Scotsman Eclipse CME686,Eclipse CME810,Eclipse CP686,Eclipse CP886,Eclipse CP1086 Technical Training Manual

• CME686

• CME810

• CP686

• CP886

Eclipse Technical Training

Eclipse Technical Training

• CP1086

In This Presentation

In This Presentation

• What Eclipse is

• Components and their functions

• Installation

• Operation

• Maintenance

• Service Diagnosis

The Eclipse System

The Eclipse System

• The remote system is made up of three parts:

– Ice Making Section or Head Unit - 115 volt

– Compressor Package - 208-230 volt

– Condenser - 208-230 volt

• Flexible Modular System

– One condenser fits two compressor packages

– One ice making head fits two compressor packages

– All are R-404A systems

Ice Making Section

Ice Making Section

• CME686 or CME810

– Remote Low Side

• 22” wide by 16.5” deep

– Three evaporators

–Three TXVs

– Three check valves

–CM3technology

• Water and Control

Systems

16.5 22”

• Rotomolded freezing

compartment

• Refrigerant

Ice Making Section

Ice Making Section

Vapor

Liquid

Line

Connections

– Vapor

– Liquid

–Suction

• All on right

side

– Designed for

Drive-Up

Suction

Window

Applications

• Ice making

compartment

• Three

evaporators

– Circuited in

parallel

– No braze joints in

Ice Making Section

Ice Making Section

freezing

compartment

– Access from the

left side or top

• Purpose: Opens

during harvest

to allow vapor

to enter the

