Page 1

IS100 and IS150

INTRODUCTION

This service manual is intended as a reference for

the installer, user, and service agent of this

Scotsman Ice Station. It includes the necessary

information to install, start up, operate, clean and

maintain this unit.

TABLE OF CONTENTS

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 2

Model Identifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 3

For the Installer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 4

Initial Start Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 5

For the Operator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 5

How it Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 6

Cleaning & Sanitizing Page 7

Service Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 9

Electrical Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 9

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 10

Parts lists and wiring diagrams are located in the center of this manual, printed on yellow

paper.

This manual contains important information, read it before beginning installation or operation.

Keep it for future reference.

Safety Symbol:

Important safety information on a

hazard that might cause serious

injury.

Page 2

IS100 and IS150

SPECIFICATIONS

The term "Ice Station" means a machine that

stores manually filled ice in an insulated, sanitary

container; upon demand it dispenses that ice into a

cup or glass.

NOTE: This ice stand is designed to dispense

cubed or Nugget ice only. Flaked ice will not

work.

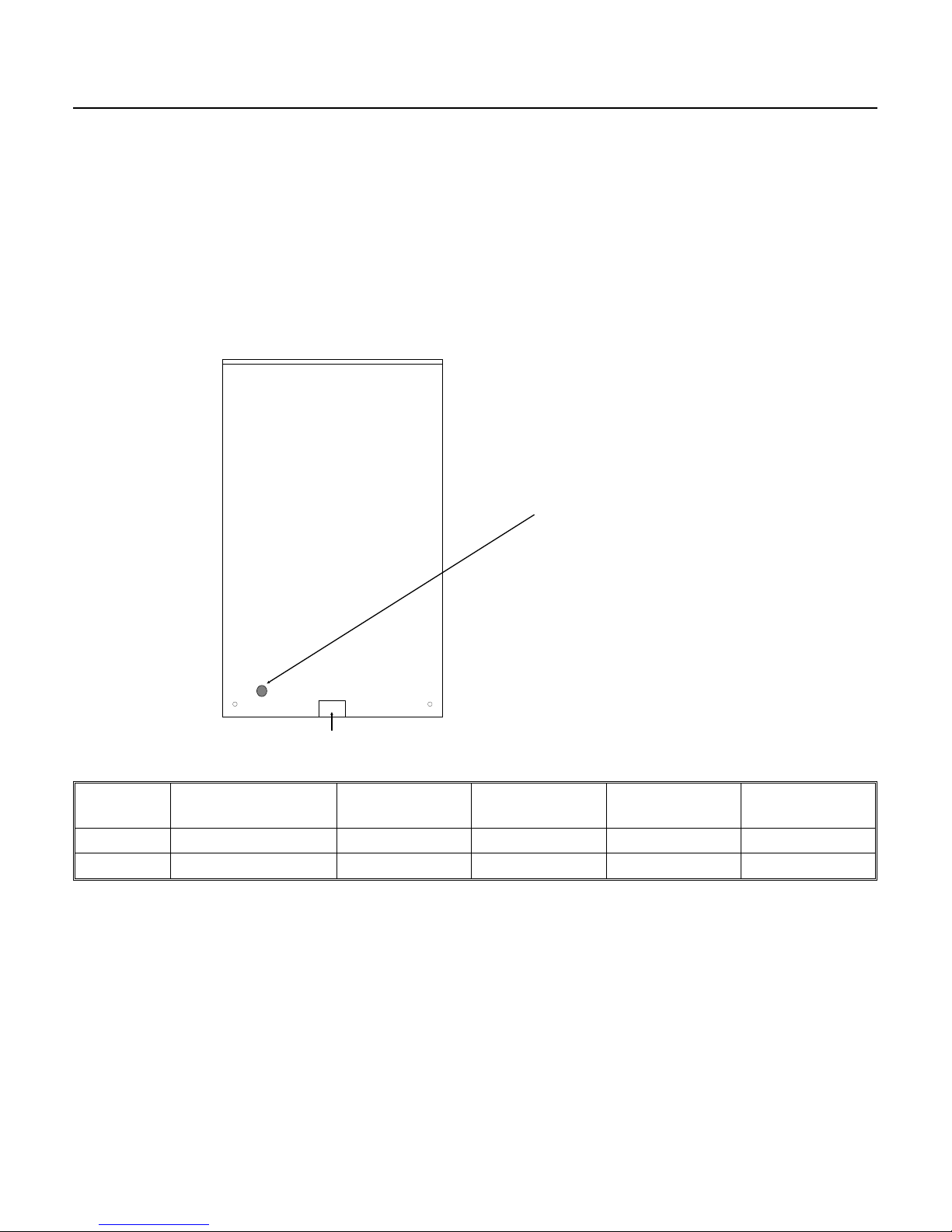

ELECTRICAL POWER CORD - 6 FT.

BACK VIEW

DRAIN

One 5⁄8" I.D. TUBE and

One 3⁄4" I.D. Tube

