Page 1

User's Manual

for Residential Ice Machine

Model

DCE33

Page 2

INTRODUCTION

DCE33

The Scotsman DCE33 is a restaurant type ice

machine designed for home use. It produces the

same high quality ice as large Scotsman

commercial ice cube machines, and stores that ice

in a heavily insulated storage bin.

This service manual is intended as a resource for

people installing, using, and servicing the DCE33.

Because it contains information on safety and

maintenance, Scotsman strongly recommends that

this manual be kept where it is readily available.

Table of Contents

TECHNICAL INFORMATION ··································· Page 2

CABINET DIMENSIONS ····································· Page 3

INSTALLATION ·········································· Page 4

TO INSTALL: Plumbing ······································ Page 5

TO INSTALL: Plumbing ······································ Page 6

TO INSTALL: Plumbing ······································ Page 7

TO INSTALL: Plumbing ······································ Page 8

TO INSTALL: Plumbing ······································ Page 9

TO INSTALL: Add On Kits ···································· Page 10

TO INSTALL: Add On Kits ···································· Page 11

AFTER INSTALLATION ····································· Page 12

AFTER INSTALLATION - OPERATION ····························· Page 13

OPERATION ··········································· Page 14

COMPONENT LOCATION ···································· Page 15

MAINTENANCE AND CLEANING ································ Page 16

CLEANING ············································ Page 17

ADJUSTMENTS ········································· Page 18

ADJUSTMENTS ········································· Page 19

HARVEST TIME ADJUSTMENT, models DCE33A-1BD, DCE33PA-1BD, DCE33A-1SSD or

DCE33PA-1SSD ········································· Page 20

SERVICE DIAGNOSIS ······································ Page 21

SERVICE DIAGNOSIS ······································ Page 22

REPAIR·············································· Page 23

REPAIR·············································· Page 24

REPAIR·············································· Page 25

REPAIR·············································· Page 26

Parts lists and wiring diagrams are located in the

center of the manual.

September 2011

Page 1

Page 3

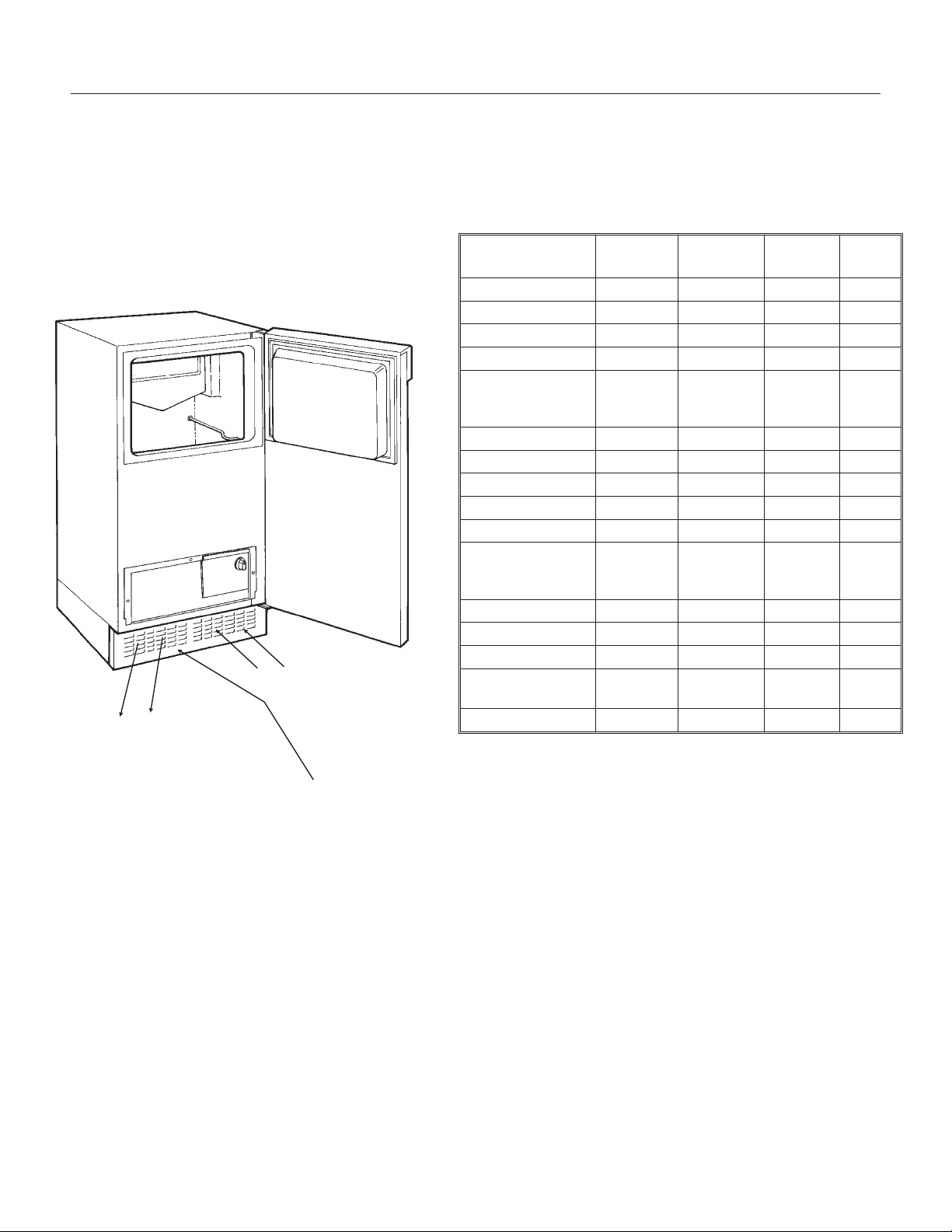

DCE33

TECHNICAL INFORMATION

Scotsman Ice Systems are designed and

manufactured with the highest regard for safety

and performance. They meet or exceed the

standards of U.L., and C.U.L.

Scotsman assumes no liability or responsibility of

any kind for products manufactured by Scotsman

that have been altered in any way, including the

use of any parts and/or other components not

specifically approved by Scotsman.

Cool Air In

Warm Air Out

Serial Number

Tag Location

Scotsman reserves the right to make design

changes and/or improvements at any time.

Specifications and designs are subject to change

without notice.

Model Number Basic

Electrical

DCE33A-1WB 115/60/1 15 amp White No

DCE33PA-1WB 115/60/1 15 amp White Yes

DCE33A-1BB 115/60/1 15 amp Black No

DCE33PA-1BB 115/60/1 15 amp Black Yes

DCE33A-1SB 115/60/1 15 amp Black

DCE33PA-1SB 115/60/1 15 amp same Yes

DCE33A-1WC 115/60/1 15 amp White No

DCE33PA-1WC 115/60/1 15 amp White Yes

DCE33A-1BC 115/60/1 15 amp Black No

DCE33PA-1BC 115/60/1 15 amp Black Yes

DCE33A-1SC 115/60/1 15 amp Black

DCE33PA-1SC 115/60/1 15 amp same Yes

DCE33A-1BD 115/60/1 15 amp Black No

DCE33PA-1BD 115/60/1 15 amp Black Yes

DCE33A-1SSD 115/60/1 15 amp Stainless

DCE33PA-1SSD 115/60/1 15 amp same Yes

Maximum

Fuse Size

Cabinet

Color

with SS

door

with SS

door

Steel

Drain

Pump?

No

No

No

Add On Kits: Stainless Steel Door Panel Kit is SS33

Cabinet Extensions: KCE18-SS (Stainless Steel) KCE18-B

(black)

Stainless steel door sleeve conversion kit is K-SS

Drain Pump Kit to convert gravity drain to pump drain, see

page 10.

Refrigerant Charge is 5 ounces of R-134a. Compressor HP

is 1/8

D series utilizes an electronic harvest timer. All others

equipped with mechanical timer.

April 2013

Page 2

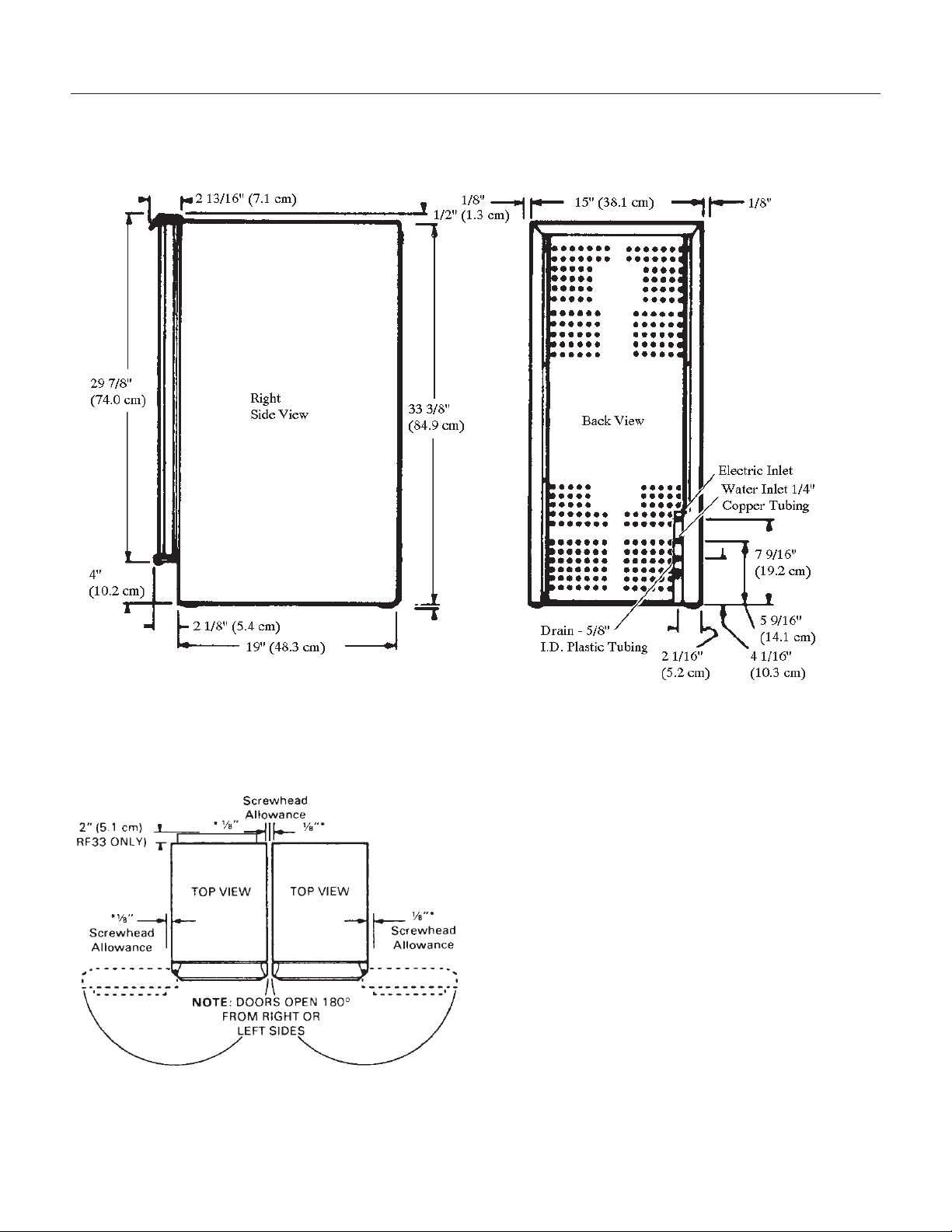

Page 4

CABINET DIMENSIONS

DCE33

DCE33 Cabinet Views

Refrig.