evaporators

• 24 volt coil

Vapor Inlet Valve

Vapor Inlet Valve

• Different port

size between

CME686 and

CME810

• Three internally

equalized valves

• Purpose: Control

individual

evaporator

superheats

– One valve per plate

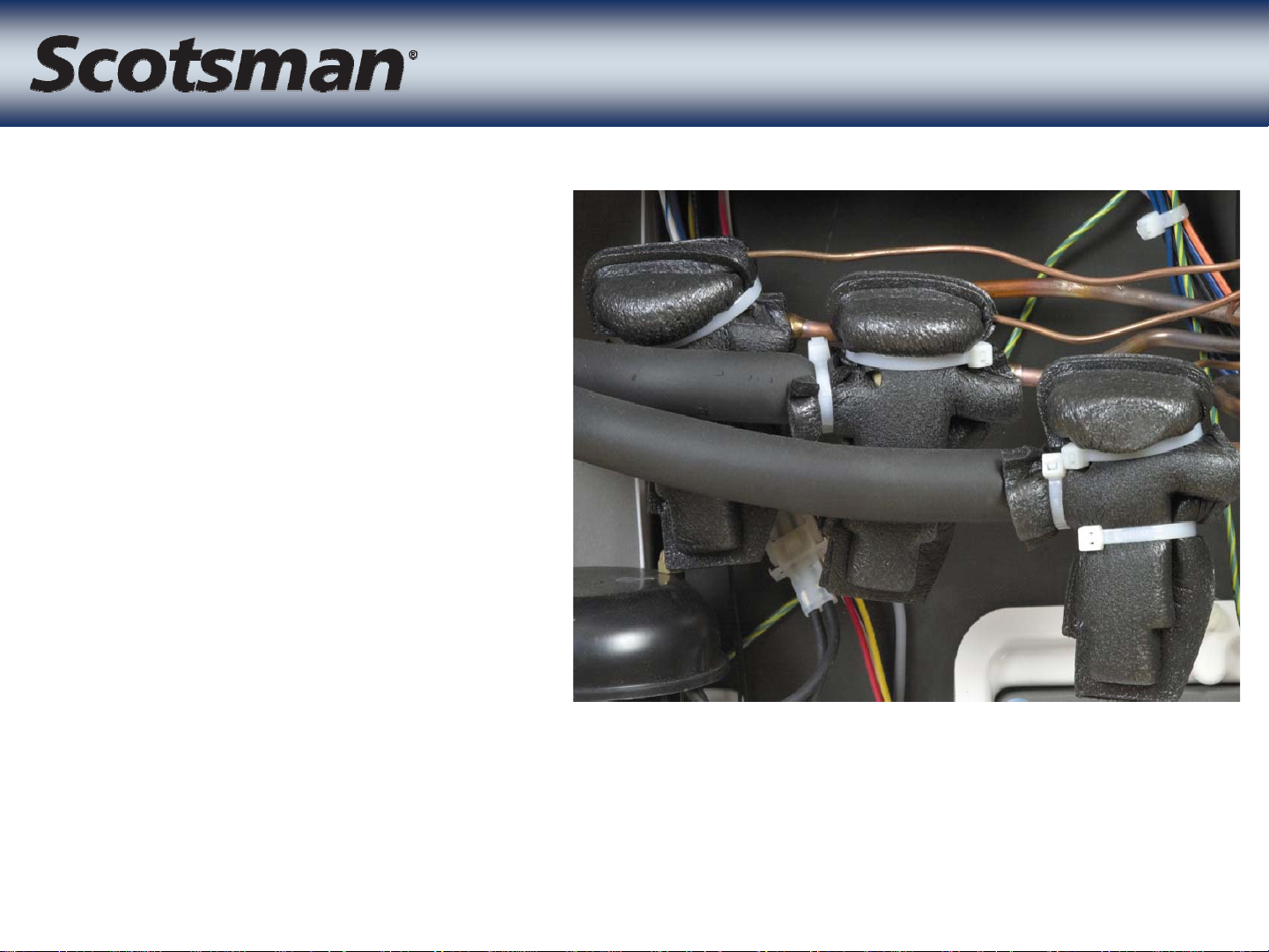

Three

Three

TXVs

TXVs

– Promotes even

plate-to-plate ice

distribution

• Check valves

keep each TXV’s

refrigeration flow

directed to a

single evaporator

– Eliminates cross-

flow during freeze

Three Check Valves

Three Check Valves

cycle

– Each TXV outlet

must flow to one

evaporator

• 115 volt pump

• Same for both

CME686 and CME810

• Pedestal type

• Pump motor separated

from reservoir

Water Pump

Water Pump

– Keeps motor drier

