Page 1

MF400

INTRODUCTION

To the owner or user: The service manual you are

reading is intended to provide you, and the

maintenance or service technician with the

information needed to install, start up, cle an ,

maintain, and service this ice system.

TABLE OF CONTENTS

For the Installer

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 2

Location/Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 4

For the Plumber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 5

For the Electrician . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 6

Final Check List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 7

Start Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 8

Component Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 9

Electrical Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 10

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 11

Maintenance & Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 13

Service Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 15

Removal and Replacement

Ice Breaker and Auger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 17

Water Seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 17

Gearmotor Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 18

Parts lists and wiring diagrams are locat ed

in the center of this manual, printed on

yellow paper.

May, 1991

Page 1

Page 2

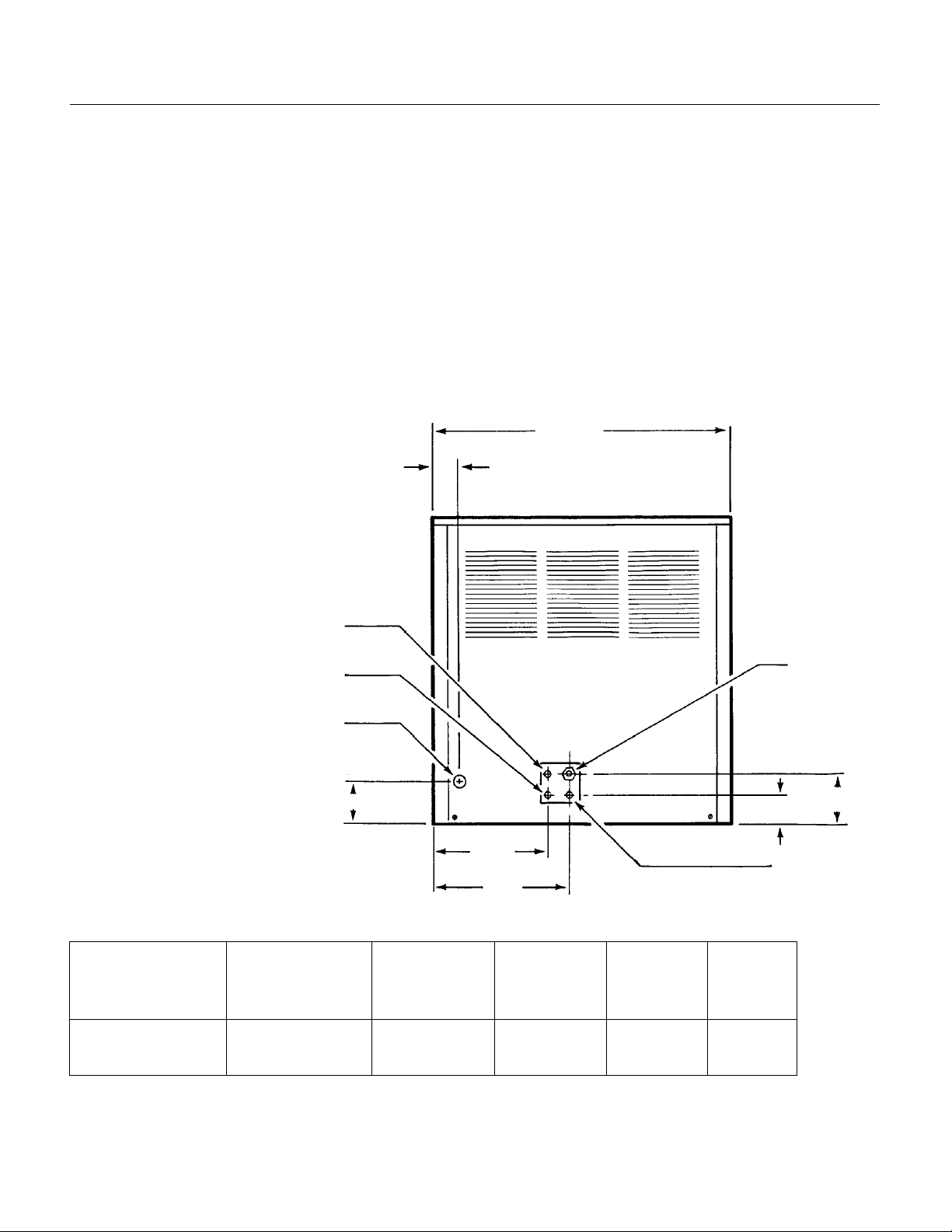

Drain 7/16" I.D.

Hose

12.7

11.4

Minimum

Circuit

Ampacity+

MF400

FOR THE INSTALLER

The MF400 is desig n ed to fit th e fo llowin g

Scotsman storage bins.

BH550 with bin top KBT20

HTB500 with bin top KBT2 0

The normal fin ish for th e mach in e is enamel

sandalwo o d. An op tio n al st ain le ss steel pan el kit

(SPKMF40 0A ) may be ord e red an d field installed

to convert the unit to a sta inless steel finish.

When installing the new system, check that

everythin g nee de d is on site :

Correct Ice Ma ch ine (v olt a ge

and type)

Correct Bin

Correct Bin Top

Legs for the bin

1 -7/16"

SPECIFICA TIONS :

21"

Condenser Drain 3/8"

O.D. Tube (Water Cooled)

Condenser Inlet, 3/8" O.D.

Tube (Water Cooled)

ICEMAKER

Electrical

Note: This servic e manua l is

for the current MF400 "B"

model, but applies in general

to the prior "A" model. The

primary differe nc es are in

the evaporator, spout and

the ice chute.

