Page 1

TO THE OWNER OR USER:

Double System RL

The service manual you are reading is intended to

provide you, and th e m ai n tenance or s ervice

techni ci a n, with the i nf or m a ti o n ne eded to ins tall,

start up, clean, maintain and service this ice

system.

The is the freezer portion of a commercial ice

machine. It is designed to be connected to the

conden s i ng s ection of a r ef r i ge r ation sys t em ,

specifically a supermarket system.

Table of Contents

FOR THE INSTALLER: Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 2

FOR THE INSTALLER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 3

FOR THE ELECTRICIAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 4

FOR THE PLUMBER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 5

FOR THE INSTALLER: Final Check List . . . . . . . . . . . . . . . . . . . . . . . . . . Page 6

INITIAL START UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 7

COMPONENT IDENTIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 8

COMPONENT DESCRIPTION: Control Box . . . . . . . . . . . . . . . . . . . . . . . . Page 9

COMPONENT DESCRIPTION: Evaporator . . . . . . . . . . . . . . . . . . . . . . . . . Page 10

ELECTRICAL SEQUENCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 11

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 12

OPERATION: Refrigeration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 13

MAINTENANCE AND CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 14

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 15

CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 16

SERVICE DIAGNOSIS: Condition - No Ice Being Produced . . . . . . . . . . . . . . . . Page 17

REMOVAL AND REPLAC EMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 18

REMOVAL AND REPLAC EMENT: Bearing And Break er . . . . . . . . . . . . . . . . . . Page 19

REMOVAL AND REPLAC EMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 20

REMOVAL AND REPLAC EMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 21

REMOVAL AND REPLAC EMENT: Evaporator . . . . . . . . . . . . . . . . . . . . . . . Page 22

REMOVAL AND REPLAC EMENT: Gearmotor . . . . . . . . . . . . . . . . . . . . . . . Page 23

CIRCUIT BOARD TESTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 24

Parts lists and wiring diagrams are in the center of this manual, printed on yellow paper.

This manual was printed on recycled paper, keep

it for future reference.

Note the Warning symbol where it appears. It

marks a potential hazard.

March 1997

Page 1

Page 2

Double System RL

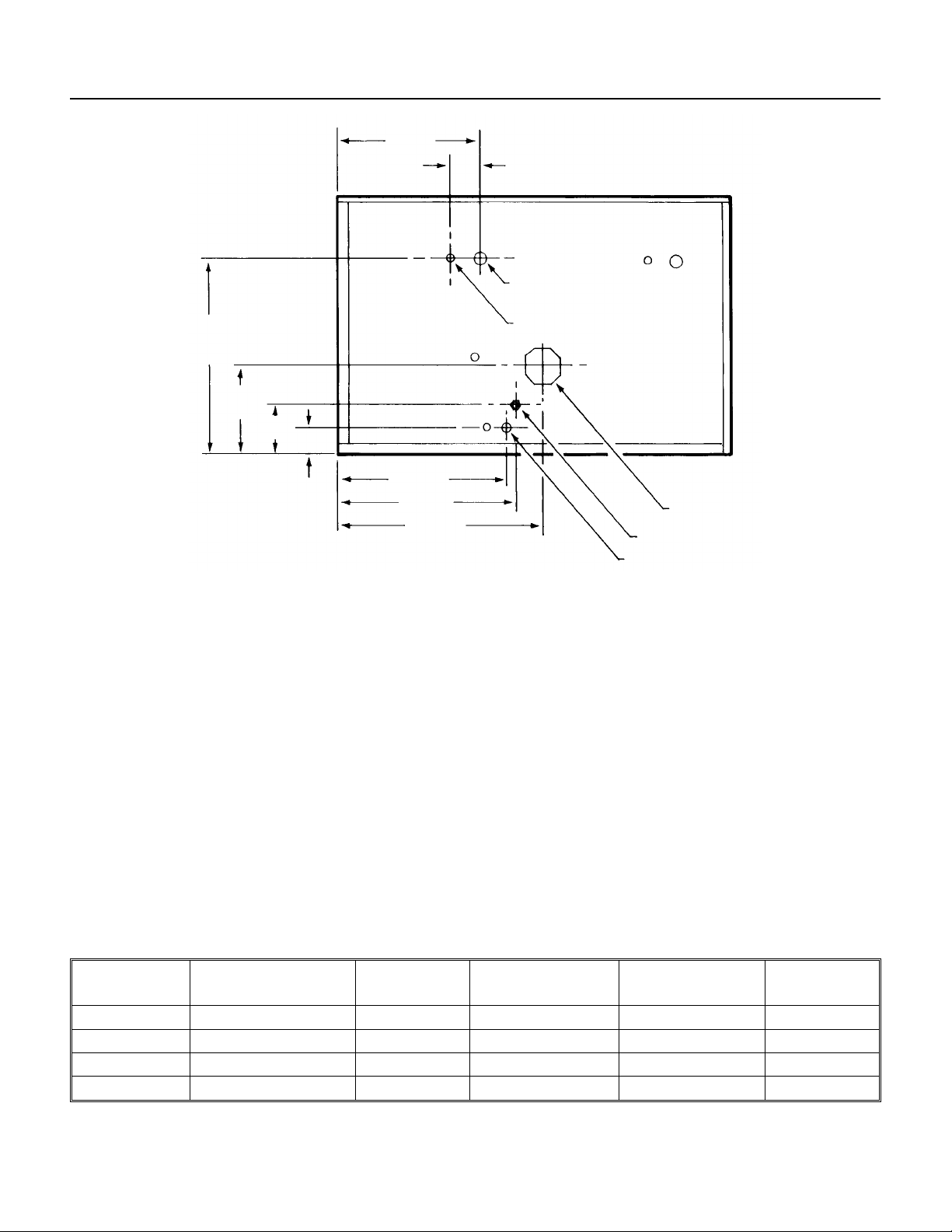

FOR THE INSTALLER: Spe cifications

BACK VIEW

20.84"

9.43"

5.25"

3"

15.53"

17.8"

18.8"

21.66"

The machine is des igned to fit the Scot sman

storage bins BH800 or B90. Leg kit KLP4 is

recommended when using both the B90 bin and

an exte nsion.

Installation Limitations:

The machine is

designed for indoor installations only. The machine

must als o be i n a co ntrolle d en v i r on m en t w he r e

the air temperatur e does not fall below 50

go above 100

The wate r tem p er a tu r e m ust be betw ee n 40

and 100

0

F.

0

F.

0

F., or

0

F.

The electrical power supp ly must not dr op below

-5% of the lowest nameplate voltage or go above

10% of the highest nameplate voltage.

3.1"

7

SUCTION LINE CONNECTION

LIQUID LINE CONNECTION

POTABLE WATER INLET 3/8" FLARE

DRAIN 3/4" FPT

"

⁄

8

1

"

⁄

2

ELECTRICAL INLET

Scotsman Ice Systems are designed and

manufactured w i th the highest regard for safety

and performanc e . Th ey m ee t or exceed th e

standards of U.L., N.S.F., and C.U.L.

Scotsman assumes no liability or responsibility of

any kind for pr o du c t s ma nu fa c t ur e d by Sc otsman

that ha ve been alt er ed in any way, including the

use of any parts and/or other components no t

specifically appr oved by Scotsman.

Scotsman reserves the right to make design

chang es and/or i mprovements at any ti me.

