MCM1462

INTRODUCTION

To the owner or user: This service manual is

intended to provide you and the maintenance or

service technician with the information needed to

install, start up, clean, maintain and service this

ice system.

Table of Contents

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

For the Installer

Location & Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Stacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

For the Electrician . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

For the Plumber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Final Check List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Initial Start Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Freeze Cycle Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Harvest Cycle Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Component Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

System Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Service Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Removal and Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Parts Lists and Wiring Diagrams are located in the

center of this manual, printed on yellow paper.

This manual was printed on recycled paper.

April, 1993

Page 1

MCM1462

FOR THE INSTALLER

The MCM1462 will fit the MDB900 ice storage bin

(48" wide). It will double-stack with kit KSMCM48.

The stacking kit includes:

••Relay box and wires to interconnect bin controls.

••Stainless steel panel bracket to retain lower unit

front panels.

••Gasket material to seal joint between cabinets.

••Heavy duty legs for installation on the bin.

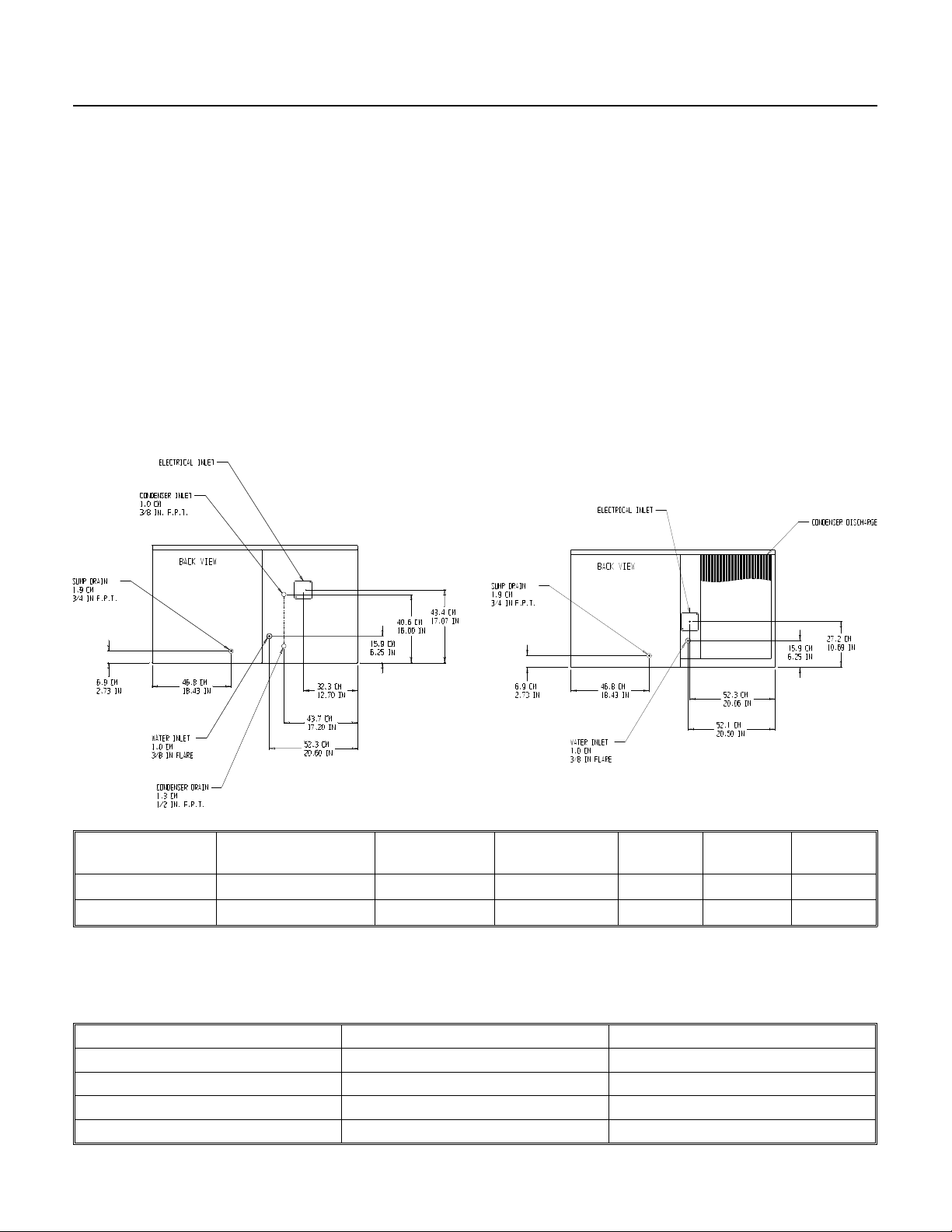

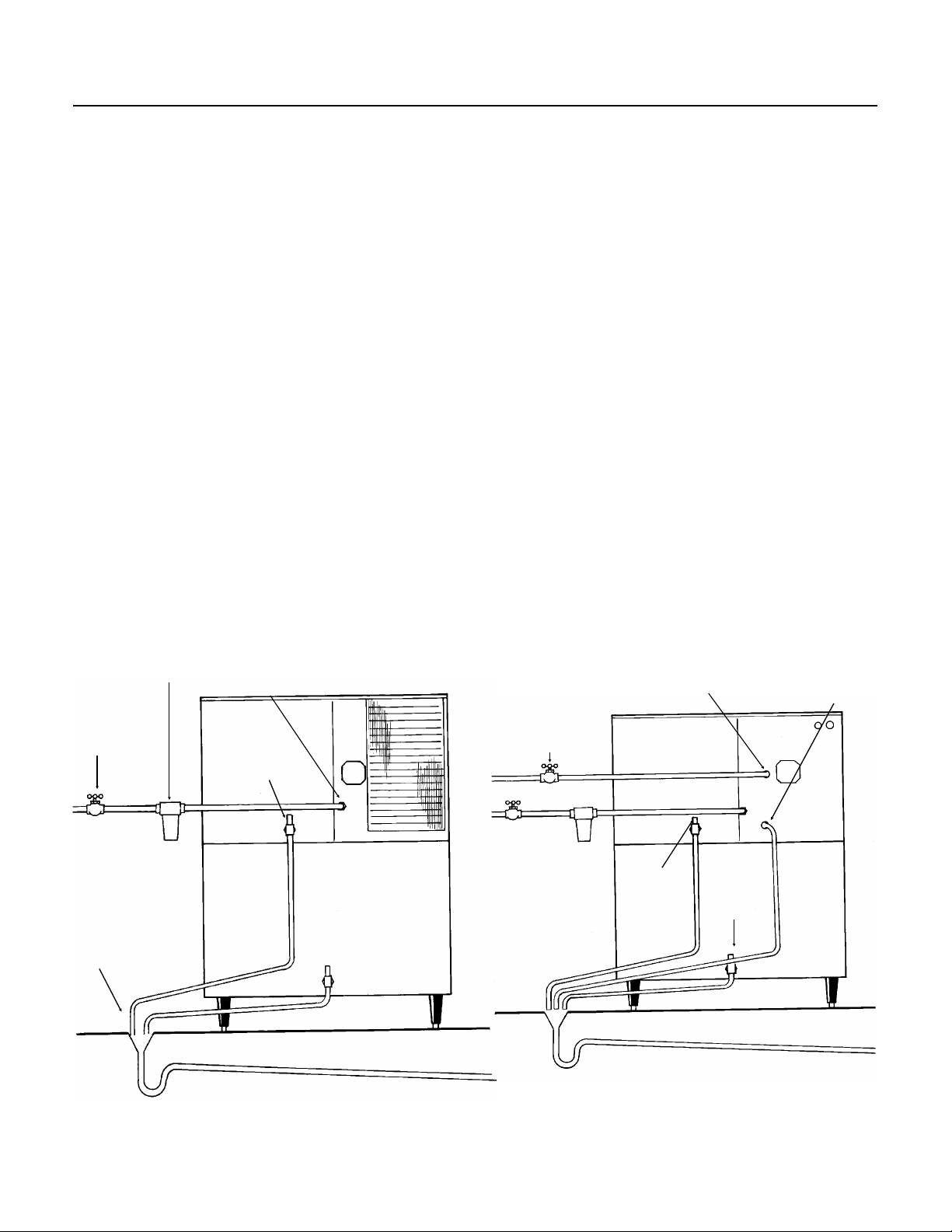

Back View, Water Cooled

Scotsman Ice Systems are designed and

manufactured with the highest regard for safety

and performance. They meet or exceed the

standards of U.L., N.S.F., and C.S.A.

Scotsman assumes no liability or responsibility of

any kind for products manufactured by Scotsman

that have been altered in any way, including the

use of any parts and/or other components not

specifically approved by Scotsman.

