Scotsman MAR 76,MAR 106,MAR 56,MAR 206,MAR 306,MAR 126 Service Manual

Page 1

Page 1

Scotsman Ice Srl

Via Lainate, 31 - 20010 Pogliano M.se - Milano - Italy

Tel. +39-02-93960.1 (Aut. Sel.)- Telefax +39-02-93550500

Direct Line to Service & Parts:

Phone +39-02-93960350 - Fax +39-02-93540449

Website: www.scotsman-ice.it

E-Mail: scotsman.europe@scotsman.it

ISO 9001 - Cert. n. 0080

SERVICE MANUAL

MAR 56

MAR 76

MAR 106

MAR 126

MAR 206

MAR 306

Scale ice machines

MS 1000.66 - REV. 06/2018

Page 2

Page 2

FOREWORD

The "MAR" ice makers make flake ice of "scale"

type which is flat, hard dry and sub-cooled, giving

to it an exceptional staying power for multiple

chilling operations.

The design simplicity accounts for the confidence

in MAR scale ice machines. Their ice making

system has only one sealed moving part, resulting

in a minimum of maintenance operations for

continuous reliable machine service.

Ice is discharges through a large opening on the

back of unit cabinet, when mounted on top of the

refrigerated room, ice is gravity fed to storage

area.

Rugged, solid, heavy duty, the stainless steel

MAR cabinet has removable panels that facilitate the accessibility to mechanical and electrical

parts. A console panel with lights monitoring

water flow pressure, and temperature operating

refrigerant pressure and motors overloading

foreworn the system malfunction before becoming

major trouble.

We suggest you to take time now to read this

manual which contains a lot of valuable

informations on the MAR ice making system.

If you have any further queries regarding the care

or operation of the machine, please contact:

NOTE: Whenever writing please state model no. and serial no. of the machine

ICE SYSTEMS

®

SCOTSMAN - EUROPE - FRIMONT SPA

Via Puccini, 22 - 20010 Bettolino di Pogliano (Milano) Italy

Tel. +39-02-93960.1 (Aut. Sel.)- Telefax +39-02-93550500

Direct Line to Service & Parts:

Phone +39-02-93960350 - Fax +39-02-93540449

Website: www.scotsman-ice.com

E-Mail: scotsman.europe@frimont.it

®

TABLE OF

CONTENTS

Foreword page 2

Table of contents 3

Specifications - MAR 56 - 76 - 106 - 126 4-5-6

Specifications - MAR 206 - 306 7-8

Remote cond. 9

Section I GENERAL INFORMATIONS & INSTALLATIONS

Description 10

Unpacking & Inspection 10

Location & Levelling 11

Electrical connections 12

Water supply & Drain connections 12

Remote air cooled condenser installation 13

Ice level control 14

Ice chute 15

Final check list 15

Unit installation practice 15-16

Section II OPERATING INSTRUCTIONS

Start-up 17

Water & Refrigerant circuit 18-19

Section III PRINCIPLES OF OPERAZION - HOW IT WORKS

Ice maker 20

Electrical / Refrigeration 21-22-23

Refrigerant charge 24

Mechanicals 24

Section IV ADJUSTMENT & REMOVAL & REPLACEMENT

PROCEDURES

Water regulator assy 25

Automatic expansion valve 25

V Belt change on pulley 25

Compressor replacement 25

Water cooled condens. replacement 26

Water regulator replacement 26

Drier replacement 26

Drive motor replacement 27

Gear Box replacement 28

Fiber key replacement 28

Section V MAINTENANCE & CLEANING INSTRUCTIONS

General 29

Ice maker 29

Cleaning instruction 29-30-31-32

Section VI SERVICE DIAGNOSIS

Ice making - Refrigerant system 33-34

Section VII WIRING DIAGRAMS 35

MAR 56-76-106-126 - Wiring diagram 36÷38

MAR 206-306 - Wiring diagram Fig. 1 e 2 39÷42

Page 4

Page 4

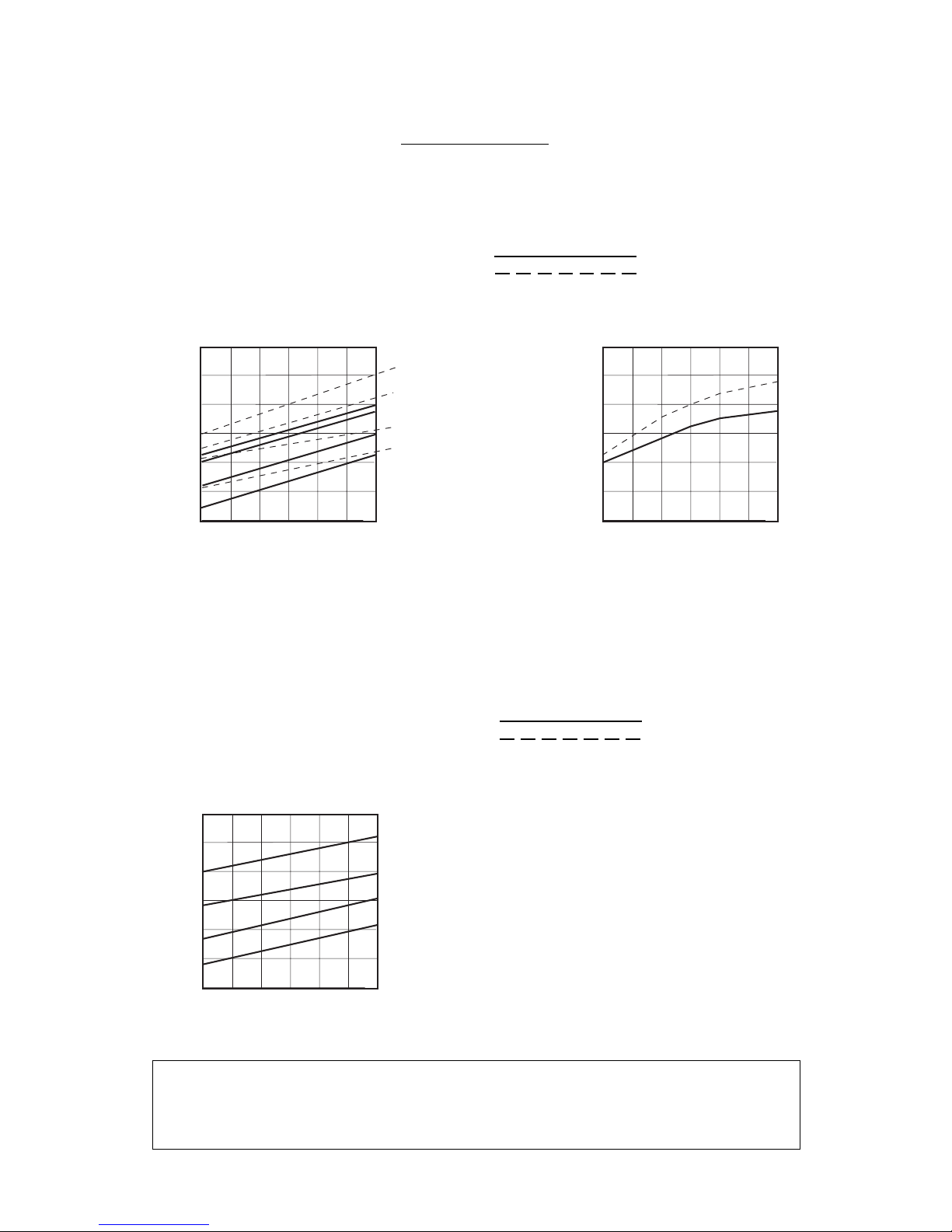

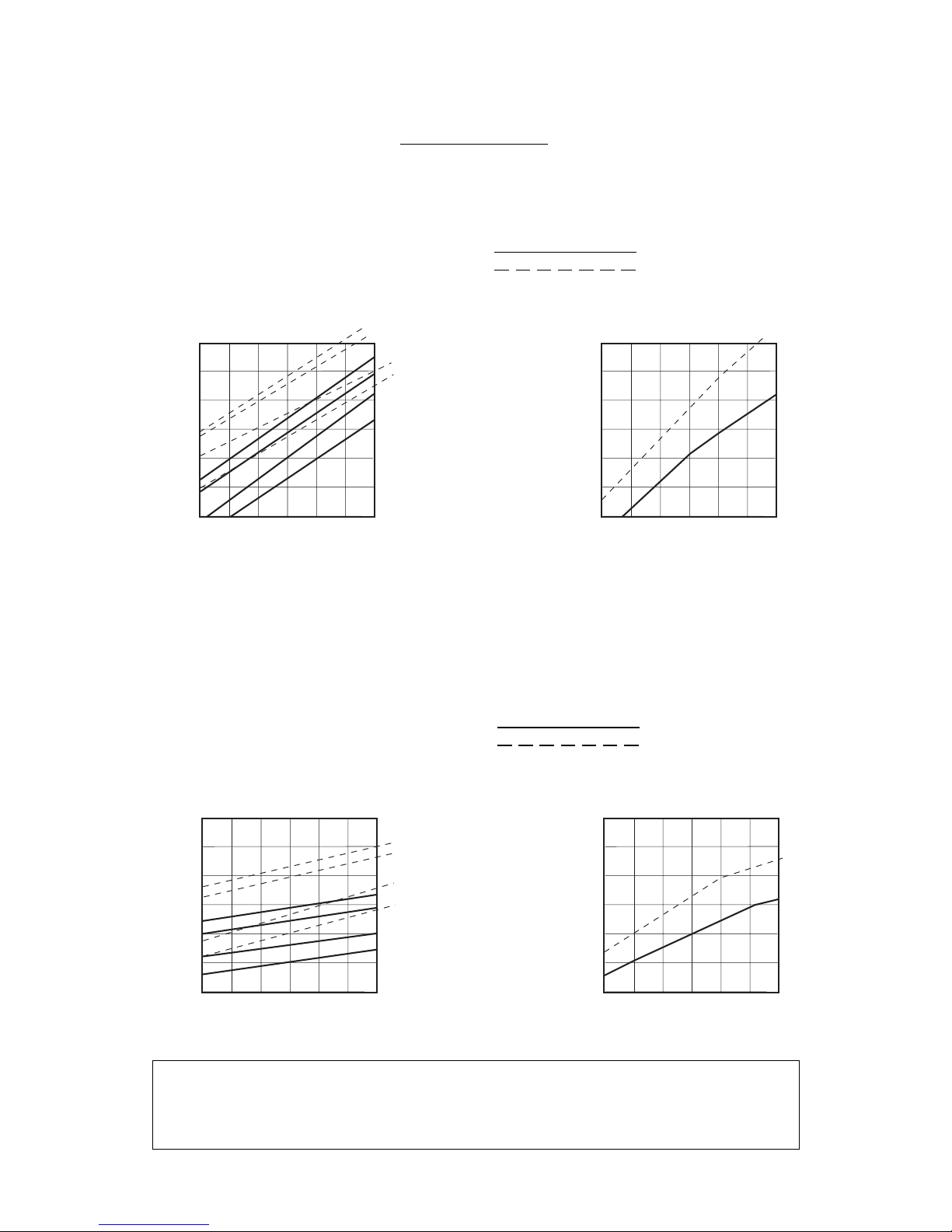

SPECIFICATIONS

NOTE. Daily ice capacity is directly related to condenser air water inlet temperature, water

temperature to make ice - and age of machine.

To keep your SCOTSMAN MAR performing at is maximum capacity, it is necessary to perform

periodic maintenance as outlined on page 29 of this manual.

MAR 56

AIR & WATER COOLED MODELS

THICK SCALE ICE

THIN SCALE ICE

ice making capacity

500

450

400

350

300

250

200

Kg./24 h

38

°C

32 27

21

15

°C

10

21

32

38

o

AIR COOLED MODELS

WA TER TEMPERATURE

AMBIENT TEMPERATURE

ICE PRODUCED PER 24 HRS.

32

38

WATER COOLED MODELS

10 5

10

21

500

450

400

350

300

250

200

Kg./24 h

38

°C

32 27

21

15

°C

DE 10 A' 38

o

WA TER TEMPERATURE

AMBIENT TEMPERATURE

ICE PRODUCED PER 24 HRS.

10 5

MAR 76

AIR & WATER COOLED MODELS

ice making capacity

THICK SCALE ICE

THIN SCALE ICE

AIR COOLED MODELS

540

500

460

420

380

340

300

Kg./24 h

38

°C

32 27

21

15

°C

o

WA TER TEMPERATURE

AMBIENT TEMPERATURE

ICE PRODUCED PER 24 HRS.