Base

Model

IS100-1B 22"w x 30"d x 34"h 110 lbs. 115/60/1 2 amps 6’ with plug

IS150-1B 30"w x 30"d x 34"h 150 lbs. 115/60/1 2 amps 6’ with plug

Rotor motor is 1/10 H.P.

Options: Lighted upper front panel. 4" leg kit. Push button actuation (factory installed).

Scotsman Ice Systems are designed and manufactured with the highest regard for safety and performance.

They meet or exceed the standards of U.L., N.S.F., and C.S.A.

Scotsman assumes no liability or responsibility of any kind for products manufactured by Scotsman that

have been altered in any way, including the use of any parts and/or other components not specifically

approved by Scotsman.

Scotsman reserves the right to make design changes and/or improvements at any time. Specifications and

designs are subject to change without notice.

Dimensions Storage

Capacity

Basic Electrical Amperage Power Cord

October 1993

Page 2

Page 3

IS100 and IS150

DISPENSER MODEL IDENTIFICATION

The complete model number of the dispenser describes many of its options:

IS 100 E -L F -1

Type Bin Cabinet Activation Display Voltage Series

Capacity Finish Method Type

In this example, the IS100E-LF-1A is an Ice Station with 100 lb. storage; it’s painted; uses levers for

dispensing; does have a lighted display; is 115 volt; and is the first series.

TYPE: IS = Ice Station. BIN CAPACITY: 100 = 100 lb. 150 = 150 lb. CABINET FINISH: E = Painted S =

Stainless. ACTIVATION METHOD: B = Push Button for ice L = Push Lever for ice. DISPLAY TYPE: F =

Lighted front panel N = No light. VOLTAGE: -1 = 115/60/1. SERIES: Design changes in alphabetical

sequence. Other variations may include brand identification.