Scotsman reserves the right to make design

changes and/or improvements at any time.

Specifications and designs are subject to change

without notice.

Back View, Air Cooled

Model Number Dimensions (w/o bin)

W" x D" x H"

MCM1462AS-3A

MCM1462WS-3A

48 x 24

48 x 24

3

⁄8 x 271⁄

3

⁄8 x 271⁄

Basic Electrical Minimum Circuit

Ampacity*

208-230/60/3 20.2 20 60 oz. R-22 Air

2

208-230/60/3 19.5 20 64 oz. R-22 Water

2

Maximum

Fuse Size

Refrigerant

Charge

Condenser

Type

* Minimum Circuit Ampacity is used to determine wire size and type per the National Electric Code. If the

numbers listed above are not the same as the nameplate, go by the nameplate.

Power cord is kit number: MPC. Caster kit is number: KBC9.

This ice system is designed to be installed indoors, in a controlled environment.

MINIMUM MAXIMUM

Air Temperature 50

Water Temperature 40

Water Pressure 20 psi 80 psi

Voltage -5% +10%

0

F. 1000F.

0

F. 1000F.

April, 1993

Page 2

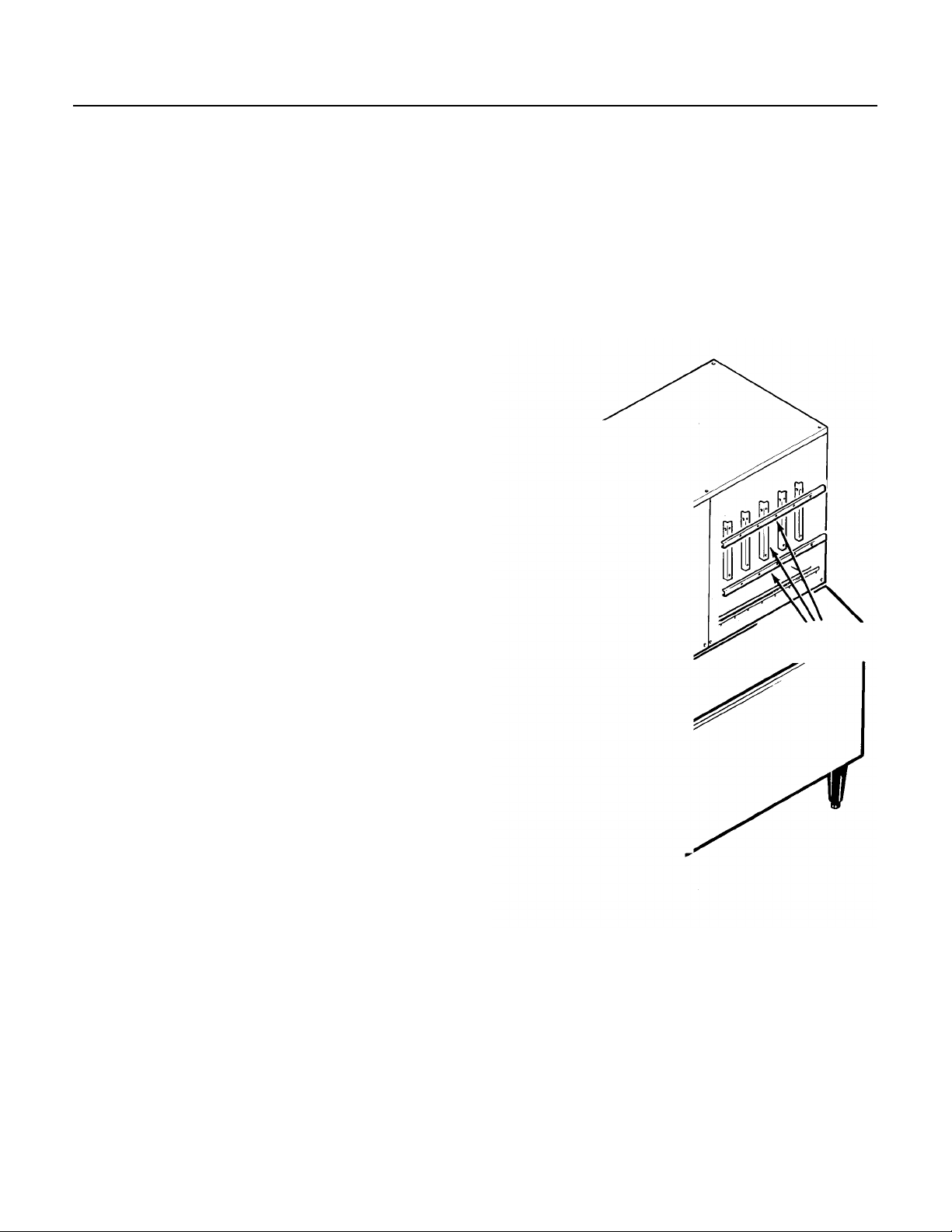

FOR THE INSTALLER: Location & Assembly

SHIPPING

BRACKETS

Location:

After uncrating and inspection, the unit is ready for

installation. It is important that the machine be

installed in a location where it has enough space

around it to be accessible for service. A minimum

of 6" must be allowed at the back for air circulation

on air cooled models. Try to avoid hot, dirty and

crowded locations. Be sure that the location for the

machine is within the envrionmental limitations.

Storage Bin:

Tip the storage bin on its back, using parts of the

carton to protect the exterior finish. Install the

casters, use a heavy duty leg kit if stacking two ice

machines on one bin.