10 5

10

21

32

38

Page 5

Page 5

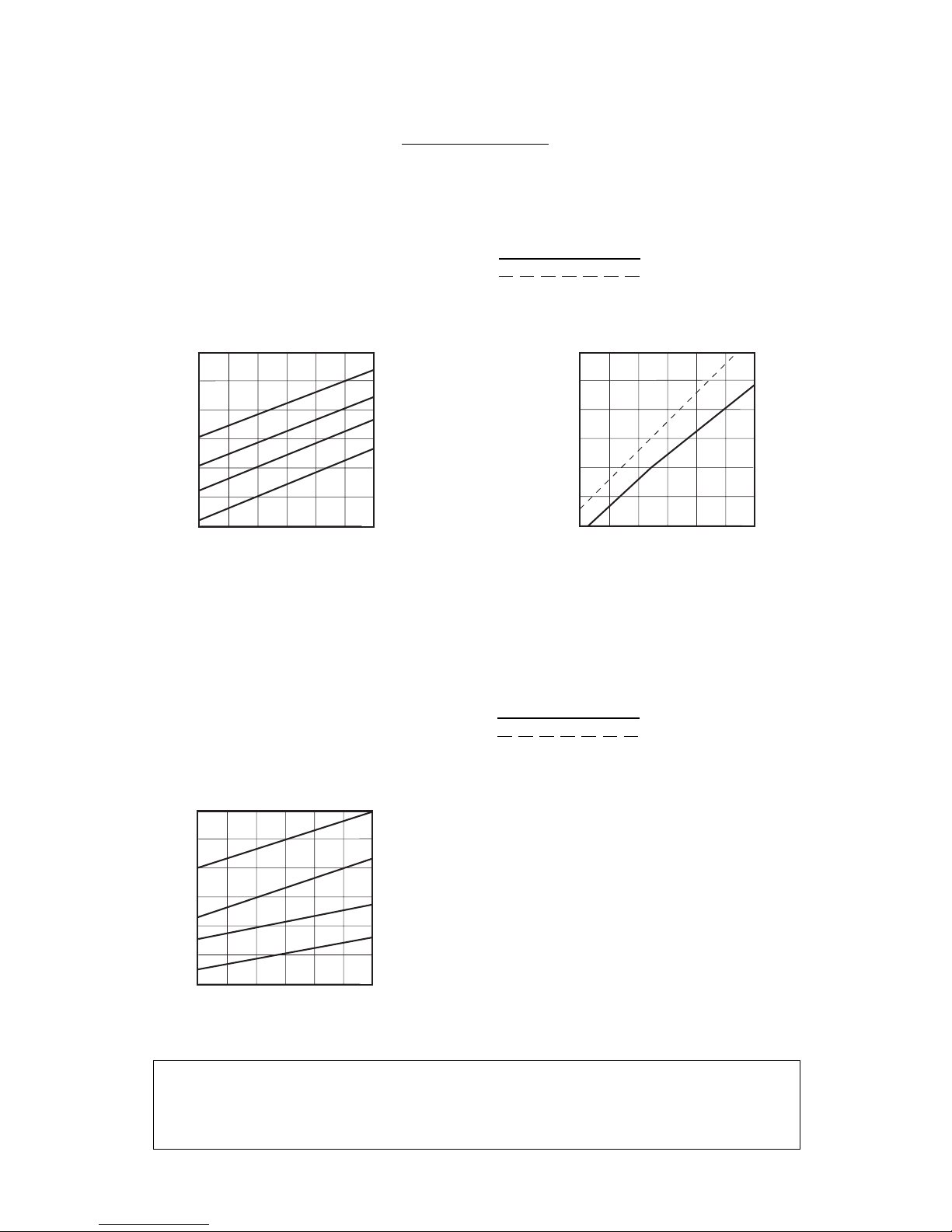

SPECIFICATIONS

NOTE. Daily ice capacity is directly related to condenser air water inlet temperature, water

temperature to make ice - and age of machine.

To keep your SCOTSMAN MAR performing at is maximum capacity, it is necessary to perform

periodic maintenance as outlined on page 29 of this manual.

MAR 106

AIR & WATER COOLED MODELS

THICK SCALE ICE

THIN SCALE ICE

ice making capacity

MAR 126

AIR & WATER COOLED MODELS

ice making capacity

THICK SCALE ICE

THIN SCALE ICE

AIR COOLED MODELS

750

700

650

600

550

500

450

Kg./24 h

38

°C

32 27

21

15

°C

o

WA TER TEMPERATURE

AMBIENT TEMPERATURE

ICE PRODUCED PER 24 HRS.

10 5

10

21

32

38

WATER COOLED MODELS

800

750

700

650

600

550

500

Kg./24 h

38

°C

32 27

21

15

°C

DE 10 A' 38

o

WA TER TEMPERATURE

AMBIENT TEMPERATURE

ICE PRODUCED PER 24 HRS.

10 5

AIR COOLED MODELS

1000

950

900

850

750

650

600

Kg./24 h

38

°C

32 27

21

°C

o

WA TER TEMPERATURE

AMBIENT TEMPERATURE

ICE PRODUCED PER 24 HRS.

10

21

32

38

Page 6

Page 6

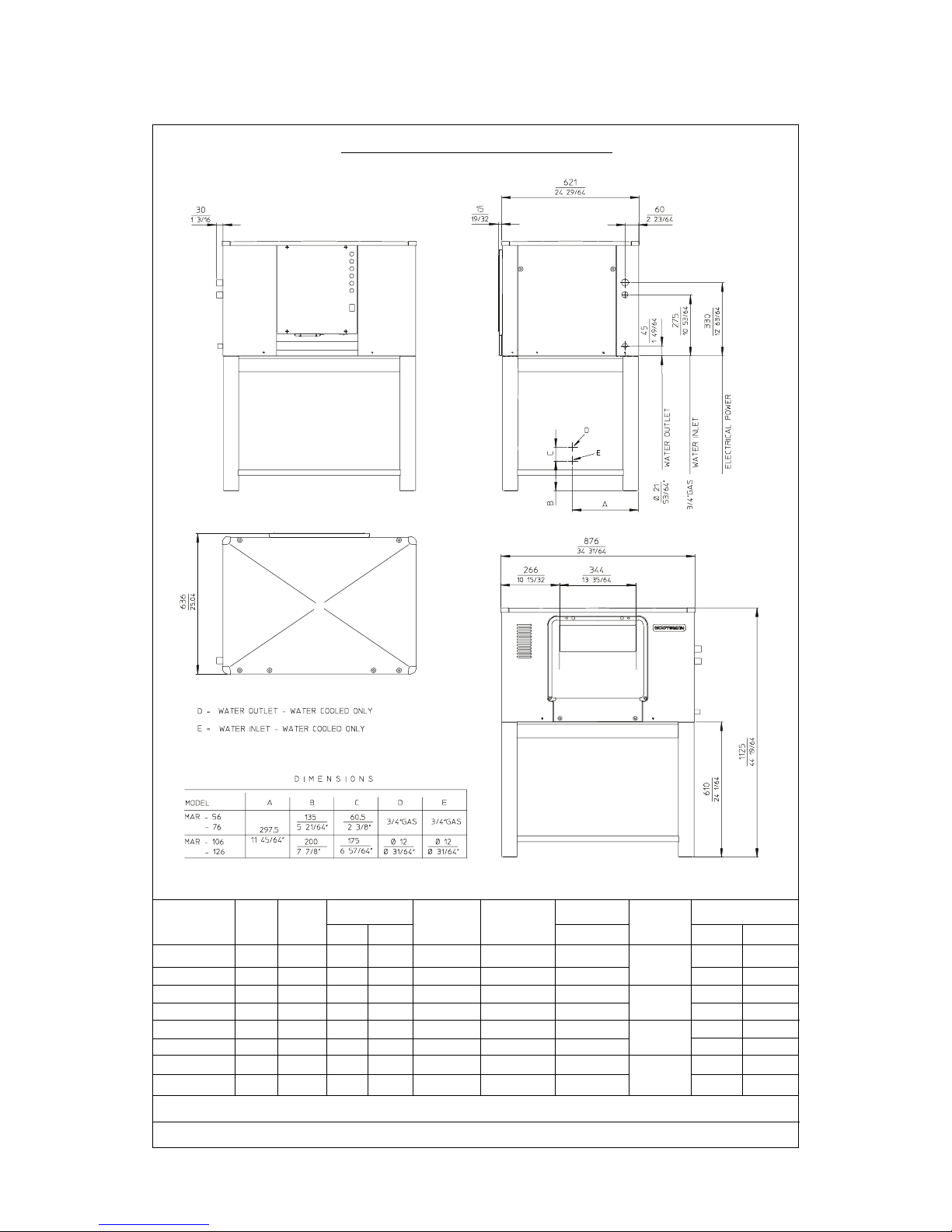

MAR 56-76-106-126 - SPECIFICATIONS

BASIC ELECTRICALS: 400/50/3N

* at 21 °C amb. / 15 °C water temp.

Water req. (l/h) Total Amps.

MODELS Finish

* Cond. Prod. 400 V kg. lbs.