Model

Number

MF400AE-1B

MF400WE-1B

Dimensions

(w/o Bin)

H" x W" x D"

21.5 x 21 x 22

Inlet

same

2.5"

Basic

Electrical

115/60/1

same

8"

9.5"

Condenser

Type

Water

Air

Water Inlet

1/4" Male Flare

3.5"

2"

Maximum

Fuse Size

15

15

*Minimum Circuit Ampa cit y is used to dete rmine

wire size and typ e pe r Na tio n al Ele ct ric Co d e.

May, 1991

Page 2

Page 3

FOR THE INSTALLER

MF400

Installation Limitations:

This ice system is designed to be installed indoors,

in a controlled environment:

Min Max

Air Temperatu re 500F. 1000F.

Water Temperature 40

Water Pre ssure 20 psi 80 psi

Voltage -10% +10%

(Compared to the Na mep la te )

Operating the machine outside of the limitations is

misuse and can void the warranty.

Scotsman Ice Systems are designed and

manufac tu red with the h igh e st rega rd for sa fe ty

and performance. They meed or exceed the

standards of UL, NSF, and CSA.

Scotsman assu me s no liability or respo ns ibilit y of

any kind for products manufactured by Scot sm an

that have been altered in any way, including the

use of any part and/or other components not

specifically approved by

Scotsman.

Scotsman res erves th e r ight

to make design changes

and/or impro vements at any

time. Specifications and

design changes are subject to

change without notice.

0

F. 1000F.

Water Limitations:

An ice machine is a food manufacturing plant; it

takes in a raw mat eria l, wa te r, and tu rns it in to a

food product, ice. The purity of the water is very

important in obtainin g pure ice and in maximizin g

product life . This se ctio n is not int e nde d as a

complete resource for water questions, but it does

offer these ge nera l reco mmendatio n s:

1. Filter the wat er u sed to make ice. That is the

water going to the “potable” water connection.

Water filters vary gre a tly in ability a nd fu n ctio n .

Install one that filters out suspended solids to a

dimension of 5 microns or smaller. The finer the

filter the bette r, but fin e r filte rs will clog soon er tha t

course ones. It may be necessary to add a course

filter ahead of the fine filter to prolong filter life.

2. Check with a water treat men t spe cia list for a

water test, and recommendations regarding filters

and t r eatm ent .

Service Limitations:

There must be space above,

to at least one side, to the

back, and of course the front

for service access.

May, 1991

Page 3

Page 4

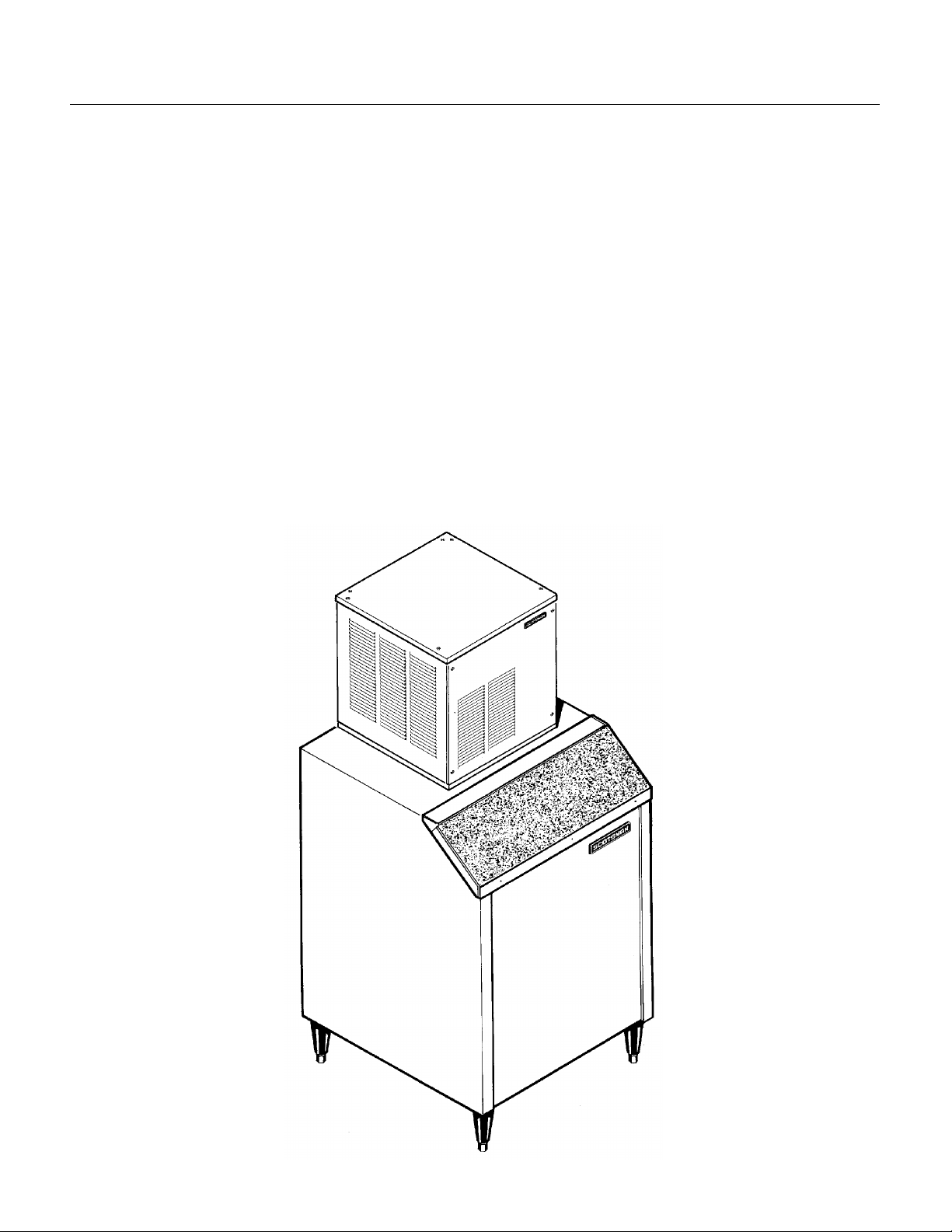

ASSEMBLED VIEW

ICE CHUTE

ICE CHUTE INSTALLATION

MF400

FOR THE INSTALLER

Location

After uncrating and inspection, the unit is ready to

be installed.

