Page 1

SERVICE MANUAL - MANUALE DI SERVIZIO

MANUEL DE SERVICE - BEDIENUNGSANLEITUNG

-

18 - 21 - 31 - 40

50 - 65 - 90

R 134 A

Ice cubers

Fabbricatori

di ghiaccio a cubetti

Machines á glaçons

Eiswürfelbereiter

REV. 02/2010

Page 2

TABLE OF CONTENTS PAGE INDICE PAG TABLE DES MATIERES PAGE INHALT SEITE

GENERAL INFORMATION INFORMAZIONI GENERALI INFORMATIONS GENERALES ALLGEMEINES UND

AND INSTALLATION 1 ED INSTALLAZIONE 11 ET INSTALLATION 21 INSTALLATION 32

Introduction 1 Introduzione 11 Introduction 21 Einleitung 32

Unpacking and inspection 1 Disimballaggio ed ispezione 11 Déballage et examen 21 Auspacken und Kontrollieren 32

Location and levelling 1

Electrical connection 1 Collegamenti elettrici 12 Branchement électrique 22 Elektrische Anschlüsse 33

Water supply and drain Alimentazione idraulica Branchement d’arrivée Wasserversorgung und

connection 2 e scarico 12 et d’évacuation eau 22 Abflußleitungen 33

Final check list 3 Controllo finale 13 Liste de contrôle final 23 Endkontrolle 34

Installation practice 3 Schema di installazione 13 Schema d’installation 23 Installation 34

Posizionamento e livellamento

11 Logement et mise de niveau 21

Stellplatz und

Aufstellung 32

a)

OPERATING INSTRUCTION 4 ISTRUZIONI DI 14 MISE EN SERVICE 24 BETRIEBSANLEITUNG 35

Start up 4 Avviamento 14 Démarrage 24 Inbetriebnahme 35

Operational checks 4 Controlli durante il funzion. 14

OPERATING PRINCIPLES 6 PRINCIPIO DI 16 PRINCIPE DE 26 BETRIEB 37

Freezing cycle 6 Ciclo di congelamento 16 Cycle de congélation 26 Gefrierzyklus 37

Harvest cycle 6 Ciclo di scongelamento 16 Cycle de démoulage 26 Abtauzyklus 37

CLEANING INSTRUCTIONS OF ISTRUZIONI PER LA PULIZIA

WATER SYSTEM 9 DEL CIRCUITO IDRAULICO 19

FUNZIONAMENTO

Contrôle pendant le fonctionn.

FUNZIONAMENTO FONCTIONNEMENT

INSTRUCTION DE NETTOYAGE

DU CIRCUIT HYDRAULIQUE

24 Kontrolle bei Betrieb 35

ANWEISUNGEN ZUR

30

WARTUNG UND REINIGUNG

40

Page 3

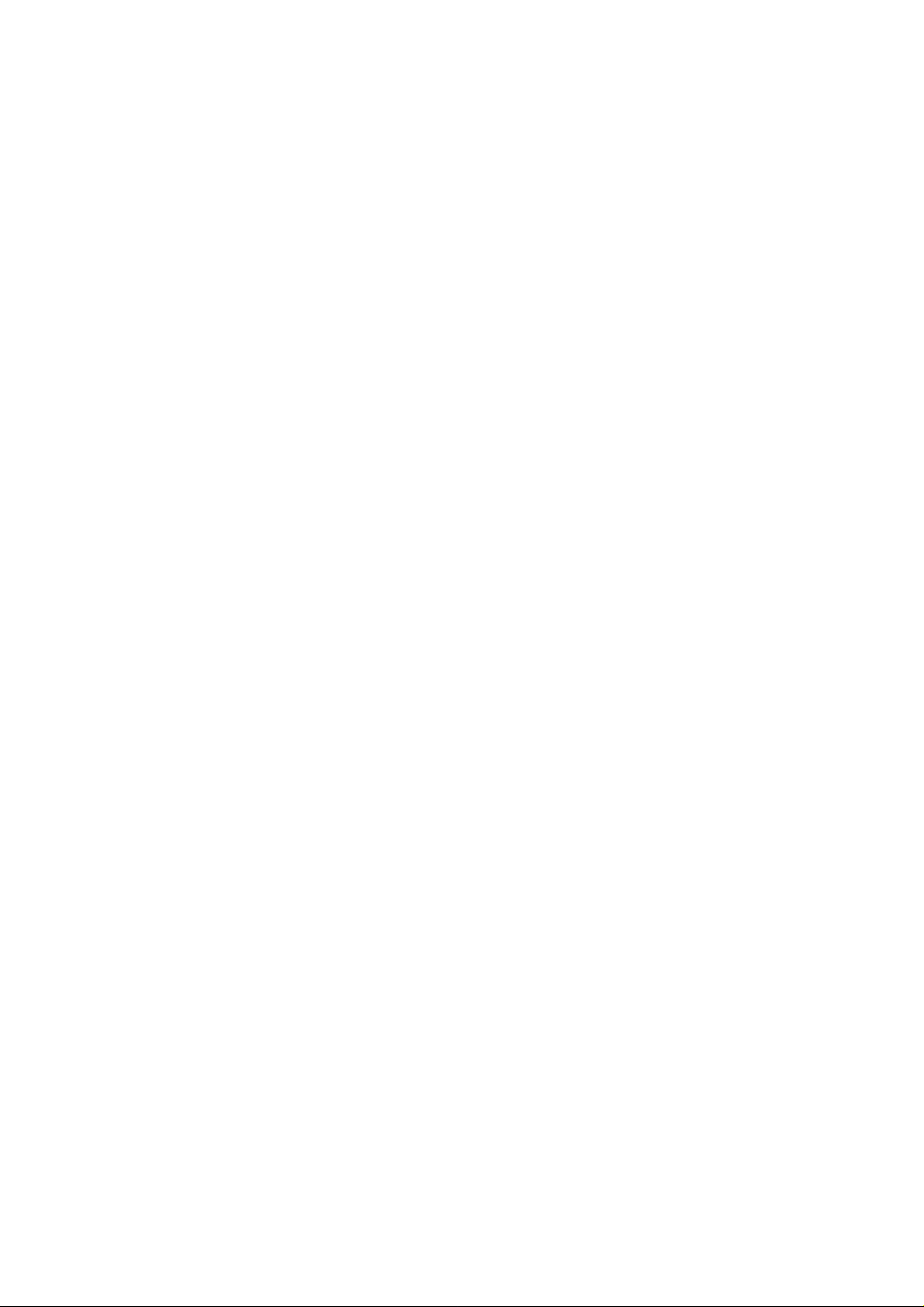

b)

B

C

18

A

B

A

21 - 31

C

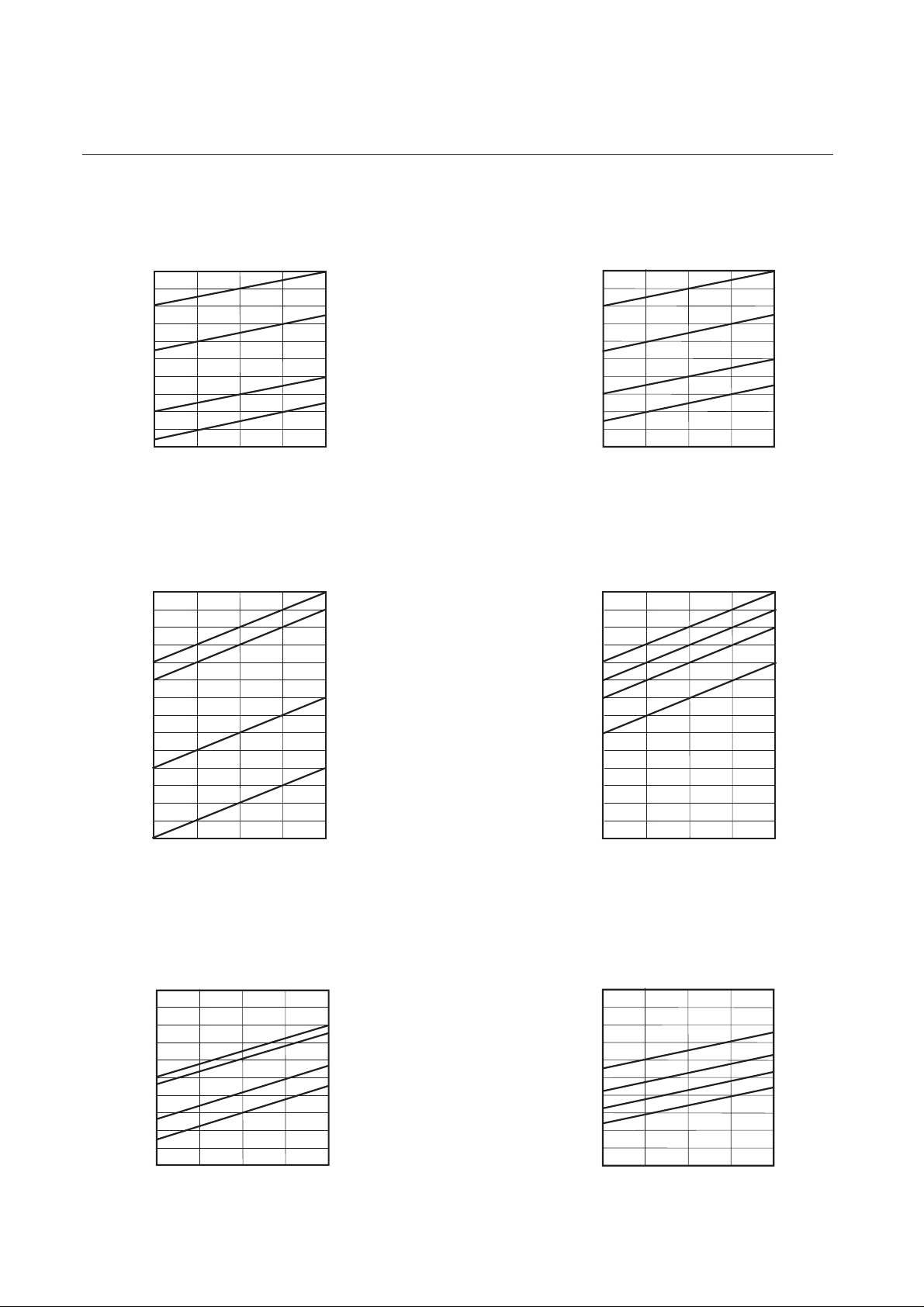

B 18 mm (inch) B 21 mm (inch) B 31 mm (inch)

A 334 (13 1/8) 389 (15 5/16) 465 (18 5/16)

B 457 (18) 515 (20 9/32) 586 (23 3/64)

C 597 (23 1/2) 640 (25 13/64) 690 (27 11/64)

Page 4

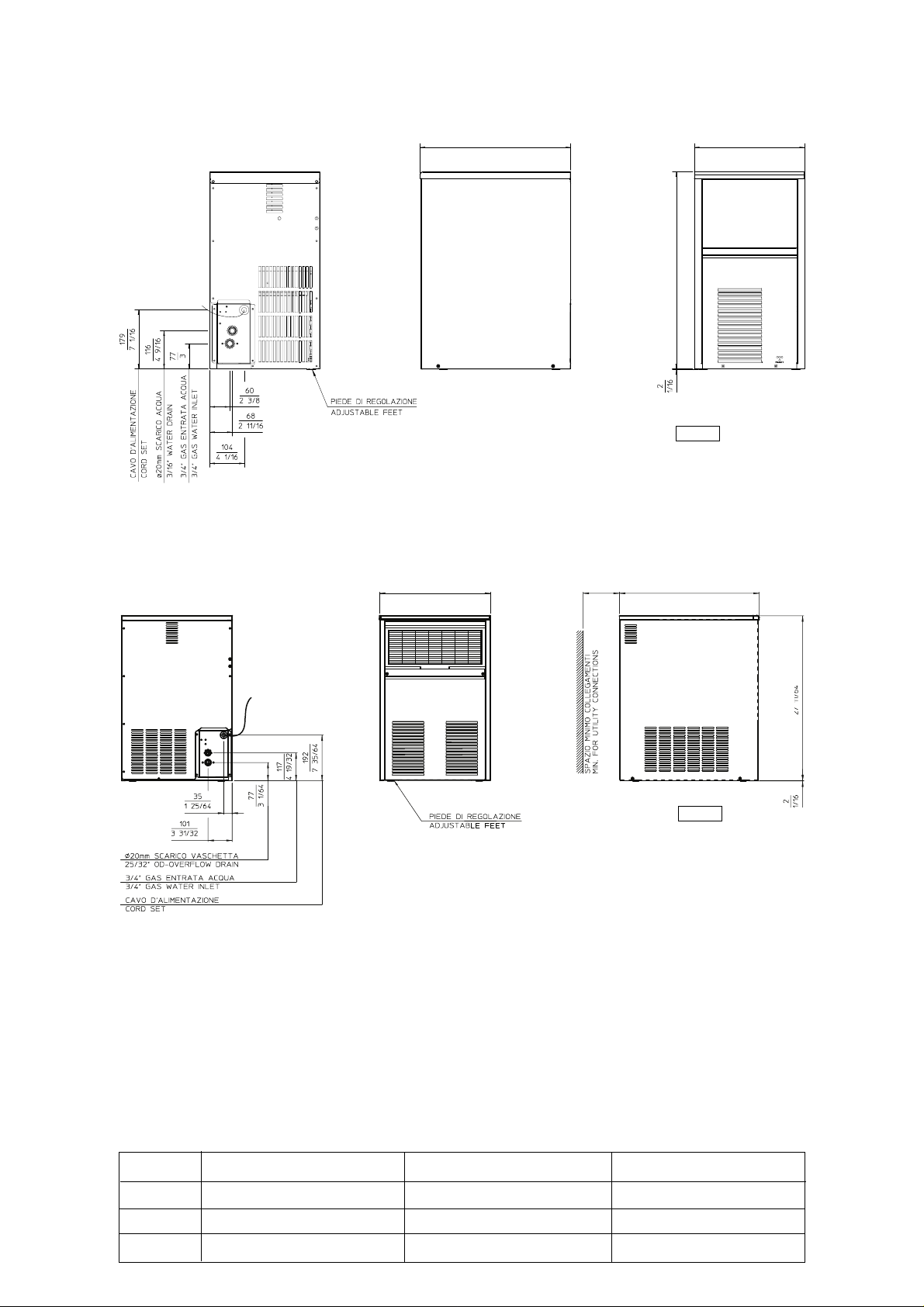

c)

A

C

B

50

A

B

C

40 - 65 - 90

B 40 mm (inch) B 50 mm (inch) B 65-90 mm (inch)

A 529 (20 19/32) 529 (20 53/64) 699 (27 11/64)

B 525 (20 43/64) 535 (21 1/16) 536 (21 1/32)

C 815 (31 5/8) 796 (31 17/64) 885 (34 17/32)

Page 5

d)

Page 6

TECHNICAL SPECIFICATIONS - SPECIFICHE TECNICHE - DONNÉES TECHNIQUE - TECHNISCHE ANGABEN

e)

Electric voltage

Alimentazione elettrica 230/50/1 230/50/1 230/50/1 230/50/1 230/50/1 230/50/1 230/50/1

Alimentation électrique -10 ÷ +10% -10 ÷ +10% -10 ÷+10% -10 ÷ +10% -10 ÷ +10% -10 ÷ +10% -10 ÷ +10%

Netzspannung

Condensation Air Water Air Water Air Water Air Water Air Water Air Water Air Water

Condensazione Aria Acqua Aria Acqua Aria Acqua Aria Acqua Aria Acqua Aria Acqua Aria Acqua

Condensation Air Eau Air Eau Air Eau Air Eau Air Eau Air Eau Air Eau

Kühlung Luft Wasser Luft Wasser Luft Wasser Luft Wasser Luft Wasser Luft Wasser Luft Wasser

Bin capacity (kg)

Capacità contenitore (kg)

Capacité bac glaçons (kg)

Lademenge (kg)

Net weight (kg)

Peso netto (kg)

Poids net (kg) 30 35 39 45 50 61 73

Nettogewicht (kg)

Cubes per cycle

Cubetti per ciclo

Glaçons par cycle 15 18 24 24 32 48 48

Würfel per Zyklus

Compressor power HP

Potenza compressore CV

Puissance compresseur CV

Kompressorleistung PS

Running amps

Amperaggio di marcia

Ampérage en marche 2,2 2,2 2,4 3,2 3,5 3,8 5,3

Ampere

Start amps

Amperaggio d’avv.