1. Arrange for proper electric, water and drain.

See instructions for the plumber and for the

electrician.

2. Single ice machine on bin: Use caster kit KBC9.

After mounting the casters, position the ice storage

bin in the selected location:

MCM1462

ICE MACHINE AND BIN ASSEMBLY

Two ice machines on a bin require stacking kit

KSMCM48. Do NOT use casters on units with two

ice machines on one bin.

Note: Allow enough space to the left and back to

service the machine. Do NOT push the bin into

postion, instead, lift it there. Pushing a bin may

damage the legs and leg mounts.

Level the bin in both the front to rear and side to

side directions by adjusting the casters. Stacked

units use non-adjustable legs, and must be leveled

with shims. Select a well ventilated location for air

cooled models.

Note: Air cooled models blow air from front to back.

3. Inspect the bin top mounting gasket which

should be flat, with no wrinkles, to provide a good

water seal when the cuber is installed on top of the

bin.

4. Install the bin bumpers onto the top edge of the

bin, so that they hang-over the back.

Ice Maker:

Install the modular cuber on top of the bin using

care to be sure a good seal is made between the

two cabinets. Use of a mechancial lift is

recommended. Align the holes in the bottom rear

of the cabinet to mate with the two mounting holes

on the top rear of the bin.

Use bolts and straps found on the back of the

icemaker to secure the ice machine to the bin.

When alignment and leveling are completed,

tighten the bolts to secure the mounting straps.

Remove the front panels, and remove the

evaporator shipping brackets and hardware.