It is important that the machine be installed in a

location where it has enough space around it for

service, and a minimum o f 6" be allo we d all sides

for air circulation. The machine, when air cooled,

draws air in the front, and exhausts it out the sides

and back.

Try to avoid hot, dirty and crowded locations. Be

sure that the location for the machine is within the

limitations described on page 3.

Storage Bin

Tip the uncrated storage bin on its back, using

parts of the carton to protect the exterior finish.

Install t he legs into th e th re ad ed ho les in th e

bottom of th e bin. Turn the leg levelers all the

way in preparatio n fo r le veling lat e r.

Return the bin to the upright position, remove

paper covering the bin gasket.

Install bin top if required.

Note: Do no t push bin int o position: but lif t it

there. Push ing a bin, espe cia lly one with ice in it,

can cause damage to the legs and the leg

mounts.

Ice Maker

The machine is heavy, so the use of a

mechanica l lif t is recommended fo r lif ting the

machine high eno ugh to install on top of the bin.

After the machine is placed on the bin, line it up

so that the ice discharge opening in the base of

the machine is over the open hole in the bin top.

Ice Chute Installation

After the MF400B has been installed on the ice

storag e bin, th e ice chut e n eed s to be inst a lled :

1. With the top panel of f, remo ve all pa ckin g

material (bub ble p ac k) from ab ove the ice chut e

and chute cap. Cut the ty-wrap holding the chute

assembly in place.

2. Remove the insula tio n halve s and ty-wrap

packed inside the cabinet, retain for later use.

3. Remove th e cardboa rd su p port fro m un d er th e

ice chute.

4. Insert the ice chute/bin thermostat assembly into

the large hole in the bottom of the ice machine.

Check that bin thermostat cap tube is free from

contact wit h most components.

5. Remove the rubb er ca p from th e to p of th e ice

chute. L eave one hose clamp on th e chu te .

6. Push the ice chute against the stainless spout

(the end of the spou t will go into th e chute ).

7. Slide the rub b er ca p ove r the to p of the sta inle ss

spout. Push do wn until it fit s tig h tly a round the

spout.

8. Secure the rubber cap to the spout with the two

hose clamps, in the molded grooves; one above

and one below. Keep hose clamp screws away

from evaporator.

9. Attach the insulation halves around the top of

the evapor ator. Secure with the ty-wrap provided.

Finish installation per service manual.

