Page 1

AFE325 Product Manual

Page 1

AFE325

Purpose of this manual: To provide detailed

installation and operation instructions; to give

insights into how the machine works; to list

possible causes for problems; and to suggest

procedures for specific types of service.

The AFE325 is an ice maker that makes and

stores flaked ice.

The refrigeration system is either air or water

cooled, and it uses R-134a as a refrigerant. The

control system uses thermostat as a bin control

and a water pressure switch as the water safety

control.

Table of Contents

Specifications: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 2

To The Installer: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 3

For The Plumber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 4

For The Electrician . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 5

Final Check List & Initial Start Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 6

User Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 7

Component Location: Control Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 8

Refrigeration System Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 9

Water System Operation: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 10

Mechanical Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 11

Sanitation and Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 12

Maintenance And Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 13

Maintenance: Air Cooled Condenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 14

Maintenance: Component Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 15

Service Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 16

Removal and Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 18

Water Seal & Bottom Bearing Replacement: . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 19

Refrigeration System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 20

Gear Reducer Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 21

Gear Reducer Rebuild . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 22

A Parts List and Wiring Diagram are located in the center of this manual, printed on yellow paper.

August 1994

Page 2

AFE325

Page 2

Specifications:

The finish for this machine is either

painted enamel or stainless steel. No

panel kit is available to convert an

enamel machine to stainless steel.

Scotsman ice machines, like the

AFE325, are designed to be installed

indoors, in a controlled environment.

The minimum and maximum

operating conditions are:

•Minimum Air Temperature:

o

50

F.

•Maximum Air Temperature:

o

100

F.

•Minimum Water Temperature:

o

40

F.

•Maximum Water Temperature:

o

100

F.

•60 Hz Voltage may vary between

104 and 126 volts.

•Water Pressure may vary

between 20 and 80 psi.

Operating the machine

outside these

conditions constitutes

misuse and voids the

warranty.

Scotsman assumes no

liability or responsibility of

any kind for products

manufactured by

Scotsman that have been

altered in any way,

including the use of parts

and/of other components

not specifically approved

by Scotsman.

Scotsman reserves the

right to make design

changes and/or

improvements at any

time. Specifications and

designs are subject to

change without notice

Scotsman Ice Systems

are designed and

manufactured with the

highest regard for

safety and

performance. They

meet or exceed the

standards of UL, NSF

and CSA.

.

Model Dimensions Basic

AFE325AE-1A

AFE325AE-6A

H’ x W" x D"

33 x 36

33 x 36

1

⁄16 x 24

1

⁄16 x 24

Electrical

115/60/1 Air Cooled 10.7 15 11 oz.

230/50/1 Air Cooled 5.4 15 11 oz.

Condenser

Type

Min. Circ.

Ampacity

Max. Fuse

Size

Refrigerant Charge

(R-134a)

August 1994

Page 3

To The Installer:

Page 3

AFE325

A professional installation of any product is critical

to the long term satisfaction of the user. The

AFE325 is designed to be installed indoors, near a

drain. Determine the location from the anticipated

use and any options planned for.

This air cooled machine blows air out the back and

left sides of the cabinet. Do not install the machine

where the air flow might be blocked.

The machine will require electrical power, water

and a drain. Follow all local codes. Rough in the

utilities before placing the machine into position

(see For The Electrician and For The Plumber).

After uncrating, install the legs or optional casters.

If the building’s drain is a floor drain near the

machine, the cabinet can be placed on the floor

and sealed around the edges.

Place the cabinet in the place where it will be

operating. Note that the electrical and water

connections need to be made.

Level the unit front to back and left to right.

Water Quality:

The quality of the water supplied to the machine

will directly affect the purity of the ice and the

reliability of the machine. While the condition of the

water supplied to a building is normally out of the

control of the user, water can be treated at the

point of use.

There are two major types of water impurities:

suspended solids (those that are carried along

with the water and may be filtered out) and

dissolved solids (those that are part of the water

and have to be treated). A water filter is always a

good idea, but does require regular maintenance

to change the cartridge. In some water conditions,

water treatment may be required. Generally this

means a polyphosphate feeder of some kind.

Water softeners are not recommended for the

AFE325.

