Page 1

Installation and User’s Manual

Models C1448R, C1848R, C2148R

Page 2

C1448, C1848, C2148

Remote Condenser Models - User Manual

Introduction

The design of this modular remote cuber is the result

of years of experience with remote ice machine

refrigeration systems. Standard features of this

product include front accessible on-off switches,

always-visible indicator lights, mechanical assist ice

harvest for extra efciency, automatically adjusting

water purge and a control system that optimizes

system operation.

This installation and user manual is divided into

three sections: Installation, Use and Operation and

Maintenance.

Contents

Installation: Product Specications ................................................... Page 2

Model Number Description ......................................................... Page 3

Product Description and Electrical Requirements ........................................ Page 4

Condenser and Machine Layouts .................................................... Page 5

Water .......................................................................... Page 6

The Installation section provides the trade person with

the information needed to properly install and start

up this ice system. The Use and Operation section

provides the user with the information needed to use

the machine. The Maintenance section contains the

instructions and schedules for the sanitation and

cleaning of the machine.

Panel Removal .................................................................. Page 7

Remote Condenser Location ........................................................ Page 8

For The Installer: Remote Condenser ................................................. Page 9

Precharged Line Routing ........................................................... Page 10

Coupling Instructions .............................................................. Page 11

Plumbing Requirements ........................................................... Page 12

Drains ......................................................................... Page 13

Electrical ....................................................................... Page 14

Final Check List: ................................................................. Page 15

Initial Start Up ................................................................... Page 16

Adjustments ..................................................................... Page 17

Use and Operation ............................................................... Page 18

Switches ....................................................................... Page 19

Options and Other Information ...................................................... Page 20

Cleaning, Sanitation and Maintenance ................................................ Page 21

Remote condenser ............................................................... Page 23

What to do before calling for service .................................................. Page 24

November 2006

Page 1

Page 3

C1448, C1848, C2148

Remote Condenser Models - User Manual

Installation: Product Specications

Location Limitations

This ice system is made up of three parts, the ice

making machine, or head; the remote condenser; and

the interconnecting tubing. The ice making machine

must be installed indoors, in a controlled environment.

Space must be provided near the machine for service

access. The remote condenser may be installed

above or below the ice machine, per the limits stated

later in this manual. The remote condenser may

be installed outdoors within the temperature limits

listed below. The interconnecting tubing must be

installed per the directions stated in this manual,

and the amount of tubing exposed to uncontrolled

temperatures must be minimized.

Space Limitations

Although the machine will function with no clearance

to the top and sides, some space must be allowed

for service access. Building the machine in with no

access will cause higher service cost, in many cases

this extra cost may not be covered by warranty.

The warranty statement for this product is provided

separately from this manual. Refer to it for applicable

coverage. In general warranty covers defects

in material and workmanship. It does not cover

maintenance, corrections to installations, or situations

when the ice machine is operated in circumstances

that exceed the limitations printed above.

Product Information

The machine is a specialized version of a modular

cuber. A modular cuber does not include any ice

storage, it is designed to be placed onto an ice

storage bin. Many installations only require the

matching bin, but some may need an adapter to

be placed between the ice machine and the bin.

Additionally, the machine must be connected to the

correct remote condenser and use the correct precharged tubing. The machine is supplied with a full

refrigerant charge, eld charging is not required.

This product cannot be stacked. See the chart for

application information.

Environmental Limitations, ice machine:

Minimum Maximum

Air temperature 50oF. 100oF.

Water

temperature

Water pressure 20 psi 80 psi

Remote condenser

Air temperature -20oF. 120oF.

Power Supply

208-230 volt

model

Warranty Information

40oF. 100oF.

Minimum Maximum

Minimum Maximum

198 volts 253 volts

November 2006

Page 2

Page 4

C1448, C1848, C2148

Remote Condenser Models - User Manual

Model Number Description

Example

• C1448SR-32B

• C=cuber

• 14=nominal capacity in 100s of pounds

• 48=nominal width of cabinet in inches

• S=cube size, S=small or half dice,

• M=medium or full dice

• R=condenser type. R=Remote

• 32=Electrical code. -32=208-230/60/1, -3= 208-

230/60/3

• B=series revision code. B=2nd series.

Note: In some areas of this manual model numbers

may include only the rst ve characters of the model

number, meaning that cube size, condenser type and

voltage differences are not critical to the information

listed there.

Other bins and applications:

Note the drop zone and optional ultrasonic sensor

locations in the illustrations.

Scotsman ice systems are designed and

manufactured with the highest regard for safety and

performance. They meet or exceed the standards of

UL and NSF.

Scotsman assumes no liability of responsibility of

any kind for products manufactured by Scotsman

that have been altered in any way, including the use

of any part and/or other components not specically

approved by Scotsman.

Scotsman reserves the right to make design changes

and/or improvements at any time. Specications and

design are subject to change without notice.

Options:

There are several options available for eld

installation. They include:

• Vari-Smart Adjustable ice level system

• Smart-Board Advanced feature control

Some installations require bin or dispenser adapters.

See the table below.

Standard bin applications – Adapter information

Model BH900* or B948 BH1100,

BH1300 or

BH1600

C1448, C1848

or C2148

Direct t, no

adapter needed

Adapter panels

included with

bin, no adapter

needed*

If stainless steel Kbafe3 has been installed, remove

it and replace with the original plastic bafe.

December 2011

November 2006

Page 3

Page 5

C1448, C1848, C2148

Remote Condenser Models - User Manual

Product Description and Electrical Requirements

Dimensions

w” x d” x h”

Model Electrical Use con-

denser

Minimum

Circuit Am-

Maximum

Fuse* Size

pacity

48 x 24 x 29 C1448SR-32 208-230/60/1 ERC311-32 17.0 30 20

same C1448SR-3 208-230/60/3 ERC311-32 12.9 30 15

same C1848SR-32 208-230/60/1 ERC611-32 24.8 30 30

same C1848SR-3 208-230/60/3 ERC611-32 15.8 30 20

same C2148SR-32 208-230/60/1 ERC611-32 33.9 50 40

same C2148SR-3 208-230/60/3 ERC611-32 21.5 30 30

*Or HACR circuit breakers.

Table notes: Medium cube models have the same

electrical characteristics as Small. Series revision

code omitted. All the listed condensers include a

headmaster valve.

