Scotsman MCS 46 A,MCS 46 W,MCM 1210 A,MCM 46 A,MCM 46 W,MCL 16 A,MCL 46 A,MCL 1210 A,MCXL 46 W Service Manual

Page 1

Page 1

Scotsman Ice Srl

Via Lainate, 31 - 20010 Pogliano M.se - Milano - Italy

Tel. +39-02-93960.1 (Aut. Sel.)- Telefax +39-02-93550500

Direct Line to Service & Parts:

Phone +39-02-93960350 - Fax +39-02-93540449

Website: www.scotsman-ice.it

E-Mail: scotsman.europe@scotsman.it

ISO 9001 - Cert. n. 0080

MC 46

Electronic

modular cubers

New PC Board

From s.n. 28850

REV. 09/2015

SERVICE MANUAL

LED STATUS

REASON WHY - SIGNIFICATION - SIGNIFICATO

ON STEADY

FIXE

FISSO

FREEZING CYCLE

EN RÉFRIGÉRATION

IN CONGELAMENTO

BLINKING

CLIGNOTANT

LAMPEGGIANTE

60 MINUTES DELAY AT START UP JUMPER J3 OUT

60 MINUTES DE RETARD AU DEMARRAGE - CAVALIER J3 OUVERTE

60 MINUTI RITARDO PARTENZA - CONTATTI J3 APERTI

ON STEADY

FIXE

FISSO

TOO HI DISCHARGE PRESSURE/TEMP.

COUPURE HP

FERMATA ALTA TEMP. CONDENSAZIONE

BLINKING

CLIGNOTANT

LAMPEGGIANTE

TOO HI EVAP. TEMP. (> 0°C) AFTER 15’ FROM START UP

COUPURE BP ( > 0°C LU PAR LA

SONDE EVAP. NON ATTEINTE APRES 15’ FONCT.)

TEMP. EVAP. > 0°C DOPO 15’ DA INIZIO CONGELAMENTO

ON STEADY

FIXE

FISSO

UNIT OFF AT BIN FULL

CABINE PLEINE

CONTENITORE PIENO

BLINKING SLOW

CLIGNOTANT LENT

LAMPEGG. LENTO

I/R BEAM CUTTED

FAISCEAU INFRA ROUGE CELLULE NIVEAU GLACE INTERROMPU

RAGGIO INFRAROSSO INTERROTTO

BLINKING FAST

CLIGNOTANT RAPIDE

LAMPEGG. VELOCE

I/R ON AFTER TRIP OFF AT BIN FULL

FAISCEAU INFRA ROUGE CELLULE NIVEAU GLACE ETABLI

RAGGIO INFRAROSSO RIPRISTINATO DOPO FERMATA A CONT. PIENO

ON STEADY

FIXE

FISSO

I/R CALIBRATION DONE

CALIBRATION FAISCEAU INFRA ROUGE CELL. NIVEAU GLACE REALISÉ

CALIBRAZIONE RAGGIO INFRAROSSO EFFETTUATA

BLINKING

CLIGNOTANT

LAMPEGGIANTE

UNIT IN CLEANING MODE OR TRIPPING OFF AFTER TEST - JUMPER TEST IN

MACHINE EN MODE DETARTRAGE OU ARRÊTE APRES LE TEST - CAVALIER TEST FERMÉ

MACCHINA NELLA FASE LAVAGGIO O FERMA DOPO IL TEST - PONTICELLO TEST CHIUSO

ON STEADY

FIXE

FISSO

CONDENSER SENSOR OUT OF ORDER

SONDE CONDENSEUR HS

SONDA CONDENSATORE MALFUNZIONANTE

BLINKING

CLIGNOTANT

LAMPEGGIANTE

EVAPORATOR SENSOR OUT OF ORDER

SONDE EVAPORATEURS HS

SONDA EVAPORATORE MALFUNZIONANTE

BLINKING ALTERNATIV.

