Page 1

Page 1

Page 1

09014400

Scotsman Ice Srl

Via Lainate, 31 - 20010 Pogliano M.se - Milano - Italy

Tel. +39-02-93960.1 (Aut. Sel.)- Telefax +39-02-93550500

Direct Line to Service & Parts:

Phone +39-02-93960350 - Fax +39-02-93540449

Website: www.scotsman-ice.it

E-Mail: scotsman.europe@scotsman.it

ISO 9001 - Cert. n. 0080

SERVICE MANUAL

MAR 78

MAR 108

MAR 128

MAR 208

MAR 308

SPLIT

RN

090144 00 - REV. 03/2016

Page 2

Page 2

Page 2

FOREWORD

SCOTSMAN MAR SPLIT UNITS are available in

five basic models MAR 78, MAR 108, MAR 128,

MAR 208 and MAR 308 operating by fresh water.

MAR 78, MAR 128 and MAR 308 only are available,

upon request, presetted to operate by sea water.

They come complete with a stainless steel cabinet,

with a drive motor at V. 230/50/3 or 400/50/3-N

Volt, with expansion valve, heat exchanger, float

reservoir, time delay switch, bin thermostat, water

pump, ice spout switch, liquid solenoid valve,

water pressure control evaporator pressure ctl.

valve.

The refrigerating and electrical system must be

completed by the purchaser as per the instructions

given in this service manual who has to provide

for the complete condensing unit, its controls and

refrigerant tubings.

We suggest to take time now to read this manual

which contains a lot of valuable informations on

the MAR Split System.

For any further queries regarding the care or

operation of the machine, please contact:

ICE SYSTEMS

®

SCOTSMAN - EUROPE - FRIMONT SPA

Via Puccini, 22 - 20010 Bettolino di Pogliano (Milano) Italy

Tel. +39-02-93960.1 (Aut. Sel.)- Telefax +39-02-93550500

Direct Line to Service & Parts:

Phone +39-0331-589305 - Fax +39-0331-584306

Website: www.scotsman-ice.com

E-Mail: scotsman.europe@frimont.inet.it

®

Page 3

Page 3

Page 3

TABLE OF

CONTENTS

Foreword page 2

Table of contents 3

Specifications 4-9

Section I GENERAL INFORMATION

General 10

Application area 10

Condensing unit 10

Control devices 11

Location considerations 12

Refrigerant lines 12

Hydraulic circuit 12

Ice storage room 12-14

Unit layout 15

Section II INSTALLATION

Unpacking and inspection 16

Location and levelling 16

Refrigerant piping connections 16

Water piping connections 17

Water and refrigerant circuit 17

Electrical connections 18

Installation practice 19

Mar Split in multiple installation 20

Typical non-code commercial installation 20

Section III TESTING

Complete system leak test 21

Complete system evacuation 21

Complete system charging 21

Start-up & Check-out 21

Operational check-out 21-23

Section IV PRINCIPLE OF OPERATION - HOW IT WORKS

ICE maker 24

MAR Split electrical/refrigeration 25-26

Section V ADJUSTMENT & REMOVAL & REPLACEMENT

PROCEDURES

MAR Split 27-28

Section VI MAINTENANCE & CLEANING INSTRUCTIONS 29-32

Section VII SERVICE DIAGNOSIS 33-34

Section VIII WIRING DIAGRAMS 35

Page 4

Page 4

Page 4

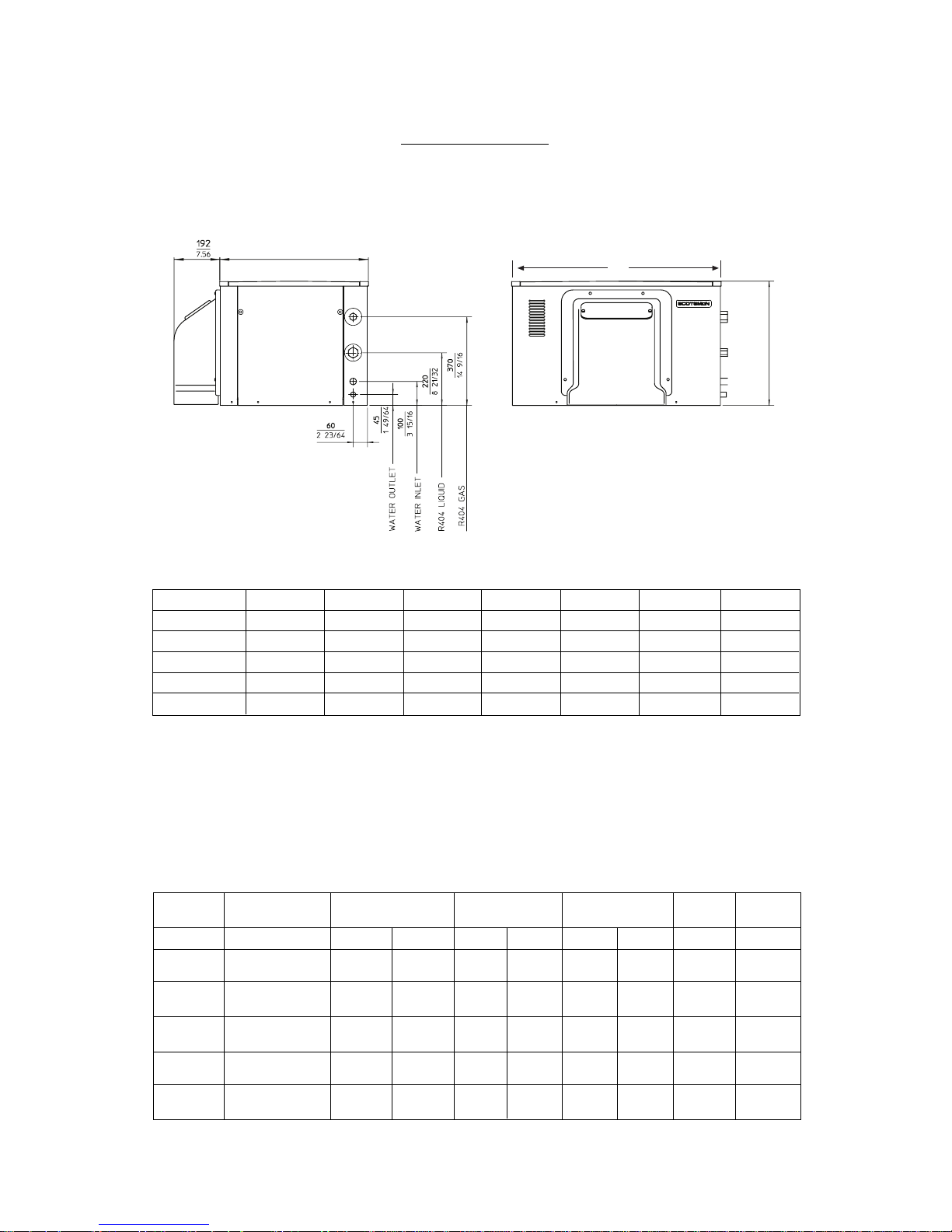

SPECIFICATIONS

MAR 78 - 108 - 128 - 208 - 308

A

B

C

Ø 1

Ø 2

Ø 3

Ø 4

(*) "THICK ICE" SETTING - AT 10°/10°C (ambient/water temp.)

TECHNICAL SPECIFICATION

SPLIT

MODEL

Basic

Electricals

Ice Production (*)

Kg/24 Hr.

Drive Motor

Finish

Shipping

Weight

V

Sea water Fresh W. Kcal/Hr Hp Amp

kg

MAR 78

400/50/3 - N

230/50/3

510

3200 1/2

SS

MAR 108

400/50/3 - N

230/50/3

670 4800 1/2

1.2

2.1

SS

MAR 128

400/50/3 - N

230/50/3

1000 6000 1/2

1.2

2.1

SS

MAR 208

400/50/3 - N

230/50/3

1650 8250 1/2

1.2

2.1

SS

MAR 308

400/50/3 - N

230/50/3

2200 9700 1/2

1.2

2.1

SS

131

131

131

223

223

****

****

850

****

Cooling req.ts

1800

Evap.T.°C

-18

-24

-24

-20

-30

1.2

2.1

A B C Ø1Ø2Ø3Ø4

MAR 78 621 876 520 3/4" gas 3/8" gas 3/4" gas 21 mm

MAR 108 621 876 520 3/4" gas 3/8" gas 3/4" gas 21 mm

MAR 128 621 876 520 3/4" gas 3/8" gas 3/4" gas 21 mm

MAR 208 661 1297 520 3/4" gas 1/2" gas 28 mm 21 mm

MAR 308 661 1297 520 3/4" gas 1/2" gas 28 mm 21 mm

Ø1

= GAS LINE CONNECTION (SUCTION)