Ratings include the remote condenser motor, as it

is designed to be powered by the ice machine. If

connecting remote condenser independently of the

ice machine, use the information on the condenser's

dataplate for fuse and wire sizes.

Scotsman Engineering approval for warranty

coverage to be in effect.

Precharged tubing kits:

The ice making head’s and the remote condenser’s

refrigeration circuits must be connected. They

are designed to be connected using precharged

refrigerant tubing, supplied in kits of liquid and

discharge tubes. Several lengths are available, order

the one that just exceeds the length needed for the

site.

Suggested

Fuse* Size

Central Condenser (Rack) Coils

The ice machine may be connected to a central

condenser coil. The requirements are:

• Coil – not previously used with mineral oil system.

Virgin coil preferred.

• Correct size (internal volume) and capacity (BTUH).

• Includes a headmaster valve for discharge pressure

control. Headmaster kit available for certain MAC

condensers, kit number is RCKCME6GX.

• Fan motor on all the time or controlled to be on

whenever the ice machine is operating.

• U.L. listed for the ice machine

• Non-Scotsman condensers must have prior

10’ 20’ 40’ 75’

C1448,

C1848,

C2148

No additional refrigerant is required.

RTE10 RTE25 RTE40 RTE75

January 2009

November 2006

Page 4

Page 6

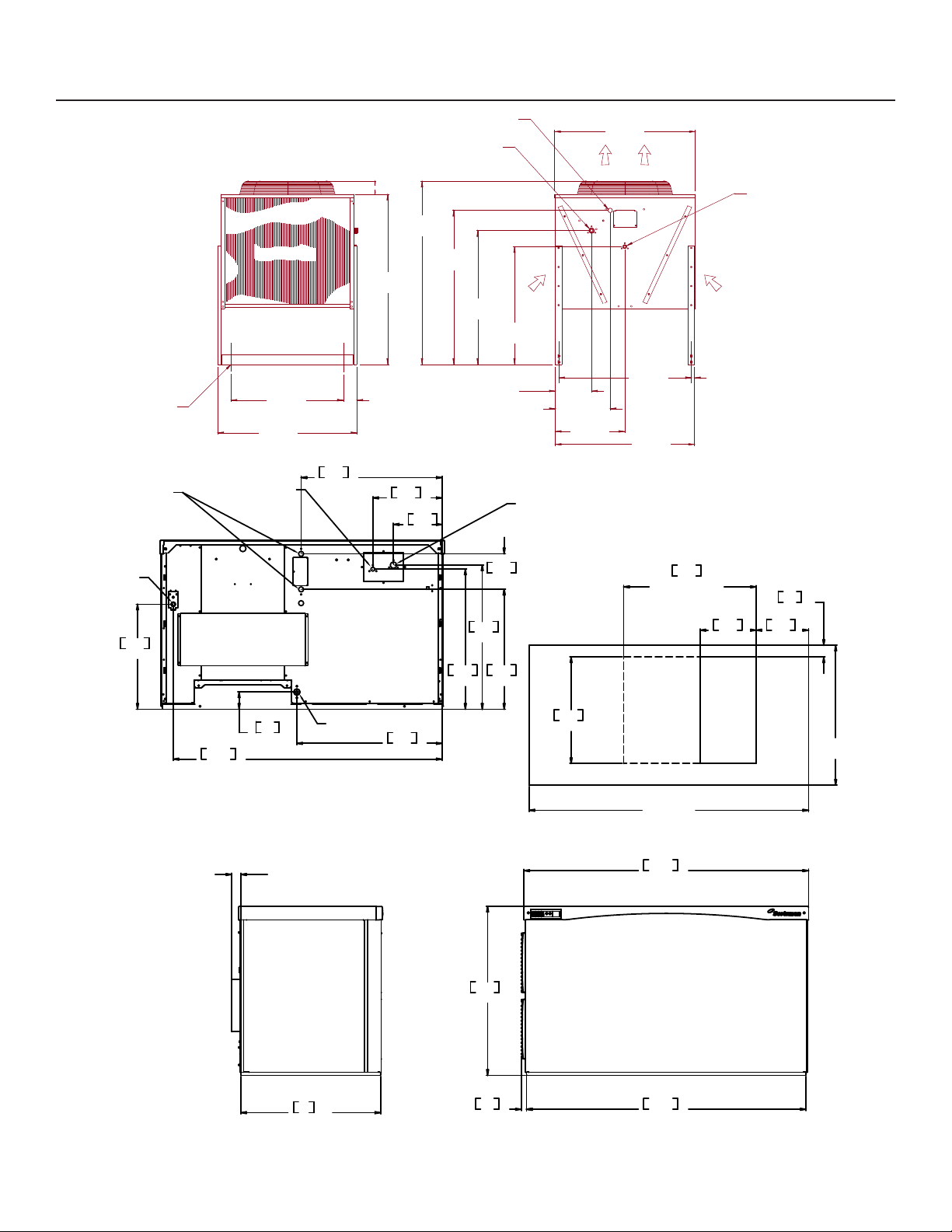

C1448, C1848, C2148

.88 DIA. ELECTRICAL

74.1 cm

Remote Condenser Models - User Manual

Condenser and Machine Layouts

3/8" FPT

WATER

INLET

45.7

18.00

.562 DIA.

MOUNTING

HOLES (4)

.88" DIA

ELECTRICAL

ACCESS (2)

REMOTE CONDENSER

LIQUID LINE

3/8 MALE CPLG.

Cond. Fins

15-0782-01

CAN CAUSE INJURY OR DEATH:DISCONNECT ALL REMOTE ELECTRICPOWER SUPPLIES BEFORE SERVICING.

RISK OF ELECTRIC SHOCK^M

WARNING

23.54 in

59.7 cm

29.15 in

74.0 cm

61.5

24.20

2.75

35.72 in

90.7 cm

2.84 in

7.2 cm

30.2

11.87

38.47 in

97.7 cm

21.2

8.33

INLET

DISCHARGE LINE

1/2" MALE CPLG.

32.32 in

82.1 cm

28.07 in

71.2 cm

62.9

24.76

61.1

24.06

24.71 in

62.7 cm

7.60 in

19.3 cm

REMOTE CONDENSER

DISCHARGE LINE

1/2 MALE CPLG.