CLIGNOTANT ALTERNÉ

LAMPEGGIO ALTERN.

I/R SENSOR OUT OF ORDER

SONDE INFRA ROUGE CELLULE NIVEAU GLACE HS

SONDA ALL’INFRAROSSO LIVELLO GHIACCIO MALFUNZIONANTE

PUSH

PUSH > 5” DURING WATER FILLING TO MOVE THE UNIT INTO FREEZING

PUSH > 5” DURING FREEZING TO MOVE THE UNIT INTO DEFROST

PUSH > 5” DURING DEFROST TO MOVE THE UNIT INTO FREEZING

PUSH 2” ÷ 5” DURING WATER FILLING TO MOVE THE UNIT INTO CLEANING

PUSH DURING THE 60 MIN START UP DELAY TIME TO BY-PASS IT

START

AMPS

MC 16 SHORT A - 230 V

MC 16 SHORT W - 230 V

MC 16 SHORT A - 400 V

MC 16 SHORT W - 400 V

MC 46 A - 230 V

MC 46 W - 230 V

MC 46 A - 400 V

MC 46 W - 400 V

MC 1210 A - 400 V

MC 1210 W - 400 V

AMPS WATTS

KWH/24HRS

REFR. CHARGE

R404a

SUCT. PRESS.

END. FREEZE

DISCHARGE

PRESSURE

7,1

3

10

5,5

11

32

18

66

14

28

1300

1400

2400

4800

580 gr

450 gr

580 gr

450 gr

1300 gr

700 gr

1300 gr

700 gr

2 x 1300 gr

2 x 700 gr

1,6 ÷ 1,7 bar

1,6 ÷ 1,7 bar

2,5 bar

16 ÷ 18 bar

17 bar

16 ÷ 18 bar

17 bar

16 ÷ 18 bar

17 bar

16 ÷ 18 bar

17 bar

13 ÷ 14 bar

13,5 ÷ 14,5 bar

14 bar

1 2 3 4

MCS 16 A

MCS 16 W

MCM 16 A

MCM 16 W

MCL 16 A

MCL 16 W

MCS 46 A

MCS 46 W

MCM 46-1210 A

MCM 46-1210 W

MCL 46-1210 A

MCL 46-1210 W

MCXL 46 W

5 6 7 8 9

10

ON

ON

OFF

OFF

OFF

OFF

ON

ON

ON

OFF

ON

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ON

ON

ON

ON

ON

ON

ON

ON

ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

OFF

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ON

ON

ON

ON

ON

ON

OFF

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

OFF

OFF

OFF

OFF

OFF

OFF

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

OFF

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

OFF

DIP SWITCH FACTORY SETTING COMBINATIONS (PER MODEL AND VERSION)

COMBINAISON DES COMMUTATEURS NUMERIQUES DU DIP SWITCH POUR MODELES ET VERSIONS

REGOLAZIONE TASTI DIP SWITCH PER MODELLO E VERSIONE

DIP SWITCH

FREEZING CYCLE

CYCLE DE CONGÉLATION

CICLO CONGELAMENTO

DEFROST CYCLE

CYCLE DE DÉMOULAGE

CICLO SBRINAMENTO

15/30"

1 2 3 4

ON ON ON ON 1 min.

OFF ON ON ON 3 min.

ON OFF ON ON 5 min.

OFF OFF ON ON 7 min.

ON ON OFF ON 9 min.

OFF ON OFF ON 11 min.

ON OFF OFF ON 13 min.

OFF OFF OFF ON 15 min.

ON ON ON OFF 17 min.

OFF ON ON OFF 19 min.

ON OFF ON OFF 21 min.

OFF OFF ON OFF 23 min.

ON ON OFF OFF 25 min.