MAR 56 AS Air 2 16 2.2 5 x 1.5 2.7 Stainless 194 427

MAR 56 WS Water 2 225 16 2.2 5 x 1.5 2.7 Steel 174 383

MAR 76 AS Air 2.5 21 2.5 5 x 1.5 2.7 Stainless 204 450

MAR 76 WS Water 2.5 300 21 2.5 5 x 1.5 2.7 Steel 201 442

MAR 106 AS Air 4 30 3.5 5 x 1.5 5 Stainless 221 487

MAR 106 WS Water 4 480 30 3.5 5 x 1.5 5 Steel 217 417

MAR 126 AS Air 4.5 41 4.5 5 x 1.5 6.5 Stainless 226 497

MAR 126 WS Water 4.5 41 4.5 5 x 1.5 6.5 Steel 222 488

Cond. Compr. Power Minimum

Unit (HP) (KW) wire size (mm)

Shipping weight

Page 7

Page 7

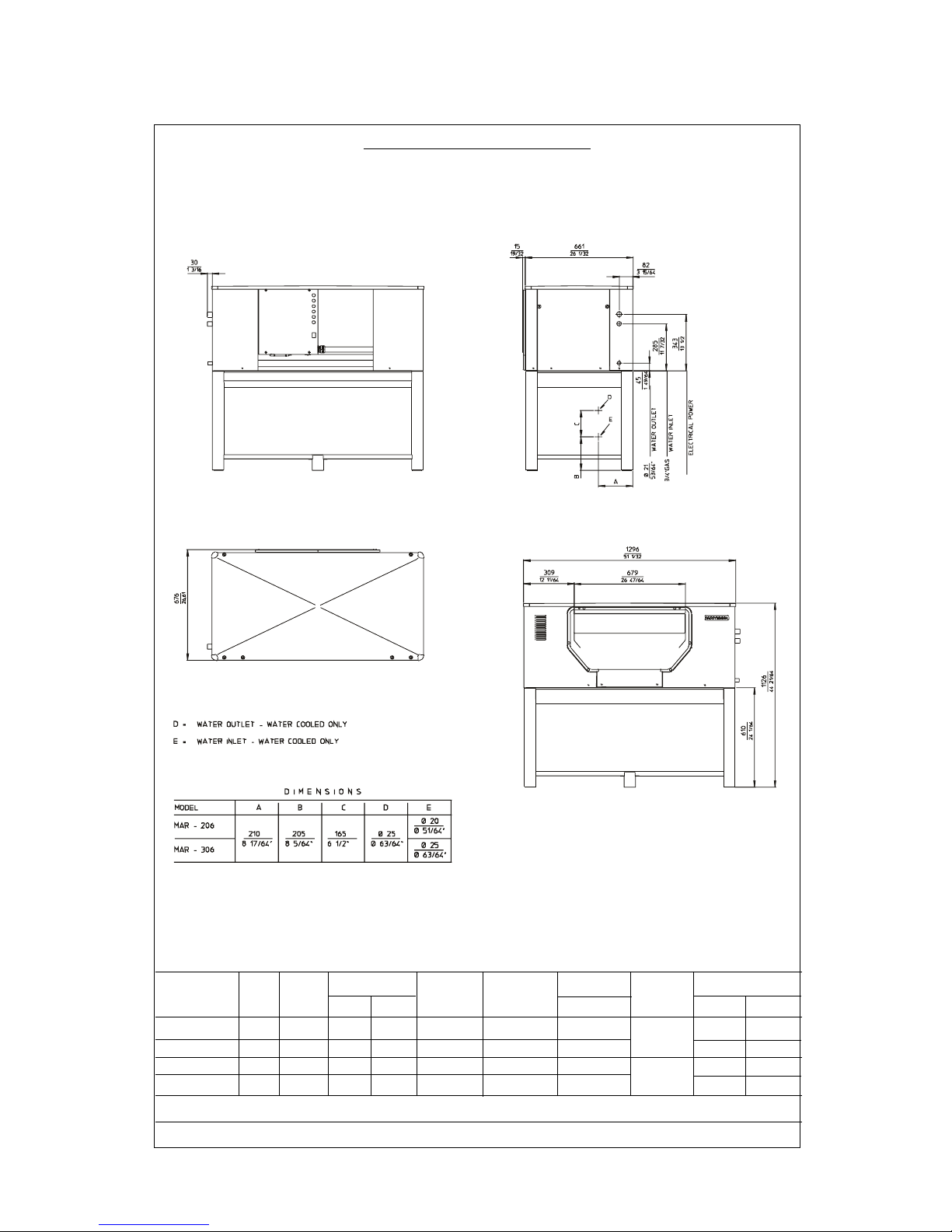

SPECIFICATIONS

NOTE. Daily ice capacity is directly related to condenser air water inlet temperature, water

temperature to make ice - and age of machine.

To keep your SCOTSMAN MAR performing at is maximum capacity, it is necessary to perform

periodic maintenance as outlined on page 29 of this manual.

MAR 206

AIR & WATER COOLED MODELS

ice making capacity

THICK SCALE ICE

THIN SCALE ICE

1700

1600

1500

1400

1300

1200

1100

Kg./24 h

38

°C

32 27

21

15

°C

32

38

AIR COOLED MACHINES

WA TER TEMPERATURE

AMBIENT TEMPERATURE

ICE PRODUCED PER 24 HRS.

32

38

WATER COOLED MACHINES

10 5

10

21

1900

1800

1700

1600

1500

1400

1300

Kg./24 h

38

°C

32 27

21

15

°C

DE 10 A' 38

o

WA TER TEMPERATURE

AMBIENT TEMPERATURE

ICE PRODUCED PER 24 HRS.

10 5

10

21

MAR 306

AIR & WATER COOLED MODELS

ice making capacity

2600

2400

2200

2000

1800

1600

1400

Kg./24 h

38

°C

32 27

21

15

°C

32

38

AIR COOLED MACHINES

WA TER TEMPERATURE

AMBIENT TEMPERATURE

ICE PRODUCED PER 24 HRS.

32

38

WATER COOLED MACHINES

10 5

10

21

2800

2600

2400

2200

2000

1800

1600

Kg./24 h

38

°C

32 27

21

15

°C

DE 10 A' 38

o

WA TER TEMPERATURE

AMBIENT TEMPERATURE

ICE PRODUCED PER 24 HRS.

10 5

10

21

THICK SCALE ICE

THIN SCALE ICE

MAR 206-306 - SPECIFICATIONS

BASIC ELECTRICALS: 400/50/3N

* at 21 °C amb. / 15 °C water temp.

Water req. (l/h) Total Amps.

MODELS Finish

* Cond. Prod. 400 V kg. lbs.

MAR 206 AS Air 5 69 7 5 x 2.5 17 Stainless 374 824

MAR 206 WS Water 5 1200 72 7 5 x 2.5 10 Steel 369 813

MAR 306 AS Air 10 88 10 5 x 4 20 Stainless 383 844

MAR 306 WS Water 10 1600 94 10 5 x 4 20 Steel 413 910

Cond. Compr. Power Minimum

Unit (HP) (KW) wire size (mm)