Specification s and designs are subject to chang e

without notice.

SPECIFICATIONS:

Model Cabinet Size System

BTUH required Voltage Ice Type

Refrigerant

FME2400RL 42"w x 27"h x 24"d R-404A 16,000 208-230 Flake

NME1850RL same R-404A 16,000 208-230 Nugget

FM2402RL same R-22 16,000 208-230 Flake

NM1852RL same R-22 16,000 208-230 Nugget

March 1997

Page 2

Page 3

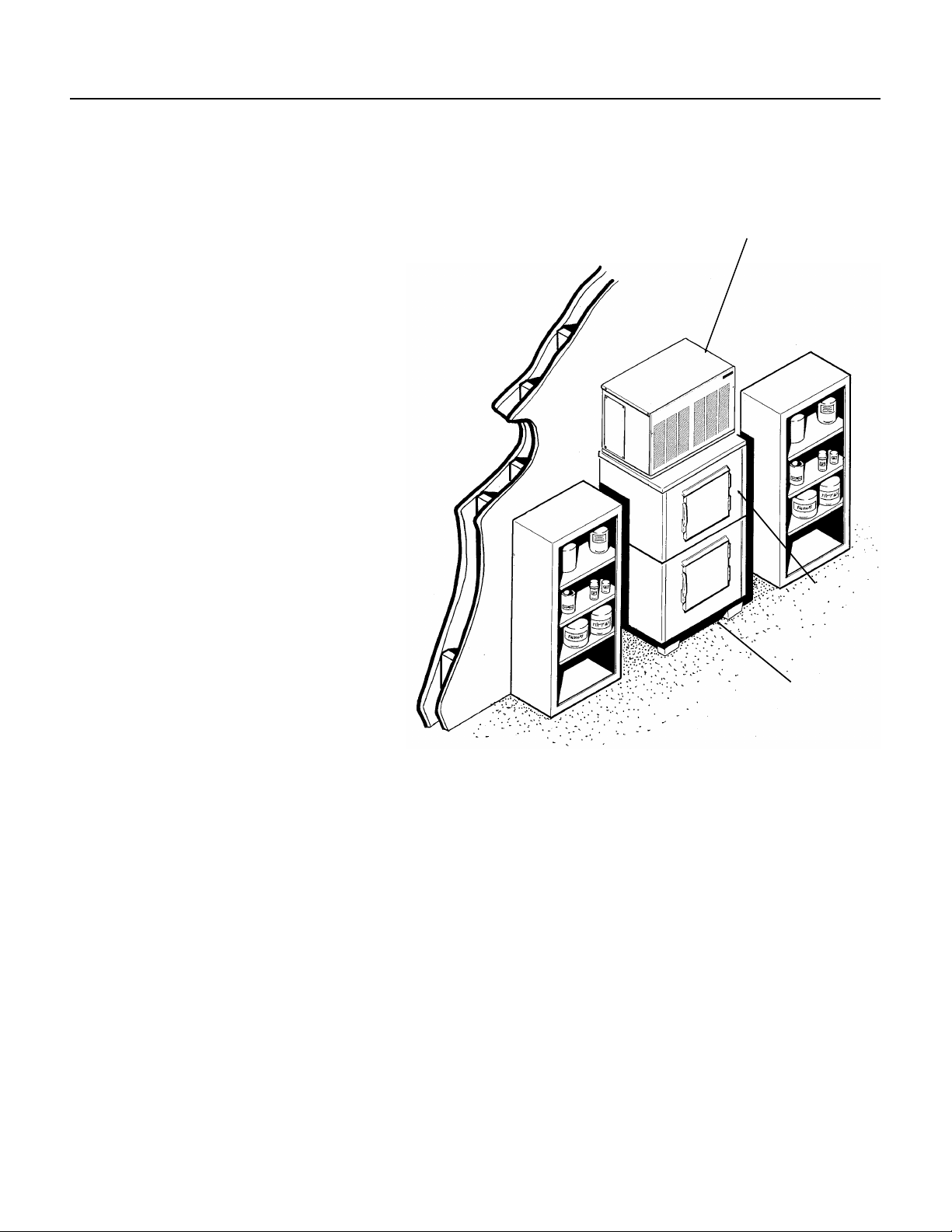

FOR THE INSTALLER

Select the Location:

The unit can only be installed indoors within

the limitations described on page 2.

The ice machine will have to be connected

to the building’s R-404A refrigeration

system, check to be sure that the system

has eno ugh extra capacity to handle a

minimu m of additional 16,000 BTU’s pe r

hour @ 110

(assume a 0

Storage Bin:

Scotsman’s B90 will be the presumed bin of

choice. If using the bin extension BX87,

install heavy duty leg kit KLP4 and place

the bin into position.

Remove the paper tape from the bin edge

gasket, and install the bin extension onto

the B90.

Remove the paper tape from the bin

extension top edge, and using a

mechanical lift, install the FME2400RH onto

the top of the storage bin assembly.

Faste n th e i ce m achine to t he bi n usi n g ( 4)

5/15-18 2.5" cap screws.

Level the assembly by:

a. Turni n g th e l eg le ve l er s i n or ou t on t he

standard legs .

b. Use shims under the heavy duty legs of

the KLP4.

Locate t h e N ameplate:

locat ed on th e ba c k panel of th e mac h i ne ,

and contains the electrical characteristics

particular to the unit being installed.

Refrigeration Installation:

The skills of a refrigeration technician are

requi r ed to connect the ice mac hine to the

buildings refrigeration system.

Notes:

•

Suctio n Line and Liquid Line Stubs are

at the ba ck of the cabinet .