Ampérage de démarr. 9 9 11 17 18 20 26

Start Ampere

Power (Watts)

Potenza (Watt)

Puissance (Watts) 310 310 380 500 550 670 830

Leistung (Watt)

Power cons. in 24 hrs (Kwh)

onsumo elettr. in 24 ore (Kwh)

C

Cons. electr. en 24 hrs (Kwh)

Stromverbrauch in 24 Std. (kWh)

Wire size (mm2)

Sezione cavi (mm2)

Section fils (mm

Kabelstärke (mm2)

Water consumption (lt/hr)

Consumo acqua (lt/ora)

Consommation eau (lt/hr) N/A N/A 3 11* 4 12* 6 16* 8 30 * 7 34* 11 42*

Wasserverbrauch (lt/std)

Refrig. charge R 134 A (gr)

Carica refrig. R 134 A (gr)

Charge refrig. R 134 A (gr) N/A N/A 250 250 260 250 290 250 320 250 450 300 450 330

Kühlmittel - Füll. R 134 A (gr)

Refrigerant metering device

Disp. espansione refrigerante

Détente du Rèfrigérant Tube Capillaire Tube Capillaire Tube Capillaire Tube Capillaire Tube Capillaire Tube Capillaire Tube Capillaire

Kühlmittel - Expansionssystem

Water - Acqua - Eau - Wasser: 15°C (60°F)

2

) 3 x 1,5 3 x 1,5 3 x 1,5 3 x 1,5 3 x 1,5 3 x 1,5 3 x 1,5

18A 18W 21A 21W 31A 31W 40A 40W 50A 50W 65A 65W 90A 90W

6,5 8 15 16181830 30

1/5 1/5 1/4 3/8 3/8 1/2 3/4

N/A N/A 6,3 7,8 10 10 13 16

Capillary tube Capillary tube Capillary tube Capillary tube Capillary tube Capillary tube Capillary tube

Tubo capillare Tubo capillare Tubo capillare Tubo capillare Tubo capillare Tubo capillare Tubo capillare

Kapillarrohr Kapillarrohr Kapillarrohr Kapillarrohr Kapillarrohr Kapillarrohr Kapillarrohr

OPERATING PRESSURES - PRESSIONI DI FUNZIONAMENTO - PRESSIONES DE FONCTIONNEMENT - BETRIEBSDRÜCKE

Discharge pressure - Pressione di mandata Suction pressure - Pressione di aspirazione

Haute pression - Hochdruckbereich Basse pression - Niederdrück

Freezing cycle - Ciclo di congelamento End of freezing cycle - Fine ciclo di congelamento

Cycle de Congélation - Gefrierfase Fin du cycle de congélation - Ende der Gefrierfase

Air cooled - Raffr. ad aria 7÷11 bar 0÷0.1 bar

Refroid. à air - Luftgekühlt 100÷155 psig 0÷1.5 psig

Air cooled - Raffr. ad aria 8.5÷10 bar 0.2÷0.3 bar

Refroid. à air - Luftgekühlt 120÷140 psig 3÷4 psig

Water cooled - Raffr. ad acqua 8.5÷10 bar 0÷0.1 bar

Refroid. à eau - Wassergekühlt 120÷140 psig 0÷1.5 psig

Water cooled - Raffr. ad acqua 9.5 bar 0.2÷0.3 bar

Refroid. à eau - Wassergekühlt 130 psig 3÷4 psig

18-21-31-40

50-65-90

18-21-31-40-50

65-90

Page 7

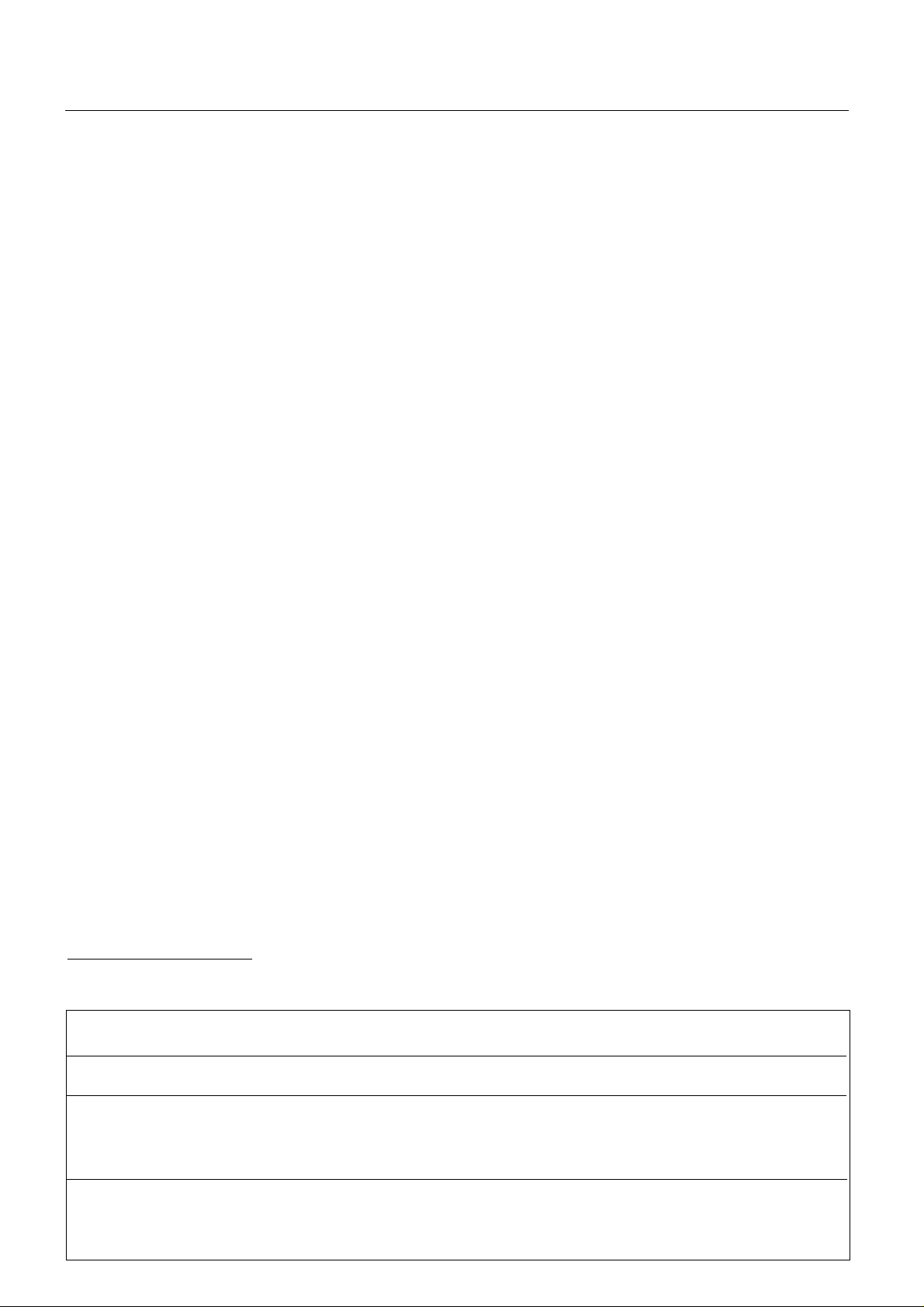

18 - 21 - 31 - 40

WIRING DIAGRAM - SCHEMA ELETTRICO - SCHÉMA ÉLECTRIQUE - SCHALTUNGSSCHEMA

AIR & WATER COOLED - RAFFREDDAMENTO AD ARIA ED AD ACQUA.

REFROIDISSEMENT A AIR ET A EAU - LUFT- UND WASSERGEKÜHLT

230/50-60/1

B - WHITE

BIANCO

BLANC

WEISS

N - BLACK

11

12

1

NERO

NOIR

SCHWARZ

A - BLUE

BLU

BLEU

BLAU

M - BROWN

MARRONE

MARRON

BRAUN

GV - YELLOW GREEN

GIALLO VERDE

JAUNE VERT

GELB - GRÜN

2

f)

5

7

9 3

12

10

8

6 4

9

3

2

10

8 7 5 6

11

4

JUST FOR WATER COOLED UNIT

SOLO PER RAFF. AD ACQUA

A

SEUL POUR REFR. A EAU

NUR FÜR WASSERGEKÜHLTE EINHEIT

1 TERMINAL BOARD - MORSETTIERA

BORNIER - ANSCHLUSSKASTEN

2 EVAPORATOR THERMOSTAT - TERMOSTATO EVAPORATORE

THERMOSTAT EVAPORATEUR - VERDAMPFERTHERMOSTAT

3 BIN THERMOSTAT - TERMOSTATO CONTENITORE

THERMOSTAT CABINE - SPEICHERTHERMOSTAT

4 COMPRESSOR - COMPRESSORE

COMPRESSEUR - KOMPRESSOR

B

5 WATER PUMP - POMPA

POMPE A EAU - WASSERPUMPE

6 FAN MOTOR - VENTILATORE

MOTOVENTILATEUR - LÜFTERMOTOR

7 WATER SOL. VALVE - VALV. INGR. ACQUA

VANNE ARRIVÉE EAU - WAISSEREINLASSVENTIL

8 HOT. GAS VALVE - VALVOLA GAS CALDO

VANNE GAZ CHAUDS - HEISSGASVENTIL

JUST FOR AIR COOLED UNIT

SOLO PER RAFF. AD ARIA

SEUL POUR REFR. A AIR

NUR FÜR LUFTGEKÜHLTE EINHEIT

9 HI TEMP. THERMOSTAT - TERMOSTATO DI MASSIMA

THERMOSTAT DE SECURITÉ - SICHERHEITSTHERMOSTAT

10 FILLING SWITCH - INTERRUTTORE CARICO

INTERRUPTEUR CHARGEMENT EAU - FÜLLSCHALTER

11 PRESSURE CTRL - PRESSOSTATO

PRESSOSTAT - DRUCKSCHALTER

12 COND. WATER SOL. VALVE - VALV. ALIM. ACQUA COND.

VANNE ARR. EAU CONDEN. - WASSEREINLASSVENTIL KOND.

Page 8

d

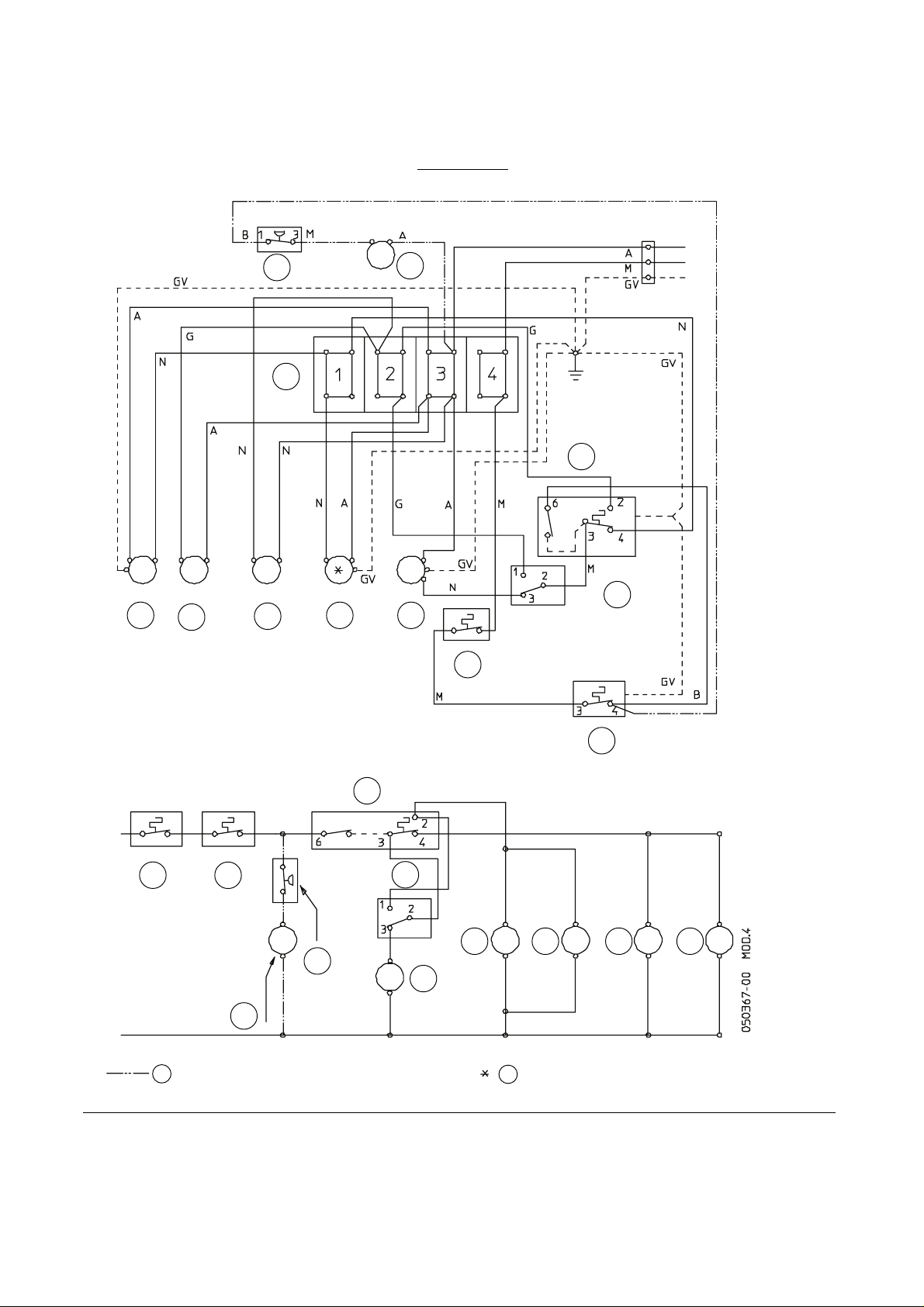

50

g)

WIRING DIAGRAM - SCHEMA ELETTRICO - SCHÉMA ÉLECTRIQUE - SCHALTUNGSSCHEMA

AIR & WATER COOLED - RAFFREDDAMENTO AD ARIA ED AD ACQUA.