Shipping weight

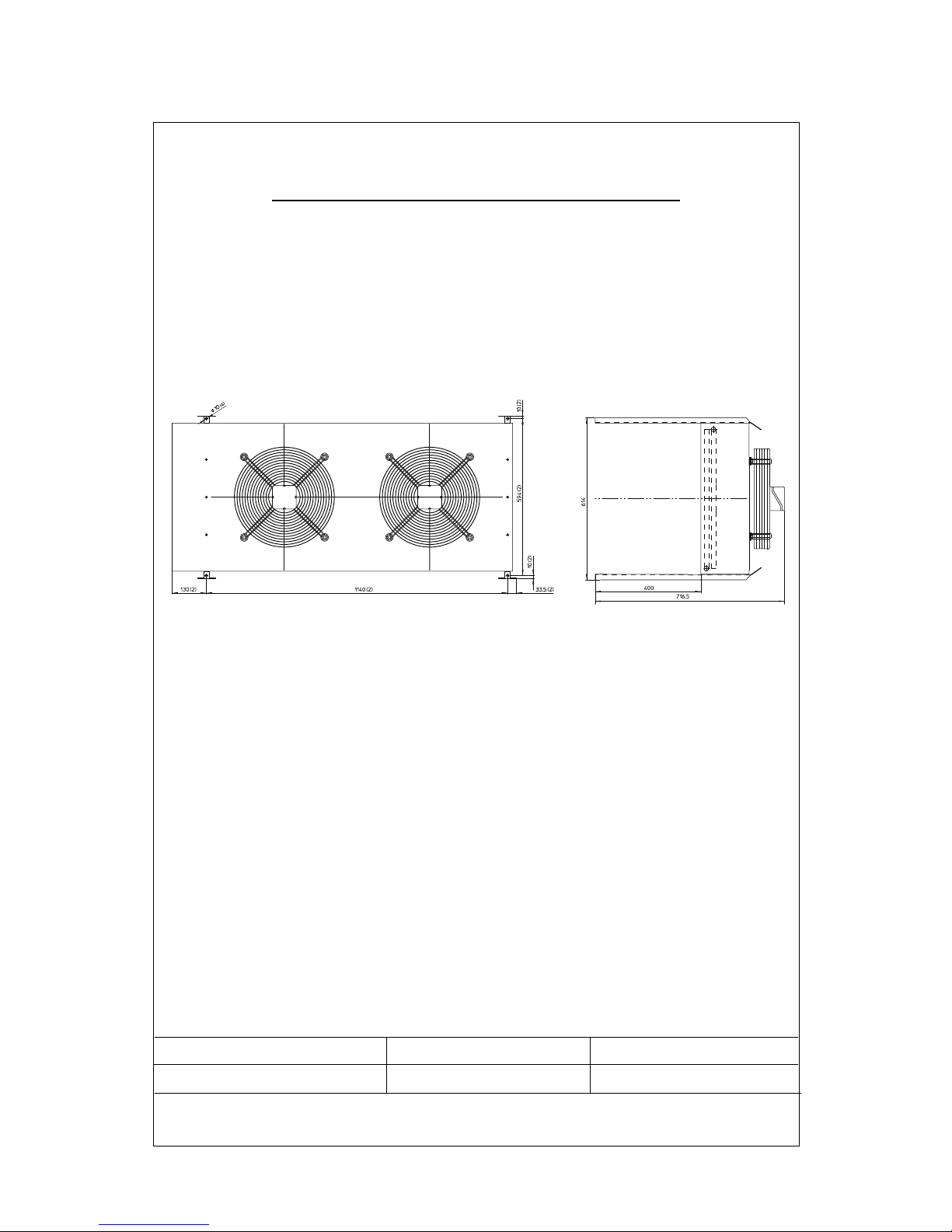

Page 8

Page 9

Page 9

CONDENSER CAPACITY FAN MOTOR AIR FLOW

20 KW - 17200 Kcal/h 230/50/1 V - 0,8 A 4320 m3/h

MAR 306 REMOTE CONDENSER

TECHNICAL SPECIFICATIONS

Page 10

Page 10

SECTION I

GENERAL INFORMATION & INSTALLATION

1. DESCRIPTION

An attractive compact cabinet of stainless steel

with control panel lights on the front. All panels

are removable to allow easy access to electrical

and mechanical components for cleaning and

maintenance.

Sealed Refrigeration System

To provide quite efficient operation of the ice

maker, the compressor is mounted on rubber

cushions. The water cooled models have a tube

within tube condenser with water regulation valve for correct condensing water flow. The air

cooled models, except the MAR 306 have a built

in condenser in copper and aluminium with the

fan motor controlled by pressure control. The

evaporator drum is powered by a separate drive

motor connected by a V-belt and pulley system to

a double gear box. The refrigerant used is R 404a

controlled by automatic expansion valve.

Storage Bin or Ice Room

Since the MAR Scale is a continuous flow type

ice maker and does not have its own attached

storage bin, it is necessary to use an auxiliary bin

or a pre-fabricated ice room for appropriate ice

storage.

Ice storage situations are of two kinds:

a) Short term storage

b) Extended terms storage

Being, as stated, scale ice made by MAR

machines flat, dry and subcooled, therefore with

the tendency to stick toghether, particular

attention is required for proper ice storage

conditions for better ice handling. An insulated

ice storage bin or rooms is always required, then

according to ice end use application, this can be

refrigerated on non-refrigerated.

Also a weight volume ratio of 2,1 cu. mt. per

ton, must be taken into consideration for correct

ice storage.

a) Non-refrigerated room for short term

storage.

The scale ice is produced continuously for 24

hours per day, whereas the use period is

generally for no longer than 8 hours per day.

Therefore storage facilities should be provided

to accomodate a minimum of 16 hours of

production, this means that every scale ice

machine must be installed with a properly

insulated storage room which should have a

minimum capacity of 2/3 the daily ice

production.

With a well insulated room and duly subcooled

scale ice, the limited losses of heat throught

the walls of a properly designed room with

adequate arrangements, are largely offset,

and excess melting will not occur. In most

situations where whole quantity of ice produced

is being used on a daily basis, it is not necessary

to provide cooling for the ice storage room.

b) Refrigerated room for extended storage

and long distance conveying.

When scale ice is to be transported at a

considerable distance, such as aboard fishing

vessels, or in locations with normal ambient

temperatures conditions, or when used in

industrial plants where demand is intermittent,

its subcooling power must be absolutely

preserved in the storage bin by a proper

cooling system keeping air temperature at a

pre-established and constant value. The ideal

ice storage room is the type with mechanically

refrigerated jacket space surrounding the ice

bin. Good practice calls for an ice storage

capacity of about two times the daily ice

machines production with an inside temperature of -6°C minimum (20°F).

2. UNPACKING AND INSPECTION

1. Call your authorized SCOTSMAN Distributor

od Dealer for proper installation.

2. Visually inspect the exterior of the shipping

container and skid and any severe damage

noted should be reported to the delivering

carrier; and a concealed damage claim filled

subject to internal inspection, with carrier

representative present.

3. Remove the packing and remove the shipping

bolts and the shipping base or skid.

4. When necessary, install the leg levellers in

the cabinet base sockets; then, raise the

cabinet to the upright position.

5. Remove screws and shipping tapes and all

doors and service panels from the cabinet and

inspect for any concealed damage.

Notify carrier of any concealed damage claims

as stated in step 2 above.

6. Remove all internal support packing, tape

and wires in machinery compartment.

7. Check that refrigerant lines do not rub or

touch lines or surfaces and that fan blades, if

any, moves freely.

8. Check that compressor is snug on all mounting

pads.

9. Use clean damp cloth or disposable paper

wiper to wipe clean the exterior surface of the

cabinet.

