Page 1

Page 1

Page 1

Scotsman Ice Srl

Via Lainate, 31 - 20010 Pogliano M.se - Milano - Italy

Tel. +39-02-93960.1 (Aut. Sel.)- Telefax +39-02-93550500

Direct Line to Service & Parts:

Phone +39-02-93960350 - Fax +39-02-93540449

Website: www.scotsman-ice.it

E-Mail: scotsman.europe@scotsman.it

ISO 9001 - Cert. n. 0080

SERVICE MANUAL

MAR 56

MAR 76

MAR 106

MAR 126

MAR 206

MAR 306

Scale ice machines

MS 1000.66 - REV. 06/2018

Page 2

Page 2

Page 2

FOREWORD

The "MAR" ice makers make flake ice of "scale"

type which is flat, hard dry and sub-cooled, giving

to it an exceptional staying power for multiple

chilling operations.

The design simplicity accounts for the confidence

in MAR scale ice machines. Their ice making

system has only one sealed moving part, resulting

in a minimum of maintenance operations for

continuous reliable machine service.

Ice is discharges through a large opening on the

back of unit cabinet, when mounted on top of the

refrigerated room, ice is gravity fed to storage

area.

Rugged, solid, heavy duty, the stainless steel

MAR cabinet has removable panels that facilitate the accessibility to mechanical and electrical

parts. A console panel with lights monitoring

water flow pressure, and temperature operating

refrigerant pressure and motors overloading

foreworn the system malfunction before becoming

major trouble.

We suggest you to take time now to read this

manual which contains a lot of valuable

informations on the MAR ice making system.

If you have any further queries regarding the care

or operation of the machine, please contact:

NOTE: Whenever writing please state model no. and serial no. of the machine

ICE SYSTEMS

®

SCOTSMAN - EUROPE - FRIMONT SPA

Via Puccini, 22 - 20010 Bettolino di Pogliano (Milano) Italy

Tel. +39-02-93960.1 (Aut. Sel.)- Telefax +39-02-93550500

Direct Line to Service & Parts:

Phone +39-02-93960350 - Fax +39-02-93540449

Website: www.scotsman-ice.com

E-Mail: scotsman.europe@frimont.it

®

Page 3

TABLE OF

CONTENTS

Foreword page 2

Table of contents 3

Specifications - MAR 56 - 76 - 106 - 126 4-5-6

Specifications - MAR 206 - 306 7-8

Remote cond. 9

Section I GENERAL INFORMATIONS & INSTALLATIONS

Description 10

Unpacking & Inspection 10

Location & Levelling 11

Electrical connections 12

Water supply & Drain connections 12

Remote air cooled condenser installation 13

Ice level control 14

Ice chute 15

Final check list 15

Unit installation practice 15-16

Section II OPERATING INSTRUCTIONS

Start-up 17

Water & Refrigerant circuit 18-19

Section III PRINCIPLES OF OPERAZION - HOW IT WORKS

Ice maker 20

Electrical / Refrigeration 21-22-23

Refrigerant charge 24

Mechanicals 24

Section IV ADJUSTMENT & REMOVAL & REPLACEMENT

PROCEDURES

Water regulator assy 25

Automatic expansion valve 25

V Belt change on pulley 25

Compressor replacement 25

Water cooled condens. replacement 26

Water regulator replacement 26

Drier replacement 26

Drive motor replacement 27

Gear Box replacement 28

Fiber key replacement 28

Section V MAINTENANCE & CLEANING INSTRUCTIONS

General 29

Ice maker 29

Cleaning instruction 29-30-31-32

Section VI SERVICE DIAGNOSIS

Ice making - Refrigerant system 33-34

Section VII WIRING DIAGRAMS 35

MAR 56-76-106-126 - Wiring diagram 36÷38

MAR 206-306 - Wiring diagram Fig. 1 e 2 39÷42

Page 4

Page 4

Page 4

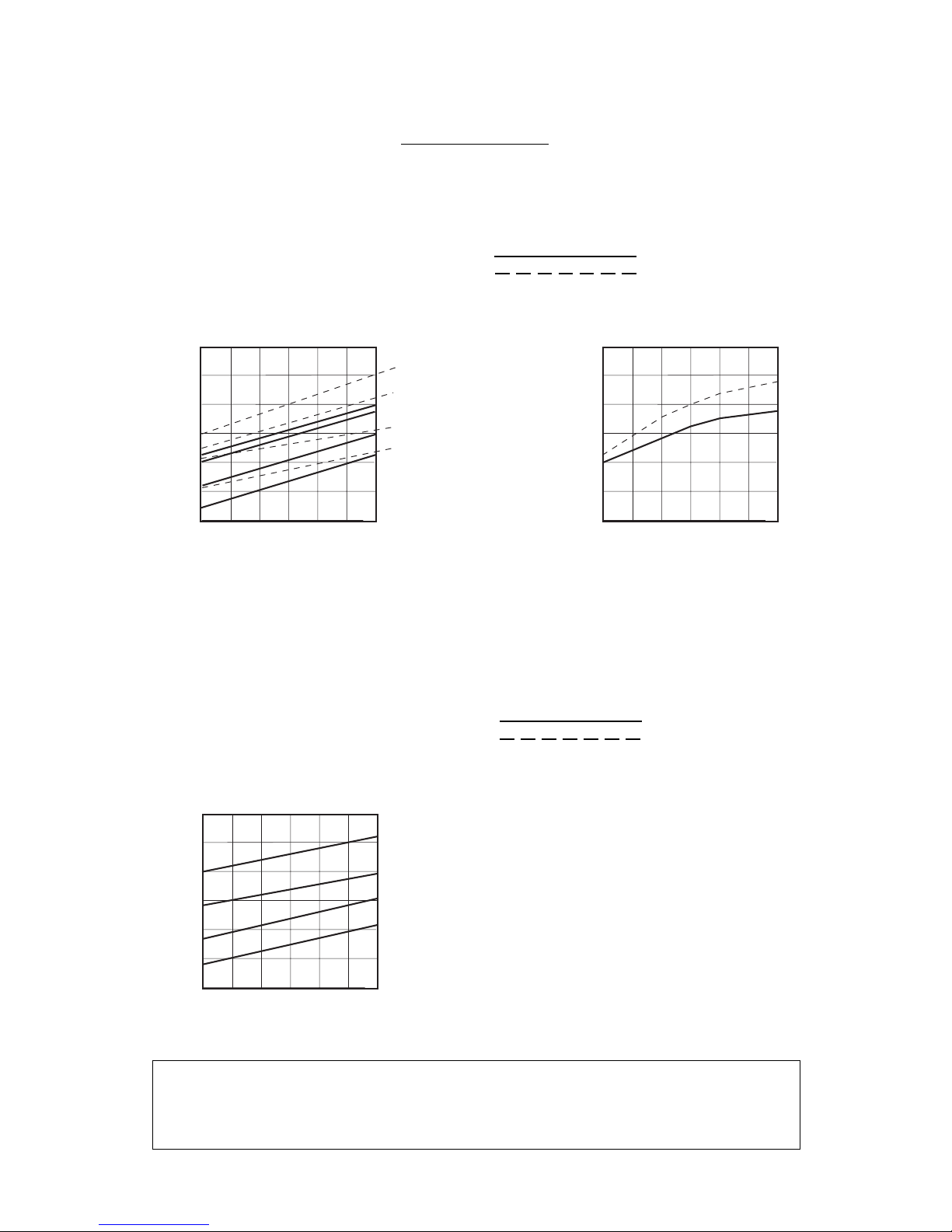

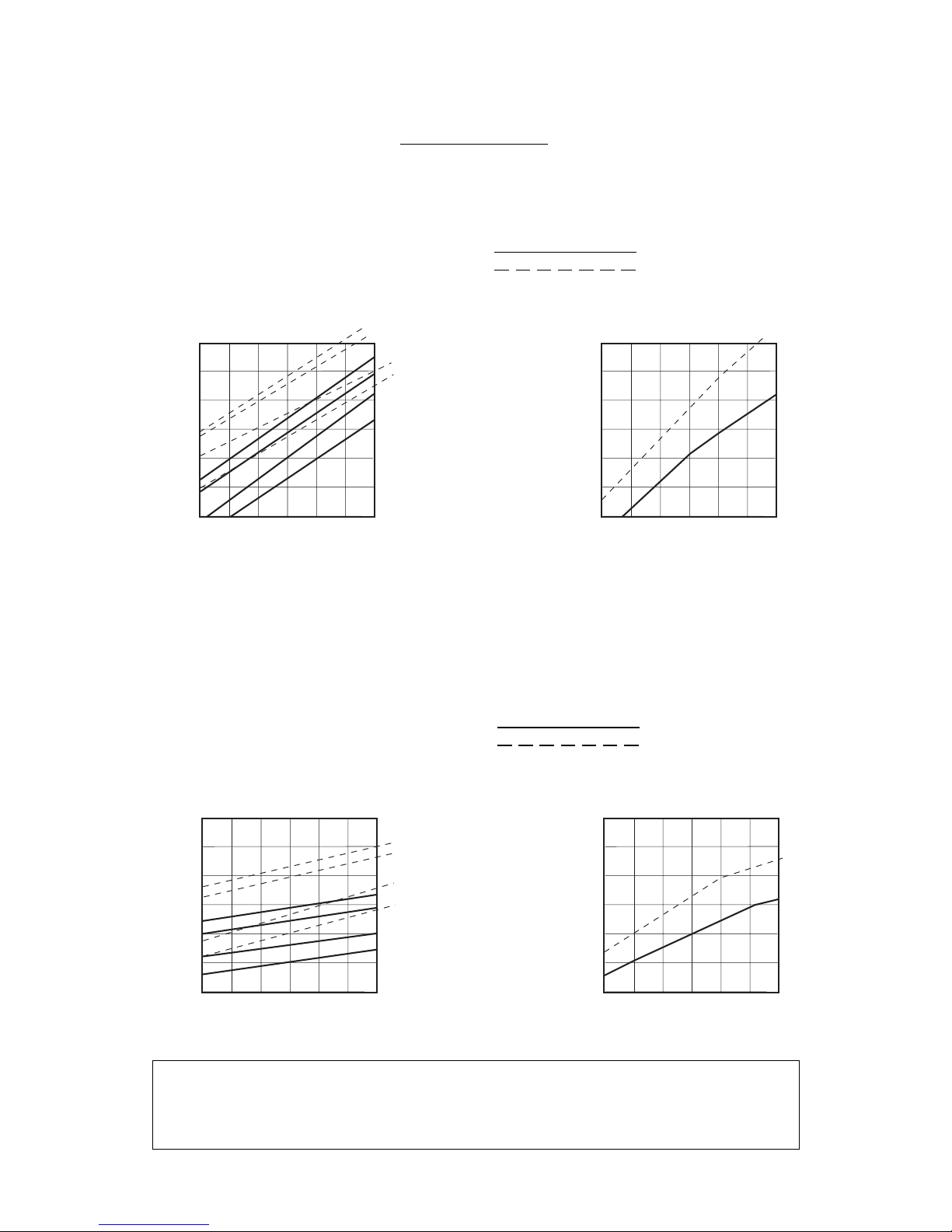

SPECIFICATIONS

NOTE. Daily ice capacity is directly related to condenser air water inlet temperature, water

temperature to make ice - and age of machine.

To keep your SCOTSMAN MAR performing at is maximum capacity, it is necessary to perform

periodic maintenance as outlined on page 29 of this manual.

MAR 56

AIR & WATER COOLED MODELS

THICK SCALE ICE

THIN SCALE ICE

ice making capacity

500

450

400

350

300

250

200

Kg./24 h

38

°C

32 27

21

15

°C

10

21

32

38

o

AIR COOLED MODELS

WA TER TEMPERATURE

AMBIENT TEMPERATURE

ICE PRODUCED PER 24 HRS.

32

38

WATER COOLED MODELS

10 5

10

21

500

450

400

350

300

250

200

Kg./24 h

38

°C

32 27

21

15

°C

DE 10 A' 38

o

WA TER TEMPERATURE

AMBIENT TEMPERATURE

ICE PRODUCED PER 24 HRS.