REFROIDISSEMENT A AIR ET A EAU - LUFT- UND WASSERGEKÜHLT

230/50-60/1

A - BLUE

AZZURRO

BLEU

BLAU

TIMER

13

14

2

3

12

B - WHITE

BIANCO

BLANC

WEISS

M - BROWN

MARRONE

MARRON

BRAUN

N - BLACK

NERO

NOIR

SCHWARZ

G - GREY

GRIGIO

GRIS

GRAU

11

9

1

4

7

8

5

106 -

12

11

13

9

2

14

1

1 TERMINAL BOARD - MORSETTIERA

BORNIER - ANSCHLUSSKASTEN

2 EVAPORATOR THERMOSTAT - TERMOSTATO EVAPORATORE

THERMOSTAT EVAPORATEUR - VERDAMPFERTHERMOSTAT

3 BIN THERMOSTAT - TERMOSTATO CONTENITORE

THERMOSTAT CABINE - SPEICHERTHERMOSTAT

4 COMPRESSOR - COMPRESSORE

COMPRESSEUR - KOMPRESSOR

5 WATER PUMP - POMPA

POMPE A EAU - WASSERPUMPE

106 -

13 8

6 FAN MOTOR - VENTILATORE

MOTOVENTILATEUR - LÜFTERMOTOR

7 WATER SOL. VALVE - VALV. INGR. ACQUA

VANNE ARRIVÉE EAU - WAISSEREINLASSVENTIL

8 HOT. GAS VALVE - VALVOLA GAS CALDO

VANNE GAZ CHAUDS - HEISSGASVENTIL

9 PRESSURE CTRL - PRESSOSTATO

PRESSOSTAT - DRUCKSCHALTER

10 COND. WATER SOL. VALVE - VALV. ALIM. ACQUA COND.

VANNE ARR. EAU CONDEN. - WASSEREINLASSVENTIL KOND.

7

5

11 SWITCH - INTERRUTTORE

INTERRUPTEUR - SCHALTER

12 HI THERMOSTAT - TERMOSTATO DI SICUREZZA

THERMOSTAT DE SECURITE - SICHERHEITSTHERMOSTAT

13 TIMER - TIMER

PENDULE - ZEITHUR

14 COMPRESSOR SWITCH - INTERRUTTORE COMPRESSORE

INTERRUPTEUR COMPRESSEUR - KOMPRESSORSCHALTER

4

Page 9

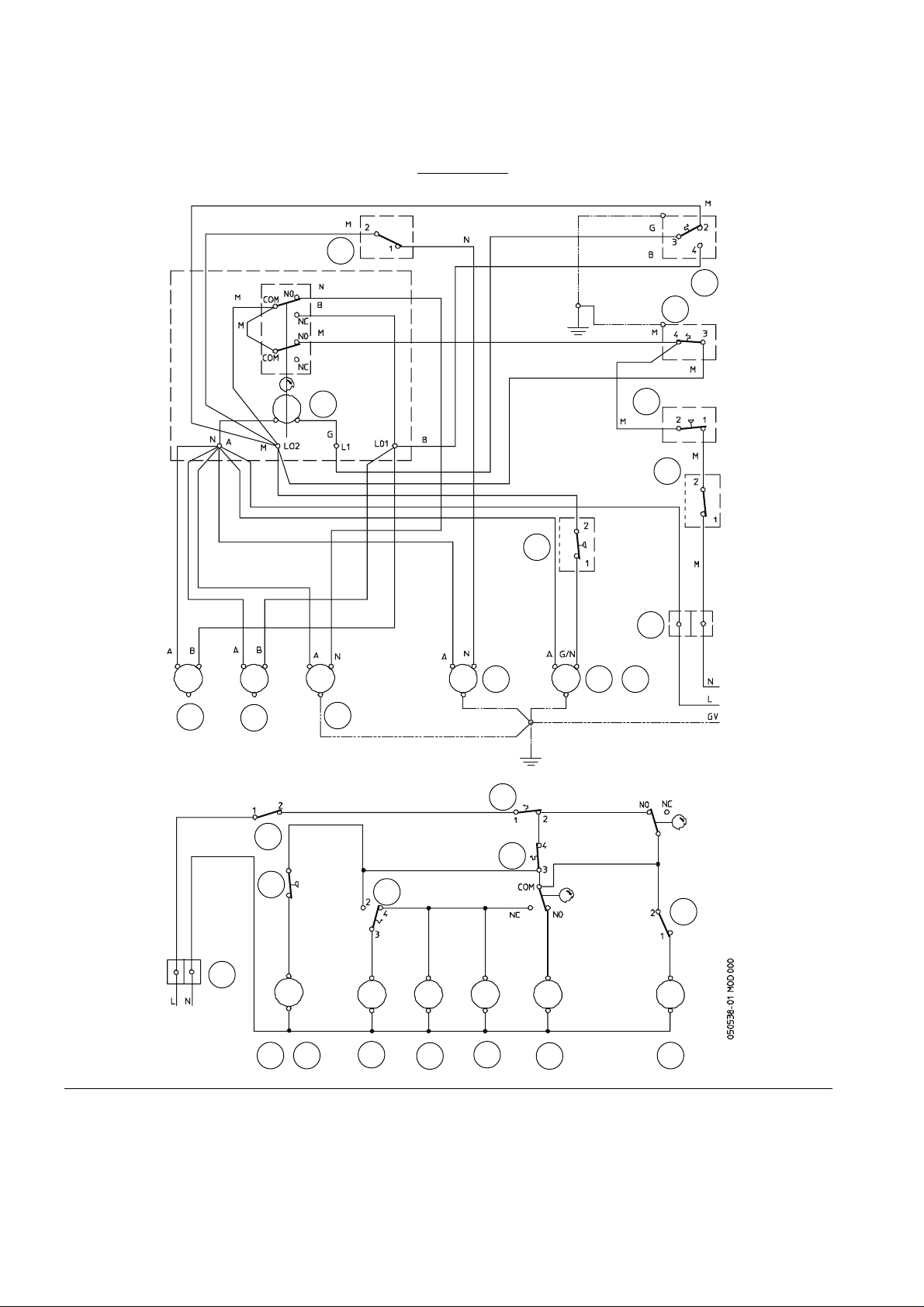

d

65 - 90

h)

WIRING DIAGRAM - SCHEMA ELETTRICO - SCHÉMA ÉLECTRIQUE - SCHALTUNGSSCHEMA

AIR & WATER COOLED - RAFFREDDAMENTO AD ARIA ED AD ACQUA.

REFROIDISSEMENT A AIR ET A EAU - LUFT- UND WASSERGEKÜHLT

230/50-60/1

A - BLUE

AZZURRO

BLEU

BLAU

TIMER

13

10

2

3

9

B - WHITE

BIANCO

BLANC

WEISS

M - BROWN

MARRONE

MARRON

BRAUN

N - BLACK

NERO

NOIR

SCHWARZ

G - GREY

GRIGIO

GRIS

GRAU

12

11

1

14

7

8

5

6

4

9

12

3

11

14

2

10

1

4

1 TERMINAL BOARD - MORSETTIERA

BORNIER - ANSCHLUSSKASTEN

2 EVAPORATOR THERMOSTAT - TERMOSTATO EVAPORATORE

THERMOSTAT EVAPORATEUR - VERDAMPFERTHERMOSTAT

3 BIN THERMOSTAT - TERMOSTATO CONTENITORE

THERMOSTAT CABINE - SPEICHERTHERMOSTAT

4 COMPRESSOR - COMPRESSORE

COMPRESSEUR - KOMPRESSOR

5 WATER PUMP - POMPA

POMPE A EAU - WASSERPUMPE

136

6 FAN MOTOR - VENTILATORE

7 WATER SOL. VALVE - VALV. INGR. ACQUA

8 HOT. GAS VALVE - VALVOLA GAS CALDO

9 HI TEMP. THERMOSTAT - TERMOSTATO DI MASSIMA

10 COMPRESSOR SWITCH - INTERRUTTORE COMPRESSORE

7

MOTOVENTILATEUR - LÜFTERMOTOR

VANNE ARRIVÉE EAU - WAISSEREINLASSVENTIL

VANNE GAZ CHAUDS - HEISSGASVENTIL

THERMOSTAT DE SECURITÉ - SICHERHEITSTHERMOSTAT

INTERRUPTEUR COMPRESSEUR - KOMPRESSORSCHALTER

8 5

11 PRESSURE CTRL - PRESSOSTATO

PRESSOSTAT - DRUCKSCHALTER

12 SWITCH - INTERRUTTORE

INTERRUPTEUR - SCHALTER

13 TIMER - TIMER

PENDULE - ZEITHUR

14 CONTACTOR - TELERUTTORE

CONTACTEUR - SCHALTSCHUTZ

Page 10

i)

e

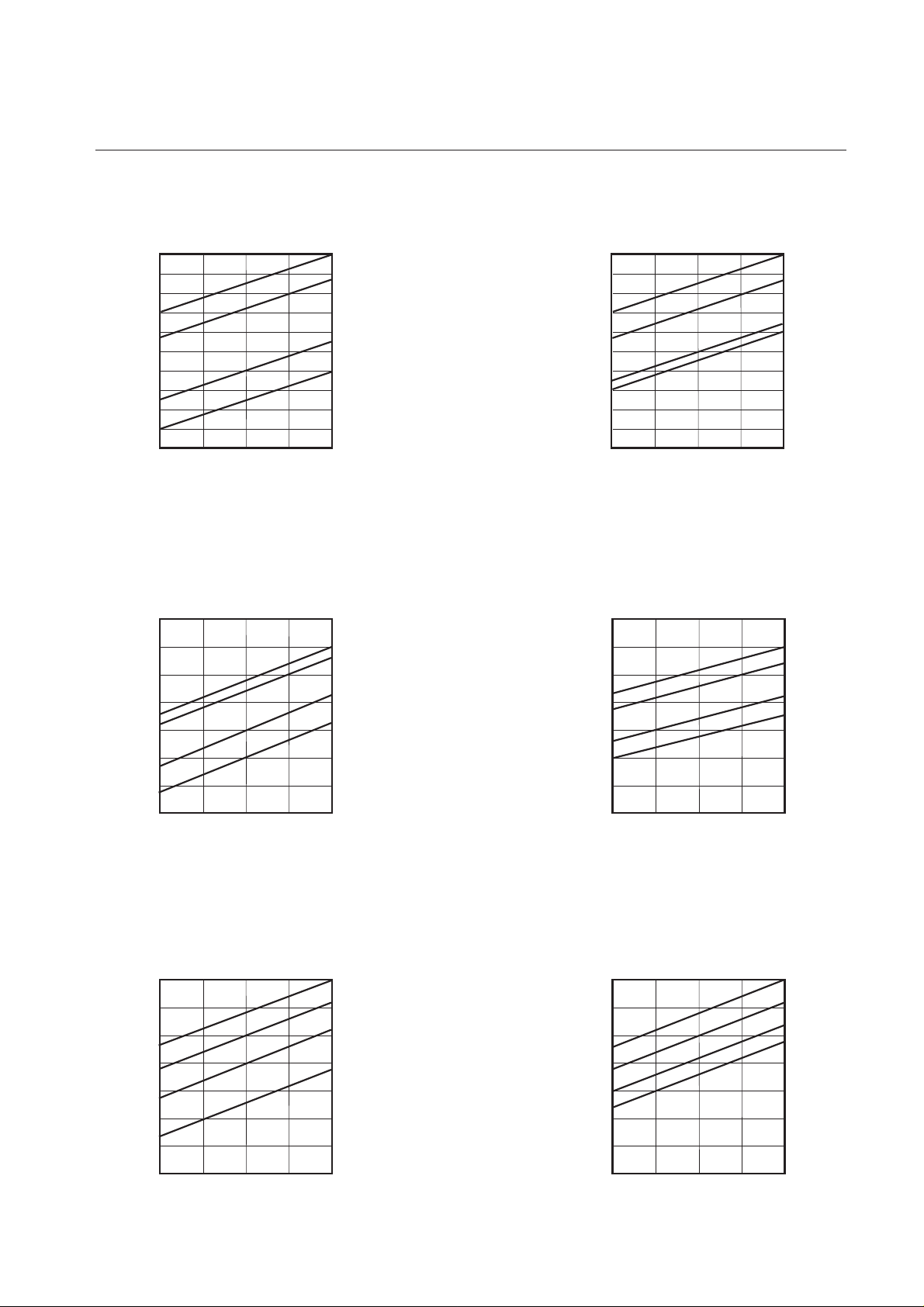

Capacità di produzione - Ice making capacity - Capacité de production - Eisproduktionskapazität

RAFFREDDAMENTO AD ARIA - AIR COOLED MODELS

CONDENSATION PAR AIR - LUFTKÜHLUNG

Kg.

23

22

21

20

19

18

17

16

15

14

13

PRODUZIONE GHIACCIO PER 24 ORE - ICE PRODUCED PER 24 HRS.

TEMPÉRATURE DE L'EAU - WASSERTEMPERATUR

PRODUCTION DE GLACE PAR 24 HEURES - EISWÜRFELPRODUKTION IN 24 STD.

RAFFREDDAMENTO AD ARIA - AIR COOLED MODELS

Kg.

28

27

26

25

24

23

22

21

20

19

18

PRODUZIONE GHIACCIO PER 24 ORE - ICE PRODUCED PER 24 HRS.

17

16

PRODUCTION DE GLACE PAR 24 HEURES - EISWÜRFELPRODUKTION IN 24 STD.

15

14

TEMPÉRATURE DE L'EAU - WASSERTEMPERATUR

27 21 15

32 2732

TEMPERATURA ACQUA - WATER TEMPERATURE

CONDENSATION PAR AIR - LUFTKÜHLUNG

27 21 15 10

TEMPERATURA ACQUA - WATER TEMPERATURE

°C

10

21

32

38

10 10

°C

10

21

32

38

TEMPERATURA AMBIENTE - AMBIENT TEMPERATURE

TEMPERATURA AMBIENTE - AMBIENT TEMPERATURE

TEMPÉRATURE AMBIANT - RAUMTEMPERATUR

TEMPÉRATURE AMBIANT - RAUMTEMPERATUR

21

31

RAFFREDDAMENTO AD ACQUA - WATER COOLED MODELS

CONDENSATION PAR EAU - WASSERKÜHLUNG

Kg.

23

22

21

20

19

18

17

16

15

14

13

PRODUZIONE GHIACCIO PER 24 ORE - ICE PRODUCED PER 24 HRS.

PRODUZIONE GHIACCIO PER 24 ORE - ICE PRODUCED PER 24 HRS.

TEMPERATURA ACQUA - WATER TEMPERATURE

TEMPÉRATURE DE L'EAU - WASSERTEMPERATUR

PRODUCTION DE GLACE PAR 24 HEURES - EISWÜRFELPRODUKTION IN 24 STD.

