Page 1

DD40 Introduction

To the owner or user: The service manual you are reading is intended to provide you and

the maintenance or service technician with the information needed to install, start up, clean

and service this ice system.

The DD40 is an ice bank with 6 electric post mix soda valves.

Table of Contents

General Information...............................................................................Page 1

Installation..............................................................................................Page 2

Soda Line Schematic.............................................................................Page 4

Optional Kit Installation..........................................................................Page 5

Start Up..................................................................................................Page 6

For the Operator ....................................................................................Page 7

Adjustments ...........................................................................................Page 9

Sanitizing................................................................................................Page 10

Service Diagnosis..................................................................................Page 11

Removal and Replacement ...................................................................Page 13

Booth Valve ...........................................................................................Page 14

Carbonator Service................................................................................Page 15

Service Parts Lists and Wiring Diagrams are in the cneter of this manual, printed on

yellow paper.

Page 2

COMPRESSOR

H.P.

1/3

SAME

RECOVERY

@ 750 F.

3.5 HOUR

SAME

SHIPPING

WEIGHT

150 LBS.

SAME

DD40 GENERAL INFORMATION

Page 1

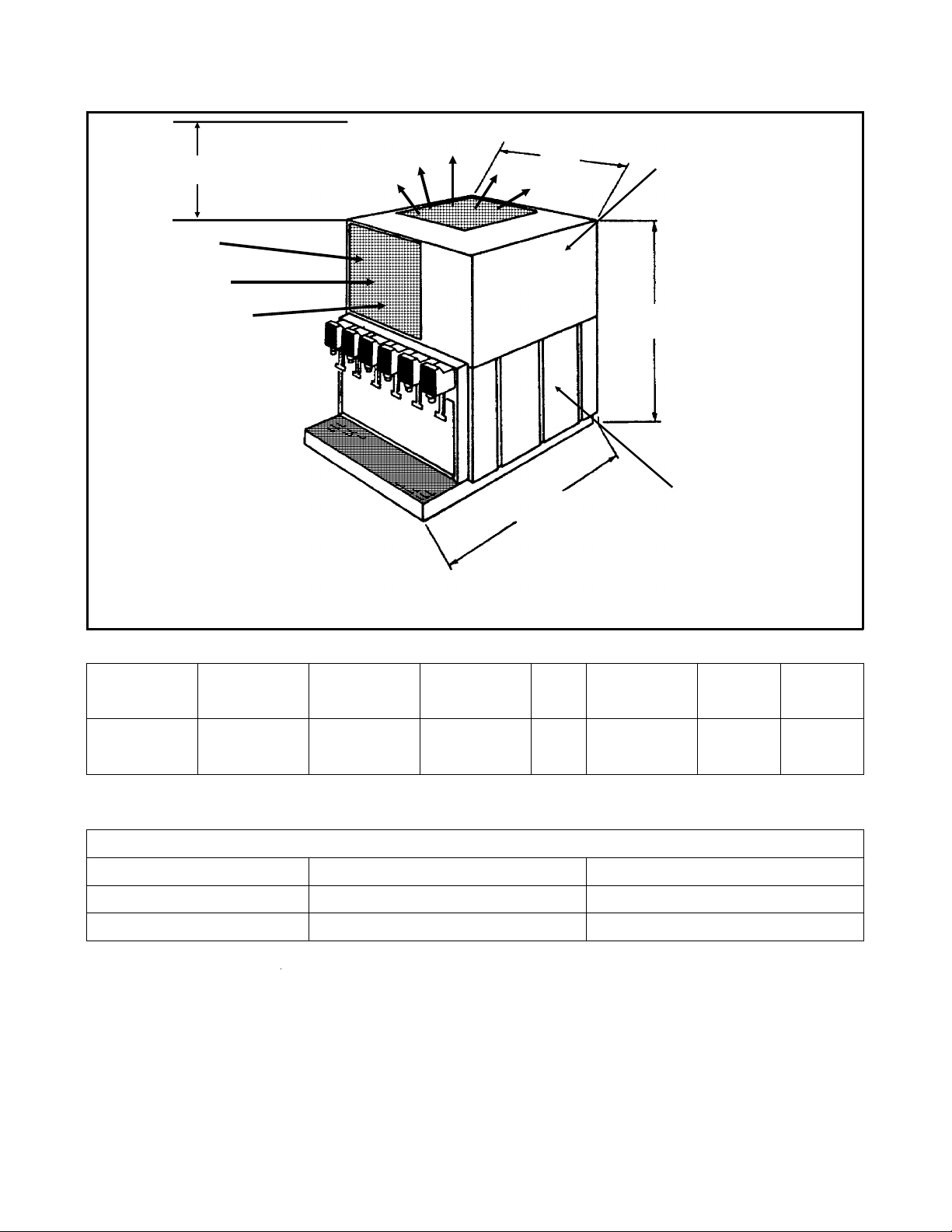

Must Have 13.5"

Clearance Above Unit

COOLING

AIR

IN

AIR OUT

26.5"

18.5"

COVER (SS)

26.5"

ICE/WATER

TANK

SPECIFICATIONS:

MODEL

DD40P+6B-1A

DD40S+6B-1A

DIMENSIONS

H" X W" X D"

26.5 X 18.5 X 26.5

SAME

TANK FINISH

Twin Wall Plastic

Stainless Steel

ELECTRCIAL

115/60/1 - 7 AMPS

SAME

ICE

BANK

40 LB.

SAME

Legs are included. Carbonator (Carb100) and installation kit (KINSDD) not included.