15.5

6.11

52.3

20.59

11.50 in

29.2 cm

14.56 in

36.9 cm

29.50 in

74.9 cm

27.56 in

70.0 cm

29.19 in

MINIMUM BIN

TOP OPENING

57.8

22.75

.65 in

1.7 cm

24.5

9.63

LIQUID LINE

3/8" MALE CPLG.

AIR FLOW

22.9

9.00

5.1

2.00

117.3

46.17

7.5

2.96

REMOTE COOLED

BACK VIEW

1.57 REFRIGERATION

AND ELECTRICAL CHASE

61

24.00

LEFT SIDE VIEW

3/4" FPT

DRAIN

63.3

24.93

73.7

29.00

2.3

.92

46.5

18.30

48.00 REF.

PLAN VIEW

124.2

48.89

121.9

48.00

FRONT VIEW

ICE DROP OPENING

24.00

REF.

November 2006

Page 5

Page 7

C1448, C1848, C2148

Remote Condenser Models - User Manual

Water

The quality of the water supplied to the ice machine

will have an impact on the time between cleanings

and ultimately on the life of the product. There are

two ways water can contain impurities: in suspension

or in solution. Suspended solids can be ltered out.

In solution or dissolved solids cannot be ltered, they

must be diluted or treated.

Scotsman lters:

A triple head lter is recommended. Either the

Scotsman SSM3 taste and odor lter system, or the

ADS-AP3 AquaPatrol system.

Water lters are recommended to remove suspended

solids. Some lters have treatment in them for

suspended solids. Check with a water treatment

service for a recommendation.

RO water. This machine can be supplied with Reverse

Osmosis water, but the water conductivity must be no

less than 10 microSiemens/cm.

Potential for Airborne Contamination

Water Purge

Cube ice machines use more water than what ends

up in the bin as ice. While most water is used during

ice making, a portion is designed to be drained out

every cycle to reduce the amount of hard water scale

in the machine. That’s known as water purge, and an

effective purge can increase the time between needed

water system cleaning.

In addition, this product is designed to automatically

vary the amount of water purged based on the purity

of the water supplied to it. The water purge rate can

also be set manually. Adjustments of purge due to

local water conditions are not covered by warranty.

Installing an ice machine near a source of yeast

or similar material can result in the need for more

frequent sanitation cleanings due to the tendency of

these materials to contaminate the machine.

Most water lters remove chlorine from the water

supply to the machine which contributes to this

situation. Testing has shown that using a lter that

does not remove chlorine, such as the Scotsman

Aqua Patrol, will greatly improve this situation, while

the ice making process itself will remove the chlorine

from the ice, resulting in no taste or odor impact.

Additionally, devices intended to enhance ice machine

sanitation, such as the Scotsman Aqua Bullet, can

be placed in the machine to keep it cleaner between

manual cleanings.

November 2006

Page 6

Page 8

C1448, C1848, C2148

Remote Condenser Models - User Manual

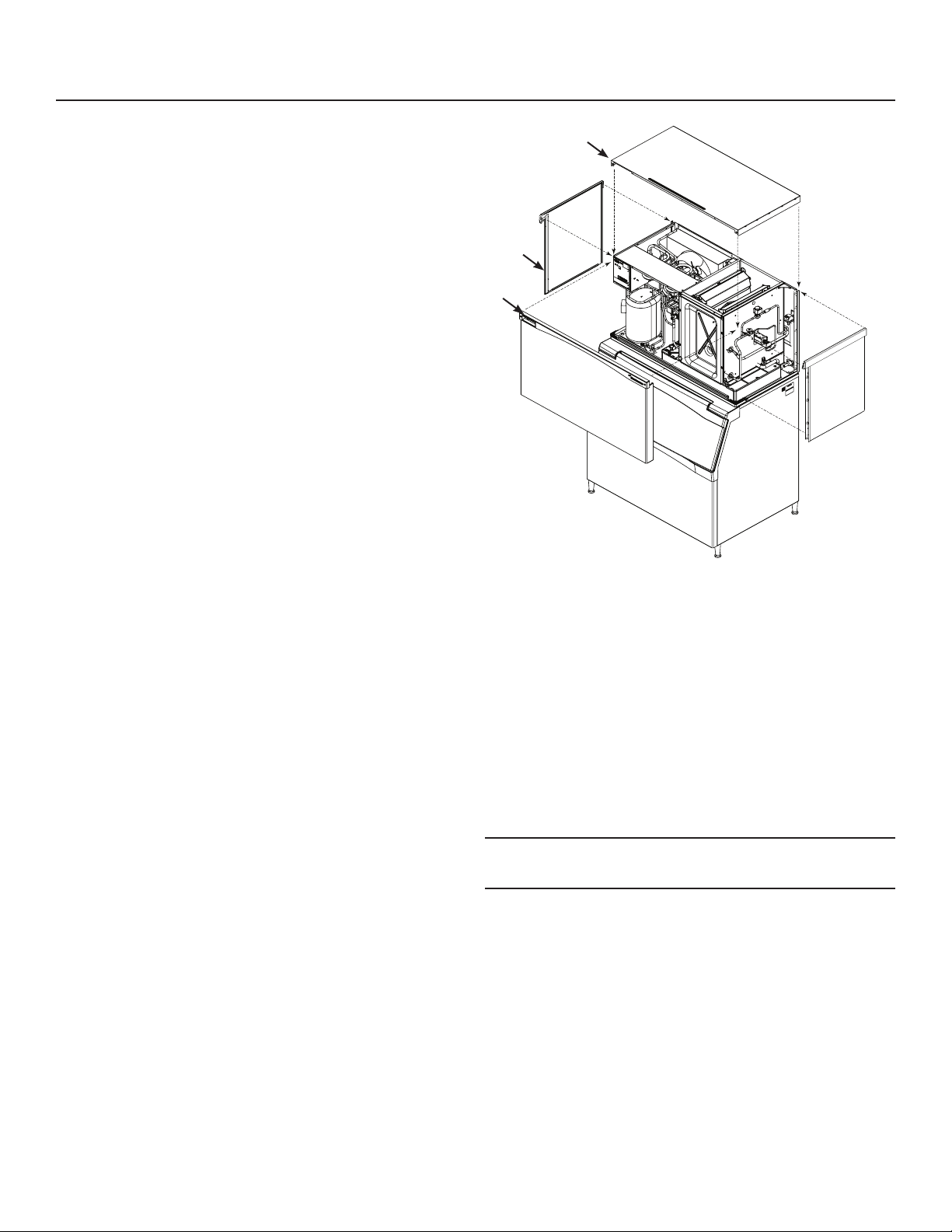

Panel Removal

1. Locate and loosen the two screws at the front

edge of the top panel.