RAFFREDDAMENTO AD ACQUA - WATER COOLED MODELS

CONDENSATION PAR EAU - WASSERKÜHLUNG

Kg.

28

27

26

25

24

23

22

21

20

19

18

17

16

PRODUCTION DE GLACE PAR 24 HEURES - EISWÜRFELPRODUKTION IN 24 STD.

15

14

TEMPERATURA ACQUA - WATER TEMPERATURE

TEMPÉRATURE DE L'EAU - WASSERTEMPERATUR

21 15

27 21 15 103232

°C

10

21

32

38

°C

10

21

32

38

TEMPERATURA AMBIENTE - AMBIENT TEMPERATURE

TEMPERATURA AMBIENTE - AMBIENT TEMPERATURE

TEMPÉRATURE AMBIANT - RAUMTEMPERATUR

TEMPÉRATURE AMBIANT - RAUMTEMPERATUR

RAFFREDDAMENTO AD ARIA - AIR COOLED MODELS

CONDENSATION PAR AIR - LUFTKÜHLUNG

Kg.

42

40

38

36

34

32

30

28

26

24

22

PRODUZIONE GHIACCIO PER 24 ORE - ICE PRODUCED PER 24 HRS.

PRODUCTION DE GLACE PAR 24 HEURES - EISWÜRFELPRODUKTION IN 24 STD.

27 15

32

TEMPERATURA ACQUA - WATER TEMPERATURE

TEMPÉRATURE DE L'EAU - WASSERTEMPERATUR

°C

10

21

32

38

TEMPERATURA AMBIENTE - AMBIENT TEMPERATURE

TEMPÉRATURE AMBIANT - RAUMTEMPERATUR

40

RAFFREDDAMENTO AD ACQUA - WATER COOLED MODELS

CONDENSATION PAR EAU - WASSERKÜHLUNG

Kg.

42

40

38

36

34

32

30

28

26

24

22

32

PRODUZIONE GHIACCIO PER 24 ORE - ICE PRODUCED PER 24 HRS.

TEMPÉRATURE DE L'EAU - WASSERTEMPERATUR

PRODUCTION DE GLACE PAR 24 HEURES - EISWÜRFELPRODUKTION IN 24 STD.

27 211021

TEMPERATURA ACQUA - WATER TEMPERATURE

15 10

°C

10

21

32

38

TEMPERATURA AMBIENTE - AMBIENT TEMPERATURE

TEMPÉRATURE AMBIANT - RAUMTEMPERATUR

Page 11

l)

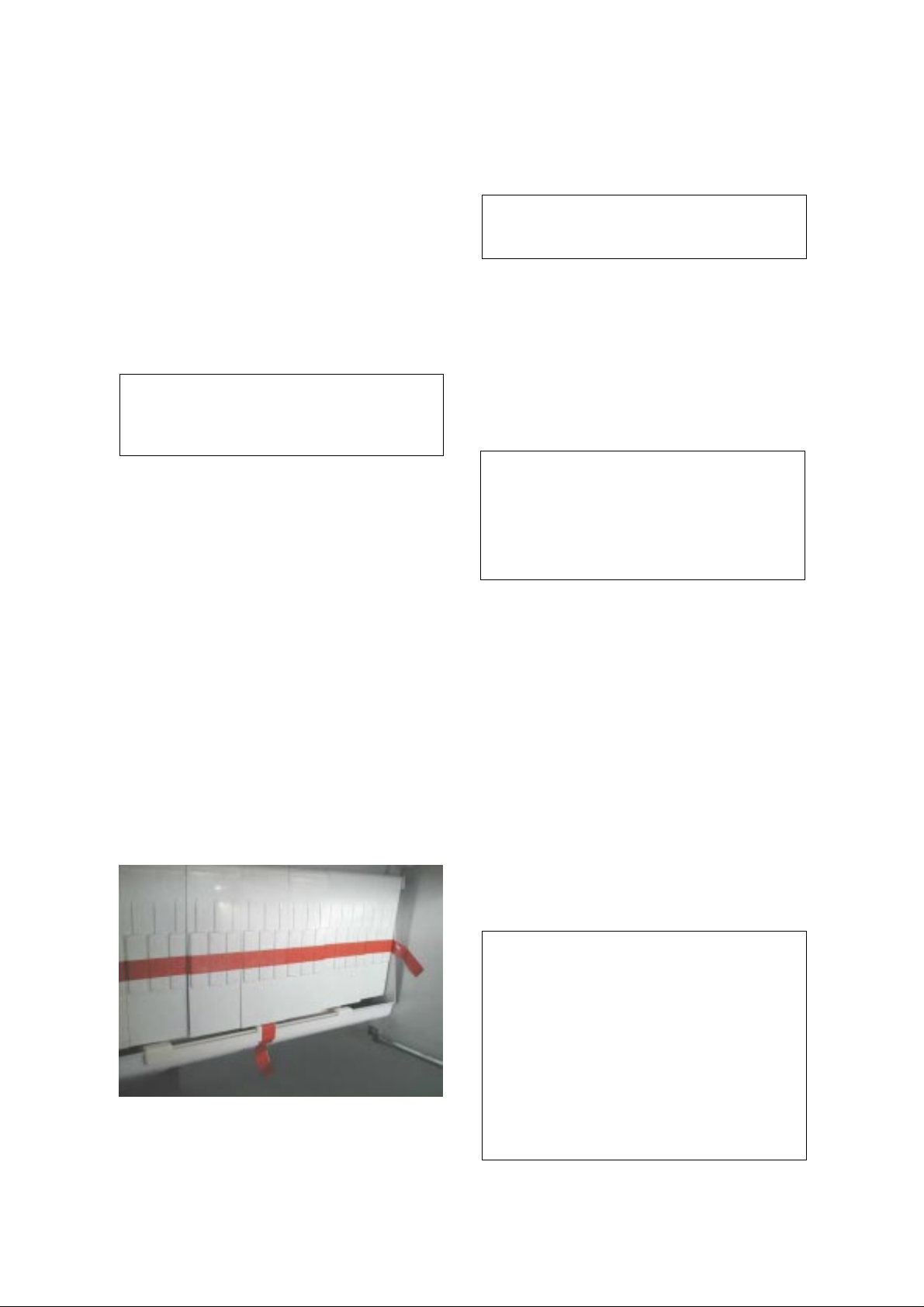

Capacità di produzione - Ice making capacity - Capacité de production - Eisproduktionskapazität

RAFFREDDAMENTO AD ARIA - AIR COOLED MODELS

CONDENSATION PAR AIR - LUFTKÜHLUNG

Kg.

50

48

46

44

42

40

38

36

34

32

30

32

PRODUZIONE GHIACCIO PER 24 ORE - ICE PRODUCED PER 24 HRS.

PRODUCTION DE GLACE PAR 24 HEURES - EISWÜRFELPRODUKTION IN 24 STD.

TEMPÉRATURE DE L'EAU - WASSERTEMPERATUR

RAFFREDDAMENTO AD ARIA - AIR COOLED MODELS

Kg.

75

70

65

60

55

27 21 15 10

TEMPERATURA ACQUA - WATER TEMPERATURE

CONDENSATION PAR AIR - LUFTKÜHLUNG

°C

10

21

32

38

°C

10

21

32

38

TEMPERATURA AMBIENTE - AMBIENT TEMPERATURE

TEMPÉRATURE AMBIANT - RAUMTEMPERATUR

50

65

RAFFREDDAMENTO AD ACQUA - WATER COOLED MODELS

CONDENSATION PAR EAU - WASSERKÜHLUNG

Kg.

50

48

46

44

42

40

38

36

34

32

30

32

PRODUZIONE GHIACCIO PER 24 ORE - ICE PRODUCED PER 24 HRS.

PRODUCTION DE GLACE PAR 24 HEURES - EISWÜRFELPRODUKTION IN 24 STD.

TEMPÉRATURE DE L'EAU - WASSERTEMPERATUR

RAFFREDDAMENTO AD ACQUA - WATER COOLED MODELS

Kg.

75

70

65

60

55

27 21 15 10

TEMPERATURA ACQUA - WATER TEMPERATURE

CONDENSATION PAR EAU - WASSERKÜHLUNG

°C

10

21

32

38

°C

10

21

32

38

TEMPERATURA AMBIENTE - AMBIENT TEMPERATURE

TEMPÉRATURE AMBIANT - RAUMTEMPERATUR

50

45

40

32

PRODUZIONE GHIACCIO PER 24 ORE - ICE PRODUCED PER 24 HRS.

PRODUCTION DE GLACE PAR 24 HEURES - EISWÜRFELPRODUKTION IN 24 STD.

TEMPÉRATURE DE L'EAU - WASSERTEMPERATUR

RAFFREDDAMENTO AD ARIA - AIR COOLED MODELS

Kg.

85

80

75

70

65

60

55

50

27 21 15 10

TEMPERATURA ACQUA - WATER TEMPERATURE

CONDENSATION PAR AIR - LUFTKÜHLUNG

32

27 21 15 10

°C

10

21

32

38

PRODUZIONE GHIACCIO PER 24 ORE - ICE PRODUCED PER 24 HRS.

TEMPERATURA ACQUA - WATER TEMPERATURE

PRODUCTION DE GLACE PAR 24 HEURES - EISWÜRFELPRODUKTION IN 24 STD.

TEMPÉRATURE DE L'EAU - WASSERTEMPERATUR

TEMPERATURA AMBIENTE - AMBIENT TEMPERATURE

TEMPERATURA AMBIENTE - AMBIENT TEMPERATURE

TEMPÉRATURE AMBIANT - RAUMTEMPERATUR

TEMPÉRATURE AMBIANT - RAUMTEMPERATUR

90

50

45

40

32

PRODUZIONE GHIACCIO PER 24 ORE - ICE PRODUCED PER 24 HRS.

PRODUCTION DE GLACE PAR 24 HEURES - EISWÜRFELPRODUKTION IN 24 STD.

TEMPÉRATURE DE L'EAU - WASSERTEMPERATUR

RAFFREDDAMENTO AD ACQUA - WATER COOLED MODELS

Kg.

85

80

75

70

65

60

55

50

27 21 15 10

TEMPERATURA ACQUA - WATER TEMPERATURE

CONDENSATION PAR EAU - WASSERKÜHLUNG

32

27 21 15 10

°C

10

21

32

38

PRODUZIONE GHIACCIO PER 24 ORE - ICE PRODUCED PER 24 HRS.

TEMPERATURA ACQUA - WATER TEMPERATURE

PRODUCTION DE GLACE PAR 24 HEURES - EISWÜRFELPRODUKTION IN 24 STD.

TEMPÉRATURE DE L'EAU - WASSERTEMPERATUR

TEMPERATURA AMBIENTE - AMBIENT TEMPERATURE

TEMPERATURA AMBIENTE - AMBIENT TEMPERATURE

TEMPÉRATURE AMBIANT - RAUMTEMPERATUR

TEMPÉRATURE AMBIANT - RAUMTEMPERATUR

Page 12

Page 1

GENERAL INFORMATION

AND INSTALLATION

A. INTRODUCTION

These Cubers are quality designed, engineered

and manufactured.

Their ice making systems are thoroughly tested

providing the utmost in flexibility to fit the needs

of a particular user.

These ice makers have been engineered to our

own rigid safety and performence standards.

NOTE.

built into this icemaker, it is important that

installation and maintenance be conducted

in the manner outlined in this manual.

B. UNPACKING AND INSPECTION

1. Visually inspect the exterior of the packing

and skid. Any severe damage noted should be

reported to the delivering carrier and a concealed

damage claim form filled in subjet to inspection of

the contents with the carrier’s representative

present.

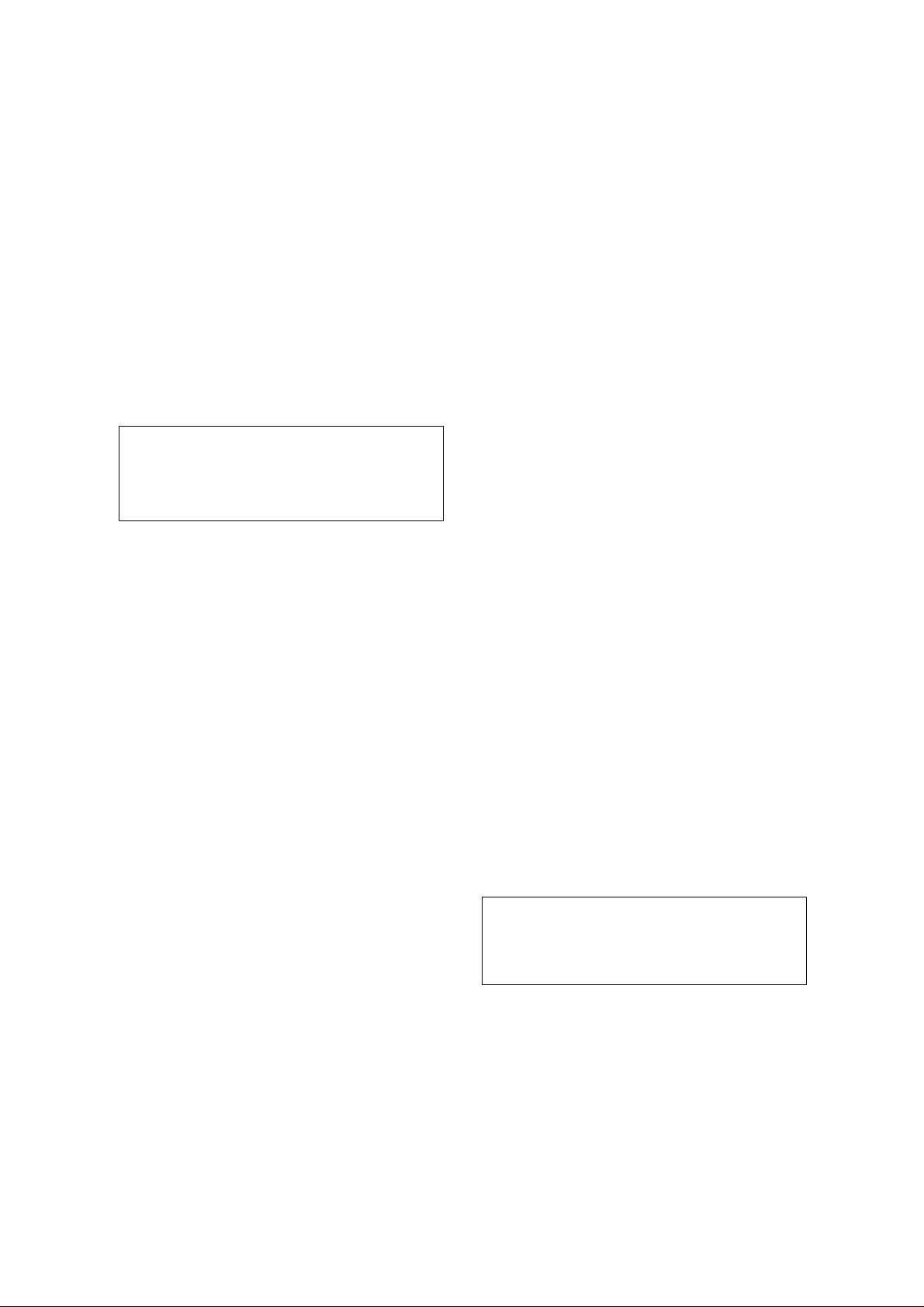

2. a) Cut and remove the plastic strip securing

the carton box to the skid.

the polystyre protection sheet.

corners and then remove the carton.