REFRIGERATION CAPACITY: Number of 12-0z. drinks at or below 400 F.

@ 900 F. product, water and ambient@ 750 product, water and ambientDrinks per minute

4

6

150

110

80

45

Scotsman Ice Systems are designed and manufactured with the highest regard for safety

and performance. They meet or exceed the standards of UL and NSF.

Scotsman assumes no liability or responsiblity of any kind for products manufactured by

Scotsman that have been altered in any way, including the use of parts and/or other

components not specifically approved by Scotsman.

Scotsman reserves the right to make design changes and/or improvements at any time.

Specifications and designs are subject to change without notice.

February, 1988

Page 3

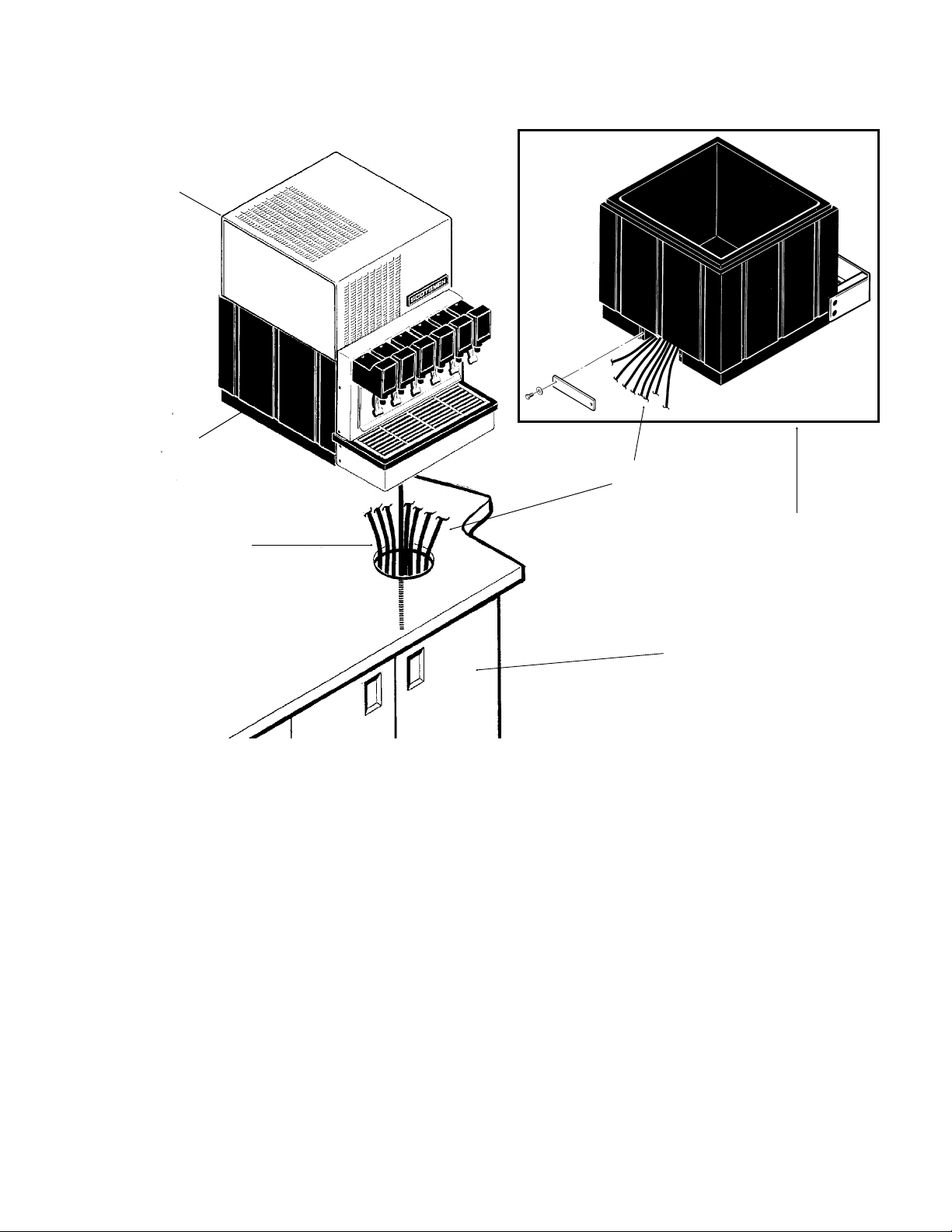

COVER

PRODUCT

HOSES

Page 2

INSTALL LEGS OR

SEAL TO COUNTER

DD40

Installation

POSSILBE

ROUTING OF

PRODUCT HOSES

1. Locate dispenser on the counter. Allow

13.5 inches vertical clearance above unit

for the removal of the cover, and for air

circulation.