Utility

Connections

Here

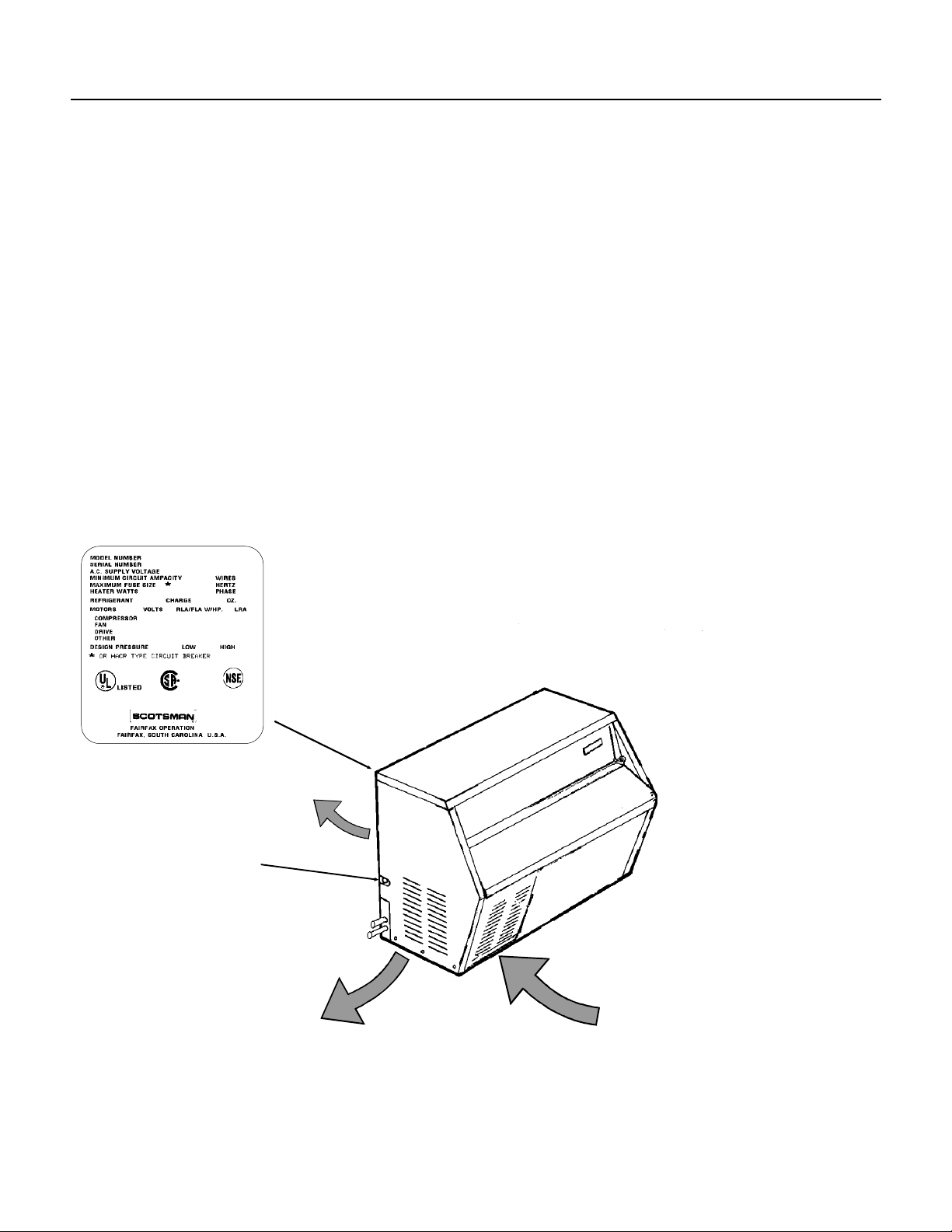

Nameplate Is Located

On The Back Panel.

Warm Air

Out

Airflow Direction

Cool Air In

Warm Air Out

August 1994

Page 4

AFE325

For The Plumber

Drains: The ice maker requires a gravity drain for

the reservoir overflow and bin drain. The pitch on

the drain tubes must be at least 1/4 inch fall per

foot of horizontal run. On long horizontal runs, a

vent at the back of the cabinet will improve

draining, and is recommended.

Water supply:

Connect cold, potable water to the machine. A

hand valve near the location is recommended. A

water filter is also a good idea.

Follow all local codes.

There are two drains and one water inlet

connection to make.

The drains are: a copper bin drain tube; and a

rubber reservoir overflow tube.

The water inlet connection is a 3/8" male flare.

Route a drain line to the reservoir overflow drain

hose. Route a separate drain to the bin drain tube.

Route the inlet water line to the fitting on the

corner post.

Water Inlet

3/8" Male Flare

Drain

7

⁄

" I.D. Flexible Hose

16

January 2005

Page 4

Page 5

For The Electrician

Page 5

AFE325

Electrical connections:

Follow All Local, State & National Codes

Check the nameplate for voltage and current

requirements. An electrical cord is not supplied.

Connect the AFE325 to a separate electrical

circuit. Wiring to the machine must conform to all

codes. A licensed electrician may be required in

some situations. The electrical connection is made

in the control box inside the machine.

This unit must be grounded.

Route the electrical power cord thru the corner

post to the control box inside the cabinet.

Top Panel

Ice Discharge Tube

(Ref)

Electrical

Inlet

To make the electrical connection, remove the

following parts:

•Top panel

•Bin door

•Rubber moulding

•Left moulding cover

•Left track

•Upper front panel

•Upper baffle

•Left side panel

•Front louvered panel

•Control box cover

If the machine will be started up later, after making

the electrical connections, replace all panels.

Control Box Cover

Upper Front

Panel

Left Side

Panel

Panel

Serial Number

Plate

Bin Door

Spacer

Bin Door

Left Track

Left Moulding

Cover

Upper BaffleFront Louvered

August 1994

Page 6

AFE325

Page 6

Final Check List & Initial Start Up

1. Is the machine located indoors where the

temperature limitations are not exceeded?