April, 1993

Page 3

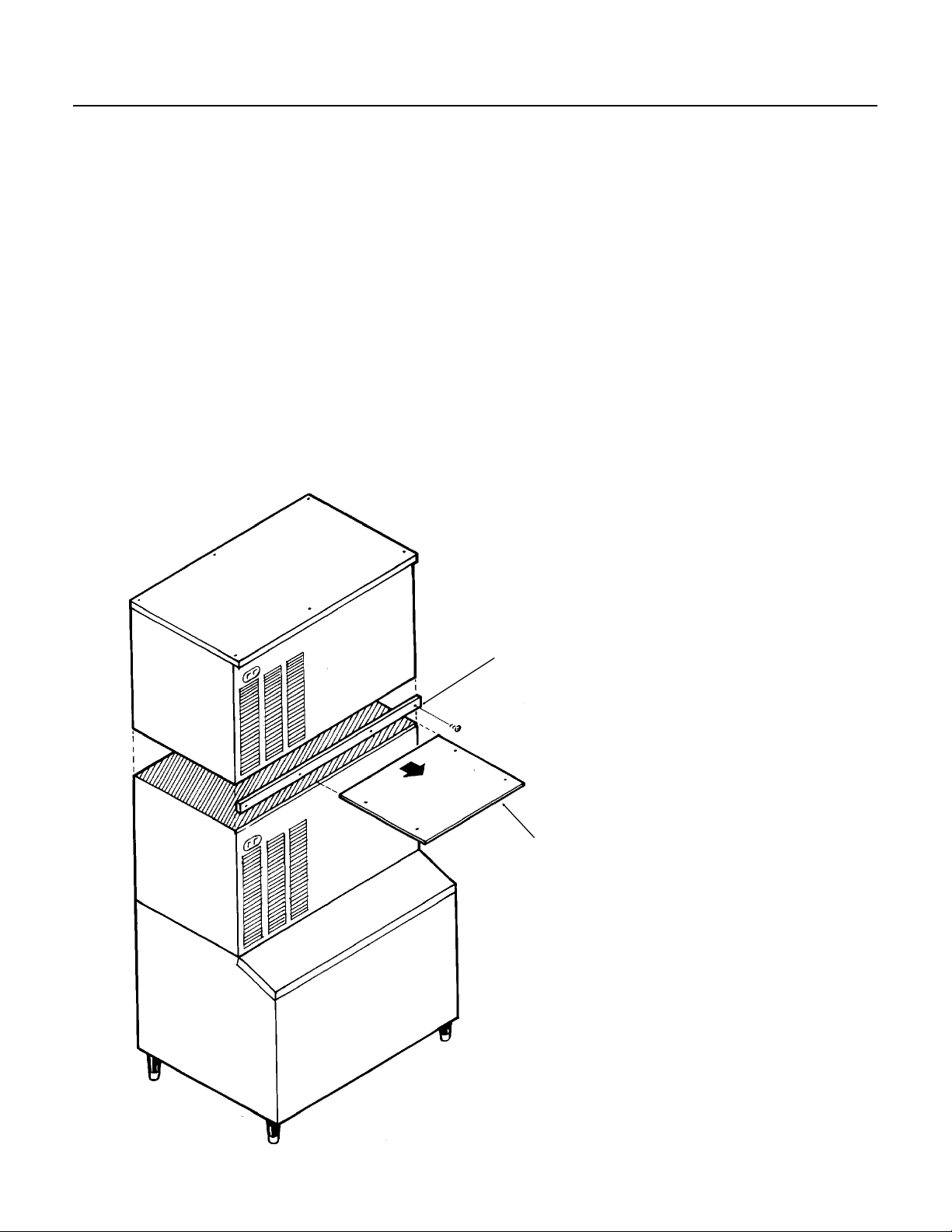

MCM1462

FOR THE INSTALLER: Location & Assembly

Stacking Instructions

A stacking kit, KSMCM48, is required to

interconnect the ice level controls, seal the

freezing compartments, support the bin with heavy

duty legs, and to retain the top edges of the

bottom unit’s front panels.

Follow the installation instructions of the stacking

kit, but in general:

Before adding a unit, the casters must be replaced

with heavy duty legs. Casters must not be used

with two ice machines on one bin.

When stacking two units, remove the top panel

and the evaporator cover from the lower icemaker.

(The top removed from the lower icemaker will no

longer have any function.)

STACKING

A stainless steel bracket (from the kit) must be

attached to the top of the bottom machine before

the units are stacked.

Place strips of gasket material (from the stacking

kit) on the top edges of the bottom unit’s freezing

compartment.

Carefully lift the uncrated top unit onto the bottom

one and align the two cabinets. Use of a

mechanical lift is recommended for this step.

At the back of the two icemakers, bolt the upper

icemaker cabinet to the lower icemaker cabinet

using the mounting straps and bolts from the

hardware package.

Add the relay box to interconnect the two ice

machine’s bin control circuits.