Page 11

Page 11

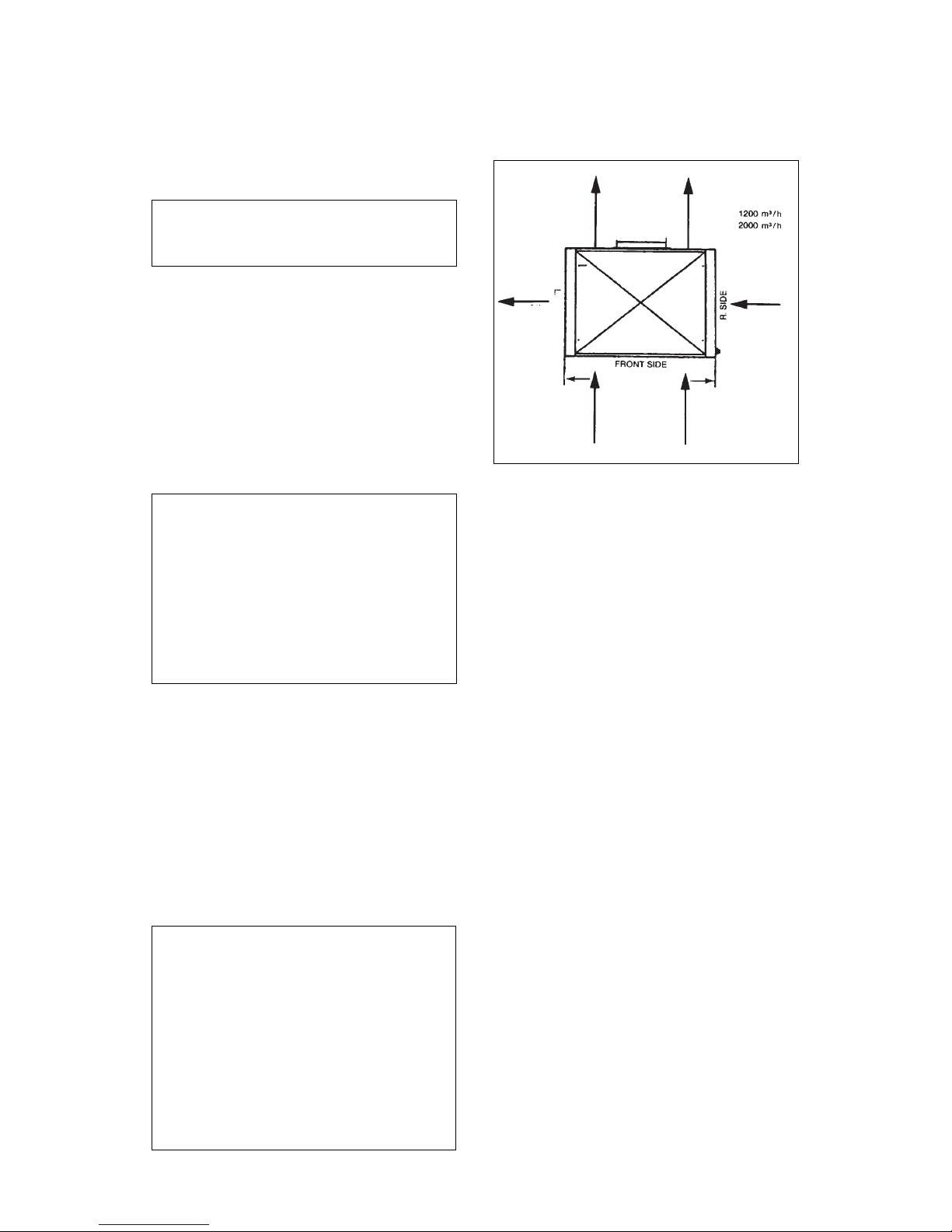

CONDENSING AIR FLOW SCHEMATIC

2. Erection - For elevations in excess of four

feet or in close quarters, chain falls of fork lift

truck should be used. For location under four

feet, the use of skid boards and rollers is practical.

3. Machine Site - When selecting the permanent

location of air cooled machines, consideration

must be given to volume size of the room and to

ventilation facilities for easy heat removal around

the machine.

In doing this it worths to take on account that:

– MAR 56 AS - has a condenser heat rejection

of 3000 Kcal/hr and fan motor draws air for

1200 m3/h.

– MAR 76 AS - has a condenser heat rejection

of 4900 Kcal/hr and fan motor draws air for

1200 m3/h.

– MAR 106 AS - has a condenser heat rejection

of 7500 Kcal/hr and the two fan motors draw

air for 1200 m3/h each.

– MAR 126 AS - has a condenser heat rejection

of 9750 Kcal/hr and the two fan motors draw air

for 1200 m3/h each.

– MAR 206 AS - has a condenser heat rejection

of 11000 Kcal/hr and the two fan motors draw

air for 2000 m3/h each.

– MAR 306 AS - has a condenser heat rejection

of 17200 Kcal/hr and the two fan motor draw air

for 4320 m3/h in total.

4. Position the MAR in the selected permanent

location level the cabinet on both the left-to-right

and front-to-rear directions. The levelling legs

can be adjusted with an opened wrench.

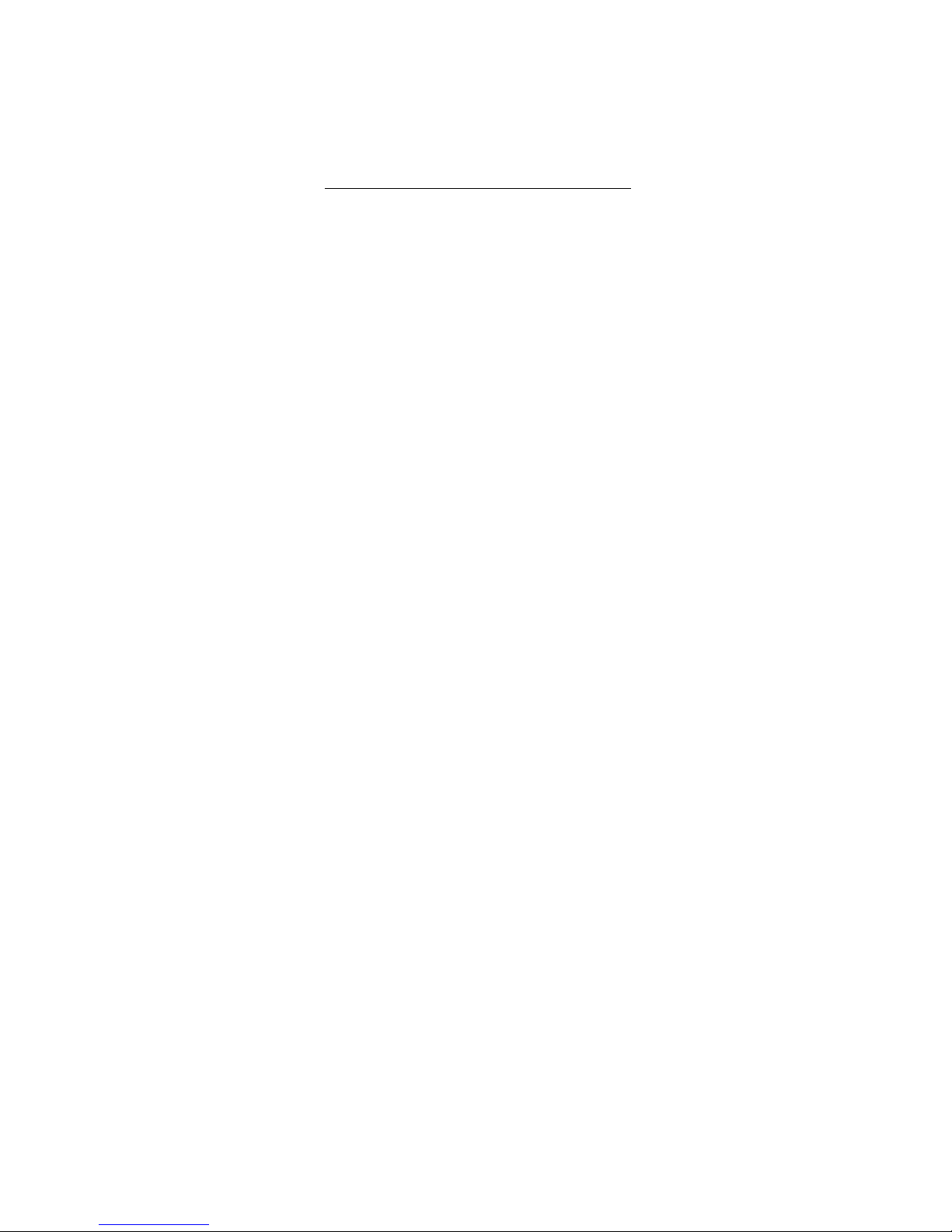

(See unit layout and dimensions at page 6 and 8).