TIMED PORTION FREEZING CYCLE

TEMPS PHASE TEMPORISÉE CONGELATION

TEMPI FASE TEMPORIZZATA CONGELAMENTO

7 8

OFF OFF

WATER PUMP OFF DURING DEFROST

POMPE A L’ARRÊT PEND. DEGIVRAGE

POMPA ACQUA DURANTE SBRINAMENTO

7 8

ON ON 0

OFF ON 30 sec.

ON OFF 60 sec.

ADDITIONAL DEFROST TIME

TEMPS AJOUTÉS

TEMPI AGG. SCONGELAMENTO

AIR/EAU

ARIA/ACQUA

27,6

28,0

50

105

Page 2

Page 2

TABLE OF

CONTENTS

Table of contents

Specifications MC 46

GENERAL INFORMATION AND INSTALLATION

Introduction

Unpacking and Inspection - Ice maker

Unpacking and Inspection - Storage bin

Location and levelling

Stacking installation

Electrical connections

Water supply and drain connections

Final check list

Installation practice

OPERATING INSTRUCTIONS

Start up

Operatiobnal checks

OPERATING PRINCIPLES (How it works)

Freezing cycle

Harvest cycle

Control sequence

Component description

ADJUSTMENT, REMOVAL AND REPLACEMENT PROCEDURES

Adjustment of the cube size

Wiring diagram

Service diagnosis

MAINTENANCE AND CLEANING INSTRUCTIONS

General

Icemaker

Cleaning instructions of water system

2

3

15

17

18

19

24

25-26-27

28

30

30

31

10

11

5

5

5

5

6

8

8

8

9

Page 3

Page 3

310

300

290

280

270

260

250

240

230

220

210

200

190

180

Kg.

32

10 °C27 21 15

MODÈLES REFROIDIS PAR AIR

TEMPÉRATURE DE L'EAU

TEMPÉRATURE AMBIANTE

PRODUCTION DE GLACE EN 24 H

32

38

10

21

°C

MODÈLES REFROIDIS PAR EAU

310

300

290

280

270

260

250

240

230

220

210

200

190

180

Kg.

32

10 °C27 21 15

TEMPÉRATURE DE L'EAU

TEMPÉRATURE AMBIANTE

PRODUCTION DE GLACE EN 24 H

10

21

32

38

°C

ice making capacity

AIR COOLED MODELS

AMBIENT TEMPERATURE

WATER TEMPERATURE

ICE PRODUCED PER 24 HRS

AMBIENT TEMPERATURE

WATER TEMPERATURE

ICE PRODUCED PER 24 HRS

WATER COOLED MODELS

SPECIFICATIONS

ELECTRONIC CUBER MODEL MC 46

I

mportant operating requirements:

MIN.

Air temperature 10°C (50°F)

Water temperature 5°C (40°C)

Water pressure 1 bar (14 psi)

Electr. voltage variations

from voltage rating

specified on nameplate -10%

MAX.

40°C (100°F)

35°C (90°F)

5 bars (70 psi)

+10%

NOTE. The daily ice-making capacity is directly related to the condenser air inlet temperature, water

temperature and age of the machine.

To keep your SCOTSMAN MODULAR CUBER at peak performance levels, periodic maintenance

checks must be carried out as indicated on maintenance section of this manual.

Production charts shown are indicating the production of MCM and MCL models. For MCS models

ice production is approx. 10% lower.

Page 4

Page 4

MC 46 AS 6 Air Stainless steel

MC 46 WS 6 Water Stainless steel

2.5

Model Cond. unit Finish Comp. HP Water req. - lt/24 HR

SPECIFICATIONS

660

3700*

MC 46 - MACHINE SPECIFICATIONS

DIMENSIONS:

HEIGHT 874 mm.

WIDTH 1074 mm.

DEPTH 534 mm.

WEIGHT 185 Kgs.