In order to comply with National Sanitation

Foundation (NSF) requirements, this unit

must be either elevated above the

countertop sufficiently to provide space for

cleaning under the unit or sealed to the

countertop.

Elevating the unit may be accomplished by

using the included legs. They will screw

into threaded holes in the base of the unit.

Sealing may be accomplished by the use

of room temperature vulcanizing (RTV)

rubber sealant such as General Electric IS

808 Industrial Sealant, Dow Corning 731

(Scotsman part number 19-0529-01) or the

equivalent.

POSSIBLE

ROUTE FOR

PRODUCT HOSES

POSSIBLE LOCATION

FOR CARBONATOR

With the unit located on the counter as

desired:

A. Tilt or lift the unit to expose the bottom

flanges of the base frame.

B. Apply the sealant to cover the bottom

flanges of the base frame.

C. Return the unit to the desired position

on the countertop.

D. Add sealant around the base frame and

countertop to provide a seal with a radius

of 1/2". Follow the sealant manufacturer’s

instructions on the package for working

with the sealant, and cleaning up.

E. Seal around all access holes in the

countertop with Permagum or Mortite caulk

or an equivalent material.

February, 1988

Page 4

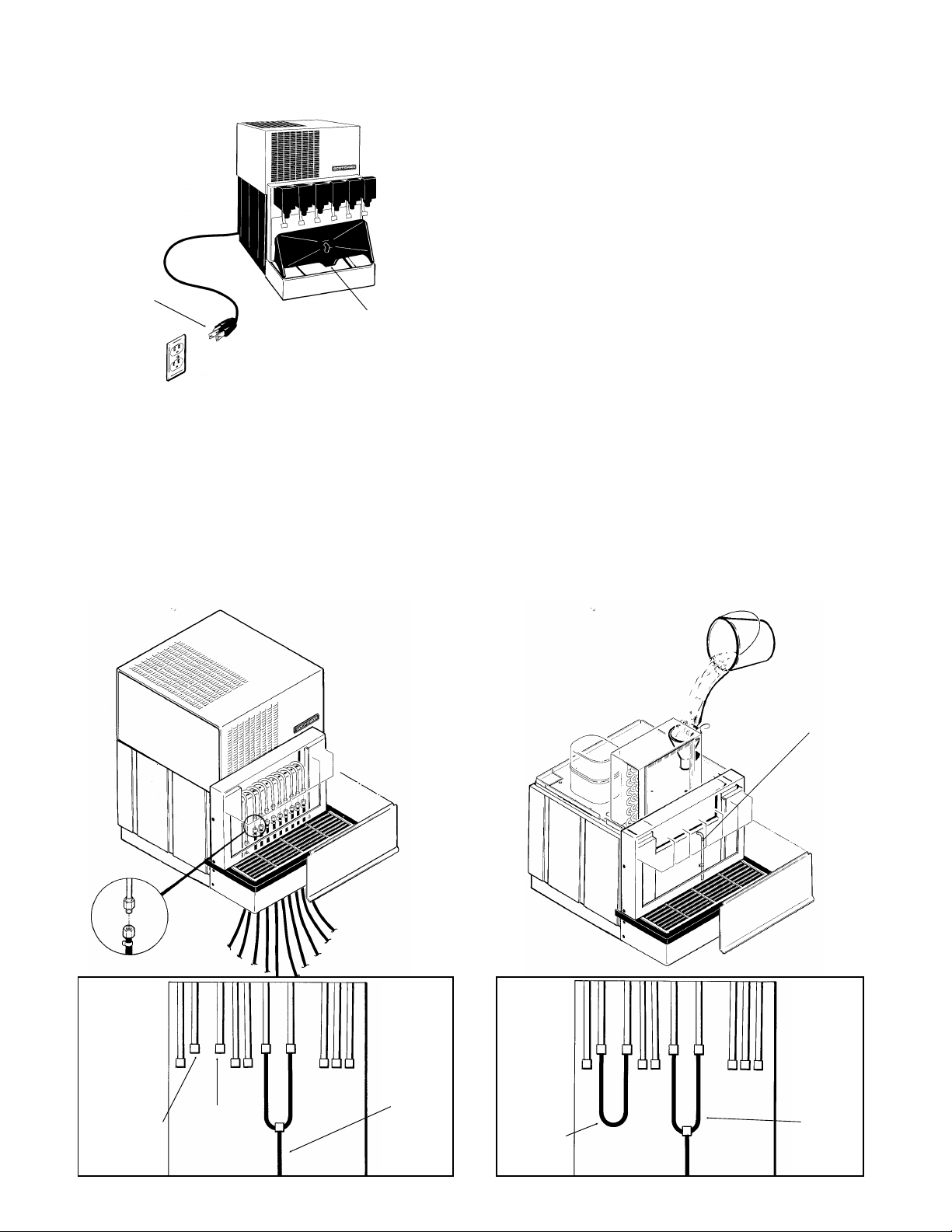

CORD

Page 3

PLUGS INTO

115 VOLT

WALL

OUTLET.