MOLDED

GROVES

RUBBER

CAP

HOSE CLAMP

RUBBER CAP

HOSE CLAMP

METAL ICE

SPOUT

HOSE

CLAMP

METAL SPOUT

HOSE CLAMP

May, 1991

Page 4

Page 5

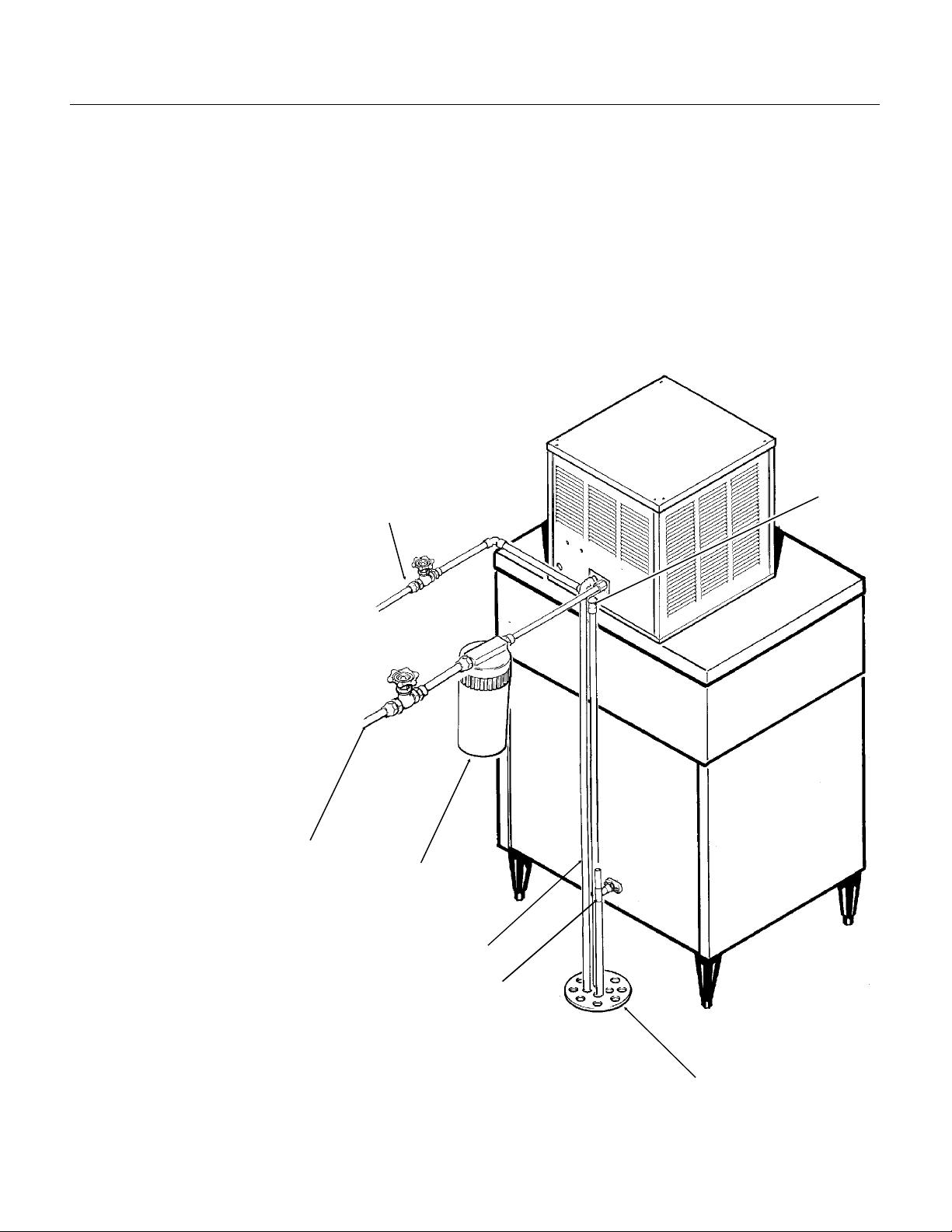

FOR THE PLUMBER

CONFORM TO ALL APPLICABLE CODES

Water Inlet

Air Cooled: The reco mme n ded wat er su pply is co ld

water. Use

1

⁄4" male flare a t the back of the ca binet. Install a

hand valve near the machine to control the water

supply.

Water Cooled: A separa te

should be connected to the condenser inlet, with a

separa te ha n d valve to c ont ro l it.

Drai n s

Air cooled: There is one 7⁄16" I.D.

hose to co nne ct to fo r a dra in. This

drain is a gravity drain, and a

minimum of 1⁄4" per foot fall is need ed

for horizontal portions of t he drain

line.

The ideal drain receptacle is a

trapped and vented floor drain.

Use only rigid tubing.

Water Cooled Models: In addition

to the above mentioned drain,

separate condenser drain must be

install e d . Connect to the

condenser drain tube.

Storage Bin: A separate gravi ty ty pe

drain needs to be run. This drain line

should be insulated.

1

⁄4" O.D. copper tubing, connect to the

3

⁄8" O.D. copper tube

CONDENSER

WATER INL ET

(Water Cooled)

3

⁄8"

MF400

OVERFLOW

DRAIN

POTABLE WAT ER

INLET

WATER FILTER

(FIELD SUPPLIED)

CONDENSER DRAIN

(Water Cooled)

BIN DRAIN

FLOOR

DRAIN GRIL L

May, 1991

Page 5

Page 6

MF400

FOR THE ELECTRICIAN

CONFORM TO ALL APPLICABLE CODES

The electrica l po we r to the unit is t o be wired

through the cabinet to the control box. In the

control box, connect to the t erminal strip provided.

Check the nameplate (located on the back of the

cabine t ) fo r th e vo lta g e requ irements, and for the

minimum circuit ampa cit y. The mach in e requ ires a

solid chassis to eart h ground wire.

The icemaker should be connected to it’s own

electrica l ci rcuit so tha t it is ind ivid u ally f u se d.

Voltage variation must remain within design

limitations, even under starting conditions.

All external wiring mus t co nfo rm to nat ion a l, st at e,

and local electrical co des. The use of e licensed

electrician is req uired to perf o rm the ele ct rical

installa tion.

ELECTRICAL POWER

SUPPLY

CONNECT ELECTRICAL

POWER TO ICEMAKER

THROUGH ELECTRICAL

INLET HOLE AND INTO

CONTRO L BOX

May, 1991

Page 6

Page 7

FOR THE INSTALLER: Final Check List

1. Is the ice syste m installed indoors in a loc at io n

where the air and water temperatures are

controlled, and where they do not e xceed the

design limita tio n s?

2. Is there an elec trica l servic e d isco nne ct with in

sight of the installed machine?

3. Have all the plumbing connections been made

and checked for leaks?

4. Has the machine and bin been leveled?

5. Is there a minimum of 6" clearance around the

machine for p rope r se rvice and air ci rcula t ion ?

6. Is the water pre ssure a minimum of 20 psig?

7. Has the ice disch arge tube been installed ?

8. Is there a wate r s hut off inst a lled ne a r the

machine?

9. Have all shipping materials been removed?

Electrical

Power?

MF400

Water Supply?

Leveled?

Drains?

May, 1991

Page 7

Page 8

MF400

START UP

1. Remove scre ws a nd the fro nt pan el.

2. Open the water shut off valve.

3. Observe that the water flows into the water

reservoir, fills up the wat e r in let tu be to th e

evapora to r, the floa t move s up with the wa te r leve l,

and the float shuts off the water flow, about

below the mold ed horizo n ta l line on th e wate r

reservoir.

4. Switch on the ele ct rica l po wer to th e unit .

5. Switch the master switch to ON.

6. After a few minutes of operation: water should

begin to flow fro m th e res ervo ir to the ev apo rat o r;

the air cooled c ond enser sh ou ld begin to di s charge

warm air, or the water cooled condenser should

begi nning to di s charge warm water ; and the un it

should begin to drop ice into the storage bin.

If desired, the refrigeration pressures can be

checke d :

••The air cooled dis charge pressu re should be

about 125-135 PSIG and the suction pressure

should be abo u t 12-1 5 PSIG.

••The wate r coo le d d isch a rge pre ssu re sh o uld be

set at 135 PSIG.

••Gearmotor amps shou ld b e abou t 2.8 - 3.2.

••Compressor amps should be about 8.5 - 9.

