Page 1

Page 1

09014400

Scotsman Ice Srl

Via Lainate, 31 - 20010 Pogliano M.se - Milano - Italy

Tel. +39-02-93960.1 (Aut. Sel.)- Telefax +39-02-93550500

Direct Line to Service & Parts:

Phone +39-02-93960350 - Fax +39-02-93540449

Website: www.scotsman-ice.it

E-Mail: scotsman.europe@scotsman.it

ISO 9001 - Cert. n. 0080

SERVICE MANUAL

MAR 78

MAR 108

MAR 128

MAR 208

MAR 308

SPLIT

RN

090144 00 - REV. 03/2016

Page 2

Page 2

FOREWORD

SCOTSMAN MAR SPLIT UNITS are available in

five basic models MAR 78, MAR 108, MAR 128,

MAR 208 and MAR 308 operating by fresh water.

MAR 78, MAR 128 and MAR 308 only are available,

upon request, presetted to operate by sea water.

They come complete with a stainless steel cabinet,

with a drive motor at V. 230/50/3 or 400/50/3-N

Volt, with expansion valve, heat exchanger, float

reservoir, time delay switch, bin thermostat, water

pump, ice spout switch, liquid solenoid valve,

water pressure control evaporator pressure ctl.

valve.

The refrigerating and electrical system must be

completed by the purchaser as per the instructions

given in this service manual who has to provide

for the complete condensing unit, its controls and

refrigerant tubings.

We suggest to take time now to read this manual

which contains a lot of valuable informations on

the MAR Split System.

For any further queries regarding the care or

operation of the machine, please contact:

ICE SYSTEMS

®

SCOTSMAN - EUROPE - FRIMONT SPA

Via Puccini, 22 - 20010 Bettolino di Pogliano (Milano) Italy

Tel. +39-02-93960.1 (Aut. Sel.)- Telefax +39-02-93550500

Direct Line to Service & Parts:

Phone +39-0331-589305 - Fax +39-0331-584306

Website: www.scotsman-ice.com

E-Mail: scotsman.europe@frimont.inet.it

®

Page 3

Page 3

TABLE OF

CONTENTS

Foreword page 2

Table of contents 3

Specifications 4-9

Section I GENERAL INFORMATION

General 10

Application area 10

Condensing unit 10

Control devices 11

Location considerations 12

Refrigerant lines 12

Hydraulic circuit 12

Ice storage room 12-14

Unit layout 15

Section II INSTALLATION

Unpacking and inspection 16

Location and levelling 16

Refrigerant piping connections 16

Water piping connections 17

Water and refrigerant circuit 17

Electrical connections 18

Installation practice 19

Mar Split in multiple installation 20

Typical non-code commercial installation 20

Section III TESTING

Complete system leak test 21

Complete system evacuation 21

Complete system charging 21

Start-up & Check-out 21

Operational check-out 21-23

Section IV PRINCIPLE OF OPERATION - HOW IT WORKS

ICE maker 24

MAR Split electrical/refrigeration 25-26

Section V ADJUSTMENT & REMOVAL & REPLACEMENT

PROCEDURES

MAR Split 27-28

Section VI MAINTENANCE & CLEANING INSTRUCTIONS 29-32

Section VII SERVICE DIAGNOSIS 33-34

Section VIII WIRING DIAGRAMS 35

Page 4

Page 4

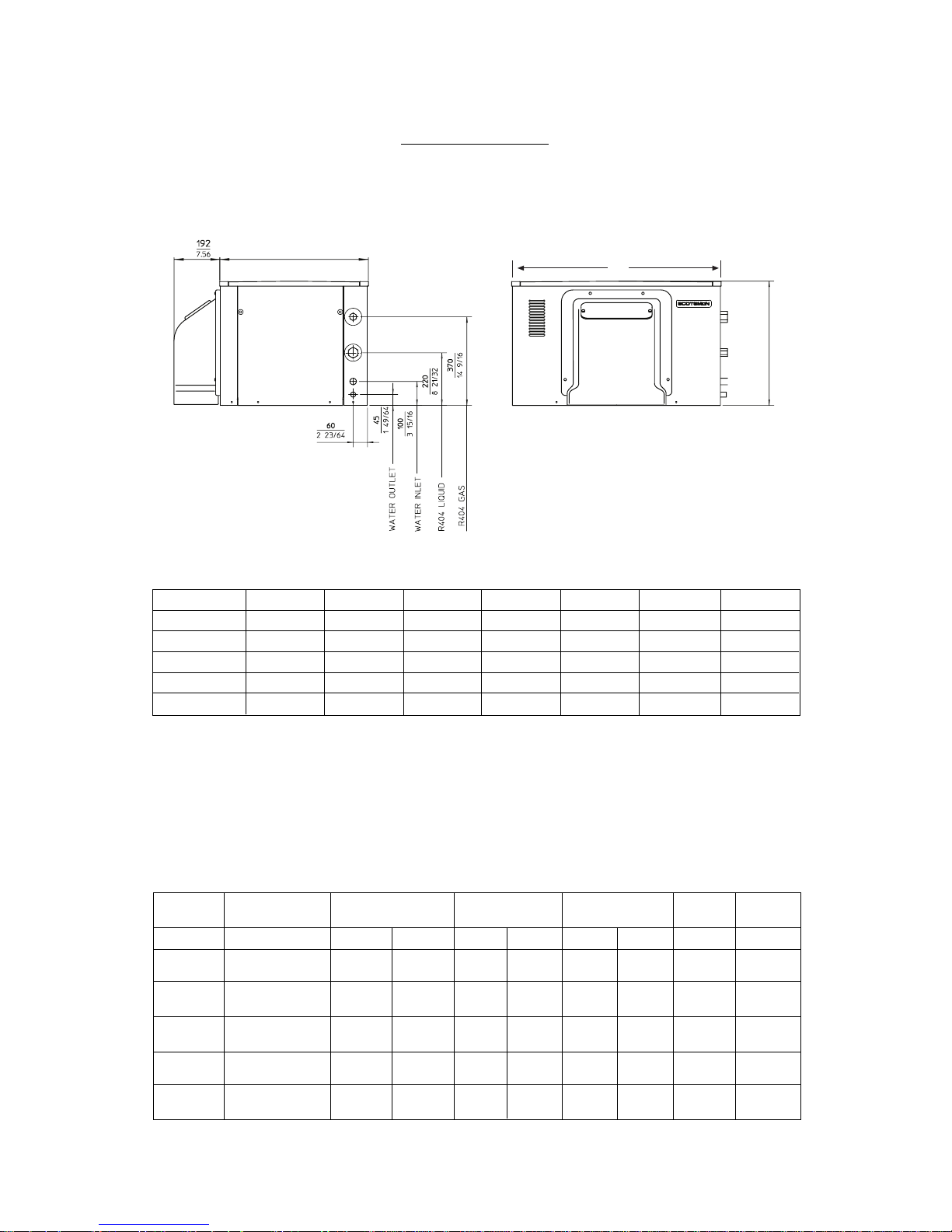

SPECIFICATIONS

MAR 78 - 108 - 128 - 208 - 308

A

B

C

Ø 1

Ø 2

Ø 3

Ø 4

(*) "THICK ICE" SETTING - AT 10°/10°C (ambient/water temp.)

TECHNICAL SPECIFICATION

SPLIT

MODEL

Basic

Electricals

Ice Production (*)

Kg/24 Hr.

Drive Motor

Finish

Shipping

Weight

V

Sea water Fresh W. Kcal/Hr Hp Amp

kg

MAR 78

400/50/3 - N

230/50/3

510

3200 1/2

SS

MAR 108

400/50/3 - N

230/50/3

670 4800 1/2

1.2

2.1

SS

MAR 128

400/50/3 - N

230/50/3

1000 6000 1/2

1.2

2.1

SS

MAR 208

400/50/3 - N

230/50/3

1650 8250 1/2

1.2

2.1

SS

MAR 308

400/50/3 - N

230/50/3

2200 9700 1/2

1.2

2.1

SS

131

131

131

223

223

****

****

850

****

Cooling req.ts

1800

Evap.T.°C

-18

-24

-24

-20

-30

1.2

2.1

A B C Ø1Ø2Ø3Ø4

MAR 78 621 876 520 3/4" gas 3/8" gas 3/4" gas 21 mm

MAR 108 621 876 520 3/4" gas 3/8" gas 3/4" gas 21 mm

MAR 128 621 876 520 3/4" gas 3/8" gas 3/4" gas 21 mm

MAR 208 661 1297 520 3/4" gas 1/2" gas 28 mm 21 mm

MAR 308 661 1297 520 3/4" gas 1/2" gas 28 mm 21 mm

Ø1

= GAS LINE CONNECTION (SUCTION)