Overhead View of DCE33 and

Companion Refrigerator Side By

Ice

Machine

Pump Drain Hose is 3/8"

ID

September 2011

Page 3

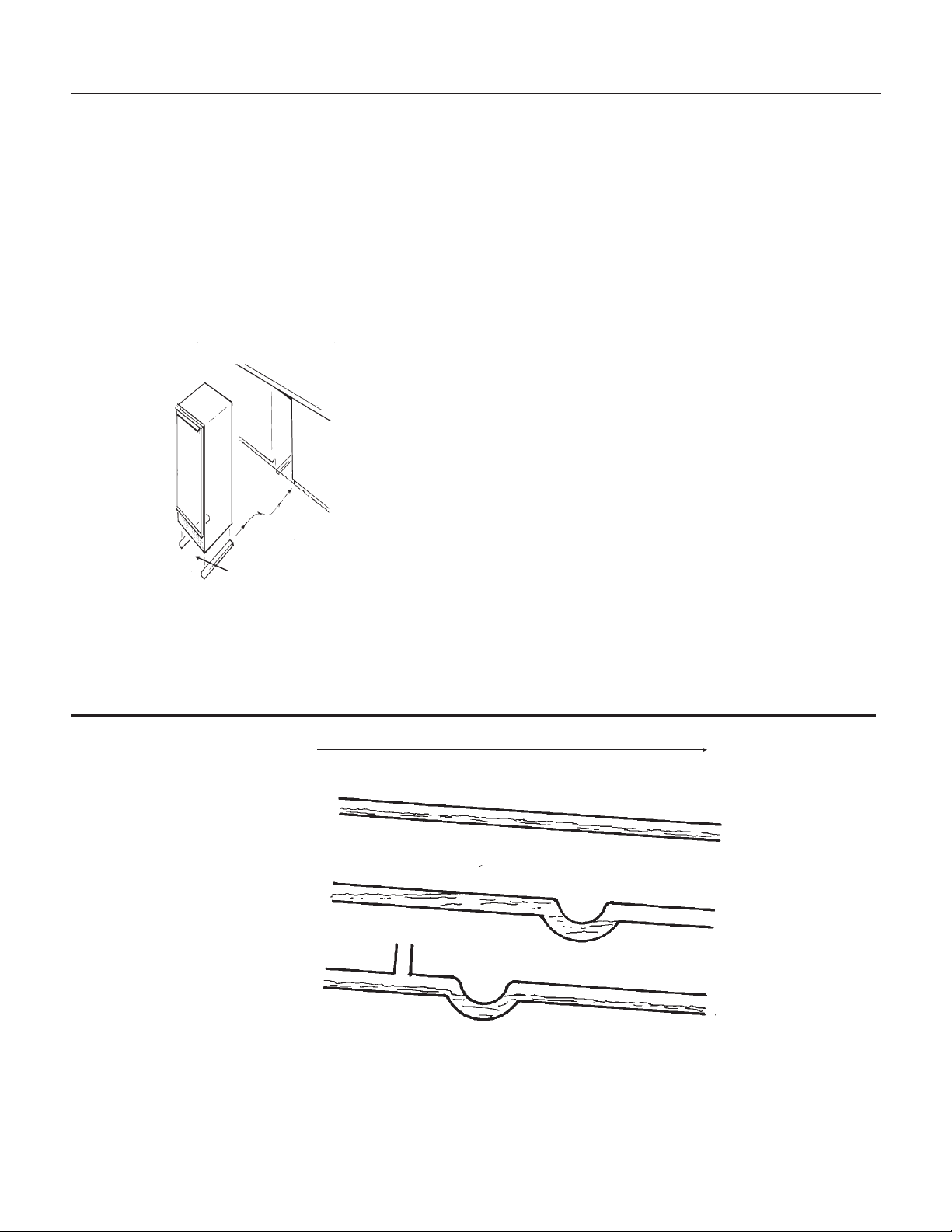

Page 5

INSTALLATION

DCE33

To properly make and store ice, the DCE33

requires access to air, potable water, 115 volt

electricity and a drain. The machine must be

installed indoors, in a controlled environment.

Air: The ice machine uses a fan to take in room air

at the front of the machine through the right side of

the kick plate. It discharges warm air out the left

side of the kick plate. Anything placed in front of

the kick plate will restrict air flow and cause a

decrease in performance and efficiency. The

minimum air temperature the machine will operate

in is 50

Water Supply: The ice machine requires a

continuous supply of potable water at no less than

20 p.s.i.g. of flowing pressure. Static water

pressure should not exceed 80 p.s.i.g. The

minimum water temperature the machine will

operate in is 40

There is no such thing as “pure” water; all water,

including potable water supplied by municipalities,

contains some “impurities”. Water absorbs

impurities from the air as rain and/or as it flows

through the ground. Some of the impurities are

solid particles, these are known as suspended

solids, and a fine particle filter will remove them.

Other impurities are chemically bonded to the

water molecules, and cannot be filtered out, these

are called dissolved solids.

0

F., and the maximum is 1000F.

0

F., and the maximum is 1000F.

Water Quality:

Ice made by the DCE33 will have a lower

mineral content than the water it was made from.

To keep the machine operating properly, these

impurities or minerals will have to be regularly

dissolved by an acid cleaning, using Scotsman Ice

Machine Cleaner. Directions for this may be found

in the section under cleaning.

In general, it is always a good idea to filter the

water. A water filter, if it is of the proper type, can

remove taste and odors as well as particles. Some

methods of water treatment for dissolved solids

include reverse osmosis, and polyphosphate

feeders. A reverse osmosis system should include

post treatment to satisfy the R.O. water’s

“aggressiveness”.

Deionized water is not recommended.

Because water softeners exchange one mineral for

another, Scotsman does not recommend their use

for ice machines. Where water is very hard,

softened water may result in white, mushy cubes

that stick together.

Scotsman suggests, that if in doubt about the

water, that a local point of use water specialist be

contacted for recommendations on water

treatment.

Electricity: The machine is supplied with a cord,

and may be plugged into a wall outlet. The ice

machine should be the only device using that

circuit.

The fuse (or circuit breaker) size should be 15

amps.

Drain: There are two DCE33 models:

Purer water will freeze first in the ice making

molds. The reason for this is that anything

dissolved in water lowers the water’s freezing

temperature.

This concentrates most of the impurities in the ice

machine water reservoir where they may form hard

deposits known as scale. The DCE33 dilutes the

concentration of minerals by over-filling the

reservoir during the harvest cycle (with the excess

water flowing down the drain). About 3 quarts of

water flow into the unit each cycle. About 1 quart

of that rinses the reservoir and goes down the

drain.

Some impurities will inevitably remain, and will

stick to the parts in the machine, and will cause

malformed ice cubes. Eventually, built up mineral

scale can shorten machine life.

September 2011

The DCE33A-1 is a gravity drain model that

requires a drain tube that’s pitched down from the

outlet at the back of the cabinet to the connection

to the sanitary sewer.

The DCE33PA-1 has a built in drain pump that will

pump water up to a drain point, such as a nearby

sink.

Page 4

Page 6

TO INSTALL: Plumbing

DCE33

The water supply and drain should be roughed in

and ready at the point of installation. A wall outlet

directly behind the ice machine will make

undercounter installation easier. All electrical,

water and drain connections must conform to local

codes.

Installation Cautions: Although the DCE33 has

been designed to be serviced in place, in some

cases it may be necessary to pull the unit out for

service. For that reason do not restrict access to

the cabinet at the front - top and bottom.

Install Unit

Flush With Floor

Installations on a slab: Use a pump

(DCE33PA-1) model and pump the water to the

point of drainage. Pump models will pump 1 story

high.

Installations over a crawl space or basement:

Either gravity drain or pump model units may be

used, if there is not enough room behind the

machine for a drain/waste receptacle, the drain will

have to be below the floor.

ALL PLUMBING MUST MEET LOCAL CODES

Note: When installed in a corner, the door

swing may be limited due to handle contact

with the wall or cabinet face.

Shims

If a floor is to be installed after the ice machine,

shims the thickness of the floor should be installed

under the DCE33 to keep the machine level with

the floor. Also, allow 1/8" clearance on each side of

the cabinet.

From Ice Machine

Normal Drain Line, Pitched

Down From Ice Machine

With Trap, Causes Poor Draining

With Trap And Vent,

Draining Is Normal

To Drain

Good Draining

Poor Draining

Good Draining

EXAMPLES OF GRAVITY DRAIN TUBE INSTALLATIONS

September 2011

Page 5

Page 7

DCE33

TO INSTALL: Plumbing

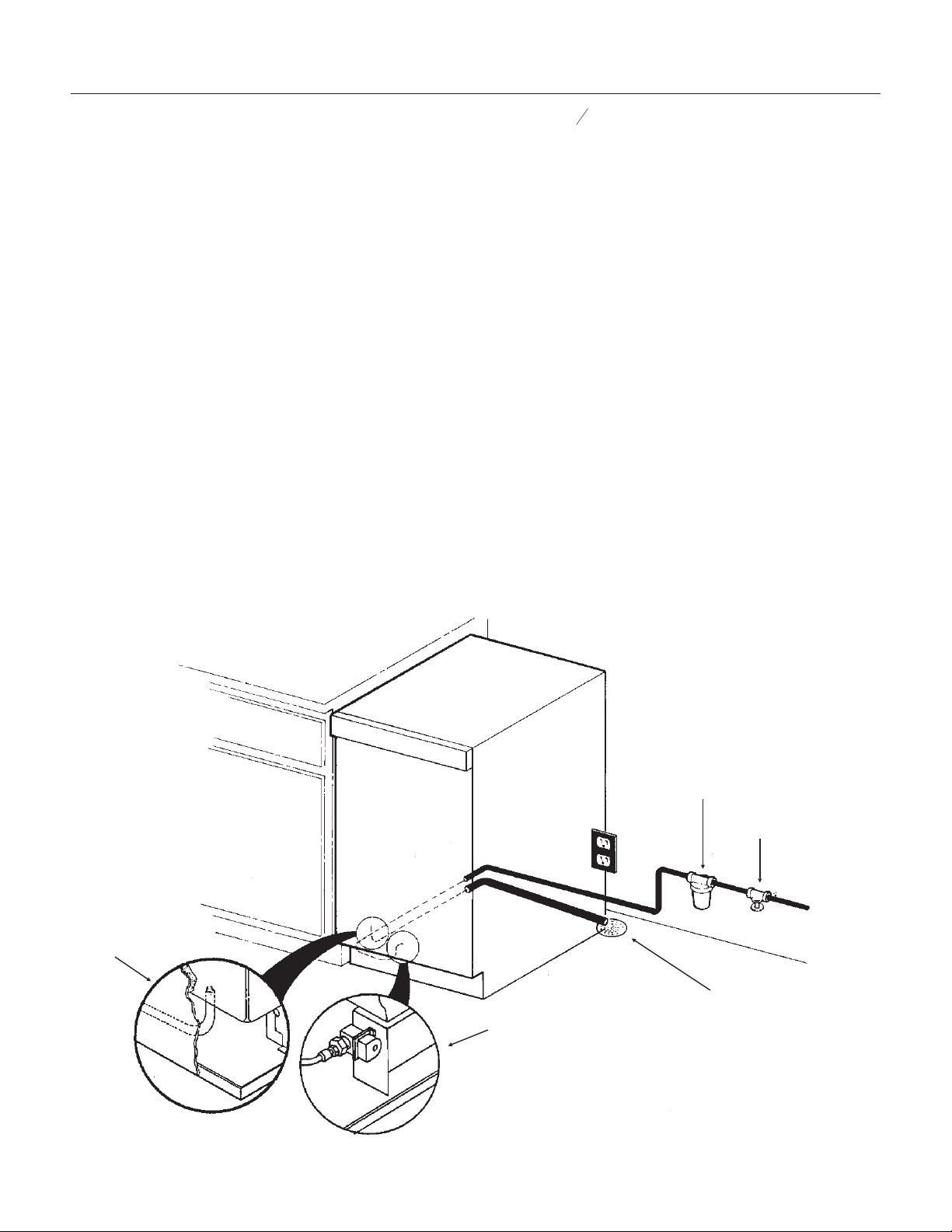

Free Standing Cabinet, Gravity Drain

Model:

All horizontal runs of drain lines must have a 1/4"

per foot fall. An air gap will likely be required

between the ice machine drain tube and the

drain/waste receptacle. A stand pipe with a trap

below it would be acceptable for the drain/waste

receptacle. A floor drain is also acceptable.