2. Is there at least 6" clearance on the left side and

the back of the cabinet for adequate air flow?

3. Is the water supply adequate, and has a shut off

valve been installed?

4. Is the cabinet level?

5. Have all of the electrical and drain connections

been made?

Note: For High Altitude Installations an Altitude

Adjustment May Be Required:

(11-0354-01, 20 Ranco brand bin thermostats only)

Adjustment Altitude (ft.

above seal level)

Range

Screw CW

2,000 35

4,000 90

6,000 145

8,000 190

Amount of

adjustment from

factory setting

o

o

o

o

Initial Start Up

1. Remove the following parts:

•Top panel

•Bin door

•Rubber molding

•Left molding cover

•Left track

•Upper front panel

•Upper baffle

•Left side panel

•Front louvered panel

•Control box cover

•the top panel.

2. Open the water shut off valve.

3. Watch the water fill the reservoir. Check that it

flows in and fills the reservoir near to the mark

molded into the side of the reservoir. Check that

the float shuts off the water flow when the tank is

full. Check for leaks. Tighten hose clamps as

needed.

4. Plug the unit in or switch on the electrical power.

5. Switch the master switch to ON.

6. Let the machine operate, listen for any unusual

noises. If needed, reposition tubing & panels to

eliminate vibration.

After the unit has been operating for about 10

minutes, there should be enough ice in the bin to

test the bin thermostat.

7. Pick up some ice and hold it up against the

bottom of the ice thermostat tube.

8. After a short time the bin thermostat should

switch the machine off.

9. Pour water into the bin and check that the drain

does not leak but drains the water rapidly.

10. Replace all panels.

11. Explain to the user the maintenance

requirements and operation of the machine.

12. Fill out the Warranty Registration and

Customer Evaluation form. Mail it to Scotsman.

13. Leave the service manual with the owner/user

and explain who should be called if service is

needed.

August 1994

Page 7

User Operation

Page 7

The AFE325 is an automatic ice flaked machine.

All it requires is cool air, clean water, a drain, and

an adequate supply of electrical power.

The user must regularly sanitize and clean the

machine.

Component Location & Function

Evaporator. This is a vertical cylinder full of water

and refrigerated. Also in the cylinder is a slowly

rotating auger. The auger forces the ice up the

evaporator walls and compresses it at the top. The

resulting flaked ice then falls by gravity into the ice

storage bin.

Water Reservoir. The water reservoir contains the

inlet float valve and the water level sensor. The

float valve controls the flow of water into the

reservoir.

Water Pressure Cut Out Switch: The purpose of

this switch is to stop the ice maker if the water

supply fails.

AFE325

Condenser. The AFE325 uses an air cooled

condenser. It blows air out, away from the fan

motor. The heat removed from the water is

exhausted from the condenser.

Compressor. The refrigeration system

compressor provides the force to move the

refrigerant around the system.

Auger Drive. The auger drive

is a direct drive gear reducer.

August 1994

Page 8

AFE325

Page 8

Component Location: Control Box

Auger Delay Pressure Control: This pressure

switch, connected to the low side of the

refrigeration system, controls the auger drive

motor.

On-Off switch: This toggle switch shuts off the

machine. It is not a complete disconnect.

Bin Thermostat: This thermostat turns the

machine on and off in response to changes in

temperature of the capillary tube. It opens at 35

and closes at 45

on the inside of the ice chute.

0

F. The capillary tube is mounted

0

F.

Toggle Switch

Auger Delay Pressure

Control

Terminal Strip

Bin Thermostat

Control Box

August 1994

Page 9

Refrigeration System Operation

Page 9

AFE325

The AFE325 uses a forced draft air cooled

condenser, capillary tube and hermetic

compressor. The system uses R-134a as a

refrigerant. High pressure, high temperature

refrigerant is forced thru the condenser where it

looses enough heat to condense. The high

pressure liquid refrigerant then passes thru the

capillary tube which causes a pressure drop in the

evaporator. As the high pressure liquid refrigerant

moves into the evaporator’s area of low pressure,

the warm water and low pressure cause the

refrigerant to evaporate and absorb heat from the

metal walls of the evaporator. After the refrigerant

has flowed thru the evaporator it goes back to the

compressor thru the suction line as a low pressure

vapor. At the compressor the cycle is repeated.

The AFE325 uses a low side pressure control as a

safety, it will shut the system down if the suction

pressure is too low for reliable operation.

Evaporator

System Characteristics:

Note: This ice machine has a sealed

refrigeration system. Tap into the system ONLY

when it’s absolutely necessary. After tapping

in, recovery, repair, evacuation and recharging,

the piercing valve must be removed and the

system re-sealed.

Typical Low Side Pressure*: 7 - 10 PSIG

Typical Discharge Side Pressure*: 130 - 165 PSIG

Typical Auger Drive Motor Amps (60 Hz): 2.8 - 3.1

Auger Drive Output RPM (60 Hz): 9.6

System Refrigerant Charge: 11 Ounces of R-134a

* Pressures depend upon air and water

temperatures. Numbers listed are for 70

o

air/50

F. water and 90oF. air/70oF. water.

Refrigeration System Schematic

o

F.