THIS UNIT

MUST BE

GROUNDED

SINK BOTTOM. SINK

DRAIN MUST BE

CONNECTED TO

BUILDING DRAIN

Remove the cover by removing one screw

on the top of the cover.

If installing a remote carbonator, locate it

nearby.

2. Connect the drain line between drain

pan and building drain.

3. Plug electrical supply cord into 115 volt

outlet so ice bank can begin to form. Do

not turn on the carbonator at this time.

DD40

Installation

4. Fill water bath until water flows out of

overflow tube.

5. Connect water supply line (field

supplied) from the remote carbonator to

the dispenser.

Connect both inlet C02 water lines to CO2

water from the carbonator.

Connect water supply line (field supplied)

from building source to carbonator.

Connect syrup lines to dispenser, and

install disconnect sockets.

6. Connect primary CO2 regulator to CO2

tank. Secure secondary regulators to wall

or other stationary surface.

7. Connect CO2 line between outlet of

primary regulator and inlet of secondary

regulators.

8. Connect CO2 lines between outlets of

secondary regulators and syrup tanks.

INSTALL DISCONNECT SOCKETS

WHEN ONE

VALVE IS

NOT

CARBONATED

CONNECT TUBING FILL WITH WATER

OVERFLOW

TUBE

CAP

WITH

GASKET

AND CAP

NUT

CONNECT

TO FRESH

WATER

CO

2

WATER

IN

February, 1988

LOOP

WHEN

NOT

USING

FRESH

WATER

CO

2

WATER IN

Page 5

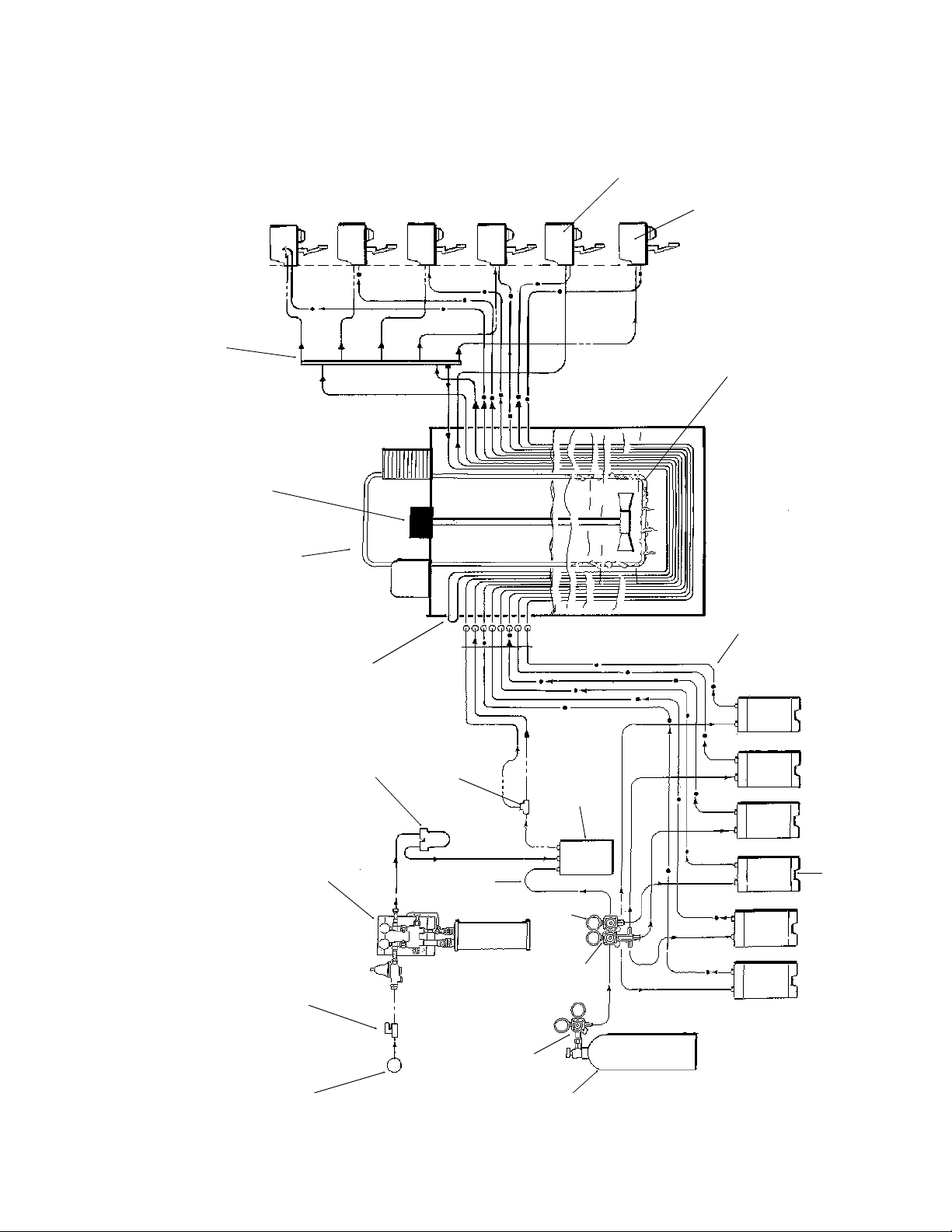

Diet Sysrup Tank

DD40

Page 4

Soda Schematic

Valve

Frese Water

Soda Valve

Carbonated

Water Manifold

Evaporator Coil

Agitator Motor

Refrigeration Unit

Inlet Loop

Fresh Water

Pump

Carbonator

Water Filter

re Water

Carbonato

In

2

CO

Tank

Carbonator

Diet

Reg.