Ø3

= WATER INLET FITTING

Ø2

= LIQUID LINE CONNECTION

Ø4

= WATER OUTLET CONNECTION

Page 5

Page 5

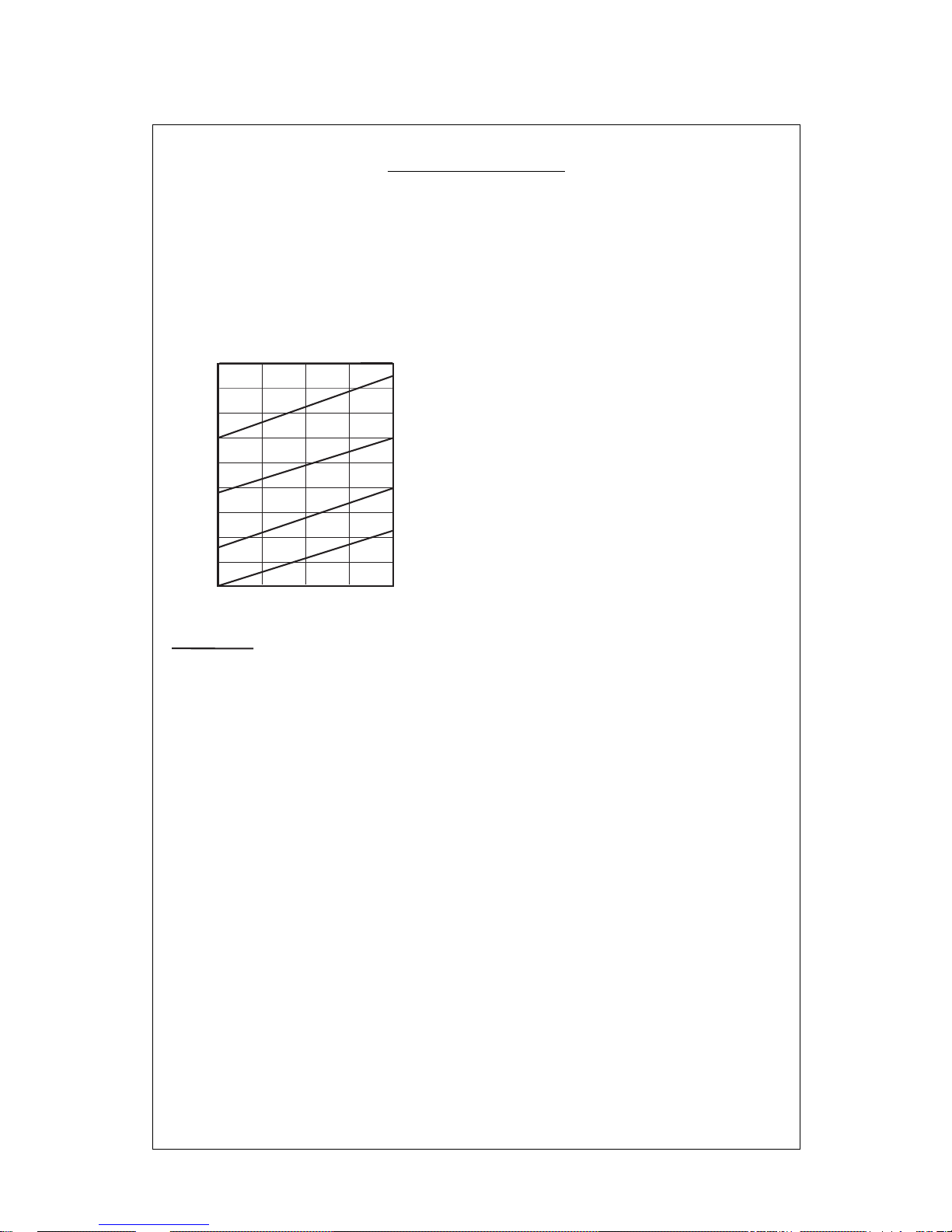

MAR 78 SPLIT

Set for Fresh water Operation

ICE MAKING CAPACITY

IMPORTANT OPERATING REQUIREMENTS:

WATER LEVEL IN DRUM RESERVOIR 115-120 mm

WITH WATER PUMP / SPRAY BAR

DRUM ROTATING SPEED 1.1 RPM (thick ice)

CONDENSING CAPACITY 4900 Kcal/hr (TD 10 ÷ 15 °C)

HEAD PRESSURE SETTING 15 ÷ 17 Bar on air cooled units

17 Bar on water cooled unit

LOW PRESSURE SETTING 2.2 Bar on air cooled units

1.8 Bar on water cooled units

HI-PRESSURE CONTROL SETTING 34 ± 2 Bar A/C

30 ± 2 Bar W/C

LO-PRESSURE CONTROL SETTING 0.2 Bar

WATER PRESSURE CONTROL SETTING 0.8 Bar

MAX. WATER TEMPERATURE 35 °C

MIN. WATER TEMPERATURE 5 °C

MIN. WATER PRESSURE 1 atm.

MAX. WATER PRESSURE 5 atm.

MIN. AMBIENT TEMPERATURE 5 °C

MAX. AMBIENT TEMPERATURE 40 °C

MAX. VOLTAGE VARIATION ± 10%

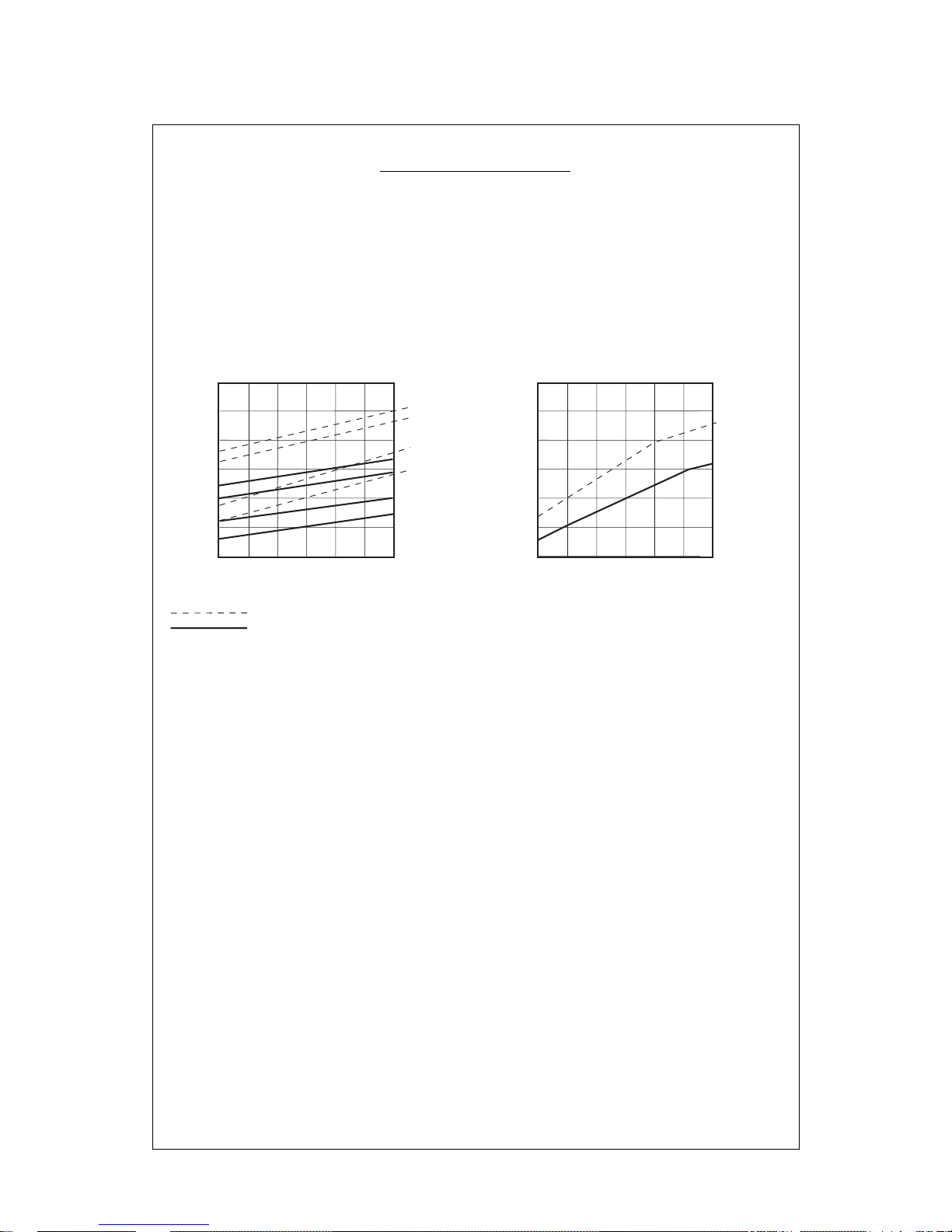

NOTE. The production diagrams herebelow represented can be used as reference, since the data

indicated have been obtained with a air/water cooled condensing unit equipped with a hermetic

compressor type U.H. TFH 2480Z providing - 3200 Kcal/hr at -18 °C Refrigerating capacity.