– Motor cap keeps

condensation off motor

™

• AutoIQplus

• Uses sensors for

– ice harvest,

– bin full indications

– water reservoir

temperature

– water level

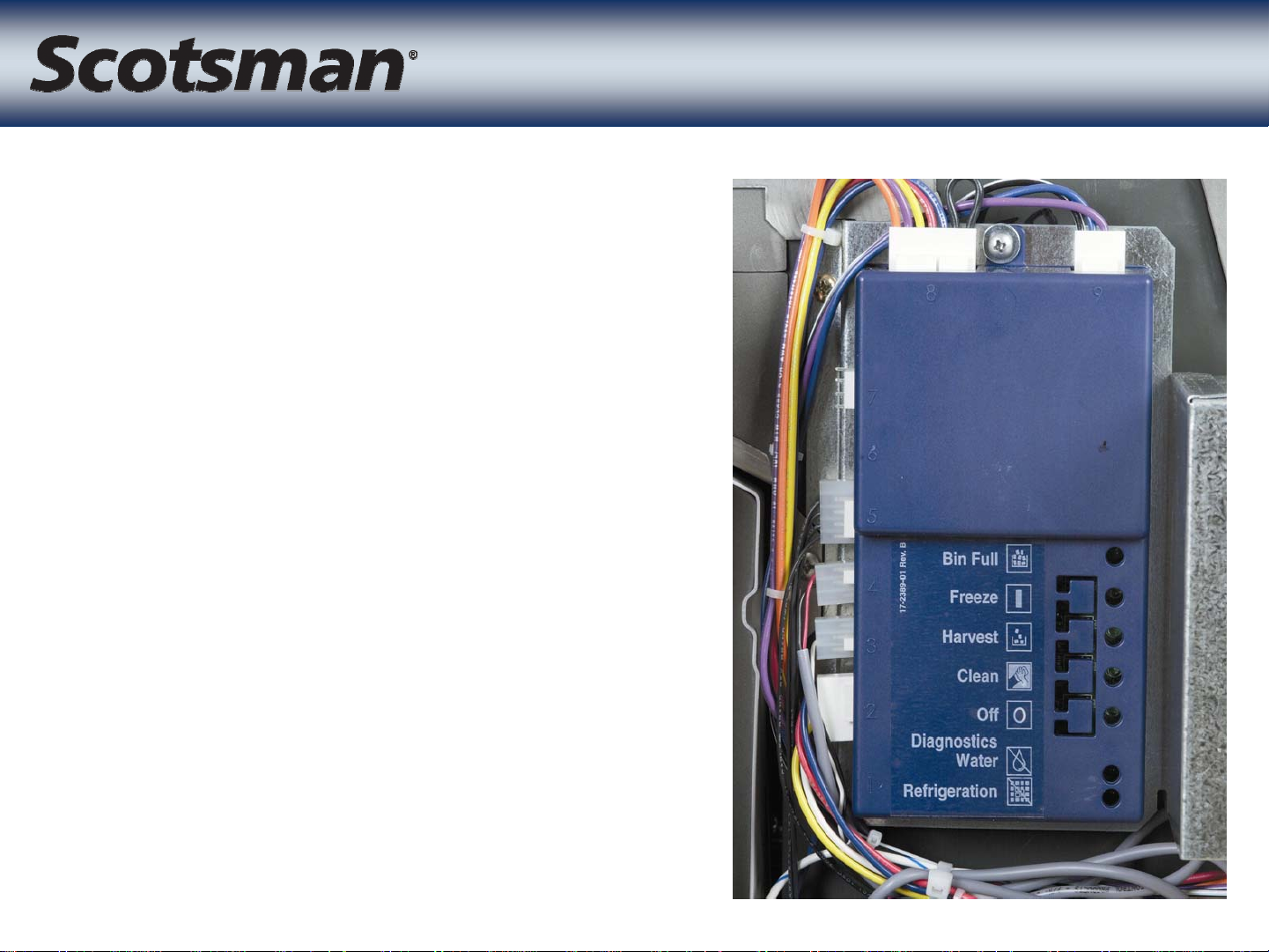

Controller

Controller

• Controls freeze and

harvest cycles

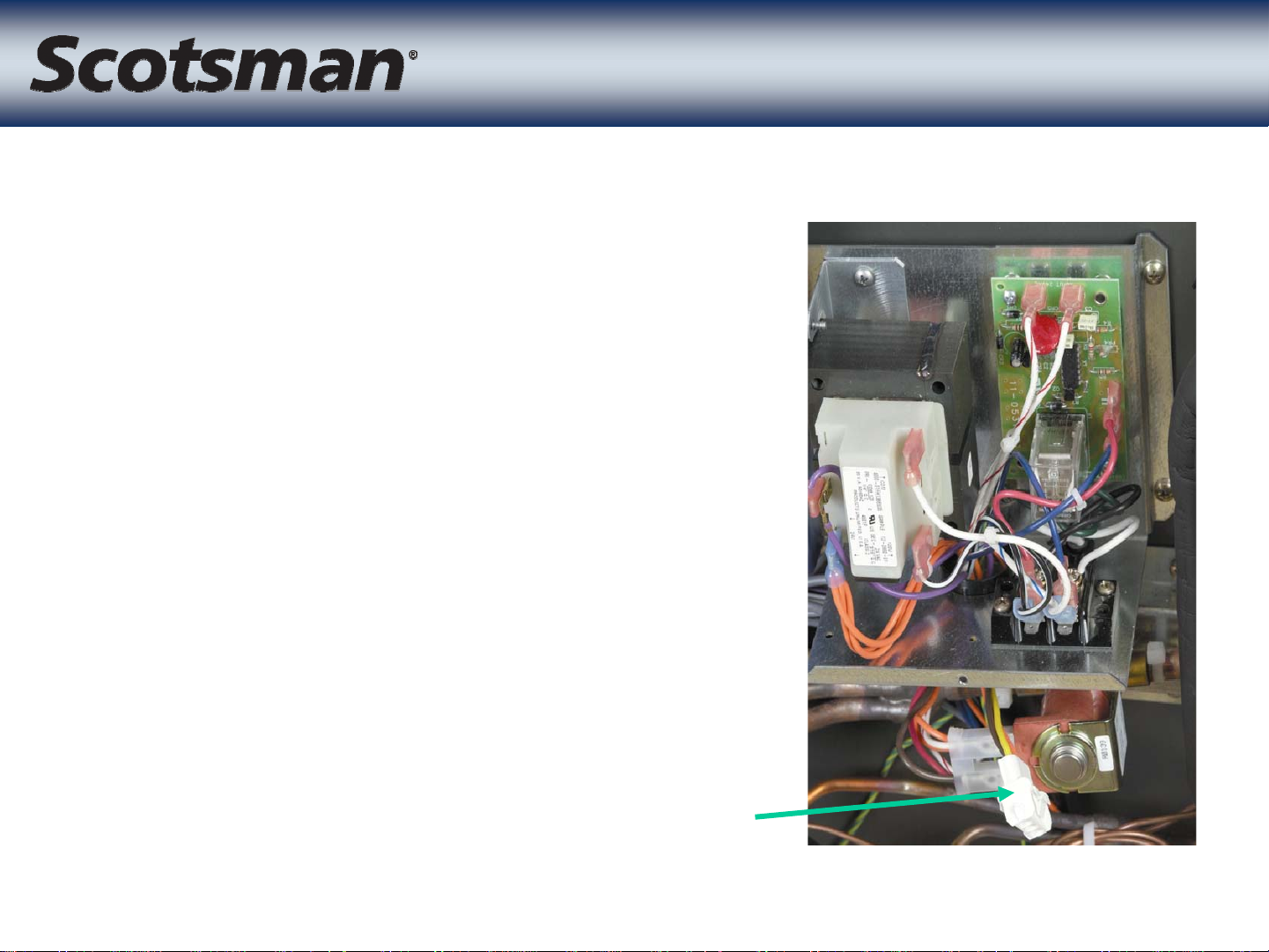

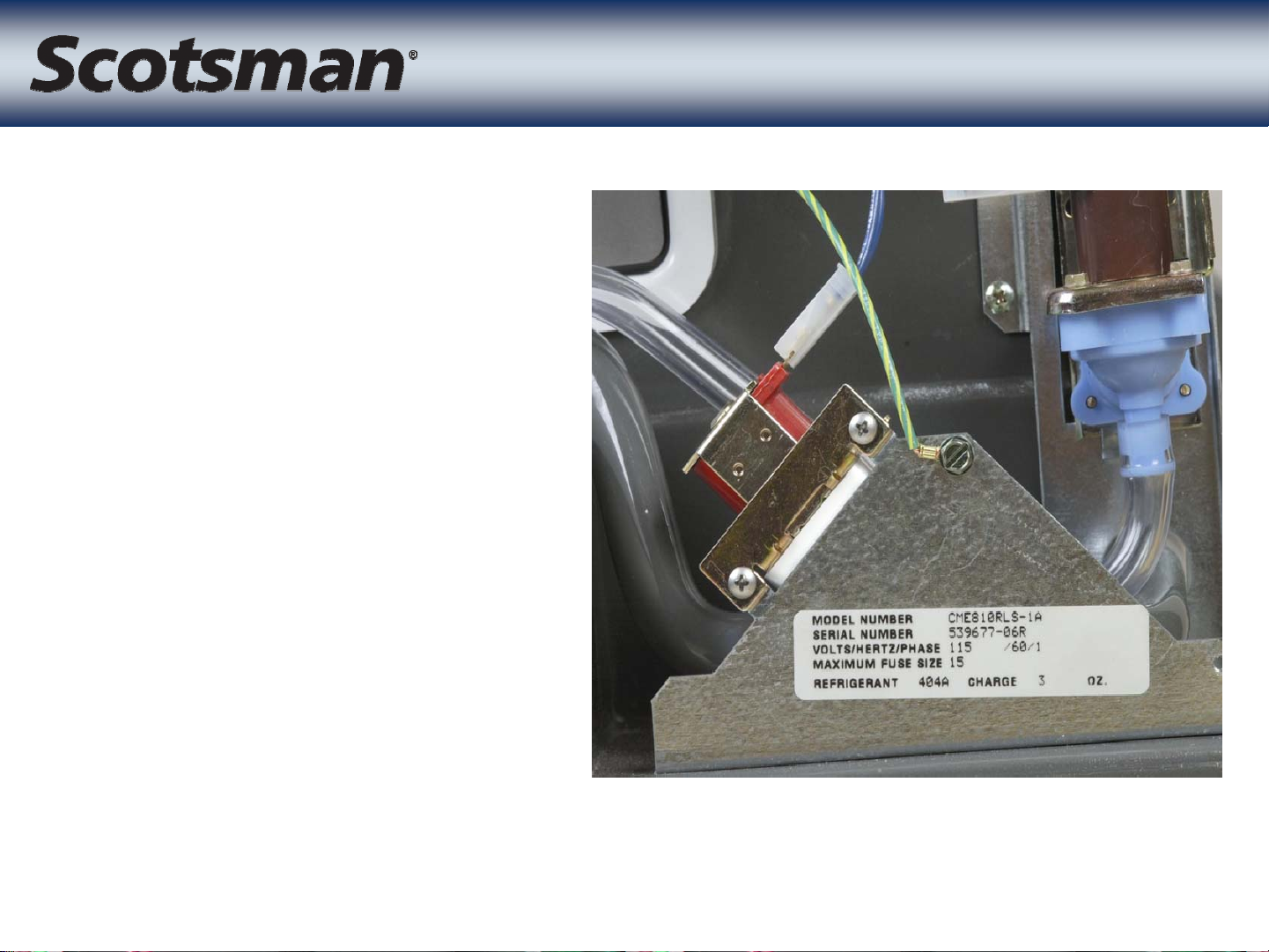

CME Electrical Box

CME Electrical Box

• Transformer 115 to 24, 85 VA

• Purge valve timer

• Control wire connection

nearby

– Wire routes to compressor

package

– Controls contactor and solenoid

valves

Control Wire Connection

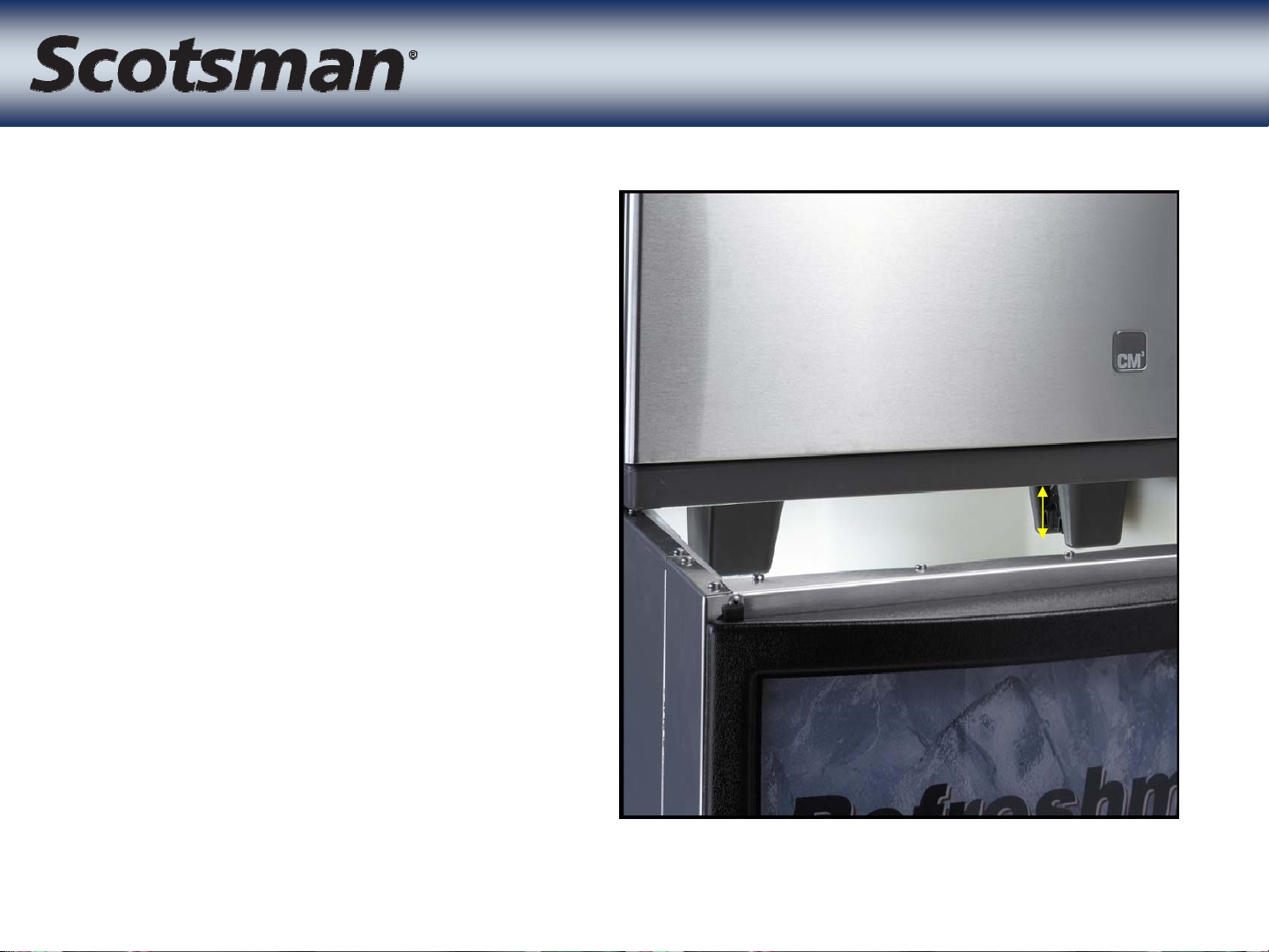

• Provides access

when left and right

side access is

limited

• Access to:

– cascading shield

– water trough

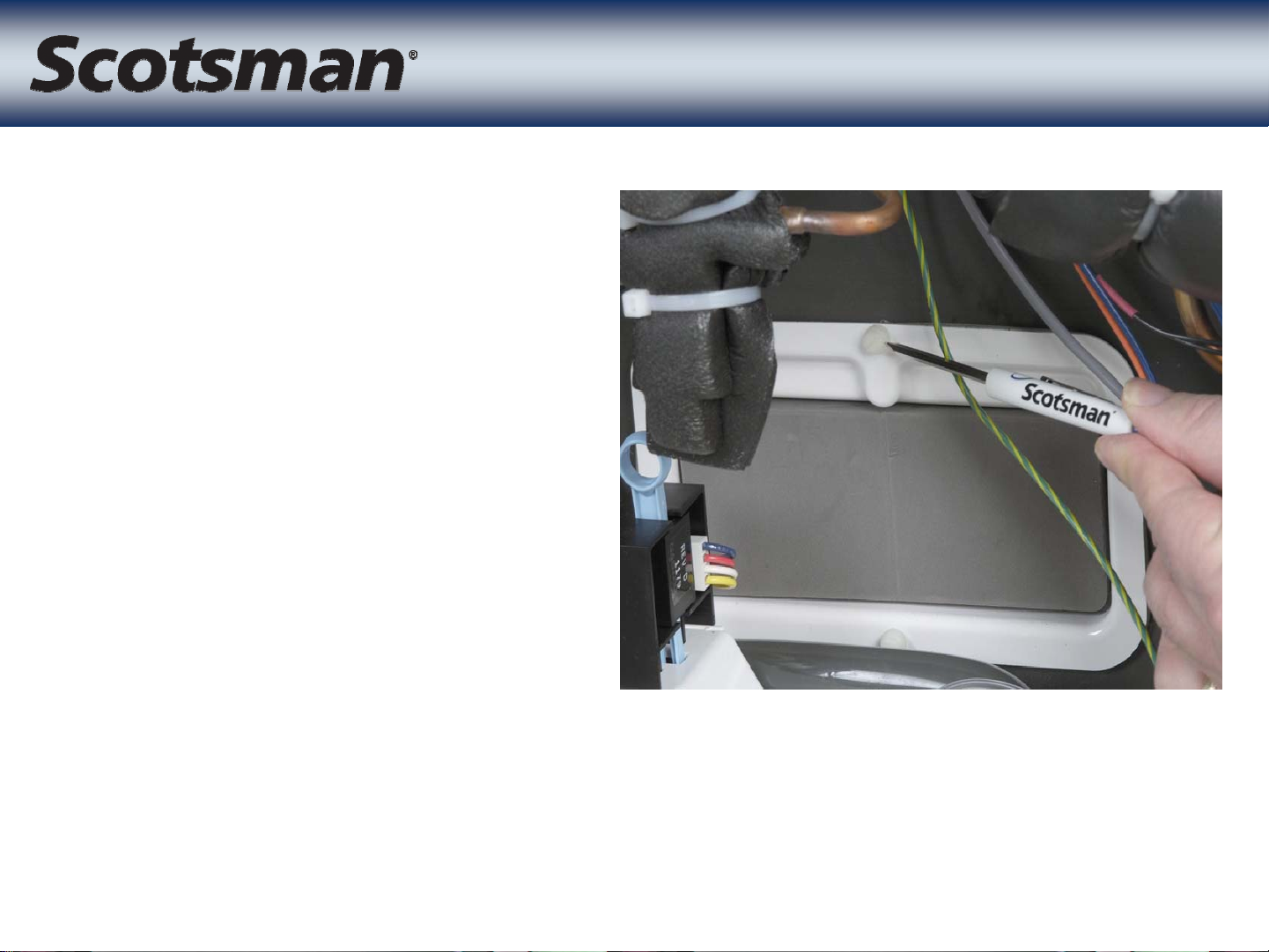

Inspection Cover

Inspection Cover

– ice sensors

• Also covers

cascading shield

fastener

• Removal

begins with

removal of the

inspection

cover

• Then remove

the one

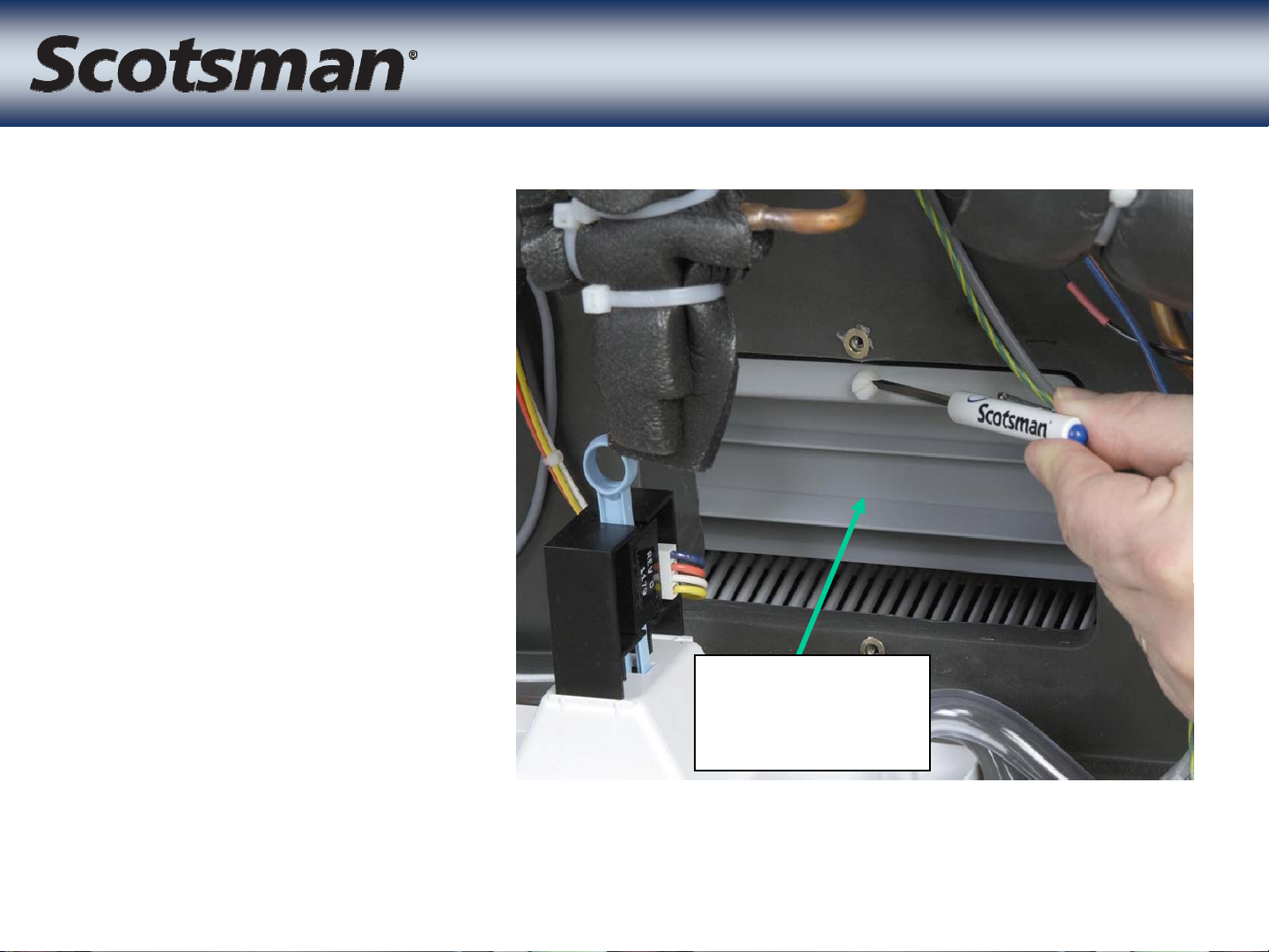

Cascading Shield

Cascading Shield

retaining

screw

Cascading

Shield

Cascading Shield

Cascading Shield

Evaporator Covers

Evaporator Covers

Freezing Compartment

Freezing Compartment

Water Trough

Cascading Shield

Temperature Sensors

Temperature Sensors

Liquid Line

Water Temp Sensor

Inlet Water Valve

Inlet Water Valve

• Located in right front corner

of unit

• 1.25 GPM valve

– Same one as on CME256,

CME506 and many others

• Opens to add water and fill

reservoir

– Adds water during harvest

– Fills at beginning of freeze

– Refills once more during

freeze

• Located in the front

of the unit

• 115 volt coil

• Opens to drain the

reservoir during

harvest

Purge Valve

Purge Valve

• Controlled by purge

valve timer

• Sensing position 3”

below base

• Control position

designed for

dispenser

Ice Sensors

Ice Sensors

applications

– Also works well on

bins

• Maximizes fill

without overfilling

3”