Bank

Syrup Out to Ice

Reg.

Syrup

Hand Valve

2

CO

Regulator

Tank

2

Water Supply

CO

February, 1988

Page 6

BRAIDED

HOSE

KINSDD KIT

DD40

Page 5

Optional Kits

SCOTSMAN FLOAT CARBONATOR

"CARB100" INSTALLATION

1. Remove from carton, inspect for freight

damage. If damaged file a claim with the

freight company immediately.

2. Locate the carbonator on a flat surface.

3. Connect the water supply to the water

"in" (3/8" male flare on pump body) Use

3/8" or larger line.

4. Connect carbonated water line from to

carbonated water "out" (on tank) to the ice

bank CO2 water "in".

5. Install CO2 regulator on CO2 tank.

6. Connect CO2 line from the high

pressure CO2 regulator to CO2 "in" fitting

on the carbonator tank.

7. Install tank disconnects on the end of

the CO2 lines.

8. Turn on CO2 tank, set the high pressure

gauge at 80-100 psi.

Set low pressure gauge at 45 psi. (Diet to

8-15 psi).

9. Check all fittings with soapy water for

possible gas leaks.

10. Turn on water to carbonator.

11. Plug electrical cord into properly

grounded 115 volt outlet.

NOTE: Grounded outlet must be used

for safety. If local codes require hard

wiring, follow these steps.

CARB 100

REMOVE: Cord plug from 115 volt outlet.

Wiring compartment cover from motor.

Wire nut from power supply wire, quick

disconnect terminal from motor terminal,

and ground wire fastener.

Cord from motor.

INSTALL: Appropriate bushing into conduit

hole in motor.

Permanent wiring to motor through bushing

into wiring compartment.

One conductor to switch cord with wire nut

removed in step 3 above.

Other conductor to terminal from power

cord was removed.

Ground wire to motor housing with green

grounding screw.

Wiring compartment cover.

Purge CO2 pressure from carbonator once

or twice while filling by pulling up on

pressure relief valve on the top of the

carbonator tank.

12. Connect syrup lines from syrup tanks

to dispensing lines on ice bank (located

behind the front panel).

13. Connect gas to syrup tanks.

14. Adjust soda valves for proper mix.

15. CO2 tanks should always be secured

to prevent them from falling over.

HIGH PRESSURE

REGULATOR

TWO LOW PRESS.

REGULATORS

February, 1988

FITTINGS

Page 7

DD40

Page 6

Start Up

(Only after ice bank has formed)

1. Turn CO2 on.

2. Set high pressure regulator to 80-100 PSI

3. Set low pressure regulator to 40-50 PSI

4. Set diet pressure regulator (if used) to 8-10 psi.

5. Connect syrup tanks and gas disconnects to syrup tanks.

6. Check for CO2 leaks by turning CO2 tanks off for 4-5 minutes. If the high pressure guage

drops, there is a CO2 leak. Then check each fitting with a soap solution.

7. Turn on the water.

8. Plug in or switch on the carbonator.

9. Purge CO2 gas pressure from the carbonator once or twice while filling by pulling up on

pressure relief valve on the top of the carbonator.

10. Actuate each valve until both water and syrup flow.

11. Check each valve for proper adjustment. Flow rate per valve should be 1.25 oz. per

second of carbonated water, and .25 oz. per second syrup for standard valves. For a fast

flow valve, flow rate should be 2.5 oz. per second of carbonated water, and .5 oz. per

second syrup.

12. Replace cover and screws.

13. Check that the CO2 tanks are secure from falling over.

14. If water noise occurs, add water to bath.

15. Allow machine to build ice bank before dispensing product at maximum draw rate.

February, 1988

Page 8

FOR THE OPERATOR

Page 7

This section covers operating controls,

daily pre-operation check, unit operation,

adjustments, replenishing CO2 and syrup

supplies, and daily cleaning.

Operating Controls.

Dispensing valve levers, located below the

dispensing valves, need only to be pressed

with a cup or glass to dispense product.

Dispensing carbonated water only. On two

of the valves there is a separate lever for

dispensing water only. On the carbonated

valve, actuating this lever will cause the

valve to dispense carbonated water only. If

there is a non-carbonated valve, activating

it will dispense plain water.

VALVES WITH

"WATER ONLY"

LEVERS

Daily Check

1. Make sure that the CO2 cylinder primary

regulator assembly 1800 psi gauge is not

in the shaded ("change CO2 cylinder")

portion of the dial. If so, CO2 cylinder is

almost empty, and must be replaced.

2. Sufficient syrup supply in all syrup tanks.

If not, replenish syrup supply.