ACCESSORIES

KSC 11: Cube stacking kit

220-230/50/1 7 2400 50 3 x

Basic electr. Amps Watts N. of wires Amps. fuse

230/50/1N 10 66 3 x 1.5 m/m

2

20

400/50/3N 5.5 14 5 x 1.5 m/m

2

10

Starts Electric power cons.

amps. Kwh x 24 HR

Cubes per harvest: MCL-46 144 large - MCM-46 204 medium - MCS 46 396 small

* At 15°C (60°F) water temperature

Page 5

Page 5

A. INTRODUCTION

This manual provides the specifications and the

step-by-step procedures for the installation, startup and operation, maintenance and cleaning for

the SCOTSMAN MODULAR CUBERS.

The Electronic Modular Cubers are quality

designed, engineered and manufactured.

Their ice making systems are thoroughly tested

providing the utmost in flexibility to fit the needs

of a particular user.

These icemakers have been engineered to our

own rigid safety and performence standards.

NOTE. To retain the safety and performance

built into this icemaker, it is important that

installation and maintenance be conducted

in the manner outlined in this manual.

Storage Bin

Since the MC series Modular Cubers do not

have their own attached ice storage bins, it is

necessary to use an auxiliary bin such as the Bin

SB 550.

B. UNPACKING AND INSPECTION

Modular Cuber

1. Call your authorized SCOTSMAN Distributor

or Dealer for proper installation.

2. Visually inspect the exterior of the packing

and skid. Any severe damage noted should be

reported to the delivering carrier and a concealed

damage claim form filled in subjet to inspection

of the contents with the carrier’s representative

present.

3. a) Cut and remove the plastic strip securing

the carton box to the skid.

b) Remove the packing nails securing the

carton box to the skid.

c) Cut open the top of the carton and remove

the polystyre protection sheet.

d) Pull out the polystyre posts from the

corners and then remove the carton.

4. Remove top and sides panels of the unit

and inspect for any concealed damage. Notify

carrier of your claim for the concealed damage

as stated in step 2 above.

5. Loose two nuts on left and rights side of the

unit base and remove it from the skid. Save the

two bolts and nuts to mount the machine on

storage bin or on top of another Modular Cuber.

GENERAL INFORMATION AND INSTALLATION

6. Remove all internal support packing and

masking tape and the hardware package.

7. Check that refrigerant lines do not rub

against or touch other lines or surfaces, and that

the fan blade moveS freely.

8. Check that the compressor fits snugly onto

all its mounting pads.

9. See data plate on the rear side of the unit

and check that local main voltage corresponds

with the voltage specified on it.

CAUTION. Incorrect voltage supplied to

the icemaker will void your parts

replacement program.

10. Remove the manufacturer’s registration

card from the inside of the User Manual and fillin all parts including: Model and Serial Number

taken from the data plate.

Forward the completed self-addressed

registration card to Frimont/Scotsman Europe

factory.

C. LOCATION AND LEVELLING

WARNING. This Ice Cuber is designed

for indoor installation only. Extended

periods of operation at temperature

exceeding the following limitations will

constitute misuse under the terms of

the SCOTSMAN Manufacturer’s Limited

Warranty resulting in LOSS of warranty

coverage.

1. Position the Bin in the selected permanent

location. Criteria for selection of location include:

a) Minimum room temperature 10°C (50°F)

and maximum room temperature 40°C (100°F).

b) Water inlet temperatures: minimum 5°C

(40°F) and maximum 35°C (90°F).

c) Well ventilated location for air cooled

models.

d) Service access: adequate space must

be left for all service connections through the

rear of the ice maker. A minimum clearance of 15

cm (6") must be left at the sides of the unit for

routing cooling air drawn into and exhausted out

of the compartment to maintain proper

condensing operation of air cooled models.

Page 6

Page 6

2. Level the Storage Bin Assy in both the left

to right and front to rear directions by means of

the adjustable legs.

3. Inspect the Storage Bin top mounting gasket

which should be flat with no wrinkles, to provide

a good sealing when the Modular Cuber is

installed on top of it.

4. Place the Modular Cuber on top of

Storage bin using care not to wrinkle or tear

the gasket.