10 5

MAR 76

AIR & WATER COOLED MODELS

ice making capacity

THICK SCALE ICE

THIN SCALE ICE

AIR COOLED MODELS

540

500

460

420

380

340

300

Kg./24 h

38

°C

32 27

21

15

°C

o

WA TER TEMPERATURE

AMBIENT TEMPERATURE

ICE PRODUCED PER 24 HRS.

10 5

10

21

32

38

Page 5

Page 5

Page 5

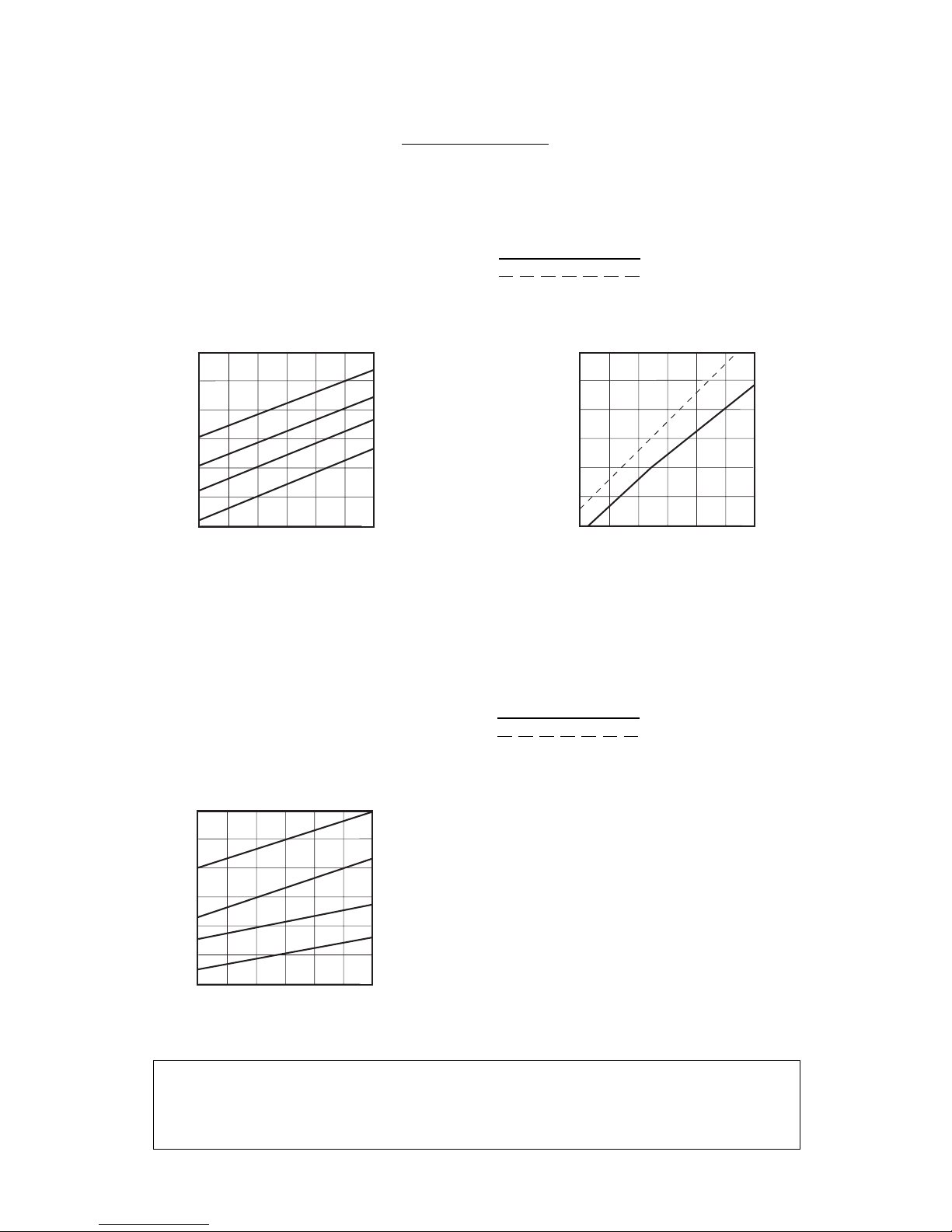

SPECIFICATIONS

NOTE. Daily ice capacity is directly related to condenser air water inlet temperature, water

temperature to make ice - and age of machine.

To keep your SCOTSMAN MAR performing at is maximum capacity, it is necessary to perform

periodic maintenance as outlined on page 29 of this manual.

MAR 106

AIR & WATER COOLED MODELS

THICK SCALE ICE

THIN SCALE ICE

ice making capacity

MAR 126

AIR & WATER COOLED MODELS

ice making capacity

THICK SCALE ICE

THIN SCALE ICE

AIR COOLED MODELS

750

700

650

600

550

500

450

Kg./24 h

38

°C

32 27

21

15

°C

o

WA TER TEMPERATURE

AMBIENT TEMPERATURE

ICE PRODUCED PER 24 HRS.

10 5

10

21

32

38

WATER COOLED MODELS

800

750

700

650

600

550

500

Kg./24 h

38

°C

32 27

21

15

°C

DE 10 A' 38

o

WA TER TEMPERATURE

AMBIENT TEMPERATURE

ICE PRODUCED PER 24 HRS.

10 5

AIR COOLED MODELS

1000

950

900

850

750

650

600

Kg./24 h

38

°C

32 27

21

°C

o

WA TER TEMPERATURE

AMBIENT TEMPERATURE

ICE PRODUCED PER 24 HRS.

10

21

32

38

Page 6

Page 6

Page 6

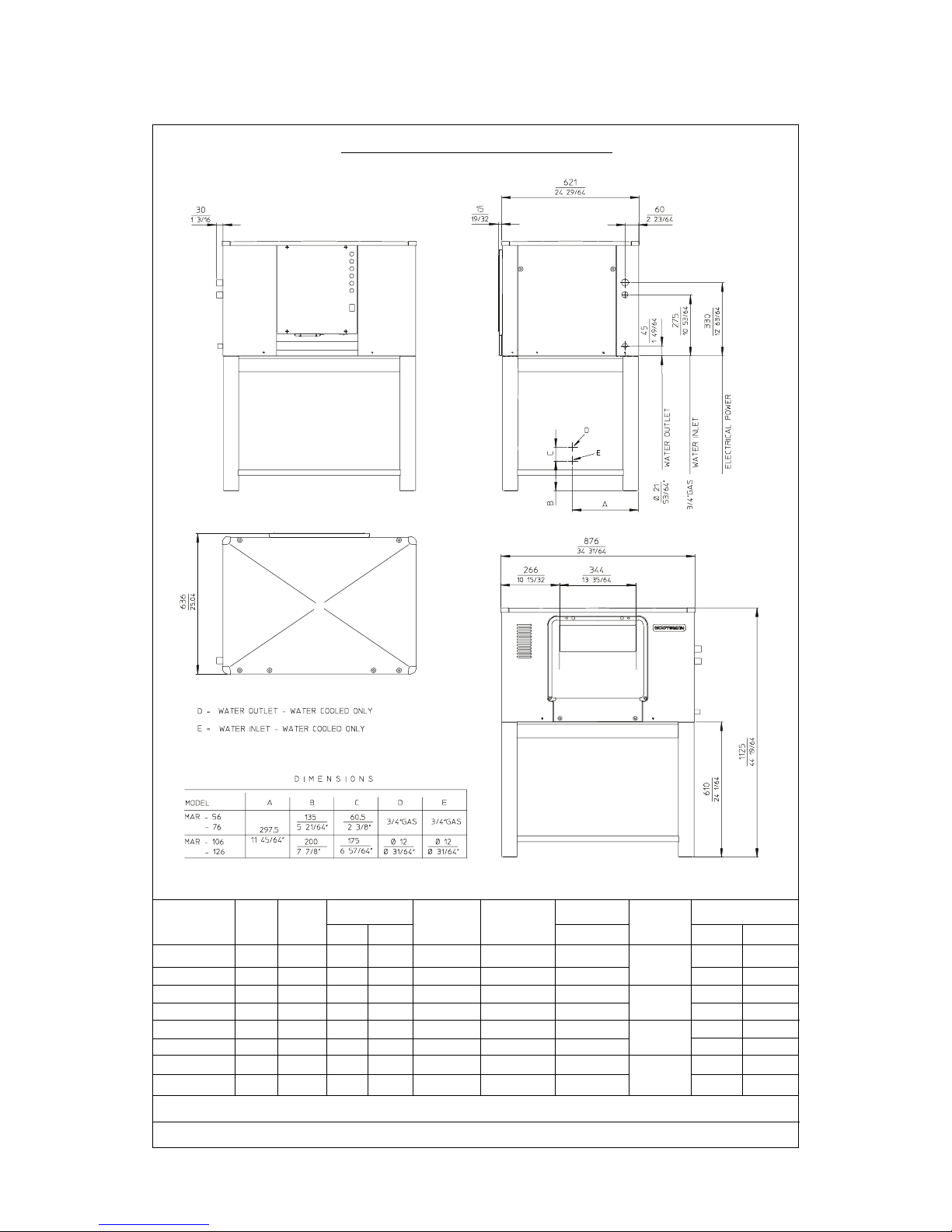

MAR 56-76-106-126 - SPECIFICATIONS

BASIC ELECTRICALS: 400/50/3N

* at 21 °C amb. / 15 °C water temp.

Water req. (l/h) Total Amps.

MODELS Finish

* Cond. Prod. 400 V kg. lbs.

MAR 56 AS Air 2 16 2.2 5 x 1.5 2.7 Stainless 194 427

MAR 56 WS Water 2 225 16 2.2 5 x 1.5 2.7 Steel 174 383

MAR 76 AS Air 2.5 21 2.5 5 x 1.5 2.7 Stainless 204 450

MAR 76 WS Water 2.5 300 21 2.5 5 x 1.5 2.7 Steel 201 442

MAR 106 AS Air 4 30 3.5 5 x 1.5 5 Stainless 221 487

MAR 106 WS Water 4 480 30 3.5 5 x 1.5 5 Steel 217 417

MAR 126 AS Air 4.5 41 4.5 5 x 1.5 6.5 Stainless 226 497

MAR 126 WS Water 4.5 41 4.5 5 x 1.5 6.5 Steel 222 488

Cond. Compr. Power Minimum

Unit (HP) (KW) wire size (mm)