7. Let the unit operate for 15-30 minutes, checking

for water leaks , or ex ce ssive noise from vibra tin g

compon e n ts.

8. Block off the ice disch a rge tu b e, and che ck if th e

bin thermostat shu ts off the mac hin e. Afte r it shut s

off the compressor, the auger moto r sho uld ru n fo r

a few minutes more. Allow the ice in the tube to fall

away, and check that the compressor restarts.

9. Explain the op eration and maintena n ce

requiremen ts to the use r, in fo rm the us er of the

telephone number of the service agency servicing

the machine, and give the user the service manual.

3

⁄8"

May, 1991

Page 8

Page 9

COMPONENT LOCATION: Control Box

Auger Delay Pressure Control: This pressure

switch, connect ed to th e low side of the

refrigeration system, controls the auger drive

motor.

Low Pressure Control: This pressu re switc h,

connect e d to th e low side of th e ref rige ration

system, is normally clos ed when the mach ine is

operatin g . If the low sid e pres su re sh ou ld dro p too

low, the contro l will open (at 0 -4 PSIG ), stop pin g

the ice maker. It is an automatic reset.

High Pressure Control: The

pressure switch, used on water

cooled models only, is designed

to open and shut off the machine

should the high side refrigeration

pres sure become too high,

usually as a result of not enough

water through the water cooled

condenser.

It is a manual reset.

On-Off switch: This toggle

switch shuts off the mach ine. It is

not a complete disconnect.

Bin Thermostat: This

thermostat turn s th e mach ine on

and off in response to chan ges in

temperature of the capillary t ube.

It opens at 35

0

F. The capillary tube is

45

mounted on the inside of the ice

chute.

0

F. and closes at

Low Pressure

Control

MF400

Auger Delay Control

Bin Thermostat

On-O ff Switch

May, 1991

Page 9

Page 10

MF400

ELECTRICAL SEQUENCE

There are two circu its in the MF4 00: one is a

series circuit with several switches connected in

series to the compre sso r. The ot h er is a para llel

branch of the series circuit, controlling the gear

driv e m otor.

••The series circuit begins at the termin a l strip in

the control b ox . F rom the re, the line sid e p owe r

is connecte d to th e Mast er Swit ch .

••When the master switch is closed, the power is

then connected to the Spout Switch. This

switch, located on the top of the ice chute , is

closed unless the ice chute has overfilled with

ice, it is an automatic reset.

••From the spout swit ch the line sid e powe r now

is connected to the Low Pressure Control (air

cooled) or the High Pressure Control and then

the Low Pre ssu re Co nt rol (wat e r coo led ). Th es e

controls, connected to the refrigeration system,

are design e d to ope n whe nev er higher (high

pressure co nt rol) pressures or lower (low

pressure c ontrol) pressures are sensed. The

high pressure control is a manual reset, the low

pressure co nt rol is an aut omatic reset.

••The line side power is also co nn ect ed , in a

parallel ci rcuit , to terminal 1 of the Auge r Dela y

pressure co nt rol. This pressure control,

connected to the low side of the refrigeration

system, is desig ned as a by-pa ss circu it to the

auger drive motor whenever the low side

refrigera n t pressure is at it’s normal ice making

range. At start up, the contacts between

terminals 1 an d 2 are op e n. The lin e side power

does not pass any further through the auger

delay pressure control, until t he compressor

starts, and the low side pressure drops.

••The next control the power is conne ct ed to is

the Low Water Pre ssure Control. This switch is

designed to open should the water press ure to

the machine drop too low.

••The next control is the Bin Thermo st at . It is

closed when there is no ice on the portion of the

control inside the ice chute. It is open when

there is ice on the portion of the control inside

the ice chu te . Clo sin g of th e bin th ermo stat

begins the process of making ice, because the

line side power now goes to the compressor,

gearmotor, a nd if air co ole d, the fa n moto r.

••Power is initia lly co nne cted to th e gearmo tor

through contacts 3 and 2 of the auger delay

pressure co nt rol. This ca u ses th e aug er mo tor

to start and run. At the same time, if the

centrifuga l switch on to p of the ge a rmo t or

closes (mea n in g the mo tor is a t full sp e ed) t he

compressor is connected to the neutral side of

the powe r sup p ly, and th e comp res sor begin s to

run.

••As the co mpre ssor run s, th e low sid e or su ct ion

pressure begins to fall, when it reaches a preset

point, the contacts within it move, opening 3 and

2, then closing 1 a nd 2. The power for the

gearmotor is then connected to a point in the

series circuit ahe ad of the lo w pres su re co nt rol,

the low water p res su re co nt rol and the bin

thermostat, so that if any of these open, the

gearmotor will con tin u e to run, pus hin g ice out

of the evaporator .

May, 1991

Page 10

Page 11

OPERATION: Water

SAFETY

SWITCH

Water enters the machine through the 1/4" male

flare at the rear of the cabinet, goes past the water

pressure switch and th en to th e wate r rese rv oir

which it enter s through the float valve. The water

then goes out the bottom of the reservoir tank to

the bottom of the evaporato r .

Reservoir ov erf lowis rout e d to the drain . Water

cooled mode ls ha ve a sep arate wat e r circu it fo r th e

cooling water: it enters the fitting at the rea r, g oes

to th e water regul ating val v e, then to th e wa ter

cooled condenser and down the drain.