Ø3

= WATER INLET FITTING

Ø2

= LIQUID LINE CONNECTION

Ø4

= WATER OUTLET CONNECTION

Page 5

Page 5

Page 5

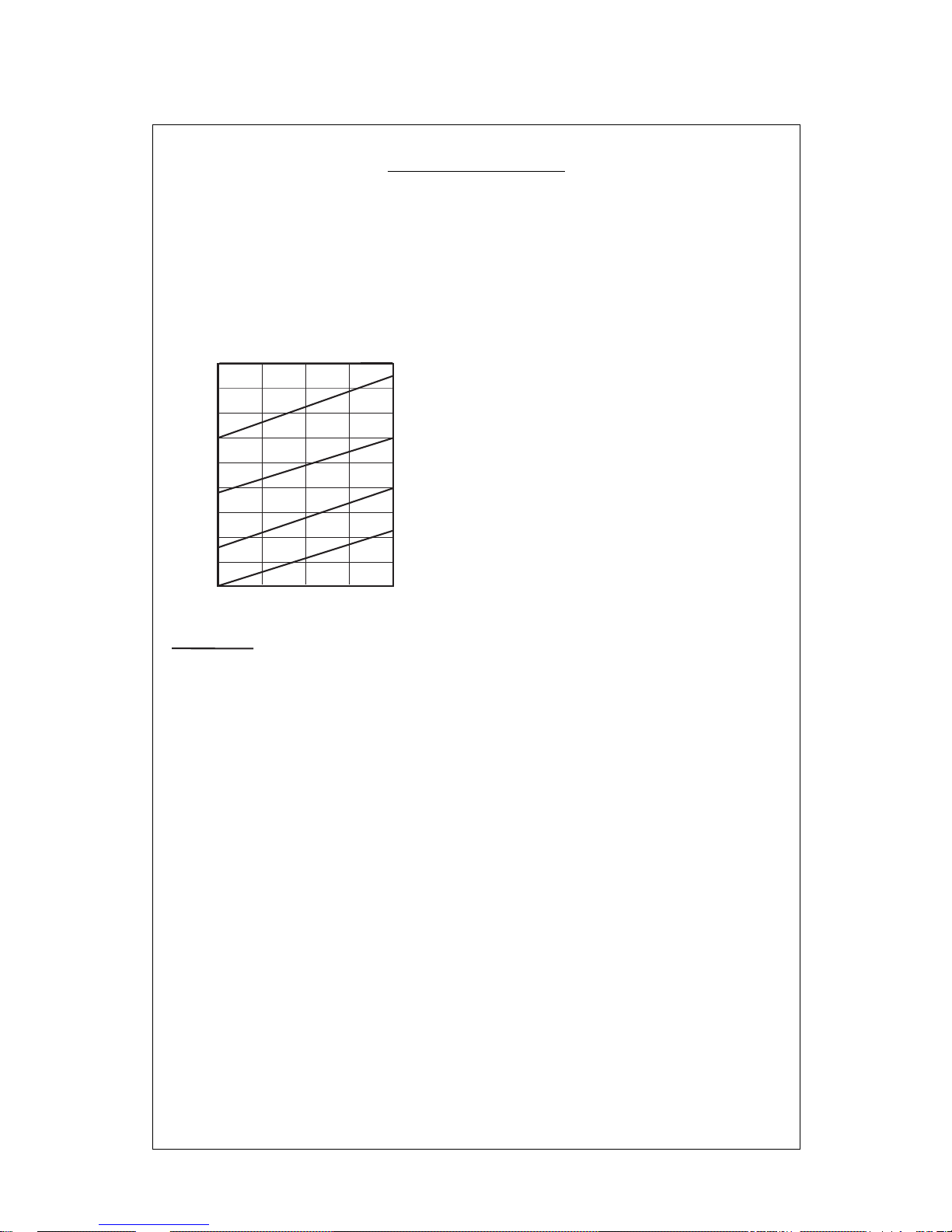

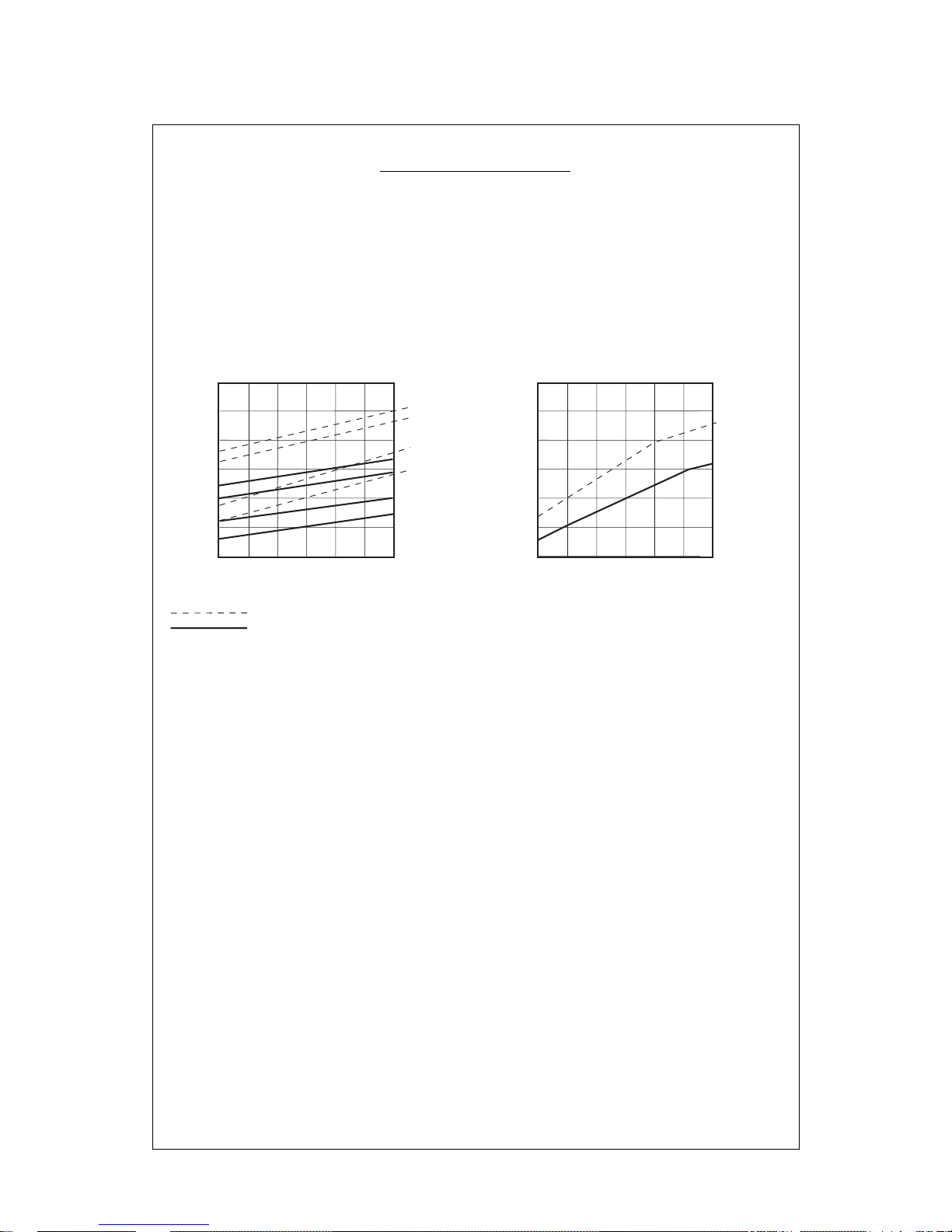

MAR 78 SPLIT

Set for Fresh water Operation

ICE MAKING CAPACITY

IMPORTANT OPERATING REQUIREMENTS:

WATER LEVEL IN DRUM RESERVOIR 115-120 mm

WITH WATER PUMP / SPRAY BAR

DRUM ROTATING SPEED 1.1 RPM (thick ice)

CONDENSING CAPACITY 4900 Kcal/hr (TD 10 ÷ 15 °C)

HEAD PRESSURE SETTING 15 ÷ 17 Bar on air cooled units

17 Bar on water cooled unit

LOW PRESSURE SETTING 2.2 Bar on air cooled units

1.8 Bar on water cooled units

HI-PRESSURE CONTROL SETTING 34 ± 2 Bar A/C

30 ± 2 Bar W/C

LO-PRESSURE CONTROL SETTING 0.2 Bar

WATER PRESSURE CONTROL SETTING 0.8 Bar

MAX. WATER TEMPERATURE 35 °C

MIN. WATER TEMPERATURE 5 °C

MIN. WATER PRESSURE 1 atm.

MAX. WATER PRESSURE 5 atm.

MIN. AMBIENT TEMPERATURE 5 °C

MAX. AMBIENT TEMPERATURE 40 °C

MAX. VOLTAGE VARIATION ± 10%

NOTE. The production diagrams herebelow represented can be used as reference, since the data

indicated have been obtained with a air/water cooled condensing unit equipped with a hermetic

compressor type U.H. TFH 2480Z providing - 3200 Kcal/hr at -18 °C Refrigerating capacity.

520

500

480

460

440

420

400

380

360

340

Kg./24 h

°C

32 27

21

15

°C

10

21

32

38

o

AIR COOLED MODELS

WA TER TEMPERATURE

AMBIENT TEMPERATURE

ICE PRODUCED PER 24 HRS.

10

Thicker scale ice

Page 6

Page 6

Page 6

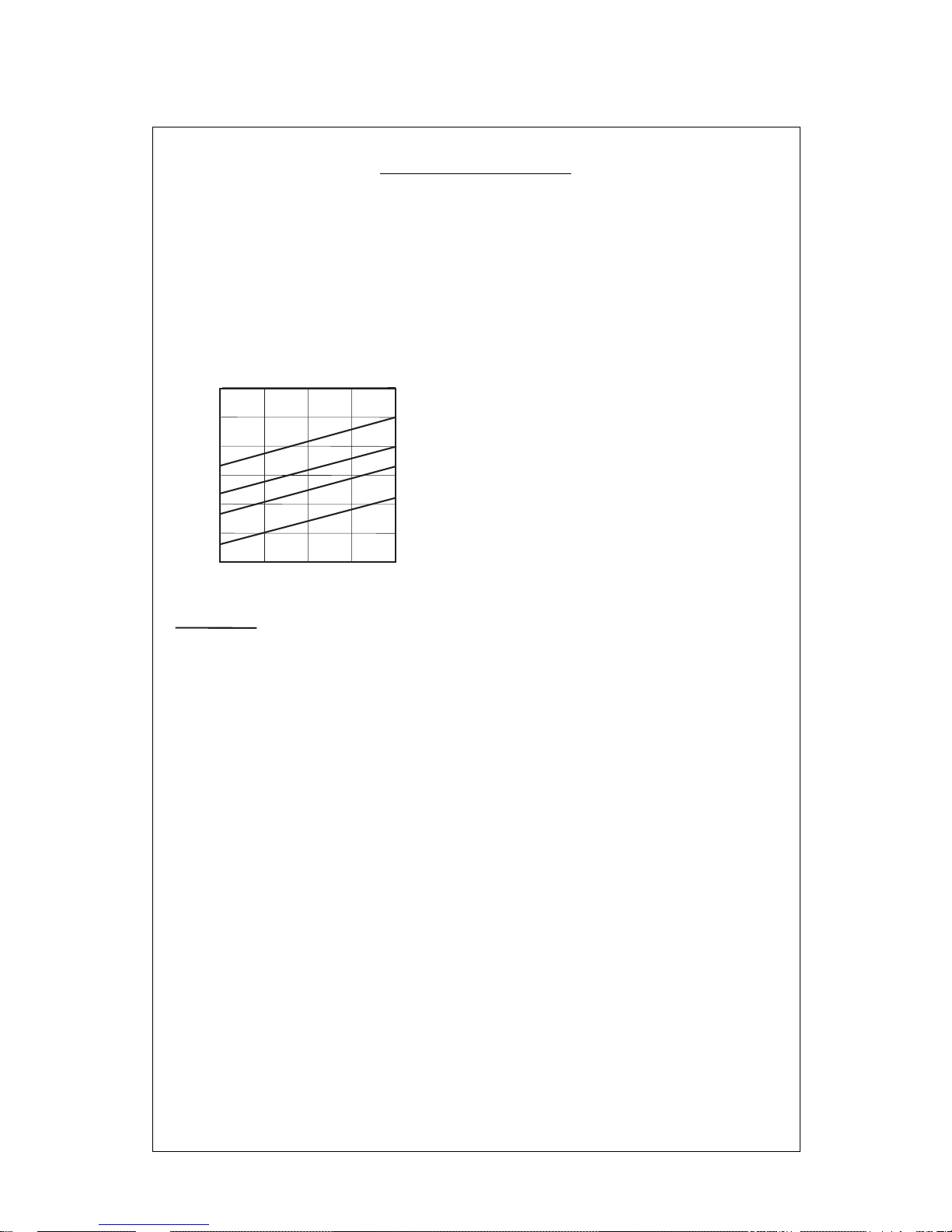

MAR 108 SPLIT

Set for Fresh water Operation

ICE MAKING CAPACITY

IMPORTANT OPERATING REQUIREMENTS:

WATER LEVEL IN DRUM RESERVOIR 115-120 mm

WITH WATER PUMP / SPRAY BAR

DRUM ROTATING SPEED 1.5 RPM (thick ice)

2.3 RPM (thin ice)

CONDENSING CAPACITY 7500 Kcal/hr (TD 10 ÷ 15 °C)

HEAD PRESSURE SETTING 15 Bar on air cooled units

15 Bar on water cooled unit

LOW PRESSURE SETTING 1.6 Bar on air cooled units

HI-PRESSURE CONTROL SETTING 36 Bar

LO-PRESSURE CONTROL SETTING 0.2 Bar

WATER PRESSURE CONTROL SETTING 0.8 Bar

MAX. WATER TEMPERATURE 35 °C

MIN. WATER TEMPERATURE 5 °C

MIN. WATER PRESSURE 1 atm.

MAX. WATER PRESSURE 5 atm.

MIN. AMBIENT TEMPERATURE 5 °C

MAX. AMBIENT TEMPERATURE 40 °C

MAX. VOLTAGE VARIATION ± 10%

NOTE. The production diagrams herebelow represented can be used as reference, since the data

indicated have been obtained with a air/water cooled condensing unit equipped with a hermetic

compressor type U.H. TAG 2516Z providing - 4800 Kcal/hr at -24 °C Refrigerating capacity.