Shipping weight

Page 7

Page 7

Page 7

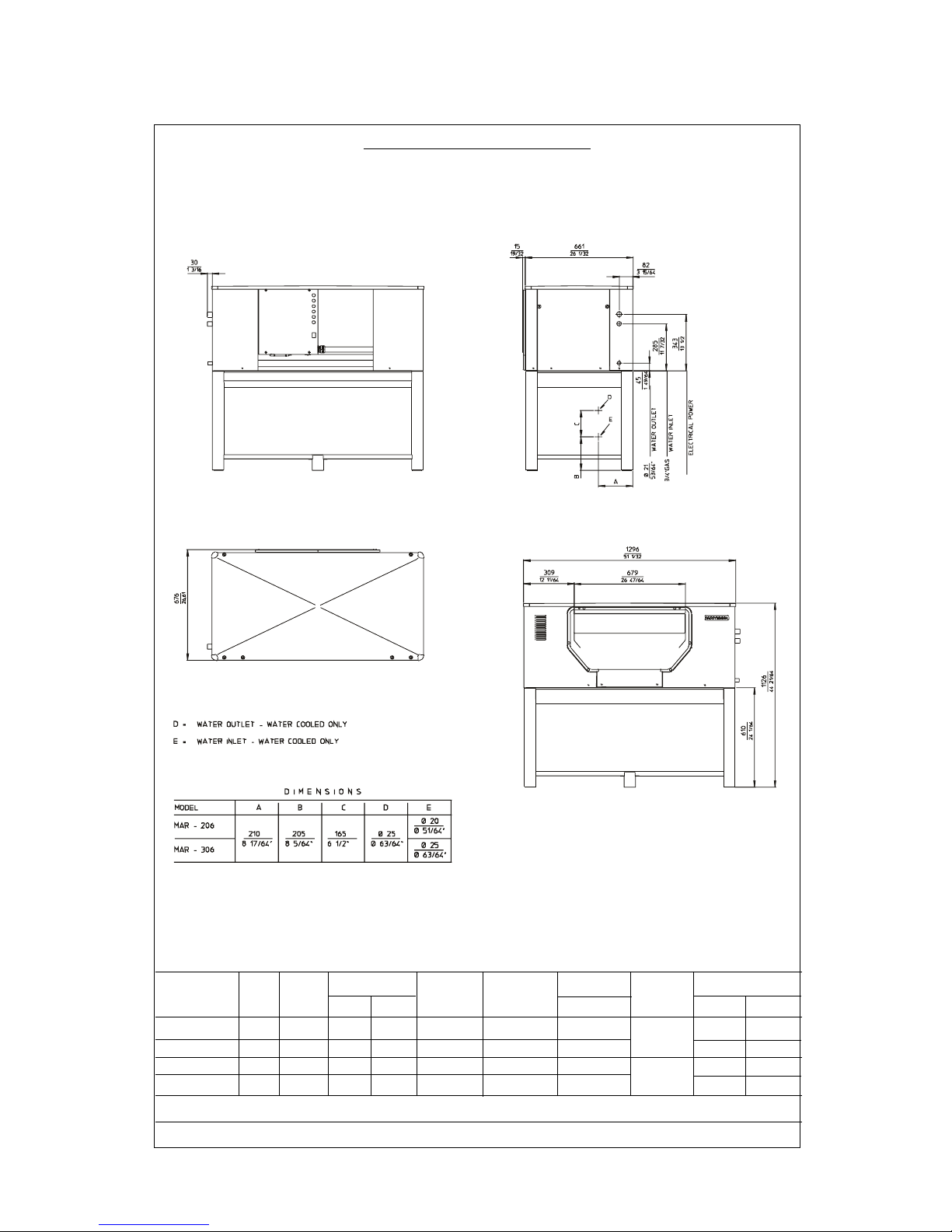

SPECIFICATIONS

NOTE. Daily ice capacity is directly related to condenser air water inlet temperature, water

temperature to make ice - and age of machine.

To keep your SCOTSMAN MAR performing at is maximum capacity, it is necessary to perform

periodic maintenance as outlined on page 29 of this manual.

MAR 206

AIR & WATER COOLED MODELS

ice making capacity

THICK SCALE ICE

THIN SCALE ICE

1700

1600

1500

1400

1300

1200

1100

Kg./24 h

38

°C

32 27

21

15

°C

32

38

AIR COOLED MACHINES

WA TER TEMPERATURE

AMBIENT TEMPERATURE

ICE PRODUCED PER 24 HRS.

32

38

WATER COOLED MACHINES

10 5

10

21

1900

1800

1700

1600

1500

1400

1300

Kg./24 h

38

°C

32 27

21

15

°C

DE 10 A' 38

o

WA TER TEMPERATURE

AMBIENT TEMPERATURE

ICE PRODUCED PER 24 HRS.

10 5

10

21

MAR 306

AIR & WATER COOLED MODELS

ice making capacity

2600

2400

2200

2000

1800

1600

1400

Kg./24 h

38

°C

32 27

21

15

°C

32

38

AIR COOLED MACHINES

WA TER TEMPERATURE

AMBIENT TEMPERATURE

ICE PRODUCED PER 24 HRS.

32

38

WATER COOLED MACHINES

10 5

10

21

2800

2600

2400

2200

2000

1800

1600

Kg./24 h

38

°C

32 27

21

15

°C

DE 10 A' 38

o

WA TER TEMPERATURE

AMBIENT TEMPERATURE

ICE PRODUCED PER 24 HRS.

10 5

10

21

THICK SCALE ICE

THIN SCALE ICE

Page 8

MAR 206-306 - SPECIFICATIONS

BASIC ELECTRICALS: 400/50/3N

* at 21 °C amb. / 15 °C water temp.

Water req. (l/h) Total Amps.

MODELS Finish

* Cond. Prod. 400 V kg. lbs.

MAR 206 AS Air 5 69 7 5 x 2.5 17 Stainless 374 824

MAR 206 WS Water 5 1200 72 7 5 x 2.5 10 Steel 369 813

MAR 306 AS Air 10 88 10 5 x 4 20 Stainless 383 844

MAR 306 WS Water 10 1600 94 10 5 x 4 20 Steel 413 910

Cond. Compr. Power Minimum

Unit (HP) (KW) wire size (mm)

Shipping weight

Page 8

Page 9

Page 9

Page 9

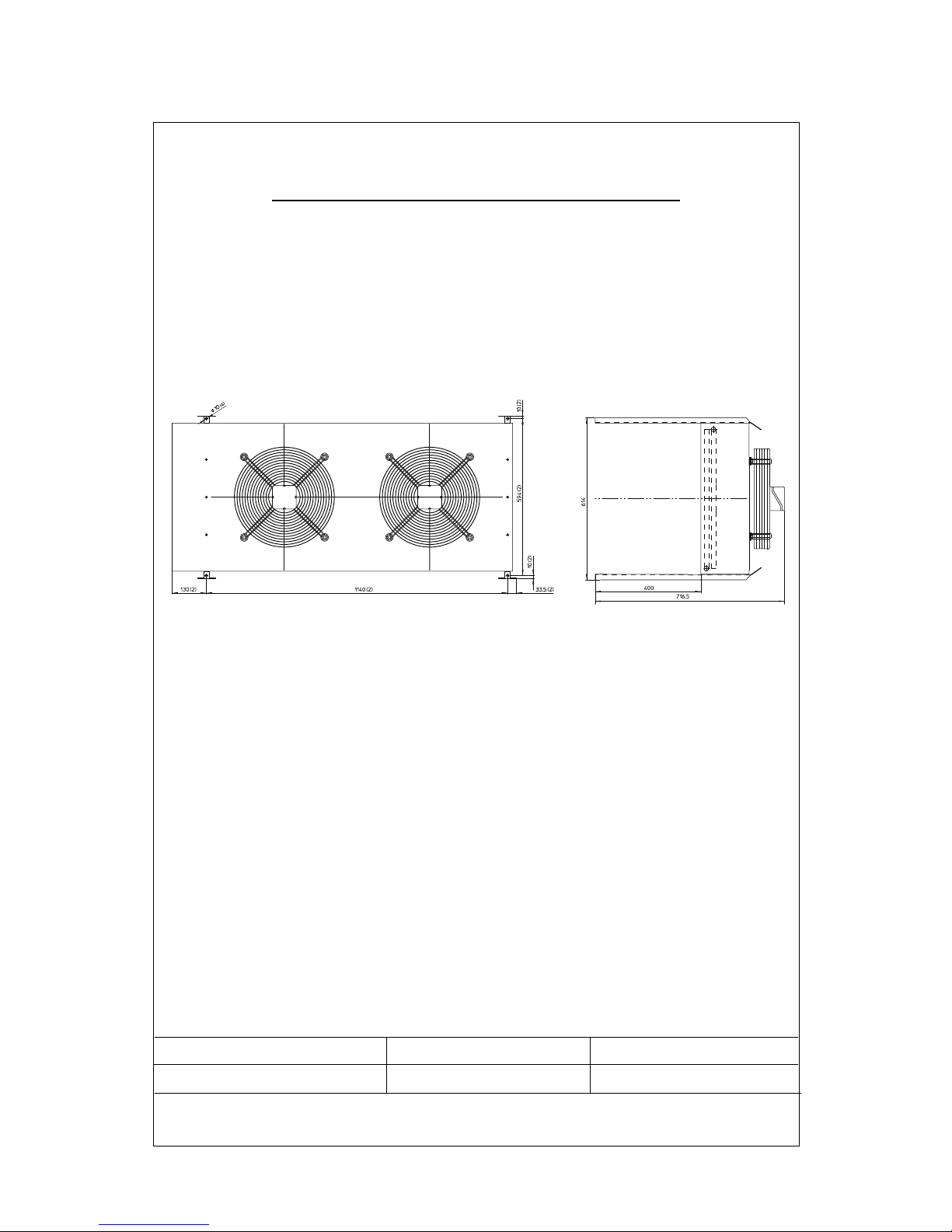

CONDENSER CAPACITY FAN MOTOR AIR FLOW

20 KW - 17200 Kcal/h 230/50/1 V - 0,8 A 4320 m3/h

MAR 306 REMOTE CONDENSER

TECHNICAL SPECIFICATIONS

Page 10

Page 10

Page 10

SECTION I

GENERAL INFORMATION & INSTALLATION

1. DESCRIPTION

An attractive compact cabinet of stainless steel

with control panel lights on the front. All panels

are removable to allow easy access to electrical

and mechanical components for cleaning and

maintenance.

Sealed Refrigeration System

To provide quite efficient operation of the ice

maker, the compressor is mounted on rubber

cushions. The water cooled models have a tube

within tube condenser with water regulation valve for correct condensing water flow. The air

cooled models, except the MAR 306 have a built

in condenser in copper and aluminium with the

fan motor controlled by pressure control. The

evaporator drum is powered by a separate drive

motor connected by a V-belt and pulley system to

a double gear box. The refrigerant used is R 404a

controlled by automatic expansion valve.

Storage Bin or Ice Room

Since the MAR Scale is a continuous flow type

ice maker and does not have its own attached

storage bin, it is necessary to use an auxiliary bin

or a pre-fabricated ice room for appropriate ice

storage.

Ice storage situations are of two kinds:

a) Short term storage

b) Extended terms storage

Being, as stated, scale ice made by MAR

machines flat, dry and subcooled, therefore with

the tendency to stick toghether, particular

attention is required for proper ice storage

conditions for better ice handling. An insulated

ice storage bin or rooms is always required, then

according to ice end use application, this can be

refrigerated on non-refrigerated.

Also a weight volume ratio of 2,1 cu. mt. per

ton, must be taken into consideration for correct

ice storage.

a) Non-refrigerated room for short term

storage.

The scale ice is produced continuously for 24

hours per day, whereas the use period is

generally for no longer than 8 hours per day.

Therefore storage facilities should be provided

to accomodate a minimum of 16 hours of

production, this means that every scale ice

machine must be installed with a properly

insulated storage room which should have a

minimum capacity of 2/3 the daily ice

production.

With a well insulated room and duly subcooled

scale ice, the limited losses of heat throught

the walls of a properly designed room with

adequate arrangements, are largely offset,

and excess melting will not occur. In most

situations where whole quantity of ice produced

is being used on a daily basis, it is not necessary

to provide cooling for the ice storage room.

b) Refrigerated room for extended storage

and long distance conveying.

When scale ice is to be transported at a

considerable distance, such as aboard fishing

vessels, or in locations with normal ambient

temperatures conditions, or when used in

industrial plants where demand is intermittent,

its subcooling power must be absolutely

preserved in the storage bin by a proper

cooling system keeping air temperature at a

pre-established and constant value. The ideal

ice storage room is the type with mechanically

refrigerated jacket space surrounding the ice

bin. Good practice calls for an ice storage

capacity of about two times the daily ice

machines production with an inside temperature of -6°C minimum (20°F).

2. UNPACKING AND INSPECTION

1. Call your authorized SCOTSMAN Distributor

od Dealer for proper installation.

2. Visually inspect the exterior of the shipping

container and skid and any severe damage

noted should be reported to the delivering

carrier; and a concealed damage claim filled

subject to internal inspection, with carrier

representative present.

3. Remove the packing and remove the shipping

bolts and the shipping base or skid.

4. When necessary, install the leg levellers in

the cabinet base sockets; then, raise the

cabinet to the upright position.

5. Remove screws and shipping tapes and all

doors and service panels from the cabinet and

inspect for any concealed damage.

Notify carrier of any concealed damage claims

as stated in step 2 above.

6. Remove all internal support packing, tape

and wires in machinery compartment.