FOLLOW ALL LOCAL PLUMBING CODES

Poor draining will cause a high rate of ice

melting in the bin.

1. Remove the kick plate and the access cover

above it.

2. Route the water supply, which should be a 1/4"

O.D. copper tube through the back of the cabinet

to the front.

3. Install a flare nut and flare the end of the tube.

4. Flush the water line and fasten the flare nut to

the male flare on the inlet water valve.

5

5. Route a

" ID (7/8" OD) drain tube through the

8

back panel of the machine and connect to the bin

drain fitting at the bottom of the bin. Secure with

hose clamps.

Be certain that the drain tube is pushed up well

past the barbs on the drain fitting. If needed to

ease installation, soak the drain hose in hot water

just before connecting to the fitting.

6. Route the drain tube from the ice machine to the

drain/waste receptacle. Note: if using a long

horizontal run (more than 5’) the drain should be

vented at back of cabinet.

7. Turn on the water supply and check for leaks.

8. Replace the kick plate and the access cover

above it.

9. Level the unit using the leg levelers.

Drain Detail

Connection Detail

September 2011

Page 6

Water Filter

(Recommended)

Shut Off Valve

Water Inlet

INSTALLATION OF WATER AND DRAIN

Floor Drain

Page 8

TO INSTALL: Plumbing

DCE33

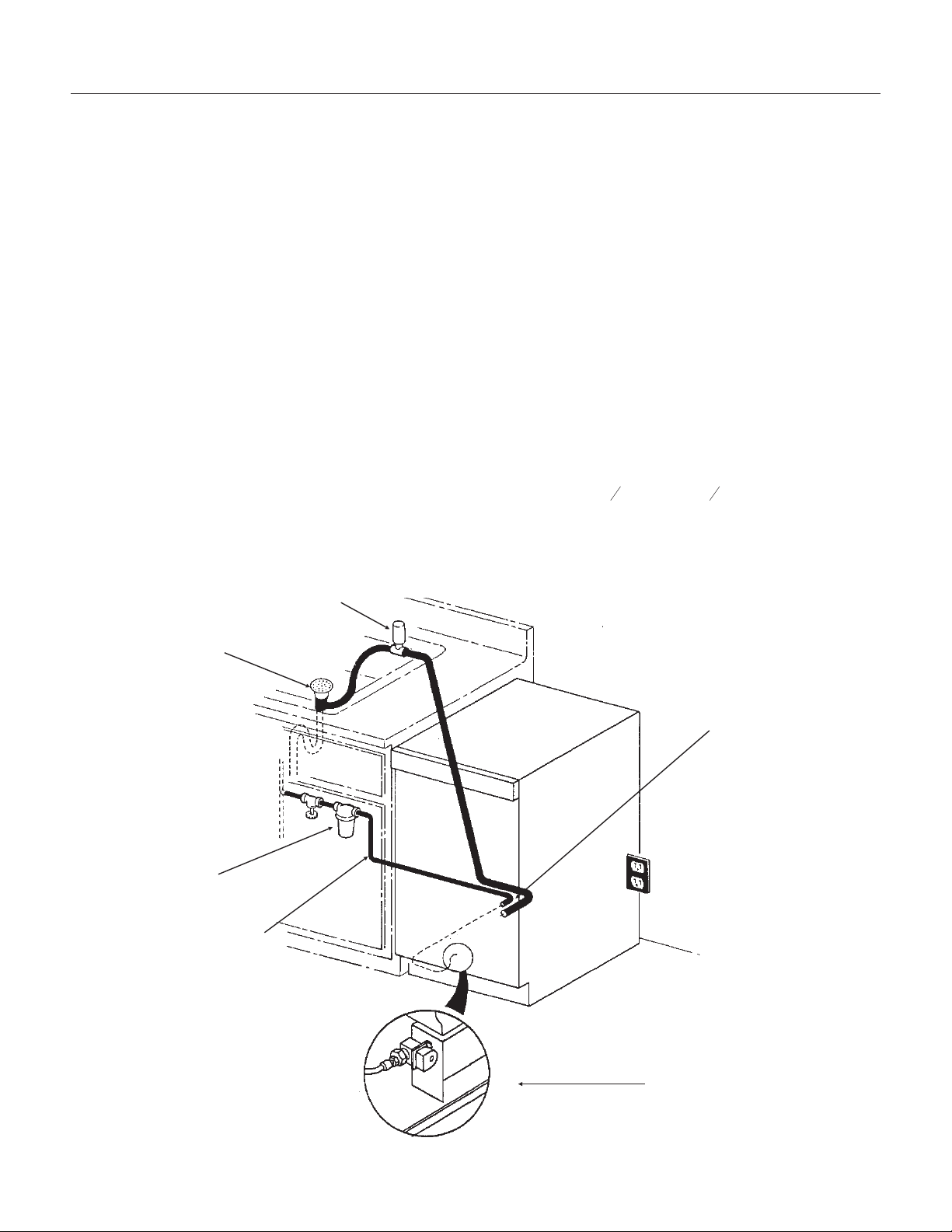

Free Standing Cabinet, Pump Model:

1. Remove the kickplate and control box cover.

2. Route the water supply, which should be a 1/4"

O.D. copper tube through the back of the cabinet

to the front.

3. Install a flare nut and flare the end of the tube.

4. Flush the water line and fasten the flare nut to

the male flare on the inlet water valve.

5. Locate the coil of 3/8" ID plastic drain tubing

secured to the back of the cabinet.

6. Route the plastic drain tubing to the drain point

connection. Do not connect to a drain/waste line

below a trap. Connect the discharge line to the

drain, per local codes. An air gap will likely be

required between the ice machine drain tube and

the drain/waste receptacle.

7. Turn on the water and plug in the ice machine.

Pour a couple quarts of water in the bin, the drain

pump should start. Check for water leaks.

8. Replace the kickplate and control box cover.

9. Level the unit using the leg levelers.

ALL PLUMBING MUST MEET LOCAL CODES

THE DCE33 WILL FIT IN A SPACE

THE DEPTH OF THE CABINET IS 22" TO

THE FRONT EDGE OF THE HANDLE.

1

"WIDEX33

15

4

3

" HIGH.

4

Air Gap Device

(Where Required)

Drain

Connection

Water Shut

Off Valve

Water Filter

(Recommended)

WATER AND DRAIN

INSTALLATION

Drain Tube

From Back Of

Machine

September 2011

Page 7

Water Inlet Connection

Page 9

DCE33

TO INSTALL: Plumbing

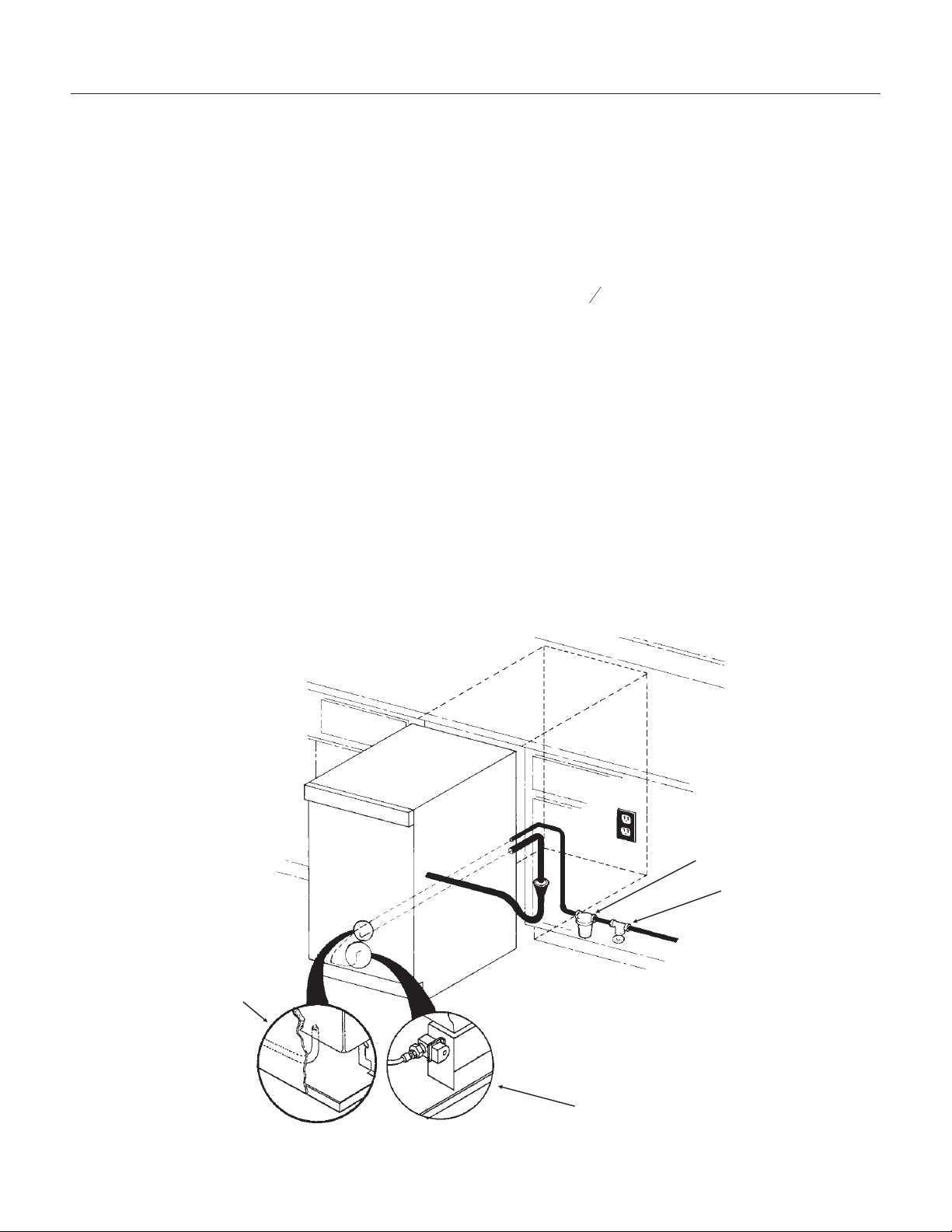

Built In, Gravity Drain Model:

The drain and inlet water tubes must be plumbed

before connecting to the ice machine. All horizontal

runs of drain lines must have a 1/4" per foot fall. An

air gap will likely be required between the ice

machine drain tube and the drain/waste

receptacle. A stand pipe with a trap below it would

be acceptable for the drain/waste receptacle.

