Page 1

Instructions

Head Pressure Control Add-On Kit

Required when a C0830R, C1030R or C1448R is to be

connected to a Remote Condenser coil that is not

equipped with a Head Pressure Control Valve.

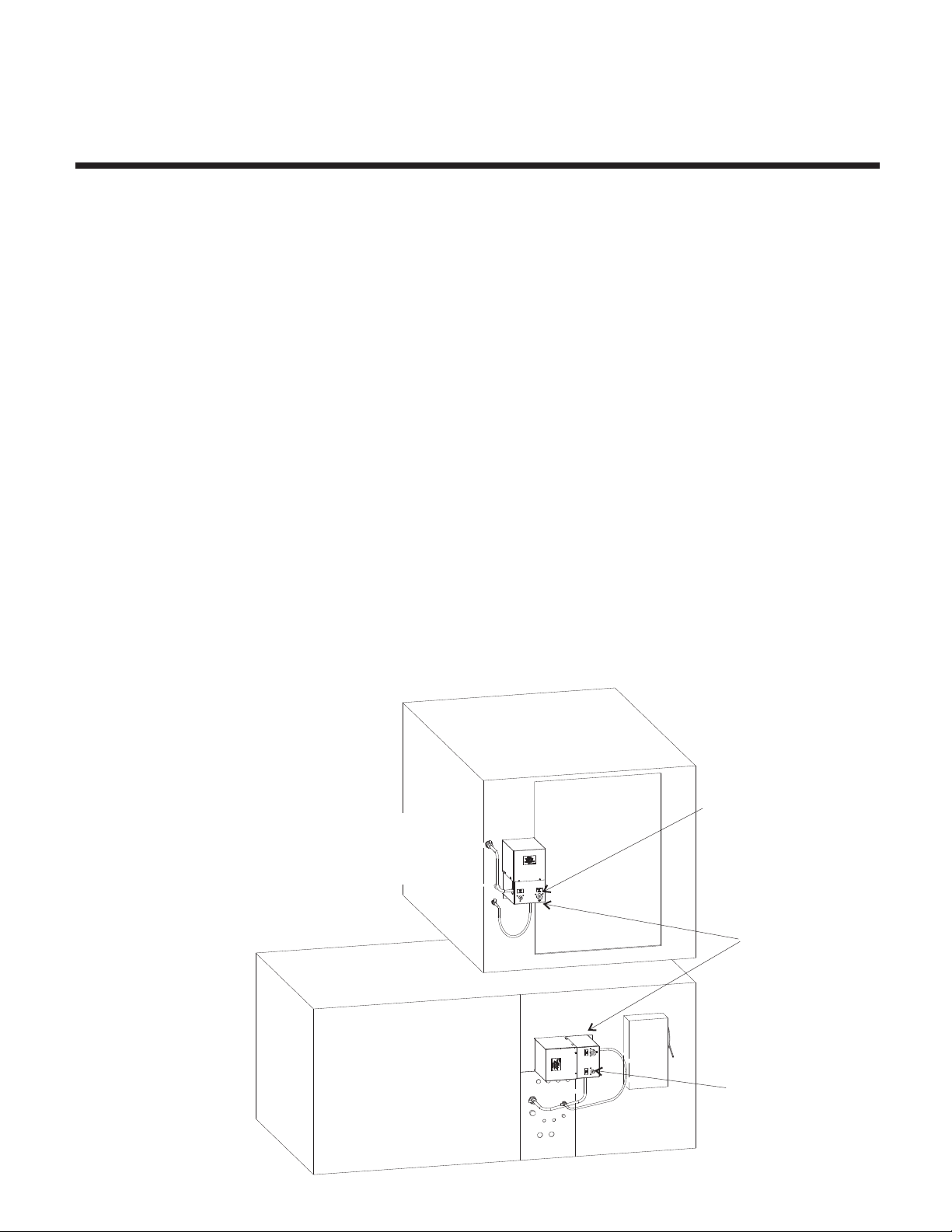

Fits two types of central condensers. Rotate the box and move the tubing to align

the fittings to those on the condenser to be used.

Required Tools: Screwdriver; Drill; 5/32" drill bit; Two Adjustable Wrenches; POE Oil

1. Remove cover from metal box.

2. Locate correct position on condenser: Note locations from illustration below.

3. Use metal box as a template, mark the positions of 4 holes to be drilled to mount the box to the

condenser.

4. Drill four .157" (#22 or 5/32" bit) dia. holes. Be SURE that there are no functional components in

line with the holes being drilled.

5. Secure the box to the condenser sheet metal.

Central

Condenser

Examples

G series

condenser

connections

X series condenser

connections

Pre-Charged Lines

from Ice Machine

Metal Box

Pre-Charged Lines

from Ice Machine

17-2985-01 Rev A page 1 of 3

Page 2

Condenser Coil Connection

The condenser coil may contain refrigerant or nitrogen or it could be empty.

Check at the access valve with a leak detector to confirm the contents. If refrigerant, it will be

R-404A and you can connect the headmaster kit.

If it is not refrigerant, purge it and then evacuate the coil. Then add a small amount of R-404A

before connecting the headmaster kit.

If it is empty, evacuate it, add some R-404A and check for a leak. If no leak is found connect the

headmaster kit.

Page 3

Coupling Attachment

Connect the coupling to the matching

fitting on the G or X series condenser,

as shown on page 1.

6. Remove plastic covers from the

condenser’s quick connects and those to

be used to connect to the condenser.

7. Thoroughly clean and lubricate the

threads and diaphragms of both the

condenser’s and the kit’s quick

connects. Use Polyolester oil.

8. Mount the box to the condenser with

the screws from the kit.

9. Start the swivel nuts by hand.

Use a back up wrench to be

•

certain that the tubing is NOT

ROTATING. Only the SWIVEL

NUTS should be rotating!

• Then use an adjustable wrench to

tighten them until no threads are

seen AND a very definite

resistance is felt.

10. Mark the positions of the swivel nuts

to the condenser panel.

11. Rotate the swivel nuts additional

one-quarter turn.

12. Place cover on metal box & secure

with screws.

13. Finish the balance of the installation.

Ice machine’s precharged line sets will

now connect to the quick connect fittings

on the metal box instead of the

condenser’s.

Clean and Lubricate Couplings

Tighten Swivel Nuts

Rotate Each Swivel Nut ¼ Turn More

Loading...

Loading...