5. Lift a little bit the Modular Cuber right side in

order to be able to mount the ice level control

bracket taking care to align the hole located on

unit base to mate with the one on the top of the

Bin.

6. Remove the PVC plastic plug closing the

round hole located on the right side of the ice

chute opening.

7. Trace the ice level control assy, secured for

the transport on top of the evaporator of the

Modular Cuber, and direct it down through the

round hole into the Storage Bin.

8. Fasten the ice level control assy on its

bracket by means of the two screws found in the

hardware package supplied with the unit.

9. Make a cut (shear) in the PVC plastic plug

that goes from its edge to the center; insert the

ice level control cable in the center of the plastic

plug so to prevent it from any sort of contact with

the unit frame, then place again the PVC plug in

the round hole keeping the cable exceeding

portion inside the unit.

10. Install the plastic ice cube deflector by

hooking it on the flange of the ice chute opening

in unit base (see illustration).

11. Secure the Modular Cuber on the top of the

Storage Bin using the two bolts and diber washer

found in the hardware package supplied with the

unit.

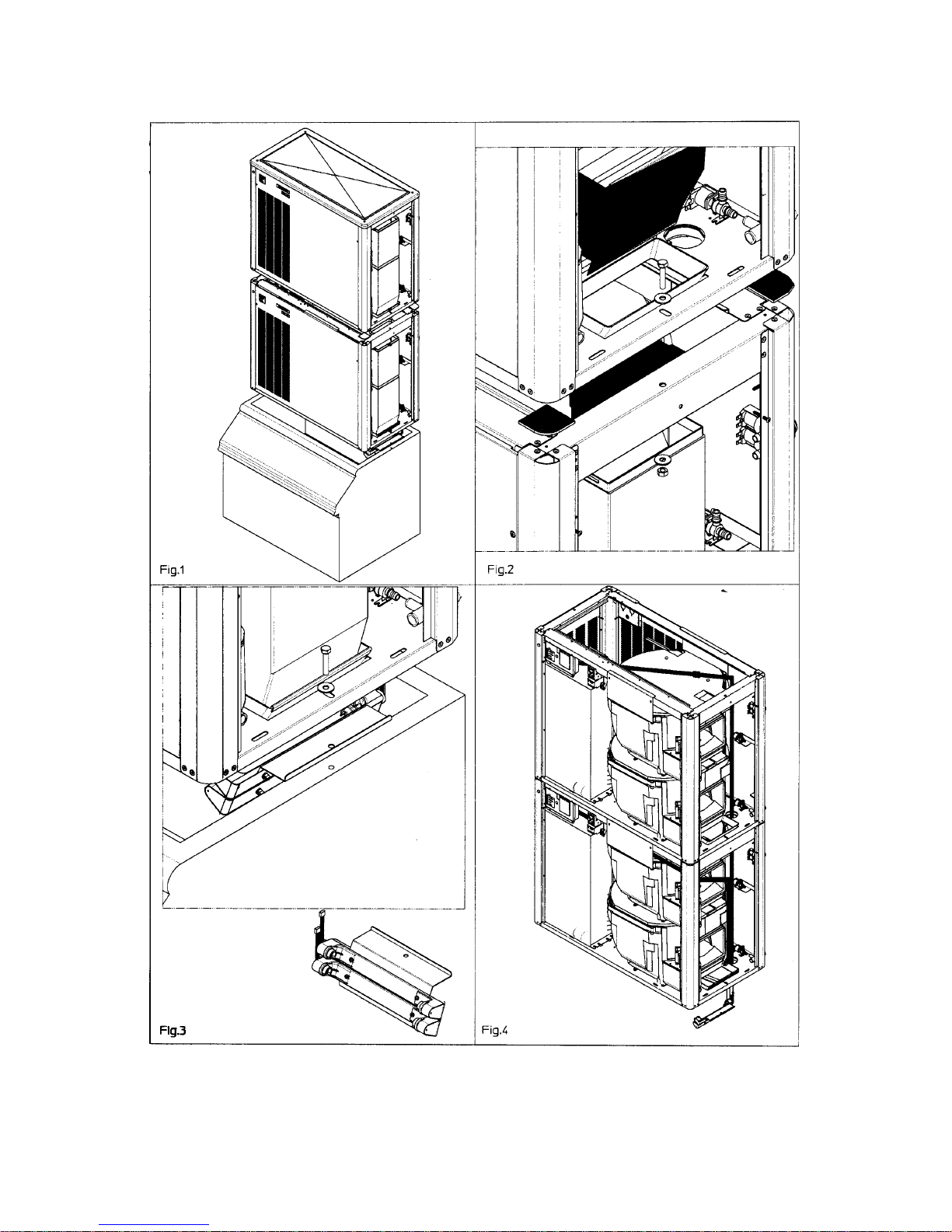

D. STACKING INSTALLATION

A Stacking Kit KSC 11 is available as an accessory

on request to allow the installation of two Modular

Cubers one on top of the other.

The Stacking Kit is consisting of:

a) unit base gasket

b) plastic reinforced ice chute

connections

Use the ice chute connections supplied in the

KSC Kits..........

... to connect the ice chute of the bottom machine

with the one of the top machine

Page 7

Page 7

Page 8

Page 8

E. ELECTRICAL CONNECTIONS

See data plate for current requirements to

determine wire size to be used for electrical

connections. All SCOTSMAN icemakers require

a solid earth wire.

All SCOTSMAN ice machines are supplied from

the factory completely pre-wired and require only

electrical power connections to the wire cord

provided at the rear of the unit.

Make sure that the ice machine is connected to

its own circuit and individually fused (see data

plate for fuse size).

The maximum allowable voltage variation should