Note: Poor draining will cause a high rate of ice

melting in the bin.

1. Place ice machine in front of installed location.

Adjust leg levelers to approximately correct

position.

2. Remove kickplate and the access cover above

it.

3. Route water inlet line, which should be a 1/4"

O.D. copper tube, from wall through ice machine to

the front.

4. Route drain line from wall position through ice

machine. Note: if using a long horizontal run (more

than 5’) the drain should be vented at back of

cabinet.

6. Push ice machine into installed position.

7. Cut off water inlet line at required length.

8. Flush water line. Place flare nut on inlet water

line and flare the end of the copper tube.

9. Attach flare nut to the male flare on the inlet

water valve.

10. Cut off the drain tube to the required length.

5

11. Route a

" drain tube through the back panel

8

of the machine and connect to the bin drain fitting

at the bottom of the bin. Secure with hose clamps.

Be certain that the drain tube is pushed up well

past the barbs on the drain fitting. If needed to

ease installation, soak the drain hose in hot water

just before connecting to the fitting.

12. Turn on the water supply and check for leaks.

13. Replace the kickplate and the access cover

above it. Level as needed.

ALL PLUMBING MUST MEET LOCAL CODES

5. If electrical outlet for ice machine is behind the

cabinet, plug in the ice machine now.

INSTALLATION OF WATER

AND DRAIN

Drain

Connection

Water Filter

(Recommended)

Shut Off Valve

September 2011

Page 8

Water Inlet Connection

Detail

Page 10

TO INSTALL: Plumbing

DCE33

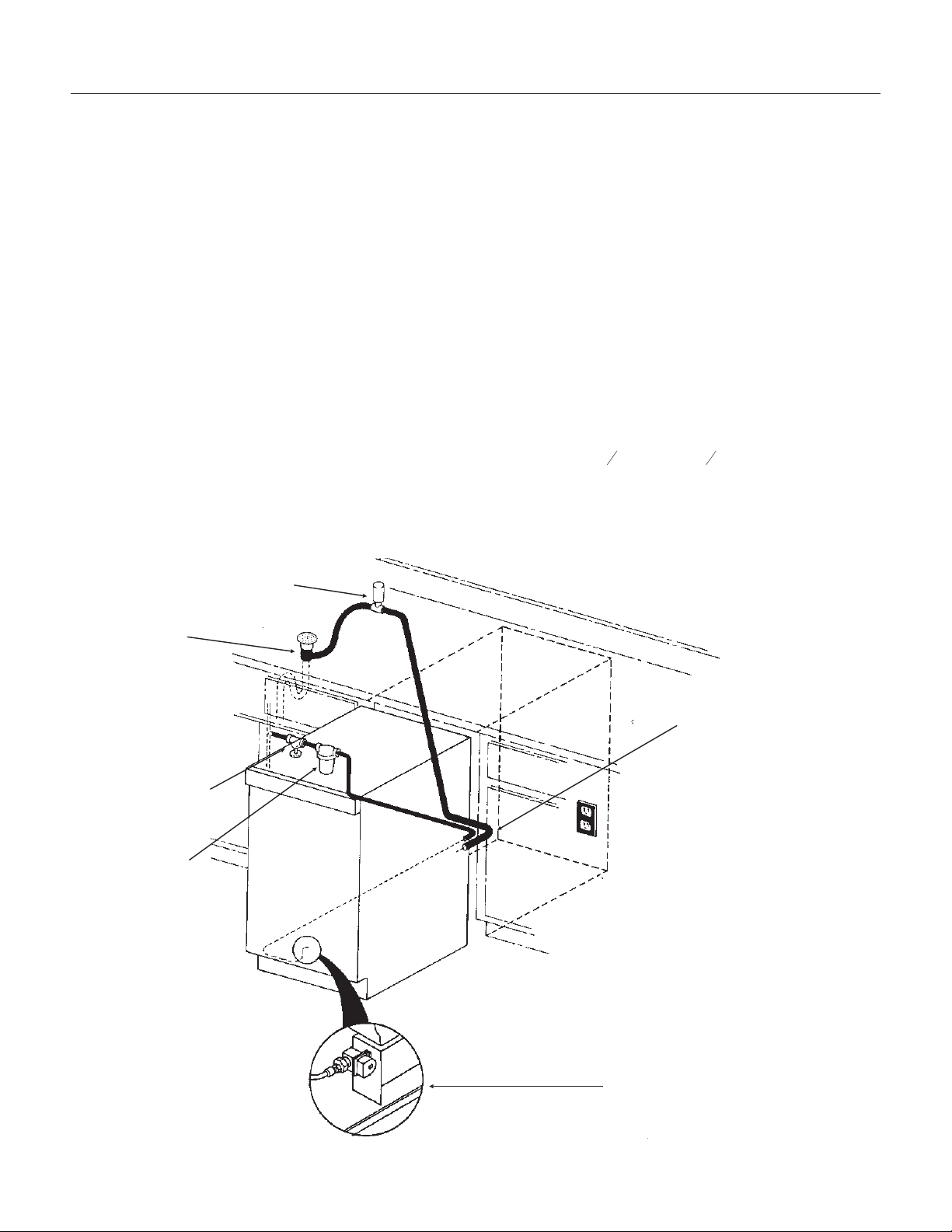

Built In Pump Model:

1. Place ice machine in front of installed location.

Adjust leg levelers to approximately correct

position.

2. Remove kickplate and control box cover.

3. Route water inlet line from wall through ice

machine to the front.

4. Locate coil of 3/8" ID plastic drain tubing

secured to the back of the cabinet.

5. Route plastic drain tube from back of cabinet to

drain connection point.

Note: Often an air gap is required by local codes

between the ice machine drain tube and the drain

receptacle.

6. If electrical outlet for ice machine is behind the

cabinet, plug in the ice machine now.

7. Push ice machine into installed position.

8. Cut off water inlet line at required length.

9. Flush water line. Place flare nut on inlet water

line and flare the end of the copper tube.

10. Attach flare nut to the male flare on the inlet

water valve.

11. Turn on the water supply, and make sure that

the ice machine is plugged in and the power is on.

12. Pour a couple of quarts of water into the

storage bin, the drain pump should start and pump

water out. Check for leaks.

13. Replace kickplate and control box cover.

14. Level the cabinet as needed.

ALL PLUMBING MUST MEET LOCAL CODES

THE DCE33 WILL FIT IN A SPACE 15

THE DEPTH OF THE CABINET IS 22" TO

THE FRONT EDGE OF THE HANDLE.

1

"WIDEX33

4

3

" HIGH.

4

Air Gap Device

(Where Required)

Drain

Connection

Water Shut Off

Valve

Water Filter

(Recommended)

WATER AND DRAIN

INSTALLATION

Drain Tube From

Back Of Machine

September 2011

Page 9

Water Inlet Connection

Page 11

DCE33

TO INSTALL: Add On Kits

Drain Pump Kit

The DCE33 is delivered either with or without a

drain pump. Models without a drain pump drain

their water by gravity. However, gravity drain

models may be converted to Pump models thru the

installation of a Drain Pump Kit and Drain Pump.

Two parts are required for this conversion:

Drain pump kit part number........A36892-020 (all except

Drain pump kit part number.................A39885-001 for DCE33A-1BD or DCE33A-1SSD

Drain pump part number..........12-2503-21

DCE33A-1BD or DCE33A-1SSD)

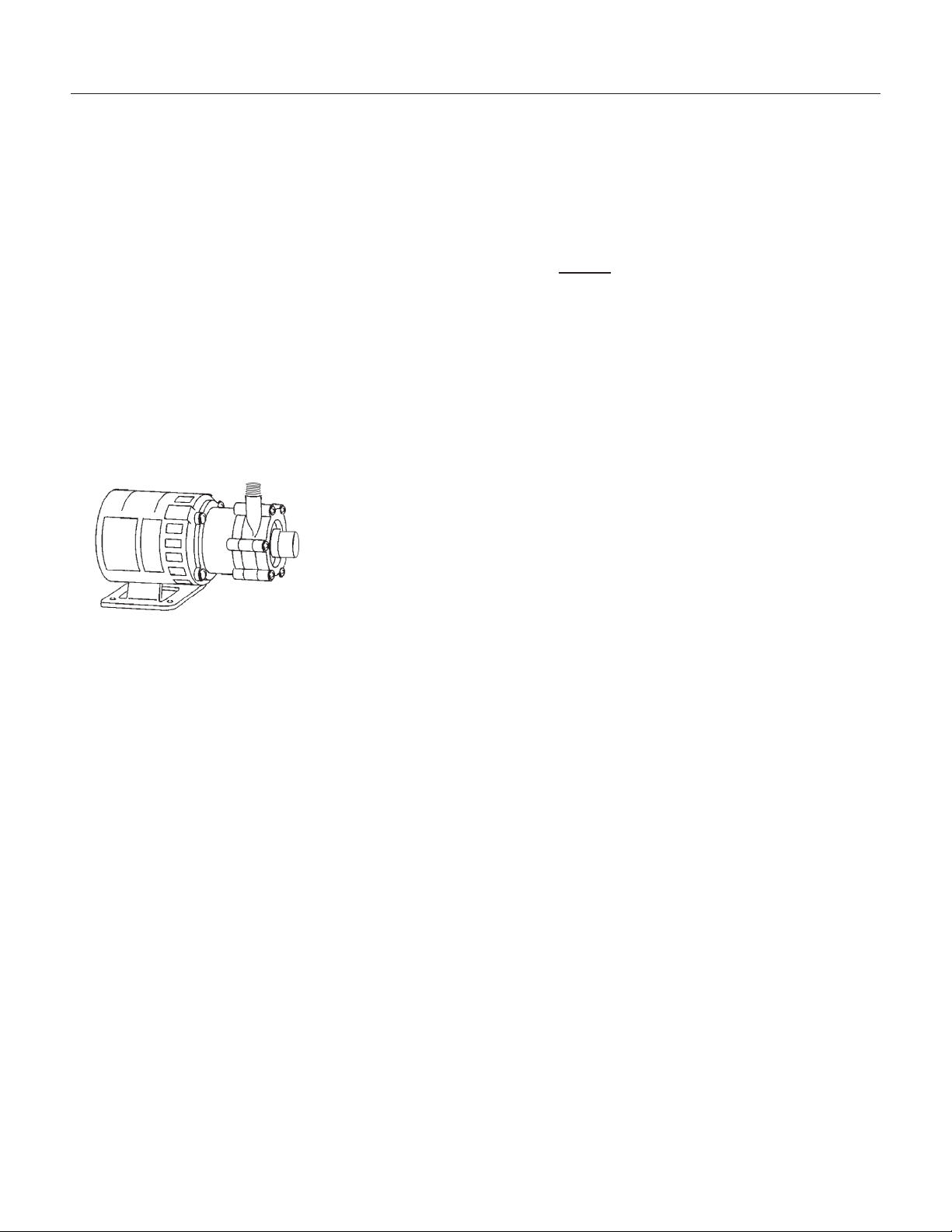

Drain Pump

Specific step-by-step instructions are included with

the kit.