750

700

650

600

550

500

450

Kg./24 h

°C

32 27

21

15

°C

10

21

32

38

o

AIR COOLED MODELS

WA TER TEMPERATURE

AMBIENT TEMPERATURE

ICE PRODUCED PER 24 HRS.

10

Thicker scale ice

Page 7

Page 7

Page 7

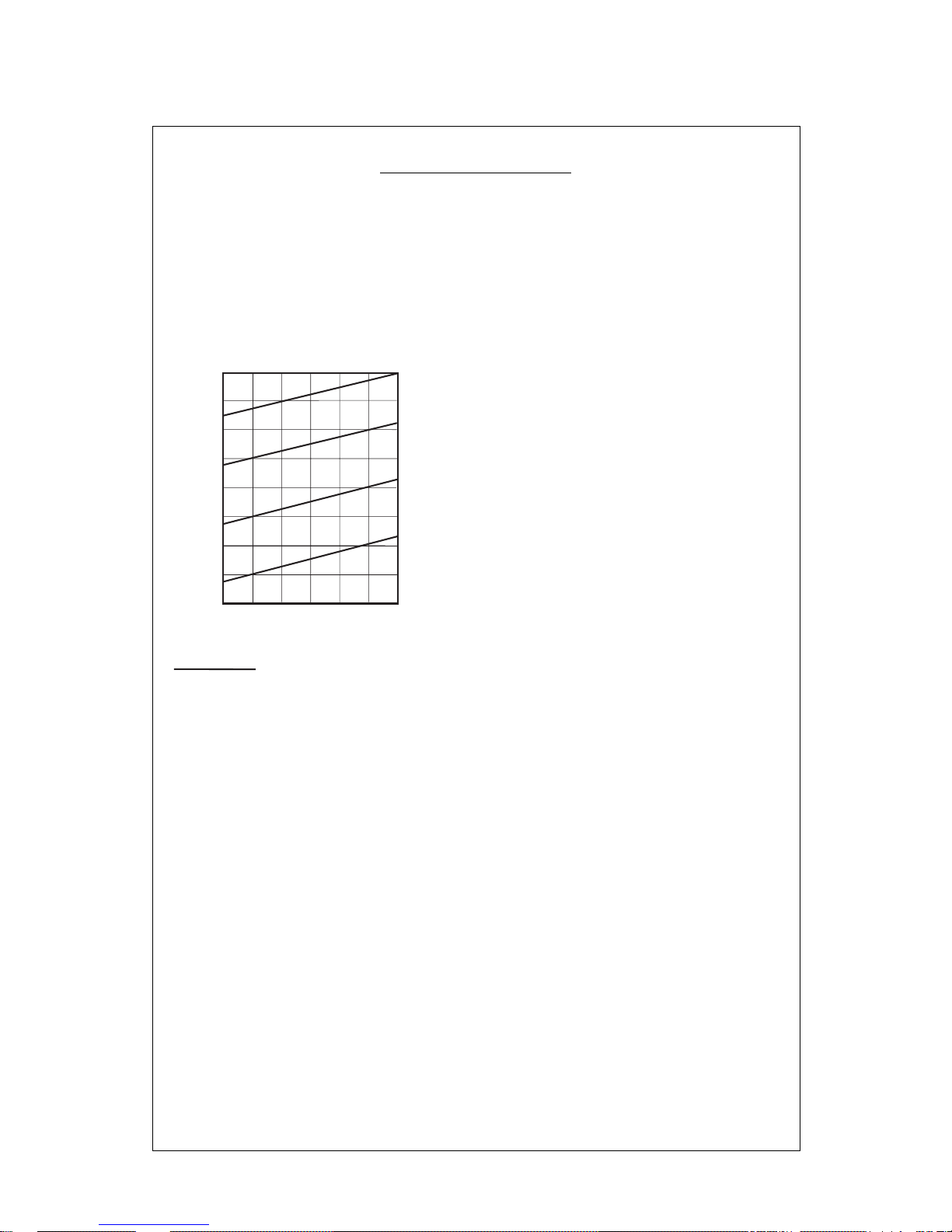

MAR 128 SPLIT

Set for Fresh water Operation

ICE MAKING CAPACITY

NOTE. The production diagrams herebelow represented can be used as reference, since the data

indicated have been obtained with a air/water cooled condensing unit equipped with a hermetic

compressor type U.H. TAG 2522Z providing - 6000 Kcal/hr at -24°C Refrigerating capacity.

IMPORTANT OPERATING REQUIREMENTS:

WATER LEVEL IN DRUM RESERVOIR 115-120 mm

WITH WATER PUMP / SPRAY BAR

DRUM ROTATING SPEED 2.4 RPM (thick ice)

CONDENSING CAPACITY 9750 Kcal/hr (TD 10 ÷ 15 °C)

HEAD PRESSURE SETTING 14 ÷ 16 Bar on air cooled units

LOW PRESSURE SETTING 1.6 Bar on air cooled units

HI-PRESSURE CONTROL SETTING 36 Bar

LO-PRESSURE CONTROL SETTING 0.2 Bar

WATER PRESSURE CONTROL SETTING 0.8 Bar

MAX. WATER TEMPERATURE 35 °C

MIN. WATER TEMPERATURE 5 °C

MIN. WATER PRESSURE 1 atm.

MAX. WATER PRESSURE 5 atm.

MIN. AMBIENT TEMPERATURE 5 °C

MAX. AMBIENT TEMPERATURE 40 °C

MAX. VOLTAGE VARIATION ± 10%

1000

950

900

850

800

750

700

650

600

38

°C

32 27

21

15

AIR COOLED UNITS

WA TER TEMPERATURE

AMBIENT TEMPERATURE

ICE PRODUCED PER 24 HRS.

32

38

10 5

10

21

Thicker scale ice

Page 8

Page 8

Page 8

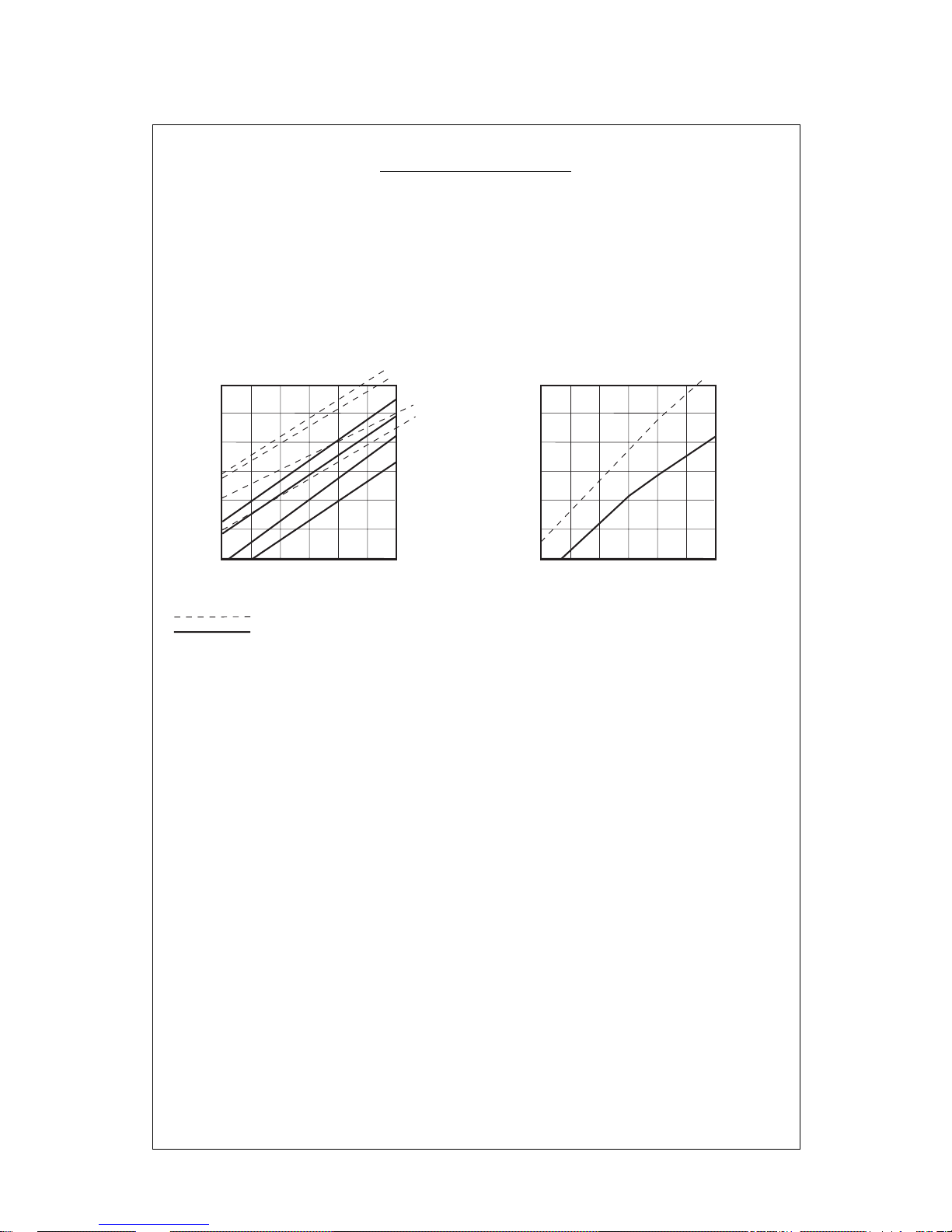

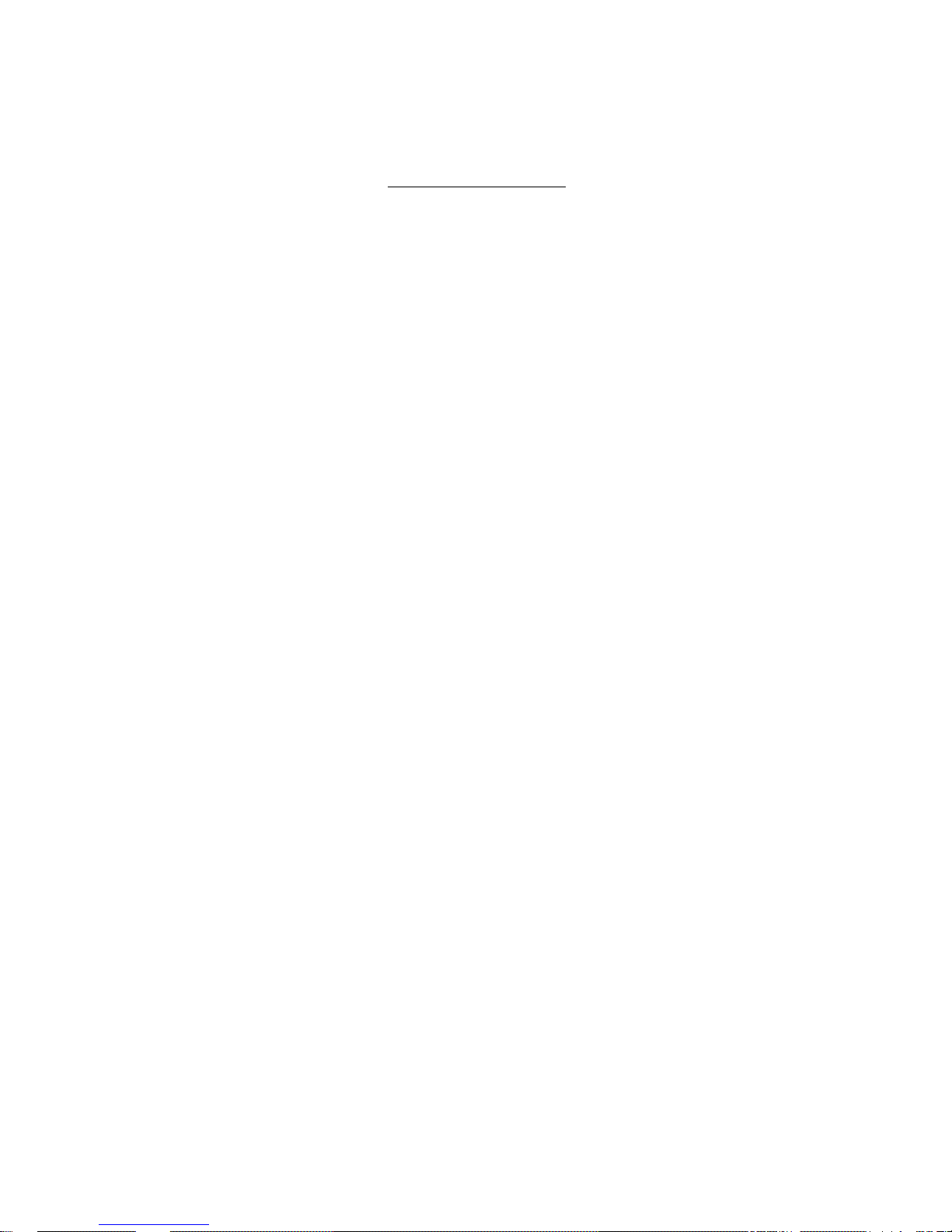

MAR 208 SPLIT

Set for Fresh water Operation

ICE MAKING CAPACITY

NOTE. The production diagrams herebelow represented can be used as reference, since the data

indicated have been obtained with a air/water cooled condensing unit equipped with a hermetic

compressor type DORIN K500 CS providing - 8250 Kcal/hr at -20 °C Refrigerating capacity.