3. Make sure drip tray and grill are clean.

4. Make sure soda valve nozzles are clean.

DD40

Replenishing CO2 Supply

Note: When indicator on CO2 cylinder

regulator 1800 psi gauge is in the shaded

area, the cylinder is almost empty and

should be changed.

1. Fully close (clockwise) CO2 cylinder

valve.

2. Slowly loosen CO2 regulator assembly

coupling nut allowing CO2 pressure to

escape, then remove regulator assembly

from CO2 cylinder.

3. Unfasten safety chain and remove

empty CO2 cylinder.

////////////////////////////WARNING/////////////////////////

To avoid personal injury and/or property

damage, always secure CO2 cylinder

with a safety chain to prevent it from

falling over. Should the valve become

accidentally damaged or broken off,

CO2 cylinder can cause serious

personal injury.

/////////////////////////////////////////////////////////////////////

4. Position CO2 cylinder and secure with

safety chain.

5. Make sure gasket is in place inside CO2

regulator coupling nut, then install regulator

on CO2 cylinder.

6. Open (counterclockwise) CO2 cylinder

valve slightly to allow lines to slowly fill with

gas, then open valve fully to back seat

valve. (Back seating valve prevents

leakage around valve shaft.)

7. Check CO2 connections for leaks.

Tighten loose connections.

Replenishing Syrup Supply.

1. Remove CO2 disconnect (grey) and

syrup disconnect (black) from empty syrup

tank, then remove tank.

2. Place full syrup tank in position, then

connect CO2 disconnect (grey) and syrup

disconnect (black) to full syrup tank.

Syrup Flavor Change.

Sanitize applicable syrup system as

instructed, then install full tank of new

flavor syrup.

February, 1988

Page 9

SPRING

CLEAN THE

CONDENSER

DD40

Page 8

FOR THE OPERATOR

Cleaning and sanitizing

1. Remove grill from sink.

2. Wash out sink, and then rinse with warm

water allowing water to run down the drain.

3. Wash the grill, then rinse with clean

water. Place back in sink.

4. Clean all exterior surfaces of the unit

with a sponge. Rinse out the sponge with

clean water, wring excess water out of the

sponge, and wipe off external surfaces of

the unit. Wipe unit with a clean soft cloth.

Do NOT use abrasive type cleaners.

5. Clean valve nozzles. Looking down from

the top of the unit, turn the nozzle

clockwise and down to remove it. Clean

with soap and water, rinse with clean hot

water, and allow to air dry. Replace on the

valve.

Clean the condenser twice per year.

1. Disconnect electrical power.

2. Remove one screw, and the cover.

3. Remove condenser filter, and clean it

with water.

4. Inspect condenser fins, if light cannot be

seen through the fins, the condenser

needs to be cleaned by either vacuum,

compressed air, or coil cleaner. Do Not use

a wire brush.

5. Replace the filter, and the cover.

6. Reconnect the electrical power.

GAS CHECK VALVES

(At the low pressure outlet of the CO

regulator).

The CO

inspected and serviced at least one per

year under normal conditions, and always

after any servicing or disruption of the CO

system.

Always replace the quad ring seal each

time the gas check valves are serviced.

tank

2

system gas check valves must be

2

2

February, 1988

QUAD RING

BALL

RETAINER

BODY

Page 10

Adjustments

Page 9

There is an adjustment for both the water

and the syrup.

Adjustment screws are located under the

valve cover, and behind the solenoid.

1. Facing the valve, the screw on the right

hand side is the syrup adjustment. The

Valve service

To remove:

Push release lever up (located under the

cover on the right side of the valve, near

the back) and pull out the valve. There are

ball checks to automatically shut off the

water and syrup.

Pull apart the electical connectors to the

valve, and remove the valve.

To service:

• Rubber Seats(ring actuators):

Remove the four screws in the back of the

rear section. This will let the front and rear

section seperate and expose the ring

actuators.

The ring actuators are reversable, and

interchangeable. When either reversing, or

replaceing them, place the rings of the

actuators into the groves and align the

DD40

FLOW

CONTROL

ADJUSTER

screw on the left hand side is the water

adjustment.

2. Turn either screw counter clockwise to

increase flow.

stainless steel lever of the actuator with the

center of the notch in the front section.

Replace the rear section, be sure that the

ring actuators seat in the groves of the

front and rear section.

• Flow Controls:

The adjusting screws and springs may be

removed by first removing solenoid and

then the entire top plate. The adjusting

screws and springs are interchangeable.

To remove pistons, remove the entire top

plate, then remove the retaining spring on

the tip of the adjusting screw. The spring

piston should slide off. Pistons are color

coded:

Water is green

Syrup is red

Diet syrup is grey.

PISTON

RING ACTUATOR

February, 1988

Page 11

SANITIZING

Page 10

The dispenser’s syrup systems should be

sanitized periodically as prescribed by the

local health authority or the syrup supplier,

whichever has jurisdiction.

Recommended sanitizing agents are

"Chlor-tergent" (Oakite Products Co.) or

"Diversal CX" (Diversey-Wyandotte

Chemical Co.)

Use an empty, clean syrup product tank in

which to mix the sanitizing solution.