PANEL RETAINING

STRIP

EVAPORATOR COVER

April, 1993

Page 4

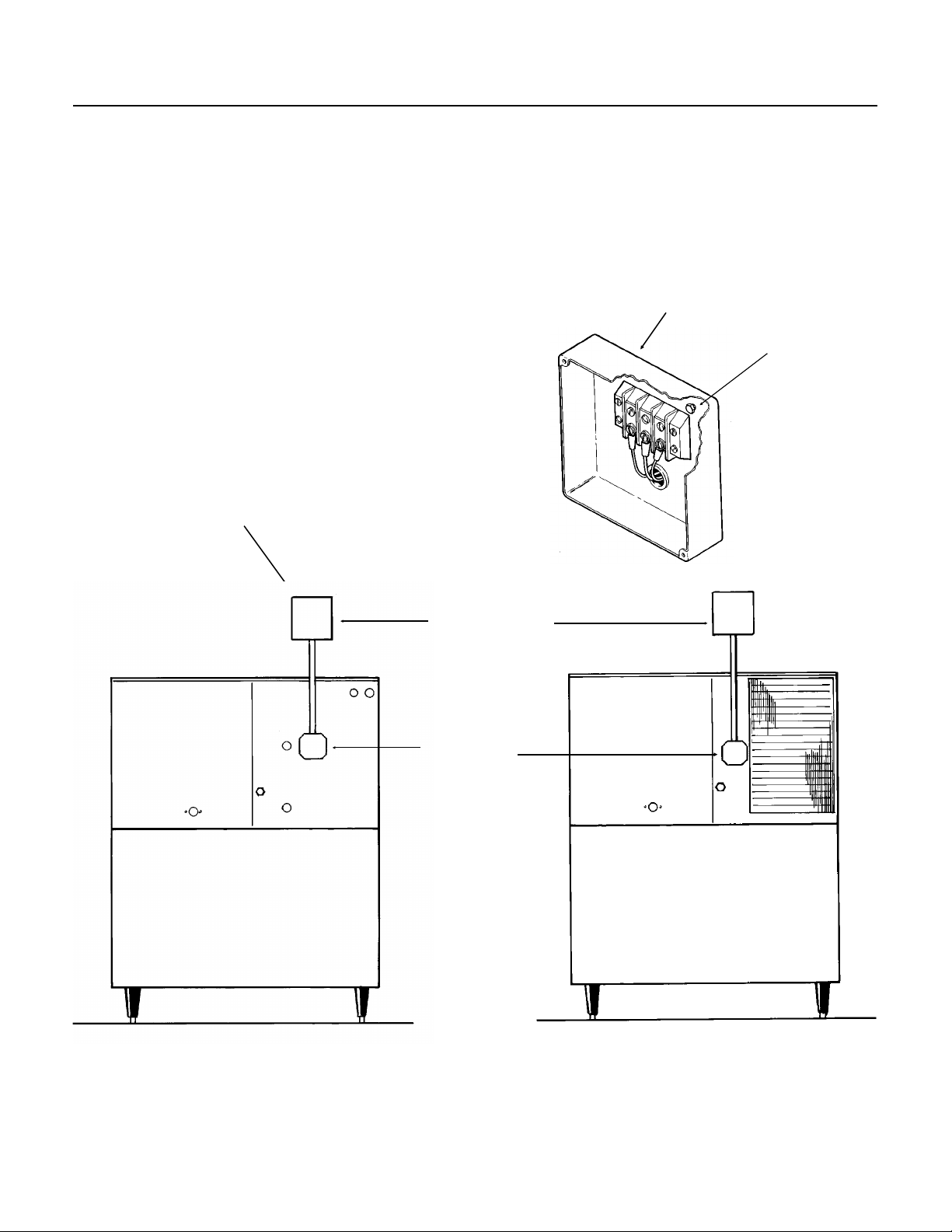

FOR THE ELECTRICIAN

BACK VIEW OF UNIT

GROUND SCREW

MCM1462

SEE NAMEPLATE for current requirements to

determine wire size to be used for electrical

hookup. The cuber requires a solid chassis to

chassis earth ground wire. See Wiring Diagram.

Be certain the cuber is connected to its own

electrical circuit and individually fused. Voltage

variation should not exceed ten percent of the

nameplate rating, even under starting conditions.

Low voltages can cause erratic operation and may

be responsible for serious damage to the

icemaker.

ELECTRICAL

POWER SUPPLY

Electrical connections are made at the rear of

the icemaker, inside the junction box.

All external wiring should conform to the

national, state and local electrical code

requirements. Usually an electrical permit and

services of a licensed electrician will be

required.

DETAIL OF

JUNCTION BOX

HAND

DISCONNECT

SWITCH

JUNCTION

BOX

ELECTRICAL CONNECTIONS, WATER COOLED

ELECTRICAL CONNECTIONS, AIR COOLED

April, 1993

Page 5

VENT

OPTIONAL

FILTER

CONDENSER

INLET

MCM1462

FOR THE PLUMBER

FOLLOW ALL LOCAL CODES:

The recommended water supply line is a 3/8-inch

O.D. copper tubing with a minimum operating

pressure of 20 PSIG and a maximum of 80 PSIG.

Connect to cold water supply line with standard

plumbing fittings, with shut off valve installed in an

accessible place between thewater supply and the

cuber. ln some cases a plumber will be required.

Water Limitations:

An ice machine is a food manufacturing plant, it

takes in a raw material, water, and turns it inot a

food product, ice. The purity of the water is very

important in obtaining pure ice and in maximizing

product life. It is generally better to filter the water,

although there is no one filter that will cure all

water problems. A good filter combined with a

polyphosphate feeder gives about the best overall

performance.