IMPORTANT OPERATING REQUIREMENTS:

WATER LEVEL IN DRUM RESERVOIR 90-95 mm

WITH WATER PUMP / SPRAY BAR

DRUM ROTATING SPEED 1.05 RPM (thick ice)

1.60 RPM (thin ice)

CONDENSING CAPACITY 11000 Kcal/hr (TD 10 ÷ 15 °C)

HEAD PRESSURE SETTING 16 ÷ 18 Bar on air cooled units

16 ÷ 17 Bar on water cooled unit

LOW PRESSURE SETTING 1.9 Bar

HI-PRESSURE CONTROL SETTING 36 Bar

LO-PRESSURE CONTROL SETTING 0.2 Bar

WATER PRESSURE CONTROL SETTING 0.8 Bar

MAX. WATER TEMPERATURE 35 °C

MIN. WATER TEMPERATURE 5 °C

MIN. WATER PRESSURE 1 atm.

MAX. WATER PRESSURE 5 atm.

MIN. AMBIENT TEMPERATURE 5 °C

MAX. AMBIENT TEMPERATURE 40 °C

MAX. VOLTAGE VARIATION ± 10%

1700

1600

1500

1400

1300

1200

1100

Kg.

38

°C

32 27

21

15

°C

32

38

AIR COOLED UNITS

WA TER TEMPERATURE

AMBIENT TEMPERATURE

ICE PRODUCED PER 24 HRS.

32

38

WATER COOLED UNITS

10 5

10

21

1900

1800

1700

1600

1500

1400

1300

Kg.

38

°C

32 27

21

15

°C

DE 10 A' 38

o

WA TER TEMPERATURE

AMBIENT TEMPERATURE

ICE PRODUCED PER 24 HRS.

10 5

10

21

Thicker scale ice

Thiner scale ice

Page 9

Page 9

Page 9

MAR 308 SPLIT

Set for Fresh water Operation

ICE MAKING CAPACITY

NOTE. The production diagrams herebelow represented can be used as reference, since the data

indicated have been obtained with a air/water cooled condensing unit equipped with a semihermetic

compressor type DORIN K1000 CS providing - 9700 Kcal/hr at -30 °C Refrigerating capacity.

IMPORTANT OPERATING REQUIREMENTS:

WATER LEVEL IN DRUM RESERVOIR 90 mm

WITH WATER PUMP / SPRAY BAR

DRUM ROTATING SPEED 1.6 RPM (thick ice - air cooled)

1.8 RPM (thick ice - water cooled)

2.9 RPM (thin ice)

CONDENSING CAPACITY 16200 Kcal/hr (TD 10 ÷ 15 °C)

HEAD PRESSURE SETTING 15 Bar on air cooled units

14 Bar on water cooled unit

LOW PRESSURE SETTING 1 Bar on air cooled units

0.75 Bar on water cooled unit

HI-PRESSURE CONTROL SETTING 34 ± 2 A/C Bar

30 ± 2 W/C Bar

LO-PRESSURE CONTROL SETTING 0.2 Bar

WATER PRESSURE CONTROL SETTING 0.8 Bar

MAX. WATER TEMPERATURE 35 °C

MIN. WATER TEMPERATURE 5 °C

MIN. WATER PRESSURE 1 atm.

MAX. WATER PRESSURE 5 atm.

MIN. AMBIENT TEMPERATURE 5 °C

MAX. AMBIENT TEMPERATURE 40 °C

MAX. VOLTAGE VARIATION ± 10%

2600

2400

2200

2000

1800

1600

1400

Kg.

38

°C

32 27

21

15

°C

32

38

AIR COOLED UNITS

WA TER TEMPERATURE

AMBIENT TEMPERATURE

ICE PRODUCED PER 24 HRS.

32

38

WATER COOLED UNITS

10 5

10

21

2800

2600

2400

2200

2000

1800

1600

Kg.

38

°C

32 27

21

15

°C

DE 10 A' 38

o

WA TER TEMPERATURE

AMBIENT TEMPERATURE

ICE PRODUCED PER 24 HRS.

10 5

10

21

Thicker scale ice

Thiner scale ice

Page 10

Page 10

Page 10

SECTION I

GENERAL INFORMATION

GENERAL

The MAR SPLIT UNITS are pratically the

"Evaporating Unit Section" complete with driving

mechanism and control devices, all encased in

their stainless steel cabinets, for making complete scale-ice maker system

The MAR SPLIT UNITS must be remotely

connected to a corresponding size "Condensing

Unit" to become a MAR scale-ice maker plant, it

is therefore of primary importance first, the

selection of the right type and size of all the

components to be used to complete the refrigerant

system and secondly - but not least - the skillness

of the refrigeration engineers that will proceed in

completing the system by making the refrigerant,

hydraulic and electrical connections.

APPLICATION AREA

The scale-ice maker system using the MAR Split

Units, applies to different sort of market situations

where scale-ice is needed. Most specific areas

are:

a) Fishing Vessels

b) Fish Markets and Fish Processing Plants

c) Supermarkets

d) Meat packaging plants

Basically they can go in any place where there is

a limited space situation or where the condensing

unit (compressor/condenser) must be located in

a room where noise and heat is not objectionable.

MAR Split can be set to produce "THICK ICE"

generally used in the fishing industry or "THIN

ICE" generally used in the meat processing

industry.

Standard versions are set for "THICK ICE"

production (about 2 mm thickness) and for fresh

water operation. Different conditions should be

specified when ordering the Units.

Modular combinations are possible to increase

output ice production.

COMPLETE SYSTEM INSTALLATION - How

it is made

The complete scale-ice making system can be

divided in three major groups, that are:

a) the compressor and condenser unit with their

own components with their own refrigerant

and water lines fittings and electric wires

terminal block.

b) the evaporator drum unit (MAR Split Unit

supplied by Frimont) complete with drive

mechanism, drive motor, refrigerant and water

lines fittings, refrigerants expansion valve and

electric wire junction box.

c) console panel and control box with compressor

ON/OFF switch, relay, timer, warning lights,

pressure gauges and electrical wire terminal

block.

For installation on board of fishing vessels where

the electrical power available is not sufficient or

adequate to run the compressor, a mechanical or

hydraulic drive transmission must be used.

These drive systems will not be covered in details

in this manual as it is assumed that their

fundamentals have been already mastered to

the installator engineer by more specific

publications.

CONDENSING UNIT

The compressor is truly the heart of the system,

when it becomes inoperative refrigeration

immediately ceases. Therefore the selection of

proper type and size of compressor together with

the proper type and size of condenser, their

components and controls, deserve the most of

attention by the refrigeration engineer.

For our MAR ice making system, the compressor

to take is consideration are ot two basic types:

a) the accessible Semi-Hermetic-Motor-

Compressor for installation on sites where the

electrical power supply is available in adequate

quantity and quality.

b) the Open Type Compressor for automative

installations (Fishing Vessels) with mechanical

pneumatic or hydraulic drive system through

a magnetic clutch.

Whatever is the type of compressor being used,

it is recommended, for its selection, to observe

the refrigerant capacity on the following table:

MAR 78 3200 Kcal/h -18°C Evap. Temp.

MAR 108 4800 Kcal/h -24°C Evap. Temp.

MAR 128 6000 Kcal/h -24°C Evap. Temp.

MAR 208 8250 Kcal/h -20°C Evap. Temp.

MAR 308 9700 Kcal/h -30°C Evap. Temp.

Page 11

Page 11

Page 11

The approximate heat transfer capacity for the

condenser selection is shown on the herebelow

table

The condenser is basically a heat exchanger

where the heat absorded by the refrigerant during

the evaporating process is given to the condensing

medium which could be the air or the water.

When using marine type condenser a marine

type, water regulating valve is requested as well

to modulate the cooling water flow within

condenser.

Recommendend valve is the pressure actuated

"PENN".

The Liquid receiver is a storage tank for liquid

refrigerant that can be useful on refrigeration

split installation to make the quantity of refrigerant

in the system less critical.

It is normally provided with two service valves

and occasionally can be built-in the bottom of

condenser. It is a common component used in

refrigeration plant and should be large enough to

hold all the refrigerant in the system.

The Oil separator should be filled with oil during

installation until the float valve just begins to

open. This oil quantity always remains in the

separator and would otherwise be taken from the

compressor.

It is well known that when the compressor

operates, small amount of oil is pumped out

along with the hot compressed vapor and to

prevent it from going any further in the system,

the oil separator traps it to return, upon opening

of its float valve, to the crankcase of the

compressor.

CONTROL DEVICES

The scale-ice maker system must be completed

with all the necessary safety devices and controls

in order to fully protect it and to minimize

operational checks and functions, however any

excess in using automatic controls and protections

may complicate the situation at the point that

some of the controls be eliminated later, by the

user.

In order to help the installator engineer to decide

with which controls he has to equip a given

system, we cover all the necessary ones

mentioning for each of them the positive factors

and eventually the negative ones.

High Pressure Control

Very important - No negative factors Set to

values shown on techn. spech. Not supplied.

Water Pressure Control

Very important - No negative factors Set to 0.8

atm-cut-in - 0.5 atm cut-out. Supplied.

Lo Pressure Control

Very important because in case of refrigerant

leaks at the evaporator, it prevents to draw in the

system some water from the drum reservoir. It

also prevents to draw air through the compressor

crank-shaft seal. This may occure during vacuum

operations of the system.

However, it may inopportunely trip-off at the

system start-up and if suction operating pressure,

on account of the excessive rotating speed of

compressor or excessive compressor capacity,

is very close and gets below its setting value,

which is 0.2 atm. Not supplied.

MAR 78 MAR 108 MAR 128 MAR 208 MAR 308

300 lt/hr 450 lt/hr 84*****h 1200 lt/hr 1600 lt/hr

Particular care must be deserved to the selection

of the water cooled condenser expecially the

marine type for fishing vessels installation.

They can be marine type (cupro-nickel) tube

within a tube condenser with plasticized heads.