3. Remove the front and the rear panels of the

unit and inspect for any concealed damage.

Notify carrier of your claim for the concealed

damage as stated in step 1 above.

4. Open the bin door and remove all internal

support packing and masking tape.

To retain the safety and performance

b) Cut open the top of the carton and remove

c) Pull out the polystyre posts from the

7. See data plate on the rear side of the unit

and check that local main voltage corresponds

with the voltage specified on it.

CAUTION. Incorrect voltage supplied to

the icemaker will void your parts

replacement program.

8. Remove the manufacturer’s registration

card from the inside of the User Manual and fillin all parts including: Model and Serial Number

taken from the data plate.

Forward the completed self-addressed

registration card to the factory.

C. LOCATION AND LEVELLING

WARNING. This Ice Cuber is designed for

indoor installation only. Extended periods

of operation at temperatures exceeding

the following limitations will constitute

misuse under the terms of the

Manufacturer’s Limited Warranty

resulting in LOSS of warranty coverage.

1. Position the unit in the selected permanent

location.

Criteria for selection of location include:

a) Minimum room temperature 10°C (50°F)

and maximum room temperature 40°C (100°F).

b) Water inlet temperatures: minimum 5°C

(40°F) and maximum 35°C (90°F).

c) Well ventilated location for air cooled

models. Clean the air cooled condenser at

frequent intervals.

d) Service access: adequate space must

be left for all service connections through the rear

of the ice maker. A minimum clearance of 15 cm

(6") must be left at the sides of the unit for routing

cooling air drawn into and exhausted out of the

compartment to maintain proper condensing

operation of air cooled models.

5. Check that refrigerant lines do not rub

against or touch other lines or surfaces, and that

the fan blade moves freely.

6. Use clean damp cloth to wipe the surfaces

inside the storage bin and the outside of the

cabinet.

NOTE.

With the unit in “built-in” conditions,

the ice production is gradually reduced in

respect to the levels shown in the graph, up

to a maximum of 10% at room temperatures

higher than 32°C.

The daily ice-making capacity is directly

related to the condenser air inlet temperature, water temperature and age of the machine.

To keep your CUBER at peak performance

levels, periodic maintenance checks must

be carried out as indicated on Cleaning

Section of this manual.

2. Level the unit in both the left to right and

front to rear directions.

Page 13

Page 2

D. ELECTRICAL CONNECTIONS

See data plate for current requirements to

determine wire size to be used on electrical

connections. All icemakers require a solid earth

wire.

The ice machines are supplied from the factory

completely pre-wired and require only electrical

power connections to wire cord provided on the

back of the unit.

Make sure that the ice machine is connected to

its own circuit and individually fused (see data

plate for fuse size).

The maximum allowable voltage variation should

not exceed -10% and +10% of the data plate

rating. Low voltage can cause faulty functioning

and may be responsible for serious damage to

the overload switch and motor windings.

NOTE.

All external wiring should conform to

national, state and local standards and

regulations.

Check voltage on the line and the ice maker’s

data plate before connecting the unit.

E. WATER SUPPLY AND DRAIN

CONNECTIONS

General

When choosing the water supply for the ice cuber

consideration should be given to:

a) Length of run

b) Water clarity and purity

c) Adequate water supply pressure

Since water is the most important single ingredient

in producting ice you cannot emphasize too

much the three items listed above.

Low water pressure, below 1 bar may cause

malfunction of the ice maker unit.

Water containing excessive minerals will tend to

produce cloudy coloured ice cubes, plus scale

built-up on parts of the water system.

fitting and a shut-off valve installed in an

accessible position between the water supply

line and the unit.

Water supply - Water cooled models

(65-90)

The water cooled versions of series 65 and 90

require two separate inlet water supplies, one for

the water sprayed for making the ice cubes and

the other for the water cooled condenser.

Connect the 3/4" male fitting of the water

regulating valve using the flexible hose supplied

with the unit to the cold water supply line with

regular plumbing fitting and a shut-off valve

installed in an accessible position between the

water supply line and the unit.

Water drain

The recommended drain tube is a plastic or

flexible tube with 18 mm (3/4") I.D. runs to an

open trapped and vented drain. When the drain

is a long run, allow 3 cm pitch per meter (1/4"

pitch per foot).

A vertical open vent, at the unit drain connection,

is also required for proper sump drainage.

Water drain - Water cooled models

The water drain line from the condenser, on

water cooled versions, is internally connected

with the drain fitting of the unit.

It is strongly recommended therefore to install a

vertical open vent on unit drain line high point to

ensure good draining and to direct the drain line

to a trapped and vented floor drain receptacle.

This to make sure of the proper flow of the

drained water as, in case of poor drainage, the

water ranning out from the condenser may

inopportunely flow, through the unit drain tubing,

into the ice storage bin.

Water supply

Connect the 3/4" male fitting of the solenoid

water inlet valve, using the flexible hose supplied,

to the cold water supply line with regular plumbing

NOTE.

The water supply and the water drain

must be installed to conform with the local

code. In some case a licensed plumber and/

or a plumbing permit is required.

Page 14

Page 3

F. FINAL CHECK LIST

1. Is the unit in a room where ambient

temperatures are within a minimum of 10°C

(50°F) even in winter months?

2. Is there at least a 15 cm (6") clearance

around the unit for proper air circulation?

3. Is the unit level? (IMPORTANT)

4. Have all the electrical and plumbing

connections been made, and is the water supply

shut-off valve open?

5. Has the voltage been tested and checked

against the data plate rating?

6. Has the water supply pressure been

checked to ensure a water pressure of at least

G. INSTALLATION PRACTICE

1 bar (14 psi).

7. Check all refrigerant lines and conduit lines

to guard against vibrations and possible failure.

8. Have the bin liner and cabinet been wiped

clean?

9. Has the owner/user been given the User

Manual and been instructed on the importance of

periodic maintenance checks?

10. Has the Manufacturer’s registration card

been filled in properly? Check for correct model

and serial number against the serial plate and

mail the registration card to the factory.

11. Has the owner been given the name and the

phone number of the authorized Service Agency

serving him?

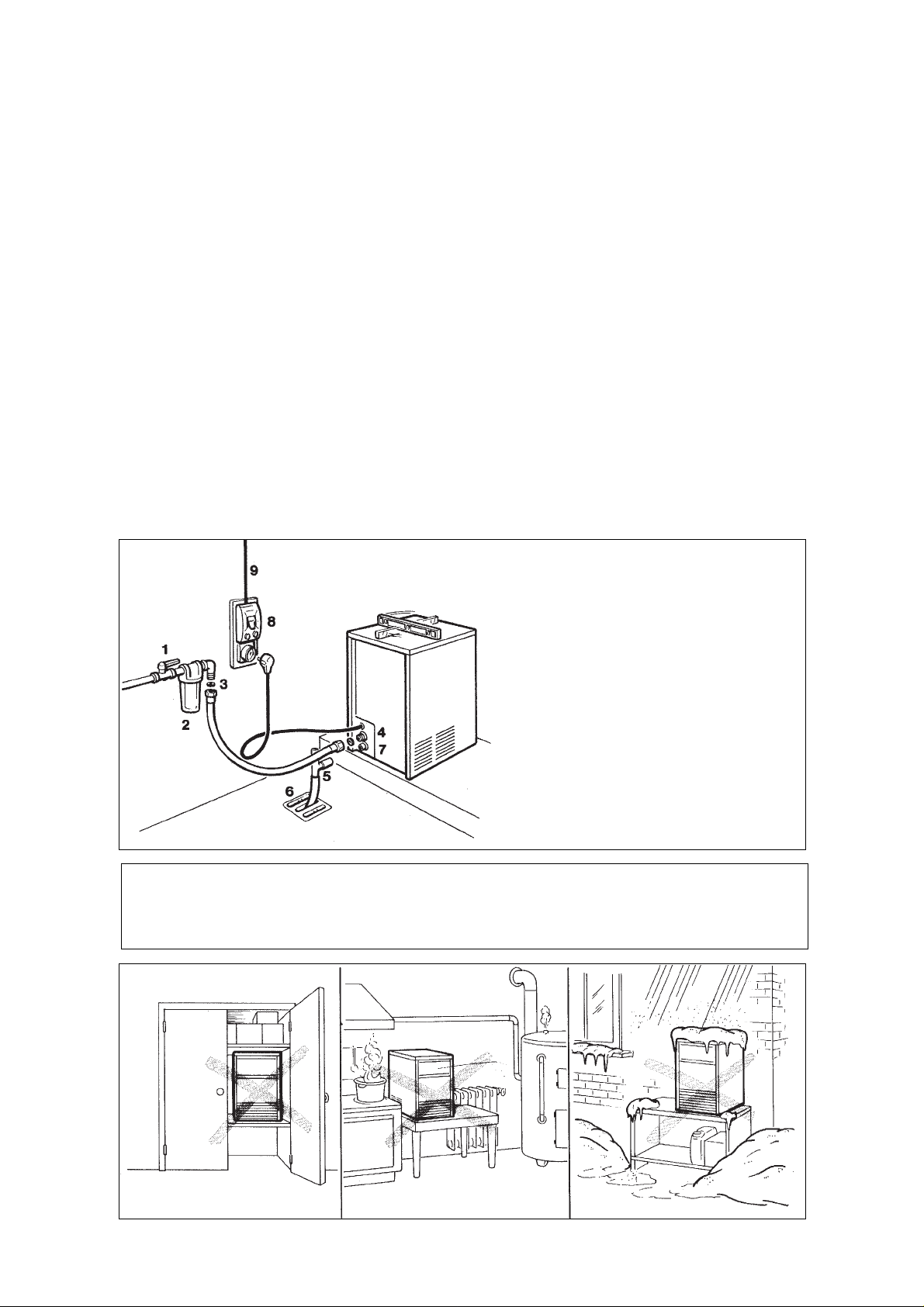

1. Hand shut-off valve

2. Water filter

3. Water supply line (flexible hose)

4. 3/4" male fitting

5. Vented drain

6. Open trapped vented drain

7. Drain fitting

8. Main switch

9. Power line

WARNING. This icemaker is not designed for outdoor installation and will not function in

ambient temperatures below 10°C (50°F) or above 40°C (100°F).

This icemaker will malfunction with water temperatures below 5°C (40°F) or above 35°C

(90°F).

Page 15

Page 4

OPERATING INSTRUCTIONS

START UP

After having correctly installed the ice maker and

completed the plumbing and electrical

connections, perform the following “Start-up” procedure.

18-21-31-40

A. Remove the unit front panel and locate the

cleaning switch on the control box.

B. Set the cleaning switch in the cleaning

position (II). This will close the electrical circuit to

the water inlet valve and to the hot gas valve.

C. Switch ON the power line disconnect

switch. Unit will start up in water filling phase

mode.

During this phase the components energized

are:

WATER INLET SOLENOID VALVE

HOT GAS SOLENOID VALVE

The Water pump and the Fan motor are also in

operation.

D. Set the master switch to the ON position.

The compressor switch must stay in the OFF

position. This will close the electrical circuit to the

water inlet valve and to the hot gas valve.

E. Switch ON the power line disconnect

switch. Unit will start up in defrost cycle mode.

During this cycle the components energized are:

WATER INLET SOLENOID VALVE

HOT GAS SOLENOID VALVE

TIMER MOTOR

F. After completion of harvest cycle (about

three minutes) move the compressor switch to

ON position.

NOTE.

During the defrost cycle, the water

inlet solenoid valve is energized. The water

flows through the valve to the back side of the

evaporator platen and then down to fill up the

icemaker sump tank for the next freezing

cycle.

D. Let unit stay in water filling phase mode for

about three/four minutes till water is coming out

from the drain hose, then move the cleaning

switch to the operation position (I).

50-65-90

A. Remove the unit front panel and locate the

timer shaft on the control box.

B. Check that master and the compressor

switch located on the lower left hand side of the

control box are both in the OFF position.

C. Rotate the timer shaft protruding through

the front of the control box clockwise, until and

audible click is heard indicating that the actuator

arm of the microswitch has dropped into the cam

slot (Fig. A).

OPERATIONAL CHECKS

A. The unit now starts its first freezing cycle

with the following components in operation:

COMPRESSOR

WATER PUMP

FAN MOTOR in air cooled version

B. Check to see through the ice discharge

opening that the spray system is correctly seated

and that the water jets uniformely reach the

interior of the inverted cup molds; also make sure

that the plastic curtain is hanging freely and there

is not excessive water spilling through it.

C. The ice making process takes place

thereby, with the water sprayed into the molds

that gets gradually refrigerated by the heat

exchanged with the refrigerant flowing into the

evaporator serpentine.

D. On units 18-21-31-40 when the evaporator

temperature reaches a preset value the

evaporator thermostat or cube size control

changes its contacts; the freezing cycle ends and

starts the defrost or harvest cycle.

E. On units 50-65-90 the time clock does not

rotate at the end of the harvest cycle. It starts

later when the cube size thermostat control bulb

(pig tail) located on the evaporator coil reaches a

temperature of approx. -15°C (5°F).

Page 16

Page 5

Freezing time will range between 20 and 22

minutes in a 21°C ambient temperature, longer if

above this temperature and shorter if below. The

average complete cycle time is between 23 and

25 minutes.

F. Check, during the first defrost/harvest

cycle, that the incoming water flows correctly into

the sump reservoir in order to re-fill it and the

surplus overflows through the overflow drain tube.

G. Check the texture of ice cubes just

released. Right size must have a small depression

(about 5-6 mm) in their crown.

If not, wait for the second defrost/harvest cycle

before performing any adjustment.

H. If required on model 18, 21, 31 and 40, the

length of the freezing cycle can be modified by

turning the knob of the cube size control or

evaporator thermostat located in front of the

control box until the desired size is achieved.

• If the temperature of the room in

which the machine

is place is below

20°C, the cubes will

tend to be partly

hollowed out (see

fig. on right).

• If, on the other

hand, the room

temperature is

above 30°C the

cubes produced

will have a jagged

rim of ice around

the crown.

It should, however, be remembered that if the

room temperature returns later to the 20 ÷ 30°C

range, the knob indicator must once again be

turned to point to the dot (see fig. below).

If the ice cubes are shallow and cloudy, it is

possible that the ice maker runs short of water

during the end of the freezing cycle or, the quality

of the supplied water requires the use of an

appropriate water filter or conditioner.

I. At the end of the defrost or harvest cycle

hold a handful of ice cubes against the bulb of the

storage bin thermostat; the icemaker switch OFF

in about one-two minutes.

Take out the ice from the storage bin thermostat.

The ice maker should restart automatically in

three-four minutes.

NOTE.

The bin thermostat is factory set at

1°C (35°F) OUT and 4°C (39°F) IN.

If it is thought necessary, the above situations

can be rectified by, in the first case, turning the

control knob (as little or as much as is required)

clockwise and, in the second case, turning the

knob to the right counterclockwise.

K. Re-fit the unit front panel then instruct the

owner/user on the general operation of the ice

machine and about the cleaning and care it

requires.