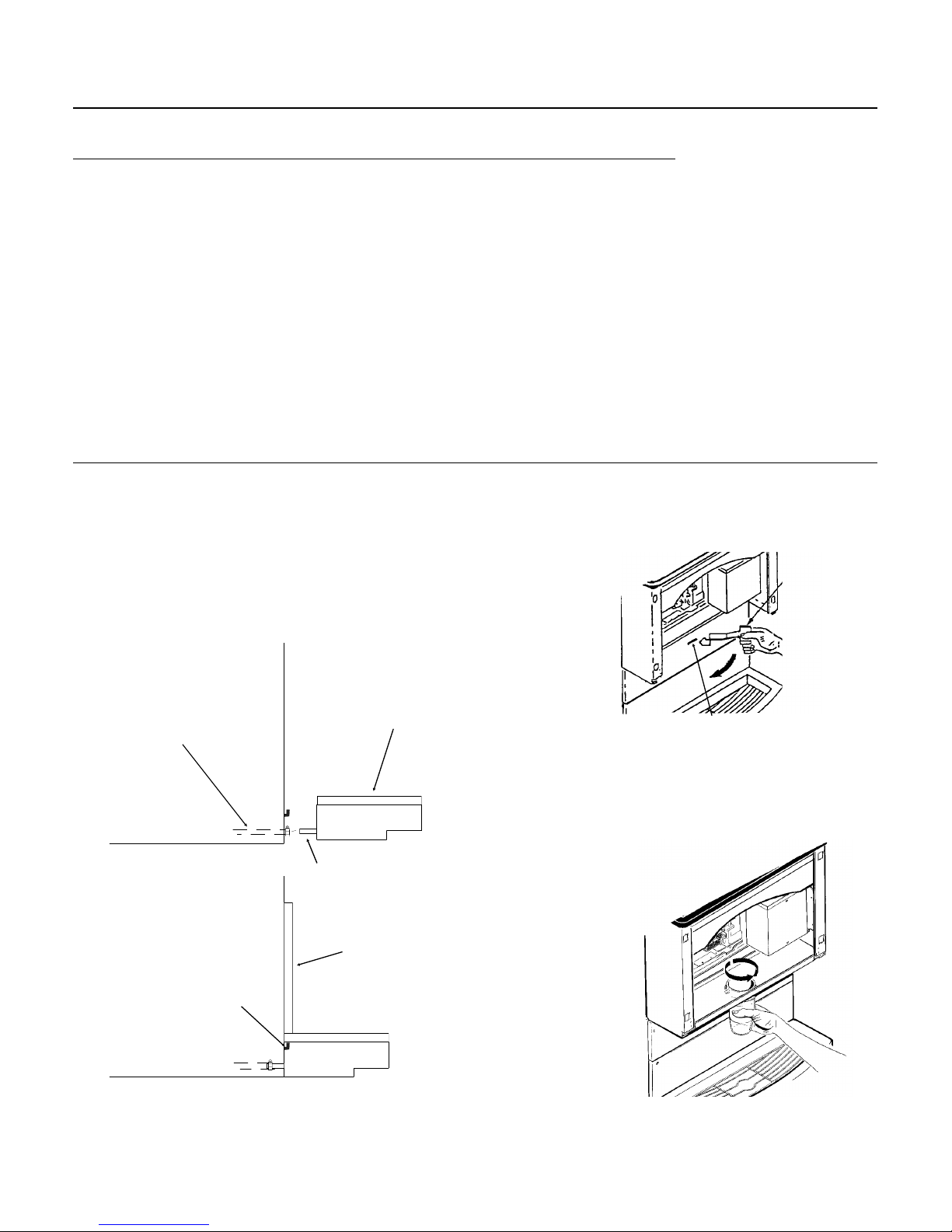

FOR THE INSTALLER: Installation of Loose Shipped Parts

A

Sink:

1. Remove splash panel from unit.

2. Slip a worm drive clamp over the drain tube as

shown.

3. Hold the drip tray up at an angle of about 30

o

Slide the drain fitting into the drain tube.

DRAIN

TUBE

DRAIN

FITTING

SINK

Ice Lever*, Ice chute, and Fluorescent Tube*

1. Slide out the

ice chute

mounting panel.

.

2. Insert the ice

lever into the

LEVER

slot as shown.

3. Swing the

lever through

the slot from

right to left and

let it hang freely.

SLOT

4. Twist the

fluorescent tube into the sockets.

5. Replace the ice chute mounting panel.

6. Insert the ice

chute into the

panel and twist

ICE CHUTE

MOUNTING

PANEL

clockwise 1/3

turn.

MOUNTING

TABS

4. Tighten the worm-drive clamp.

5. Hang the drip tray onto the mounting tabs at the

base of the unit. Replace the splash panel.

SPLASH

PANEL

7. Attach the

upper front

cover by

pushing the

strikes on the

cover into the

catches on the

unit.