520

500

480

460

440

420

400

380

360

340

Kg./24 h

°C

32 27

21

15

°C

10

21

32

38

o

AIR COOLED MODELS

WA TER TEMPERATURE

AMBIENT TEMPERATURE

ICE PRODUCED PER 24 HRS.

10

Thicker scale ice

Page 6

Page 6

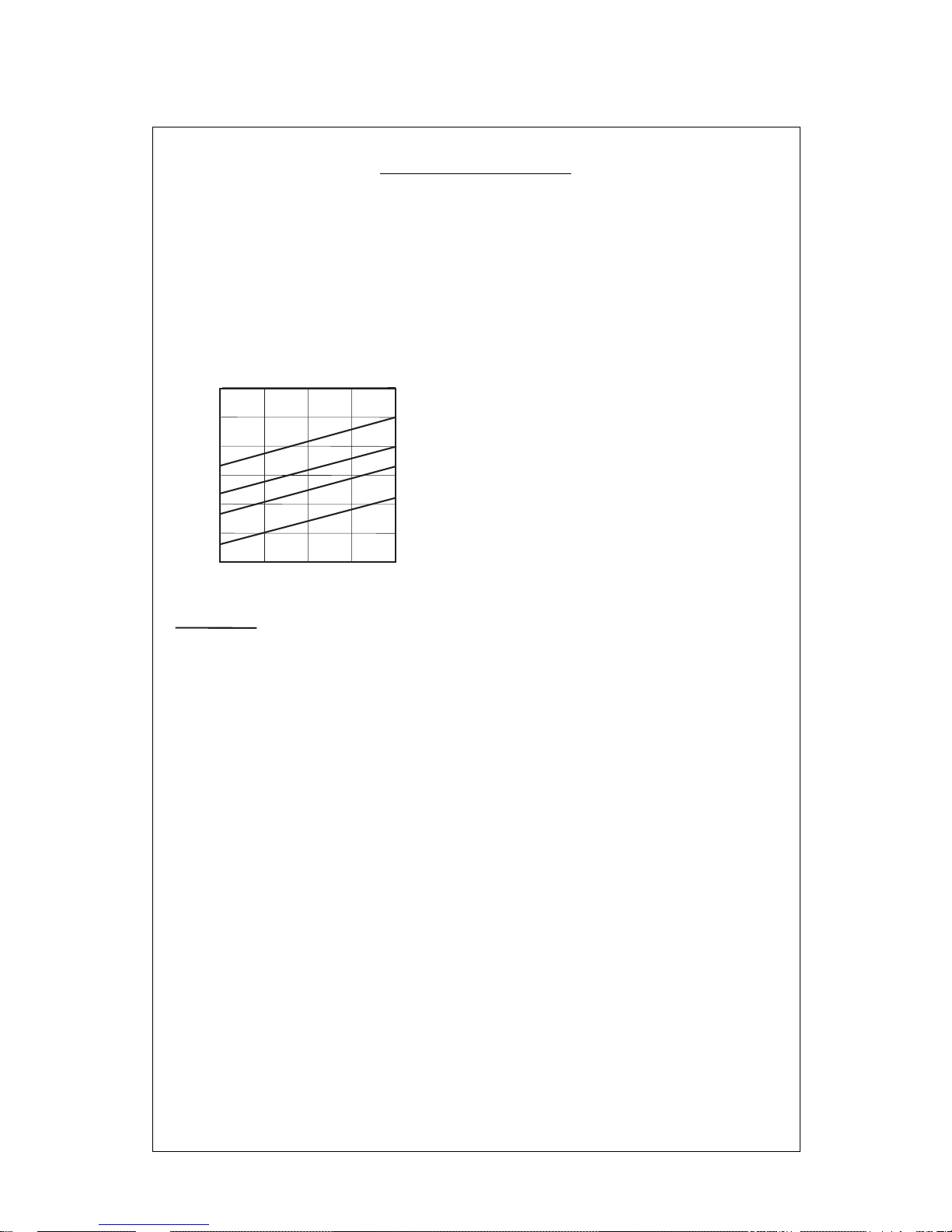

MAR 108 SPLIT

Set for Fresh water Operation

ICE MAKING CAPACITY

IMPORTANT OPERATING REQUIREMENTS:

WATER LEVEL IN DRUM RESERVOIR 115-120 mm

WITH WATER PUMP / SPRAY BAR

DRUM ROTATING SPEED 1.5 RPM (thick ice)

2.3 RPM (thin ice)

CONDENSING CAPACITY 7500 Kcal/hr (TD 10 ÷ 15 °C)

HEAD PRESSURE SETTING 15 Bar on air cooled units

15 Bar on water cooled unit

LOW PRESSURE SETTING 1.6 Bar on air cooled units

HI-PRESSURE CONTROL SETTING 36 Bar

LO-PRESSURE CONTROL SETTING 0.2 Bar

WATER PRESSURE CONTROL SETTING 0.8 Bar

MAX. WATER TEMPERATURE 35 °C

MIN. WATER TEMPERATURE 5 °C

MIN. WATER PRESSURE 1 atm.

MAX. WATER PRESSURE 5 atm.

MIN. AMBIENT TEMPERATURE 5 °C

MAX. AMBIENT TEMPERATURE 40 °C

MAX. VOLTAGE VARIATION ± 10%

NOTE. The production diagrams herebelow represented can be used as reference, since the data

indicated have been obtained with a air/water cooled condensing unit equipped with a hermetic

compressor type U.H. TAG 2516Z providing - 4800 Kcal/hr at -24 °C Refrigerating capacity.

750

700

650

600

550

500

450

Kg./24 h

°C

32 27

21

15

°C

10

21

32

38

o

AIR COOLED MODELS

WA TER TEMPERATURE

AMBIENT TEMPERATURE

ICE PRODUCED PER 24 HRS.