Suction Line

Compressor

Capillary Tube

Drier

Air Cooled

Condenser

August 1994

Page 10

AFE325

Page 10

Water System Operation:

The water system consists of a float valve and

reservoir. The water level in the reservoir tank is

the same level as that inside the evaporator.

Building water supply flows to the float valve and

the float valve opens to add water to the reservoir

as water flows out to the evaporator.

Inside the evaporator there is a water seal. This

seal is the type that has a rotating half and a

stationary half. The area where the two seals

touch are smooth flat surfaces. When the auger is

installed in the evaporator, it forces the rotating

half of the seal against the stationary half. The

stationary half is spring-loaded and provides a firm

pressure against the auger portion of the seal.

.

Reservoir

Float

Water Inlet

Water Line

Bin Drain

Clamp

Ice

Bin

Thermostat

Bracket

Grommet

Ice Tube

Spout

Evaporator

Reservoir Overflow

Gear Reducer

Water System Schematic

August 1994

Page 11

Mechanical Operation

Page 11

AFE325

ELECTRICAL SEQUENCE

There are two circuits in the AFE325: one is a

series circuit with several switches connected in

series to the compressor. The other is a parallel

branch of the series circuit, controlling the gear

drive motor.

•The series circuit begins at the terminal strip in

the control box. From there, the line side power

is connected to the Master Switch.

•When the master switch is closed, the power is

then connected to the Spout Switch. This

switch, located on the top of the ice chute, is

closed unless the ice chute has overfilled with

ice, it is a manual reset.

•The line side power is also connected, in a

parallel circuit, to terminal 1 of the Auger Delay

pressure control. This pressure control,

connected to the low side of the refrigeration

system, is designed as a by-pass circuit to the

auger drive motor whenever the low side

refrigerant pressure is at it’s normal ice making

range. At start up, the contacts between

terminals 1 and 2 are open. The line side power

does not pass any further through the auger

delay pressure control, until the compressor

starts, and the low side pressure drops.

•The next control the power is connected to is

the Low Water Pressure Control. This switch is

designed to open should the water pressure to

the machine drop too low.

•The next control is the Bin Thermostat. It is

closed when there is no ice on the portion of the

control inside the ice bin. It is open when there

is ice on the portion of the control inside the ice

bin. Closing of the bin thermostat begins the

process of making ice, because the line side

power now goes to the compressor, gearmotor,

and if air cooled, the fan motor.

•Power is initially connected to the gearmotor

through contacts 3 and 2 of the auger delay

pressure control. This causes the auger motor

to start and run. At the same time, if the

centrifugal switch on top of the gearmotor

closes (meaning the motor is at full speed) the

compressor is connected to the neutral side of

the power supply, and the compressor begins

to run.

•As the compressor runs, the low side or suction

pressure begins to fall, when it reaches a preset

point, the contacts within it move, opening 3

and 2, then closing 1 and 2. The power for the

gearmotor is then connected to a point in the

series circuit ahead of the low pressure control,

the low water pressure control and the bin

thermostat, so that if any of these open, the

gearmotor will continue to run, pushing ice out

of the evaporator.

The refrigeration system uses a hermetic

compressor (specifically designed for R-134a),

forced draft air cooled condenser, capillary tube

and vertical flaked ice evaporator. Inside the

evaporator is a slowly rotating auger. The auger is

supported by bearings at each end, and there is a

face-type water seal above the bottom bearing.

The auger is driven by a 1/10 HP direct drive gear

reducer. The auger drive motor has a speed

operated switch on it that will keep the compressor

from operating if the auger motor is not turning at

full speed.

Water flows from the building supply to the

reservoir . Water from the reservoir is used to

make ice.

The bin and reservoir overflow have separate

drains.

August 1994

Page 12

AFE325

Sanitation and Cleaning

Maintenance:

The water and ice making systems will need to be

periodically sanitize d and de-min era lized . Th e air

cooled condens er will also ne ed to be kept clea n.

Detailed ins tru ctio ns are pro vided on page 14.

Schedule the sanitation, cleaning and

de-mineralization on a regular basis to keep the

ice clean an d the machine operating effi ciently

Water System:

The water system requires periodic sanitation and

de-mineralization.

Schedule & Responsibi li ty:

A Sco tsman Ice System represe nt s a sizable

investmen t of time an d mon ey in any compa ny’ s

business . In order to receiv e the best ret urn for

that investme nt, it MUST rece ive periodic

maintenance.

It is the USER’S RESPONSIBILITY to see that the

unit is properly maintained . The following is a list

of recommended main tena nce that will help keep

the machine running with a minimum of prob lems.

Maintenanc e an d Cleaning should be sched ule d at

a minimum of twice per year .

ICEMAKING SYSTEM: In place cleaning

1. Check and clean any water treatment devices, if

any are insta lled .

2. Remove screws and remov e the top and front

panels.

3. Move the ON - OFF switch to OFF.

4. Ope n the door to t he ice stora ge bin, and

remove the ice.