Cold, potable water must be supplied to the water

inlet fitting.

CONNECTIONS:

All drains are gravity type and must have a

minimum of 1/4-inch fall per foot on horizontal

runs. The drains to be installed to conform with the

local plumbing code. Install a vertical open vent on

drain line high point to insure good draining. The

ideal drain receptacle is a trapped and vented floor

drain. Recommended bin drain is 5/8 inch O.D.

copper tubing and should be vented and run

separately. Insulation for high humidity areas is

recommended.

Water Cooled models require another inlet

connection to the condenser, and another drain for

the condenser. The drain must be separate from

the bin drain.

Bin Drain: The bin drains from the bottom, and

needs no vent unless there is a long horizontal run.

Terminate drains above the drain receptacle with

the proper air gap per local code.

The ice machine sump drain is 3/4" FPT. There

must be a vent at this connection for proper sump

drainage.

POTABLE

WATER

SUPPLY

AIR GAP

BETWEEN

DRAIN LINES

AND

BUILDING

DRAIN

3/8" MALE

FLARE

3/4" FPT

AIR COOLED

CONNECTIONS

HAND SHUT OFF

VALVE

SUMP DRAIN

MUST BE

VENTED

WATER COOLED

CONNECTIONS

CONDENSER

DRAIN

BIN

DRAIN

BACK VIEW OF

PLUMBING HOOK UP

WATER SUPPLY AND DRAIN CONNECTION

April, 1993

Page 6

FINAL CHECK LIST

1. Is the cabinet in a room where ambient

temperatures are within the minimum and

maximum temperatures specified?

2. Is there at least six inches clearance at the left

and back sides of the cabinet for proper air

circulation? (Air Cooled models)

3. Has water supply pressure been checked to

insure a minimum of 20 PSIG and a maximum of

80 PSIG operating pressure?

4. Is the cabinet level?

5. Check that any shipping material has been

removed from inside the cabinet.

6. Check that the reservoir is properly secured to

the bottom of the evaporator plates.

7. Have all electrical, water and drain connections

been made?

8. Is the water supply line shut off valve installed

and electrical wiring properly connected?

MCM1462

9. Check all refrigerant lines and conduit lines, to

guard against vibration or rubbing and possible

failure.

10. Have the bin and cabinet been wiped clean?

11. Has the Manufacturers Registration form been

properly filled out? Check for correct model and

serial numbers from Serial nameplate, then mail

the completed card to the SCOTSMAN factory.

12. Has the owner/user been given the Service

Manual and instructed how to operate and

maintain the icemaker?

13. Has the owner been given the name and

telephone number of the authorized SCOTSMAN

Service Agency serving him?