Prepare the sanitizing solution by

dissolving the required amount of

concentrate to supply 200 PPM (parts per

million) available sanitizer in enough water

to flush and sanitize the number of circuits

to be cleaned; five gallons of sanitizer

should be adequate for sanitizing a five

flavor dispenser. Water temperature should

be between 750F. and 1250F.

To sanitize syrup systems:

1. Remove quick disconnect sockets from

syrup product tank. Wash sockets in warm

potable water, connect sockets to tank

containing sanitizing solution.

2. Open dispensing valve to allow

sanitizing solution to push syrup out of

product line, cooling coil, and valve.

DD40

Continue drawing until sanitzing solution

has purged all syrup from system and then

close valve.

3. Allow sanitizing solution to remain in

system for ten (10) minutes.

4. To remove sanitizing solution from

system, remove tank containing solution

and connect a tank containing clean,

uncontaminated syrup. Operate dispensing

valve until all sanitizing solution has been

removed from the system.

/////////////////////////Caution//////////////////////////////

Failure to remove all sanitizer could create

a health hazard.

///////////////////////////////////////////////////////////////////

Repeat sanitizing procedure for each syrup

system (valve) in the dispenser.

/////////////////////////////WARNING////////////////////////

To Avoid Possible Personal Injury Or

Property Damage, Do Not Attempt To

Remove Cover From The Pressurized

Tank Until All Pressure Has Been

Released From The Tank.

/////////////////////////////////////////////////////////////////////

Clean, rinse, and dry utensils. Store them

for future use.

February, 1988

Page 12

DD40

he

re.

e

re

,

Page 11

SERVICE DIAGNOSIS

Symptom

..........Probable Cause

.....................Remedy

Water to syrup ratio too low or too high

..........1. Dispensing valve syrup flow regulator not properly adjusted.

.....................1. Adjust Water to Syrup ratio.

..........2. CO2 gas pressure to syrup tanks insufficient to push syrup out of the tank

.....................2. Adjust syrup tanks secondary CO2 regulator as instructed.

Adjustment of dispensing valve syrup flow regulator does not increase to desired

water to syrup ratio.

..........1. No syrup supply

.....................1. Replenish syrup supply as needed.

..........2. Syrup tank quick disconnects not secure

.....................2. Secure quick disconnects

..........3.Syrup tanks secondary CO2 regulator out of adjustment

.....................3.Adjust syrup tanks secondary CO2 regulator.

..........4.Dispensing valve, syrup tank quick disconnect, or syrup line restricted.

.....................4.Sanitize syrup system as instructed.

Dispensed product carbonation too low.

..........1. Carbonator primary CO2 regulator out of adjustment for existing water conditions or

..........temperature.

.....................1. Adjust carbonator primary CO2 regulator

..........2. Air in carbonator tank

.....................2. Vent air out of carbonator tank through relief valve. Actuate dispensing valve

.....................carbonated water lever to make carbonator pump cycle on.

..........3. Water, oil, or dirt in the CO2 supply.

.....................3. Remove contaminated CO2. Clean CO2 system (lines, regulators, etc.) using a

..................... mild detergent. Install a clean CO2 supply.

Dispensed product produces foam as it leaves dispensing valve.

..........1. No ice in ice bank.

.....................1. Check if overusing, if not, refrigeration system may have a dirty condenser. If t

.....................condenser is clean, and the agitator motor is running, the refrigeration system

.....................may need service.

..........2. Carbonator CO2 regulator pressure too high for existing water conditions or temperatu

.....................2. Reduce carbonator CO2 regulator pressure setting.

..........3. Syrup over carbonated with CO2 as indicated by bubbles in inlet syrup lines leading

.......... to the unit.

.....................3. Remove syrup tanks quick disconnects. Relieve tank CO2 pressure, shake tank

..................... vigorously, then relieve tank CO2 pressure as many times as necessary to remov

..................... over carbonation.

..........4. Dispensing valve restricted or dirty.

.....................4. Sanitize syrup system as instructed.

..........5. Dirty water supply.

.....................5. Check water filter. Replace cartridge. NOTE: If the water supply is dirty, be su

.....................to flush lines & carbonator completely. If needed, remove lines to carbonator tank

.....................invert tank and flush tank and all inlet lines to remove any foreign particles or dirt.

February, 1988

Page 13

g

DD40

Page 12

SERVICE DIAGNOSIS

No product (only water) dispensing from all valves.

..........1. Out of CO2

.....................1. Check CO2 supply.

Must push cup lever further back than normal to dispense product.

..........1. No power to unit.

.....................1. Check that it is plugged in.

..........2. Coil in valve not working.

.....................2. Replace coil.

..........3. Micro switch not working.

.....................3. Replace microswitch.

..........4. Disconnected or broken wiring to dispensing valves.

.....................4. Connect or replace wiring.

..........4. Transformer not working.

.....................4. Replace transformer.

Only carbonated water dispensed.

..........1. Quick disconnects not secure on syrup tanks.

.....................1. Secure quick disconnects on syrup tanks.

..........2. Out of syrup.

.....................2. Replenish syrup supply as instructed.