not exceed -10% and +10% of the data plate

rating. Low voltage can cause faulty functioning

and may be responsible for serious damage to

the overload switch and motor windings.

NOTE. All external wiring should conform to

national, state and local standards and

regulations.

Check voltage on the line and the ice maker’s

data plate before connecting the unit.

F. WATER SUPPLY AND DRAIN

CONNECTIONS

General

When choosing the water supply for the ice flaker

consideration should be given to:

a) Length of run

b) Water clarity and purity

c) Adequate water supply pressure

Since water is the most important single ingredient

in producting ice you cannot emphasize too

much the three items listed above.

Low water pressure, below 1 bar may cause

malfunction of the ice maker unit.

Water containing excessive minerals will tend to

produce cloudy coloured ice cubes, plus scale

build-up on parts of the water system.

Water supply

Connect the 3/4" GAS male fitting of the solenoid

water inlet valve, using flexible tubing or a 3/8"

O.D. copper pipe, to the cold water supply line

with regular plumbing fitting and a shut-off valve

installed in an accessible position between the

water supply line and the unit.

Water supply - Water cooled models

The water cooled versions of SCOTSMAN Ice

Makers require two separate inlet water supplies,

one for the water sprayed for making the ice

cubes and the other for the water cooled

condenser.

Connect the 3/4" GAS male fitting of the water

inlet, using the flexible tubing or a 3/8" O.D.

copper pipe, to the cold water supply line with

regular plumbing fitting and a shut-off valve

installed in an accessible position between the

water supply line and the unit.

Water drain

The recommended drain tube is a plastic or

flexible tube with 18 mm (3/4") I.D. which runs to

an open trapped and vented drain. When the

drain is a long run, allow 3 cm pitch per meter

(1/4" pitch per foot).

A vent at the unit drain connection is also required

for proper sump drainage.

Water drain - Water cooled models

Connect the 3/4" GAS male fitting of the

condenser water drain, utilizing a second flexible

tubing or a 3/8" O.D. copper tubing, to the open

trapped and vented drain.