2. Pull the front panel out at the top until it clears the

top panel.

3. Lift the front panel up and off the machine.

4. Remove two screws from the front edge of the top

panel.

5. Lift up the front of the top panel, push it back an

inch, then lift to remove.

6. Locate and loosen the screw holding each side

panel to the base.

7. Pull the side panel forward to release it from the

back panel.

This manual covers several models of remote cubers.

The model number on the ice machine can be found

either on the dataplate, which is on the back panel, or

the serial number tag, which is behind the front panel.

See the illustration for the locations of the dataplate

and the serial number tag.

The remote condenser has a separate model and

serial number. Its model and serial number is on the

dataplate on the condenser near the quick connect

ttings.

Write the model and serial number of the ice machine

here:

Write the model and serial number of the remote

condenser here:

Write the model and serial number of the ice storage

bin here:

Write the day of initial start up here: That day starts

the warranty period.

Uncrate and Set Up

5

6

1

Panel Removal

Check the bin top gasket for tears or gaps. If recycling

an older bin, replace the gasket or repair with food

grade sealant prior to placing the ice machine on the

bin.

Install the bin top adapter, if one is required for the

application.

If the ice machine has not been unpacked, do so

now. Remove the carton from the skid. Cut away any

shipping strapping. Lift the ice machine off the skid

directly onto the bin.

Note: The machine is heavy. Use a mechanical lift if

necessary.

Secure the ice machine to the bin with the hardware

provided (two metal straps and four bolts).

Begin with the ice storage bin. Remove the carton,

and, using part of the carton as a cushion, tip the bin

on its back to remove the skid. Attach the supplied

legs or optional casters. Return the bin to a normal,

upright position.

November 2006

Page 7

Page 9

C1448, C1848, C2148

22.87"

17.15"

40.35"

Remote Condenser Models - User Manual

Remote Condenser Location

Use the following for planning the placement of the

condenser relative to the ice machine

Location Limits - condenser location must not exceed

ANY of the following limits:

• Maximum rise from the ice machine to the

condenser is 35 physical feet

• Maximum drop from the ice machine to the

condenser is 15 physical feet

• Physical line set maximum length is 100 feet.

• Calculated line set length maximum is 150.

Calculation Formula:

• Drop = dd x 6.6 (dd = distance in feet)

• Rise = rd x 1.7 (rd = distance in feet)

• Horizontal Run = hd x 1 (hd = distance in feet)

• Calculation: Drop(s) + Rise(s) + Horizontal

Congurations that do NOT meet these requirements

must receive prior written authorization from

Scotsman.

Do NOT:

• Route a line set that rises, then falls, then rises.

• Route a line set that falls, then rises, then falls.

Calculation Example 1:

The condenser is to be located 5 feet below the ice

machine and then 20 feet away horizontally.

5 feet x 6.6 = 33. 33 + 20 = 53. This location would be

acceptable

Calculation Example 2:

The condenser is to be located 35 feet above and

then 100 feet away horizontally. 35 x 1.7 = 59.5.

59.5 +100 = 159.5. 159.5 is greater than the 150

maximum and is NOT acceptable.

Run = dd+rd+hd = Calculated Line Length

Max 35’

hd

dd

Remote Condenser Located

ABOVE Ice Machine

Condenser Distance &

Location Schematic

rd

Max 15’

Remote Condenser Located

BELOW Ice Machine

November 2006

Page 8

Page 10

C1448, C1848, C2148

Remote Condenser Models - User Manual

For The Installer: Remote Condenser

Locate the condenser as near as possible to the

interior location of the ice machine.

Note: The location of the condenser is relative to the

ice machine is LIMITED by the specication on the

prior page.

Meet all applicable building codes.

Remote

Condenser

Roof Attachment

Install and attach the remote condenser to the roof

of the building, using the methods and practices of

construction that conform to the local building codes,

including having a roong contractor secure the

condenser to the roof.

Interconnecting Tubing

Power

Supply

Ice Machine

November 2006

Page 9

Page 11

C1448, C1848, C2148

Remote Condenser Models - User Manual

Precharged Line Routing

Do not connect the precharged tubing until all routing

and forming of the tubing is complete. See the

Coupling Instructions for nal connections.

1. Each set of pre-charged tubing lines contains a 3/8”

diameter liquid line, and a 1/2” diameter discharge

line. Both ends of each line have quick connect

couplings, the end without access valves goes to the

ice maker.

Note: The openings in the building ceiling or wall,

listed in the next step, are the minimum sizes

recommended for passing the refrigerant lines

through.

Minimize tubing routed

outside of the controlled

space.

2. Have the roong contractor cut a minimum hole for

the refrigerant lines of 1 3/4”. Check local codes, a

separate hole may be required for the electrical power

supply to the condenser.

Caution: Do NOT kink the refrigerant tubing while

routing it.

3. Route the refrigerant tubes thru the roof opening.

Follow straight line routing whenever possible. Excess

tubing may EITHER be coiled up INSIDE the building

OR cut out prior to connection to the ice maker and

condenser.

If the excess tubing is cut out, after re-brazing the

tubing must be evacuated prior to connection

to the ice maker or condenser.

If the excess tubing is to be coiled, spiral it

horizontally to avoid excess trapping in the

lines.

5. Have the roong contractor seal the holes

in the roof per local codes

Best Practice: Coil excess

tubing inside the building in a

horizontal coil.

November 2006

Page 10

Page 12

C1448, C1848, C2148

Remote Condenser Models - User Manual

Coupling Instructions

The couplings on the ends of the pre-charged line

sets are self-sealing when installed properly.

Follow these instructions carefully.

These steps must be performed by an EPA Certied

Type II or higher technician.

Initial Connections

1. Remove the protector caps and plugs. Wipe the

seats and threaded surfaces with a clean cloth to

remove any possible foreign matter.