..........3. Syrup tanks secondary CO2 regulator not properly adjusted.

.....................3. Adjust syrup tanks secondary CO2 regulator.

..........4. Inoperable dispensing valve.

.....................4. Repair dispensing valve.

..........5. Dispensing valve syrup flow regulator not properly adjusted.

.....................5. Adjust dispensing valve.

..........6. Dispensing valve, syrup tank quick disconnects, or syrup lines restricted.

.....................6. Sanitize syrup system.

Only Syrup Dispensed

..........1. Plain water inlet supply line shutoff valve closed.

.....................1. Open plain water inlet supply line shutoff valve.

..........2. Carbonator power cord unplugged from the electrical outlet.

.....................2. Plug carbonator in.

..........3. Carbonator primary CO2 regulator not properly adjusted.

.....................3. Adjust carbonator primary CO2 regulator.

Dispensed product comes out of the dispensing valve clear but foams in the cup or

glass.

..........1. Oil film or soap scum in cup or glass.

.....................1. Use clean cups or glasses.

..........2. Ice used for finished drink is too cold.

.....................2. Do not use ice directly from a freezer. Allow the ice to become "wet" before usin

February, 1988

Page 14

DD40 REMOVAL AND REPLACEMENT

FERRULE CRIMP TOOL

Page 13

/////////////////////WARNING////////////////////////////

Disconnect Electrical Power before

beginning work on the machine.

////////////////////////////////////////////////////////////////////

Ice Thickness Thermostat:

1. Unplug machine from the power source.

2. Remove the cover.

3. Remove the thermostat cover.

4. Pull bulb and capillary line out of bulb

well.

5. Disconnect wires from thermostat.

6. Remove screws holding body to frame,

remove thermostat from ice bank.

7. Reverse to reassemble.

Agitator Motor:

1. Unplug machine from power source.

2. Remove cover.

3. Disconnect wires from motor at junction

plug.

4. Remove two screws, and pull motor up

and out of the ice bank.

5. Reverse to reassemble.

Soda Valve:

1. Switch off Carbonator

2. Turn off Water.

3. Unplug ice bank.

4. Turn off CO2, and at a working valve,

dispense until syrup/water stops.

5. At the valve to be removed:

Remove two screws, pull valve cover up

and off

Move metal lever found in valve up.

Pull valve body out of the mounting block.

Disconnect electrical wires at the junction

plug.

6. After repair or replacement of the valve,

reverse to reassemble.

Refrigeration Chassis:

1. The refrigeration section of the DD40

can be removed from the soda lines,

valves and main body. This is useful when

taking it to the shop for repair or cleaning.

A. Disconnect electrical power.

B. Remove cover.

C. Unplug refrigeration power from the

connection at the right front of the unit.

D. Unplug the low voltage (transformer to

soda valves) connection at the junction

plug at the right front of the machine.

E. Remove 4 screws holding the chassis to

the base.

F. Lift up and remove chassis.

2. After repair or cleaning, reverse to

reassemble.

BRAIDED TUBING INSTALLATION

When installing the braided tubing using

the kit KINSDD, note that the kit contains

two types of clamps; oetiker an ferrule.

If using the oetiker clamps, a pincer

specifically designed for this is

recommended.

KETIKER PINCER

When using the ferrule type, the use of a

special crimp tool is mandatory.

Instructions are porvided with the tool.

Die set No. 47 works well with the ferrule

and tubing provided with the kit.

February, 1988

Page 15

QUICK

DISCONNECTRELEASE

QUICK DISCONNECT SECTION

DD40

Page 14

BOOTH VALVE

ADJUSTING

SCREW

TOP PLATE

TOP PLATE

GASKET

SOLENOID

ASSEMBLY

O-RING

PISTON

CUP

ACTUATOR

SOLENOID

LEAD

MICRO

SWITCH

RETAINING ROD

REAR SECTION BODY

VALVE COVER

RELEASE ACTUATOR

VALVE NIPPLE

CARB. WATER

ACTUATOR

FRONT BODY

SECTION

SPOUT INSERT

RING ACTUATOR

COVER PLATE

BOTTOM

SPOUT

February, 1988

ACTUATOR

SPRING

Page 16

CARB100 REMOVAL AND REPLACEMENT

Page 15

(OPTIONAL EQUIPMENT)

////////////////////////WARNING/////////////////////////////

Disconnect electrical power before

beginning to work on the unit.

//////////////////////////////////////////////////////////////////////

1. Unplug Carbonator.

2. Turn off CO2

3. Turn off water.

4. Bleed CO2 pressure off at soda valve or

relief valve on carbonator tank.

5. Any component in the Carbonator may

now be removed and replaced, including:

PUMP MOTOR

DD40

Float Control, disconnect wires at the

motor, and remove three screws from the

collar at the top of the carbonator tank, pull

float control up and out.

Check Valves, unscrew selected valve from

tank.

Carbonator pump, no internal service parts,

remove and replace.

Carbonator motor, no internal service parts,

remove and replace.

6. Reverse steps of removal to reassemble.

FLOAT PROBE

PUMP

WATER

CHECK

VALVE

February, 1988

Loading...

Loading...