WATER RESERVOIR -

FLOAT VALVE

PRESSURE

SWITCH

MF400

WATER SEAL

SPOUT

WATER

INLET

RESERVOIR

OVERFLOW

ICE

CHUTE

DRAIN

AUGER DRIVE

MOTOR

ICE AND WATER SCHEMAT I C

"B" MODEL

May, 1991

Page 11

BIN

THERMOSTAT

BRACKET

Page 12

CONDENSER

MF400

OPERATION: Refrigeration

Beginnin g at the co mpre ssor, the refrig e ran t is

compressed into a high temperature gas. The

discharge line directs this gas to the condenser. At

the condenser (air or water cooled) the gas is

cool ed by either air or water and it then condenses

into a liquid. This high pressure liqu id then go e s

through the liq uid line to the cap illary tu be . The

capillary tube meters liquid refrigerant into th e

evaporator, the volume of liquid refrigerant

depending upon the temperature of the evaporator;

warmer evaporators get more refrigerant and

colder ev apo rat o rs get les s.

At the evaporator, th e refrig era n t ent ers a n area of

relative ly low pre ssu re , whe re it can easily “bo il of f”

or evaporate. As it evaporates, it absorbs heat

from the evaporator and whatever is in contact with

it (such as the water inside it). After the evaporator,

the refrigerant, now a low pressure vapor, goes

through the su ct ion line back to compress or, whe re

the cycle is repeated.

COMPRESSOR

EVAPORATOR

ACCUMULATOR

CAPILL A RY TUB E

DRYER

May, 1991

Page 12

Page 13

MF400

MAINTENANCE AND CLEANING

/////////////////////////////////////////////////////////////////////////// //////////////////////// //////////////////////// ///////////////////////////////

A Scotsman Ice System represents a sizable investment of time and money in any company’s

business. In order to recei ve the best return for that investment, it MUST receive periodic

maintenance.

It is the USER’S RESPONSIBILITY to see that the unit is properly maintained. It is always

preferable, and less costly in the long run, to avoid possible down time by keeping it clean;

adjusting it as needed; and by replacin g worn part s before they can cause failure. The follo wing

is a list of recommended maintenance that will help keep the machine runn ing with a minimu m of

probl ems.

Maintenance and Cleaning should be scheduled at a min imum of twice per year.

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

//////////////// // //// //// // /WARNING//////////////////////// // /

Electrical power will be ON when doing in

place cleaning.

Switch it OFF before

completing the cleaning procedures.

///////////////////////////////////////////////////////////////////////////

ICEMAKING SYSTEM: In place cleaning

1. Check and cle an a ny water t rea t men t de vice s, if

any are installed.

2. Remove scre ws an d remov e the top and front

panels.

3. Move the ON-OFF switch to OFF.

4. Open the door to the ice storage bin, and

remove the ice.

5. Remove th e cove r to the wat e r res ervo ir a n d

block the float up.

6. Drain the wa ter re serv oir and free ze r ass embly.

//////////////// //////// ///W ARNING //// //////// //////// /////////

Scotsman Ice Machine Cleaner contains

Phosphoric and Hydroxyacetic acids. These

compounds are corrosive and may cause

burns. If swallowed, DO NOT induce

vomiting. Give large amounts of water or

milk. Call Physician immediately. In case of

external contact, flush with water. KEEP OUT

OF THE REACH OF CHILDREN.

//////////////////////////////////////////////////////////////////////////

7. Prepare the cleaning solution: Mix eight ounces

of Scotsma n Ic e Ma ch ine Cleaner with three

quar ts of hot w ater. The w ater should be between

90-115 degrees F.

8. Slowly pour the cleanin g solution into the water

reservoir un til it is full. Wait 1 5 minut e s, the n

switch the master switch to ON.

9. As the ice maker begins to use water from the

reservoir, co n tin u e to add more clea ning solution

to maintain a full rese rvoir.

10. After all of the cleaning solution has been

added to the reservoir, and the reservoir is nearly

empty, switch the master switch to OFF.

11. After draining the reservoir, as in step 6, wash

and r inse the water reservoir.

12. Remov e the block from the float in the water

reservoir.

13. Switch the maste r switch to ON

14. Contin u e ice making for at least 15 minu t es , to

flush out any cleaning solution. Check ice for acid

taste - continue icemaking until ice tastes sweet.

/

/////////////////////////////WARNING//////////////////////////

DO NOT USE any ice produced from the

cleaning solution.

Be sure no ice remains in the bin.

//////////////////////////////////////////////////////////////////////////

15. Remove all ice from the storage bin.

16. Add warm water to the ice storage bin and

thoroughly wash and rinse all surfaces within the

bin.

17. Sanitize the bin interior with an app rove d

sanitizer using th e di rect io ns for tha t sa nit ize r.

18. Replace the top and the front panels.

May, 1991

Page 13

Page 14

MF400

MAINTENANCE AND CLEANING

///////////////////////////WARNING////////////////// ///////////

Disconnect electrical power and shut off the

water before beginning.

//////////////////////////////////////////////////////////////////////////

In some areas, the water supply to the ice maker

will contain a high conc ent ration of mine rals , and

that will result in an evaporator and auger

becoming coat ed with th ese min era ls, requirin g a

more freque n t remo va l th an twice per year. If in

doubt abou t the cond itio n of the evap o rat o r and

auger, the auger can be removed so the parts can

be insp ected.

Note: Wate r filt e rs can filte r ou t su sp e nde d solid s,

but not disso lve d solid s. “Sof t” wat er may not be

the complete answer. Check with a water

treatmen t sp ecialist regarding water treatment.

For more information on removal of these

parts, see REMOVAL AND REPLACEMENT.

To Inspect The Top Bearing:

1. Remove perma gum and two screws fro m th e

side of the evaporator .

2. Remove the sna p ring and ca p, and remov e the

bolt from the ice bre ake r an d auge r asse mb ly to

separate th e ice bre a ke r asse mbly from the au ger.

Pull the ice bre ake r with bea ring out of the to p of

the evaporator: the auger should stay in the

evaporator.