10. See DATAPLATE on the cabinet base and

check that the location source voltage

corresponds with the voltage specified on

the dataplate.

CAUTION - Unproper voltage supplied to

the icemaker will void your parts

replacement program.

11. Remove the Manufacturer's registration Card

from its envelope and fill in all spaces

including: Model Number and serial Number

taken from the aluminium plate located on

the front of the Chassis base, with Front

Panel removed.

Forward the completed, self addressed,

registration card to the Scotsman Europe

Frimont Factory.

3. LOCATION AND LEVELLING

WARNING - The MAR Flakers are NOT

designed for outdoors installation where

air temperature are below 5°C (40°F) or

above 40°C (100°F) and the water temperature is below 5°C (40°F) or above 35°C

(95°F).

Extended periods of operation at

temperatures exceeding these limitations

will constitute misuse, under the terms of

the SCOTSMAN Manufacturer's limited

warranty coverage.

1. Stands - A special stands should be built if

the machine is located beside the bin.

Care should be exercised in making the

stand strong enough to support the weight.

In designing the stand plan for the servicing

of the machine from front, top and sides.

It is also possible to locate the machine on

top of the bin. Care should be used in selecting

a bin that has been specially reinforced.

Standard bins are usually not sufficiently

reinforced for this purpose. An unsteady

platform will cause excessive vibration.

Specially built bins can provide proper support

and allow for a servicing platform.

WARNING - Air Cooled version of MAR 76

,

MAR 106, MAR 126 and MAR 206 have the

condensing air exhaust throughout the

lower rear area (ice spout side) therefore

it is necessary to avoid to position the ice

maker with the rear side against any sort

of wall that will prevent proper warm air

dissipation.They must

have on their rear

side an air gap of 200 mm.

MAR 56 has the

air cooled condenser on the right side

while MAR 306 has a se-parate remote air

cooled condenser. (See instructions for

remote condenser at 6).

MAR 76-106-126

MAR 206

MAR 56

MAR 76-106-126

MAR 206

MAR 56

SIDE

MAR 106 MAR 206 -

Page 12

Page 12

4. ELECTRICAL CONNECTIONS

The machine has been wired ready for electric

connections. See nameplate for current

requirements to determine wire size to be used

for electrical hook-up. The MAR flaker requires a

solid earth ground wire. See wiring diagram.

Be certain the unit is connected to its own electrical

circuit and individually fused.

The maximum allowable voltage variation, should

not exceed ten percent of the nameplate rating,

even under starting conditions.

Low voltages can cause erratic operation and

may be responsible for serious damage to the

overload switch and motor windings.

All external wiring should conform to the National,

State and local electrical permit and services of

a licensed electrician will be required.

WARNING - The compressor is equipped

with a crankcase heater which has to be

energized even when the ice maker is

switched-off. So, make sure to connect

the unit with the compressor crankcase

heater constantly energized. After long

inoperative periods remember to give

current to the heater 4 hours before the

ice-maker start-up.

Fuse protection of the unit should be made as

follows:

MAR 56-76-106-126-206 - 3x16 Amps/400V

MAR 306 WS - 3x24 Amps/400V

MAR 306 ASR - 3x32 Amps/400V

WARNING - Drum drive motor is threephases type. At unit start up, correct wiring

is assured by 3 phases monitoring relay

at power in. In addition proper drum

rotation speed is monitored by a Hall

Effect sensor. In case the drum is not

rotating at all or it rotates too slow (less

then 1/4 turn every 30 seconds) a special

Electronic Control trips the unit OFF so to

avoid that compressor can operate with

the drum OFF (in case of fiber keys

, drive

motor or gear reducer breakage).

In case of any field drive motor replacement,

care must be taken to its wiring, checking the

correct evaporator drum rotation that MUST

be toward ice blade.

In case of wrong evaporator drum rotation,

turn the unit OFF and exchange two phases

connection at drive motor control box.

5.

WATER SUPPLY AND DRAIN CONNECTIONS

Separate water supplies are recommended.

A.Evaporator or ice making supply water should

be run through a hand shut-off valve before

entering unit. Evaporator supply water

connection has a 3/4" male pipe fitting. This

line also has factory installed water strainer

internally mounted. Incoming water goes

through the float reservoir and then to the

drum reservoir. Connect to a good cold water

supply with minimum 1/2 O.D. line. A check

valve on this line will be required in some

cases depending on local plumbing codes.

The recommended minimum water pressure

is 1 bar (14 Psi). Do not operate this unit with

fresh water supply below 1 bar (14 Psi).

Maximum water pressure 5 bar (70 Psi).

B.The condenser water supply line connects to

the following fitting sizes:

MAR 56 - 76

3/4" gas male

MAR 106 - 126 12 mm O.D. fitting

MAR 206 20 mm 0.D. fitting

MAR 306 25 mm

Water supply line size must be adequate to

water flow which, at 15°C temperature water, is:

225 lt/hr for MAR 56

300 lt/hr for MAR 76

480 lt/hr for MAR 106

lt/hr for MAR 126

1200 lt/hr for MAR 206

1600 lt/hr for MAR 306

Incoming water goes throughout the water

regulating valve first and then to the water

cooled condenser. Observe arrow on water

regulating valve. Water supply must be installed

to conform with local code. In some case a

licensed plumber and/or a plumbing permit will

be required.

Water Quality

Water quality is a factor of extreme importance

for good operation of MAR machine. Water

shouldn't be too hard neither too soft.

Hard water will tend to create mineral deposits in

water reservoir, evaporator drum and scraping

blade, rendering rough the chute surface which

prevents ice scales from sliding properly into ice

channel. On the contrary, water too soft, (demineralized) will cause the ice skin to stick

excessively on drum surface rendering difficult

the scraping operation of same.

The ideal water should have a total hardness

of about 15-20 french degrees.

Precaution Against Water Frost

Like for any other ice maker all necessary

measures must be taken when the cold season

is approaching to protect the water supply line

and the MAR water system against winter

freezing. If cooling tower is used several

precautions should be observed, too.

1. Leave water regulating valve in the system.

2. Separate the make-up water for the reservoir

from the tower water.

3. Use 3/4" tower water lines or larger, depending

on the lenght of run. Over 30 feet, use 1" O.D.

lines.

4. NOTICE: a cooling tower can freeze in the

winter time and the MAR flaker will be in

operation 12 months per year. An indoor tower

and pump can be used with outdoors air ducted

in and out if the fan cycles on water temperature to prevent freezing. An indoor sump can

be used. An auxiliary tower and city-water

hook-up will prove satisfactorily in some

climates. Fresh water in the winter and tower

water during the summer. Consult your tower

and pump manufacturers for proper sizing. In

no event should less than a Nominal 3 to 4 tons

tower, or less than 3/4 HP high pressure tower,

or less than 3/4 HP high pressure tower pump

be used.

Page 13

Page 13

C.Drain (When not re-used).

The recommenden tubes for the condenser

waste line are:

- MAR 56-76 - 3/4" GAS female fitting.