With water inlet temperature of +20°C and outlet

of +30°C at condensing temperature of 32°C the

water consumption should be:

MAR 78 MAR 108 MAR 128 MAR 208 MAR 308

4900 Kcal/h 7500 Kcal/h 9750 Kcal/h 11000 Kcal/h 16200 Kcal/h

Page 12

Page 12

Page 12

LOCATION CONSIDERATION

WARNING - The MAR SCALE ICE MAKERS

are not designed for outdoors installations

where air temperature falls below 5°C

(40°F) and may exceed 40°C (100°F)

Operating a machine with an unacceptable

configuration will void the refrigeration system

warranty.

For installation on board of fishing vessels, the

location for the condensing unit is generally the

engine room, while the evaporator unit can be

permanently placed in some area of the deckhouse or if it is not too cold (not below 5°C), inside

the fish and ice hold.

In case a stand is going to be made and used plan

for adequately fastening the MAR SPLIT UNIT.

The stand must be steady made to do not cause

excessive vibrations and must have the possibility

to be securely fastened to the wall or to the floor.

In relation to evaporator position and situation a

certain kind of ice chute is required. Make sure to

have it available for the start-up of the system.

REFRIGERANT LINES

Inner diameter of refrigerant lines going from

condensing unit to evaporator unit and back,

must be of adequate size in relation to tubing

lenght.

The table below show the recommended sizes of

refrigerant lines:

MODELL Lenght of tubes Suction line Liquid line

MAR 78 5 to 15 mt 18 mm 12 mm

MAR 108 5 to 15 mt 18 mm 12 mm

MAR 128 5 to 15 mt 18 mm 12 mm

MAR 208 5 to 15 mt 28 mm 12 mm

MAR 308 5 to 15 mt 42 mm 12 mm

2. Insulate lines that will be exposed to outside

temperature that will be below freezing for

extended period of time.

3. Follow straight line routing, when possible,

however give to the suction line a certain pitch

(2 cm per meter).

On liquid line be sure to do not have restrictions.

Bends and fittings should be the minimum

necessary as they can increase the resistance

to the fluid flow.

4. To prevent any condensing unit vibration

travelling into the lines, vibration absirbers

may be installed in the suction and the liquid

lines near the condensing unit.

Because the appearence of an installation is

important, the piping should be put-in as

neathly as possible.

For best sound absorb-tion, it is best to put-in

two absorbers in each line, one vertically and

one horizontally.

For evacuation and charging operations two

service valves must be provided.

One on the liquid line and one on the suction

line.

5. A drier and a sight glass should be installed

in the liquid line at the condensing unit.

HYDRAULIC CIRCUIT

Another item that requires a preliminarly attenzion

for the MAR SPLIT installation is the water

supply to the ice making section and to the

condensing unit case a water cooled condenser

is being used. Separate water linea are

recommended with hand shut-off valve and water

filter on individual line.

Remember:

– Maximum Water Temperature 35°C

– Minimum Water Temperature 5°C

– Minimum Water Pressure 1 atm

– Maximum Water Pressure 5 atm

The Ice Making Section (MAR SPLIT UNIT)

generally requires:

– 21 lt/hr MAR 78

– 29 lt/hr MAR 108

– 42 lt/hr MAR 128

– 70 lt/hr MAR 208

– 91 lt/hr MAR 308

of constant water supply.

The water consumption of the water cooled

condenser (in case of water cooled condensing

unit) to be taken on account, with water inlet

temperature at 15°C is:

– 300 lt/hr MAR 78

– 480 lt/hr MAR 108

– 1200 lt/hr MAR 128

– 1500 lt/hr MAR 208

– 1600 lt/hr MAR 308

For installation on fishing vessels, using

seawater, to carry sea water from sea chest to

the condensing unit and to evaporating unit

through appropriate strainers, you may use

aluminium brass pipes or PHE plastic pipes to

avoid corrosion problems.

Never use copper tubes.

ICE STORAGE ROOM

Ice storage situations are of two kinds:

a) Short terms storage

b) Extended terms storage

Being, as stated scale ice made by MAR

machines flat, dry and subcooled, therefore with

the tendency to stick toghether, particular

attention is required for proper ice storage

conditions for better ice handling. An insulated

ice storage bin or room is always required, then

according to ice end use application, this can be

refrigerated or non-refrigerated.

Page 13

Page 13

Page 13

Also a weight volume ratio of 2.1 cm. mt. per ton,

must be taken into consideration for correct ice

storage.

a) Non-refrigerated room for short term

storage

The scale ice is produced continuously for 24

Hours per day, whereas the use period is

generally for no longer than 8 hours per day.

Therefore storage facilities should be provided

to accomodate a minimum of 16 hours of

production, this means that every MAR ice

machine must be installed with a properly

insulated storage room which should have a

minimum capacity of 2/3 the daily ice

production.

With a well insulated room and duly subcooled

scale ice, the limited losses of heat through the

walls of a properly designed room with

adequate arrangements, are largely offset,

and excess melting will not occur. In most

situations where whole quantity of ice produced

is being used on a daily basis, it is not necessary

to provide cooling for the ice storage room.

b) Refrigerated room for extended storage

and long distance conveying

When scale ice is to be transported at a

considerable distance, such as aboard fishing

vessels, or in locations with normal ambient

temperatures conditions, or when used in

industrial plants where demand is intermittent,

its subcooling power must be preserved

absolutely in the storage bin by a proper

cooling system keeping air temperature at a

pre-established and constant value. The ideal

ice storage room is the type with mechanically

refrigerated jacket space surrounding the ice

bin.

Good practice calls for an ice storage capacity

of about two times the daily ice machines

production with an inside temperature of -6°C

minimum (20°F).

Page 14

Page 14

Page 14

NON REFRIGERATED ICE STORAGE ROOM

1 Condensing unit

2 Liquid line

3 Evaporator drum unit

4 Suction line

5 Power supply line

6 Hand disconnect switch

7 Water supply line

8 Hand shut-off valve

9 Water filter

10 Condenser water inlet

11 Condenser water outlet

12 Evaporator water supply

13 Water drain line

14 Liquid line service valve

15 Suction line service valve

REFRIGERATED ICE STORAGE ROOM

(Jacket system)

1 Condensing unit

2 Liquid line

3 Evaporator drum unit

4 Suction line

5 Power supply line

6 Hand disconnect switch

7 Water supply line

8 Hand shut-off valve

9 Water filter

10 Condenser water inlet

11 Condenser water outlet

12 Evaporator water supply

13 Water drain line

14 Refrigerant coil

15 Insulated panel

16 Air gap

17 Ice bulkhead

Page 15

Page 15

Page 15

MAR 78-108-128 MAR 208-308

mm (inch) mm (inch)

A 621 (24.45) 661 (26.02)

B 876 (34.48) 1296 (51.03)

C 520 (20.38) 520 (20.38)

D 813 (32) 853 (33.58)

E 231 (9.09) 440 (17.32)

F 3/4" GAS 28 mm

G 3/8" GAS 1/2"

UNIT LAYOUT AND OVERALL DIMENSIONS

A

B

C

D

E

F

G

Page 16

Page 16

Page 16

SECTION II

INSTALLATION

MAR SPLIT UNIT - UNPACKING AND

INSPECTION

1. Visually inspect the exterior of the shipping

container and skid and any severe demage

noted should be reported to the delivery carrier;

and a concealed damage claim filled subject

to internal inspection with carrier representative present.

2. Remove the packing and remove the side

panels to unloose the shipping bolts securing

the unit to the skid.

3. Remove screw and all panels from cabinet

and inspect for any concealed damage. Notify

carrier of any concealed damage claims as

stated in step 1 above.

4. Remove all internal packing from unit

compartment.

5. Check that refrigerant lines do not rub or

touch lines or surfaces and that all wires are

securely fastened to their terminals.

6. Use clean damp cloth or disposable paper

wiper to wipe clean the exterior surface of the

cabinet.

7. See DATA PLATE on the cabinet base and

check that the location source voltage

corresponds with the voltage specified on the

dataplate.

CAUTION - Unproper voltage supplied to

the icemaker will void your parts

replacement programm.

MAR SPLIT UNIT - LOCATION AND

LEVELLING

1. Position the MAR SPLIT UNIT in the selected

permanent location which could be on top of

ice storage cabinets, on the side of cold

storage room supported by special pre-set

stands or, in case of fishing vessel installation,

inside or on top of the fish hold.

2. After having placed the unit on the support

stand, level the cabinet on both the left to righ

and front to rear directions, by inserting

between the unit base and a support stand

few rubber pads. Fit in unit base holes in the

cabinet, appropriate bolts to fasten unit to

stand.

Make sure to leave enough space around the

unit to allow access to internal components

for inspection and servicing and also for the

fitting of the ice chute if needed.

3. Proceed to position the condensing unit in its

location and to mount it firmly to avoid a

sudden shift that would endager the refrigerant

lines. Precautions to be observed vary with

the kind of situation in which the unit is to be

placed. The area should be well ventilated to

permit escape of refrigerants in case unit

develops a leak.

MAR SPLIT UNIT - REFRIGERANT PIPING

CONNECTION

Fitting sizes:

Liquid Line Suction Line

MAR 78-108-128 3/8" Gas 3/4" Gas

MAR 208 1/2" Gas Ø 28 mm

MAR 308 1/2" Gas Ø 42 mm

Take extreme care to keep refrigeration tubing

clean and dry prior to installation.

Following procedure should be followed:

a) Do not leave dehydrated compressor or filter-

drier open to the atmosphere any longer than

it is absolutely necessary. (One or two minutes

maximum suggested).

b) Use only refrigeration grade copper-tubing,

properly sealed against contamination.

c) Permanent suction lines filters and liquid line

filter-driers are recommended in all filled

installed system.

d) When brazing refrigerant lines, an inert gas

should be passed through the line at low

pressure to prevent scaling and oxidation

inside the tubing. Dry nitrogen is preferred.

e) Line connection to vibration eliminators be

made with silver solder alloy.

Arrange that refrigerant lines run along the walls

and cellings and be supported at intervals frequent

enough to keep tubing atraight and firmly in

place. In all cases the tubing should be run

horizontally and vertically with neat looking bends

of as perfect radius as possible.

The liquid line presents no difficulties as to its

sland and position, but you must install the suction

line so the tubing will drain toward the compressor.

During preparation of liquid line take the necessary

measure to install after evacuation of system, the

filter-drier of suitable size for constant operation.

You may as well consider to install on suction line

a suction tube filter, specially if the required

cleaness cannot be guaranteed.

After all lines are connected, the entire system

must be leak tested.

The complete system should be pressurized to

no-more than 12-13 atm. with refrigerant and dry

nitrogen or dry CO2 for being leak tested by

means of an electronic type leak detector.

Page 17

Page 17

Page 17

For pressurizing, evacuating and charging the

system, two service valves are necessary; one

should be in the Suction Line at the inlet side of

suction filter and one should be in the Liquid Line

at the outlet side of filter dryer.

The two Service Valves, if properly capped can

be left permanently in the system. Connection

should be 3/8" or 1/2" size.

MAR SPLIT UNIT - WATER PIPING

CONNECTIONS (PLUMBINGS)

MAR SPLIT UNIT is supplied with float valve in

position to maintain the water level in drum

reservoir at the height required for fresh water

operation or if required, for sea water operation.

Water inlet line must go directly to float valve line

fitting of 3/4" gas, (copper tube is not

recommended for sea water supply) also make

sure to fit on this same a hand shut-off valve

close enough to MAR unit and a proper kind and

size of filter strainer.

Incoming water geoes through the float reservoir

first and then to drum basin.

Outlet water line should be shaped adequately to

drain by gravity any water passing through it.

Water outlet fitting from float reservoir requires a

20 m/m I.D. water hose.

All plumbing connections should be made in

accordance with local plumbing codes.