7. Check that refrigerant lines do not rub or

touch lines or surfaces and that fan blades, if

any, moves freely.

8. Check that compressor is snug on all mounting

pads.

9. Use clean damp cloth or disposable paper

wiper to wipe clean the exterior surface of the

cabinet.

Page 11

Page 11

Page 11

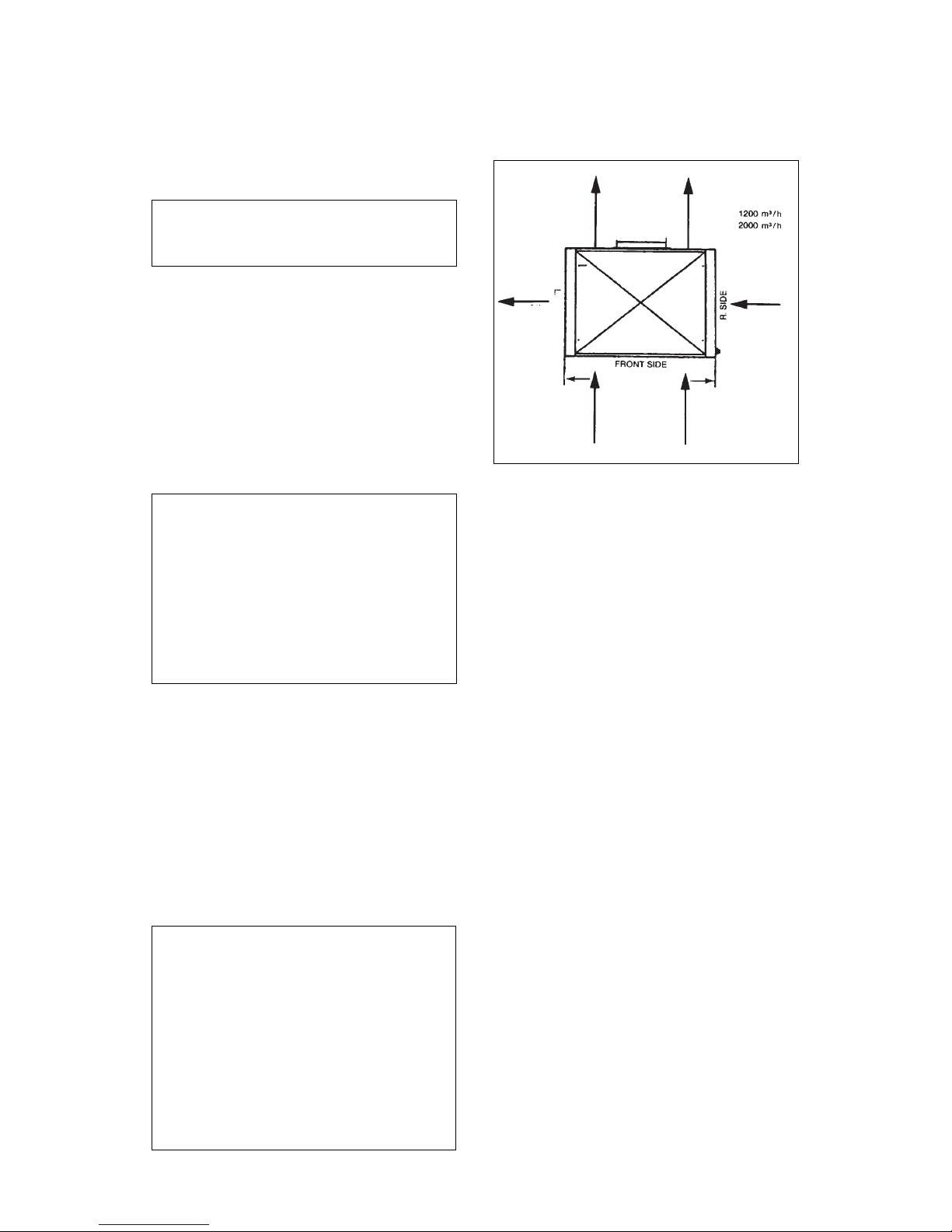

CONDENSING AIR FLOW SCHEMATIC

2. Erection - For elevations in excess of four

feet or in close quarters, chain falls of fork lift

truck should be used. For location under four

feet, the use of skid boards and rollers is practical.

3. Machine Site - When selecting the permanent

location of air cooled machines, consideration

must be given to volume size of the room and to

ventilation facilities for easy heat removal around

the machine.

In doing this it worths to take on account that:

– MAR 56 AS - has a condenser heat rejection

of 3000 Kcal/hr and fan motor draws air for

1200 m3/h.

– MAR 76 AS - has a condenser heat rejection

of 4900 Kcal/hr and fan motor draws air for

1200 m3/h.

– MAR 106 AS - has a condenser heat rejection

of 7500 Kcal/hr and the two fan motors draw

air for 1200 m3/h each.

– MAR 126 AS - has a condenser heat rejection

of 9750 Kcal/hr and the two fan motors draw air

for 1200 m3/h each.

– MAR 206 AS - has a condenser heat rejection

of 11000 Kcal/hr and the two fan motors draw

air for 2000 m3/h each.

– MAR 306 AS - has a condenser heat rejection

of 17200 Kcal/hr and the two fan motor draw air

for 4320 m3/h in total.

4. Position the MAR in the selected permanent

location level the cabinet on both the left-to-right

and front-to-rear directions. The levelling legs

can be adjusted with an opened wrench.

(See unit layout and dimensions at page 6 and 8).

10. See DATAPLATE on the cabinet base and

check that the location source voltage

corresponds with the voltage specified on

the dataplate.

CAUTION - Unproper voltage supplied to

the icemaker will void your parts

replacement program.

11. Remove the Manufacturer's registration Card

from its envelope and fill in all spaces

including: Model Number and serial Number

taken from the aluminium plate located on

the front of the Chassis base, with Front

Panel removed.

Forward the completed, self addressed,

registration card to the Scotsman Europe

Frimont Factory.

3. LOCATION AND LEVELLING

WARNING - The MAR Flakers are NOT

designed for outdoors installation where

air temperature are below 5°C (40°F) or

above 40°C (100°F) and the water temperature is below 5°C (40°F) or above 35°C

(95°F).

Extended periods of operation at

temperatures exceeding these limitations

will constitute misuse, under the terms of

the SCOTSMAN Manufacturer's limited

warranty coverage.

1. Stands - A special stands should be built if

the machine is located beside the bin.

Care should be exercised in making the

stand strong enough to support the weight.

In designing the stand plan for the servicing

of the machine from front, top and sides.

It is also possible to locate the machine on

top of the bin. Care should be used in selecting

a bin that has been specially reinforced.

Standard bins are usually not sufficiently

reinforced for this purpose. An unsteady

platform will cause excessive vibration.

Specially built bins can provide proper support

and allow for a servicing platform.

WARNING - Air Cooled version of MAR 76

,

MAR 106, MAR 126 and MAR 206 have the

condensing air exhaust throughout the

lower rear area (ice spout side) therefore

it is necessary to avoid to position the ice

maker with the rear side against any sort

of wall that will prevent proper warm air

dissipation.They must

have on their rear

side an air gap of 200 mm.

MAR 56 has the

air cooled condenser on the right side

while MAR 306 has a se-parate remote air

cooled condenser. (See instructions for

remote condenser at 6).

MAR 76-106-126

MAR 206

MAR 56

MAR 76-106-126

MAR 206

MAR 56

SIDE

MAR 106 MAR 206 -

Page 12

Page 12

Page 12

4. ELECTRICAL CONNECTIONS

The machine has been wired ready for electric

connections. See nameplate for current

requirements to determine wire size to be used

for electrical hook-up. The MAR flaker requires a

solid earth ground wire. See wiring diagram.

Be certain the unit is connected to its own electrical

circuit and individually fused.

The maximum allowable voltage variation, should

not exceed ten percent of the nameplate rating,

even under starting conditions.

Low voltages can cause erratic operation and

may be responsible for serious damage to the

overload switch and motor windings.

All external wiring should conform to the National,

State and local electrical permit and services of

a licensed electrician will be required.

WARNING - The compressor is equipped

with a crankcase heater which has to be

energized even when the ice maker is

switched-off. So, make sure to connect

the unit with the compressor crankcase

heater constantly energized. After long

inoperative periods remember to give

current to the heater 4 hours before the

ice-maker start-up.

Fuse protection of the unit should be made as

follows:

MAR 56-76-106-126-206 - 3x16 Amps/400V

MAR 306 WS - 3x24 Amps/400V

MAR 306 ASR - 3x32 Amps/400V

WARNING - Drum drive motor is threephases type. At unit start up, correct wiring

is assured by 3 phases monitoring relay

at power in. In addition proper drum

rotation speed is monitored by a Hall

Effect sensor. In case the drum is not

rotating at all or it rotates too slow (less

then 1/4 turn every 30 seconds) a special

Electronic Control trips the unit OFF so to

avoid that compressor can operate with

the drum OFF (in case of fiber keys

, drive

motor or gear reducer breakage).

In case of any field drive motor replacement,

care must be taken to its wiring, checking the

correct evaporator drum rotation that MUST

be toward ice blade.

In case of wrong evaporator drum rotation,

turn the unit OFF and exchange two phases

connection at drive motor control box.

5.

WATER SUPPLY AND DRAIN CONNECTIONS

Separate water supplies are recommended.

A.Evaporator or ice making supply water should

be run through a hand shut-off valve before

entering unit. Evaporator supply water

connection has a 3/4" male pipe fitting. This

line also has factory installed water strainer

internally mounted. Incoming water goes

through the float reservoir and then to the

drum reservoir. Connect to a good cold water

supply with minimum 1/2 O.D. line. A check

valve on this line will be required in some

cases depending on local plumbing codes.

The recommended minimum water pressure

is 1 bar (14 Psi). Do not operate this unit with

fresh water supply below 1 bar (14 Psi).

Maximum water pressure 5 bar (70 Psi).

B.The condenser water supply line connects to

the following fitting sizes:

MAR 56 - 76

3/4" gas male

MAR 106 - 126 12 mm O.D. fitting

MAR 206 20 mm 0.D. fitting

MAR 306 25 mm

Water supply line size must be adequate to

water flow which, at 15°C temperature water, is:

225 lt/hr for MAR 56

300 lt/hr for MAR 76

480 lt/hr for MAR 106

lt/hr for MAR 126

1200 lt/hr for MAR 206

1600 lt/hr for MAR 306

Incoming water goes throughout the water

regulating valve first and then to the water

cooled condenser. Observe arrow on water

regulating valve. Water supply must be installed

to conform with local code. In some case a

licensed plumber and/or a plumbing permit will

be required.

Water Quality

Water quality is a factor of extreme importance

for good operation of MAR machine. Water

shouldn't be too hard neither too soft.

Hard water will tend to create mineral deposits in

water reservoir, evaporator drum and scraping

blade, rendering rough the chute surface which

prevents ice scales from sliding properly into ice

channel. On the contrary, water too soft, (demineralized) will cause the ice skin to stick

excessively on drum surface rendering difficult

the scraping operation of same.

The ideal water should have a total hardness

of about 15-20 french degrees.

Precaution Against Water Frost

Like for any other ice maker all necessary

measures must be taken when the cold season

is approaching to protect the water supply line

and the MAR water system against winter

freezing. If cooling tower is used several

precautions should be observed, too.

1. Leave water regulating valve in the system.

2. Separate the make-up water for the reservoir

from the tower water.

3. Use 3/4" tower water lines or larger, depending

on the lenght of run. Over 30 feet, use 1" O.D.

lines.

4. NOTICE: a cooling tower can freeze in the

winter time and the MAR flaker will be in

operation 12 months per year. An indoor tower

and pump can be used with outdoors air ducted

in and out if the fan cycles on water temperature to prevent freezing. An indoor sump can

be used. An auxiliary tower and city-water

hook-up will prove satisfactorily in some

climates. Fresh water in the winter and tower

water during the summer. Consult your tower

and pump manufacturers for proper sizing. In

no event should less than a Nominal 3 to 4 tons

tower, or less than 3/4 HP high pressure tower,

or less than 3/4 HP high pressure tower pump

be used.