5. Remove the cover to the wate r reserv oir and

block the float up.

6. Drain the water res ervo ir and free zer assembly.

7. Prepare the cleaning solution: Mix 4 ounces of

Scotsman Ice Machin e Clea ne r with 1

hot water. The wat er should be between 90-115

Scotsman Ice Mac hine

Cleaner conta ins aci ds.

These compounds may

cause burns.

If swallowed, DO NO T

induce vomiting. Give

large amounts of wat er or

milk. Call Physician

immediately. In case of

external contact, flush

with water.

KEEP OUT OF THE

REACH OF CHILDREN.

1

⁄2 quarts of

o

F.

8. Slowly pour the cleaning solu tio n into th e water

reservoir until it is full. Wait 15 minutes, then

switch the master switch to ON.

9. As the ice maker be gin s to use wat er fro m th e

reservoi r, contin ue to add more clea nin g solu tio n

to maintain a full reservoir.

10. After all of th e cle aning solution ha s been

added to the reservoir, and the reservoir is nearly

empty, switch the mast er switc h to OFF.

11. After draining the reservoir, as in step 6, wash

and rinse the water rese rvo ir.

12. Go thru steps 13 - 18 to sanit ize th e ice

machine wat er syst em.

13. Mix two gallons of sanitize r solution. Use an

approved sanitizer.

A possib le san itzer solution may be obtaine d by

mixing two gallons of warm (90-115

water with 1 ounce of household bleach.

14. Slowly pout the sanitizer solution into the water

reservoir until it is full, then switch the mast er

switch to ON.

15. As the ice machine uses wat er f rom t he

reservoi r, continue to add sanitizing solution to

keep the reservoir full.

16. After

added to the reservoir, and the reservoir is nearly

empty, s witch the master switch OFF.

17. Drain the reservoir and thoro ughly wash the

interior of the res ervo ir and cover wit h sanit izer

solution.

18. Remove the block from the flo at in the wate r

reservoi r.

19. Switch the master switch to ON.

20. Continue ice makin g for at lea st 15 minu tes, to

flush out any cleaning solution . Switch the mast er

switch OFF.

DO NOT USE any ice produced from the

cleaning solution. Be sure no ice remains in

the bin.

21. Remove all ice from the stora ge bin.

22. Add warm water to the ice storage bin and

thoroughly wash and rins e all surfac es with in th e

bin.

23. Sanitize the bin int erio r by tho rou gh tly washin g

all interior surf ace s of the bin with the balance of

the sanitizer so lut ion .

24. Switch the master switch ON.

25. Replace th e top and the fro nt panels.

1

⁄2 of the sanitizer solutio n has been

o

F.) potable

January 1996

Page 12

Page 13

Maintenance and Cleaning

Page 13

AFE325

In some areas, the water supply to the ice maker

will contain a high concentration of minerals, and

that will result in an evaporator and auger

becoming coated with these minerals, requiring a

more frequent removal than twice per year. If in

doubt about the condition of the evaporator and

auger, the auger can be removed so the parts can

be inspected.

Note: Water filters can filter out suspended solids,

but not dissolved solids. ‘‘Soft’’ water may not be

the complete answer. Check with a water

treatment specialist regarding water treatment.

For more information on removal of these

parts, see REMOVAL AND REPLACEMENT.

To Inspect The Top Bearing:

1. Disconnect electrical power and shut off the

water.

Electrical Shock Hazard

Disconnect electrical

power before beginning.

To Inspect the Auger:

1. Disconnect electrical power and shut off the

water.

2. Remove the two screws from the spout at the

side of the evaporator. Pull the spout away from

the evaporator.

3. Remove screw holding spout plate to evaporator.

4. Pull up on cap hook located in the top of the

freezer assembly to remove the ice breaker

assembly, auger, and the top portion of the water

seal.

5. Inspect the auger and the water seal. Clean the

auger of any mineral build up. Scotsman Ice

Machine Cleaner and a scouring pad work well to

clean the auger. DO NOT USE steel wool.

6. Replace the water seal, see the instructions

under "Removal and Replacement".

2. Remove the two screws from the spout at the

side of the evaporator. Pull the spout away from

the evaporator.

3. Remove screw holding spout plate to evaporator.

4. Remove the snap ring and cap, and remove the

bolt from the ice breaker and auger assembly to

separate the ice breaker assembly from the auger.

Pull the ice breaker with bearing out of the top of

the evaporator: the auger should stay in the

evaporator.

The bearings may be inspected for rust, wear, and

roughness. Reverse to reassemble.

August 1994

Page 14

AFE325

Page 14

Maintenance: Air Cooled Condenser, Bearings

1. Disconnect electrical power.

Electrical Shock Hazard

Disconnect electrical

power before beginning.

2. Remove front louvered panel

3. Wipe the lint off the front of the condenser. If

needed, clean the interior of the condenser.

4. Use pressurized air to blow the lint from the

inside of the condenser. A vacuum cleaner hose

should pick up most of the dust. Check for interior

dirt. If needed, use coil cleaner to de-grease the

condenser.