WATER AND REFRIGERANT CIRCUIT - SPLIT UNITS

1. Liquid line

2. Heat exchanger

3. Automatic expansion valve

4. Suction line

5. Water inlet

6. Float valve

7. Water basin

8. Evaporation drum

9. Scraping blade

10. Water pump

11. Spray bar

12. Water tube - Pump / spray bar

13. Liquid line valve

Page 18

Page 18

Page 18

MAR SPLIT UNIT - ELECTRICAL

CONNECTION

The supply power, voltage frequency and phase

must coincide with unit nameplate. MAR Split

units are internally wired and ready for field

wiring connections which must be made in

accordance with any local codes that may apply.

Wires should be of adequate size to handle the

connected load, individually fused (see

specifications at page 5) and provided with ground

line.

The maximum allowable voltage variation, should

not exceed ten percent of the nameplate rating,

even under starting conditions.

Low voltages can cause erratic operation and

may be responsible for serious damages to the

overload switch and motor windings.

Make the necessary steps so that the MAR Split

Unit be electrically connected to the condensing

unit control box contactor as illustrated on the

following wiring diagrams representing three

different electric supply line situation which are

respectively. 230/50/3 or 400/50/3-N.

WARNING - Correct Drum rotation - The

evaporator drum drive motor being a

threephase motor wired for 380 V. It is of

estreme importance to check immediately

upon unit start-up that motor rotates

CLOCKWISE in order that gear motor

pulley rotates in the direction of the

ARROW on it indicated. Should the motor

turn counterclockwise, it is necessary to

instantly switch-off the unit and

interchange one polarity at terminal block

connection at main electric cord.

Page 19

Page 19

Page 19

INSTALLATION PRACTICE SPLIT

UNIT ASHORE

1 Condensing unit

2 Liquid line

3 Evaporator drum unit

4 Suction line

5 Power supply line

6 Hand disconnect switch

7 Water supply line

8 Hand shut-off valve

9 Water filter

10 Condenser water inlet

11 Condenser water outlet

12 Evaporator water supply

13 Water drain line

INSTALLATION PRACTICE SPLIT UNIT

ON OFFSHORE FISHING VESSEL

1 Deck house

2 Control panel & main switch

3 Ice chute

4 Evaporator drum unit

5 Ice hold

6 Fishing room

7 Réfrigérant lines

8 Condensing unit

9 Engine room

Page 20

Page 20

Page 20

MAR SPLIT IN MULTIPLE INSTALLATION

In multiple installation various types of commercial

refrigerating equipment are connected to the

same condensing unit, which is normally located

in the machine room, as often occurs in

supermarkets.

MAR SPLIT can be one of the refrigerant units

connected to a multiple use condensing unit.

In this kind of installation it will be best to replace

the standard AEV refrigerant control with a

corresponding size AMXV control, which, in

relation to the multiple installation situations (great

evaporating temperature difference) could be of

two temperature type.

Also a manifold with hand shut-off valves on

both liquid and suction line is recommended for

these installations.

In many multiple installations check valves are

put in the suction line of the coldest evaporator to

prevent that warmer higher pressure low-side

vapor moves into colder evaporator during the off

periods.

Also a pressure control valve is installed on

MAR SPLIT suction line to maintain constant

pressure on evaporator drum.

Therefore, for the MAR SPLIT multiple installation

you may need:

1. Automatic Expansion valve

The automatic expansion valve is the leading

multiple evaporator system refrigerant control

as it does not regulate the low side pressure,

but, rather control the filling of the evaporator

with refrigerant, it is important to use a valve

for the correct capacity.

2. Solenoid valve

Two-ways type to be connected in series with

any MAR SPLIT protecting and starting device.

3. Pressure Control valve

On the MAR SPLIT suction line. It will mantain

constant pressure on MAR SPLIT evaporator

drum.

4. Manifold with hand shut-off valve

One to be placed on the liquid line and the

other on suction line to isolate MAR SPLIT

unit when necessary.

Installation of MAR SPLIT in multiple system

should be done in the following order.

1. Put MAR SPLIT unit in place.

See Sec. II Location & Levelling.

2. Install valves and controls.

3. Install tubings.

See Sec. II Refrigerant piping connections.

4. Make water piping connections.

See Sec. II Plumbing.

5. Make electrical connections

See Sec. II Electrical connections.

6. Check for leaks.

See Sec. II Leak Test.

7. Dehydrate installation.

See Sec. III Evacuation / Charging.

8. Start unit.

See Sec. III Operazional Check-out.

TYPICAL NON-CODE COMMERCIAL INSTALLATION

1. Power line

2. Main switch

3. Relay / Starter

4. Suction line shutoff valves

5. Liquid line shutoff valves

MAR SPLIT ICE MAKER

DISPLAY CASE

MEET ROOM

CONDENSING UNIT

Page 21

Page 21

Page 21

SECTION III

TESTING

COMPLETE SYSTEM LEAK TESTS

During pressure testing for leaks, keep the

compressor suction service valve and discharge

service valve closed to prevent air and moisture

from entering the compressor. All other valves in

the system must be open.

Sufficient liquid refrigerant shall be charged into

the system to raise the pressure to 2.5 atm. and

dry nitrogen added to obtain the desired test

pressure (20.5 atm is sufficient).

Leak testing shall be performed with an electronic

leak detector, unless the use of a halide torch is

specifically authorized by the owner.

Refrigeration piping will not be acceptable unless

it is gas tight.

If any leaks are found, isolate the defective area,

discharge the gas and repair the leaks and then

repeat the test. When testing has been completed

release all pressure freely to atmosphere.

COMPLETE SYSTEM EVACUATION

The system shall be evacuated with a vacuum

pump specifically manufactured for vacuum duty,

having a capacity of pulling a vacuum of 50

microns or less.

Evacuation of the system must never be done by

the use of the refrigerant compressor. The pump

should be connected to both the low and high

side evacuation valves with vacuum hoses. The

compressor service valves should remain closed.

A high vacuum gauge capable of registering

pressure in microns should be attached to the

system pressure readings.

Never put the compressor in operation. To check

system pressure, a hand valve must be provided

between the pressure gauge and the vacuum

pump which can be closed to isolate the system

and check the pressure.

Evacuate the system to an absolute pressure not

exceeding 1,500 microns. Creak the vacuum to

excess pressure of 0,15 atm (1 psig) with the

refrigerant to be used in the system.

Repeat the evacuation process again breaking

the vacuum with refrigerant. Install a definitive

drier of the required size in the liquid, open the

compressor suction and discharge valves and

evacuate to an absolute pressure not exceeding

500 microns. Leave the vacuum pump running

for not less than two hours without interruption.

Raise the system pressure to 0,15 atm (1 psig)

with refrigerant and remove the vacuum pump.

COMPLETE SYSTEM - CHARGING

Refrigerant shall be charged directly from original

drums through a combination filter drier.

Charge the system by means of a charging fitting

in the liquid line.

Wheigh the refrigerant drum before charging so

that an accurate record can be kept of the weight

of refrigerant put in the system. It refrigerant is

added to the system through the suction side on

the compressor, charge in vapor form only. The

process used most often to determine correct

refrigerant charge is to observe the refrigerant

flow in the sight glass in the liquid line.

As steady supply of liquid is necessary for proper

functioning of expansion valves; it can be

assumed that the system has been correctly

charged when a clear flow of liquid refrigerant is

visible.

Bubbles or foam usually indicate insufficient

refrigerant, even if there could be other reason

for the bubbles or foam to appear in the sight

glass. So, the practice to relay on the sight glass

only to determine whether the systems is correctly

charged is certainly good but not fully positive.

After the final leak test, refrigerant lines exposed

high ambient conditions should be insulated to

reduce heat pick-up and prevent the formation of

flash gas in the liquid lines.

Suction line should be insulated if exposed, to

prevent condensation.

START-UP - CHECK-OUT

Compressor and condensing unit will normally

be delivered to the job with sufficient oil for

average installation.

Check compressor for proper oil level and, if

necessary, add sufficient oil to bring the level to

the center of the cranckase sight glass.

Use only refrigeration oil recommended by the

compressor manufacturer.

Remove or loosen shipping retainers under

motor-compressor. Make sure hold down nuts

on spring mounted compressor are not touching

the compressor feet.

Check electrical connections. Be sure they are

all tight. Check high and low pressure control,

water valves, pressure regulating valves, safety

controls and adjust if necessary.

OPERATION CHECK-OUT

After system has been charged and checked-out

make sure to correctly position, attached to the

unit ice spout, the require chute (not supplied).

Perform a through re-check of entire system as

per following steps.

1. Make sure to open the water supply line shutoff valve and that water flows freely from float

valve into float reservoir and from this to the

drum basin.

Page 22

Page 22

Page 22

2. Provide power to the unit.

3. Observe the water filling operations.

a) Water flows into the float reservoir first.

b) Water is filling the freezing drum basin.

c) Float moves up as water level rises in water

reservoir.

d) Float stops water flow when water reaches

suitable operation level.

Now, water surrounds bottom half of freezing

drum.

4. Move the manual ON-OFF toggle of main

disconnect switch to ON position. The green

light on console panel will glow.

5. MAR uses an electrical "three phases

monitoring relay" which alerts installer in case

of wrong wiring by keeping green LED ON

only. In this case change phase connection

wiring.

6. Correct wiring is shown by both LEDs Green

and Orange steady ON together.

7. Observe immediately that evaporator drum

rotates in the right direction, namely toward

the scraping blade.

8. Meanwhile unit is under power KT1 relay

compressor device is energized as well in

order to delay compressor start up by 18'

(KT1 orange LED blinks during this delay). On

normal operation - compressor ON - KT1

LEDs (orange and green) are steady ON

together.

NOTE. In case on any temporally Ice maker

trip OFF (not alarm) due to NO/LOW water

pressure, bin full, ice spout switch activation

unit stops by only keeping drive motor operating

for 18' in order to clear evaporator by ice.

KT2 delay relay LEDs steady ON (orange

and green) during this delay.

WARNING - Drum drive motor is three

phases type. At unit start up, correct wiring

is assured by 3 phases monitoring relay

at power in. In addition proper drum

rotation speed is monitored by a Hall

Effect sensor. In case the drum is not

rotating at all or it rotates too slow (less

then 1/4 turn every 30 seconds) a special

Electronic Control trips the unit OFF so to

avoid that compressor can operate with

the drum OFF (in case of fiber keys, drive

motor or gear reducer breakage). In case

of any field drive motor replacement, care

must be taken to its wiring, checking the

correct evaporator drum rotation that must

be toward ice blade. In case of wrong

evaporator drum rotation, turn the unit

OFF and exchange two phases connection

at drive motor control box.

Page 23

Page 23

Page 23

9. Check compressor head and suction

pressure. If not within system design limits,

determine why and take corrective action.

10. For water cooled condensing unit check the

water flowing out of the condenser to see if it

drains properly.

11. Observe if ice skin tends to cover entire drum

surface and is being scraped-off correctly by

the blade.

12. Check liquid line sight glass and expansion

valve operation. If there are indications that

more refrigerant is required leak test all

connections before adding refrigerant.

13. Observe oil level in compressor crankcase

sight glass and add oil as necessary to bring

level to center of the sight glass.

Indicative Operating Pressure - With Fresh Water Supply - Water Cooled System

MAR 78 MAR 108 MAR 128 MAR 208 MAR 308

Head Pressure (bar) 17 15 16 16 14

Suction 1.8 1.6 1.6 1.9 0.75

Drum R.P.M. (thick ice) 1.1 1.5 2.4 1.05 1.8

Indicative Operating Pressure - With Sea Water Supply - Water Cooled System

MAR 121 MAR 301

Head Pressure (bar)

Suction

Drum R.P.M. (thick ice) 1.52 1.82

14. Let the system operate for at least two hours,

then check one by one the operation of each

individual control and protective device for

proper setting.