April, 1993

Page 7

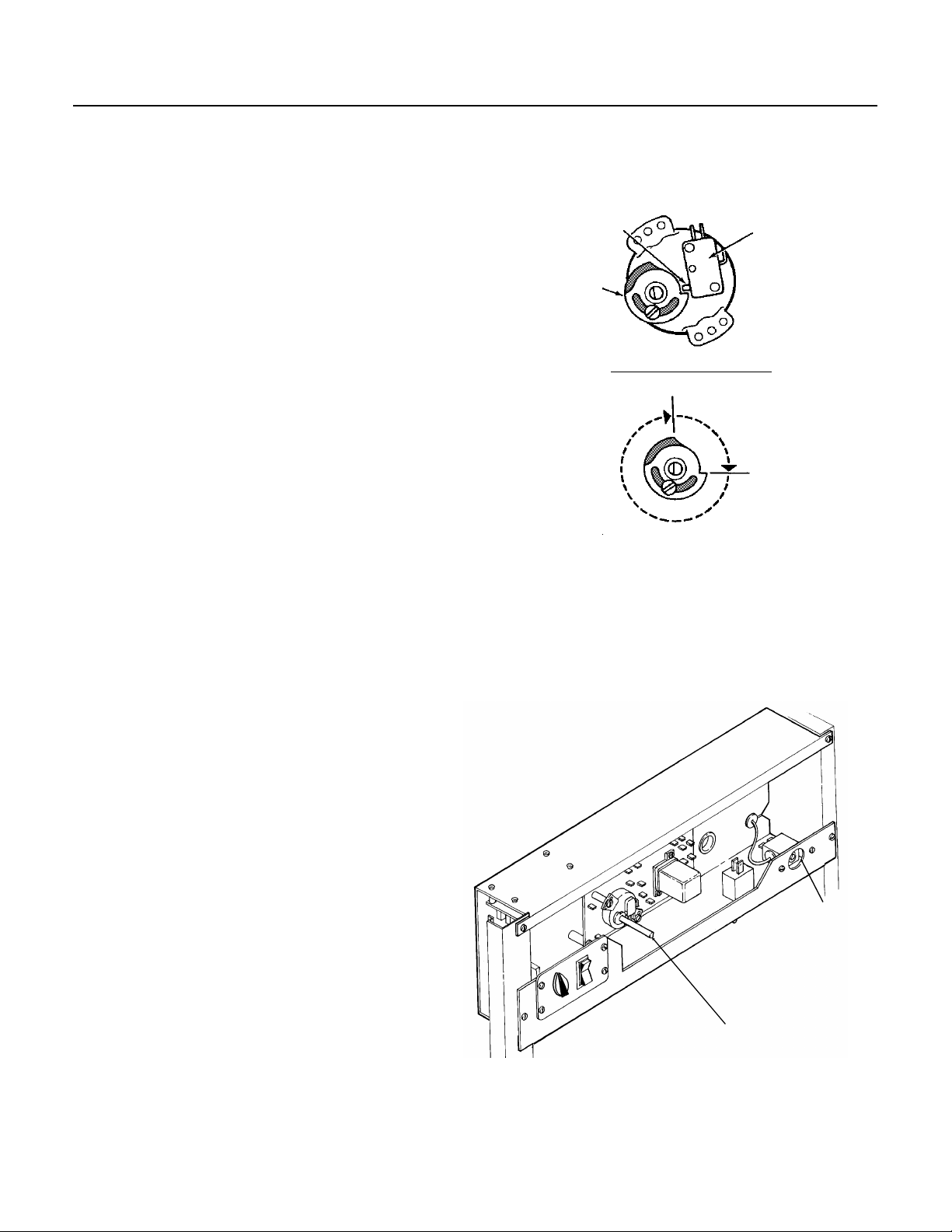

TIMER

MCM1462

INITAL START UP

1. Remove the front panels by removing screws at

the base and pulling out.

2. Remove two screws and the control box cover.

3. Check that the two switches on the control box,

the ICE-OFF-WASH rocker switch and the

COMPRESSOR ON-OFF toggle switch are in the

OFF position.

4. OPEN the water supply line shut off valve.

5. Inside the control box is the shaft of the timer

and the switch assembly. Rotate the shaft of the

timer and switch assembly clockwise to start the

timer. The timer starts when the actuator arm on

the microswitch drops off outer cam into cam slot.

See “Front View of Timer”.

6. Move the ICE-OFF-WASH rocker switch, to the

ICE position.

7. Observe water fill cycle: Water pump operates

and water inlet solenoid valve OPENS, incoming

water flows from the valve through the tubing, the

reservoir fills and excess water is overflowed

through the stand pipe. This continues through the

harvest cycle (about 3 and a half minutes). When

the freeze cycle is started, the timer and relay will

close the water inlet solenoid valve and the water

fill cycle is complete. If the sump is not full, rotate

the timer once again to repeat the harvest cycle.

The water pump should be pumping water through

the tygon tubes up to the water distributor at the

top of each evaporator plate, where water is

uniformly dispensed and cascades down both

sides of the evaporator plates and drains back into

the sump assembly for recirculation.

FRONT VIEW OF TIMER

ACTUATOR

BUTTON

CAM

FREEZE

PORTION

CONTROL BOX

MICROSWITCH

HARVEST

PORTION

8. When the sump has filled, move the compressor

ON-OFF toggle switch, to the ON position.

9. Check operation of the freezing cycle: The

compressor is operating.The icemaking process

begins; feeling the metal parts of the evaporator

plate reveals cold temperature, very shortly ice

begins to form. Tubing will become frosted at the

top of the evaporator plate. The first cycle will be

the longest, after that freezing time will range

between 12 and 15 minutes. Longer time for

temperatures above 70 degrees F. and shorter

time required when temperatures are below

70-degrees F. Average complete cycle time is

about 16 minutes.

CUBE SIZE

CONTROL

April, 1993

Page 8

Loading...

Loading...