10

Thicker scale ice

Page 7

Page 7

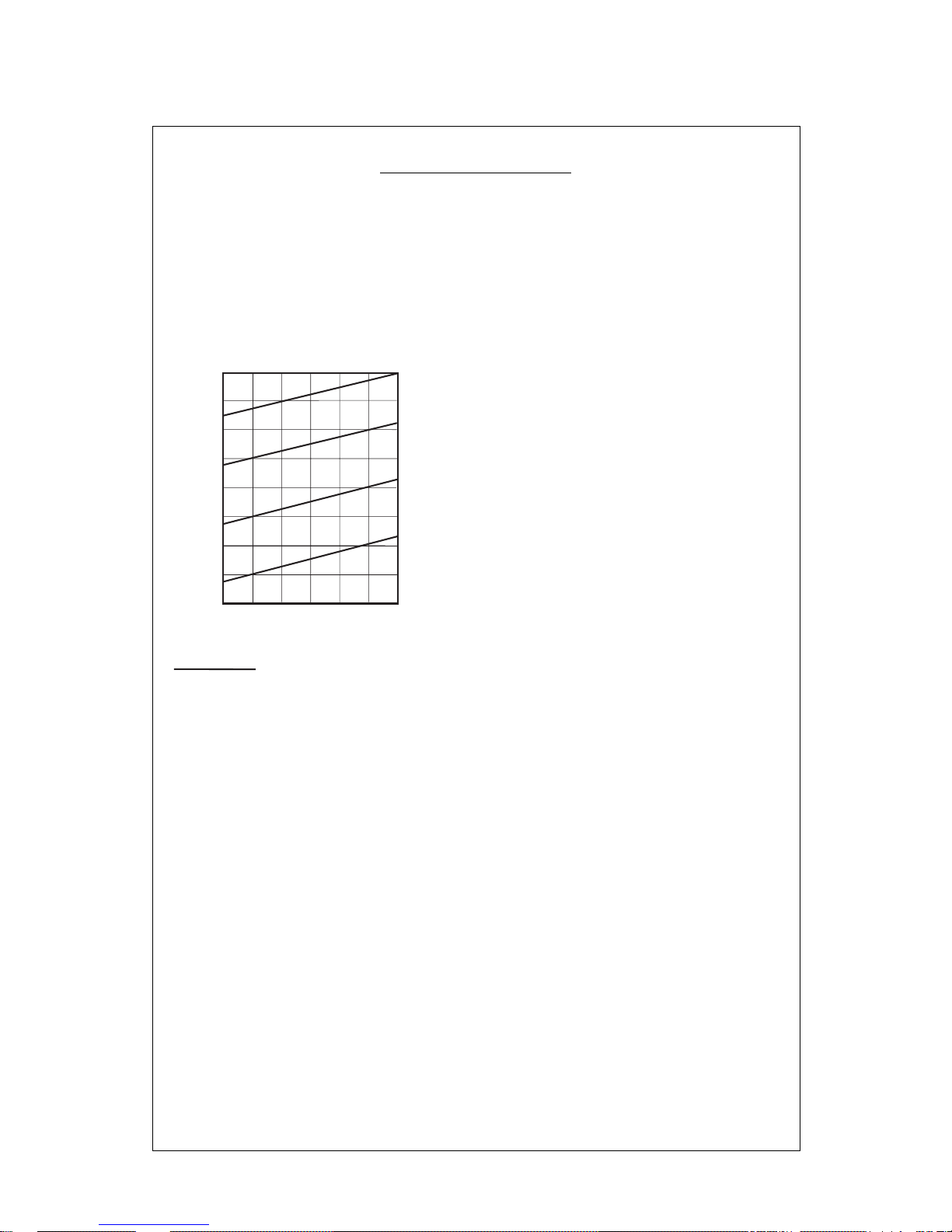

MAR 128 SPLIT

Set for Fresh water Operation

ICE MAKING CAPACITY

NOTE. The production diagrams herebelow represented can be used as reference, since the data

indicated have been obtained with a air/water cooled condensing unit equipped with a hermetic

compressor type U.H. TAG 2522Z providing - 6000 Kcal/hr at -24°C Refrigerating capacity.

IMPORTANT OPERATING REQUIREMENTS:

WATER LEVEL IN DRUM RESERVOIR 115-120 mm

WITH WATER PUMP / SPRAY BAR

DRUM ROTATING SPEED 2.4 RPM (thick ice)

CONDENSING CAPACITY 9750 Kcal/hr (TD 10 ÷ 15 °C)

HEAD PRESSURE SETTING 14 ÷ 16 Bar on air cooled units

LOW PRESSURE SETTING 1.6 Bar on air cooled units

HI-PRESSURE CONTROL SETTING 36 Bar

LO-PRESSURE CONTROL SETTING 0.2 Bar

WATER PRESSURE CONTROL SETTING 0.8 Bar

MAX. WATER TEMPERATURE 35 °C

MIN. WATER TEMPERATURE 5 °C

MIN. WATER PRESSURE 1 atm.

MAX. WATER PRESSURE 5 atm.

MIN. AMBIENT TEMPERATURE 5 °C

MAX. AMBIENT TEMPERATURE 40 °C

MAX. VOLTAGE VARIATION ± 10%

1000

950

900

850

800

750

700

650

600

38

°C

32 27

21

15

AIR COOLED UNITS

WA TER TEMPERATURE

AMBIENT TEMPERATURE

ICE PRODUCED PER 24 HRS.