15. Eliminate any excessive vibration or noise

and pulleys misalignement.

16. Observe that evaporator drum is frosted all

over from end to end. If this is not the case

setting of refrigerant expansion valve may be

necessary. For proper adjustement of this

valve turn the valve setting stem of one eight

of a turn counter-clockwise to allow more

refrigerant to flow until the evaporator drum

surface is evenly frosted from end to end.

In case there is an excessive frost back on

the suction line and frost start to form on

compressor suction service valve, slightly

turn clockwise the expansion valve setting

stem until the frost back on the compressor

service valve melts over.

17. Observe that ice slides through spout opening

with no difficulties. Clearence between the

blade and drum surface must be 0,10 mm.

Transparent plastic chute must be flat.

18. When the system is performing satisfactorily

go over with the owner/user to all significant

specifications, the start-up and operations.

Answer alla questions about the care and

attention to give to the ice making system.

Page 24

Page 24

Page 24

SECTION IV

PRINCIPLES OF OPERATIONS - HOW IT WORKS

1. ICE MAKER

The revolving drum which may be of two different

sizes depending on the ice maker capacity, is

basically made of a cylinder skeleton covered by

a stainless steel jacket.

There is a channel, about 15 m/m deep and 15 m/m

wide on the surface of the cylinder skeleton

which, in a spiral pattern, goes from one end to

the other of cylinder.

Both the ends of the channel communicate with

a bore made in the left cylinder journal. The head

manifold on the left side is for either liquid

refrigerant inlet and vapor refrigerant outlet.

When a cylinder stainless steel jacket is forced

and sealed on the drum, the spiral pattern channel

made for the refrigerant flow becomes virtually

the evaporator serpentine.

The metered refrigerant that reaches the

evaporator serpentine by passing throught the

head manifold in the left side cylinder journal,

boils and evaporatores as it comes into contact

with the drum metal jacket. About one third of the

cylinder drum is constantly submerged in water

this will allow the cylinder metal jacket to draw a

film of water that, as soon as it comes afloat,

freezes almost instantly due to the heat absorption

created by the boiling refrigerant circulating in the

inner serpentine and scrubbing with the jacket

inner surface.

2. PRINCIPLES OF OPERATION - HOW IT WORKS

On fresh water installation a combination of water

pump and water distributor tube provides a

constant flow of cold water to the upper side of

the evaporator drum so to have an extended

metal jacket surface covered by water and a

thicker ice layer.

Then the ice layer of the emerged cylinder sector

has a fraction of time to solidify, dry and eventually

subcool before contacting the edge of the

horizontal scraping blade.

The scraping blade, of heavy duty metal, cause

the peel off of the ice sheet formed on the drum

jacket by racking it while it advances on the

revolving drum.

The ice sheet is so dry that, when it gets in contact

with the scraping blade, it cracks in a form of

irregular shaped chips. The refrigerant leaves

the evaporator serpentine to return to the

compressor via suction line through the inner

bore of the left side cylinder journal.

The refrigerant sealing in inlet/outlet head

manifold is assured by specially designed sealing

device, the cylinder is driven by separate drive

motor and gear reducer located on the right basin

frame.

The gear reducer, the driving belt with its pulley,

the revolving drum with the rotating part of the

sealing devices and the water pump on fresh

water installation are the mechanical parts in

motion.

1. Water drawing area

2. Water sprayed freezing cooling area

3. Sub-cooling area

4. Float valve

5. Water feeding line

6. Scraping blade

7. Water pump

8. Water basin

9. Revolving drum

10. Water distributor tube

Page 25

Page 25

Page 25

3. MAR SPLIT - ELECTRICAL /

REFRIGERATION

The electrical circuit consists of drive motor,

water pump, water pressure switch, spout switch

and time delay safety device.

A. Drive motor

The evaporator drum drive motor is a three

phase motor of 1/2 HP wired for 380/220 Volts

50/60 Hz - 1,2/2,1 Amps - 1400 R.P.M. with

inherent thermal protector.

IMPORTANT - When this motor is

disconnected or the entire unit is disconnected,

it is necessary - when resuming the electrical

connection to immediately make sure that

drive motor rotates clockwise facing the

unit front.

Failure to this, may result in wrong rotation of

evaporator drum with the risk of major

damages to the system.

B. Water failure Switch

This switch used as safety device when low or

interrupted supply water conditions are

encountered.

Operates on pressure between supply line

and feed line to water reservoir.

Range is 0,8 bar (10 psi) off and 1,2 bar

(17 psi). Cuts off complete unit and Resets

automatically.

C. Ice Spout Safety Switch

Located on top of the Ice Spout, the Safety

Switch is operated by a plate on top of the ice

chute by the ice backing up in the spout.

The switch will shut-off entire ice making

mechanism.

D. Liquid valve Delay timer

Delays belay 18' refrigerant liquid valve

opening at every start up of the ice maker.

Supplied.

E. Drum rotation delay timer

Delays drum STOP by 18' at every trip OFF of

the ice maker. Supplied.

F. 3 - phases monitoring relay

On the power IN, it checks and assures correct

rotation of the drive motor - evaporator drum.

Supplied.

G. Drum rotation control

It operates using the Hall effect sensor/

principle. In case the drum is not rotating at all

(or it rotates too slow - less then 1/4 turn every

30") such relay trips the unit OFF so to avoid

that in case of fiber keys breakage, the drive

motor - gear reducer and compressor can

operate with the drum OFF. Supplied.

H. Automatic Expansion Valve (A.E.V.)

The automatic expansion valve controls the

refrigerant when passing from the liquid line

to the evaporator. As the pressure decreases

on the low side, the expansion Valve open

and refrigerant escapes into the evaporator

drum channel where it absorbs heat from

water while evaporating. The valve maintains

a constant pressure in the evaporator coil

when the system is running indipendently of

the amount of refrigerant in the system.

This valve has an adjustment which may be

manually regulated to give the evaporator coil

the desired amount of refrigerant.

Turning the adjustment to the left,

counterclockwise, will increase the rate of

flow which is controlled by the pressure in the

evaporator.

When the compressor is not running the valve

remains closed as the low side pressure

will be high enough to close the expansion

valve.

- MAR Split 78-108-128 - is equipped with an

expansion valve having an orifice of 2,5 m/m

.

- MAR Split 208-308 - is equipped with an

expansion valve having an orifice of 4,5 m/m.

I. Evaporator Drum

Refrigerant inlet/outlet takes place on left

side journal.

The drum body is covered by a jacket in

special stainless steel resistant to the water

corrosion.

The front edge of the scraping blade must

have a clearance of minimum 0.10 m/m from

cylinder metal jacket.

L. Refrigerant Seal System

Housed in the refrigerant inlet/outlet manifold

located on the evaporator drum left side

journal, is a leakproof joint. This joint is made

with seals that are carefully designed and

installed. The seals use two rubbing surfaces.

One surface tourns with the cylinder journal

and is sealed on it with on O ring of synthetic

material. The other surface is stationary and

fitted in its housing with leak-proof O rings.

The rubbing surfaces (optically flats) are made

of two different material that are: hardenend

steel for the rotating ring and graphite for the

stationary ring.

The rotating parts are:

a) the spring collar

b) the compression spring

c) the stainless steel seal ring with O ring.

The stationary parts are:

a) the graphitic ring with O ring

b) the stainless steel housing ring with gasket

and O rings.

M. Heat Exchanger

MAR Split 78, 108, 128, 208 and 308 have a

heat exchanger mounted in the suction and

Page 26

Page 26

Page 26

liquid line to reduce flash gas in the liquid line,

to reduce liquid refrigerant in the suctionand

to subcool the liquid refrigerant thereby

increasing the operating efficiency.

N. Strainer Filter

All MAR Splits mount on liquid line a wiremesh

type of filter to prevent that screen of filter of

the expansion valve could becopme clogged

from dirt thereby stopping the refrigerant flow.

connections.

O. Motor Shaft Pulley

MAR Split units are generally equipped with

"Step pulley" and by changing the belt from

one groove to the other the speed of drum can

be changed.

MAR Machines are factory delivered with V

belt on smaller dia V groove of step pulley to

rotate the evaporator drum at the lowest

possible R.P.M. to obtain "THICK" (2 m/m

gauge) scale ice.

Normal drum R.P.M. for "THICK" ice

production are:

MAR 78 - 1.1 RPM

MAR 108 - 1.5 RPM

MAR 128 - 2.4 RPM

MAR 208 - 1.05 RPM

MAR 308 - 1.6 RPM

P. V Belt

V belts used on motor shaft pulley and gear

box are type:

MAR MAR MAR MAR MAR

78 108 128 208 308

X PZ 750 X PZ 900 X PZ 937

When changing the V belt from one groove to

another, be careful to adjust it for proper

tension and alignement.

It should be snug not tight. A way to roughly

check belt tension is to apply a firm hand

pressure in the middle of the longest belt

span. If the belt is correctly tensioned, you

should be able to depress it about 5 m/m out

of line.

Q. Gear Reducer

The gear reducer is mounted on the right side

frame of evaporator drum basin to which it is

firmaly secured with four nuts.

The gear reducer bore in which passes the

drum shaft to be driven, has a keyway.

Two fiber keys are used to engage the gear

reducer to the drum shaft, they are in series in

the gear reducer bore, and shaft keyways.

Should the driving strain be excessive, the

two fiber keys will shear.

MAR 78, 108 and 128 are equipped with a

gear reducer having a ratio of 1/570.

MAR 208 and 308 have a gear reducer with a

ratio of 1/525.

The gear reducers are greased for life,

therefore they do not require any maintenance.

R. Water pump / spay bar

Used only on FRESH WATER version the

water pump is mounted on the rear left side of

evaporator drum basin. It supplies water

under gentle pressure to the spray bar

located on top of evaporator drum.

S. Ice Level Control

Could not be necessary - It is subject to

corrosion in marine application. Supplied.

T. ON/OFF switch

The manual start-up or switching of the entire

system requires the attention of the operator

who may instantly keep control of the situation,

therefore it is preferable to any timed switch.

Supplied.

U. Warning Lights

Monitoring unit performance and interventions

of safety controls. Supplied.

V. Master Relay or Contactor

With electric coil connected in series with

safety controls for operation in safe conditions

of condensing and evaporating unit. Supplied.

W.Time Delay Relay

Mar Split series are equipped by two time

relay delay (KT1 and KT2) which control

operating condition of drive motor - gear

reducer and liquid solenoid valve opening.

On each ice maker start up, at first, drive

motor-gear reducer operates and KT1 liquid

solenoid valve delay by 18' its opening,

afterward opens and refrigerant pass through

the same (KT1 Yellow LED steady).

In case of any ice maker devices trip OFF,

KT2 relay keeps drive motor operating farther

for 18' in order to clean up the evaporator

from ice thus to assure easier/freely torque

forcing of the same on next start up (KT2

Yellow LED blinks).

X. Daily timer

Could not be necessary - Can be used in

place of the ice level control and of the ON/

OFF switch. Upon request.

Y. Liquid Line - Solenoid Valve

Necessary to stop refrigerant flow when not

desired. To be located on the liquid line past

the drier is electrically connected to

compressor contactor or relay to stop flooding

the evaporator and suction side during

compressor off periods. Supplied.

Z. Hi and Lo Pressure indicating gauges

Could not be necessary - They are subject to

setting alternations. Not supplied.

Page 27

Page 27

Page 27

The procedures provided in this section are

arranged in order to make specific adjustment

and removal and replacement information easy

to locate.

Read the instructions throughly before performing

any adjustment or removal or replacement

procedures.