April 2013

Page 10

Page 12

TO INSTALL: Add On Kits

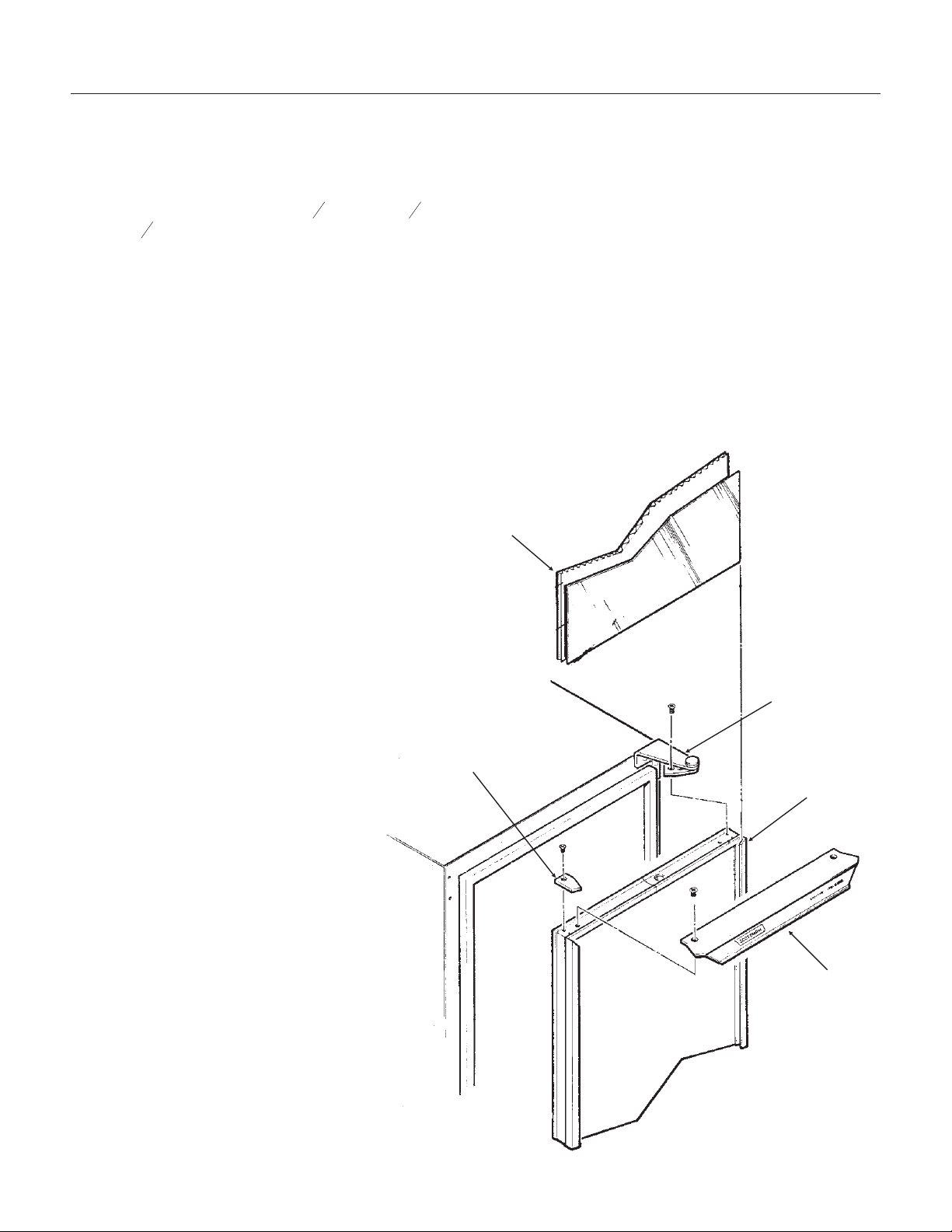

Door Kit: The door may be modified to accept a

decorator door panel.

Customizing Door Panel:

A custom door panel may be installed in front of

3

the standard one. Any panel 14

1

high and

" thick or less at the edges may be used

4

" wide, 28

4

as a decorator panel. Examples of decorator

panels include wood to match the adjacent

cabinets; metal of different colors to match nearby

appliances; or just about any material that will fit.

Scotsman has a stainless steel panel available to

fit this machine, the kit number is SS33.

If the material is less than 1/4" thick, the space

between the new panel and the original may be

filled with cardboard.

1. Remove single screw and the left

hand hinge filler plate from the top of the

door.

2. Remove two screws from the top of

the door and lift off the door handle.

15

"

16

Custom Panel,

Thin Panel

Shown With Filler

DCE33

Parts Involved in Customizing Door Panel

3. Open the door slightly, about one-third

or so; then, remove the front screw

holding the hinge to the door.

4. Loosen the rear screw of the hinge

just enough to allow the door to sag or

move forward. This will allow access to

the top of the channels at the right and

left edges of the door.

5. From the top of the door, insert the

decorator panel (pre-cut) evenly into the

channels; carefully slide the panel all the

way down until the panel is fully into the

bottom channel.

6. Check that the panel is the in all the

way and does not protrude past the top

edge of the door.

7. Push the top hinge corner of the door

IN to align screw hole in the hinge with

the screw hole in the door. Install the

screw previously removed. Tighten the

other screw.

Hinge

Filler Plate

Hinge

Door With

Groove

Door Handle

8. Replace the door handle and filler

plate; secure with screws previously

removed.

September 2011

Page 11

Page 13

DCE33

AFTER INSTALLATION

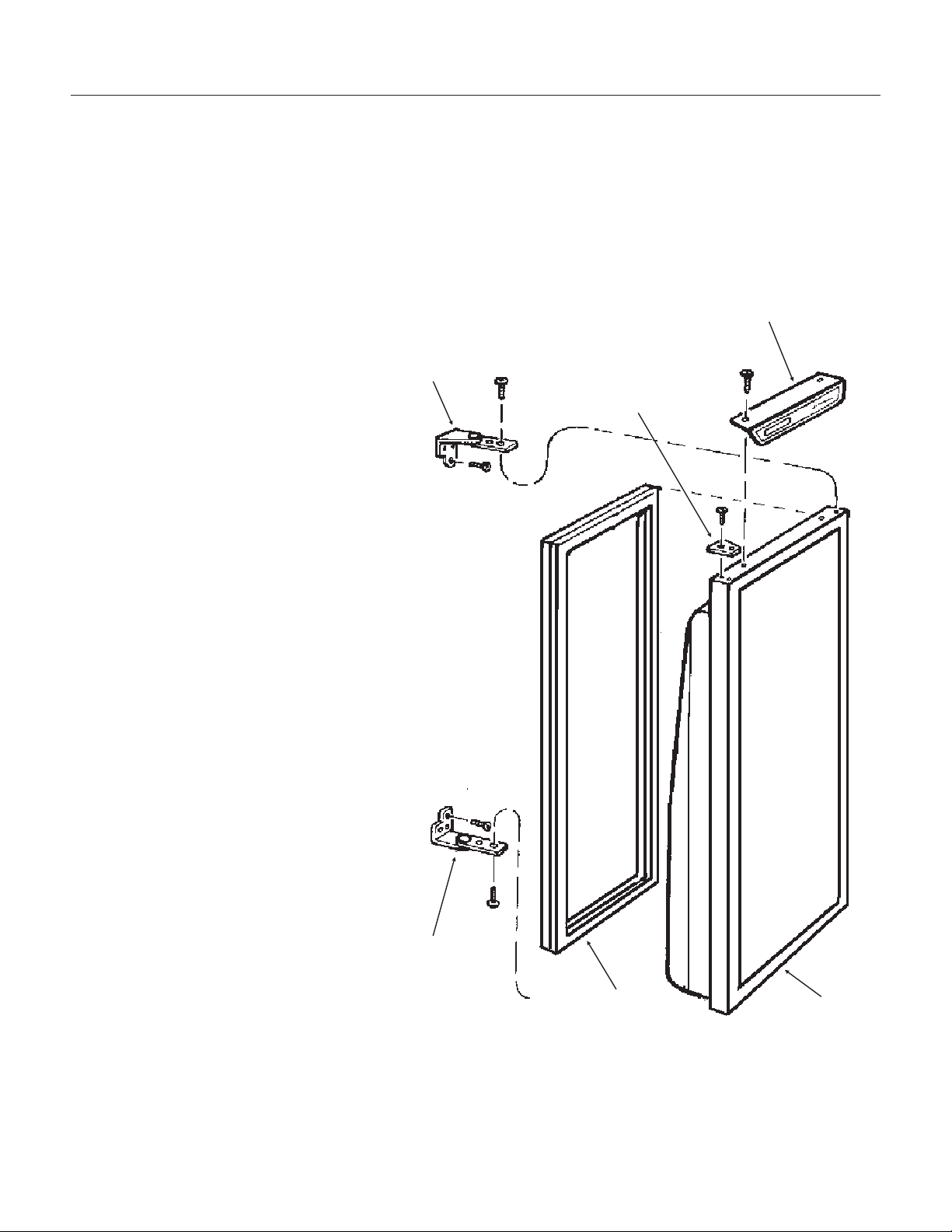

Reversing Door Swing:

The hinged side of the door may be reversed to

the other side if desired:

The DCE33 was shipped with the door hinged at

the right. The door and hinges are designed for

placing the hinges on either the right or the left

side of the cabinet. Moving the hinges to the left

allows the door to pivot from the left side.

Note: There is a part, packed with the machine,

that is required for this procedure.

1. Open the door and remove the three screws

holding the lower hinge to the cabinet.

2. With the door open enough to see both

screws at the top door hinge, remove the two

screws. The door is now free of the cabinet.

3. Remove the single screw and the hinge

filler plate from the top of the door.

4. Install the other filler plate (shipped inside

refrigerator compartment) onto the top corner

of the door where the hinge was.

5. Remove the three plastic plugs from the

top front corner where the hinge will mount.

6. Remove the three plastic plugs from the

lower front corner where that hinge will

mount.

7. Remove the three screws holding the top

hinge to the cabinet. Remove that hinge from

the top and, flipping it upside down, install it

onto the bottom of the door, on the opposite

side using the original screws.

Hinge

Door Handle

Filler Plate

8. Remove the hinge assembly from the

bottom of the door, and flip it upside down;

secure it to the cabinet at the opposite side

top position with the original screws.

9. Hold the door up to the cabinet. Secure

the door to the top hinge with the original

screws.

10. Secure the bottom hinge to the cabinet

with the original screws.

11. Place the plastic plugs removed earlier

into the empty holes.

12. Check operation of the door by opening

and closing it.

Hinge

September 2011

Page 12

Magnetic

Gasket

Reverse Hinges From Top to Bottom and

Left to Right to Reverse Door Swing

Door

Page 14

AFTER INSTALLATION - OPERATION

DCE33

Final Check List

1. Has the machine been properly uncrated, and

have all packing materials and tape been removed

from inside the bin?

2. Have the installation instructions been followed,

including connecting the machine to water, drain

and electricity?

3. Has the machine been leveled?

Initial Start Up - DCE33A-1BD,

DCE33PA-1BD, DCE33A-1SSD or

DCE33PA-1SSD

1. Turn on water supply.

2. With unit plugged in, rotate ice machine control

knob to the ON position.

3. Allow the unit to operate for 1 hour, and check

the size of the cubes, if they are not correct, adjust

as recommended on page 18.

4. After the cubes are confirmed to be the correct

size, replace all panels.