0

F. liquid line temperature

0

F. evaporator temperature).

The nam ep l ate is

Double System RL

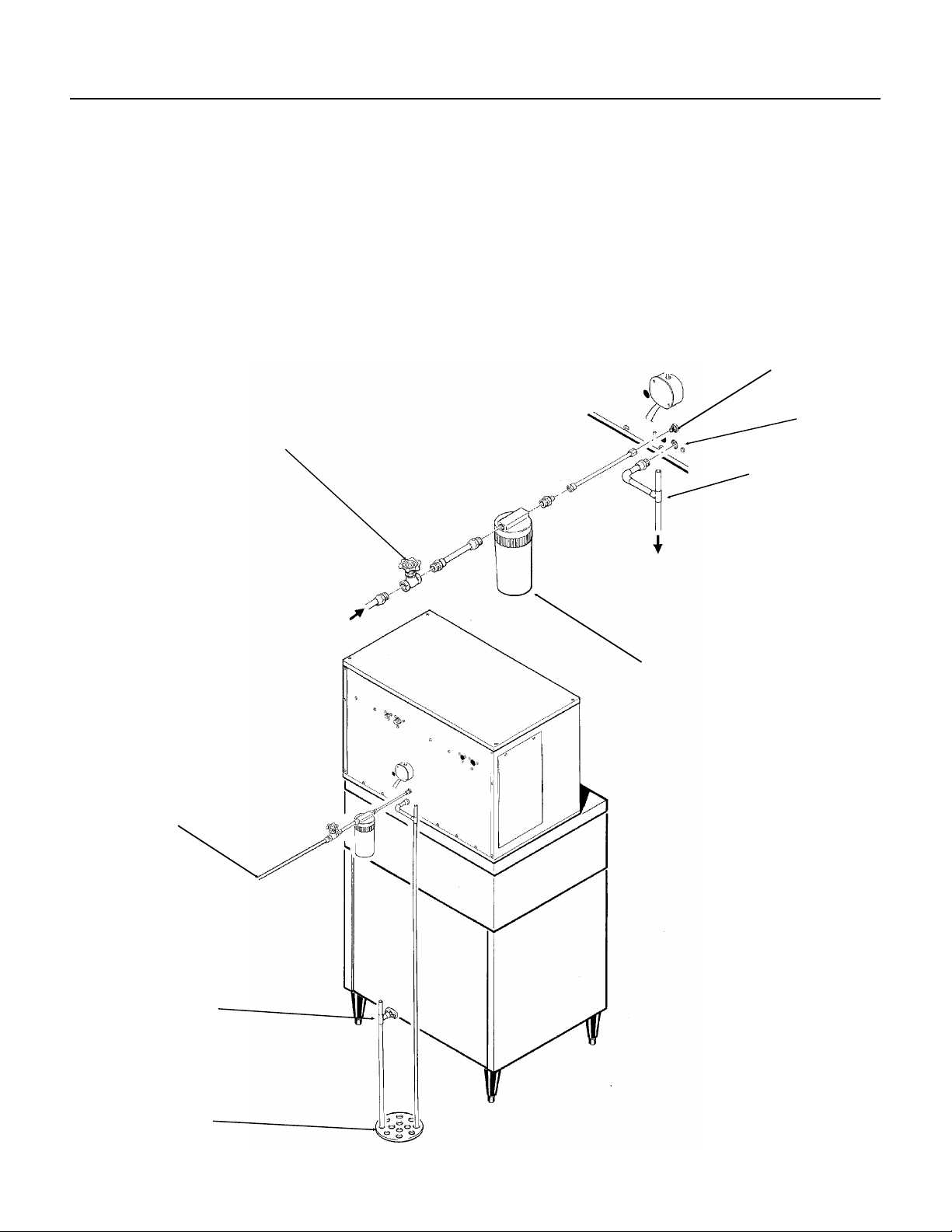

TYPICAL INSTALLATION: ALLOW ROOM FOR SERVICE ACCESS

Ice Machine

BX87 BIN

EXTENSION

B90 STORAGE BIN

•

1.5 ounc es of t he app r op r i at e r ef r i ge r an t i s in

the system as a holding charge.

•

Be sure there is enought BT U capacity.

•

Be sure the liquid connection is NOT in series

with another liquid line valve.

•

Local Codes must be observed.

•

A P-trap should be installed where there will be

more than 10’ of vertical rise in the suction line.

March 1997

Page 3

Page 4

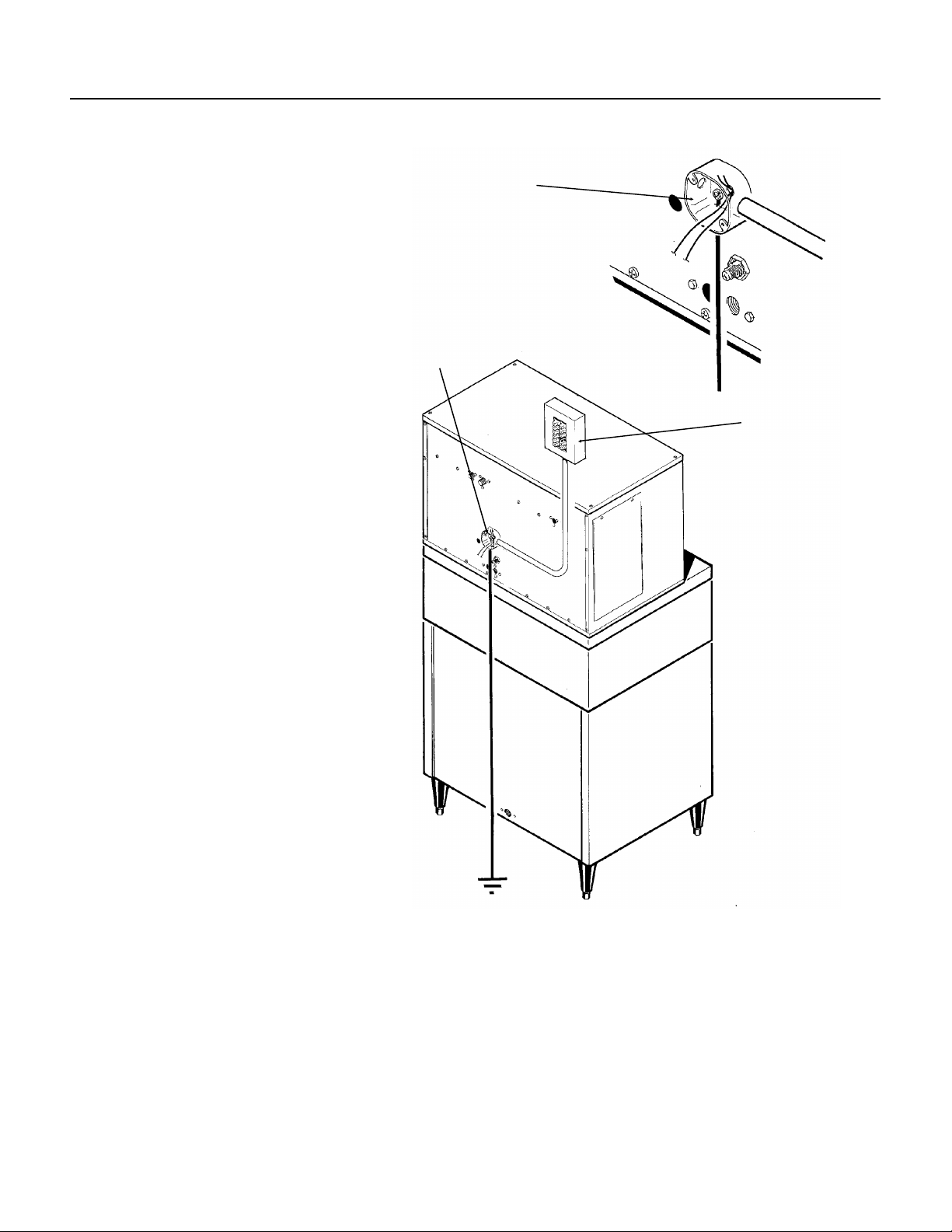

Double System RL

FOR THE ELECTRICIAN

CONFORM TO ALL APPLICABLE CODES

Electrical Connections:

Locate the nameplate for the current

requirements, and then determine the

wire size and type per the National

Electric Code. The machine requires a

solid chassis to earth ground wire.

Refer to the wiring diagram. The ice

machine should be connected to it’s

own electrical circuit, and be

indivi dually fused.

Voltage, when the unit is under full

load, must remain within the limitations

listed on page 2.

LOW VOLTAGE CAN CAUSE

EQUIPMENT MALFUNCTION

AND/OR DAMAGE

All external wiring should conform to

the Nati on al , State, and local el e c tr ical

codes. Usually the services of a

licensed electrician will be required.