Page 13

Page 13

Page 13

C.Drain (When not re-used).

The recommenden tubes for the condenser

waste line are:

- MAR 56-76 - 3/4" GAS female fitting.

- MAR 106-126 - 12 mm I.D.

- MAR 206-306 - 25 mm I.D.

Water drip tray drain line is 21 m/m I.D. Tube

to be connected with clamp to a 21 m/m hose

barbed fitting for all models.

Waste water line must run to an open trapped

vented drain. If drain is a long run, allow a pitch

of 3 cm per meter.

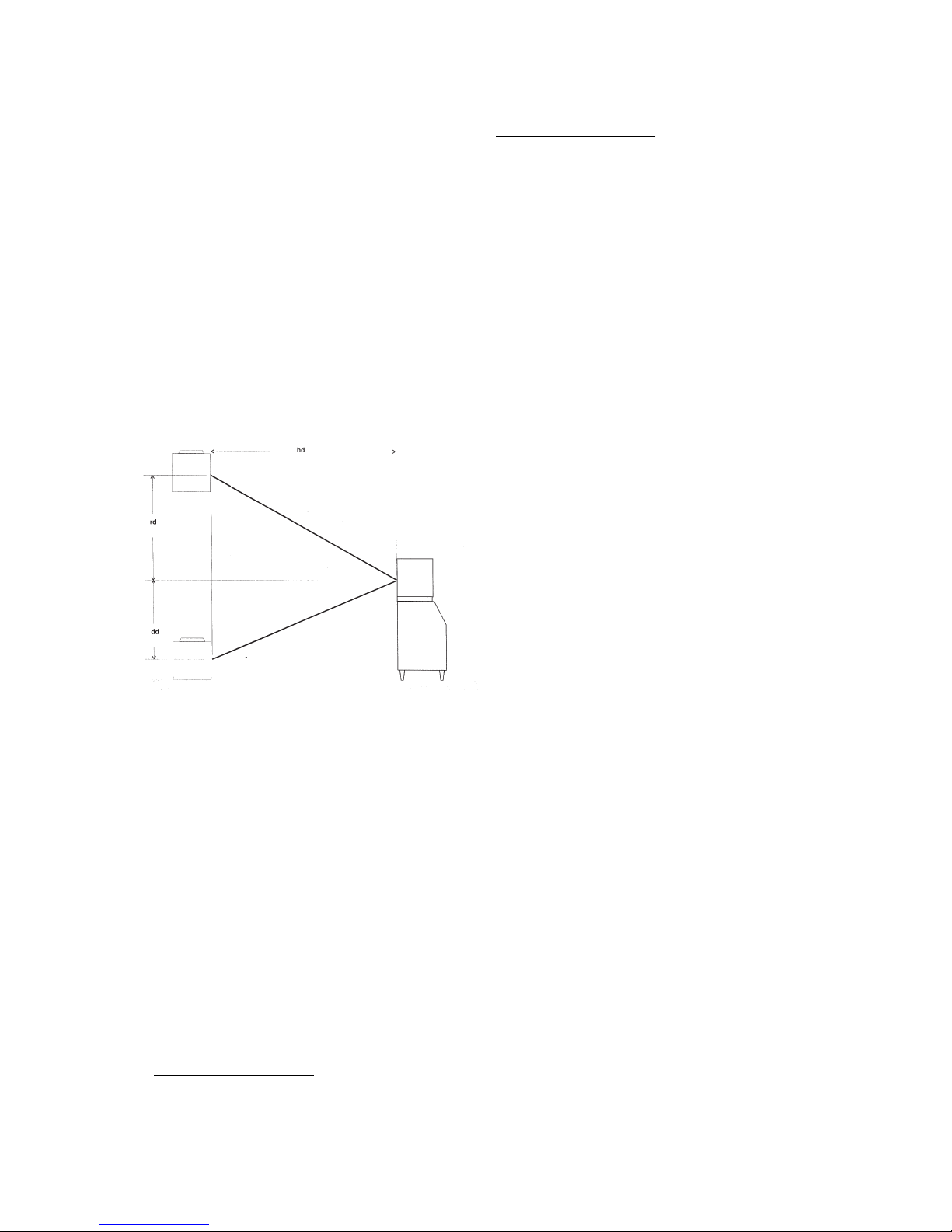

6. REMOTE AIR-COOLED CONDENSER

AND PRECHARGED REFRIGERANT

LINES INSTALLATION (MAR 306 ONLY)

Use the following for planning the placement of

the condenser relative to the ice machine

Location Limits - condenser location must

not exceed ANY of the following limits:

• Maximum rise from the ice machine to the

condenser is 3 physical meters

• Maximum drop from the ice machine to the

condenser is 1 physical meter

• Physical line set maximum length is 6 meters

• Line set length maximum is 9 meters.

Calculation Formula:

• Drop = dd x 6.6 (dd = distance in meters)

• Rise = rd x 1.7 (rd = distance in meters)

•

Horizontal Run = hd x 1 (hd = distance in meters)

• Calculation: Drop(s) + Rise(s) + Horizontal

Run = dd+rd+hd = Calculated Line Length.

Configurations that do NOT meet these

requirements must receive prior written

authorization from Scotsman.

Do NOT:

• Route a line set that rises, then falls, then rises.

• Route a line set that falls, then rises, then falls.

Calculation Example 1:

The condenser is to be located 0.9 meter below

the ice machine and then 3 meters away horizontally.

0.9 mt x 6.6 = 5.94 + 3 = 8.94. This location would

be acceptable.

Calculation Example 2:

The condenser is to be located 4 meters above

and then 3 meters away horizontally.

4 x 1.7 = 6.8 6.8+3 = 9.8.

9.8 is greater than

the 9 maximum and is NOT acceptable.

Operating a machine with an unacceptable

configurationg will void the refrigeration

system warranty.

In a crate, separated by the unit crate are packed:

1. The air-cooled condenser mounted on the

platform base with the electrical junction box,

condenser shround, fan motors, fan protection

grid, fan motor speed, control and the

refrigerant lines connection couplings.

2. One set of pre-charged refrigerant line with

connection couplings on both ends of following

variety. Liquid I.D. 12 m/m - Gas I.D. 16 m/m

- 10 mts length.

The pre-charged refrigerant lines, 6 meters long,

are equipped with self-sealing coupling

connections and can be connected or disconnect

few times without loosing the refrigerant charge.

The electric cord line, approx. 10 meters long,

located on the left side of the unit has to be

connected to the condenser junction box

terminals.

The condenser fan motors are originally wired for

230 V single phase and have the following

specifications:

RPM 1420

WATTS 2x180

AMPS 2x0,80

They operate at 230 V 50 Hz and are controlled

by an Electronic Fan Speed Control set at 16 bar.

A. Location consideration:

1. Limit to 10 meters the lenght of the precharged

refrigerant lines from the ice-maker to the

remote condenser.

2. Maximum vertical rise of 3 meters between

the ice maker and the remote condenser.

3. Best available location, protected from the

extremes of dirt, dust, rain, sun and wind.

B. Unpacking and inspection:

1. Visually inspect the exterior of the shipping

container and any severe damage noted,

should be reported to delivering carrier; and a

concealed damage claim filled subject to

internal inspection with carrier representative

present.

2. Uncrate the remote condenser and precharged refrigerant lines and inspect for any

concealed damage claims, as stated in step 1

above.

3. Check that the pre-charged refrigerant lines

are intact, not kinked, and that there is no

sealed puncture or loss or refrigerant.

Max 3 m

Max 1 m

Condenser

Distance &

Location

Schematic

Remote

Condenser

Located BELOW

Ice Machine

Remote

Condenser

Located ABOVE

Ice Machine

Page 14

C. Remote condenser - Wall attachment

1. Install and attach the remote condenser to the

wall of the building, using the methods and

practices of building standards that conforms

to and meets the local building code

requirements in your area.

D. Remote Condenser Electrical connection

Connect t he electric cable from Remote

Condenser to the terminal board of the machine

as described in the following.

1. Remove jumper from contact 17 and 18 of the

machine terminal board.

2. Connect Remote Condenser BLU wire to

Neutral (N) of machine terminal board.

3. Connect Remote Condenser BROWN wire to

contact n. 18 of machine terminal board.

4.

Connect Remote Condenser GREEN/YELLOW

wire to the grounding related screw.

E. Pre-charged refrigerant lines

1. The set of pre-charged refrigerant lines

consists of a self-sealing liquid line and a selfsealing discharge line.

One coupling on each line is fitted with a

Schrader valve, which provides the

servicemen with access for refrigerant

evacuation through tubes, refrigerant charging

and service gauges application when

necessary.

2. When possible, route the maximum lenght of

the pre-charged refrigerant lines inside the

building, with the minimum lenght outside, to

prevent vandalism and to minimize the

condenser effect that exposed lines can produce in cold weather.

Insulate lines that be exposed to outside

temperatures that will be below freezing, for

extended periods of time.

CAUTION - Each coupling on the set of

pre-charged refrigerant lines, the

refrigerant fittings on the remote

condenser and on the icemaker chassis

are self-sealing and should be tightened

1/4 turn more than snug tight.

ALWAYS USE TWO WRENCHES WHEN

TIGHTENING THESE FITTINGS ONE AS A

BACKUP WRENCH TO PREVENT

TWISTING OF TUBING AND POSSIBLE

KINKING OR LINE RUPTURE.

3. Connect the small dia refrigerant line coupling

to the unit fitting labelled "LIQUID" on the right

side of the icemaker chassis.

4. Connect the large dia refrigerant line coupling

to the unit fitting labelled "GAS" on the righ

side of the icemaker chassis.

5. Connect the small dia refrigerant line coupling

with Schrader valve to the condenser fitting

labelled "LIQUID".

6. Connect the large dia refrigerant line coupling

with Schrader valve to the condenser fitting

labelled "GAS".

F. Excess lenght of pre-charged refrigerant lines;

at installations where the icemaker chassisto-remote condenser refrigerant line path is

substantially less than the lenght of precharged refrigerant lines to be installed, route

and dress the excess refrigerant line as

follows.

1. Follow straight line routing when possible.

2. Retain excess pre-charged refrigerant line

inside the building.

3. Spiral the excess lenght of the precharged

refrigerant lines in the best selected inside

lo

cation and in a manner that prevents

refrigerant trapping.

Page 14

Page 15

CAUTION - DO NOT kink or crimp the

refrigerant lines.

DO NOT bend excess refrigerant lines in

a vertical loop (s), which allow trapping

of refrigerant in LOW sections during

OFF time.

Bend and shape excess refrigerant lines

in VERTICAL spirals, not HORIZONTAL

spirals. See Figure above.

7. ICE LEVEL CONTROL

The MAR flake ice system are equipped with

and adjustable thermostatic control that cuts off

ice making operation when its sensing bulb gets

in contact with the ice deposited in the storage

bin. The temperature range dial goes from +10°C

to -35°C and its long capillary (3.5 m.) attaching

the liquid filled bulb, should be conveniently

positioned in the storage room at the desired

height by holding it with an appropriate bracket

to be arranged in accordance with the location

possibilities. These controls may or may not be

used, it depends of storage room arrangement

and its inner temperature that must be higher,

anyway, to that of the ice produced.

In case of a prevailing low themperature (below

-20°C) created by the sub-cooled ice that is

staging above the ice level, which will prevent a

positive function of the ice level thermostatic

control, the thermostatic sensing bulb must be

removed from the storage room.

The MAR ice system are also equipped with a

timer which allows to present the system

operations time in relation to the quantity (level)

of the ice desired. This timer function takes

place of the ice level control.

8. ICE CHUTE

Mar compact unit are supplied with its own ice

chute. In addition optional kits for various

solutions are available on request.

9. FINAL CHECK LIST

1. Is the cabinet level 3 (IMPORTANT).

2. Have all electrical and piping connections

been made?

3. Has the voltage been tested and checked

against the nameplate rating?

4. Is the water supply line shut-off valve installed

and electrical wiring properly connected?