5. Replace all panels and reconnect electrical

power.

Auger and Bearing Inspection

While in most areas regular in-place cleaning with

Scotsman Ice Machine Cleaner will be adequate to

keep the interior of the evaporator free of

excessive mineral build up, some water conditions

may require more intense methods. In addition,

the auger bearings require physical inspection to

determine that they are not wearing. This physical

inspection is recommended twice per year for the

top bearing and once per year for the auger and

both bearings.

Whenever the auger is removed, replacement of

the water seal is recommended.

If a bearing requires replacement, the other

bearing must also be replaced.

1. Unplug or disconnect electrical power.

2. Shut off the water supply.

3. Remove top panel.

4. Remove right side panel.

5. Drain the evaporator and reservoir.

6. Remove the two screws from the spout at the

side of the evaporator.

7 Remove screw holding spout plate to evaporator.

8. Remove spout.

9. Pull up on the pull ring to remove the auger. If it

is difficult to pull:

A. Remove the breaker cover by taking the snap

ring out.

B. Unscrew the auger bolt.

C. Use threaded rod or a slide hammer puller and

screw into the auger, slide the weight up against

the stop to remove the auger.

If the auger still will not move, bearing replacement

is mandatory. See Bearing Removal and

Replacement.

August 1994

Page 15

Maintenance: Component Inspection

Page 15

AFE325

Auger. The auger is made of stainless steel. It has

a polished surface that may be very shinny or dull.

Allow the auger to dry, if mineral scale is found on

the auger’s surface, clean off the auger with ice

machine cleaner and a scrubbing pad.

Remove the water seal and clean off the shoulder

of the auger.

Bearings: The top bearing should spin freely with

no rough spots. If it feels rough when spun by

hand, replace it. There should be minimal rust or

dirt. If in doubt, replace the bearing.

The bottom bearing must be removed from the

evaporator when replacing the water seal.

Remove the three bolts holding the evaporator to

the gearmotor adapter and lift the evaporator up

slightly. Tap the water seal and bottom bearing out

from the top down. Check the bottom bearing the

same way as the top.

Replace the water seal and install a new bearing

set if needed.

To replace the water seal:

10. Push the auger down, and rotate the breaker

until the screw hole lines up with the pilot hole in

the evaporator.

11. When the auger is completely seated, reinstall

the breaker screws.

12. Replace spout and rubber top.

13. Switch on the water supply.

14. Observe operation. The unit should make

minimal noise while producing ice. Catch first 2

minutes of ice and discard it.

15. Replace all panels.

Coupling

Use the grease zerk on the side of the coupling to

add grease once per year.

That concludes normal maintenance. If the fan

motor has an oil plug, it may be oiled after 10

years of operation.

1. Remove old rotating half from the auger. Clean

the mounting area.

2. Place a bead of food grade sealant (such as

Scotsman part number 19-0529-01) onto the

shoulder of the auger where the rotating half of the

water seal will be installed.

3. Wash the new seal in water. While wet, slip it

onto the bottom of the auger, rubber side toward

the auger. Push up until seated against the

sealant. Do not allow any sealant to come into

contact with the face of the seal.

4. Wash the stationary half the water seal with

water. Slip it up into the bottom of the evaporator

until the bottom of the seal is inside the evaporator

about 1/4".

5. Push the bottom bearing against the water seal

until the bottom bearing is inside the evaporator

about 1/16".

6. Replace the evaporator on the adapter, and

re-attach the stand using the original bolts.

7. Attach the auger to the top bearing and breaker.

8. Return the auger to the evaporator and slide it

down until the splines touch the coupling.

9. Rotate the auger until the coupling splines align

with the auger.

August 1994

Page 16

AFE325

Page 16

Service Diagnosis

Problem Possible Cause Probable Correction

No ice, nothing is operating. Unit has no power. Restore power. If breaker or fuse

tripped, check for overloaded

circuit or short circuit.

Master switch off Switch unit on. Determine why

switch was off.

No water (water safety switch

open)

Spout switch open Check bin thermostat for failure to

Bin thermostat open Check air temp, it must be over

Auger drive motor will not start. Check windings of auger drive

Auger delay switch open Replace auger delay.

Restore water supply. Check

filters or strainer.

open and shut off machine.

Check spout for internal pitting.

o

50

F. for thermostat to start unit.

motor. Check for seized gears.

No ice, auger drive is operating. Centrifugal switch is open. Check/replace switch

Compressor will not start. Check voltage.

Check start relay

Check start capacitor

Check compressor

Lack of refrigerant Check system. Locate leak.

Recover remaining refrigerant,

replace drier, evacuate to 200

microns and weigh in the system

charge.

No condensing Fan not turning, or blade broken.

Unit will not shut off. Bin thermostat stuck closed. Replace thermostat.

Auger motor will not shut off. Auger delay stuck Replace auger delay

System pressures to low to switch

auger delay off.

Check pressures. If low, check for

restriction or leak.