5. Locate the nameplate on the control box cover.

Record the serial number and date of start up here

in the manual. Keep the manual handy for future

reference.

Serial Number:___________________________

Date of initial start up:_____________________

6. Fill out and mail the Warranty Registration.

How To Use:

The ice machine is extremely simple to use, just

turn the ice machine control knob to the on

position. The DCE33 will automatically begin to

freeze ice and will continue to do so until the bin is

full. A new machine, warm out of the box, could

take as long as 48 hours to fill and shut off.

Use the scoop to remove ice and place the ice

scoop in the holder provided (do not leave the

scoop on the ice, as it will gradually disappear into

the ice).

What to expect from the DCE33

The DCE33 will release a batch of 8 ice cubes

about every 30 minutes. At the same time the

cubes fall into the storage bin, water will be

entering the ice machine and draining out.

Ice: The ice cubes are tapered cylinders about 1

in diameter at the widest end; taper down to 1"

1

wide at the top; and are 1

" high. When the

8

machine is adjusted properly, there should be a

indent in the base of the cube. The ice will appear

wet when fresh, this is normal. It may also develop

frost on the outside and look cloudy - this is also

normal (the frost will disappear when liquid is

poured over the ice).

Storage: All restaurant type ice machine operate

on this principal: The ice storage bin is not

refrigerated; instead it’s heavily insulated, much

like a picnic cooler or ice chest. If the ice bin were

to be refrigerated, the ice would freeze together

into one very large cluster of ice, and would begin

to evaporate. This would yield ice that is very poor

in quality, and difficult to remove from the machine.

1

1

4

"

4

"

The DCE33 will continue to operate until ice builds

up high enough to contact the bin thermostat

sensor tube, then it will shut off. Models with a

drain pump will occasionally pump out melt water

when the machine is off. The pump will only be on

for a few seconds.

Run Time: The amount of time the DCE33 will run

to replace melted ice is about 6 hours per day. The

amount of time the ice machine will run to replace

ice removed is dependent upon how much is

removed, how clean the ice machine is, and how

hot the air and water supplied to the machine are.

A machine that has been emptied will usually take

about 24-36 hours to re-fill.

April 2013

Page 13

Page 15

DCE33

OPERATION

How does the machine make ice?

There are two distinct cycles: freeze and harvest.

1 freeze cycle + 1 harvest cycle = 1 batch of 8

cubes.

The Freeze cycle happens when water is sprayed

against the freezing surface. The Harvest cycle is

when the ice is released and water enters the

machine. A complete cycle takes about 30

minutes.

Freeze: During the freeze cycle the compressor is

pumping refrigerant, the fan motor is blowing air,

and the water pump is circulating water. As the

refrigerated surface absorbs heat from the water

sprayed against it, that heat is moved to the area

where the fan is blowing air. The heat is

transferred to the air, and the warmed up air is

discharged from the ice machine. At the same time

ice is forming on the refrigerated surface (located

at the upper back of the machine). When the

refrigerated surface gets cold enough, the ice

machine’s timer will start. After a few minutes the

timer will stop the freeze cycle and begin the

harvest.

Harvest: During the harvest cycle the compressor

is still operating, but the spray pump and fan motor

have stopped. Two other components have been

energized; the hot gas valve and the inlet water

valve. These two valves open and warm up the

freezing surface, allowing the cubes to fall into the

bin. The timer is still turning, and when it gets to

the end of the harvest cycle, the freeze cycle will

restart.

How does the machine use water? The ice

machine begins with a fixed charge of water that is

contained in the reservoir. As the water is sprayed

against the freezing surface, the part of water that

does not contain mineral impurities will freeze and

stick to the ice cup molds. The water containing

impurities falls back into the reservoir. Gradually,

during the freezing portion of the ice making cycle,

the water in the reservoir will become highly

concentrated with mineral impurities.

During the harvest cycle fresh water flows into the

machine to dilute the reservoir water and to rinse

the concentrated minerals down the drain.

Schematic Diagram - Shown In

Harvest Cycle

Compressor

Evaporator

Water

Inlet

Cube Molds

Weep

Hole

Spray Jets

Water Tube

Reservoir

Condenser

September 2011

Page 14

Page 16

COMPONENT LOCATION

Curtain

Reservoir

DCE33

Door Gasket

Bin

Thermostat

Bracket

Control Box

Control Knob

Cover

Kickplate

September 2011

Page 15

Page 17

DCE33

MAINTENANCE AND CLEANING

What shouldn’t be done?

Never keep anything in the ice storage bin that is

not ice; objects like wine or beer bottles are not

only unsanitary, but the labels may slip off and plug

up the drain.

Never allow the machine to operate without regular

cleaning. The machine will last longer if it is kept

clean. Regular cleaning should happen at least

once per year, and preferably twice. Some water

conditions will dictate even more frequent cleaning

of the ice making section, and some carpets or

pets will dictate more frequent cleaning of the

condenser.

What should be kept clean?

There are 5 things to keep clean:

1. The outside cabinet & door.

2. The ice storage bin.

3. The condenser.

4. The ice making system.

5. The ice scoop.

How to clean the condenser.

The condenser is like the radiator on a car, it has

fins and tubes that can become clogged. To clean:

1. Remove the kickplate.

2. Locate the condenser surface.

3. Vacuum the surface, removing all dust and lint.

Caution: Do not dent the fins.

Condenser

Surface

4. Replace the kickplate.

Winterizing

1. Clean the machine as explained on the next

page.

How to clean the cabinet.

Wipe off any spills on the surface of the door and

handle as they occur. If anything spilled on the

door or gasket dries onto the surface, wash with

soap and warm water to remove.

How to clean the ice storage bin.

The ice storage bin should be sanitized

occasionally. It is usually convenient to sanitize the

bin after the ice making system has been cleaned,

and the storage bin is empty.

A sanitizing solution can be made of 1 ounce of

household bleach and two gallons of hot (95

0

F.) water. Use a clean cloth and wipe the

115

interior of the ice storage bin with the sanitizing

solution, pour some of the solution down the drain.

Allow to air dry.

Note: To use after winterizing,

reconnect pump hose and water line.

Repeat Initial Start Up.

0

F. -

September 2011

2. Turn off the water supply.

3. Drain the water reservoir. See page 24, Spray

Pump Repair and follow the instructions to remove

the pump hose (step 2, bottom hose only).

4. Disconnect the incoming water line at the inlet

water valve.

Inlet Water

Valve

Water Line

5. Remove control box cover and turn the timer

into the harvest cycle.

6. With the machine operating, blow air through the

inlet water valve; a tire pump could do the job.

7. Drain pump models should have about

of RV antifreeze (propylene glycol) poured into the

ice storage bin drain.

Note: Automotive antifreeze must NOT be used.

8. Replace control box cover. Switch off and

unplug the machine.

Page 16

1

gallon

2

Page 18

CLEANING

DCE33

How to clean the ice making system.

1. Open the door and

turn the ice machine

control knob to off.

2. Scoop out all of the ice, either discard it or save

it in a ice chest or cooler.

4. Turn the ice machine control to ON.

5. Allow the machine to operate for about 2 hours.

3. Pour 4 ounces of Scotsman Ice Machine

Cleaner (available from a local Scotsman

Distributor or Dealer, ask for part number

19-0343-06 - an 8 ounce bottle) into the ice

machine reservoir.

Scotsman Ice Machine

Cleaner contains acids.

These compounds may

cause burns.

If swallowed, DO NOT

induce vomiting. Give

large amounts of water or

milk. Call Physician

immediately. In case of

skin contact, flush with

water. Keep out of the

reach of children.

0

6. Pour hot (95

melt the ice that has formed. That ice will likely be

white and frosty looking.

7. Clean the bin liner of mineral scale by mixing

some ice machine cleaner and hot water, and

using that solution to scrub the scale off of the

liner.

8. Rinse the liner with hot water.

9. Sanitize the bin interior.

10. Replace the ice removed in step 2.

The ice scoop should be washed regularly, wash it

just like any other food container.

F.-1150F.) water into the bin to

September 2011

Page 17

Page 19

DCE33

ADJUSTMENTS

There are three items that may be adjusted: Cube

Size, Harvest Time, and Bin Level. Note: Cube

Size and Harvest Time adjustments should only be

done by a qualified service person.

Cube size control.

The cube size control should only be adjusted to

bring the cubes to the correct shape, the overall

size cannot be adjusted. Try to adjust the cube

size control when the ice machine is in the harvest

cycle, or in the first 10 minutes of the freeze cycle.

1. Open the door and remove the control box

cover.

2. Locate the cube size adjustment screw, and to

make fuller cubes, turn the screw clockwise about

SIDE VIEW OF CUBES

TOO

BIG

1/4 turn. This will make the freezing cycle longer.

3. To shorten the freezing cycle and make cubes

that are not as full, turn the adjustment screw 1/4

turn counterclockwise.

4. After the next freezing cycle, the cubes should

have responded to the adjustment, if another

adjustment is required, do it early in the freeze

cycle.

CORRECT

SIZE

CUBE SIZE ADJUSTMENT

TOO

SMALL

September 2011

Page 18

Page 20

ADJUSTMENTS

DCE33

Bin’s ice level.

When the ice machine shuts off the ice level in the

bin should be even with the metal tube inside the

bin. If the ice in the bin is too high or low, turn the

ice machine control knob to adjust the bin

thermostat.

1. To lower the ice level, turn the knob

counterclockwise. Usually a 1/8 turn will be

enough.

2. To increase the ice level, turn the knob

clockwise. Usually a 1/8 turn will be enough.

Timer - up to DCE33A-1BD, DCE33PA-1BD,

DCE33A-1SSD or DCE33PA-1SSD

The amount of harvest time may be adjusted. It is

preset from the factory at about 3 minutes, which

should be adequate to release all cubes and fill the

reservoir. If the timer needs to be adjusted:

Electrical Shock Hazard

Disconnect Electrical

Power Before Beginning

Removal of Parts

1. Unplug or disconnect the electrical power.

2. Remove the kickplate.

3. Remove the control box cover.

4. Locate the timer, and loosen the set screw that

holds the two halves of the timer cam together.

Timer Set Screw

5. Rotate one half of the cam to open or close the

lower portion of the cam. More of an opening

equals more harvest time and less of an opening

means less harvest time.

6. Tighten the set-screw.

7. Replace the control box cover and kickplate.

8. Reconnect the electrical power.

April 2013

Page 19

ADJUSTMENT OF THE TIMER

Page 21

DCE33

HARVEST TIME ADJUSTMENT, models DCE33A-1BD, DCE33PA-1BD,

DCE33A-1SSD or DCE33PA-1SSD

The harvest time can be adjusted so that all the ice

is released during the harvest period, with a few

seconds extra for a safety margin. The adjustment

range is between 2 to 5 minutes.

There is an adjustment screw on the surface of the

electronic timer. Rotate the screw CCW to reduce

harvest time, and CW to increase it. It should be

set to match the machine's performance. If the

machine takes 2 and a half minutes to release the

ice, the harvest time should be set to about 3

minutes.

September 2011

Page 20

Page 22

DCE33

SERVICE DIAGNOSIS

PROBLEM POSSIBLE CAUSE PROBABLE CORRECTION

The machine does not operate The machine is unplugged Plug the machine in.

Breaker tripped or fuse is blown. Reset breaker/replace fuse - if it

happens again, call for service to

check for a short circuit in the

machine.

Ice machine control turned to

OFF.

Bin thermostat open keeping

machine off.