32

38

10 5

10

21

Thicker scale ice

Page 8

Page 8

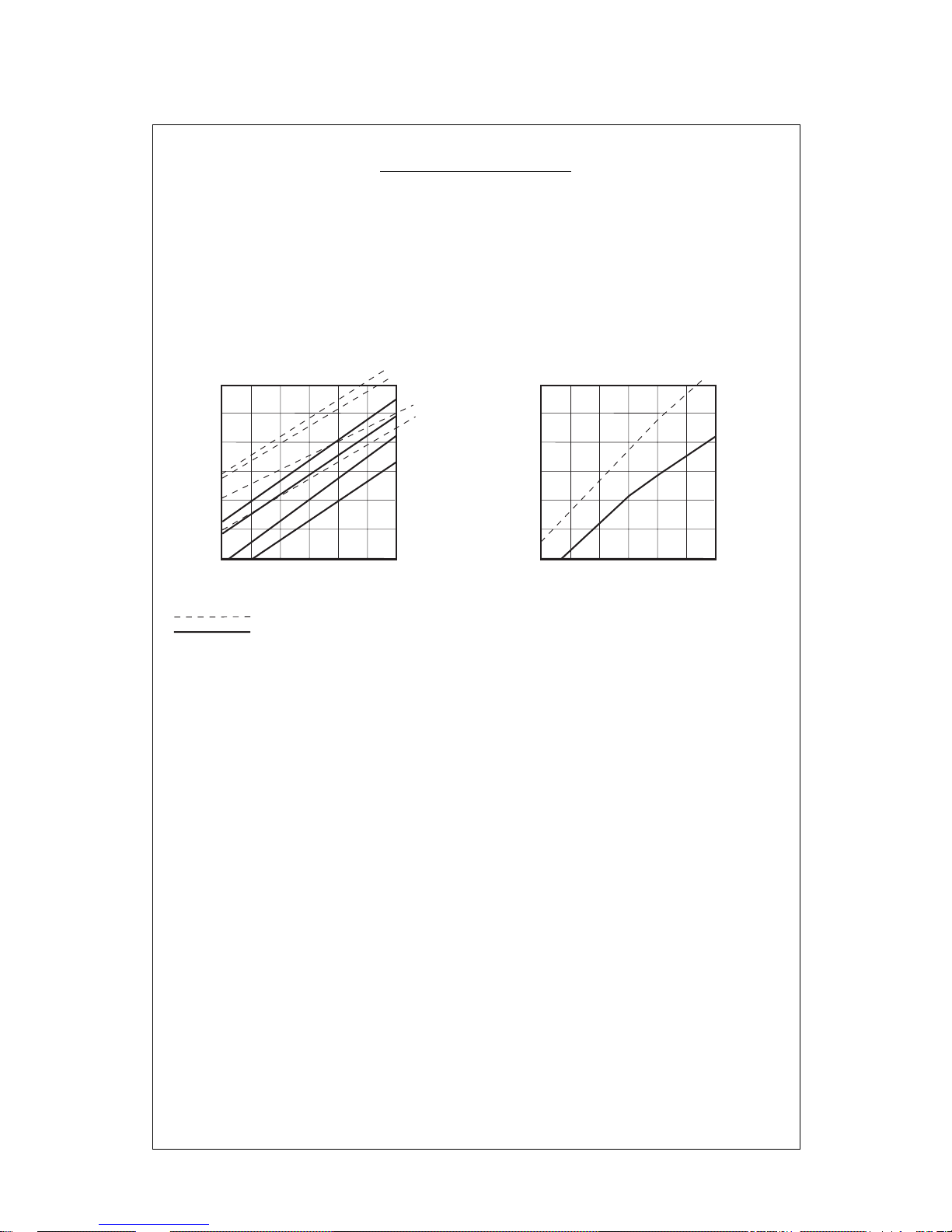

MAR 208 SPLIT

Set for Fresh water Operation

ICE MAKING CAPACITY

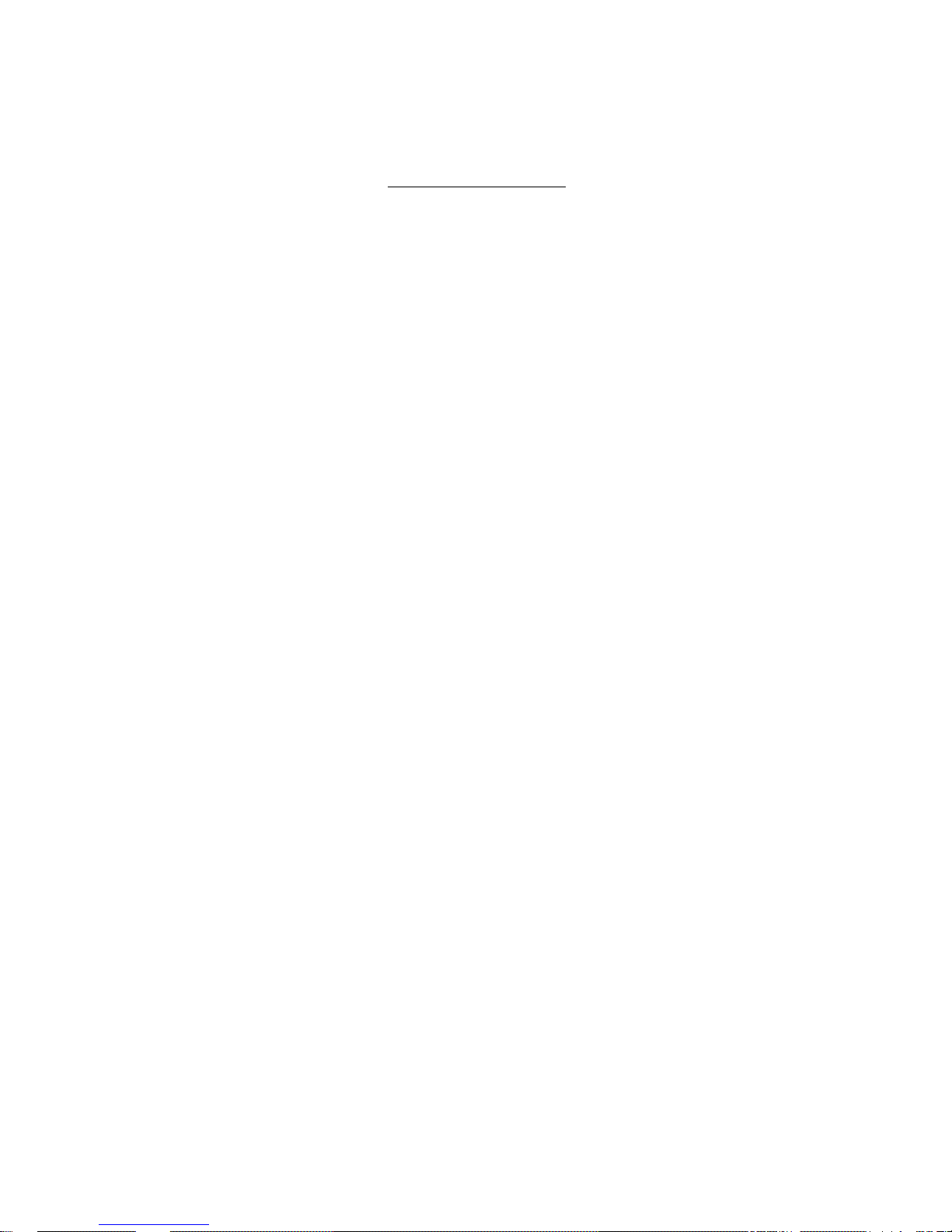

NOTE. The production diagrams herebelow represented can be used as reference, since the data

indicated have been obtained with a air/water cooled condensing unit equipped with a hermetic

compressor type DORIN K500 CS providing - 8250 Kcal/hr at -20 °C Refrigerating capacity.

IMPORTANT OPERATING REQUIREMENTS:

WATER LEVEL IN DRUM RESERVOIR 90-95 mm

WITH WATER PUMP / SPRAY BAR

DRUM ROTATING SPEED 1.05 RPM (thick ice)

1.60 RPM (thin ice)

CONDENSING CAPACITY 11000 Kcal/hr (TD 10 ÷ 15 °C)

HEAD PRESSURE SETTING 16 ÷ 18 Bar on air cooled units

16 ÷ 17 Bar on water cooled unit

LOW PRESSURE SETTING 1.9 Bar

HI-PRESSURE CONTROL SETTING 36 Bar

LO-PRESSURE CONTROL SETTING 0.2 Bar

WATER PRESSURE CONTROL SETTING 0.8 Bar

MAX. WATER TEMPERATURE 35 °C

MIN. WATER TEMPERATURE 5 °C

MIN. WATER PRESSURE 1 atm.

MAX. WATER PRESSURE 5 atm.

MIN. AMBIENT TEMPERATURE 5 °C

MAX. AMBIENT TEMPERATURE 40 °C

MAX. VOLTAGE VARIATION ± 10%

1700

1600

1500

1400

1300

1200

1100

Kg.

38

°C

32 27

21

15

°C

32

38

AIR COOLED UNITS

WA TER TEMPERATURE

AMBIENT TEMPERATURE

ICE PRODUCED PER 24 HRS.

32

38

WATER COOLED UNITS

10 5

10

21

1900

1800

1700

1600

1500

1400

1300

Kg.

38

°C

32 27

21

15

°C

DE 10 A' 38

o

WA TER TEMPERATURE

AMBIENT TEMPERATURE

ICE PRODUCED PER 24 HRS.

10 5

10

21

Thicker scale ice

Thiner scale ice

Page 9

Page 9

MAR 308 SPLIT

Set for Fresh water Operation

ICE MAKING CAPACITY

NOTE. The production diagrams herebelow represented can be used as reference, since the data

indicated have been obtained with a air/water cooled condensing unit equipped with a semihermetic

compressor type DORIN K1000 CS providing - 9700 Kcal/hr at -30 °C Refrigerating capacity.