NOTE. The water supply and the water drain

must be installed to conform with the local

code. In some case a licensed plumber and/

or a plumbing permit is required.

G. FINAL CHECK LIST

1. Is the unit in a room where ambient

temperatures are within a minimum of 10°C

(50°F) even in winter months?

2. Is there at least a 15 cm (6") clearance

around the unit for proper air circulation?

3. Is the unit level? (IMPORTANT)

4. Have all the electrical and plumbing

connections been made, and is the water supply

shut-off valve open?

5. Has the voltage been tested and checked

against the data plate rating?

6. Has the water supply pressure been

checked to ensure a water pressure of at least 1

bar (14 psi).

7. Have the bolts holding the compressor down

been checked to ensure that the compressor is

snugly fitted onto the mounting pads?

8. Check all refrigerant lines and conduit lines

to guard against vibrations and possible failure.

9. Have the bin liner and cabinet been wiped

clean?

10. Has the owner/user been given the User

Manual and been instructed on the importance of

periodic maintenance checks?

11. Has the Manufacturer’s registration card

been filled in properly? Check for correct model

and serial number against the serial plate and

mail the registration card to the factory.

Page 9

Page 9

H. INSTALLATION PRACTICE

1. Hand shut-off valve

2. Water filter

3. Water supply line (flexible hose)

4. 3/4" gas male fitting

5. Power line

6. Main switch

7/9. Drain fitting

8/10. Vented drain line

11. Open trapped vented drain

WARNING. This icemaker is not designed for outdoor installation and will not function in

ambient temperatures below 10°C (50°F) or above 40°C (100°F).

This icemaker will malfunction with water temperatures below 5°C (40°F) or above 35°C

(90°F).

Page 10

Page 10

OPERATING INSTRUCTIONS

NOTE.

Ice maker pcb is equipped by jumper

cleaning reminding setting (see pag. 20)

suitable to alert users after certain time of unit

operation. This would advice for preventive

maintenance.

This time can be adjusted for 6 or 12 months

operation (upon installer advice related to

installation site water and ambient condition);

once selected time is elapsed RED front panel

lamp blinks slowly and ice maker will keep on

working anyway.

Pcb is also equipped by 3 (standard) or 60

(machines operating at 400/50/3) minutes

jumper setting start up delay (see pag. 20).

In case of pcb setting to 60 minutes ice maker

doesn't start until this time is elapsed. After

having correctly installed the ice maker and

completed the plumbing and electrical

connections, perform the following “Start-up”

procedure.

START UP

After having correctly installed the ice maker and

completed the plumbing and electrical

connections, perform the following “Start-up” procedure.

A. Give power to the unit to start it up by

switching "ON" the power line main disconnect

switch.

NOTE.