5. Have the Bin and Cabinet benn wiped clean?

6. Have the compressor hold down bolts been

en checked to be sure the compressor is floating

on the mounting springs?

7. Has the owner/user been instructed on how

to operate the ice maker?

8. Has the Manufacturer's Registration Card

been properly filled out? Check for correct Model

and Serial numbers from serial nameplate then

mail the completed card to the Frimont Scotsman

Europe Factory.

9. Check all refrigerant lines and conduit lines,

to guard against vibration or rugging and possible

failure.

10. Is the cabinet in a room where ambient

temperatures are a minimum of 5°C (40°F) all

year around?

11. Has water supply pressure been checked to

insure a minimum of 1 bar (14 psi) and max of 5

bar (70 psi)?

12.Has the owner been given name and

telephone number of the authorized SCOTSMAN

Service Agency serving him?

1 Power supply line

2 Hand disconnect switch

3 Water supply line

4 hand shut off valve

5 Water filter

6 Water supply in.

(Run separate water inlet

for condenser)

7 Water drain line

8 Open trapped or vented drain

10. UNIT INSTALLATION PRACTICE ON NON-REFRIGERATED ICE-ROOM

Page 15

Page 16

Page 16

Page 16

11. UNIT INSTALLATION PRACTICE ON REFRIGERATED ICE STORAGE ROOM

(Jacket system)

1 Power supply line

2 Hand disconnect switch

3 Water supply line

4 Hand shut off valve

5 Water filter

6 Water supply in.

(Run separate water inlet

for condenser)

7 Water drain line

8 Open trapped or vented drain

9 REFRIGERANT COIL

10 Insulated panel

11 Air gap

12 Ice bulkhead

Page 17

Page 17

Page 18

SEZIONE II

OPERATING INSTRUCTION

1. COMPLETE UNIT START-UP

1. Remove all panels and open the water supply

line shut-off valve for both the evaporator

drum and in the case of a water cooled

machine, to the condenser.

2. Observe the water filling operations.

a) Water flows into the float reservoir first.

b) Water is filling the freezing drum basin.

c) Float moves up as water level rises in water

reservoir.

d) Float stops water flow when water reaches

suitable operation level.

Now, water surrounds bottom half of freezing

drum.

3. Move the manual ON-OFF toggle of main

disconnect switch to ON position. The green

light on console panel will glow.

4. MAR uses an electrical "three phases

monitoring relay" which alerts installer in case

of wrong wiring by keeping green LED ON

only. In this case change phase connection

wiring.

5. Correct wiring is shown by both LEDs Green

and Orange steady ON together.

6. Observe immediately that evaporator drum

rotates in the right direction, namely toward

the scraping blade.

7. Meanwhile unit is under power KT1 relay

compressor device is energized as well in

order to delay compressor start up by 18' Later

(KT1 orange LED blinks during this delay). On

normal operation - compressor ON - KT1 LEDs

(orange and green) are steady ON together.

NOTE. In case on any temporally Ice maker

trip OFF (not alarm) due to NO/LOW water

pressure, bin full, ice spout switch activation

unit stops by only keeping drive motor operating

for 18' in order to clear evaporator by ice.

KT2 delay relay LEDs steady ON (orange

and green) during this delay.

WARNING - Correct Drum rotation - The

evaporator drum drive motor is a

threephase motor wired for 400 V. It is of

extreme importance to check immediately

upon unit start-up that motor rotates

CLOCKWISE in order that gear motor

pulley rotates in the direction of the

ARROW. Should the motor turn

counterclockwise, it is necessary to

instantly switch-off the unit and

interchange one polarity at terminal block

connection of main electric cord.

Page 18

Page 19

Page 18

Motor Shaft Pulley

MAR units are generally equipped with two

pulleys (not on MAR 126) and by changing

from one to the other the speed of drum can

be changed.

MAR Machines are factory delivered with

pulley to rotate the evaporator drum at the

lowest possible R.P.M. to obtain "THICK"

(2 mm gauge) scale ice. Replacing standard

by alternative/supplied pulley on motor shaft

evaporator drum R.P.M. increases to the point

to produce "THIN" (1 mm gauge) scale ice.

8. Make sure that the automatic expansion valve

opens and that refrigerant fluid starts to flow

through it.

NOTE. At first compressor start-up, the suction

pressure declines rapidly to 0.2 bar, causing

the intervention of the pressure control, which

will interrupt the entire unit operation. This

control being automatic re-set type, will

resume the unit operation after few seconds.

The unit will start and stop few more times,

due to the lo-pressure control cut-out and in,

until system refrigerant pressure set on their

normal values.

9. After two or three minutes of operation, observe

that ice skin begin to form on the revolving

drum surface and it is scraped by the blade.

10.Left the system operate for about 20 minutes.

Check for any excess noise beyond normal

compressor noise.

a) Vibrating type from touching lines.

b) Compressor loose at one or more holddown

bolts.

c) Drivemotor pulley misaligned with gear box

pulley causing V belt vibration.

d) Check compressor oil level through sight

glass (Except MAR 56/76/106/126).

11.On water cooled machine check the water

flowing out from condenser to see if it is

correct. Cooling water flow is controlled by a

pressure water regulating valve. No valve

adjustment of water valve should be

necessary unless the inlet temperature of

cooling water is relatively high. Normal head

pressure should be 17 bar on MAR 56, MAR

76, MAR 106 and MAR 126; 16 bar on MAR

206 and 14 bar on MAR 306.

12.Observe that evaporator drum is frosted allover from end to end. If this is not the case

setting of the refrigerant expansion valve

may be necessary. For proper adjustment of

this valve turn the valve setting steam of one

eight of a turn counterckwise to allow more

refrigerant flow until the evaporator drum

surface is evenly frosted from end to end.

In case you have an excessive frost back in

the suction line and frost starts to form on

compressor suction service valve slightly

turn clockwise the expansion valve setting

stem until the frost back on compressor

service valve melts over.

The suction pressure should range

between 0.6 bar and 2.5 bar depending on

model, water temperature and level.

See indications on page 25.

2. WATER AND REFRIGERANT CIRCUIT

1. Compressor

2. Condenser

3. Discharge line

4. Drier

5. Liquid line

6. Heat exchanger

13. Drum water basin

14. Evaporator drum

15. Refrig. lines manifold.

16. Scraping blade

17. Float reservoir

18. Spray bar

7. Expansion valve

8. Vapor line

9. Vibration absorbers

10. Condensing water-inlet

11. Condensing water-outlet

12. Water regulating valve

Page 19

Page 19

Page 20

WARNING - Whenever stopping the

machine to keep it off operation for some

time, it is recommendable to shut close

the water inlet valve to interrupt the water

supply.

13. Throughly explain the owner/user the

significant specifications of the MAR ice

maker, the start-up and operation, going

through the procedure in the operating

instructions. Answer all questions about the

icemaker, by the owner and inform the owner

of the name and telephone number of the

Scotsman Service station serving him.

14. Fit and secure all unit panels previously

removed.

Page 20

Page 21

Page 20

SECTION III

PRINCIPLES OF OPERATION - HOW IT WORKS

1. ICE MAKER

The revolving drum which may be of different size

depending on the ice maker capacity, is basically

made of a cylinder skeleton covered by a stainless

steel jacket.

A channel, about 15 m/m deep and 15 m/m wide

is machined in a spiral pattern that goes from one

end to the other of the cylinder skeleton.

The end of the machined channel communicate

with a bore made in the left cylinder journal. The

head manifold on the left side is for both liquid

refrigerant inlet and vapor refrigerant outlet.

When cylinder metal jacket is forced and sealed

on the cylinder skeleton, the spiral pattern channel

made for the refrigerant flow becomes virtually

the evaporator serpentine.

The metered refrigerant that reaches the

evaporator serpentine by passing throught the

bore in the left side cylinder journal, boils and

evaporatores as it comes in contact with the drum

metal jacket. About one third on the cylinder drum

is constantly submerged in water.

This will allow the cylinder metal jacket to draw a

film of water that, as soon as it comes afloat,

freezes almost instantly due to the heat absorption

created by the boiling refrigerant circulating in the

inner serpentine and scrubbing with the jacket

inner surface.

2. PRINCIPLES OF OPERATION - HOW IT WORKS

The ice layer of the emerged cylinder sector has

a fraction of time to solidify, dry and eventually

subcool before contacting the edge of the

horizontal scraping blade.

The scraping blade, of heavy duty metal, cause

the peels off of the ice sheet formed on the drum

jacket by racking it while it advances on the

revolving drum.

The ice sheet is so dry that, when it gets in contact

with the scraping blade, it cracks in a form of

irregular shaped chips. The refrigerant leaves

the evaporator serpentine to return to the

compressor via suction line through the bore of

the head manifold on the left side cylinder.

The refrigerant sealing in the manifold is assured

by an especially designed sealing device.

The cylinder is driven by a separate drive motor

and gear reducer located on the right side.

Four motors are constantly in motion:

a) the compressor

b) the drive motor

c) the fan motor

d) water pump

The gear reducer, the driving belt with its pulley

and the revolving drum with the rotating part of

the sealing devices are the mechanical parts in

motion.

1. Water drawing area

2. Water sprayed freezing cooling area

3. Sub-cooling area

4. Water reservoir float valve

5. Water feeding line

6. Scraping blade

7. Spray bar

8. Water reservoir

9. Revolving drum

10. Water pump

11. Water drain hole

Page 21

Page 21

Page 22

3. ELECTRICAL / REFRIGERATION

The electrical circuit consists of the compressor

motor, drive motor, water pump, condenser fan

motor and control (on air cooled version), main

controls (ON-OFF compressor Switch - Timer Contactor), safety controls - Thermal protection

for compressor - Hi and Lo pressure switches water failure switch, compressor and drive motor

delay timer, three phases monitoring relay.

A. Compressor unit - (see Technical Specifi-

cation Table for H.P.).

The compressor used on the MAR 56 - 76

- 106 - 126 is hermetic reciprocating type

compressors while on MAR 206 and 306 is

semihermetic type. All of them operating with

R 404a.

All compressors are equipped with a

crankcase heater element and are thermally

protected. Cooling is achieved with refrigerant

passing through suction valve and by a separate fan motor on water cooled version only.

a) Compressor Crankcase Heater

Must be constantly energized particularly

during OFF period of ice maker operations.

The temperature provided by the heating

element into the crankcase prevents that

refrigerant dilutes with oil.

b) Compressor Thermal Protector

(Thermistor) on MAR 206 and 306

A thermistor is a solid state semiconductor

which permits or allows more electrons to

flow throught it as the material's temperature increases. Today thermistors are used

in place of a bimetal strip or in place of a

temperature sensitive power element as a

safety device in electric motors by stopping

the electric power flow to a motor if the

motor windings temperature increases to

the danger point.

B. Drive Motor

The evaporator drum drive motor is a three

phase motor of 1/2 HP wired for 380/220 Volts

50/60 Hz - 1,2/2,1 Amps - 1400 R.P.M. with

inherent thermal protector.

IMPORTANT - When this motor is disconnected or the entire unit is disconnected, it is

necessary - when resuming the electrical

connection to immediately make sure that

drive motor rotates clockwise facing the

unit front.

Failure to this, may result in wrong rotation of

evaporator drum with the risk of major

damages to the system.

C. Timer

It will be mainly used to pre-set the system

operation time in relation to the desired amount

to ice.

Therefore it takes the function of an Ice Level

Control in the storage area. This timer can be

remotely located if desired.

D. Hi Pressure Cut-Out Hand Reset

This high pressure control prevents operation

at high refrigerant pressure.

Shuts-off entire system in case of water failure

to condenser on water cooled units and of fan

motor failure on air cooled machines.

Factory cut-out setting are:

air cooled 34±2 bar (480±30 psi)

water cooled 30 bar (420 psi)

E. Water Failure Switch

This switch used as safety device when low or

interrupted supply water conditions are

encountered.

Operates on pressure between supply line

and feed line to water reservoir.

Range is 0.5 bar (7 psi) off and 0.8 bar

(12 psi) on.