DETAIL OF

JUNCTION BOX

JUNCTION

BOX

POWER SUPP LY

March 1997

Page 4

Page 5

FOR THE PLUMBER

CONFORM TO ALL APPLICABLE CODES

Double System RL

Water Supply:

The recommended water supply line is 3/8" O.D.

copper tu bi n g, with a mi ni m u m operation press ur e

of 20 PSIG, and a maximum of 80 PSIG. Connect

to cold water using the male flare connection at the

back of the ma ch i ne . In stall a shut of f v alve in an

accessible spac e between the ice maker and the

water supply.

SHUT OFF

VALVE

Drain System:

All drains are of the gr avity ty pe, and must have a

minimum of 1/4" fall per foot of horizontal run. The

drains must be installed to conform to local

plumbing codes. The use of a vent at the machine

and at the bin will allow the system to drain

properly. Use on ly rigid tub ing for drains; insulation

of the bin drain is recommended.

3/8" MALE FLARE

3/4" FPT

VENT THIS DRAIN

WATER INLET

BIN DRAIN

FLOOR DRAIN

FIELD

SUPPLIED

WATER FILTE R

March 1997

Page 5

Page 6

Double System RL

FOR THE INSTALLER: Final Check List

1. Is the unit inst al led where th e ai r an d w at er

temperatures are within and will remain within the

limitations for the unit?

2. Is ther e 6" clearance at the rear of the machine

for utility connections?

3. Has the water supply line be checked for

pressures between 20 and 80?

4. Has the unit been leveled?

5. Has the shipping material been removed from

inside the cabinet?

6. Have the electrical connections been made?

7. Have the drains been installed and checked for

leaks?

8. Has the refrigeration supply been installed and

checked for leaks?

9. Has the bin and cabinet been wiped clean or

sanitized?

10. Has the warranty registration card been

properly filled out and mailed to Scotsman?

11. Has the owner been given the service manual

and been ins t r uc t ed on ho w to m ai n ta i n th e i c e

maker?

13. Has the ow ne r bee n gi ve n the name an d

telephone num ber of the local Scotsman servic e

agency?

March 1997

Page 6

Page 7

INITIAL START UP

Double System RL

1. Remove the top and front panels.

2. Open the water valve, and observe that the two

float reservoirs fill up with water and shut off.

3. Swit ch on the electrical power.

4. Open th e ha nd v al ve s ( in the liqui d l ine s ) .

5. Open th e ba l l val ves (in th e suction li ne s ) .

6. Switch on one master switch, and observe:

That liquid line valve opens

The gearmotor runs

Within a short time, that side of the machine

begins to m ak e i c e.

Water fl ow s from th e water rese r vo i r , an d the float

drops, letting in more water.

7. Switch on the other master switch, observe that:

The liquid line valve opens

The gearmotor runs

Within a short time, that side of the machine

begins to m ak e i c e.

Water fl ow s from th e water rese r vo i r , an d the float

drops, letting in more water.

8. With both sides operating, the sight glass

should remain full, and the low side pressure will

be about

2400 or 185 0 m od el s (R-404 A) 36 PSIG, + or - 2

2402 or 185 2 m od el s (R-22) 25 PSIG, + or - 2

Gearmotor amp draw should not exceed the

namepl ate rati ng .

9. Check the system very carefully for any

refrigerant leaks, repair as needed.

March 1997

Page 7

Page 8

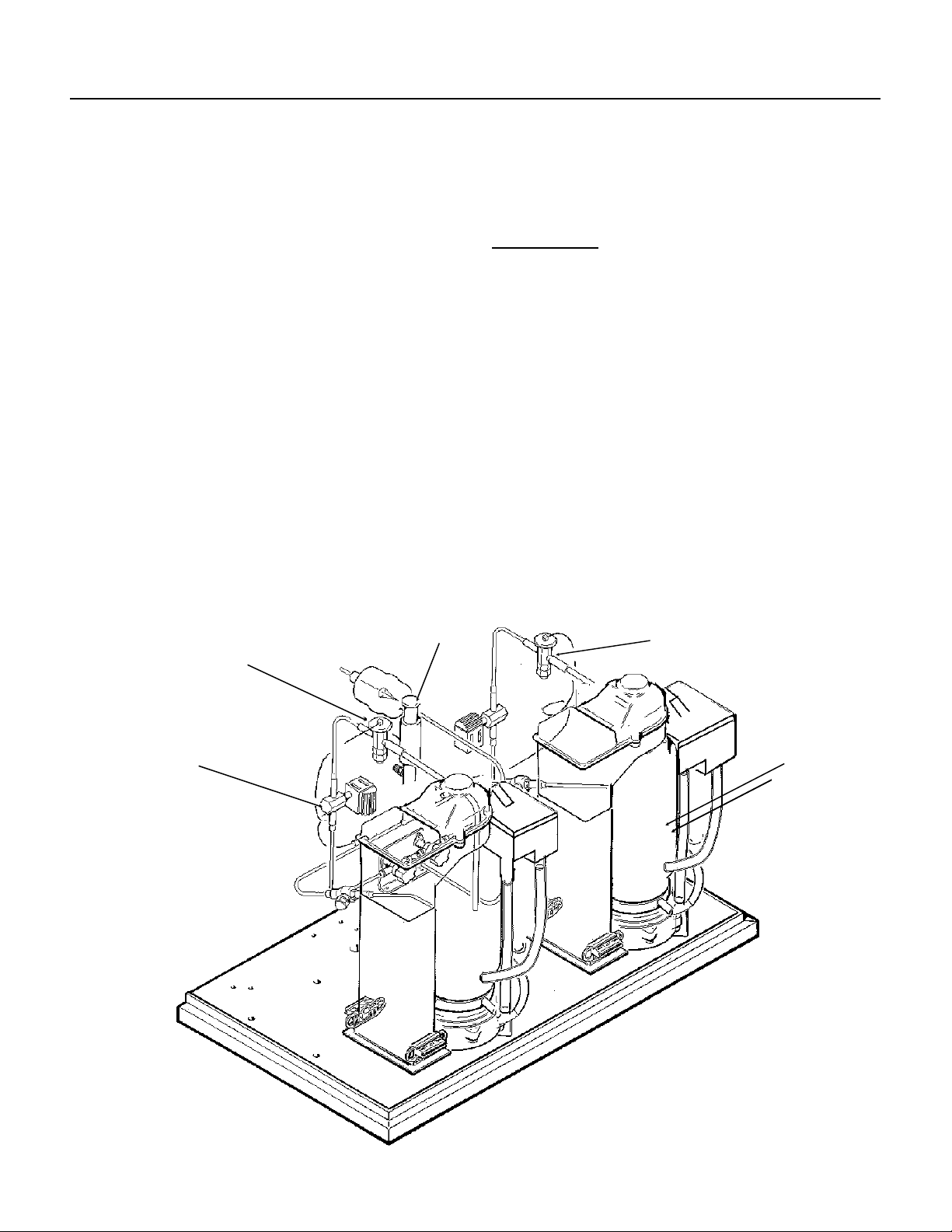

Double System RL

COMPONENT IDENTIFICATION

Liquid line valve(s)

These v alves operate to turn the ice making

process on and off.

When the i c e level drops i n th e i ce ch ut e, the ice

level sensor will cause the circuit board to close

the liquid line relay, which energizes the liquid line

valve for that side of the system. The liquid line

valve opens, and liquid refrigerant flows to the

thermos tatic expa nsion valve.