Timer contacts open. Replace timer.

Cubes are too big Cube size control set too cold. Adjust cube size control for a

Cubes are too small Cube size control set too warm. Adjust cube size control for a

Not enough water. Check water supply - filter may be

Cube size control stuck closed timer runs all the time.

Cubes are partially formed - have

ragged sides

Machine makes ice, but bin does

not fill up with ice

Cubes are partially formed - are

white at the bottom

Spray jets partially clogged. Clean ice making system with ice

The bin should fill up and the

machine shut off in 24-36 hours. If

not, the condenser may be dirty.

The bin drain may be partially

restricted

The air flow to the ice machine

may be obstructed.

Not enough water in the reservoir. Check water supply - filter may be

Turn ice machine control to ON.

Ice on sensor tube - its then

normal for the machine to be off.

Ice machine in a room below 50

degrees - room needs to be

warmer for machine to operate.

Bin thermostat stuck open, needs

to be replaced.

smaller cube.

larger cube.

restricted.

Check inlet water valve - inlet

screen may be restricted.

Replace cube size control

machine cleaner.

Clean the condenser.

Clean out the drain, check the

installation.

Check the installation - the

machine must be free of

obstructions at the kick plate.

restricted

Check inlet water valve - inlet

screen may be restricted.

Check for a water leak at the

reservoir.

Water leaking into bin from torn or

mis-positioned curtain. Check

curtain position and condition.

Reposition or replace as needed.

September 2011

Page 21

Page 23

DCE33

SERVICE DIAGNOSIS

PROBLEM POSSIBLE CAUSE PROBABLE CORRECTION

No ice falling in bin, but machine

operates

Ice may be stuck in the evaporator

and the unit is “frozen up”.

Too much heat load. Inlet water valve leaks thru, needs

No water spray Water pump does not work,

Cube size control will not close See “Too much heat load” or “not

No airflow Fan motor not turning, needs to

Not enough refrigerant Add low side access valve, locate

Restricted system Add low side access valve,

Hot gas valve leaks thru Add low side access valve,

Compressor will not operate or

pumps poorly.

Check water supply - filter may be

restricted

Check inlet water valve - screen

may be restricted, or valve does

not operate.

Hot gas valve may not operate check and repair/replace.

Harvest time set too short - timer

needs adjustment.

to be replaced.

replace it.

Water leak from reservoir, locate

and repair.

enough refrigerant”

Control defective - must be

replaced.

be replaced.

Fan blade broken, needs to be

replaced.

Condenser completely blocked

up, needs cleaning.

leak, recover refrigerant, repair,

replace dryer, evacuate and weigh

in the nameplate charge.

recover refrigerant, replace dryer,

evacuate and weigh in the

nameplate charge.

recover refrigerant, replace hot

gas valve and dryer, evacuate and

weigh in the nameplate charge.

Start relay or capacitor needs to

be replaced.

Add low side access valve,

recover refrigerant, replace

compressor and dryer, evacuate

and weigh in the nameplate

charge.

September 2011

Page 22

Page 24

REPAIR

DCE33

Curtain

Electrical Shock Hazard

Disconnect Electrical

Power Before Beginning

Removal of Parts

The curtain keeps the water that sprayed by the

pump from falling in the bin.

The “sheet” type curtain is replaced by:

1. Removing 4 screws holding the curtain and the

curtain stiffener to reservoir.

2. Pulling the curtain and curtain stiffener out of the

machine.

3. Replace with a new curtain and install as shown.

Inlet Water Valve

The inlet water valve may need to be cleaned or

replaced. If there is not enough water coming into

the machine, the valve may need to be cleaned. If

the valve does not work at all, or does not shut off

tightly, it should be replaced.

1. Unplug or disconnect electrical power.

2. Shut off water supply

3. Remove kickplate

4. Remove the control box cover.

5. Unscrew flare nut from inlet water valve inlet . If

the valve is being replaced, proceed to step 10.

6. Unscrew brass fitting from body of inlet water

valve.

SERVICE OF THE INLET

WATER VALVE

Inlet Water Valve

Curtain

Sheet

Type:

Curtain

Stiffener

Bottom Edge

Angle to Rear

Curtain and Curtain Stiffener MUST Be Installed

As Shown

Curtain

Screw

Front Edge of

Reservoir

Screen

Inlet

Outlet

Check the screen of the valve, it may be clogged

and is restricting the flow of water into the

machine. If that is the problem, clean the screen

and reverse the steps so far to reassemble.

7. Loosen the screws in the back of the control

box, and remove the inlet water valve.

8. Remove the discharge hose from the outlet of

the water valve.

9. Unplug the wire harness from the top of the

valve.

10. Replace with a new valve, and reverse the

above steps to reassemble.

September 2011

Page 23

Page 25

DCE33

REPAIR

Timer - All except DCE33A-1BD,

DCE33PA-1BD, DCE33A-1SSD or

DCE33PA-1SSD

Electrical Shock Hazard

Disconnect Electrical

Power Before Beginning

Removal of Parts

The timer may need to be replaced if it does not

turn, or if it turns and then stops (except at the end

of the harvest cycle - the timer will ALWAYS stop at

the end of the harvest cycle), or if the microswitch

mounted to it does not switch the machine from the

freeze to the harvest and back again.

Caution: The timer is controlled by the cube size

control, and will not turn if the cube size control

does not work.

1. Unplug or disconnect the electrical power to the

ice machine.

Harvest Timer - DCE33A-1BD, DCE33PA-1BD,

DCE33A-1SSD or DCE33PA-1SSD

1. Disconnect electrical power.

2. Remove service panel.

3. Remove screw in center of timer, pull out and

disconnect wires.

4. Reverse steps to reassemble.

2. Remove the kickplate.

3. Remove the control box cover.

4. Remove the screws holding the timer to the

control box.

Timer

5. Disconnect the wires at the timer microswitch.

6. Disconnect the wires from the timer motor at the

terminal board.

7. Remove the timer from the ice machine.

8. Reverse the above steps to replace.

April 2013

Page 24

Page 26

REPAIR

DCE33

Cube Size Control

Electrical Shock Hazard

Disconnect Electrical

Power Before Beginning

Removal of Parts

The cube size control controls the timer during the

freeze cycle. If the timer will not start, the cube size

control may be the problem. Removal of the cube

size control requires removal of the ice storage bin.

1. Unplug or disconnect the electrical power to the

ice machine.

2. Remove the kickplate.

3. Go thru the steps to remove the ice storage bin.

4. Remove screws holding cube size control body

to control box.

5. Remove wires connected to the cube size

control.

Bin Thermostat

The bin thermostat is the automatic on-off control

for the ice machine.

1. Unplug or disconnect the electrical power to the

ice machine.

2. Pull the machine out from its installed location.

3. Remove the back panel.

4. Remove the kickplate.

5. Remove the control knob

6.. Remove the control box cover.

7. Remove the screws holding the bin thermostat

to the control box.

Capillary Tube

6. Carefully pull cube size control and attached

capillary tube from the control box, and follow the

capillary tube to the top of the evaporator.

7. The end of the cube size control is inserted into

a socket attached to the evaporator.

8. Remove the cube size control from the socket

and from the ice machine.

9. Reverse the above steps to replace.

CUBE SIZE CONTROL

REPLACEMENT

Socket

Pig Tail

Bin Thermostat

8. Remove the wires attached to the bin

thermostat.

9. Pull the bin thermostat and capillary tube from

the control box, trace the capillary tube to the bin

level control tube and remove the capillary tube

from the tube. Remove the bin thermostat from the

ice machine.

10. Reverse the above steps to replace.

10. Adjust the cube size control per the adjustment

sequence on page 16.

September 2011

Page 25

Page 27

DCE33

REPAIR

Spray Pump

Electrical Shock Hazard

Disconnect Electrical

Power Before Beginning

Removal of Parts

The water pump that forces the water from the

reservoir through the spray jets.

1. Disconnect electrical power.

2. Open the bin door and locate the three hoses

connected to the water pump.

A. Loosen the hose clamps from the pump hoses.

B. Remove the pump hoses from their

connections.

3. Disconnect water and drain tubes.

Pump Hose Removal

Spray Jets

Spray Jets are small nozzles that are under the

freezing surface, they spray a narrow pattern of

water at the freezing surface. If plugged or

restricted, poorly shaped ice cubes will form.

If the spray jets are removed the o-rings between

the water inlet tube and the spray jet bases must

be in place (see illustration).

Curtain

Curtain Stiffener

Cap

Spinner

Jet Base

Reservoir

Body

Spray Pump

(for reference)

Suction

Hose

Reservoir

(for reference)

Hose Clamp

4. Carefully pull machine out from its installed

location to expose the back panel.

5. Remove the back panel.

6. Disconnect wires from the top of the pump

motor.

7. Remove two screws holding pump to bin, and

remove the pump from the ice machine.

8. Reverse the above steps to re-assemble.

O-Ring

Pump

Discharge

Cube

Chute

O-Ring

Back view of

Reservoir

September 2011

Page 26

Page 28

DCE33 SERVICE PARTS

The section contains the parts list for the DCE33. The DCE33 has been manufactured in either a White,

Black or Stainless Steel finish.

A "D" series model was introduced in 2011 (as in DCE33A-1BD

diagram.

Please check the part description before ordering any part.

Table of Contents

Cabinet ····································································································································· Page 2

Pump, Evaporator, Storage Bin ································································································ Page 3

Drain Pump Components ········································································································· Page4

Condensing Unit ······················································································································· Page 5

Reservoir ·································································································································· Page 6

), it has a different timer and wiring

CONTROL BOX - all models except DCE33A-1BD, DCE33PA-1BD, DCE33A-1SSD or

DCE33PA-1SSD ······················································································································· Page 7

CONTROL BOX - for DCE33A-1BD, DCE33PA-1BD, DCE33A-1SSD or DCE33PA-1SSD ··· Page 8

Compressor ······························································································································ Page 9

Drain Pump Model Wiring Diagram - Prior to August 2000 ····················································· Page 11

Gravity Drain Model Wiring Diagram - Prior to August 2000 ··················································· Page 12

Drain Pump Model Wiring Diagram after August 2000 up to D series ···································· Page 13

Gravity Drain Model Wiring Diagram after August 2000 up to D series ·································· Page 14

Wiring Diagram for DCE33A-1BD, DCE33PA-1BD, DCE33A-1SSD or DCE33PA-1SSD ······· Page 15

Schematic Diagram DCE33A-1BD, DCE33PA-1BD, DCE33A-1SSD or DCE33PA-1SSD ····· Page 16

Page 29

DCE33 SERVICE PARTS

Cabinet

18

17

23

22

20

19

14

15

21

13

8b

Note for SSD models only: Magnetic strips

inside cabinet - 02-4738-01 and 02-4738-02.

Note: Items 20 and 23. Item 20 only available

for use with flat head screws. Prior cabinets

8

8a

2

6

16

9

used pan head screws.

7

10

3,

includes 5

4

5

11

7

1,

includes items

2,3,4,5,6, & 7

Item Part

Number Number Description

1. A32117-003 White Door Assembly

A32117-010 Black door assembly

A28866-012 Stainless door assembly

2. 13-0826-04 Gasket

3. A29043-001 Alum. Door Handle (white)

A29043-003 Alum. Door Handle, (black)

4. 03-1607-01 Head Screw (2)

5. 15-0730-01 Nameplate strip (white)

15-0730-02 Nameplate strip (black)

6. 15-0648-01 Alum. Hinge Fill Plate, Rt.