Cuts off complete unit and Resets automatically.

F. Lo-Pressure Cut-Out Automatical Reset

Lo Pressure Control prevents operation at

vacuum refrigerant suction pressure.

Shuts off entire system in case of refrigerant

failure in the system.

Factory setting cut-out: 0,2 bar.

G. Condenser Fan Motor

Air Cooled Units

The fan Motors used are permanent capacitor

type fan motors. Electrical supply to the fan

motors is 230 V, 50 Hz - 0,7 Amp. for

MAR 56, 76, 106, 126 10 and 306 - 0,9 Amp.

for MAR 206.

H. Fan Motor Pressure Control

MAR Air Cooled version are equipped with a

pressure control which is a reverse acting

automatic re-set control directly connected to

the fan motor. Its function is to maintain the

head pressure between the cut-in and cut out

setting values which are 15÷17 bar.

I. Control Console

Located on the front of the unit cabinet, is a

visual control console that monitors unit performance automatically.

Any interruption or significant reduction in

water or electrical supply causes an instant

stop to the operation of the MAR flaker

system. At the same time a warning light is

activated on the control console telling the

user of the ice maker stoppage and also the

reason why.

Page 22

Page 23

Page 22

If the stoppage is caused by its refrigerant

pressures or overloading in the compressor a

red light glows. Both controls that activate the

red lights are manual reset type controls,

therefore the cause of the stoppage should

be diagnosed and corrected before

reoperating the ice maker.

J. Water Cooled Condenser

Tube within a tube condenser.

K. Water Regulating Valve

Penn made. Valve must be set to maintain

head pressure at 17 bar (240 psi) for

MAR 56-76, 15 bar (210 psi) for MAR 106-126,

16 bar (225 psi) for MAR 206 and 14 bar

(195 psi) for MAR 306.

L. Automatic Expansion Valve (A.E.V.) M.O.P.

The automatic expansion valve controls the

refrigerant when passing from the liquid line

to the evaporator. As the pressure decreases

on the low side, the expansion Valve open

and refrigerant escapes into the evaporator

drum channel where it absorbs heat from

water while evaporating. The valve maintains

a constant pressure in the evaporator coil

when the system is running indipendently of

the amount of refrigerant in the system.

This valve has an adjustment which may be

manually regulated to give the evaporator

coil the desired amount of refrigerant.

Turning the adjustment to the left,

counterclockwise, will increase the rate of

flow which is controlled by the pressure in the

evaporator.

When the compressor is not running the

valve will remain closed as the low side

pressure will be high enough to close the

expansion valve.

- MAR 56 -76 - 106 - 126 are generally equipped with an expansion valve having an

orifice of 2,5 mm set for 3,0 bar of pressure.

- MAR 206 - 306 is also equipped with an

expansion valve having an orifice of 4,5 mm

set for 3.0 bar of pressure.

M. Evaporator Drum

Refrigerant inlet/outlet takes place on left

side journal.

The drum body is covered by a jacket in

special stainless steel resistant to the water

corrosion.

The front edge of the scraping blade must

have a clearance of minimum 0.05 mm from

cylinder metal jacket.

N. Refrigerant Seal System

Housed in the refrigerant inlet/outlet manifold

located on the evaporator drum left side

journal, is a leakproof joint. This joint is made

with seals that are carefully designed and

installed. The seals use two rubbing surfaces.

One surface tourns with the cylinder journal

and is sealed on it with on O ring of synthetic

material. The other surface is stationary and

fitted in its housing with leak-proof O ring.

The rubbing surfaces (optically flats) are made

of two different material that are: hardenend

steel for the rotating ring and graphite for the

stationary ring.

Page 23

The rotating parts are:

a) the clip retainer ring

b) the spring collar

c) the compression spring

d) the stainless steel seal ring with O ring.

The stationary parts are:

a) the graphitic ring with O ring

b) the stainless steel housing ring with gasket

and O rings.

O. Heat Exchanger

A heat exchanger is mounted in the suction

and liquid line to reduce flash gas in the liquid

line, to reduce liquid refrigerant in the suction

line and to subcool the liquid refrigerant

thereby increasing the operating efficiency.

P. Sight Glass

A sight glass is installed in the liquid line. The

sight glass will show bubbles if the system is

low on refrigerant.

Q. Filter Drier

All MAR units mount a "Solid-core antiacid

filter drier" on liquid line. This drier may be

installed in any position provided that the

arrow on its body point in the direction of

refrigerant flow.

R. Contactor

MAR contactors have 3 or 5 contacts normally

open and 1 contact normally closed. The N.C.

contact is generally used to keep the

crankcase heater energized during the OFF

periods. The contactor coil is generally at

230 V 50 Hz 1 Ph and kept energized by the

system controls that are connected in series.

S. Thermostat (Ice level control)

When storage room temperature is higher to

that of the ice being made, the ice level can be

positively controlled by this thermostat, the

sensing bulb of which must be positioned to

the wanted level that will, abviously correspond

to the desired ice level in storage room.

The temperature range dial must be set on to

the proper temperature in order that the control

may cut-out or may cut-in respectively when

its sensing bulb gets buried into the ice cone

and when is freed from the ice.

This thermostat can be a valid control if it is

used in non-refrigerated storage rooms as in

these cases it is influenced just by the ice

temperature.

T. Ice Spout Safety Switch

Located on top of the Ice Spout, the Safety

Switch is operated by a plate on top of the ice

chute by the ice backing up in the spout.

The switch will shut-off the entire ice making

mechanism.

U. Ice Level Control

Must have its sensing capillary extended into

ice room in a way that it could be contacted by

the ice when storage ice room becomes filled.

It terminates ice production when its capillary

gets in contact with ice. It is wired in series

with all other controls. It is factory set to cutout at 1,5°C and cut-in at 4°C.

V. ON/OFF switch

The manual start-up or switching of the entire

system requires the attention of the operator

who may instantly keep control of the situation,

supplied.

W.Compressor Delay timer

Delays the start up of the compressor by 18'

at every start up of the ice maker. Supplied.

X. Drum rotation delay timer

Delays drum STOP by 18' at every trip OFF of

the ice maker. Supplied.

Y. 3 - phases monitoring relay

On the power IN, it checks and assures correct

rotation of the drive motor - evaporator drum.

Supplied.

Z. Drum rotation control

It operates using the Hall effect sensor /

principle. In case the drum is not rotating at all

(or it rotates too slow - less then 1/4 turn every

30") such relay trips the unit OFF so to avoid

that in case of fiber keys breakage, the drive

motor - gear reducer and compressor can

operate with the drum OFF. Supplied.

Page 23

Page 24

4. REFRIGERANT CHARGE

WATER COOLED MODELS

The below refrigerant charge is approximate.

When charging, set at 15 or 17 bar head pressure

according to the model and charge so that frost

line extends out of the evaporator two third way

to compressor after fifteen minutes of operation.

AIR COOLED MODELS

When charging set at 16 bar (225 psi) the head

pressure.

5. MECHANICALS

A. Motor Shaft Pulley

MAR units are generally equipped with two

pulley and by changing the belt from one to

the other, the speed of drum can be changed.

MAR Machines are factory delivered with

pulley to rotate the evaporator drum at the

lowest possible R.P.M. to obtain "THICK" (2

mm gauge) scale ice.

Replacing standard by alternative/supplied

pulley on motor shaft evaporator drum R.P.M.

increases to the point to produce "THIN"

(1 mm gauge) scale ice.

R.P.M. R.P.M.

for "thick" ice for "thin" ice

MAR 56 AS/WS 0.9 1.25

MAR 76 AS/WS 1.1 1.25

MAR 106 AS/WS 1.5 2.3

MAR 126 AS/WS 2.4 ****

MAR 206 AS/WS 1.05 1.6

MAR 306 AS 1.6 2.9

MAR 306 WS 1.8 2.9

V belts used on motor shaft pulley and gear

box are type:

MAR MAR MAR MAR MAR MAR

56 76 106 126 206 306

XPZ750 XPZ 900 XPZ 937

B. V Belt

V belt used on motor shaft pulley and gear

box. When changing the V belt be careful to

adjust it for proper tension and alignement.

It should be snug not tight. A way to roughly

check belt tension is to apply a firm hand

pressure in the middle of the longest belt

span. If the belt is correctly tensioned, you

should be able to depress it about 10 m/m out

of line.

C. Gear Reducer

Then gear reducer is mounted on the right

side frame of evaporator drum basin to which

it is firmaly secured with four nuts.

The gear reducer bore in which passes the

drum shaft to be driven, has a keyway.

Two fiber keys are used to engage the gear

reducer to the drum shaft, they are in series in

the gear reducer bore, and shaft keyways.

Should the driving strain be excessive, the

two fiber keys will shear.

MAR 56-76-106-126 are equipped with a gear

reducer having a ratio of 1/600.

MAR 206 and 306 have a gear reducer with a

ratio of 1/552.

The gear reducers are greased for life,

therefore they do not require any maintenance.

REFRIGERANT CHARGE AND OPERATING PRESSURES

MAR 56-76 MAR 106 MAR 126 MAR 206 MAR 306

A WAWAWAW AW

Refrig. charge (gr) 1500 1000 2000 1150 2200 1250 4100 2300 5900 2500

Head press. (bar) 15-17 17 15-17 15 15-17 15 15-17 16 15-17 14

Head press. (psi)

212-245

245

212-245

212

212-245 212 212-245

230

212-245

200

Suction press. (bar) 2.2 1.8 1.6 1.6 1.6 1.6 1.9 1.9 1.0 1.75

Suction press. (psi) 32 26 23 23 23 23 27 27 14 11

Page 24

Page 25

Page 25

Page 26

SECTION IV

ADJUSTMENT & REMOVAL & REPLACEMENT PROCEDURES

The procedures provided in this section are

arranged in order to make specific adjustment

and removal and replacement information easy

to locate.

Read the instructions throughly before performing

any adjustment or removal or replacement

procedures.

1. ADJUSTMENT OF THE WATER

REGULATOR ASSY

(Water Cooled Models)

Adjustements can be performed on the Water

Regulator Assembly to increase or decrease the

head pressure.

To adjust the Water Regulator Assembly:

A. To INCREASE the Head Pressure: rotate the

adjusting screw on the Water Regulator

Assembly IN or CLOCKWISE.

B. To DECREASE the Head Pressure: rotate

the adjusting screw on the Water Regulator

Assembly OUT or COUNTERCLOCKWISE.

2. ADJUSTMENT OF THE AUTOMATIC

EXPANSION VALVE

The end to end frost on evaporator drum is the

result of the correct expansion valve setting.

This valve may be manually regulated by means

of the adjusting stem.

Turning the adjustment to the left counterclockwise, will increase the rate if refrigerant

flow.

Turning the adjustment to the right (clockwise),

the refrigerant flow to the evaporator is reduced.

Use hex head wrench for manual adjusting

operations.

WARNING - Be sure the electrical power

supply and water supply are OFF, before

starting any of the following REMOVAL

AND REPLACEMENT procedures as a

precaution to prevent possible personal

injury or damage to equipment.

3. CHANGING V BELT FROM SMALLER

PULLEY GROOVE TO LARGER

PULLEY GROOVE TO MAKE THIN ICE.

1. Remove top, front right panel and right side

panels.

2. Through the front, by means of socket wrench,

slightly unloose two head hex screw securing

the sleigh that supports the motor.

3. Through the right side, slightly unloose the

nut located in correspondence of the sleigh

button hole.

4. The sleigh with the motor should be able to

slide vertically.

5. Slid-off V belt from motor pulley.

6. Unloose and remove hex head screw that

secure step pulley on motor shaft.

7. Remove step pulley from motor shaft and

replace the same with alternative-supplied

one.

8. Tighten pulley on motor shaft by means of

hex head screw previously removed.

9. Place V belt on groove of motor pulley and of

gear box pulley.

10. Raise the sleigh with motor and pulley to give

a rough tension to V. Belt.

11. Tighten slightly the two hex head bolts and

the nut previously unloosed.

12. Correct tension of V belt by moving upward or

downward the Sleigh/Drive Motor assembly.