August 1994

Page 17

AFE325

Page 17

Service Diagnosis

PROBLEM POSSIBLE CAUSE PROBABLE CORRECTION

Unusual noise Mineral scale in evaporator Clean water system with ice

machine cleaner.

Auger coupling dry Grease coupling

Auger coupling worn Replace coupling and adapter

stand.

Bearings worn Replace bearings and water seal.

Gearmotor loose on frame Tighten bolts, check grommets

Low water level Check water level in reservoir

Tubing vibrating Check tubing for contact

Tooth on a gear missing Check gears in auger drive

Compressor too loud Replace compressor

Gear noise Check gearmotor for oil leak

Water leaks from cabinet Evaporator water seal worn or

cracked

Tubing to evaporator leaks Replace tubing/fittings

Drain leaks Check drain tubes and fittings

External drain restricted Clean out drain

No refrigeration Gearmotor does not turn Check motor

Centrifugal switch does not close Check switch

Fan motor does not turn Check fan motor

Lack of refrigerant Add refrigerant, if problem is

Compressor does not pump Check/replace start capacitor

Replace seal and bearings

reduced, locate leak and repair it.

Check/replace start relay

Check/replace compressor

August 1994

Page 18

AFE325

Page 18

Removal and Replacement

Water System

The water system consists of the reservoir and

inlet water valve.

Reservoir.

1. Shut off the water supply.

2. Remove the top panel.

3. Remove the left side panel.

4. Drain the water reservoir and evaporator.

5. Disconnect inlet and outlet tubes from the

reservoir.

6. Remove screws holding reservoir to its

mounting bracket.

7. Remove reservoir from the machine.

8. Reverse to reassemble.

Bearings, Water Seal and Auger

1. Disconnect electrical power.

4. Thread in a threaded rod and weight or

slide-hammer puller into the auger.

5. Use the threaded rod & weight or slide hammer

puller to remove the auger.

Or

1. Remove three cap screws holding evaporator to

the adapter stand.

2. Lift evaporator up slightly and tip the bottom out

to expose the splined end of the auger.

3. Use a plastic mallet or dead-blow hammer to tap

the bottom of the auger and force the auger up. Do

NOT damage the splines of the auger or the auger

will have to be replaced.

If the auger is "frozen" to the bottom bearing, do

not force the bottom bearing thru the evaporator.

Replacement

1. Replace the bearings and water seal. Replace

the auger if the splines are damaged. Replace the

evaporator if more than 1/3 of the vertical rifle

grooves are gone. Sand or hone and sand the

inside of the evaporator if mineral build up is heavy.

Electrical Shock Hazard

Disconnect electrical

power before beginning.

2. Shut off the water supply.

3. Remove the top panel.

4. Remove the front and side panels.

5. Drain the reservoir and evaporator.

6. Remove rubber cap from the top of the

evaporator.

7. Remove the two bolts from the spout on the side

of the evaporator.

8. Remove the screw holding the bearing retainer

to the evaporator.

9. Pull up on the ring to lift the auger out of the

evaporator.

If the auger will not lift out:

Top Bearing Replacement:

If the inner race is secure, use an arbor press to

push the top bearing out of the breaker. If the inner

race has separated from the bearing, replace the

breaker.

Insert a new bearing in the breaker.

Replace the "O" ring in the breaker.

Push the bearing in, push only on the outer race.

1. Remove snap ring holding bearing cover to

breaker.

2. Remove bearing cover.

3. Unscrew bolt holding bearing to auger.

August 1994

Page 19

Water Seal & Bottom Bearing Replacement:

Page 19

AFE325

1. Remove old rotating half from the auger. Clean

the mounting area.

2. Place a bead of food grade sealant (such as

Scotsman part number 19-0529-01) onto the

shoulder of the auger where the rotating half of the

water seal will be installed.

3. Wash the new seal in water. While wet, slip it

onto the bottom of the auger, rubber side toward

the auger. Push up until seated against the

sealant. Do not allow any sealant to come into

contact with the face of the seal.

4. Wash the stationary half the water seal with

water. Slip it up into the bottom of the evaporator

until the bottom of the seal is inside the evaporator

about 1/4".

5. Push the bottom bearing against the water seal

until the bottom bearing is inside the evaporator

about 1/16".

6. Replace the evaporator on the adapter, and

re-attach the stand using the original bolts.

7. Attach the auger to the top bearing and breaker.

Evaporator

Follow all steps to remove the auger & bearings.

1. Recover the refrigerant charge. Note: The

refrigeration system must not remain open for

more than 15 minutes.

2. Unsweat suction and cap tube connections.

3. Remove evaporator from the machine.

4. Remove old drier.

5. Install new evaporator.

6. Install new HFC type drier.

Note: The refrigeration system uses an HFC type

refrigerant and MUST use an HFC type drier.

7. Braze the drier connections, cap tube and

suction line together.

8. Evacuate to 200 microns, and weigh in the

system charge.

8. Return the auger to the evaporator and slide it

down until the splines touch the coupling.

9. Rotate the auger until the coupling splines align

with the auger.

10. Push the auger down, and rotate the breaker

until the screw holes line up with the pilot holes in

the evaporator.