2. Lubricate the inside of the couplings, especially

the O-rings, with refrigerant oil.

It is important that ONLY the nut on the pre-charged

tube be turned, or the diaphragms will be torn out

by the piercing knives and they will be loose in the

refrigeration system.

Note: As the couplings are tightened, the diaphragms

in the quick connect couplings will begin to be

pierced. As that happens, there will be some

resistance to tightening the swivel nut.

3. Position the ttings on the correct connections on

the condenser and ice machine.

• The discharge line (schrader valve end) goes to the

remote condenser tting marked “discharge line”.

• The 3/8" liquid line (schrader valve end) goes to the

remote condenser tting marked “liquid line”.

• The discharge line goes to the ice maker tting

marked “discharge line”.

• The 3/8" liquid line goes to the ice maker tting

marked “liquid line”.

Final Connections:

4. Begin by tightening the couplings together by

hand until it is certain that the threads are properly

engaged.

5. Then using two wrenches tighten the coupling

until it bottoms out or a denite increase in

resistance is felt.

6. Continue tightening the swivel nut until it bottoms

out or a very denite increase in resistance is felt

(no threads should be showing).

7. Use a marker or pen to mark a line on the

coupling nut and unit panel. Then tighten the

coupling nut an additional one-quarter turn. The

line will show the amount that the nut turns. Do

NOT over tighten.

8. After all connections have been made, and after

the king valve has been opened (do not open yet),

check the couplings for leaks.

November 2006

Page 11

Page 13

C1448, C1848, C2148

Remote Condenser Models - User Manual

Plumbing Requirements

All models require connection to cold, potable water.

A hand actuated valve within site of the machine

is required. There is a single 3/8” FPT inlet water

connection.

Water Fitting

Water Filters

Install a new cartridge if the lters were used with a

prior machine

December 2011

November 2006

Page 12

Page 14

C1448, C1848, C2148

Remote Condenser Models - User Manual

Drains

All models require drain tubing to be attached to them.

There is a single ¾” FPT drain tting in the back of the

cabinet.

Install new tubing when replacing a prior ice machine,

as the tubing will have been sized for the old model

and might not be correct for this one.

1. Connect water supply to water inlet ttings.

2. Connect drain tubing to drain tting.

3. Route the drain tubing to building drain. Follow

local codes for air gap.

4. Use rigid drain tubes and route them separately –

do not Tee into the bin’s drain.

Vent the reservoir drain. A vertical vent at the back of

the drain, extended about 8 – 10” will allow the gravity

drain to empty and also keep any surges during

draining from discharging water.

Horizontal runs of drain tubing need a ¼” per fall per

foot of run for proper draining.

Follow all applicable codes.

November 2006

Page 13

Page 15

C1448, C1848, C2148

To Remote

Condenser

Fan Motor

Junction

Box

Cover

Power

Supply

Wires

Ground

Wire

Connection

Install

Strain

Relief

Install

Strain

Relief

Remote Condenser Models - User Manual

Electrical

The machine is not supplied with a power cord, the

machine must be hard-wired.

The dataplate on the back of the cabinet details

the power requirements, including voltage, phase,

minimum circuit ampacity and maximum fuse size.

HACR type circuit breakers may be used in place of

fuses. Extension cords are not permitted. Use of a

licensed electrician is recommended.

The ice maker is designed to operate on its own

electrical circuit and must be individually fused.

Voltage variation must not exceed the limits listed

earlier.

The remote condenser is designed to be powered

from the ice machine. A separate knockout hole has

been provided in the ice maker electrical junction box.

Electrical connections are made inside the junction

box in the back panel of the ice machine.

1. Remove the junction box cover and route the

power cord through the access hole and properly

attach the power supply wires to the leads in the

junction box.

2. Attach the remote condenser fan motor wires to

the wires in the junction box tagged “fan motor

leads”.

3. Install eld supplied strain reliefs per code. Attach

a ground wire to the ground connection in the

junction box.

4. Check voltage when complete.

5. Return the junction box cover to its original

position and secure with the original screws.

Follow all applicable local, state and national

codes.

November 2006

Page 14

Page 16

C1448, C1848, C2148

Remote Condenser Models - User Manual

Final Check List:

1. Is the unit located indoors in a controlled

environment?

2. Is the condenser located where it can receive

adequate cooling air?

3. Has the correct electrical power been supplied to

the machine?

4. Have all the water supply connections been

made?

5. Have all the drain connections been made?

6. Has the remote condenser been properly

installed?

7. Has the interconnecting tubing been properly

routed between the remote condenser and the ice

machine?

8. Have the quick connects been properly

connected?

9. Has the power supply wire from the ice machine

to the remote condenser been properly run and

connected?

10. Has the unit been leveled?

11. Have all unpacking materials been removed?

12. Is the water pressure adequate?

13. Have the drain connections been checked for

leaks?

14. Has the bin interior been wiped clean or sanitized?

15. Have any water lter cartridges been replaced?

16. Have all required kits and adapters been properly

installed?

November 2006

Page 15

Page 17

C1448, C1848, C2148

Remote Condenser Models - User Manual

Initial Start Up

1. Remove front and left side panels. Check machine

for any packing or wires rubbing moving parts.

Note location of control board in upper left corner

of the machine’s front.

2. Switch on the electrical power to the machine.

Observe that some of the control’s indicator lights

glow and its display shows O.

3. Wait 4 hours for the compressor’s crankcase

heater to warm up the oil in the compressor.

4. Open the water supply valve.

5. Turn the receiver’s outlet valve to the full open

position.

6. Push and release the ON button.

The indicator light will begin to blink F. The purge

valve will open and the water pump will start. The inlet

water valve will open to add water to the reservoir.

After a few seconds the purge valve will close and the

water pump will stop. Water will ow into the machine

until the reservoir is full. The hot gas valves and

harvest assist devices will activate and the liquid line

solenoid valve will open, then the compressor, remote

fan motor and water pump will start. The display will

show a continuous F. Five seconds later the hot gas

valves will close and the harvest assist devices will

return to their standby positions. Warm air will be

discharged from the condenser coil.

7. During the Freeze cycle move the curtain and

observe that the SW1 or SW2 light on the control

board blinks ON when the curtain moves away

from the evaporator and OFF when returned to its

normal position.