Thermostatic Expansion Valve

The metering device of each system, the valve(s)

sense the tem peratu r e of t he s uction lin e an d v a r y

the amoun t of liquid refr i g er a nt t ha t pa s se s

through the valve into the evaporator, thus

maintaining a constant level of refrigeration. TXV’s

are factory set. Do not adjust unnecessarily.

DO NOT ADJUST THE TXV UN TIL THE EPR

HAS BEEN SET.

The super h eat settin g i s 4-8

temperature of the evaporator outlet at the TXV

bulb, and check the low side pressure at the EPR

valve. Convert the pressure to temperature (using

a temperature pressure chart) and subtract the

amount from the ou tlet temperature. The resul t is

the supe r he at . U se an el ectronic thermom et er .

THERMO VALVE

0

F. Measure the

EPR VALVE

EPR: Evaporator Pressure Regulator Valve

This valve maintains a constant pre ss ure on its

inlet (evaporators) side regardless of the pressure

on the out l et (s uc t i on ) s i de . The EPR is fac tory set,

adjust only if needed. After adjusting, re-check

TXV superheat.

EPR Settings:

R-22 models (2402/1852): 25 PSIG

R-404 A m odels (2400/1850): 36 PSIG

Evaporators:

Where the water is frozen into ice crystals. As the

water cools, it begins to turn into ice, and the

slowly turning auger lifts the ice, as it is being

made, and forces it up and out of the "breaker" or

spout w he r e th e extra wat er i s com p r essed out of

the ice. The ice then drops through the chute, into

the storage bin.

THERM O

VALVE

LIQUID LIN E

VALVE

EVAPORATO R

March 1997

Page 8

Page 9

COMPONENT DESCRIPTION: Control Box

Double System RL

Circuit Board:

through sensors and relays. The sensors are: ice

level, and water level. The rel ays are for the gear

motor (with a built in time delay to clear the

evaporator of ice when the unit turns off) and for

the liquid line valve.

Transformer:

board.

On/Off Switch:

machine.

ON/OFF SWITCH

Controlling the ice machine

Supplies low voltage to the circuit

Manual co ntrol for that side of the

TRANSFORMER

CIRCUIT

BOARD

TERMINAL STRIP

March 1997

Page 9

Page 10

Double System RL

COMPONENT DESCRIPTION: Evaporator

Evaporator

water an d c o nt ai n i ng a wa te r se al and auger .

Auger:

it push es th e i ce crystals up to the top of the

evapor ator.

Water Seal :

rotat ing with the au ger, the bo tt om ha l f s t ationary ,

the sealing action being where the two seal "faces"

meet.

Ice Swee p:

with the auger to "sweep" th e ice into the ice chut e.

Divider

of the extra water is squeezed out of it before it is

discha r ge d i nt o the bin.

BEARING

: A refrigerated vertical tube filled

A solid sta inl e s s s te el do ub l e s p i r al auger,

A two part "face" seal , the top half

A plastic cap with "fingers". It revolves

: Where th e i c e is compres se d and much

Motor:

reducer.

Bearing:

the auger is thrust down, and pressure from the

auger thrust is taken up by this bearing.

A split phase motor th at drives the gear

As the ice is pushed up the evaporator,

ICE SWEEP

DIVIDER

WATER

SEAL

EVAPORATO R

AUGER

March 1997

Page 10

MOTOR

Page 11

ELECTRICAL SEQUENCE

Double System RL

Refer the wiring diagram as needed.

Each syst e m is separate

If the machine is switched off at the master switch,

but is ot he r w i se r ea dy to go, swi tching th e mas t er

switch to on does the following:

•

The bin em pty light on the circuit board goes on

•

There is a 15 sec o nd del a y

•

If there is enough water in the reservoir, the

circuit board will allow the machine to start up.

Start up consists of:

•

The liquid line relay and auger motor relay

become energized, connecting power to the

windings of the auger motor.

•

The auger m ot or starts, an d the centr i fu gal

switch closes, connecting power to the liquid

line valve coil.

•

The liquid line valve opens, and the refrigerant

flows to the ther m os t a ti c expansio n v a l ve and

into the evaporator.

•

As ice goes past the ice level sensors, the bi n

empty light will stay on, and the machine will

continue to run, unless the ice stays between

the sensors for more than 15 seconds (bin full).

At that point, the bin empty light goes out, and

the machine shuts down.

Shut Down consists of:

•

The liquid line relay opens.

•

The liquid line valve closes

•

Ice making stops

•

The auger motor is run by the circuit board for 2

more minutes, clearing out ice in the

evapor a to r , and then

•

The auger m otor rela y op en s , an d the auger

motor stops.

If the ice level sensor is clear (bin empty) for more

than 15 seconds, the machine will start up again.

Anothe r pur p ose of the cir cuit boa rd i s to tu r n th e

machine off if there is not enough water in the

machine.

•

When the water level in the reservoir falls

below the water level sensor, the machine will

"shut down"

•

When the water refills the reservoir, the

machine will start up again.

Separate from the circuit board:

•

The mast er s w it c h i s t he ma nu al co ntrol for

each system, but it is not a service disconn ect.

March 1997

Page 11

Page 12

Double System RL

OPERATION

Water

Water enters the machine through the 3/8" male

flare at the rear of the cabinet, goes to the water

reservoir which it enters thr ough the float valv e.

WATER

INLET

RESERVOIR

ICE CHUTE

The water then goes out the bottom of the

reservoir tank to the bottom of the evaporator.

Reserv oi r overflow or evaporator condensation is

routed to the drain.

WATER LEVEL

EVAPORATO R

WATER INLET

DRIP PAN DRAIN

WATER SCHEMATIC

March 1997

Page 12

Page 13

OPERATION: Refr igeration

Double System RL

The remote high side

supplies high pressure

liquid refrigerant to the

liquid line connection on

the ice machine. After

the sight glass, there are

two sepa r ate liquid l ines,

each leading to a liquid

line valve. When the

individual ice lev el

sensor causes the circuit

board t o en er g i z e the

liquid line valve, the

valve opens, allowing

the liqu id r ef r i ge r an t to

enter that expans i o n

valve. The thermostatic

expans ion valv e meters

the liquid refrigerant into

HAND VALVE

LIQUID LINE

VALVE

THERMO VALVE

LIQUID

LINE

SIGHT GLASS

the evap or a tor, wher e i t

boils off (evapo r at es)

and abso r bs heat. It

then moves through the

ball valve and into the

evaporator pressure

regulator valve, or EPR.

The EPR keeps the

evaporator pressure

above a pr e determ ined

point, ev en though th e

suction line pressure of

the remote high side

system may vary. The

refrigerant, now a low

pressure gas, moves

into the suction line of

the remote high side

system.

SUCTION LINE

EVAPORATORS

BALL VALVES

EPR VALVE

March 1997

Page 13

Page 14

Double System RL

MAINTENANCE AND CLEANING

A Scotsman Ice System represents a sizable investment of time and mon ey in any company’s business. In

order to receive the best return for that investment, it MUST receive periodic maintenance.

It is the USER’S RESPONSIBILITY to see that the unit is properly maintained. It is always preferable, and

less costly in the lo ng run, to avoid possible down time by kee ping it clean; adjusting it as ne eded; an d by

replacing worn parts before they can cause failure. The following is a list of recommended maintenance

that will help keep the machine running with a minimum of problems.

Maintenance and Cleaning should be scheduled at a minimum of twice per year.