IMPORTANT OPERATING REQUIREMENTS:

WATER LEVEL IN DRUM RESERVOIR 90 mm

WITH WATER PUMP / SPRAY BAR

DRUM ROTATING SPEED 1.6 RPM (thick ice - air cooled)

1.8 RPM (thick ice - water cooled)

2.9 RPM (thin ice)

CONDENSING CAPACITY 16200 Kcal/hr (TD 10 ÷ 15 °C)

HEAD PRESSURE SETTING 15 Bar on air cooled units

14 Bar on water cooled unit

LOW PRESSURE SETTING 1 Bar on air cooled units

0.75 Bar on water cooled unit

HI-PRESSURE CONTROL SETTING 34 ± 2 A/C Bar

30 ± 2 W/C Bar

LO-PRESSURE CONTROL SETTING 0.2 Bar

WATER PRESSURE CONTROL SETTING 0.8 Bar

MAX. WATER TEMPERATURE 35 °C

MIN. WATER TEMPERATURE 5 °C

MIN. WATER PRESSURE 1 atm.

MAX. WATER PRESSURE 5 atm.

MIN. AMBIENT TEMPERATURE 5 °C

MAX. AMBIENT TEMPERATURE 40 °C

MAX. VOLTAGE VARIATION ± 10%

2600

2400

2200

2000

1800

1600

1400

Kg.

38

°C

32 27

21

15

°C

32

38

AIR COOLED UNITS

WA TER TEMPERATURE

AMBIENT TEMPERATURE

ICE PRODUCED PER 24 HRS.

32

38

WATER COOLED UNITS

10 5

10

21

2800

2600

2400

2200

2000

1800

1600

Kg.

38

°C

32 27

21

15

°C

DE 10 A' 38

o

WA TER TEMPERATURE

AMBIENT TEMPERATURE

ICE PRODUCED PER 24 HRS.

10 5

10

21

Thicker scale ice

Thiner scale ice

Page 10

Page 10

SECTION I

GENERAL INFORMATION

GENERAL

The MAR SPLIT UNITS are pratically the

"Evaporating Unit Section" complete with driving

mechanism and control devices, all encased in

their stainless steel cabinets, for making complete scale-ice maker system

The MAR SPLIT UNITS must be remotely

connected to a corresponding size "Condensing

Unit" to become a MAR scale-ice maker plant, it

is therefore of primary importance first, the

selection of the right type and size of all the

components to be used to complete the refrigerant

system and secondly - but not least - the skillness

of the refrigeration engineers that will proceed in

completing the system by making the refrigerant,

hydraulic and electrical connections.