Note: Moving the curtain during the Freeze cycle has

no affect on unit operation.

8. Observe the Ready for Harvest indicator light. It

may blink early in the freeze cycle, that is normal.

The control will ignore that signal for the rst 6

minutes of freeze.

10. The display shows an H.

The hot gas valves open and the harvest assist

mechanisms are activated. The purge valve opens to

drain some water, when it does the inlet water valve

opens to rell the reservoir. After a few seconds the

purge valve closes but the inlet water valve continues

to ll the reservoir. Harvest continues until the ice is

released as a unit from each evaporator and forces

each curtain to open.

11. When both curtains have opened and re-closed

the controller returns the unit to a freeze cycle.

12. Check the ice harvested for proper bridge

thickness. The ice bridge is factory set at 3/16

inch. If needed, adjust bridge thickness. Do NOT

make it too thin.

13. Determine the water purge setting from the table

on the next page. If desired, change the setting to

accommodate the local water conditions.

14. Return the panels to their normal positions and

secure them to the machine.

15. Instruct the user in the operation of the machine

and its maintenance requirements.

16. Fill out and mail the warranty registration form.

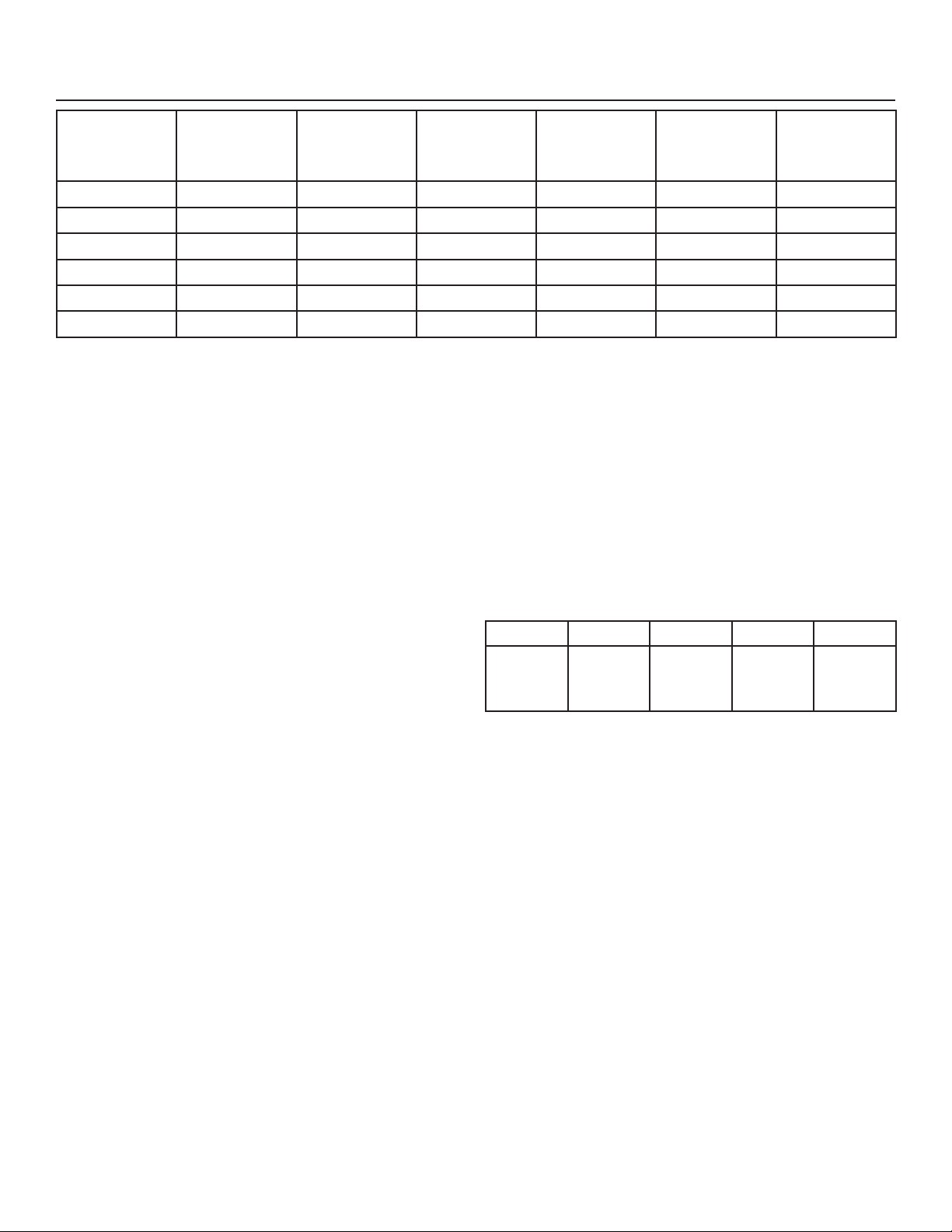

Typical Ice Making Cycle Times (minutes)

Listed times are for clean machines. Cycle times at

startup will be longer until the system stabilizes.

Model 70oF. cond air

/50oF. water

90oF. cond air

/70oF. water

C1448R 11 14-15

C1848R 9-10 11

C2148R 10 12

9. When the ice has frozen enough, the Ready for

Harvest indicator light will be on steady. After it’s

been on steady for a few seconds Harvest will

begin.

December 2011

November 2006

Page 16

Page 18

C1448, C1848, C2148

Remote Condenser Models - User Manual

Adjustments

Bridge Thickness - For A Service Tech Only

1. Push and hold Off till the machine stops.

2. Remove evaporator cover.

3. Remove left curtain.

4. Use a box wrench and rotate the bridge thickness

adjustment screw in 1/8 turn increments CW to

increase bridge thickness.

5. Rotate CCW to decrease bridge thickness.

Caution: Do not make the bridge too thin or the

machine will not harvest properly. Bridge thickness

adjustments are not covered by warranty.

6. Return curtain to its normal position.

7. Push and release the On button. Check next

harvest of ice. Repeat steps 1-6 if needed.

Too Big

1/8 - 3/16” bridge

Just Right for

Small Cube

Ice Bridge Thickness Check

Just Right for

Medium Cube

Too

Thin

Water purge setting

The water purge is factory set to the automatic

position, suitable for most water conditions. The

setting can be changed to one of 5 manual settings or

left on automatic.