ICE CHUTE

* Optional depending upon unit configuration.

October 1993

Page 3

Page 4

IS100 and IS150

FOR THE INSTALLER

1. Locate the Ice Station on the counter.

Allow vertical clearance above unit for the

removal of the cover, and for pouring ice

into the hopper.

2. Plan the unit drain. Two tubes (5/8" and

3/4" I.D.) are located at the back of the

cabinet. Routing is either thru the back or

base. Sufficient fittings are indluded with

the unit to install in most cases.

3. In order to comply with National

Sanitation Foundation (NSF)

requirements, this unit must be either

elevated above the counter top sufficiently

to provide space for cleaning under the

unit or sealed to the counter top.

Elevating the unit may be accomplished

by using the optional legs. They will screw

into threaded holes in the base of the unit.

CABINET DRAIN

TUBES

If the unit is to be sealed to the counter

top, the drain and soda tubing should be

available and planned such that the

connections may be finished after the unit

has been sealed to the counter.

Sealing may be accomplished by the use

of room temperature vulcanizing (RTV)

rubber sealant such as General Electric

IS 808 Industrial Sealant, Dow Corning

731 (Scotsman part number 19-0529-01)

or the equivalent.

With the unit located on the counter as

desired:

A. Tilt or lift the unit to expose the bottom

flanges of the base frame.

B. Apply the sealant to cover the bottom

flanges of the base frame.

C. Return the unit to the desired position

on the counter top.

D. Add sealant around the base frame

and counter top to provide a seal with a

radius of 1/2". Follow the sealant

manufacturer’s instructions on the

package for working with the sealant, and

cleaning up.

E. Seal around all access holes in the

counter top with Permagum or Mortite

caulk or an equivalent material.

USE LEGS OR

SEAL TO

COUNTERTOP

October 1993

Page 4

Page 5

INITIAL START UP

IS100 and IS150

1. Sanitize the ice storage system as instructed on

page 8.

2. Fill hopper with sanitary ice.

Ice hopper contains parts

that can move at any

time, and will cause

injury if hands are in the

way.

Do

not remove cover

until the unit has been

unplugged from the

electrical power.

3. Plug the unit’s power cord into an electrical

outlet, if the unit has a lighted sign, it should come

on. Dispense several containers of ice.

FOR THE OPERATOR

This section covers operating controls, daily

pre-operation check, and unit operation.

Note: there is a timer in the control box that will

activate the rotor in the ice bin every two hours.

The amount of time that the rotor turns is factory

set at 2 seconds, and is adjustable between one

tenth of a second and 4 seconds. Agitation of the

ice keeps it from fusing together after long periods

in the bin.

The dispenser must always contain ice to have ice

available for use.

OPERATING CONTROLS - Units have either a

lever or a push button.

Lever: Ice will continue to be dispensed for as long

as the lever is held in, or until the hopper is empty.

Push Button: When the ice dispense button is

pushed, ice will be dispensed for as long as the

button is held in or until the hopper is empty.

Daily Check

1. Make sure drip tray and grill are clean.

2. Remove cover and pour sanitary ice into the

hopper.

Do NOT use bagged ice directly from a freezer.

The ice must be broken up in the bags first before

adding to the hopper.

Large chunks of ice can NOT be dispensed.

Keep the cover in place, and check the ice supply

regularly during operating hours.

3. Keep sink clear of spilled ice.

4. At the end of the day:

Remove the grill from the sink, clean the sink, grill

and splash panel, make sure the sink drain is open

by pouring hot water into the sink. Return the grill

to the sink.

HOT

WATER

October 1993

Page 5

Page 6

DOOR

UPPER ICE

CHUTE

IS100 and IS150

HOW IT WORKS

The ice is stored in a hopper, and the hopper is

sloped towards the front. At the front there is an

angled rotor: when that rotor turns, it scoops the

ice, lifts it to the top of the ice chute and drops it

through that chute into the user’s container.