13. When satisfied with V belt tension, which

should be snug but not tight, proceed to

definitively tighten the hex head bolts and

nuts that secure motor support sleigh to side

frame of drum basin.

4. REMOVAL AND REPLACEMENT OF THE

COMPRESSOR ASSEMBLY

NOTE. Always install a replacement Drier,

anytime the sealed Refrigeration System is

opened. Do not replace the Drier until all

other repairs or replacements have been

completed.

A. To remove the Compressor Assembly:

1) Remove cover from the Compressor Junction

Box.

2) Disconnect the electrical leads at the

Compressor Junction Box that originate in the

Control Box.

3) Recover the refrigerant from the system and

transfer it in a bottle so to reclaim or recycle it.

4) Disconnect the suction line from the

compressor.

Page 26

Page 27

Page 26

5) Disconnect the discharge line from the

compressor.

6) Remove four bolts, lockwashers and washers

which secure the compressor to the Chassis

mounting base.

7) Slide the compressor and remove it through

the rear side opening of the Cabinet.

B. To replace the Compressor Assembly, reverse

the removal procedures.

5. REMOVAL AND REPLACEMENT OF THE

WATER COOLED CONDENSER.

NOTE. Always install a replacement Drier,

anytime the Sealed Refrigeration System is

opened. Do not replace the Drier, until all

other repairs or replacements have been

completed.

A. To remove Condenser:

1) Recover the refrigerant from the system and

transfer it in a bottle so to reclaim or recycle it.

2) Unsolder the refrigerant inlet and outlet lines

from the condenser.

3) Disconnect the water inlet and outlet lines

from the condenser.

4) Remove bolts, lockwashers and washers

which secure the Condenser to the Chassis

mounting base.

5) Remove the Condenser from cabinet.

NOTE. Throughly evacuate the System to

remove moisture and non-condensable.

B. To replace the Condenser, reverse the

removal procedures.

6. REMOVAL AND REPLACEMENT OF THE

WATER REGULATOR ASSEMBLY

(Water-cooled Models)

A. To remove the Water Regulator Assembly:

1) Recover the refrigerant from the system and

transfer it in a bottle so to reclaim or recycle it.

2) Unsolder the capillary line from the Water

regulator assembly where connected at the

process header.

3) Disconnect the water inlet line at the rear of

the water regulator.

4) Disconnect the condenser water inlet tube at

the front of the water regulator.

5) Remove two screws, lockwashers and

washers which attach the Water Regulator

Assembly bracket to the Chassis base and

remove the Water Regulator Assembly and

bracket.

NOTE. Throughly evacuate the System to

remove moisture and non-condensables.

B. To replace the Water Regulator Assembly

reverse the removal procedures.

7. REMOVAL AND REPLACEMENT OF THE

DRIER

A. To remove the Drier:

1) Recover the refrigerant from the system and

transfer it in a bottle so to reclaim or recycle it.

2) Unsolder the refrigeration lines at each end of

Drier and remove the Drier.

B) To replace the Drier:

CAUTION - 1. If the factory seal is broken

on the replacement drier, exposition it to

the athmosphere, more than a few

minutes, the Drier will absorb moisture

from the atmosphere and loose

substantial ability for moisture removal.

2. Be sure the replacement Drier is

installed with the arrow positioned in the

direction of the refrigerant flow.

1) Remove the factory seals from the

replacement drier and install the drier in the

refrigerant lines with the arrow positioned in

the direction of the refrigerant flow.

2) Solder the refrigeration lines at each end of

drier.

3) Purge the system and check for leaks.

4) Throughly evacuate the system to remove

moisture and non-condensables.

5) Charge the system with refrigerant, by weight.

SEE NAMEPLATE.

6) Re-mount all Service Panels.

8. INSTRUCTION FOR REMOVAL AND

REPLACEMENT OF REFRIGERANT

MECHANISMS OF SCOTSMAN ICE

MAKERS "MAR" SERIES

1. Before removing the refrigerant manifold it is

necessary - at first - to close the valve on

liquid line. Upon low pressure switch cut-off,

the main switch must be put in "OFF"

position,then it is necessary to purge the

refrigerant system. After these operations,

the flare fitting at the inlet of refrigerant manifold

can be disconnected as shown.

2. Remove the 4 allen screws of refrigerant

outlet fitting to manifold.

3.

Unloose and remove the 6 nuts with respective

washers that secure the refrigerant manifold (1).

4. When removed the refrigerant manifold

unloose and remove one of the three screws

(11) securing the seal mechanism ring to the

drum shaft journal.

Page 27

Page 27

Page 28

5. Fit in place of it the screw of 4 MA supplied in

the kit then tighten its nut.

6. Gradually unloose the two remaining screws

and the nut till release the spring of seal

mechanism.

7. Unloose the last screw to remove the seal

mechanism ring as well as the seal

mechanism S.S. ring and its spring.

8. Withdraw entirely the stainless steel ring (6)

that houses the graphitic seal ring.

9. Check to see the surface conditions of

cylinder shaft journal. It is of extreme

importance that this surface be clean, smooth

and polished.

In case of scored surface it is

necessary to stroke on it a very fine sand

paper stripe. Check to see that washer (5) be

properly clean and positioned with keyway to

match the key.

10. If necessary replace the 0 rings of the S.S.

ring that houses the graphitic ring.

11. Proceed attentively to examine the graphitic

sulface of the seal ring. If this surface is no

more perfect and optically flat, proceed to

replace the seal ring in the following way.

Lubricate the outer surface of the new seal

ring with compressor oil and place it at the

inferior of the housing ring.

12. Place on drum shaft the steel ring housing

the graphite.

13. Mount on drum shaft journal the remaining

portion of seal mechanism (S.S. ring and

spring) (9) then the seal mechanism ring (10).

14. Fit the screw of 4 MA with its nut in one of the

three threaded holes then screw down the

nut in order to compress the spring.

15. When the seal mechanism spring has been

partially compressed fit the other two screws

and full compress the spring by screwing

down gradually the three tightening point.

16. After have tightened the screws unloose the

tie rod screw and replace it with the third one.

17. Clean carefully the inner surface of refrigerant

manifold. Check to see the good condition of

the seal ring (8) and fit it in its seat inside the

refrigerant manifold. Fit on shaft end the

washer (12) which keeps in place the seal

ring (13) inside the refrigerant manifold and

fit inside the manifold the gasket.

18. Position the manifold on the six monting

studs, fit the six mounting nuts and washers

and tighten all them down by means of a 10

mm. wrench.

19. Connect the outlet refrigerant line to the

corresponding port of the manifold and tighten

it with the four head necessed screw.

20. Connect the refrigerant inlet line on its

manifold fitting and tighten the fitting flarenut.

9. REMOVAL AND REPLACEMENT OF

THE DRIVE MOTOR

A. To remove the drive motor assembly:

1) Remove screws and front, top and right side

panels.

2) Slid-off V belt from motor pulley.

3) Unloose and remove hex head screw

securing the pulley to motor shaft.

4) Disconnect wire leads to motor.

5) Remove two hex head bolts, lockwashers

and washer, and nut which attach the sleigh

support plate of motor to the side frame of

evaporator drum basin.

6) Lift the sleigh plate with the drive motor out of

the Chassis.

7) Unloose and remove 4 Nuts securing the

motor to the sleigh plate.

B. To replace the Drive Motor Assembly reverse

the removal procedure.

Page 28

Page 29

Page 28

10. REMOVAL AND REPLACEMENT OF

GEAR BOX

A. Remove screws and front, top and right side

panels.

1) Slid-off V Belt from gear box pulley.

2) Remove screw securing pulley on gear box

inpul shaft.

3) Remove four nuts and washers which secure

the gear box to the evaporator basin side

frame.

4) With a mallet hit a bit the gear box to create

some looseness.

5) With the help to two screw driver inserted

between basin wall and flanged end of gear

box, force the gear box to clear away from

basin wall if you encounter an excessive

resistance in this. It better to use a Puller.

6) When gear box is cleared away from the wall

where it is mounted, pull it out from cylinder

shaft.

B. To install the Gear Box Assembly reverse

the removal procedure taking care to center

keyway of gear box bore to keys on cylinder

shaft.

11. REPLACEMENT OF FIBER KEYS

A. The replacement of fiber keys is necessary

only when the keys are broken, so that they

do not engage the gear motor with the

evaporator drum drive shaft.

In practical terms, the gear box does not

drive the evaporator drum.

B. To reach the fiber keys to be replaced it is

necessary to remove the complete gear box.

For this operation perform all steps at point

11.

Page 29

Page 29

Page 30

SECTION V

MAINTENANCE & CLEANING INSTRUCTIONS

1. GENERAL

The periods and procedure for maintenance and

cleaning are given as guides and are not to be

construed as absolute or invariable.

Cleaning especially will vary depending upon

local water conditions and the ice volume

produced and each ice maker must be maintained

individually in accordance with is own particolar

location requirements.

2. ICEMAKER

THE FOLLOWING MAINTENANCE MUST BE

SCHEDULED AT LEAST TWO TIMES PER

YEAR ON THIS ICE MAKER. CALL YOUR AUTHORIZED SCOTSMAN SERVICE AGENCY.

1. Check and clean water line Strainer in water

inlet fittings.

2. Remove top panel and evaporator cover

depress the float to ensure that a full stream

of water enters Drum Reservoirs.

3. Check that the ice maker cabinet is level in

side-to-side and front-to-rear directions.

4. Clean the drum basin and exterior of the

drum assembly using a solution of

SCOTSMAN Ice Machine Cleaner. Refer to

procedure VI-3, CLEANING ICE MAKER.

NOTE. Cleaning requirements vary according

local water conditions and individual user

operation.

5. When doubtful about refrigeration charge,

check gauge for compressor head pressure.

Please refer to the operating pressures as

printed on page 26.

6. Check gauge for Suction Line Pressure which

varies between:

2.2 bar (32 psi) MAR 56-76 AS

1.8 bar (26 psi) MAR 56-76 WS

1.6 bar (22 psi) MAR 106-126 AS-WS

1.9 bar (27 psi) MAR 206 AS-WS

1.0 bar (14 psi) MAR 306 AS

0.75 bar (10 psi) MAR 306 WS

Depending upon water inlet temperature.

7. Check setting and function of all the pressure

controls also make sure that their

corresponding lights will glow.

8. Check drive motor operation.

Normal operating temperatures are about

60°C (160°C) which is hot to touch. Check

with amperometer Amps drawn.

9. Check V belt for concealed signs of wear and

that has the correct tension. Check pulleys

alignements and also that drive motor and

gear box hold down bolts are tight enough.

10. Make sure that water lines in water cooled

condenser are free from any excess of water

minerals: otherwise arrange to clean the tubes

with a power driven wire brush or running

through it a weak acid solution made with 20

percent of hydrocloric acid.

11. Check for refrigerant leaks and for proper

frost line, which should frost out of accumulator

at least half way to the compressor and in

some areas, back to service valve.

12. Check for water leaks. Tighten drain line

connections. Pour water down drain to be

sure that drain line is open and clear.

13. Check the quality of ice. Ice flakers should be

dry and have a thickness gauge of about

1.5÷2.0 m/m.

14. Check the thermostatic Ice Control Bulb

(whenever used) location and thermostatic

function.

15. Check compressor oil level through sight

glass (where used). Stop unit operation and

after 10" see that oil level is 2/3 millimeters

above center line of sight glass.

16. Be sure that plexiglass chute at spout opening

is securely fastened with is hold down button

and that its surface is smooth and clean from

any water mineral deposit.

3A.CLEANING INSTRUCTION

(MAR 56-76-106-126)

1. Disconnect power front the unit.

2. Remove screws and top panel

3. Remove evaporator cover panel

4. Close water inlet valve located at evaporator

side onto water inlet line.

Page 30

Page 31

Page 30

5. Press water hose clamp in order to release it

6. Lift the water pump up to release it from

sliding holding screw

7. Carefully push little bit water sump bracket

in ordet to release it

8. Lift the water reservoir up for a while and

bend it in order to dump contained liquid