The bearings may be inspected for rust, wear, and

roughne ss. Reverse to reassemb le.

To Inspect the Auger:

1. Remove perma gum and two screws fro m th e

side of the evaporator .

2. Pull up on cap hook located in the top of the

freezer assembly to remove the ice breaker

assembly, a ug er, an d th e top portio n of the wat er

seal.

3. Inspect the auger and the water seal. Clean the

auger of any mineral build up. Scotsman Ice

Machine Clea n e r and a sco u ring pa d wo rk well to

clean the auger. DO NOT USE steel wool.

//////////////// // //// //// /WAR N ING//////////////////// // //// ///

Scotsman Ice Machine Cleaner contains

Phosphoric and Hydroxyacetic acids. These

compounds are corrosive and may cause

burns. If swallowed, DO NOT induce

vomiting. Give large amounts of water or

milk. Call Physician immediately. In case of

external contact, flush with water. KEEP OUT

OF THE REACH OF CHILDREN.

//////////////////////////////////////////////////////////////////////////

4. Replace th e wa ter sea l, se e the ins tructions

under "Removal and Replacement".

TOP

BEARING

AUGER

May, 1991

Page 14

Page 15

SERVICE DIAGNOSIS: Condition - No Ice Being Produced

MF400

STATUS:

A. Check: Vo ltage to the unit, restore it if there is none. Compare to the nameplate.

B. Check: The master switch, switch ON if off .

C. Check: The 3 reset switches, (circuit board, high and low pressure): depress and release eac h switch.

If the still does not sta rt, check : th e spo ut switc h; the high an d th e low side pre ssu res .

D. Check the low pressure cut out, if closed, go to E; if it is open, it could be due to:

ICE MAKER DOES NOT OPERATE

••Low refrigerant cha rg e

••The auge r no t tu rnin g

••Restrict ed sys tem

1. Check the low side pressure, the low pressure cut out o pens at pressure below 4 psig.

If open, reset and:

a. Check if the

Check for internal damage, repair and replace in the machine.

b. Check for low charg e , add some ref rig e rant , if th e un it will op erate , (no rmal

low side pressure being about 13 psig) stop and look for a leak, repair, rep lace the

drier, evac uat e, an d weig h in the nameplate charge. If, with a dde d cha rge , the un it

not operate:

does

Check for a restrict ed syst e m, rep la ce the drie r, ev ac uat e, and weig h in a

nameplate charge.

D. On Wa t er Coo led, check th e high pressure cut out, if closed, go to E; if open:

1.The pressure control opens at 250 psig. Chec k the hig h side pre ssure, reset the control,

and observe: that wate r soo n beg ins to flow fro m the co nd en se r d rain ;

If the unit trips out on

pressure s be lo w 2 50 p sig , rep la ce the co nt rol.

poi nt, and the u nit shuts down:

a. Check for adequate water flow on through the condenser, if adequate, clean the interior

of the conden se r. If the pre ssu res are st ill to o high rep la ce the wat e r reg ulating valve.

E. Check the spout switch. It opens from excess pressure of ice inside the ice chute: this should only

happen when the machine does not shut off when the ice storage bin is full. This switch will reset when the

ice melts,

F. Check the water pressure to the unit. The machine will not run if the re is no t e nou gh wa te r pres su re.

1. Restore/adjust water supply.

auger is tu rnin g , if it is not, remo ve the gearbox and :

If the pressure s rise abo ve the trip out

May, 1991

Page 15

Page 16

MF400

SERVICE DIAGNOSIS: Condition - No Ice Being Produced

STA T US:

H. Check: Th e g ear motor , if it will not run, the compressor will no t run. If no powe r to it:

Check that the Bin The rmo stat is close d . If open, with no ice on it, repla ce the bin the rmos ta t.

Check th at th e Aug e r De lay con ta ct s 3-2 are close d . If ope n, and the low sid e (suct ion) pre ssu re is ov er 32

PSIG, repla ce th e aug er d elay pressu re co ntrol.

If power to the auge r drive mot or, an d it does n ot ru n, rep la ce the aug e r drive mo to r.

STATUS:

A. Check the au ge r drive moto r cen trifugal switch. If, when the d riv e moto r is runn in g,

the compressor has no power, and all of the above switches have been

checked, rep lac e the cent rif ugal switch.

B. Check the compressor

1. Check the compressor start relay.

2. Check the start capacitor.

3. Check the windings of the compressor for open windings or shorts to ground.

Replace those items found defective.

ICE MAKER DOES NOT OPERATE

GEARMOTOR OPERATES, COMPRESSOR DOES NOT

May, 1991

Page 16

Page 17

REMOVAL AND REPLACEMENT

MF400

Ice Breaker and Auger Removal

1. Remove perma gum and two screws fro m th e

side of the evaporator .

2. Pull up on cap hook located in the top of the

freezer assembly to remove the ice breaker

assembly, a ug er, an d th e top portio n of the wat er

seal.

3. Remove the sna p ring and ca p, and remov e the

bolt from the ice bre ake r an d auge r asse mb ly to

separate th e ice bre a ke r asse mbly from the au ger.

The bearings may be replace or the ice breaker

and bearing s may be rep laced as an asse mbly.

Water Seal Installation

Inspe ct the water seal in

it’s package. Do no us e if

mating surfaces are

scratched or cracked.

1. Remove aug e r, unb olt

evaporator from adaptor

stand. Drive out old

bottom bea ring an d wat er

seal from the top down.

2. Remove th e old rota ting

half of the water seal from

the auger and clean the

auger at the seal

mounting area.

