine will drain and refill the reservoir

repeatedly to purge out the ice machine scale

remover and residue.

9. Allow the drain and refill process to continue

for at least 20 minutes.

10. Push and release the Off button. The clean

cycle will stop and the display will show O.

Note: If unit has not been de-scaled for an

extended period of time and significant mineral

scale remains, repeat steps 5-10.

11. Mix a cleaning solution of 1 oz of ice machine

scale remover to 12 ounces of water.