APPLICATION AREA

The scale-ice maker system using the MAR Split

Units, applies to different sort of market situations

where scale-ice is needed. Most specific areas

are:

a) Fishing Vessels

b) Fish Markets and Fish Processing Plants

c) Supermarkets

d) Meat packaging plants

Basically they can go in any place where there is

a limited space situation or where the condensing

unit (compressor/condenser) must be located in

a room where noise and heat is not objectionable.

MAR Split can be set to produce "THICK ICE"

generally used in the fishing industry or "THIN

ICE" generally used in the meat processing

industry.

Standard versions are set for "THICK ICE"

production (about 2 mm thickness) and for fresh

water operation. Different conditions should be

specified when ordering the Units.

Modular combinations are possible to increase

output ice production.

COMPLETE SYSTEM INSTALLATION - How

it is made

The complete scale-ice making system can be

divided in three major groups, that are:

a) the compressor and condenser unit with their

own components with their own refrigerant

and water lines fittings and electric wires

terminal block.

b) the evaporator drum unit (MAR Split Unit

supplied by Frimont) complete with drive

mechanism, drive motor, refrigerant and water

lines fittings, refrigerants expansion valve and

electric wire junction box.

c) console panel and control box with compressor

ON/OFF switch, relay, timer, warning lights,

pressure gauges and electrical wire terminal

block.

For installation on board of fishing vessels where

the electrical power available is not sufficient or

adequate to run the compressor, a mechanical or

hydraulic drive transmission must be used.

These drive systems will not be covered in details

in this manual as it is assumed that their

fundamentals have been already mastered to

the installator engineer by more specific

publications.

CONDENSING UNIT

The compressor is truly the heart of the system,

when it becomes inoperative refrigeration

immediately ceases. Therefore the selection of

proper type and size of compressor together with

the proper type and size of condenser, their

components and controls, deserve the most of

attention by the refrigeration engineer.

For our MAR ice making system, the compressor

to take is consideration are ot two basic types:

a) the accessible Semi-Hermetic-Motor-

Compressor for installation on sites where the

electrical power supply is available in adequate

quantity and quality.

b) the Open Type Compressor for automative

installations (Fishing Vessels) with mechanical

pneumatic or hydraulic drive system through

a magnetic clutch.

Whatever is the type of compressor being used,

it is recommended, for its selection, to observe

the refrigerant capacity on the following table:

MAR 78 3200 Kcal/h -18°C Evap. Temp.

MAR 108 4800 Kcal/h -24°C Evap. Temp.

MAR 128 6000 Kcal/h -24°C Evap. Temp.

MAR 208 8250 Kcal/h -20°C Evap. Temp.

MAR 308 9700 Kcal/h -30°C Evap. Temp.

Page 11

Page 11

The approximate heat transfer capacity for the

condenser selection is shown on the herebelow

table

The condenser is basically a heat exchanger

where the heat absorded by the refrigerant during

the evaporating process is given to the condensing

medium which could be the air or the water.

When using marine type condenser a marine

type, water regulating valve is requested as well

to modulate the cooling water flow within

condenser.

Recommendend valve is the pressure actuated

"PENN".

The Liquid receiver is a storage tank for liquid

refrigerant that can be useful on refrigeration

split installation to make the quantity of refrigerant

in the system less critical.

It is normally provided with two service valves

and occasionally can be built-in the bottom of

condenser. It is a common component used in

refrigeration plant and should be large enough to

hold all the refrigerant in the system.

The Oil separator should be filled with oil during

installation until the float valve just begins to

open. This oil quantity always remains in the

separator and would otherwise be taken from the

compressor.

It is well known that when the compressor

operates, small amount of oil is pumped out

along with the hot compressed vapor and to

prevent it from going any further in the system,

the oil separator traps it to return, upon opening

of its float valve, to the crankcase of the

compressor.

CONTROL DEVICES

The scale-ice maker system must be completed

with all the necessary safety devices and controls

in order to fully protect it and to minimize

operational checks and functions, however any

excess in using automatic controls and protections

may complicate the situation at the point that

some of the controls be eliminated later, by the

user.

In order to help the installator engineer to decide

with which controls he has to equip a given

system, we cover all the necessary ones

mentioning for each of them the positive factors

and eventually the negative ones.

High Pressure Control

Very important - No negative factors Set to

values shown on techn. spech. Not supplied.

Water Pressure Control

Very important - No negative factors Set to 0.8

atm-cut-in - 0.5 atm cut-out. Supplied.

Lo Pressure Control

Very important because in case of refrigerant

leaks at the evaporator, it prevents to draw in the

system some water from the drum reservoir. It

also prevents to draw air through the compressor

crank-shaft seal. This may occure during vacuum

operations of the system.

However, it may inopportunely trip-off at the

system start-up and if suction operating pressure,

on account of the excessive rotating speed of

compressor or excessive compressor capacity,

is very close and gets below its setting value,

which is 0.2 atm. Not supplied.

MAR 78 MAR 108 MAR 128 MAR 208 MAR 308

300 lt/hr 450 lt/hr 84*****h 1200 lt/hr 1600 lt/hr

Particular care must be deserved to the selection

of the water cooled condenser expecially the

marine type for fishing vessels installation.

They can be marine type (cupro-nickel) tube

within a tube condenser with plasticized heads.

With water inlet temperature of +20°C and outlet

of +30°C at condensing temperature of 32°C the

water consumption should be:

MAR 78 MAR 108 MAR 128 MAR 208 MAR 308

4900 Kcal/h 7500 Kcal/h 9750 Kcal/h 11000 Kcal/h 16200 Kcal/h