ICEMAKING SYSTEM: In place cleaning

1. Check and clean any water treatment devices,

if any are installed.

2. Pull ou t and remove the front panel.

3. Move the ON-OFF switch to OFF.

4. Remove al l the ice from the storage bin.

5. Remove the cover to the water reservoir and

block the float up.

6. Drain the water reservoir and freezer assembly

using the drain tube attached to the freeze r water

inlet. Return the drain tube to its normal upright

position and replace the end cap.

7. Prepare the cleaning solution: Mix eight

ounces of Scotsm a n Ice Machi ne Cle aner with

three quarts of hot water. The water should be

between 90-115 degrees F.

Scotsman Ice Machine

Cleaner contains acids.

These compounds may

cause burns.

If swallowed, DO NOT

induce vomiting. Give

large amounts of water or

milk. Call Physician

immediately. In ca se of

external contact, flush with

water.

Keep out of the reach of

children.

8. Slowly po ur th e cl ea ni n g solution in to the wa te r

reservoir until it is full. Wait 15 minutes, then

switch the master switch to ON.

9. As the ice m aker begins to use wat er from the

reservoir, continue to add more cleaning solution

to maintain a full reservoir.

10. After all of the cleaning s olution has been

added to the reservoir, and the reservoir is nearly

empty , sw i tch the mast er sw itch to OFF.

11. After draining the reservoir, as in step 6, wash

and rinse the wat er r es e r voir.

March 1997

12. Go thru steps 13-19 to sanit ize th e ice machin e

water system.

13. Mix two gallons of sanitizer soluti on. Use an

approved sanitizer.

A possib l e sanitiz er so l ut i on ma y be ob ta i ne d by

mixing tw o gallons of warm (90-115

o

F.) pota ble

water with 1 ounce of household bleach.

14. Slowly pout the sanitizer solution into the water

reservoir until the float rises, then switch the

master switch ON.

15. As th e ice machine uses water from the

reservoir, continue to pour the sanitizer solution

into the reservoir.

16. Afte r

1

of the sani t i zer s o l ut i on has be en

⁄

2

added to the reservoir, and the reservoir is nearly

empty , s wi tch the master switch OFF.

17. Drain the reservoir and thoroughly wash the

interior of the reservoir and cover with sanitizer

solution. Be sure the drain hose is upright and

capped.

18. Remove the block from the float in the water

reservoir.

19. Switch the master switch to ON

20. Continue ice making for at least 15 minute s, to

flush ou t any cleani ng solu tion.

DO NOT USE any ice produced from the

cleaning solution. Be sure no ice remains in

the bin.

21. Remove all ice from the storage bin.

22. Add war m w at er to the ice storag e bi n and

thoroug hl y wash and r i ns e al l sur faces wi th i n th e

bin.

23. Sanitize the bin interior by washing the interior

of the bi n w it h the balanc e of the sanitizer sol ution.

24. Switch the master switch ON.

Page 14

Page 15

MAINTENANCE

Electrical Shock Hazard

Electrical shock can cause

personal injury.

Disconnect electrical

power before beginning.

1. The bin control uses devices that sense light,

therefore they must be kept clean enough so that

they can "see". At least twice a year, remove the

bin control sensors from the base of the i ce chute,

and wipe the inside clean, as illustrated.

2. The ice machin e s e nses water l evel by a pro be

located in the water reservoir. At least twice a

year, the probe should be removed from the

reservoir, and the tip wiped clean of mineral

build-up.

Double System RL

SLIDE ICE

LEVEL

CONTROLS OUT

OF CHUTE

CLEAN THE ICE

LEVEL CONTROL

SENSORS

RESERVOIR

CLEAN THE

WATER LEVEL

SENSOR

/////////////////////////////

CAUTION: THE

TIMP IS MADE OF

GLASS

///////////////////////////////

3. The bearing in the breaker should also be

checked at least

Check the bearing by:

•

pushing the bail clamp back and removing the

ice chute c over

two times p er year

.

Inspe ct the ass embly, looking for wear.

See Remo v a l and Re pl a c em e nt t o r ep l ace bearing

or seals. Reverse to reassemble.

4. Check and tighten all bolts and screws.

ICE SWEEP

BREAKER

COVER

•

unscrewing the ice swee p

•

unscrewing the breaker cover

•

unscrewing the auger stud

March 1997

Page 15

Page 16

Double System RL

CLEANING

In some installations the water supply to the ice

maker will be so concentrated with dissolved

minerals, (such as calcium carbonate) that as ice

is mad e, the evaporator and au ge r become

coated with the minerals, requiring a more frequent

cleaning than twice per year. If in doubt about the

condition of the evaporator and au ger, the auger

can be removed so the parts can be inspected.

Note: Water filters can filter out suspended solids,

but not dissolv ed sol i ds . "S of t" w at er m ay no t be

the complete answ er . Check with a w ater

treatm en t s p eci a l i st re ga r di n g w at er treatment.

ALLEN HEAD

DIVIDER, AUGER

AND SLOTTED

COLLAR

SCREWS

Switch off electrical power, and shut off the

water supply.

For more information on removal of these

parts, see REMOVAL AND REPLACEMENT.

1. To remove the auger, remove front and top

panel. If top panel ca nnot be removed, or i f th er e is

less tha n 6" c learance over th e top of the ma chine,

the gearmotor/evaporator may be slid out for

service access. See Removal And Replacement.

2. Push bail clamp back and remove ice chute

cover.

3. Unscrew and remove ice sweep.

4. Loosen band cla m p un der ice chu t e , and

remove i ce chute from evaporator.

5. Remove 4 allen he ad screws ho l di n g br e aker to

evapor a to r .

6. Pull up on breake r to r emove au ger.

Allow the auger to dr y, the sta inless steel of the

auger and evaporator

Clean the auger and evaporator as required. DO

NOT HONE THE EVAPORATOR.

7. Replac e th e w at er s ea l.

8. Reverse to reassemble.

be clea n an d br i g ht.

must

March 1997

Page 16

Page 17

Double System RL

SERVICE DIAGNOSIS: Condition - No Ice Being Produced

STATUS:

Check:

A.

Check: The

B.

. Check the

C

reservoir. Restore/adjust water level.

STATUS:

. Check: The gear

D

Check: The

shoul d be OF F

1. If the

side should have between 208-230 volts. If the line side has the correct voltage and the

2. If the tr ansform er is good, and the

INFORMATION

3. If the tr a nsf or m e r is fi ne , an d the "no water " l i gh t i s ON , check the

NOTHING OPERATES

Voltage

to the uni t, restore it if there is none. Compare to the nameplate.

mast er sw it ch

wate r level

, switch ON i f of f.

in the reservoir. The machine will not run if there is not enough water in the

NOTHING OPERATES

motor

indicator lights

.

bin empty

a. Transformer "load" side should have 12 to 15 volts. If not, check the "l ine" sid e. The line

load side does not, replace the tran sformer.

a. Remove sensors by sliding them sideways out of the ice chute. Visually inspect them,

clean if ne ed ed.

b. Look through the ice chute "eye" hole for somet hing block ing the ice chute.

c. If the unit still does not run, replace the ice level sensors.

d. If the bin empty light is still OFF, check the

a. Check the water level in the

b. Remove the water level sensor from the reservoir and clean the tip if dirty.