1. ADJUSTMENT OF THE AUTOMATIC

EXPANSION VALVE

The end to end frost on evaporator drum is the

result of the correct expansion valve setting.

This valve may be manually regulated by means

of the adjusting stem.

Turning the adjustment to the left counterclockwise, will increase the rate if refrigerant

flow.

Turning the adjustment to the right clockwise, the

refrigerant flow to the evaporator is reduced.

Use hex head wrench for manual adjusting

operations.

WARNING - Be sure the electrical power

supply and water supply are OFF, before

starting any of the following REMOVAL

AND REPLACEMENT procedures as a

precaution to prevent possible personal

injury or damage to equipment.

SECTION V

MAR SPLIT

ADJUSTMENT & REMOVAL & REPLACEMENT PROCEDURES

2. REMOVE AND REPLACEMENT OF

EVAPORATOR DRUM REFRIGERANT

SEALING DEVICES

1. Before removing the refrigerant manifold it is

necessary - at first - to close the valve on

liquid line. Upon low pressure switch cut-off,

the main switch must be put in "OFF" position,

then it is necessary to purge the refrigerant

system.

After these operations, the flare fitting at the

inlet of refrigerant manifold can be

disconnected as shown.

2. Remove the 4 allen screws of refrigerant

outlet fitting to manifold.

3.

Unloose and remove the 6 nuts with respective

washers that secure the refrigerant manifold (1).

4. When removed the refrigerant manifold

unloose and remove one of the three screws

(11) securing the seal mechanism ring to the

drum shaft journal.

5. Fit in place of it the screw of 4 MA supplied in

the kit then tighten its nut.

6. Gradually unloose the two remaining screws

and the nut till release the spring of seal

mechanism.

7. Unloose the last screw to remove the seal

mechanism ring as well as the seal

mechanism S.S. ring and its spring.

8. Withdraw entirely the stainless steel ring (6)

that houses the graphitic seal ring.

Page 28

Page 28

Page 28

9. Check to see the surface conditions of cylinder

shaft journal. It is of extreme importance that

this surface be clean, smooth and polished.

In case of scored surface it is necessary to

stroke on it a very fine sand paper stripe.

Check to see that washer (5) be properly clean

and positioned with keyway to match the key.

10. If necessary replace the 0 rings of the S.S.

ring that houses the graphitic ring.

11. Proceed attentively to examine the graphitic

sulface of the seal ring. If this surface is no

more perfect and optically flat, proceed to

replace the seal ring in the following way.

Lubricate the outer surface of the new seal

ring with compressor oil and place it at the

inferior of the housing ring.

12. Place on drum shaft the steel ring housing

the graphite ring.

13. Mount on drum shaft journal the remaining

portion of seal mechanism (S.S. ring and

spring) (9) then the seal mechanism ring (10).

14. Fit the screw of 4 MA with its nut in one of the

three threaded holes then screw down the

nut in order to compress the spring.

15. When the seal mechanism spring has been

partially compressed fit the other two screws

and full compress the spring by screwing

down gradually the three tightening point.

16. After have tightened the screws unloose the

tie rod screw and replace it with the third one.

17. Clean carefully the inner surface of refrigerant

manifold. Check to see the good condition of

the seal ring (8) and fit it in its seat inside the

refrigerant manifold. Fit on shaft end the

washer (12) which keeps in place the seal

ring (13) inside the refrigerant manifold and

fit inside the manifold the gasket.

18. Position the manifold on the six monting

studs, fit the six mounting nuts and washers

and tighten all them down by means of a 10

mm. wrench.

19. Connect the outlet refrigerant line to the

corresponding port of the manifold and tighten

it with the four head necessed screw.

20. Connect the refrigerant inlet line on its

manifold fitting and tighten the fitting flarenut.

3 REMOVAL AND REPLACEMENT OF

THE DRIVE MOTOR

A. To remove the drive motor assembly:

1) Remove screws and front, top and right side

panels.

2) Slid-off V belt from motor pulley.

3) Unloose and remove hex head screw

securing the pulley to motor shaft.

4) Disconnect wire leads to motor.

5) Remove two hex head bolts, lockwashers

and washer, and nut which attach the sleigh

support plate of motor to the side frame of

evaporator drum basin.

6) Lift the sleigh plate with the drive motor out

of the Chassis.

7) Unloose and remove 4 Nuts securing the

motor to the sleigh plate.

B. To replace the Drive Motor Assembly reverse

the removal procedure.

4. REMOVAL AND REPLACEMENT OF

GEAR BOX

A. Remove screws and front, top and right side

panels.

1) Slid-odd V Belt from gear box pulley.

2) Remove screw securing pulley on gear box

input shaft.

3) Remove four nuts and washers which secure

the gear box to the evaporator basin side

frame.

4) With a mallet hit a bit the gear box to create

some looseness.

5) With the help to two screw driver inserted

between basin wall and flanged end of gear

box, force the gear box to clear away from

basin wall if you encounter an excessive

resistance in this. If better to use a 2-jaws

Puller.

6) When gear box is cleared away from the wall

where it is mounted, pull it out from cylinder

shaft.

A. To install the Gear Box Assembly reverse

the removal procedure taking care to center

keyway of gear box bore to keys on cylinder

shaft.

5. REPLACEMENT OF FIBER KEYS

A. The replacement of fiber keys is necessary

only when the keys are broken, so that they

do not engage the gear motor with the

evaporator drum drive shaft.

In practical terms, the gear box does not

drive the evaporator drum.

B. To reach the fiber keys to be replaced it is

necessary to remove the complete gear box.

For this operation perform all steps at point

12.

Page 29

Page 29

Page 29

SECTION VI

MAINTENANCE & CLEANING INSTRUCTIONS

1. GENERAL

The periods and procedure for maintenance and

cleaning are given as guides and are not to be

construed as absolute or invariable.

Cleaning especially will vary depending upon

local water conditions and the ice volume

produced and each ice maker must be maintained

individually in accordance with is own particolar

location requirements.

2. ICEMAKER/CONDENSING UNIT

THE FOLLOWING MAINTENANCE MUST BE

SCHEDULED AT LEAST TWO TIMES PER

YEAR ON THIS ICE MAKER. CALL YOUR AUTHORIZED SCOTSMAN SERVICE AGENCY.

1. Check and clean water line Strainer.

2. Remove top panel and depress the float to

ensure that a full stream of water enters both

Float & Drum Reservoirs.

3. Check that the ice maker cabinet is level in

side-to-side and front-to-rear directions.

4. Check that the water level in the Drum basin

is high enough to surround the wanted portion

of revolving drum.

5. Clean the water reservoir and exterior of the

drum assembly using a solution of

SCOTSMAN Ice Machine Cleaner. Refer to

procedure VI-3, CLEANING ICE MAKER.

NOTE. Cleaning requirements vary

according local water conditions and

individual user operation.

6. When doubtful about refrigeration charge,

check gauge for compressor head pressure

according to model technical specification.

7. Check gauge for Suction Line Pressure

which varies depending upon models, inlet

water temperature and ambient temperature.

8. Check drive motor operation.

Normal operating temperatures are about

60°C (160°C) which is hot to touch. Check

with amperometer Amps drawn.

9. Check V belt for concealed signs of wear and

that has the correct tension. Check pulleys

alignements and also that drive motor and

gear box hold down bolts are tight enough.

10. Make sure that water lines in water cooled

condenser are free from any excess of water

minerals: otherwise arrange to clean the

tubes with a power driven wire brush or

running through it a weak acid solution made

with 20 percent of hydrocloric acid.

11. Check for refrigerant leaks and for proper

frost line, which should frost out of

accumulator at least half way to the

compressor and in some areas, back to

service valve. Check for dryness of system

through moisture indicator if any.

12. Check for water leaks. Tighten drain line

connections. Pour water down drain to be

sure that drain line is open and clear.

13. Check the quality of ice. Ice flakers should be

dry and have a thickness gauge of about

2 m/m.

14. Check compressor oil level through sight

glass. Stop unit operation and after two/three

minutes see that oil level is 2/3 millimeters

above center line of sight glass.

15. Be sure of proper position and condition of

plexiglass chute on spout opening.

3A.CLEANING INSTRUCTION

(MAR 78-108-128)

1. Disconnect power front the unit.

2. Remove screws and top panel

3. Remove evaporator cover panel

4. Close water inlet valve located at evaporator

side onto water inlet line.

5. Press water hose clamp in order to release it

Page 30

Page 30

Page 30

6. Lift the water pump up to release it from

sliding holding screw

7. Carefully push little bit water sump bracket

in ordet to release it

8. Lift the water reservoir up for a while and

bend it in order to dump contained liquid

9. Push water hose quick fitting ring

......to release the nylon tube

......and remove water sump from evaporator basin

10. By the help of flat screwdriver easily open

little bit float valve holding arms and remove

it from holders

11. Check nozzle orifice condition. In case of

obstruction clean it by pin

12. Prepare a solution in a bucket by mixing for

1/2 liter of SCOTSMAN CLEANER with

5 liters of warm (40-50°C) water.

WARNING: When using any chemical,

wear hands protection (gloves).

SCOTSMAN Ice Machines Cleaner contains

phosphoric and Hydroxiacetic acid. These

compound are corrosive and may cause

burns if swallowed. DO NOT induce

vomiting. Give large amount of water or

milk. Call Physician immediately. In case

of external contact, flush with fresh water.

KEEP OUT OF THE REACH O CHILDREN.

Page 31

Page 31

Page 31

13. Dip the water reservoir removed at #7 into the

cleaning solution and clean it by sponge and/

or suitable brush.

14. Once reservoir is duly cleaned, dump float

valve in the solution and remove any kind of

scale or mineral deposit then rinse the same

by fresh water.

15. Place again float valve into its bracket

16. Reinstall water sump with float valve.

17. Reinstall water pump removed at #6.

18. Reconnect water inlet hose removed at #5.

19. Slowly pour the solution mixed at #12 in the

water reservoir till to 2 cm (7,87") below top

edge.

20. Plug IN the ice maker and let the unit in

operation for about 10 minutes.

21. Disconnect again unit from power.

22. Repeat again from #5 to #9 thus to dump

reservoir from chemical solution and later

rinse all parts by fresh water.

23. Reinstall all removed part from #9 to #5.

24. Prepare as per #12 using SCOTSMAN

sanitizer rather then cleaner. Possible

sanitizing solution could be by mixing 1,5 cl

(5 oz) of sanitizer with 5 lt (1 gallon)

NEVER MIX CLEANING WITH SANITIZING

SOLUTION

25. Pour sanitizing solution in the water reservoir.

26. Plug IN again the unit and let the sanitizing

solution re-circulating for about 5 minutes.

27. Repeat #5 to #8.

28. Lift the water sump up for a while in order to

dump sanitizing solution stored in the same

then relocate the same.

29. Reinstall water pump and connect water

inlet hose.

30.

Open water inlet valve previously closed at #4.

31. Ice produced during the first 5 minutes must

be thrown away in order to avoid any possible

chemical contamination.

CAUTION - NEVER use ice produced from

any chemical solution. Be sure none falls

into storage bin.

3B.CLEANING INSTRUCTION

(MAR 208-308)

1. Disconnect power front the unit.

2. Remove screws and top panel

3. Remove evaporator cover panel

4. Close water inlet valve located at evaporator

side onto water inlet line.

Page 32

Page 32

Page 32

5. Bend down the plastic hose and drain out rthe

water from the water sump than move it up

again.

6. Prepare a solution in a bucket by mixing

1 liter of SCOTSMAN CLEANER with 10

liters of warm (40-50°C) water.

WARNING: When using any chemical, wear

hands protection (gloves).

SCOTSMAN Ice Machines Cleaner

contains phosphoric and Hydroxiacetic

acid. These compound are corrosive and