CUT AWAY VIEW

ICE

ROTOR

ICE CHUTE

October 1993

Page 6

Page 7

CLEANING AND SANITIZING

The sink, grill and splash panel area should be

cleaned daily.

The ice storage system should be sanitized

monthly.

Daily:

1. Lift up and remove grill from sink.

2. Use soap, hot water, and a clean cloth to wash

sink and splash panel; rinse with hot water,

allowing plenty of hot water to run down the drain.

3. Wash the grill, then rinse with clean water. Place

back in sink.

4. Clean all exterior surfaces of the unit with warm

water and a sponge. Rinse out the sponge with

clean water, wring excess water out of the sponge,

and wipe off external surfaces of the unit. Wipe unit

with a clean soft cloth. Do NOT use abrasive type

cleaners.

IS100 and IS150

POUR HOT WATER

DOWN SINK TO CLEAN

OUT DRAIN.

October 1993

Page 7

Page 8

UPPER ICE

CHUTE

SNAP OFF

PANEL

IS100 and IS150

CLEANING AND SANITIZING

MONTHLY & INITIAL START UP:

Sanitize the Ice Storage System.

Note: this should only be done by qualified

personnel.

1. Unplug the Ice Stand’s electrical cord from the

electrical power.

Ice hopper contains parts

that can move at any

time, and will cause

injury if hands are in the

way.

Do

not remove cover

until the unit has been

unplugged from the

electrical power.

2. Remove cover and discard all remaining ice.

3. Mix a solution of 1 ounce of household bleach to

2 gallons of potable water, or: mix a solution of any

approved sanitizer, following the directions for

mixing and applying that sanitizer.

A. Twist the clear ice chute 1/3 turn, and pull down

to remove.

B. Locate the two

thumbscrews holding

the lower brace.

Remove them and the

brace.

C. Locate the three

thumb screws holding

the upper ice chute;

remove them (1 on

CLEAR

CHUTE

top and 2 below).

Remove the upper ice

chute from the

machine.

Thoroughly wipe the surfaces of the bin door and

both ice chutes with the sanitizing solution, and

allow to air dry.

4. Remove the ice chute (if used) by lifting one end

and pulling out of the slots. Unscrew the sweep

arm (plus shield and bearing if used) from the rotor

shaft, and pull the rotor from hopper.

SWEEP

ARM

BEARING*

ICE SHIELD*

*NOT USED ON ALL UNITS

5. Using a clean cloth or sponge, wipe all interior

surfaces of the ice storage hopper with the

sanitizing solution, allow to air dry.

6. Wipe all surfaces of the rotor (plus ice chute,

shield and bearing if used) with the sanitizing

solution, and allow to air dry.

7. Pull out and remove the upper front panel.

ROTOR

Place the upper ice chute back onto the dispenser,

secure with the three thumb screws.

Place the lower brace back onto the unit and

secure with the two thumbscrews.

Place the clear ice chute back onto dispenser.

Place the upper front panel back onto the machine.

8. Wipe the inside surface of the cover with the

sanitizing solution, and allow to air dry.

9. Reassemble the rotor and hopper (plus ice

chute, shield and bearing if used, re-wipe the

surfaces of the rotor and allow to air dry.

10. Wipe the top edge of the ice hopper with the

sanitizing solution, allow to air dry.

11. Pour in fresh, sanitary ice and replace the

cover. Plug the unit in, and it is now ready to

dispense ice.

October 1993

Page 8

Page 9

IS100 and IS150

SERVICE DIAGNOSIS

PROBLEM PROBABLE CAUSE CORRECTION

Will not dispense ice 1. No ice in hopper 1. Fill hopper with ice

2. Vend switch does not close 2. Check vend switch, replace if

open

3. Drive motor will not run 3. Check drive motor, replace if

not working

4. Door solenoid will not open

door

5. Rotor will not turn 5. Check hub of rotor

6. Relay for vend switch does

not close during operation.