Every time the unit returns under

power, after having been switched off, the

water inlet valve, the hot gas valve and the

water drain valve get energized for a period

of 5 minutes, thus to admit new water to the

machine sump reservoir to fill it up and,

eventually, to wash-off any dirt that can have

deposited in it during the unit off period

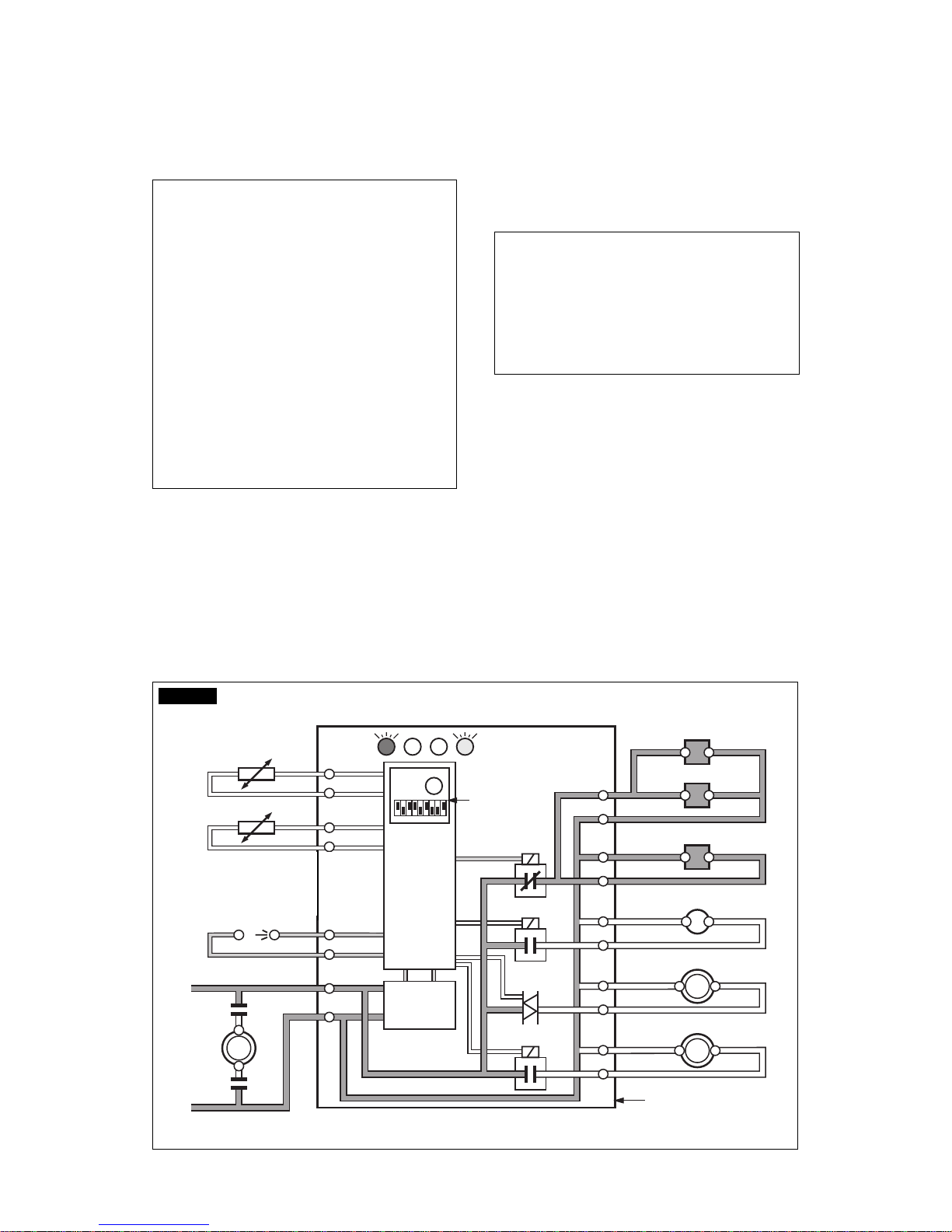

(Fig.1).

B. During the water filling operation, check to

see that the incoming water dribbles, through the

evaporator platen dribbler holes, down into the

sump reservoir to fill it up and also that the

incoming surplus of water flows out through the

overflow pipe into the drain line.

During the water filling phase the components

energized are:

THE WATER INLET SOLENOID VALVE

THE HOT GAS SOLENOID VALVE

THE WATER DRAIN SOLENOID VALVE/S

for the first 30 seconds.

16

15

14

13

2

1

7

8

9

10

3

4

5

6

11

12

Rx Tx

WATER IN VALVE

HOT GAS VALVE

CONTACTOR COIL

FAN MOTOR

WATER PUMP

- EVAPORATOR

- AMBIENT

- CONDENSER

TEMPERATURE SENSORSBINCOMPRESSOR

TRANSF.

DATA

PROCESSOR

ELECTR.

TIMER

DIP

SWITCH

ELECTRONIC CARD

L

N

RELAYS

RELAY

TRIAC

WATER DRAIN VALVE

FIG. 1

Loading...

Loading...