15-0648-02 Alum. Hinge Fill Plate, Lt.

7. 03-1418-24 Screw (10)

8. 13-0828-01 Gasket (white)

13-0828-02 Gasket (grey)

8a 03-1419-08 Screw - not for ss

03-1404-26 Screw for SS cabinets

8b 02-2701-01 Spacer

9. 03-1419-26 Screw, black

03-1419-29 Screw, white

10. 15-0799-01 Hinge

Item Part

Number Number Description

11. 15-0799-02 Hinge

13. 02-3141-01 Knob, Bin Thermo

14. A34877-002 Cont Box cover - white

A34877-003 Cont Box cover - black

A40162-001 Cont Box cover - SS

14a 17-3465-01 Bin level control label

15. 03-1404-07 Screw (6)

16. 02-2243-02 Kickplate - black

17. A29102-001 Rear Panel

18. 03-1404-08 Screw (9)

19. 02-2481-01 Plug (6) (white)

02-2481-02 Plug, black

02-1874-11 Plug, nickel

20. A38803-021 Cabinet (white)

A38803-022 Cabinet (black)

for flat head screws, use began w/sn 05111320015862

A40159-001 Cabinet (stainless steel)

21. A26787-001 Insulation (in Bag)

22. 12-2571-01 Power cord & wire harness

12-1638-21 For D series

23 03-1431-00 Screw, pan head

03-1419-29 Flat head screw, white

April 2013

Page 2

Page 30

DCE33 SERVICE PARTS

Pump, Evaporator, Storage Bin

21

1

4

5

2b

2c

18

19

20

15

2a

12

16

13

7

1

14

9

17, includes 3, & res. drain

11

8

3

SCOOP

(not shown)

PN: 02-3070-01

(plastic)

08-0664-01

(metal)

6

2

Item Part

Number Number Description

1. 02-2274-01 Platen Cover

2. 13-0674-01 Tube, 37"

2a A27027-001 Copper inlet tube

2b no number Tube holder

2c 02-1727-01 Hose clamp

3. A34816-001 Bin Thermostat bracket

4. 02-3489-20 Evaporator, does NOT

include suction line and accumulator

5. A36699-020 Evaporator, Complete

6. 13-0899-01 Res. drain hose

7. 13-0674-16 Tube, 5/8" Req. 4.25"

8. 13-0674-15 Tube,1/2", Req 3.25"

9. 13-0674-15 Tube, 1/2", Req. 3-5/8"

10. 02-1775-02 Clamp (2)

11. 02-0534-02 Clamp (4)

12. 02-1719-00 Fan Blade

13. A30625-001 Spray Pump

14. 13-0687-00 Gasket

17a,17b,

17c

15. 03-1719-01 Screw

16. no longer used Speed Nut (2)

17. A36930-020 Bin Assembly, includes

reservoir drain hose & drain fittings

17a 02-3323-01 Drain fitting

(foamed in bin)

17b 13-0617-13 O-Ring

17c 03-1394-05 Pal nut

18 12-2569-03 Clip, Hot Gas Valve

19. 12-2569-02 Coil, Hot Gas Valve

replaces coils that have encapsulated wires

11-0562-22 Coil, hot gas valve

replaces coils that have terminals

20. 11-0562-21 Hot Gas Valve kit

21 02-3490-01 Drier

September 2011

Page 3

Page 31

DCE33 SERVICE PARTS

Drain Pump Components

9

4

5

15

6

1

3

13

2

12

11

7

10

Item Part

Number Number Description

1. A36892-020 Drain Pump Kit, for all except DCE33A-1BD and DCE33A-1SSD

A39885-001 Drain pump kit, for DCE33A-1BD or DCE33A-1SSD

use to convert any DCE33 gravity model to pump type. Pump must be ordered separately.

2 12-2503-21 Drain pump only,

use to replace drain pumps or w/kit to convert.

Pump Kit Service Parts

3 02-3369-01 Inlet hose

4 02-3522-01 Elbow

5 02-3374-01 Check valve

6 13-0617-08 O-ring

7 11-0504-01 Pressure switch

8 obsolete Impeller & housing kit

9 A37334-001 Discharge hose

10 05-0591-01 Switch hose

11 A36746-001 Mounting bracket

12 02-3406-01 Barbed connector

13 02-2814-11 Clamp

14 12-2580-01 Harness

12-3001-01 Harness, for converted-to-pump DCE33A-1BD, DCE33PA-1D, DCE33A-1SSD

or DCE33PA-1SSD

15 03-3904-01 Check valve spring

April 2013

Page 4

Page 32

DCE33 SERVICE PARTS

Condensing Unit

11

5

1

12

6

13

9

7

Support Bracket

8

10

Item Part

Number Number Description

1. 03-1404-08 Screw (4)

2. 18-3710-01 Fan Blade

3. A28798-001 Fan Motor Bracket

4. 12-2396-21 Fan Motor

18-8752-10 Blade pad

18-8752-11 Blade nut

5. 02-2871-01 Fan Shroud

6. 18-3729-01 Condenser

7. 18-4700-28 Grommet

8. 03-1608-01 Leg Leveler

9. 03-1407-08 Washer

03-3821-01 Clip

10. A29015-001 Bracket

4

3

2

14

1

15

Item Part

Number Number Description

11 12-1213-10 Bushing

12 A37732-001 Upper base plate

13 13-0609-00 Foam tape

14 A28921-001 Lower base plate

A38638-001 Lower base plate

use began w/sn 05111320015862

Support brackets part of item 12

A40164-001 Base pan for -1SSD

15 03-1531-01 Screw

April 2013

Page 5

Page 33

DCE33 SERVICE PARTS

Reservoir

1

2

4

5

6

8

9

12

3

7

10

11

13

Item Part

Number Number Description

1. 02-2479-21 Curtain

2. A24155-001 Curtain stiffener

3. 03-1404-16 Screw

4. 02-1841-00 Nozzle

5. A09543-000 Spinner

6. 02-1840-00 Jet Base

7. A22518-000 Cube Chute

Item Part

Number Number Description

8. 13-0617-08 O-ring

9. 02-2704-01 Spray Bar Assembly

10. 05-0593-01 SS nipple

11. 13-0617-01 O-ring

12. 02-1923-01 Bin Insert

13 A22532-001 Bin insert assy

September 2011

Page 6

Page 34

DCE33 SERVICE PARTS

CONTROL BOX - all models except DCE33A-1BD, DCE33PA-1BD, DCE33A-1SSD or

DCE33PA-1SSD

4

Brass Inlet Water Valve Mounts to

Control Box As Shown

9

6

Blue Valve Shown

5

8

8

7

Item Part

Number Number Description

1. A25981-001 Terminal Board

2. 03-1638-01 Screw

3. 12-1980-01 Timer And Switch

4. 11-0503-21 Cube Size Control

5. 11-0407-21 Bin Level Control

02-3141-01 Knob for item 5

6. 12-2907-21 Inlet Water Valve Kit

(includes new fittings)

12-2907-31 Coil only for brass valve

12-2410-31 Coil only for plastic valve

3

11

10

12

1

2

Item Part

Number Number Description

7. 12-1213-12 Bushing

8. 03-1403-17 Screw

9 12-1213-04 Snap bushing

10 03-1638-02 Screw

11 02-2242-06 Stand off

12 02-2242-05 Stand off

Not Shown

13 A39918-001 Kit to retrofit electronic

timer to prior model.

April 2013

Page 7

Page 35

DCE33 SERVICE PARTS

CONTROL BOX - for DCE33A-1BD, DCE33PA-1BD, DCE33A-1SSD or DCE33PA-1SSD

2

1

6

3

4

5

Item Part

Number Number Description

1 11-0503-21 Cube size control

2 11-0407-21 Bin level control

3 12-2985-01 Timer

03-1419-16 Screw

4 12-1213-12 Snap bushing

5 12-2907-21 Inlet water valve kit, includes new fittings

12-2907-31 Coil only for inlet water valve

6 12-1213-04 Snap bushing

April 2013

Page 8

Page 36

DCE33 SERVICE PARTS

Compressor

2

4

3

1

Item Part

Number Number Description

1. 18-8776-21 Compressor Kit, Includes Relay, Overload, Instructions

2. 18-8776-51 Relay

3 18-8776-52 Overload

4. 18-8776-54 Cover

September 2011

Page 9

Page 37

K-SS Door Sleeve Kit

02-3846-01 Sleeve

02-3847-01 Handle

03-1403-50 Screw for handle

03-1407-06 Washer

03-1410-03 Lockwasher

03-3811-01 Screw

DCE33 SERVICE PARTS

Kit Parts

September 2011

Page 10

Page 38

DCE33 SERVICE PARTS

Drain Pump Model Wiring Diagram - Prior to August 2000

September 2011

Page 11

Page 39

DCE33 SERVICE PARTS

Gravity Drain Model Wiring Diagram - Prior to August 2000

September 2011

Page 12

Page 40

DCE33 SERVICE PARTS

Drain Pump Model Wiring Diagram after August 2000 up to D series

September 2011

Page 13

Page 41

DCE33 SERVICE PARTS

Gravity Drain Model Wiring Diagram after August 2000 up to D series

September 2011

Page 14

Page 42

BU

Y

TIMER

BK

BK

W

BK/W

BK

2

1

6

C

NC

NO

COMPRESSOR

RELAY - CURRENT

OVERLOAD

1

M

S

3

1

Y

2

1

3

CONTROL

CUBE SIZE

W

DRAIN

PUMP

MOTOR

W

BK

R

BK

PUMP

PRESSURE

SWITCH

NO

COMM

NC

R

SAFETY

PRESSURE

SWITCH

NO

COMM

NC

W

PUMP

MOTOR

BU

W

W

R/W

WATER

SOLENOID

FAN

MOTOR

R

HOT GAS

SOLENOID

BN

GN/Y

EARTH GROUND

ONOFF

BIN

LEVEL

CONTROL

POWER IN

W

BK

GN/Y

W

W

IF DRAIN PUMP

IS INSTALLED

DCE33 SERVICE PARTS

Wiring Diagram for DCE33A-1BD, DCE33PA-1BD, DCE33A-1SSD or DCE33PA-1SSD

April 2013

Page 15

Page 43

DCE33 SERVICE PARTS

HARVEST TIME

ADJUSTABLE

FROM 120 TO 300 SEC.

FACTORY SET TO 170

TIMER

2

1

6

C

NC

NO

CUBE SIZE

CONTROL

(INITIATE

TIMER

SWITCH)

COMPRESSOR

SWITCHES ON THIS UNIT

SHOWN IN TIMED PORTION

OF THE FREEZE CYCLE

WITH DRAIN PUMP IN OPERATION

BIN LEVEL

CONTROL

SAFETY

PRESSURE

SWITCH

DRAIN PUMP

PRESSURE

SWITCH

DRAIN

PUMP

HOT GAS

SOLENOID

FAN

MOTOR

L1

N

WATER

PUMP

WATER

SOLENOID

IF DRAIN PUMP

IS INSTALLED

Schematic Diagram DCE33A-1BD, DCE33PA-1BD, DCE33A-1SSD or DCE33PA-1SSD

April 2013

Page 16

Page 44

SCOTSMAN ICE SYSTEMS

775 Corporate Woods Parkway

Vernon Hills, IL 60061

800-726-8762

www.scotsman-ice.com

17-2419-01 Rev A.

Loading...

Loading...