Outer Race

Sealant Here

Rubber

Metal

Water

Seal

3. Apply Scotsman part number 19-0529-01 food

grade sealan t to the auger shou lder before

pushing on the water seal. Place just enough

sealant onto the shoul der of the auger , so that

when the water seal is placed on the auger, the

gap between the auger shoulder and the water

seal is complet e ly fille d with th e seala nt.

4. Clean th e in sid e of th e eva p ora to r at the bot to m

bearing and wat e r seal mou nt in g area. L ubrica te

the outsid e e dge of the stationary seal with water.

5. Carefully p us h the sta tio n a ry part of the wat e r

seal up into the bot tom of the evaporator. It m ust

go in straigh t and mus t not be push ed in b ey ond

1/4" past the bottom of the evaporator.

6. Install a new bottom

bearing , push it int o the

evaporator unde r the new

water seal. It must be pushed

in straight, but do not push it in

past 1/8" from the bottom of

the evaporator tube.

7. Mount the adaptor stand to

the bottom of the evaporator.

Wider at Top

Han d tighten th e th r ee cap

screws until the stand flange is

tight against the bottom of the

evaporator. Hand tighten the

three cap screws until the

stand flange is tight against

the bottom bearing . Then,

tighten the screws in a rota ting

pattern to insure proper

alignment.

8. The top be a ring should also

be changed at this time. Be

sure to mount the top

breaker/bearing assembly

onto the auger before

installing the auger into the

evaporator tube.

9. Lower the auger into the

evaporat or, twist it to en ga ge

the splines of the coupling.

Secur e the breaker and

bearing to the evapora tor tube

with the two screws removed

in step 1 of “Ice Breaker an d

Auger Remova l”. Tes t the unit.

May, 1991

Page 17

Page 18

MF400

REMOVAL AND REPLACEMENT: Gearmotor Assembly

Rebuilding The Gearmotor Assembly

Drive Motor Parts:

To replace the cen trifugal switch and mechanism

or the motor winding or the motor roto r, re mo va l of

the gearbox as se mbly is not nece ssa ry.

1. Disconnect elect rical p ower.

2. Remove th e cove r f rom the to p of th e cen trifugal

switch assembly and remove the electric wires

from the microswitch. To replace just the

centrifugal switch , remo ve two machine screws

retaining th e switch , and remo ve the switc h. To

replace , reverse the procedure to th is point.

3. If the motor is to be removed, the next step is to

remove the four screws holding down the plastic

switch assemb ly housing and lift the housing of f of

the motor top.

4. Remove the cen trifugal switch mechanism fro m

the rotor by uns crewin g the ma ch ine scre w at th e

top of the rotor.

5. The motor and housing may now be removed.

Lift off the motor fan housing, and pull off the

plastic fan . Th e nex t part to be re mo ve d is the

motor winding . Disconn ect th e elect ric al le ads o f

the motor from its control box location and lift off

the winding .

6. The rotor is all that remains of the motor in the

gear motor asse mbly . Use a pry bar to carefu lly

pry up the rotor. (The only thing holding it in is the

tight fit of the bottom rotor bearing into the top of

the gear case.) To replace any of the above parts,

reverse th e disa sse mb ly procedure.

Removal of the Gearmotor Assembly

1. Remove the top and righ t side pan el.

2. Remove the ice ch ut e asse mb ly.

3. Unscrew the th ree cap scre ws reta in in g the

evaporator assembly to the gearmotor assembly.

4. Unscrew the bolts holdin g the gearmotor

mounting plate to the ice machine chassis.

5. Remove the motor and centrifugal switch

electrical leads from their connections.

6. Raise the evapo rator as se mbly up enoug h that

the output shaft clears the freezer adaptor.

7. Remove the gearmo to r ass embly from the ice

machine.

Gearcase Service

After removal of the gear motor from the unit ,

inspect the inte rn al parts from this g earmo to r.

1. Place the gearbox on a flat surface, covered

with rags to absorb a ny spilled lub rican t .

2. Using a punch, drive the roll pins out of the

casing.

3. Remove the four c ap scre ws on th e top of the

gearcase and the two under the motor.

4. Pry the two case s apa rt.

When inspecting the internal parts, look for:

••Condition and quantity of lubricant. (The proper

oil level is near the top of the output (biggest)

gear. This ta ke s 5 oz. Use Sco ts man oil, pa rt

number A25835-001.

••Bearing condition

••Gear and Shaft condition

••Woodruff key between output gear and shaft.

••Grease seals, back to back.

••Vent hole

Be sure to count and retain the spacer washers as

they come out of the gearbox.

Replace the parts as required, using the part

numbers found in the parts section of this manual.

Replace th e gears into a CLE AN b ot to m ge a rca se ,

after adding some grease to the bearings. Replace

the spacers in th e same qua n tit y as th e y were

removed. If no cou nt wa s kep t , use the numbers

found in the parts list.

Note: Some bearing grease should be placed in all

bearings before assembly to insure proper

lubricat ion upo n sta rt up .

Reass em b l y

1. Set top gearcase on gears and spacers and oil.

Be sure O-ring is in place .

2. Drive roll pins ba ck int o loca ting ho le s.

3. Replace cap scre ws int o gea rca se cov er, and

torque at 80-90 inch pounds.

4. Bench tes t the gearmo to r ass embly.

Test for noise, amp draw (must not be in excess of

ice maker nameplate for gearmotor) and oil leaks.

Return the ge armo t or asse mbly to the unit. Be

certain all mounting surfaces are clean and

reassemble to the gea rmotor mounting plate. Then

bolt back onto ice machine chassis.

May, 1991

Page 18

Page 19

Gearmotor Service

MF400

MOTOR COVER

WINDING

SHAFT SEALS

FAN

OUTPUT

SHAFT

ROTOR

KEY

FIRST GE AR

AND PINION

May, 1991

Page 19

Loading...

Loading...