Purge

setting

Water

Type

To set:

1. Switch the machine OFF by holding the Off button

in until a number or the letter A shows on the display.

2. Press and release the On button repeatedly until

the number on the display corresponds to the desired

setting.

3. Press and release the Off switch again to return to

the normal control state.

1 Minimum

RO

water or

equivalent

2 Moderate

3 - Standard 4 - Heavy 5 -

Factory

Setting for

typical water

High TDS

Ice Thickness Sensor

A - Automatic

Maximum

Any with conductivity

water

not less than 10

microSiemens/cm

November 2006

Page 17

Page 19

C1448, C1848, C2148

Remote Condenser Models - User Manual

Use and Operation

Once started, the ice machine will automatically make

ice until the bin or dispenser is full of ice.

When ice level drops, the ice machine will resume

making ice. There are four indicator lights at the

front of the machine that provide information on the

condition of the machine.

Caution: Do not place anything on top of the ice

machine, including the ice scoop. Debris and moisture

from objects on top of the machine can work their way

into the cabinet and cause serious damage. Damage

caused by foreign material is not covered by warranty.

Indicator Lights:

• Power

• Status

• Water

Note: A Component Indicator Light switches ON to

indicate that the component is operating.

Note: There are two Curtain Switch lights, SW1 and

SW2. A curtain switch light is ON when a curtain is

either open or not present.

• Clean

Indicator Lights & Their Meanings

Power Status Water De-Scale & Sanitize

Steady Green Normal Normal – bin full or

making ice

Blinking Green Self Test Failure Switching on or off - Blinking Red - Diagnostic shutdown

or, if making ice,

temperature sensor

failure

Yellow - - - Time to de-scale and

Blinking Yellow - - - In Cleaning mode

Light off No power Switched off Normal Normal

All Blinking Unit remotely locked out – check with leasing company

If the Water light is on, the machine has sensed a

lack of water. Check the water supply to the machine.

The water may have been shut off or the water lter

cartridges need to be changed.

- -

Lack of water -

sanitize

If the Clean light is on, the machine has determined

that it may need to be cleaned. Contact an authorized

Scotsman service agent and have the machine

cleaned, de-scaled and sanitized.

November 2006

Page 18

Page 20

C1448, C1848, C2148

Remote Condenser Models - User Manual

Switches

The two switches – on and off - can be accessed from

the front of the machine.

To switch the machine OFF, push and release the Off

button. The machine will shut off at the end of the next

cycle.

To switch the machine ON, push and release the

On button. The machine will go through a start up

process and then resume ice making.

Power

Status

De-Scale

Water

Off

On

Control Options

There are two optional, eld installed controls that can

be on this machine.

02-4294-01

Bin

Full

Graphic Rev. B

Rotate knob to set ice level

Yellow Arrow = Max Ice

White Arrow = Min Ice

Left Green = Dispenser high

Norm = Lower in Dispenser

m

r

o

L

N

o

w

e

r

Adjust Ice Level

Vari-Smart Control Area

• Certain dispenser applications where maximum ice

level is not desired

Use of adjustable ice level control

There are several positions the ice level can be set

to, including Off (knob and label indicators lined up),

where it lls the bin until the standard bin control shuts

the machine off. See the kit’s instructions for complete

details.

Rotate the adjustment post to the desired ice level.

The machine will ll up to that level and when it shuts

off the indicator light next to the adjustment post will

be On.

• KVS Adjustable ice level control

• KSBU Advanced Feature control

Adjustable ice level control

When this option is present there is an adjustment

post and an additional indicator light to the right of the

four indicator lights mentioned above. The ultrasonic

ice level control allows the user to control the point

that the ice machine will stop making ice before the

bin or dispenser is full. Reasons for this include:

• Seasonal changes in ice used

• Planning to sanitize the bin

• Faster turnover for fresher ice

Note: Ice will build up in the bin or dispenser at an

angle, the distances listed above will be from the

sensor to the top of the ice directly beneath it.

The actual distance between the highest point of the

ice may be closer or further away, depending upon

the angle of the ice.

June 2007

November 2006

Page 19

Page 21

C1448, C1848, C2148

SmartBoard Advanced Feature Control

™

See Instructions for Available Features

34

SEL

02-4293-01

Re v A .

ESC

Remote Condenser Models - User Manual

Options and Other Information

Smart-Board

When this option is present there is an additional

display panel in the area below the main control

board. It is not visible when the front panel is on.

The Smart-Board’s features include:

• Seven day programmable ice level setting when

used with the optional Vari-Smart ice level control

• Recording of machine operation, including cycle

time.

• Calculation of average cycle time

the bin. When removing ice, tap the groups of ice with

an ice scoop to separate them into smaller units. In a

dispenser, this ice will break up into mostly individual

cubes as the dispense mechanism moves the ice.

Heat

Most heat is exhausted at the remote condenser. The

ice machine should not generate signicant heat.

Noise

The ice machine will make noise when it is in ice

making mode. The compressor and water pump all

produce some sound. It is also normal to hear some

cracking just before the harvest cycle begins.

The ice harvests as a unit or slab, which makes some

noise when it impacts the bin or dispenser. These

noises are all normal for this machine.

• Recall of malfunctions with the time they occurred.

Ice

The cuber drops ice in large sections. That ice will

break up into random parts as it falls into the bin, but

some large sections may remain on top of the ice in

November 2006

Page 20

Page 22

C1448, C1848, C2148

Remote Condenser Models - User Manual

Cleaning, Sanitation and Maintenance

This ice system requires three types of maintenance:

• Remove the build up of mineral scale from the ice machine’s water system and sensors.

• Sanitize the ice machine’s water system and the ice storage bin or dispenser.

It is the User’s responsibility to keep the ice machine and ice storage bin in a sanitary condition. Without

human intervention, sanitation will not be maintained. Ice machines also require occasional cleaning of their

water systems with a specically designed chemical. This chemical dissolves mineral build up that forms during

the ice making process.

Sanitize the ice storage bin as frequently as local health codes require, and every time the ice machine is

cleaned and sanitized.

The ice machine’s water system should be cleaned and sanitized a minimum of twice per year.