Page 17

Page 6

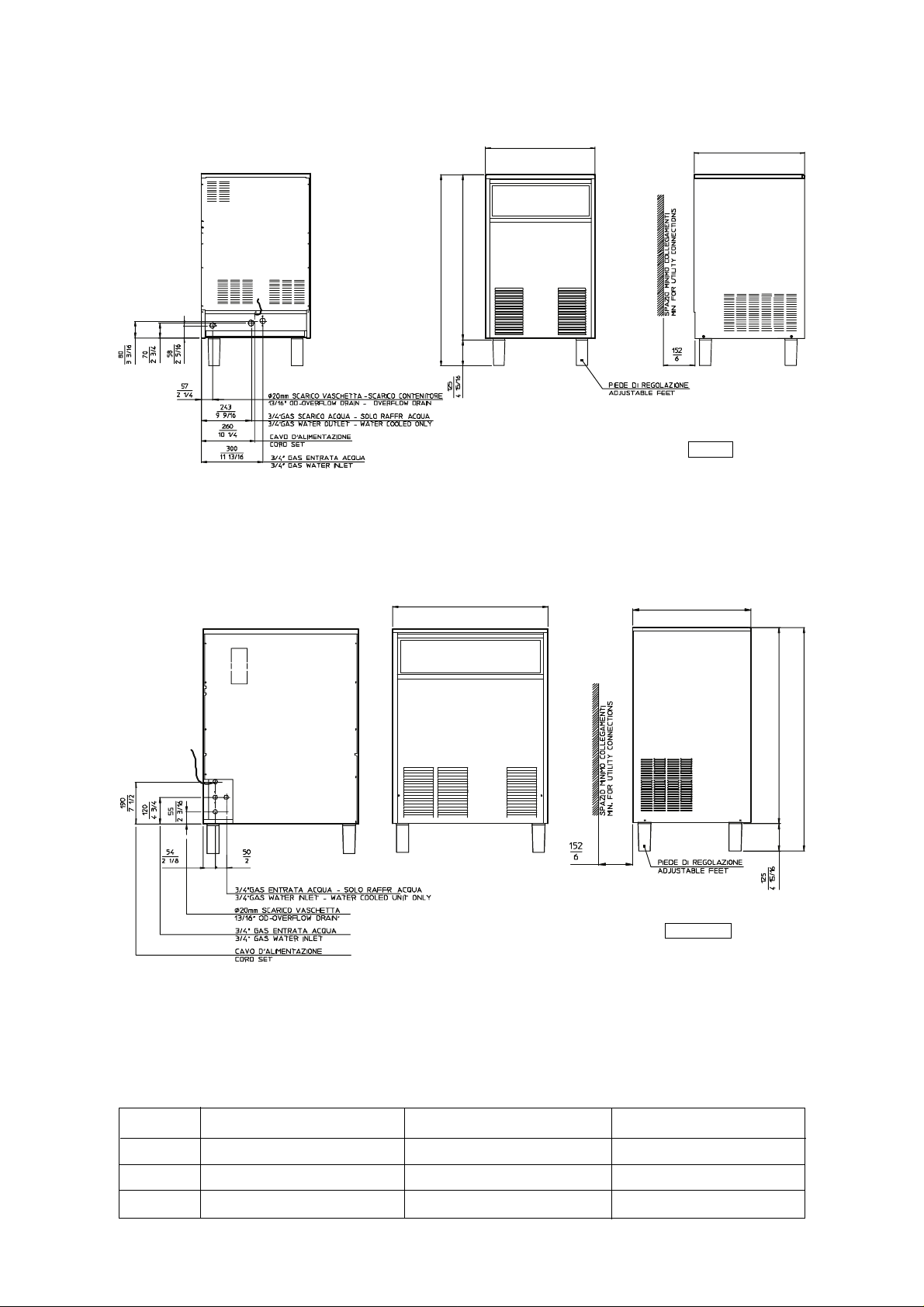

PRINCIPLE OF OPERATION

How it works

In the ice makers the water used to make the ice

is kept constantly in circulation by a water pump

which primes it to the spray system nozzles from

where it is diverted into the inverted cup molds of

the evaporator (Fig. A).

A small quantity of the sprayed water freezes into

ice; the rest of it cascades by gravity into the

sump assembly below for recirculation.

FREEZING CYCLE (Fig. B)

The hot gas refrigerant discharged out from the

compressor reaches the condenser where, being

cooled down, condenses into liquid. Flowing into

the liquid line it passes through the drier/filter,

then it goes all the way through the capillary tube

where it looses its pressure.

Next the refrigerant enters into the evaporator

serpentine (which has a larger diameter then the

capillary tube) and starts to boil off; this reaction

is emphasized by the heat transferred by the

sprayed water.

The refrigerant then increases in volume and

changes entirely into vapor.

The vapor refrigerant then passes through the

suction accumulator (used to prevent that any

small amount of liquid refrigerant may reach the

compressor) and through the suction line. In both

the accumulator and the suction line it exchanges

heat with the refrigerant flowing into the capillary

tube (warmer), before to be sucked in the

compressor and to be recirculated as hot

compressed refrigerant gas.

The freezing cycle on18-21-31-40 is controlled

by only the evaporator thermostat which has its

bulb in contact with the evaporator serpentine

while in 50-65-90 there is an second phase

controlled by a timer.

The electrical components in operation during

the freezing cycle are:

COMPRESSOR

WATER PUMP

FAN MOTOR (in air cooled version)

On 18-21-31-40 air cooled versions the refrigerant

head pressure is gradually reduced from a value

of approx. 11 bars (155 psig) at the beginning of

the freezing cycle with the unit at 21°C (70°F)

ambient temperature, to a minimun value of

approx. 7 bars (100 psig) just at the end of the

freezing cycle few seconds before the starting of

the defrost cycle.

On 50-65-90 air cooled versions the refrigerant

head pressure is kept between two pre-set values

(10÷8,5 bar - 140÷ 120 psig) with the unit a 21°C

(70°F) ambient temperature.

The declining of the pressure is relied to the

reduction of the evaporating pressure, caused

by the progressive growth of the ice thickness

into the inverted cup molds and to the flow of air

drown through the air cooled condenser by the

fan motor. The above values are in relation as

well to the ambient temperature of the ice maker

site and they are subject to rise with the increase

of this temperature.

On 18-21-31-40-50 water cooled versions the

refrigerant head pressure ranges between 8.5

and 10 bars (120÷140 psig) being controlled by

an automatic hi pressure control that energizes a

water solenoid valve located on the water line to

the condenser, which rates the cooling water to

the condenser.

On 65-90 water cooled versions the head

pressure is constant at 9.5 bar (135 psig)

controlled by a water regulating valve.

At starting of freezing cycle the refrigerant suction

or lo-pressure lowers rapidly to 1.0 bar - 14 psig

then it declines gradually - in relation with the

growing of the ice thickness - to reach, at the end

of the cycle, approx. 0÷0.1 bar - 0÷1.5 psig on

the models 18, 21, 31 and 40 and 0.2÷0.3 bar

(3÷4 psig) on models 50, 65 and 90 with the

cubes fully formed in the cup molds.

The total length of the freezing cycle ranges from

23 to 25 minutes.

DEFROST OR HARVEST CYCLE (Fig. D)

On 18-21-31-40 the temperature of the evaporator

thermostat, in contact with the evaporator

serpentine, drops to a pre-set value it changes its

electrical contacts energizing the herebelow

shown components.

(On 50-65-90 when the timer microswitch drops

down into the lower portion of the cam it changes

its electrical contacts energizing the same

components).

COMPRESSOR

WATER INLET SOLENOID VALVE

HOT GAS SOLENOID VALVE

The incoming water, passing through the water

inlet valve and the flow control, runs over the

evaporator platen and then flows by gravity

through the dribbler holes down into the sump/

reservoir (Fig. C).

The water filling the sump/reservoir forces part of

the surplus water from the previous freezing

cycle to go out to the waste through the overflow

pipe. This overflow limits the level of the sump

water which will be used to produce the next

batch of ice cubes.

Meanwhile the refrigerant, as hot gas discharged

from the compressor, flows through the hot gas

valve directly into the evaporator serpentine bypassing the condenser.

The hot gas circulating into the serpentine of the

evaporator warms up the copper molds causing

the harvest of the ice cubes. The ice cubes,

released from the cups, drop by gravity onto a

slanted cube chute, then through a curtained

opening they fall into the storage bin.

Page 18

Page 7

On 18-21-31-40 when the temperature of the

evaporator thermostat bulb reaches the value of

+3÷4°C their electrical contacts move back to the

previous position activating a new freezing cycle

and deenergizing both the hot gas and the water

inlet valves (closed).

On 50-65-90 as soon as the timer microswitch

completes the bottom part of the cam and it is

pushed again, it activates a new freezing cycle

deenergizing both the hot gas and the water inlet

valves (closed).

NOTE. On models 18, 21, 31 and 40 the

length of the defrost/harvest cycle (not

adjustable) changes according to the

ambient temperature (shorter for hi ambient

temperature and longer for low one).

COMPONENTS DESCRIPTION

A. WATER PUMP

The water pump operates continually throughout

the freezing cycle. The pump primes the water

from the sump to the spray system and through

the spray nozzles sprays it into the inverted cup

molds to be frozen into crystal clear ice cubes.

B. WATER INLET SOLENOID VALVE -

3/4 MALE FITTING

The water inlet solenoid valve is energized only

during the defrost cycle.

When energized it allows a metered amount of

incoming water to flow over the evaporator cavity

to assist the hot gas in defrosting the ice cubes.

The water running over the evaporator cavity

drops by gravity, through the dribbler holes of the

platen, into the sump reservoir.

On 18-21-31-40-50 water cooled versions the

water inlet solenoid valve has one inlet and two

outlets with two separate solenoids energized

the first (ice productioon) by the contacts 3-2 of

the evaporator thermostat and the second (water

cooled condenser) by a specific hi pressure

control.

C. HOT GAS SOLENOID VALVE

The hot gas solenoid valve consists basically in

two parts: the valve body and the valve coil.

During the defrost cycle the hot gas valve coil is

activated so to attract the hot gas valve piston in

order to give way to the hot gas discharged from

compressor to flow directly into the evaporator

serpentine to defrost the formed ice cubes.

D. BIN THERMOSTAT

The bin thermostat control body is located in the

front of control box behind the front panel.

The thermostat sensing tube is located into a

bulb holder on the side wall of the ice storage bin

where it automatically shuts the icemaker OFF

when in contact with the ice and re-starts the

icemaker when the ice is removed. Factory

settings are 1°C (35°F) OUT and 4°C (39°F) IN.

E. CUBE SIZE CONTROL (EVAPORATOR

THERMOSTAT)

18-21-31-40

The cube size control (evaporator thermostat)

body is located in the control box behind the front

panel; it’s basically a reverse acting temperature

control which closes the contacts 3-2 when its

temperature decreases and closes the opposite

contacts 3-4 when the temperature rises.

The thermostat sensing bulb is located into a

plastic tube (bulb holder) secured by two clips

directly to the evaporator serpentine.

This control determines the length of the freezing

cycle and correspondingly the size of the cubes.

A lower setting will produce a larger cube

(oversize) while a higher setting a smaller cuber

(shallow size).

When closed on contacts 3-2 it activates the

defrost or harvest cycle components.

The cube size control is set up in the factory

(knob in the black dot position) and doesn't

require any adjustment when the ambient

temperature remains between 20 and 30°C

(70 and 90°F).

50-65-90

The evaporator thermostat with its sensing bulb

intimately in contact with the regrigerant outlet

tube from the evaporator senses the evaporating

refrigerant temperature (which declines in the

course of the freezing cycle) and when this one

reaches the pre-set value, it switches its contacts

from 3-4 to 3-2 to activate the finishing cycle (2nd

phase) which has a pre-set extension determined

by the large diameter lobe of the timer cam.

F. FAN MOTOR (Air cooled version)

The fan motor on 18-21-31-40 is electrically

connected in parallel to the water pump and it

operates continuously only during the freezing

cycle keeping the proper head pressure by

circulating air through the condenser fins.

On 50-65-95 the operation of fan motor is

controlled by a fan pressure control adjusted at

preset values.

G. COMPRESSOR

The hermetic compressor is the heart of the

refrigerant system and it is used to circulate and

retrieve the refrigerant throughout the entire

system. It compresses the low pressure

refrigerant vapor causing its temperature to rise

and become high pressure hot vapor (hot gas)

which is then released through the discharge

valve.

H. WATER SPRAY SYSTEM

Through its nozzles it sprays the water in each

individual cup to be frozen into ice.

I.

SAFETY HI TEMPERATURE THERMOSTAT

Located in the control box it is a manual reset

switch that trips OFF the operation of the machine

when its bulb (located on the liquid line just

before the drier) reaches the temperature of

70°C (158°F).

Page 19

Page 8

J. CLEANING SWITCH (only 18-21-31-40)

Located on the bottom left side of the control box

is used to energize the water inlet and the hot gas

valves so to charge the water into the sump tank

of the machine.

K. HI PRESSURE CONTROL (Water cooled

version)

Used only on 18-21-31-40-50 water cooled

versions it operates to keep between 8.5 and 10

bars (120 ÷ 140 psig) the hi-side or discharge

pressure of the refrigerant system by energizing

the coil of the water inlet solenoid valve that

control the cooling water flow to the condenser.