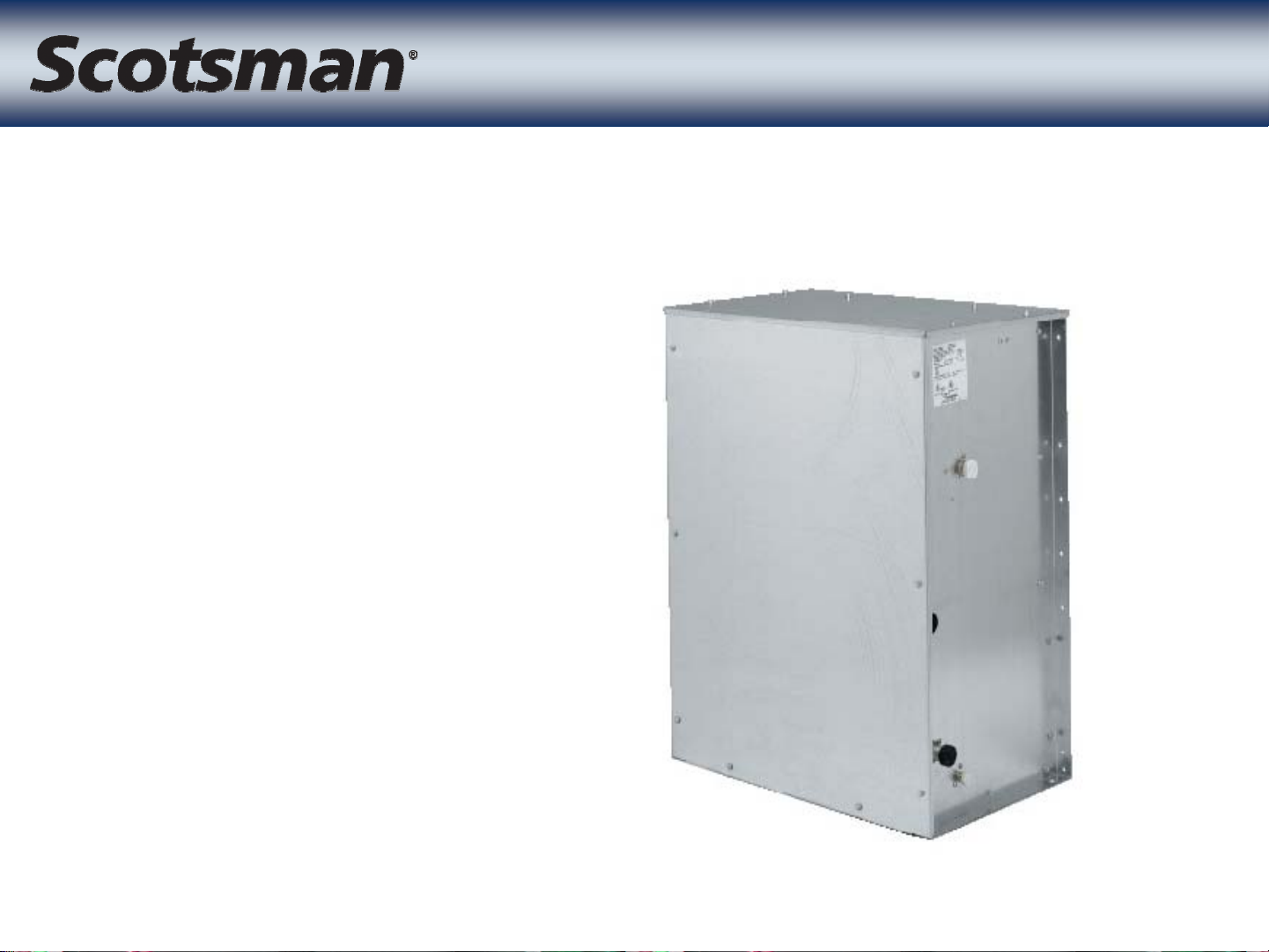

• Three models

–CP686

–CP886

– CP1086

Compressor Package

Compressor Package

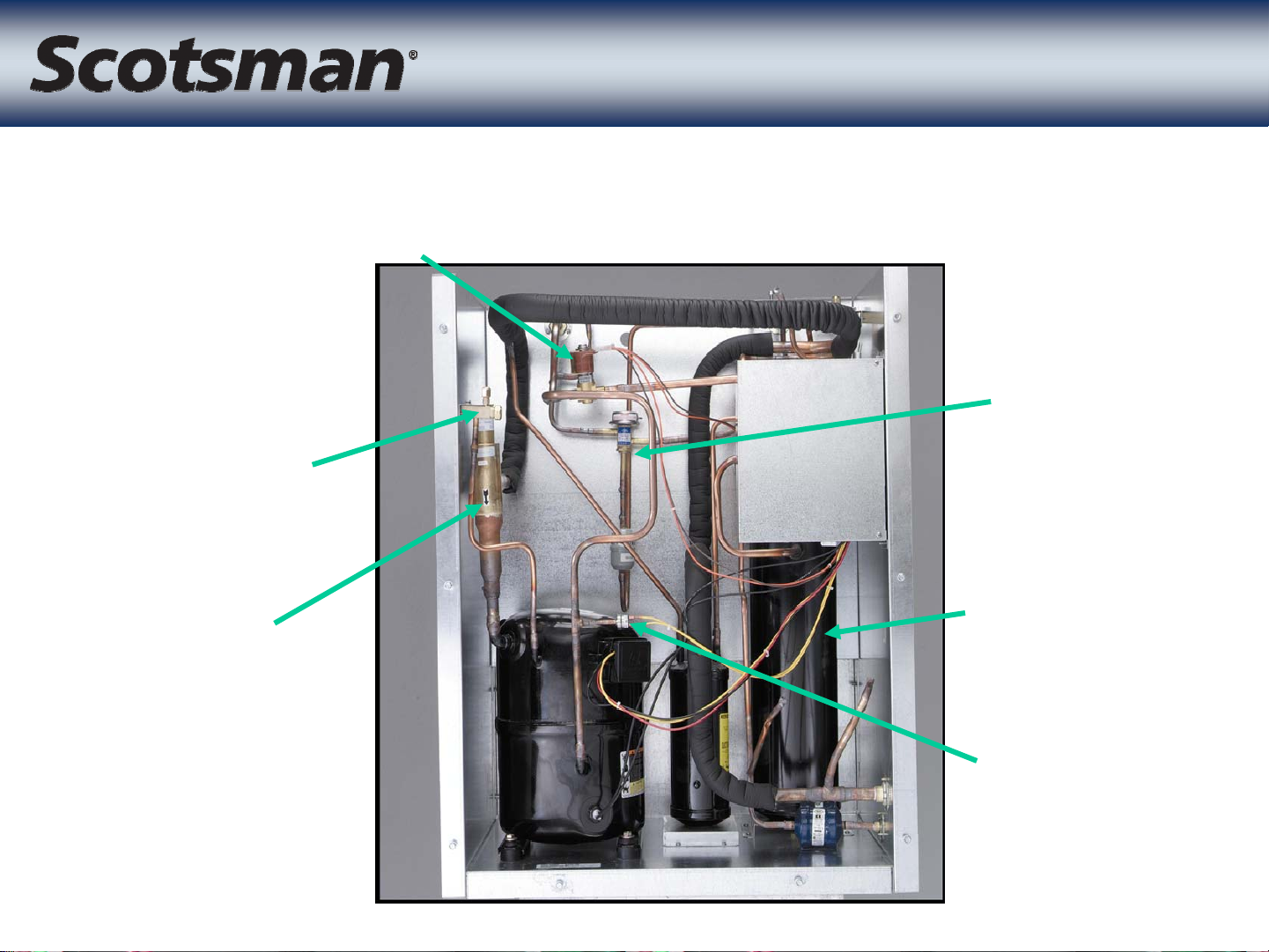

Condenser Bypass Valve

Low Side

Access Valve

CP Unit

CP Unit

Headmaster

CPR Valve

Receiver

High

Pressure Cut

Out - Auto

Reset

Crankcase Pressure Regulato

r

Crankcase Pressure Regulato

• CPR valve restricts

compressor dome

pressure during

harvest

– 55 to 60 PSIG

– Pre-set - don’t adjust

it!

• Low Side Access

valve has evaporator

pressure during

freeze, but not during

harvest

Loading...

Loading...