Page 1

Installation Instructions for

Prodigy Eclipse Condensing Unit

models ECC0800, ECC1200, ECC1410, ECC1800

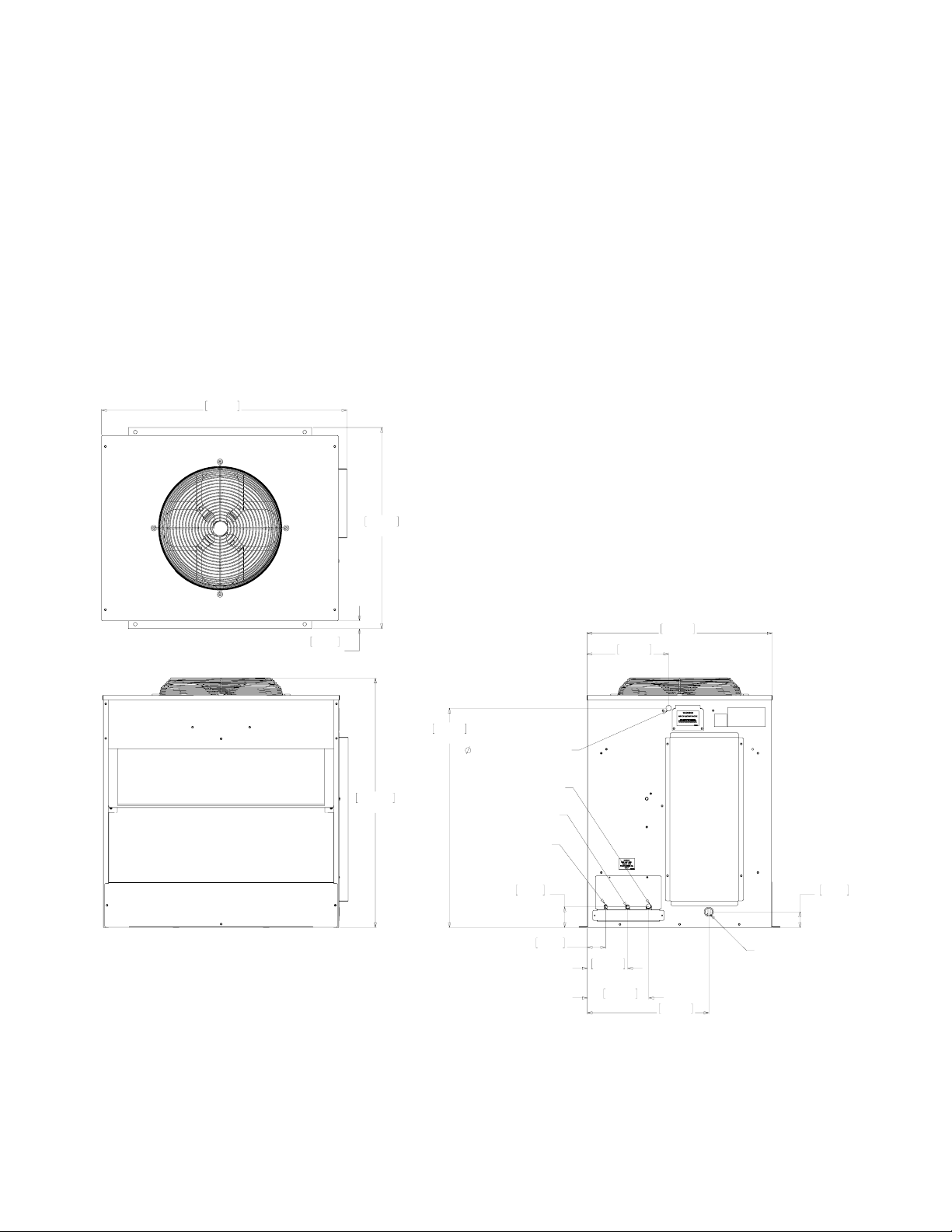

TOP VIEW

992.81

39.09

814.22

32.06

FRONT VIEW

32.05

1.26

TYP.

1009.65

39.75

887.73

34.95

.88" ELECTRICAL INLET

1/2" COOL VAPOR LINE

3/4" SUCTION LINE

3/8" LIQUID LINE

83.67

3.29

SIDE VIEW

LINE SET AND ELECTRICAL ATTACHMENT SIDE

330.86

13.03

74.12

2.92

163.02

6.42

248.87

9.80

750.06

29.53

491.69

19.36

INTERFACE HARNESS

ACCESS HOLE

63.50

2.50

17-3456-01

Page 2

Introduction

A remote low side cuber system consists of two systems: an ice making section and a remote condensing unit.

This instruction manual covers the Condensing Unit.

Unpack

1. Remove the carton.

2. Disconnect condensing unit from skid

3. Remove both side panels.

4. Locate and retain communication wire.

Placement

The footprint of the condensing unit is 39” x 32”. Have roof equipment rails prepared for it. Plan on attaching

the unit per local building codes, including any hurricane requirements.

Location

The condensing unit requires unobstructed air ow to operate efciently. A four foot space between each intake

side and a wall or other cabinet is recommended.

Do not place where it will pick up hot discharged air from an air conditioner or other refrigeration system

condensing unit.