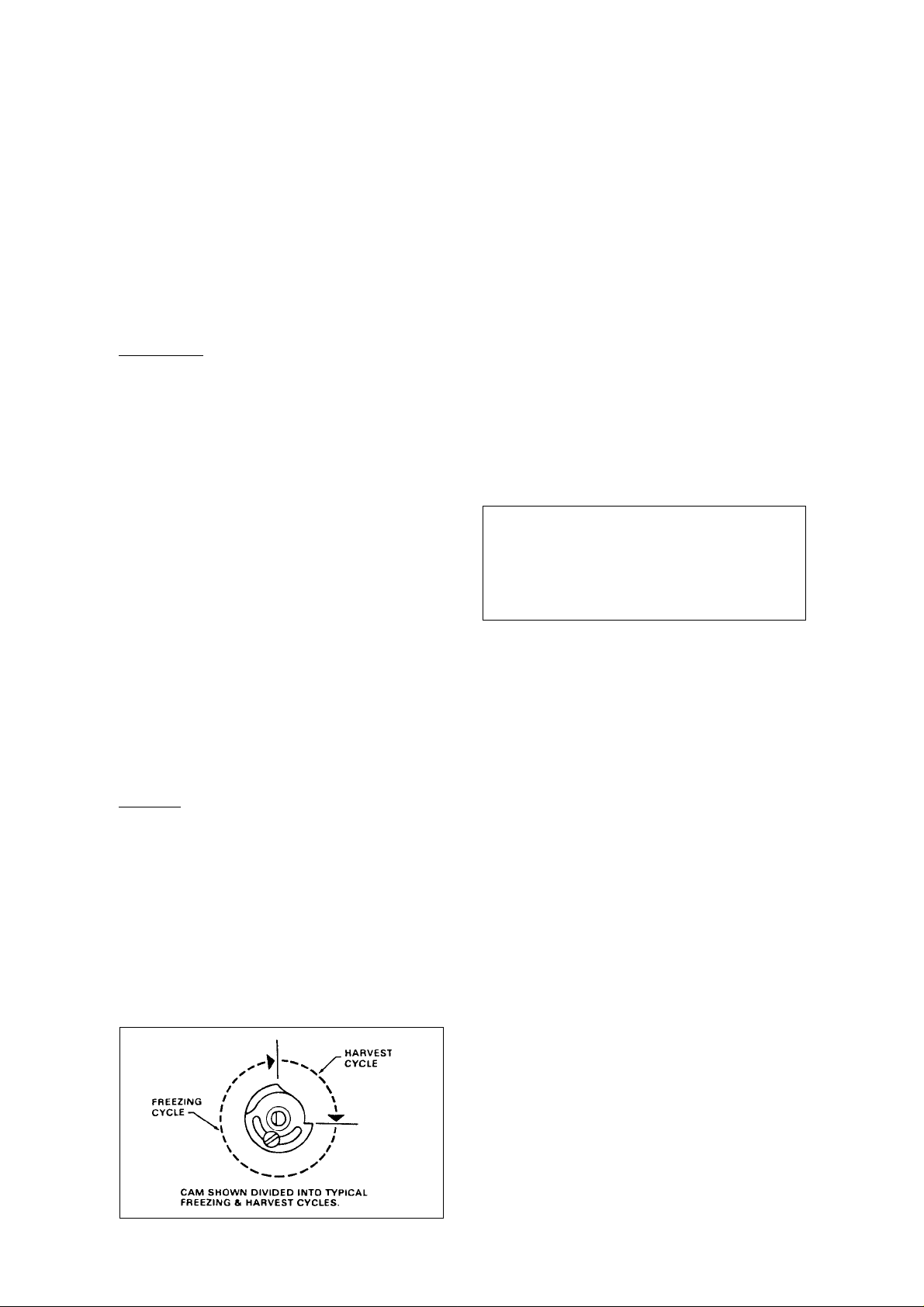

L. TIMER (only 50-65-90)

Equipped with two microswitches which plungers

ride one timer cam, the timer is located inside the

control box.

The function of the timer begins when activated

by the cube size control (evap. thermostat).

The large diameter lobe of its cam determines

the length of the 2nd portion of the freezing cycle,

while the cam small diameter lobe, determines

the time cycle for the harvest sequence.

The timer cam can be adjusted to vary the defrost

time as required.

WARNING. Never set the defrost time for

longer than 4 minutes as this will

jeopardize the compressor motor

windings.

Consequently any variation made at the timer

cam setting requires a compensation adjustment,

very fine and very accurate, of the evaporator

thermostat.

M. MASTER SWITCH (only 50-65-90)

Fitted in the control box the master switch has to

be used to start-up and to stop the ice maker

operation.

N. COMPRESSOR SWITCH (only 50-65-90)

Located in the control box is used to de-energized

the compressor during the cleaning.

O. FAN PRESSURE CONTROL

(only 50-65-90)

Used on air cooled ice makers to maintain the

head pressure within the preset values.

P. WATER REGULATING VALVE

(only 65-90 Water cooled version only)

This valve controls the head pressure in the

refrigerant system by regulating the flow of water

going to the condenser.

As pressure increases, the water regulating valve opens to increase the flow of cooling water.

It goes without saying that an extension of the

defrost period will directly reduce the timed portion

of the freezing cycle and viceversa.

Q. CONTACTOR (65-90 only)

It operates in order to close or open the electrical

circuit to the compressor.

Page 20

MAINTENANCE AND CLEANING INSTRUCTIONS

Page 9

CLEANING INSTRUCTIONS OF WATER

SYSTEM

1. Remove the front and top panels to gain

access either to the control box and to the

evaporator.

2. Make sure that all ice cubes have been

released from their cups, then switch OFF the

machine at main power switch, on models 18-2131-40, and on compressor and master switches

on models 50-65-90.

3. Scoop out all the ice cubes stored into the

bin in order to prevent them from being

contaminated with the cleaning solution.

4. On 18-21-31 remove the plastic cup located

on the bottom of sump/freezing chamber to drain

out all water and scale deposits.

5. Remove the curtain then, using a bottle,

poor fresh water into the bottom of the sump/

freezing chamber to clean out any possible scale

deposit.

6. Install again the curtain as well as the

bottom plastic cup.

Allow the ice maker to operate for about 20

minutes. Then turn the cleaning toggle switch to

the "cleaning" position (II) till the release of the

ice cubes from their cups.

NOTE.

The amount Cleaner and the time

needed for the cleaning of water system

depends of the water conditions.

2. Turn the cube size control knob

counterclockwise to the OFF position to shut-off

the ice maker then flush out the cleaning solution

from the sump reservoir then pour onto the

evaporator cavity two or three liters of clean

potable water to rinse the mold cups and the

platen.

3. If necessary remove the water spray platen

to clean it separately.

7. On all other models, flush out the water from

the sump reservoir by removing the overflow

stand pipe.

8. Prepare the cleaning solution by diluting in

a plastic container one or two liters of warm water

(45°-50°C) with a 0,1-0,2 liters of Ice Machine

Cleaner (on 18-21-31-40) and 0,2-0,3 liters on

50-65-90.

WARNING. The Ice Machine Cleaner

contains Phosphoric and Hydroxyacetic

acids.

These compounds are corrosive and may

cause burns if swallowed, DO NOT induce vomiting. Give large amounts of water

or milk. Call Physician immediately.

In case of external contact flush with

water. KEEP OUT OF THE REACH OF

CHILDREN.

9. Remove the evaporator cover then slowly

pour onto the evaporator platen the cleaning

solution. With the help of a brush dissolve the

most resistant and remote scale deposits in the

platen.

18-21-31-40

1. On 18-21-31-40 switch ON again the

machine at main power switch to start the

icemaking process.

4. Turn again the cube size control knob to the

normal operating position (black dot). The water

pump is again in operation to circulate the water

in order to rinse the entire water system.

Do the operation as per steps 8 and 9 twice so to

be sure no more traces of descaling solution

remains into the sump.

Pour on the upper side of the evaporator platen

fresh water with a capfull of disinfectant solution

then turn again the machine in normal operating

mode so to sanitize all the water system for

approx. 10 minutes.

NOTE.

Do not mix descaling with disinfectant

solution to avoid the generation of a very

aggressive acid.

5. Flush out the disinfectant solution from the

sump reservoir then with the switch in "cleaning"

position, turn the cube size control knob to the

normal operating position.

When water starts overflowing through the

drain line, set the switch to "operation" position.

The unit is now ready to resume normal

operation.

Page 21

Page 10

50-65-90

1. On 50-65-90 slowly rotate the clock knob

clockwise with the aid of a screwdriver until the

microswitch actuator arm is at the start position of

the freezing cycle.

Immediately set the master switch to the ON

position. Leave the compressor switch in the

OFF position.

2. Allow the system to operate for about 20

minutes into the freezing cycle. No ice will be

produced because the compressor is not in

operation.

8. Pour on the upper side of the evaporator

platen fresh water with a capfull of disinfectant

solution then put again the master switch in ON

position so to sanitize all the water system for

approx. 10 minutes.

NOTE.

Do not mix descaling with

disinfectant solution to avoid the generation

of a very aggressive acid.

9. Flush out the disinfectant solution from

the sump reservoir.

Slowly rotate the time clock knob clockwise

until the microswitch actuator arm is in the

START position of the harvest cycle and then

set the master switch to the ON position. Let

the unit run normally through this part of the

cycle. When the defrost has been completed

rotate the time clock knob manually until the

defrost cycle starts again. Do this two times.

Once the water reservoir is properly filled up,

set the compressor switch to the ON position.

The unit is now ready to resume the normal

operation.

10. Place again the evaporator cover and the

unit service panels.

11. Place again the evaporator cover and the

unit service panels.

3. At the end of this period set the master

switch to the OFF position to shut off the icemaker.

4. Remove the overflow drain tube from its

seat to drain out all the cleaning solution and

most of the mineral concentration through the

drain tube and then replace it in its seat.

5. Pour onto the evaporator cavity two or three

liters of clean potable water to rinse the mold

cups and the platen.

6. If necessary remove the water spray platen

to clean it separately.

7. Set again the master switch in ON position.

The water pump is again in operation to circulate

the water in order to rinse the entire water

system.

12. At completion of the freezing and harvest

cycle make sure of proper texture and clearness

of the ice cubes and that, they do not have any

acid taste.

ATTENTION. In case the ice cubes are

cloudy-white and have an acid taste, melt

them immediately by pouring on them

some warm water. This to prevent that

somebody could use them.

13. Wipe clean and rinse the inner surfaces of

the storage bin.

REMEMBER.

To prevent the accumulation

of undesirable bacteria it is necessary to

sanitize the interior of the storage bin with an

anti-algae disinfectant solution every week.

Page 22

Pagina 11

INFORMAZIONI GENERALI

ED INSTALLAZIONE

A. INTRODUZIONE

I fabbricatori di ghiaccio in cubetti sono stati

progettati e costruiti con un elevato standard

qualitativo.

Essi vengono collaudati interamente per diverse

ore e sono in grado di assicurare il massimo

rendimento relativamente ad ogni particolare

uso e situazione.

NOTA.

caratteristiche di qualità e sicurezza di questo fabbricatore di ghiaccio si raccomanda,

nell’effettuare l’installazione e le operazioni

periodiche di manutenzione, di attenersi scrupolosamente a quanto prescritto in questo

manuale.

B. DISIMBALLAGGIO ED ISPEZIONE

1. Ispezionare visivamente l’imballo esterno

in cartone e il basamento in legno usati per la

spedizione. Qualsiasi danno evidente sull’imballo esterno deve essere riferito allo spedizioniere;

in questo caso, procedere ad ispezionare l’apparecchio con il rappresentante dello spedizioniere

presente.

2. a) Tagliare e rimuovere i nastri in plastica

che mantengono sigillato l’imballo di cartone.

togliere i fogli e gli angolari protettivi di polistirolo.

l’apparecchio.

3. Togliere il pannello frontale ed il pannello

posteriore dell’apparecchio ed ispezionare lo

stesso onde accertare se abbia subito danni.

Notificare allo spedizioniere eventuali danni subiti come riportato al punto 1.

4. Aprire lo sportello e togliere tutti i supporti

interni usati per la spedizione e i nastri adesivi di

protezione.

Per non compromettere o ridurre le

b) Aprire la parte superiore dell’imballo e

c) Sollevare l’intero cartone sfilandolo dal-

5. Controllare che le tubazioni del circuito

refrigerante non tocchino altre tubazioni o superfici, e che il ventilatore giri liberamente.

6. Usando un panno pulito e umido, pulire le

pareti interne del contenitore del ghiaccio e le

superfici esterne dell’apparecchio.

7. Osservare i dati riportati sulla targhetta

fissata alla parte posteriore del telaio vicino ai

raccordi idraulici ed elettrici, e verificare che il

voltaggio della rete elettrica disponibile corrisponda a quello riportato sulla targhetta dell’apparecchio.

ATTENZIONE. Un errato voltaggio dell’alimentazione elettrica annullerà automaticamente il vostro diritto alla garanzia.

8. Compilare la cartolina di garanzia posta

all’interno del Manuale d’Uso, segnando sia il

modello che il numero di serie dell’apparecchio

rilevandolo dalla targhetta fissata al telaio.

Spedire la cartolina debitamente compilata al

costruttore.

C. POSIZIONAMENTO E LIVELLAMENTO

ATTENZIONE. Questo fabbricatore di

ghiaccio è stato progettato per essere

installato all’interno di locali in cui la

temperatura ambiente non scenda mai al

di sotto di 10°C ne superi i 40°C.

Periodi prolungati di funzionamento a temperature al di fuori dei seguenti limiti

costituiscono cattivo uso secondo i termini di garanzia e fanno decadere automaticamente il vostro diritto alla garanzia.

1. Posizionare l’apparecchio nel luogo di installazione definitivo.

I criteri per la sua scelta sono:

a) Minima temperatura ambiente 10°C e

massima temperatura ambiente 40°C.

b) Temperature dell’acqua di alimentazio-

ne: minima 5°C massima 35°C.

c) Luogo ben aerato per assicurare un

efficace ventilazione all’apparecchio e quindi un

corretto funzionamento del condensatore.

d) Spazio adeguato per i collegamenti di

servizio previsti nella parte posteriore dell’apparecchio. Lasciare almeno 15 cm di spazio attorno

all’unità così da permettere una corretta ed efficace circolazione d’aria soprattutto nei modelli

raffreddati ad aria.

Page 23

Pagina 12

2. Livellare l’apparecchio in entrambe le direzioni, dall’anteriore alla posteriore e da sinistra a

destra mediante i piedini.

NOTA.

Questo fabbricatore di ghiaccio incorpora dei componenti delicati e di massima precisione pertanto bisogna evitargli urti

e scossoni violenti.

D. COLLEGAMENTI ELETTRICI

Osservare la targhetta dell’apparecchio così da

determinare, in funzione dell’amperaggio indicato, tipo e sezione del cavo elettrico da usarsi.

Tutti gli apparecchi sono muniti di un cavo di

alimentazione elettrica per cui si richiede un

collegamento dello stesso ad una linea elettrica

provvista di cavo di messa a terra e che faccia

capo ad un proprio interruttore magneto-termico

munito di fusibili adeguati, come indicato nella

targhetta di ogni singolo apparecchio.

La variazione massima di voltaggio consentita

non deve eccedere il 10% del valore di targa o

essere inferiore al 10% dello stesso. Un basso

voltaggio può causare un funzionamento anomalo e può essere la causa di seri danni alle

protezioni ed agli avvolgimenti elettrici.

NOTA.

Tutti i collegamenti esterni devono

essere fatti a regola d’arte in conformità con

quanto stabilito dalle norme locali da parte di

personale qualificato.

Prima di collegare il fabbricatore di ghiaccio alla

linea elettrica accertarsi ancora una volta che il

voltaggio dell’apparecchio, specificato sulla

targhetta, corrisponda al voltaggio misurato.

E. ALIMENTAZIONE IDRAULICA E

SCARICO

Premessa

Nella scelta dell’alimentazione idraulica al

fabbricatore di ghiaccio a cubetti si deve tenere

presente:

a) Lunghezza della tubazione

b) Limpidezza e purezza dell’acqua

c) Adeguata pressione dell’acqua di ali-

mentazione

Una bassa pressione dell’acqua di alimentazione, inferiore ad 1 bar, può causare dei disturbi di

funzionamento dell’apparecchio. L’uso di acque

contenenti una quantità eccessiva di minerali

darà luogo ad una produzione di cubetti di ghiaccio opachi e ad una notevole incrostazione delle

parti interne del circuito idraulico.

Alimentazione idraulica

Collegare il raccordo da 3/4 di pollice maschio

della valvola solenoide di ingresso acqua alla

linea di alimentazione idrica utilizzando il tubo in

plastica rinforzato del tipo alimentare atossico

fornito.

La linea di alimentazione idraulica deve essere

munita di un rubinetto di intercettazione posto in

un luogo accessibile nei pressi dell’apparecchio.