CAUTION: THE TIP IS MADE OF GLASS

c. Replace the water level sensor. If the no water light is still on, check that the

"water sen" plug is firmly plugged into the circuit board.

d. If the no water light is still on, SEE LAST PAGE FOR TESTER INFORMATION

e. If after the above, the machine still will not run, replace the water level sensor

, if it will not run, the liquid line valve will not open. If no power to it:

and

on the circuit board, the

no water

lights are off, check the

bin empty

reservoir,

bin empty

light is OFF, check the

circuit board

restore if low. If the water level is ok:

light sh ould be ON, the

transformer

.

ice level sensors

. SEE LAST PAGE FOR TESTER

water level sensor.

no water

.

light

STATUS:

Check the

A.

The relay is on th e circuit board, if it does not supply power to the liquid line valve, the

valve will not open.

1. Check for power at the valve coil, if none:

2. Check the valve coil. If the coil is open, replace the liquid line valve.

3. Check th e auger dri ve motor centrifugal switch. If, when the drive motor is running,

contac t 4 (b l ac k wi r e re m oved) has no pow er, and al l of the abov e sw i tches ha ve been

checked, replace the centrifugal switch, or the drive motor.

4. If the liquid line valve relay on the circuit board has power on the NO contact, but not on the COM

contac t , r ep l ace the cir cuit board .

GEARMOTOR OPERATES, BUT NO ICE IS MADE

liquid li n e va lv e re la y.

Check for po w er at t he liq ui d li n e val ve relay at th e ci r c u i t bo ar d .

a.

If there is power at the relay, but none at the liquid line valve coil,

Check for an open wire between the relay and the valve.

March 1997

Page 17

Page 18

Double System RL

REMOVAL AND REPLACEMENT

WATER RESERVOIR

1. Shut of f th e w at er su pply to the ic e ma ker .

2. Remove front panel and reservoir cover.

3. To remove

tube, push in the tab behind the reservoir and pull

valve assembly out of the reservoir tank.

4. To remove reservoir, disconnect water inlet

compression fitting at reservoir inlet.

5. Remove drain hose from reservoir.

6. Remove evapor ator inle t ho se from res e r vo i r .

7. Remove mounting screws from reservoir

bracket, and remove reservoir from ice maker.

8. Reverse to reassemble.

Internal

Plunger

float only, disconnect water inlet

BIN CONTROLS (Ice Level Sensors)

1. Disconnect electrical power.

2. Remove front panel.

3. Remove control box cover.

4. Locat e i c e ch ute, at the base of the c hu te , in

front of an d behind it ar e two plas t i c bi n co ntrol

mounts.

5. Slide each bin control to the left, and in the

contr ol bo x , di sconne ct the electrica l le ad s

connecting the bi n co ntrol to the circui t boa r d.

6. Reverse to reassemble, be certain that the bin

contro ls are aligned so that the ice lev el sensors

are visible (centered) through the holes in the cube

chute.

SLIDE BIN

CONTROLS

IN AND OUT

Float Valve

March 1997

Page 18

Page 19

Double System RL

REMOVAL AND REPLACEMENT: Bearing And Breaker

Note: Removal of the auger, water seal,

evapo r ator and ge armotor mu st begin a t the top of

the assem b l y .

To Remove the Breaker Bearing Assembly:

Electrical Shock Hazard

Electrical shock can cause

personal injury.

Disconnect electrical

power before beginning.

1. Remove panels and disconnect electrical power.

2. Push ba c k bail clam p, re m ove insulation

retaining strap and insulation, remove ice chute

cover.

3. Unscrew and remove ice sweep.

4. Loosen band cla m p un der ice chu t e , l i ft up and

remove ice chute.

5. The bre aker may be re moved from th e au ger

and evaporator without disturbing the auger.

a. Unscrew breaker cover from breaker (left hand

threads)

b. Unscrew auger stud from top of auger.

c. Unsc rew 4 al l e n he ad ca p sc r e w s ho l di n g

breake r to evaporator.

Step 5- a Step 5-b Step 5-c and Step 6

d

. Lift up , an d r em o ve br eaker/be ar i n g assembl y

from auger & evaporator.

6. Service the bearing. Check for rust, rough spots

and damage.

a. The bear ing is pressed into the breaker, to

remove the bearing and rep l ace it an arbor press

is need ed .

b. Replace lower seals before installing new

bearin g i n br e aker.

Note: seals must be pressed in with a tool pushing

against the outer edge only, they will not install by

hand.

Replac e parts as required. R e- g r ea s e be ar ing with

Scotsman part no. 19-0609-01 bearing grease.

Replac e top seal, an d check the o- r ings, repl ac e i f

cut or torn.

7. Reverse to reassemble: specific tools and

materi a l s ar e re qu i r ed t o ins t al l pr o perly.

a. Add food grade gr ease such as Scotsm an part

number 19-0569-01 to the seal area before

installing on the auger.

b. Check the seal to shaft areas for cuts, or rough

spots: none are permitted.

ICE SWEEP

BREAKER

COVER

BEARING

SEALS

SLOTTED

COLLAR

AUGER

STUD

DIVIDER

March 1997

Page 19

Page 20

Double System RL

REMOVAL AND REPLACEMENT

To Remove the Auger:

Turn off the water to the machine, and uncli p the

evapor ator drain hose, pull i t down and drain the

evaporator into the bin or a container.

Electrical Shock Hazard

Electrical shock can cause

personal injury.

Disconnect electrical

power before beginning.

1. The top panel must be removed.

2. Remove ice ch ut e c over.

3. Unscrew ice sweep.

4. Loosen band clamp and remov e i ce chute body.

5. The auger and bre aker/bearing may no w be

removed as an asse m bl y .

a. Unscrew 4 allen head cap screws holding

breake r to evaporator.

b. Lift up on br e aker and r em o v e au ge r fr om

evapor a t o r .

d. Lift up and re m ove breaker from evapora t o r .

e. If the auger is stuck use a slide hammer type

pulle r to pull on th e auger at the threaded hole.

The siz e of t ha t ho l e i s 5/ 8" - 18 .

Inspect the auger, the crit ical areas of the auger

are:

1. The auger body. It should be clean and

shining. Sometimes an auger will appear clean

when wet, but after it is dry it will be seen to be

stained. Scrub the auger with ice machine cleaner

and hot water.

Ice machine cleaner is an acid. Handle it with

extreme care, keep out of the reach of children.

2. The water seal area. Because the auger has

been removed, the water seal will have to be

replaced. Remo ve the wat e r seal top half from the

auger, and inspe ct the auger for m inerals cle an as

required.

DIVIDER

AND

AUGER

ASSEMBLY

Note: If the auger is stuck, the breaker must be

removed from the auger.

The bre a ker may be re moved from the auger and

evaporator without disturbing the auger.

a. Use spanner wrench and unscrew breaker

cover fr om breaker (l eft hand thr eads)

b. Unscrew auger stud from top of auger.

c. Unsc rew 4 al l e n he ad ca p sc r e w s ho l di n g

breake r to evaporator.

SLIDE HAMMER

PULLER

THREAD INTO THE

AUGER HERE

March 1997

Page 20

Page 21

REMOVAL AND REPLACEMENT

Moving Parts Hazard.

Moving parts can cause

personal injury.

Disconnect electrical

power before beginning.

To Remove the Water Seal:

(Assum i n g al l s t ep s to r em o v e the auger ha ve

been performed.)