Space must also be reserved for service on the condensing unit.

Roof preparation

Most installations of this system will place the condensing unit on the roof of a building. The roof must be

physically able to accept the load of the equipment and the roong material must be prepared to prevent water

leaks.

Roof Piercing:

The roof (or wall) must have a passage large enough for the three refrigeration tubes and the control wire

to pass through. The minimum recommended size is 4” ID. In most areas the power supply may also pass

through the same passage. If there isn’t a passage one must be created. In most cases this must be done by a

licensed and bonded roofer in order to maintain the roof’s integrity.

Roof Pipe Curb or Pitch Pocket:

To avoid potential kinking of the refrigeration tubing, avoid small, tight radius types of covers on pitch pockets.

Suggestions:

• Orient the assembled unit so that the unit’s refrigeration connections are nearest to the tubing.

• Do NOT place the unit directly onto roof rock.

Position the unit

In most cases a crane will be required to lift the unit to a roof location.

Mount unit to roof rails or curbs and secure with lag screws or similar eld supplied fasteners.

Electrical ConnectIon

Electrical power must be supplied to the condensing unit, it will be separate from the head. Locate condensing

unit dataplate for Voltage, Phase, Miniumum Circuit Ampacity and Maximum Fuse Size.

Page 3

Model Voltage Minimum

Circuit

Ampacity

ECC0800-32 208-230/60/1 14.8 20 192 32 x 39 x 39.75

ECC0800-3 208-230/60/3 10.6 15 192 32 x 39 x 39.75

ECC1200-32 208-230/60/1 17.8 20 224 32 x 39 x 39.75

ECC1410-3 208-230/60/3 9.1 15 224 32 x 39 x 39.75

ECC1410-32 208-230/60/1 14.5 20 224 32 x 39 x 39.75

ECC1800-3 208-230/60/3 19.0 20 232 32 x 39 x 39.75

Connect electrical power to the wires in the junction box on the side of the unit. A eld supplied service

disconnect is recommended. Use caution when mounting the disconnect, do not drill into condenser coils.

Route interconnecting communication wire harness thru access hole and connect to control box. The harness

is included with the condensing unit. One end plugs into the ice making section and the other into the

condensing unit. The system will NOT operate without this harness.

Refrigeration Tubing

Important: Minimize the amount of tubing exposed outdoors.

The line set must be routed between the condensing unit and the ice maker’s location. During the transition

from quick connects to braze connections, the ice maker or line set may or may not have quick connects, use

this chart as a guideline for the proper action based on what is available at the site.

Maximum

Fuse Size

System

Charge

Cabinet Size

w x d x h

Condensing unit has sweat connections

Ice making head has sweat connections If line set does not have quick connects, route and use as is.

If line set has quick connects, recover refrigerant from line set

and cut all quick connects off.

Ice making head has quick connects If line set has quick connects, recover refrigerant from line set

and cut one end of quick connects off.

If line set does not have quick connects, must use KTE6-EH

stub kit to add for ice machine end.

In all cases the line set will need to be shortened to t.

Do NOT leave excess line set exposed outdoors, especially on a roof.

Line Routing:

• Allowed: One rise after a drop.

• Allowed: One drop after a rise.

• Not Allowed: More than one rise after a drop

• Not Allowed: More than one drop after a rise.

17-3456-01

Page 4

Connect Refrigeration

Requires brazing, steps must be performed by an

EPA certied type II or higher technician.

At Head:

1. Remove protective plugs from all three

connections and vent the nitrogen from the ice

machine.

2. Route the each of the three tubes to its

connection.

3. Remove the top panel and attach a refrigeration

hose with depressor to the 1/2” vapor line access

valve so the valve is OPEN. This is a vent for

nitrogen purging.

4. Remove screws holding tubing bracket to back

panel and lower it out of the way for brazing.

5. Clean tubing ends and position into stubs.

At Condensing Unit

1. Conrm connection valves are fully closed.

3. Pull tubing bracket up and secure to back panel.

At Condensing Unit

1. Remove nitrogen source.

2. Return valve cores to access valves.

3. Connect vacuum pump to all three access valves

(use two manifolds or two extra hoses and a tee)

and evacuate the tubing and head to at least a

300 micron level.

4. Remove vacuum pump and add R-404A vapor to

all three tubes to provide a positive pressure.

5. Leak check the braze connections and repair any

leaks.

6. Open all three valves to full open.

Note: The full refrigerant charge is contained in the

receiver of the ice machine.

2. Remove protective plugs from all three

connections.

3. Remove caps from access valve connections.

4. Remove cores from access valves.

5. Connect refrigeration hoses to access valves.

6. Connect dry nitrogen source to liquid line

connection and vapor line connection.

7. Shorten tubing to correct length, clean ends and

insert them into valve stubs.

Note: Be sure tube and stubs are round, dress with

swage tool if needed.

8. Add heat sink material to ball valve body.

9. Open nitrogen and ow 1 psi nitrogen into liquid

line and vapor line tubes and braze the liquid

line, vapor line and suction line tubes to the valve

stubs.

At Head

1. With nitrogen owing from condensing unit, braze

the liquid, vapor and suction line connections.

2. Remove refrigeration hose from head. Be sure

valve cap is on tight.

Loading...

Loading...