Alimentazione idraulica - Modelli raffreddati

ad acqua

Nei modelli raffreddati ad acqua la valvola di

ingresso acqua è dotata di due raccordi di uscita

uno collegato al condensatore, il secondo per la

produzione del ghiaccio.

Scarico acqua

Usare, come tubo di scarico, il tubo in plastica

rigida spiralato avente diametro interno di 18 mm.

fornito in dotazione

Lo scarico dell’acqua in eccesso avviene per

gravità; per avere un regolare deflusso è indispensabile che lo scarico disponga di una presa

d’aria e vada in un sifone aperto.

Scarico acqua - Modelli raffreddati ad acqua

Lo scarico dal condensatore, nei modelli raffreddati ad acqua, è raccordato internamente allo

scarico dell’apparecchio.

Prestare particolare attenzione a raccordare

correttamente lo scarico dell’apparecchio al sifone aperto del locale in quanto l’acqua scaricata

dal condensatore, qualora lo scarico non fosse

correttamente realizzato (pendenza inadeguata,

strozzature, ecc.) potrebbe ritornare all’interno

del contenitore del ghiaccio.

NOTA.

Tutti i collegamenti idraulici devono

essere eseguiti a regola d’arte in conformità

con le norme locali. In alcuni casi è richiesto

l’intervento di un idraulico patentato.

Page 24

Pagina 13

F. CONTROLLO FINALE

1. L’apparecchio è stato installato in un locale

dove la temperatura ambiente è di almeno 10°C

anche durante i mesi invernali?

2. Ci sono almeno 15 cm di spazio dietro ed ai

lati dell’apparecchio onde avere una efficace

ventilazione del condensatore?

3. L’apparecchio è ben livellato? (IMPORTANTE)

4. L’apparecchio è stato collegato alla linea di

alimentazione elettrica? É stato eseguito il collegamento alle tubazioni dell’acqua di alimentazione e di scarico?

5. É stato controllato il voltaggio della linea di

alimentazione elettrica? Corrisponde al voltaggio specificato sulla targhetta dell’apparecchio?

6. É stata controllata la pressione dell’acqua

di alimentazione in modo da assicurare all’apparecchio una pressione di ingresso di almeno 1

bar?

7. Controllare tutte le tubazioni del circuito

G. SCHEMA DI INSTALLAZIONE

refrigerante e del circuito idraulico verificando se

esistono vibrazioni o sfregamenti. Controllare

inoltre che le fascette stringitubo siano ben serrate e che i cavetti elettrici siano fermamente

collegati.

8. Sono stati controllati i bulloni di ancoraggio

del compressore? Permettono a questi di oscillare sui propri supporti?

9. Le pareti interne del contenitore del ghiaccio e le pareti esterne dell’apparecchio sono

state pulite?

10. É stato consegnato il libretto di istruzione e

sono state date al proprietario le istruzioni necessarie per il funzionamento e la manutenzione

periodica dell’apparecchio?

11. La cartolina di garanzia è stata compilata?

Controllare il numero di serie ed il modello sulla

targhetta dell’apparecchio, quindi spedirla al

costruttore.

12. É stato dato al proprietario il nome ed il

numero telefonico del servizio di assistenza tecnica autorizzato della zona?

1. Rubinetto di intercettazione

2. Filtro acqua

3. Linea di alimentazione idraulica

4. Raccordo da 3/4 di pollice

5. Scarico ventilato

6. Scarico acqua con sifone ventilato

7. Raccordo di scarico

8. Interruttore principale

9. Linea elettrica

ATTENZIONE. Questo fabbricatore di ghiaccio non è stato progettato per essere installato

all’aperto o per funzionare a delle temperature ambienti inferiori a 10°C o superiori a 40° C.

Lo stesso vale per la temperatura dell’acqua di alimentazione che non deve essere inferiore

a 5°C o superiore a 35°C.

Page 25

Pagina 14

ISTRUZIONI DI

FUNZIONAMENTO

AVVIAMENTO

Dopo aver correttamente installato l'apparecchio ed averlo collegato alla rete elettrica ed

idraulica, seguire la seguente procedura per

l'avviamento.

18-21-31-40

1. Togliere dal fabbricatore di ghiaccio il pan-

nello frontale e localizzare l'interruttore di lavaggio.

2. Spostare l'interruttore di lavaggio sulla posizione "Lava - II". Questo chiude il circuito

elettrico della valvola di ingresso dell'acqua e

della valvola gas caldo.

3. Spostare, a questo punto, l'interruttore posto sulla linea di alimentazione elettrica sulla

posizione ON (acceso). L'apparecchio partirà

nella fase di caricamento acqua con i seguenti

componenti in funzione:

VALVOLA INGRESSO ACQUA

VALVOLA GAS CALDO

Sono in funzione anche la Pompa ed il

Motoventilatore.

4. Lasciare funzionare la macchina nella fase

di caricamento acqua per circa tre - quattro

minuti fino ad avere dell'acqua allo scarico dell'apparecchio. Quindi spostare l'interruttore di

lavaggio sulla posizione "Funziona - I".

50-65-90

1. Togliere dal fabbricatore di ghiaccio il pannello frontale e localizzare la scatola elettrica.

2. Controllare che l'interruttore principale e

l'interruttore del compressore posti nella scatola

elettrica siano sulla posizione OFF (spento).

3. Ruotare il gambo del timer (fig. B) che

sporge dalla scatola elettrica, in senso orario

finchè si udirà un click; ciò indicherà che il

microinterruttore del timer è scattato nella parte

bassa della camma, parte che corrisponde al

ciclo di sbrinamento.

4. Mettere in funzione l'apparecchio all'interruttore principale (posizione ON). L'interruttore

del compressore deve rimanere sulla posizione

OFF.

5. Ripetere quanto descritto al punto 3.

6. Dopo il completamento del secondo ciclo di

sbrinamento (circa tre minuti) mettere in funzio-

ne il compressore tramite il relativo interruttore

(posizione ON).

B

CICLO DI

SBRINAMENTO

CICLO DI

CONGELAMENTO

CAMMA CON LE INDICAZIONI DEL CICLO

DI CONGELAMENTO E SBRINAMENTO

NOTA.

Durante la fase di sbrinamento l'acqua entra nell'apparecchio, attraverso la valvola solenoide di ingresso dell'acqua, eccitata durante questa parte del ciclo, e attraverso

l'apposita tubazione è indirizzata sulla parte

superiore dell'evaporatore. Dopo aver coperto l'intera superficie di plastica

dell'evaporatore, l'acqua viene scaricata, attraverso tre fori di drenaggio, nella vaschetta

di raccolta, riempiendola.

CONTROLLI DURANTE FUNZIONAMENTO

A. L'apparecchio inizia così il suo primo ciclo

di congelamento con i seguenti componenti in

funzione:

COMPRESSORE

POMPA

MOTOVENTILATORE per i modelli raffreddati

ad aria.

B. Osservare attraverso l’apertura di scarico

dei cubetti che la piastra spruzzante sia correttamente posizionata e che l’acqua venga uniformemente spruzzata all’interno dei bicchierini

rovesciati dell’evaporatore.

Verificare che la tendina di plastica sia posizionata correttamente impedendo la fuoriuscita

dell’acqua attraverso le proprie lamelle.

C. Il processo di fabbricazione del ghiaccio ha

così inizio con l’acqua che viene continuamente

spruzzata all’interno dei bicchierini rovesciati e

con la temperatura dell’evaporatore che gradualmente si abbassa.

D. Nei modelli 18-21-31-40 quando la temperatura dell'evaporatore raggiunge un valore

predeterminato il termostato evaporatore commuta i suoi contatti dando luogo alla fine del ciclo

di congelamento ed all'inizio del ciclo di

scongelamento.

E. Nei modelli 50-65-90 all'inizio del ciclo di

congelamento il termostato evaporatore è la

"mente" che regola la durata della prima fase del

ciclo di congelamento. Come si raggiunge la sua

temperatura di intervento, questi inverte i suoi

contatti chiudendo il circuito al motorino del timer

attraverso i contatti normalmente aperti del

microinterruttore.

Page 26

Pagina 15

Il ciclo di congelamento prosegue per altri 12

minuti finchè il microinterruttore raggiunge la

parte bassa della camma.

A questo punto il microinterruttore del timer inverte i suoi contatti diseccitando così la bobina

dei relé di comando per i tre minuti corrispondenti

al ciclo di sbrinamento o di caduta dei cubetti.

Con la bobina del relé di comando diseccitata i tre

contatti del medesimo assumono la posizione

opposta chiudendo il circuito del motorino del

timer per i tre minuti corrispondenti ed il circuito

della bobina della valvola di ingresso acqua e

della valvola del gas caldo. La camma del timer

continua a girare fino ad azionare il pulsante del

microinterruttore facendo così iniziare un nuovo

ciclo di congelamento.

Il microinterruttore del timer ha un contatto normalmente aperto ed un contatto normalmente

chiuso che rappresentano rispettivamente la fase

di congelamento e la fase di sbrinamento.

L'azione della camme apre i contatti normalmente aperti e chiude i contatti normalmente chiusi; il

motore del timer continua ad operare attraverso

i contatti del relé di comando e i contatti normalmente chiusi del microinterruttore.

F Verificare che durante la fase di

scongelamento l’acqua di alimentazione vada a

reintegrare quella precedentemente usata per la

produzione dei cubetti e che quella eccedente

trabocchi nel tubo di troppo pieno e fluisca nella

tubazione di scarico dell’apparecchio.

G. Osservare i cubetti di ghiaccio prodotti.

Questi devono essere della giusta dimensione

con una cavità nella parte della corona di circa

4-5 mm.

Nel caso contrario, attendere il secondo ciclo di

produzione del ghiaccio, prima di effettuare qualsiasi regolazione.

H. Se necessario, nei modelli 18, 21, 31 e 40 la

durata del ciclo di congelamento può essere

modificata ruotando la manopola del termostato

evaporatore posta nella scatola elettrica fino al

raggiungimento della dimensione ottimale.

• Se la temperatura del locale in cui

è posto l'apparecchio è inferiore a

20°C, i cubetti prodotti possono avere un incavo pronunciato al loro intervento (Vedi figura a lato).

• Se invece la temperatura ambiente

sarà superiore a

30°C i cubetti prodotti tenderanno

ad avere delle

frastagliature di

ghiaccio attorno

alla corona.

Chi lo ritenesse necessario, può migliorare le

sopra illustrate situazioni di cubetti ruotando nel

primo caso in senso orario il volantino di comando e, nel secondo caso, in senso antiorario.

Occorre però tener presente che, qualora la temperatura ambiente rientrasse entro i 20 ÷ 30°C,

l'indicatore del volantino andrà riportato in corrispondenza del punto di riferimento (Vedi illustrazione sotto).

Controllare l'aspetto dei cubetti di ghiaccio prodotti: cubetti aventi delle corrette dimensioni

esterne ma particolarmente opachi, indicano che

il fabbricatore di ghiaccio ha avuto una mancanza d'acqua durante la fase finale del ciclo di

congelamento o che, l'acqua usata per la produzione del ghiaccio è di pessima qualità e quindi

si rende necessario l'uso di filtri adeguati o di un

condizionatore d'acqua.

I. Durante il ciclo di sbrinamento, coprire con

una manciata di cubetti il bulbo sensibile del

termostato contenitore e verificare lo spegnimento dell'apparecchio dopo circa due o tre

minuti. Togliere la manciata di cubetti dal bulbo

sensibile e controllare che l'apparecchio si rimetta in moto in circa tre o quattro minuti.

NOTA.

Il termostato contenitore é tarato per

spegnere la macchina a +1°C e riaccenderla

a +4°C.

K. Rimontare i pannelli precedentemente rimossi quindi istruire il proprietario sul funzionamento del fabbricatore di ghiaccio così come

sulle operazioni di pulizia ed igienizzazione del

medesimo.

Page 27

Pagina 16

PRINCIPIO DI

FUNZIONAMENTO

Nei fabbricatori di ghiaccio l’acqua usata per la

produzione del ghiaccio è tenuta costantemente

in movimento da una pompa elettrica che attraverso un sistema spruzzante dirige l’acqua a

pressione moderata all’interno dei bicchierini

rovesciati dell’evaporatore.

Qui una parte dell’acqua spruzzata ghiaccia all’istante; il rimanente di essa ricade nel sottostante

serbatoio di recupero per essere ricircolata.

CICLO DI CONGELAMENTO

Il refrigerante allo stato gassoso ed ad alta

temperatura viene pompato dal compressore e,

passando poi attraverso il condensatore, si trasforma in refrigerante allo stato liquido.

La linea del liquido permette al refrigerante di

fluire dal condensatore al tubo capillare attraverso il filtro deumidificatore. Durante il passaggio

attraverso il tubo capillare il refrigerante allo

stato liquido perde gradualmente parte della sua

pressione e conseguentemente parte della sua

temperatura. Successivamente raggiunge ed

entra nella serpentina dell’evaporatore.

L’acqua spruzzata nei bicchierini rovesciati

dell’evaporatore cede calore al refrigerante circolante all’interno della serpentina, causandone

l’evaporazione, ed il conseguente cambiamento

del suo stato fisico, cioè da liquido diviene vapore. Il refrigerante allo stato vaporoso dopo essere passato attraverso l’accumulatore viene aspirato nuovamente nel compressore tramite la

linea di aspirazione.

Nei modelli 18-21-31-40 il ciclo di congelamento

è regolato solo da un controllo della temperatura

(termostato evaporatore) che determina la durata del ciclo e di conseguenza la dimensione dei

cubetti; nei modelli 50-65-90 esiste una seconda

fase del ciclo di congelamento controllato da un

timer.

I componenti in funzione durante il ciclo di

congelamento sono:

IL COMPRESSORE

LA POMPA

IL VENTILATORE (nei modelli raffreddati ad aria)

Nei modelli 18-21-31-40 raffreddati ad aria la

pressione di mandata del sistema refrigerante

(alta pressione) cala progressivamente da un

valore di circa 11 bar (con temperatura ambiente

di 21°C), che si riscontra all’inizio del ciclo di

congelamento, fino ad un valore minimo di 7 bar

proprio alla fine del ciclo di congelamento.

Nei modelli 50-65-90 la pressione di mandata è

controllata da un pressostato ventilatore tra

10-8.5 bar. Questi valori sono influenzati della

temperatura dell’ambiente in cui è installato l’apparecchio e aumentano proporzionalmente con

l’aumentare di quest’ultima.

Nei modelli 18-21-31-40-50 raffreddati ad acqua

le pressioni di mandata del sistema refrigerante

sono mantenute tra due valori prestabiliti

(8.5 - 10 bar) tramite l’azione di un pressostato

automatico che comanda elettricamente una

valvola solenoide di ingresso acqua posta sulla

linea di alimentazione al condensatore.

Nei modelli 65-90 raffreddati ad acqua la pressione di mandata é mantenuta a 9.5 bar tramite

l'ausilio di una valvola pressostatica.

Con apparecchi installati in condizioni normali

(21°C ambiente) la pressione di aspirazione o

bassa pressione scende rapidamente a 1 bar

all’inizio del ciclo di congelamento, cioè quando

il cubetto di ghiaccio inizia a formarsi, declinando