- MAR 106-126 - 12 mm I.D.

- MAR 206-306 - 25 mm I.D.

Water drip tray drain line is 21 m/m I.D. Tube

to be connected with clamp to a 21 m/m hose

barbed fitting for all models.

Waste water line must run to an open trapped

vented drain. If drain is a long run, allow a pitch

of 3 cm per meter.

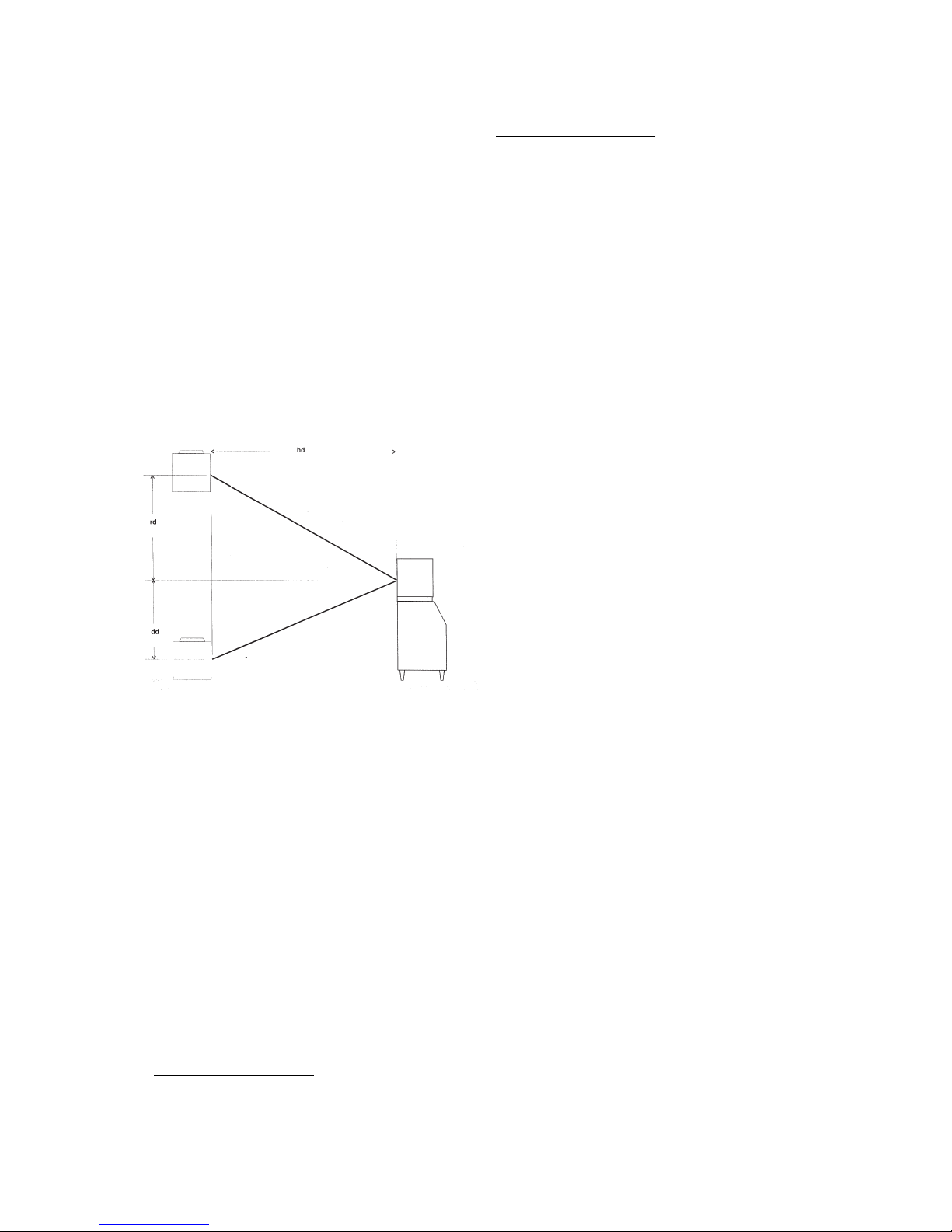

6. REMOTE AIR-COOLED CONDENSER

AND PRECHARGED REFRIGERANT

LINES INSTALLATION (MAR 306 ONLY)

Use the following for planning the placement of

the condenser relative to the ice machine

Location Limits - condenser location must

not exceed ANY of the following limits:

• Maximum rise from the ice machine to the

condenser is 3 physical meters

• Maximum drop from the ice machine to the

condenser is 1 physical meter

• Physical line set maximum length is 6 meters

• Line set length maximum is 9 meters.

Calculation Formula:

• Drop = dd x 6.6 (dd = distance in meters)

• Rise = rd x 1.7 (rd = distance in meters)

•

Horizontal Run = hd x 1 (hd = distance in meters)

• Calculation: Drop(s) + Rise(s) + Horizontal

Run = dd+rd+hd = Calculated Line Length.

Configurations that do NOT meet these

requirements must receive prior written

authorization from Scotsman.

Do NOT:

• Route a line set that rises, then falls, then rises.

• Route a line set that falls, then rises, then falls.

Calculation Example 1:

The condenser is to be located 0.9 meter below

the ice machine and then 3 meters away horizontally.

0.9 mt x 6.6 = 5.94 + 3 = 8.94. This location would

be acceptable.

Calculation Example 2:

The condenser is to be located 4 meters above

and then 3 meters away horizontally.

4 x 1.7 = 6.8 6.8+3 = 9.8.

9.8 is greater than

the 9 maximum and is NOT acceptable.

Operating a machine with an unacceptable

configurationg will void the refrigeration

system warranty.

In a crate, separated by the unit crate are packed:

1. The air-cooled condenser mounted on the

platform base with the electrical junction box,

condenser shround, fan motors, fan protection

grid, fan motor speed, control and the

refrigerant lines connection couplings.

2. One set of pre-charged refrigerant line with

connection couplings on both ends of following

variety. Liquid I.D. 12 m/m - Gas I.D. 16 m/m

- 10 mts length.

The pre-charged refrigerant lines, 6 meters long,

are equipped with self-sealing coupling

connections and can be connected or disconnect

few times without loosing the refrigerant charge.

The electric cord line, approx. 10 meters long,

located on the left side of the unit has to be

connected to the condenser junction box

terminals.

The condenser fan motors are originally wired for

230 V single phase and have the following

specifications:

RPM 1420

WATTS 2x180

AMPS 2x0,80

They operate at 230 V 50 Hz and are controlled

by an Electronic Fan Speed Control set at 16 bar.

A. Location consideration:

1. Limit to 10 meters the lenght of the precharged

refrigerant lines from the ice-maker to the

remote condenser.

2. Maximum vertical rise of 3 meters between

the ice maker and the remote condenser.

3. Best available location, protected from the

extremes of dirt, dust, rain, sun and wind.

B. Unpacking and inspection:

1. Visually inspect the exterior of the shipping

container and any severe damage noted,

should be reported to delivering carrier; and a

concealed damage claim filled subject to

internal inspection with carrier representative

present.

2. Uncrate the remote condenser and precharged refrigerant lines and inspect for any

concealed damage claims, as stated in step 1

above.

3. Check that the pre-charged refrigerant lines

are intact, not kinked, and that there is no

sealed puncture or loss or refrigerant.

Max 3 m

Max 1 m

Condenser

Distance &

Location

Schematic

Remote

Condenser

Located BELOW

Ice Machine

Remote

Condenser

Located ABOVE

Ice Machine

Loading...

Loading...