1. The gearmotor/evaporator assembly will have to

be exposed.

2. Remove the 4 hex hea d c a p sc r e w s hol d i ng the

evapor a to r t o th e ge ar m o to r ass e m bl y. Lift the

evapor a to r up an d off of the gearmotor .

3. Remove the snap ring or wire retainer from the

grove under the water seal.

4. Pull or dr ive out the l ow e r hal f of th e w ater seal.

Double System RL

To Replace the Water Seal:

1. Lubricate the water seal with water, and push

the water s e al into the bott om of the evapor a t o r

slightly past the grove for the snap ring.

2. Replace the snap ring and pull the water seal

down agai n s t it.

3. The part of the water seal that rotates with the

auger mu s t al so be re pl a c e d. Rem o ve the old part

from the auger and clean the mounting area.

4. Place a small bead of food grade silastic sealant

(such as 732 RTV or Scotsman part number

19-0529-01) on the area of the auger where the

water seal is to be mounted.

5. Carefully push the water seal (rubber side

agains t the auger shoulder and th e si l a st ic.)

CAUTION

Do not get an y s i lastic onto the face of the seal .

6. Allow the auger and seal to air dry until the

silastic is dry on the surface.

7. If the original water seal was leaking, it would be

a good idea to inspect the interior of the gearmotor.

WATER

SEAL

RETAINING

RING

PLACE FOOD

GRADE SEALANT

HERE

March 1997

Page 21

Page 22

Double System RL

REMOVAL AND REPLACEMENT: Evaporator

To Replace the Evaporator:

(Assum i n g al l th e steps for r em o val of the th r ust

bearin g, breaker, auge r , an d w ater seal have been

performed.)

1. Shut th e ha nd valves in th e l i qu i d an d s uc t ion

lines to the evaporator being serviced; then

discharge the refrigerant.

2. Unsweat the refrigerant connections:

a) At the thermostatic expansion valv e outlet.

CAUTION

Heat sink the TXV body when unsweating or

resweating the adjacent tubing.

b) At the suction line at the joint about 3" from the

evaporator.

3. Remove the

evaporator.

4. Unsweat the drier

from the l iquid line.

5. After installing a

new water seal in the

new eva po r ator (see

"To Rep lac e t he

Water Seal") sweat in

the new evaporator at

the old co nn ections.

6. Install an new drier

in the liquid line.

7. Evacuate the

system until

dehydrated, then

weigh in the

namepl ate charge.

Check for leaks.

8. Instal l auger,

breake r , br eaker

bearin g assemb ly ,

and ice di sc h ar g e

chute i n r ev e r se order

of disassembly. See

"To Reassemble

Evapor ator and Auger"

ICE SWEEP

BEARING

To Reassemble the Evaporator and Auger

1. After the gearmotor has been inspected, fasten

the evap or a tor to the ge ar m ot or , tor que the bolts

to 110 inc h pounds.

2. Lower the auger into the evaporator barrel,

slightly turning it to match up with the drive end.

Do Not Drop Into the Evaporator.

3. Complete the reassembly by reversing the

disassembly for the breaker & thrust bearing

assembly.

AUGER

EVAPORATOR

DRIP PAN

March 1997

Page 22

DIVIDER/BREAKER

Page 23

REMOVAL AND REPLACEMENT: Gearmotor

Double System RL

To Remove and Repair the Gearmotor

Assembly:

(Assuming that the procedures through removal of

the water seal have been performed.)

1. Remove the el ectr ical wires from the gear dr ive

motor.

2. Unscrew the 4 cap screws holding the

gearmotor to the gearmotor plate.

3. Remove the gearmotor from the ice maker.

To Inspect the gearmotor.

A) Remove the cap screws holding the gearmotor

case halves together and pr y the two cases apar t.

B) To lift off the cover, lift up until you can feel

internal contact, then pull the cover towards the

output gear end, and then

lift the cover (with drive

motor attached) up and

away from the gear motor

case.

Note: The case cover

output gear, bearings, and

shaft are one pressed

together assembly.

Replace as a unit.

C) Inspect the oil, gears,

and bearings. If the oil

level and condition is

acceptable, quickly check

the gears and bearings.

They are likely to be fine if

the oil is.

If there is evidence of

water in the oil (rusty

bearings and gears; the oil

having a creamy white

appearance; oil level too

high) carefully inspect the

bearings and gears. If in

doubt about the condition

of a part, replace it. The oil

quantity is 14 fluid ounces,

do not overfill.

Note: The gears and

bearings are available only

as pressed together sets.

GEARCASE

D) After replacing parts as required, (if any)

reassemble the gearcase. The two smaller gears

and the oil should be in the lower case, the output

gear will be with the cover. As you lower the cover

onto the lower case, cover will have to be moved

closer to the second gear after the output gear has

cleared the second gear top bearing.

E) After the case is together, and the locati ng pins

are secure in both ends, replace all cap screws.

4. Bench test the gearmotor, check for oil leaks,

noise , an d am p draw.

SEAL

MOTOR

BEARING

GASKET

March 1997

Page 23

Page 24

Double System RL

CIRCUIT BOARD TESTING

These procedures require the machi ne to be connected to the power supply . The voltages of the

elect ronic circ uit are ver y lo w, but HIGHER VO LT A GES ARE PRES EN T IN T HE U N IT. Do not touc h

anythi n g bu t the tester wh i le the unit is be i ng checked out . M ak e al l connecti on s to th e c ir c u i t bo ar d with

the ELECTRICAL POWER OFF.

INSTRUCTIONS FOR USING TESTER,

(These instructions assume that the unit

(Optiona l , or d er pa r t no . A3 39 42 - 001)

will not run,

and prior investigation of electric power, controls,

and mechanical parts indicates that the electronic circuit may be at fault.)

Note: All testing is done with the electrical power

on, the master switch on.

1. Unplug “photo trans” and “LED” connectors from

the circuit board .

2. Plug “photo trans” and “LED” connectors from

the test er i nt o th e ci r cuit board .

3. Unplug "water sen" connector from the circuit

board.

4. Plug "water sen" connec tor from Scotsman

tester into the circ u i t bo ar d .

Bin Control:

a. Move the “bin full” switch on the tester to Full.

The light on the tes ter should be ON.

If the li ght on the tester is no t on, the circuit board

shoul d be re pl a c ed .

b. If the light on the tester IS on, move the “bin

full” switch to Bin Empty. The light on the tester

should go OFF, and the Bin Empty light on the

circuit board shou ld go ON.

If the Bin Empty light is ON, wait 10-20 seconds for

the machine to start, if the machine starts, replace

the ice level sensors.

If the Bin Empty light does not come ON, the

circuit board shou ld be replaced.

Water Level

a. Move “water” switch on tester to No Water

position. The No Water light on the circuit board

should go ON. If not, replace the circuit board.

b. Move the “water” switch on the tester to the

Water position. The No Water light on the board

shoul d go OF F. I f no t r ep l ace t he ci r cui t board. If

the ligh t do es go off, repl a c e th e w at er l evel senso r .

If the Bin Empty light is ON, wait 10-20 seconds for

the mac hine to start. The machine shou l d start.

LIGHT GOES ON

LED

SWITCH TO

"FULL"

PHOTO TRANS

WATER SENS

LIGHT GOES

ON

SWITCH TO

"NO WATER"

March 1997

Page 24

Loading...

Loading...