1. Remove the front panel.

2. Remove the evaporator cover.

3. If the machine is operating, push and release the

Harvest button. When the machine completes the

Harvest cycle it will stop. If the bin is full (b shows

in display) push and release the Off button.

4. Remove all ice from the storage bin or dispenser.

5. Push and release the Clean button. The yellow

Clean light will blink and the display will show C.

The machine will drain the reservoir and rell it.

Go onto the next step when the purge valve light

goes out.

6. Pour 24 ounces of Scotsman Clear 1 Scale

Remover into the reservoir.

7. Allow the ice machine cleaner to circulate in the

water system for at least 10 minutes.

Ice machine cleaner contains

acids. Acids can cause burns.

9. Allow the drain and rell process to continue for at

least 20 minutes.

10. Push and release the Off button. The clean cycle

will stop and the display will show O.

Note: If unit has not been de-scaled for an extended

period of time and signicant mineral scale remains,

repeat steps 5 - 10.

11. Mix a cleaning solution of 1 oz of ice machine

scale remover to 12 ounces of water.

12. Locate curtains, push in on edge of curtain by

pivot pin to release it. Pull curtains out of machine

Push Here

If concentrated cleaner comes

in contact with skin, ush with

water. If swallowed, do NOT

induce vomiting. Give large

amounts of water or milk. Call

Physician immediately. Keep

out of the reach of children.

8. Push and release the Clean button again. The

yellow Clean light will be on continuously and the

machine will drain and rell the reservoir to ush

out the ice machine cleaner and residue.

November 2006

Pull here

Page 21

Page 23

C1448, C1848, C2148

Remote Condenser Models - User Manual

13. Remove water distributors from ice machine.

Inspect each distributor for restricted orice holes.

Be sure all holes are full open.

Squeeze tabs together, slide out until it stops, then lift

to remove.

Inspect Orifice Holes

Note; A possible sanitizing solution may be made by

mixing 1 packet of Stera Sheen Green Label sanitizer

(available from Scotsman) with 2 gallons of warm (95-

115oF.) potable water.

17. Thoroughly wash all surfaces of the ice thickness

sensor, water level sensor, curtain and water

distributor with the sanitizer solution.

18. Thoroughly wash all interior surfaces of the

freezing compartment, including evaporator

frames, back wall, evaporator cover and the

part of the top panel covering the freezing

compartment with the sanitizer solution.

19. Return water level sensor, ice thickness sensor,

water distributors and curtains to their normal

positions.

20. Push and release the clean button again and

when the purge valve indicator light goes out,

immediately pour the remaining cleaning solution

into the reservoir.

14. Locate ice thickness sensor. Squeeze mounting

legs together to release sensor. Wash the metal

surfaces of the sensor and the adjustment screw

with ice machine cleaner solution. Also wash the

water distributor and curtain with the ice machine

cleaner solution.

15. Locate water level sensor. Squeeze catches

together and pull up to remove sensor. Separate

probes from housing and wash all surfaces with

ice machine scale remover solution. Return

probes to holder.

Holder

21. Circulate the sanitizer solution for 10 minutes,

then push and release the Clean button.

22. Allow the water system to be ushed of sanitizer

for at least 20 minutes, then push and release the

Off button.

23. Return the evaporator cover and front panel to

their normal position and secure with the original

fasteners.

24. Push and release the On button to resume ice

making.

Ice Storage Bin

Remove and discard all ice. Mix a solution of

Scotsman Clear 1 ice machine scale remover and

wash all interior surfaces of the ice storage bin to

remove any mineral scale build up. Pour excess

cleaner solution into the bin’s drain.

Mix a solution of sanitizer and thoroughly wash all

interior surfaces of the ice storage bin.

16. Mix a solution of locally approved sanitizer. Use

an EPA approved food equipment sanitizer at

the solution mix recommended by the sanitizer

manufacturer.

March 2013

November 2006

Page 22

Page 24

C1448, C1848, C2148

Remote Condenser Models - User Manual

Remote condenser

The condenser ns will need to be cleaned.

Push and release the Off button. Wait until the

machine stops.

Note: Lock out the controller or the ice machine power

supply to prevent an unauthorized fan motor restart.

If there is imbedded grease, use a commercial coil

cleaner to wash out the grease. Dust can be blown

out with compressed air from the inside or use a

vacuum cleaner and soft brush. Be careful not to

damage the condenser’s ns. Use a n comb to

straighten any bent ns.

Exterior Panels

The front and side panels are durable stainless steel.

Fingerprints, dust and grease will require cleaning

with a good quality stainless steel cleaner.

Water lters

If the machine has been connected to water lters,

check the cartridges for the date they were replaced

or for the pressure on the gauge. Change cartridges

if they’ve been installed more than 6 months or if the

pressure drops too much when the ice machine lls

with water.

November 2006

Page 23

Page 25

C1448, C1848, C2148

Remote Condenser Models - User Manual

What to do before calling for service

Reasons the machine might shut itself off:

• Lack of water.

• Freeze cycle takes too long.

• Harvest cycle takes too long.

• High discharge temperature.

• Controller self test failure.

• Very high voltage

Check the following:

1. Has the water supply to the ice machine or

building been shut off? If yes, the ice machine will

automatically restart within 25 minutes after water

begins to ow to it.

2. Has power been shut off to the ice machine? If

yes, the ice machine will automatically restart

when power is restored.

3. Has someone shut the power off to the remote

condenser while the ice machine still had power?

If yes, the ice machine may need to be manually

reset.

4. Is a curtain open because some ice is stuck under

it? If so, remove the ice and the machine should

start in a few minutes.

Note: Curtains can be removed & replaced anytime

the machine is in a standby mode or when it is in a

freeze cycle. Removal of both curtains during harvest

terminates harvest at that point and, if left off, will

result in the machine shutting off.

To Manually Reset the machine.

Push and release the Off button.

Push and release the On button.

To Shut the Machine Off:

1. Push and hold the Off button for 3 seconds or until

the machine stops.

Check For

Ice Stuck

Under Curtain

November 2006

Page 24

Page 26

SCOTSMAN ICE SYSTEMS

775 Corporate Woods Parkway

Vernon Hills, IL 60061

800-726-8762

www.scotsman-ice.com

17-3083-04 Rev D. Print Rev E

Loading...

Loading...