ELECTRICAL SEQUENCE

Refer to the wiring diagram.

Ice Vending:

Ice is dispensed as long as the ice vend lever or

push button is pushed, or until the hopper is empty

of ice.

••When the ice vend lever or push button is

pushed, the vend switch closes, and makes a

circuit to the coil of relay A.

••When relay A is energized, relay A’s contacts

6-9 and 7-4 close. Relay A’s contacts 7-1 open.

••When relay A’s contacts 6-9 close, they make a

circuit to the door solenoid, which opens the ice

door.

••When relay A’s contacts 7-4 close, they make a

circuit to the coil of relay B.

••When relay A’s contacts 7-1 open, the circuit to

the timer is opened.

••When relay B’s coil is energized, it closes a

circuit to the gearmotor, and the motor turns the

rotor.

4. Check/replace door and

solenoid

6. Check relays, replace if

necessary.

Stand By:

••Relay A’s contacts 7-1 are closed and make a

circuit to the timer.

••The timer is energized when the unit is not

dispensing. The timer switch will close for a few

seconds every two hours.

••When the timer switch is closed, it makes a

circuit to relay B’s coil.

••When relay B is energized, it powers the

gearmotor, and the rotor is turned.

October 1993

Page 9

Page 10

IS100 and IS150

REMOVAL & REPLACEMENT

To Replace Vend Switch:

1. Disconnect Electrical Power.

Electrical Shock

Hazard.

Unplug unit before

servicing.

2. Pull out and remove upper front panel.

Lever Type

A. Twist ice chute 1/3 turn and pull down to remove.

B. Remove screws holding mounting plate to

cabinet. Pull plate assembly out and away from

cabinet. Switch is mounted to valve plate.

Push Button

A. Locate vend switch behind push button.

B. Remove wires from switch.

C. Remove screw & nut retaining switch to

mounting plate, and remove switch from dispenser.

3. Reverse steps to reassemble.

To Replace Gear Motor Assembly:

1. Disconnect electrical power.

2. Remove cover from hopper.

3. Unscrew sweep arm holding rotor to gearmotor

shaft.

4. Remove rotor from gearmotor shaft.

5. Remove splash panel

6. Twist ice chute 1/3 turn and pull down to remove.

12. Remove (4) screws holding bracket to cabinet.

13. Pull gearmotor bracket from cabinet.

14. Dismount gearmotor from dispenser.

15. Reverse to reassemble. Gearmotor bracket

should be installed where it was, so that the rotor

should clear bin surface by 1/8" to 1/4". If needed,

the slots on the gearmotor bracket will allow the

position of the rotor to be adjusted.

To Replace Solenoid:

1. Disconnect electrical power.

2. Pull out and remove upper front panel. Remove

fluorescent tube light if used.

3. Remove 2 thumb screws holding lower brace

and remove.

4. Remove 3 thumb screws holding upper ice

chute cover, and remove cover.

5. Disconnect electrical leads from solenoid.

6. Straighten cotter pin, and remove pin from

solenoid plunger.

7. Remove rubber mounting screws holding

solenoid to cabinet, and remove solenoid from

cabinet.

8. Reverse to reassemble.

To Replace Light: (Optional)

1. Disconnect electrical power.

2. Pull out and remove upper front panel.

3. Twist fluorescent tube out of sockets.

4. Reverse to reassemble.

7. Remove ice chute mounting plate.

8. Remove screws holding valve mounting plate to

cabinet. Pull valve assembly out and away from

cabinet.

9. Mark location of gearmotor bracket on cabinet.

10. Disconnect gearmotor electrical leads in

control box.

11. Remove (4) screws holding gearmotor to

bracket..

LIGHT TUBE

October 1993

Page 10

Loading...

Loading...