11. When the auger is completely seated, reinstall

the breaker screws.

12. Replace permagum and foam top.

13. Switch on the water supply.

14. Check bin cover for electrical grounds and

switch on the electrical power.

15. Observe operation. The unit should make

minimal noise while producing ice. Catch first 2

minutes of ice and discard it.

16. Replace the bin cover and all panels.

Water Line

Coupling

Gasket

Gear

Reducer

August 1994

Page 20

AFE325

Page 20

Refrigeration System

This ice machine uses R-134a as the refrigerant.

This refrigerant has no chlorine, and therefore

requires polyolester type refrigerant oil. This oil

requires specific service procedures.

Service Recommendations:

This ice machine has a sealed refrigeration

system. It must not be tapped into unless

absolutely necessary. If access is required, tap into

the "process" tubes (dead-end tubing that has

been pinched-off and brazed shut).

After recovery, repair, evacuation and re-charging,

remove the piercing valves:

1. Pinch off the process tube below the valve.

2. Remove the valve.

3. Braze the end of the tube shut.

A HFC type liquid line drier is required. "Standard"

driers may not take out enough moisture and may

affect the oil additives.

The time that the refrigeration system is open to

the air must not exceed 15 minutes. The oil will

rapidly absorb moisture from the air, and the

contact time must be kept to a minimum.

A special or very sensitive electronic leak detector

will be needed to locate refrigerant leaks. Many

are on the market that will sense R-134a.

Recovery and vacuum equipment should use

polyolester oil to minimize cross-contamination.

A HFC type drier must be used.

As with any other refrigerant, do not place

pressurized air or oxygen into the refrigeration

system.

Evacuation to 200 microns is recommended.

Temperature Pressure Chart, Selected Points

Temperature in

-10 2.0

-6 3.7

-4 4.6

-2 5.5

0 6.5

1 7.0

2 7.5

3 8.0

4 8.6

5 9.1

10 12.0

12 13.2

14 14.4

16 15.7

18 17.1

20 18.4

25 22.1

30 26.1

31 26.9

32 27.8

33 28.6

34 29.5

35 30.4

40 35.0

45 40.0

50 45.4

75 78.7

90 104.3

110 146.4

120 171.1

130 198.7

150 262.8

0

F. PSIG of R-134a

August 1994

Page 21

Gear Reducer Removal

Page 21

1. Disconnect electrical power.

Electrical Shock Hazard

Disconnect electrical

power before beginning.

2. Shut off the water supply.

3. Remove the top, front and side panel.

4. Remove the control box cover.

5. Remove the centrifugal switch cover on the top

of the auger drive motor.

6. Disconnect the electrical wires from the

centrifugal switch.

7. Drain the evaporator and reservoir.

AFE325

8. Disconnect the water inlet tube from the

evaporator.

9. Remove the three screws holding the

evaporator to the adapter stand.

10. Lift the evaporator up high enough for the

auger to clear the adapter stand.

11. Remove the mounting bolts holding the gear

reducer to the cabinet frame.

12. Trace auger drive motor wires back to the

control box.

13. Disconnect the drive motor wires from the relay

on the circuit board.

14. Pull the wires back to the auger drive motor.

15. Pull the gear reducer out the side of the

cabinet to remove it from the machine.

Note: If there is evidence of water near the output

shaft of the gear reducer, it would be a wise

precaution to pull the auger from the evaporator

and check the bearings.

16. Rebuild or replace the gear reducer.

August 1994

Page 22

AFE325

Page 22

Gear Reducer Rebuild

1. After the gear reducer has been removed, the

internal components may be inspected and/or

replaced. Remove all bolts holding the two case

halves together.

2. Tap against the roll pins at each end of the gear

cases to split them.

3. Pry the case halves apart.

4. Check the internal condition of the gear reducer.

If rusty or water is present, replace the complete

assembly. The oil should be black and the proper

oil level is 1/8" from the top of the biggest gear

(with all gears installed). Check the input seal.

The gears may be replaced individually.

Auger Drive Motor

The windings or top bearing & cover may be

replaced without removing the evaporator or gear

reducer from the machine.

1. Disconnect electrical power.

If the windings are to be replaced, remove the left

side panel and control box cover.

1. Locate the auger drive motor wires plugged into

a relay on the circuit board.

2. Disconnect the auger motor’s wires and pull

them back to the auger drive motor.

3. Lift the auger motor windings off the gear

reducer.

If the rotor needs to be removed:

1. Run a screw into the top of the rotor.

2. Grasp the screw with a grip pliers.

3. Pull and/or tap on the pliers to pull the rotor &

bearing out of the gear reducer.

4. Inspect the bearing and input seal. Replace

them if worn.

Note: When the rotor is re-installed, be certain that

the bearing is fully seated in the gear case.

Electrical Shock Hazard

Disconnect electrical

power before beginning.

2. Shut off water supply.

3. Remove top panel.

4. Remove right side panel.

5. Drain the reservoir and evaporator.

6. Disconnect the reservoir outlet tube from the

bottom of the reservoir.

7. Remove screws holding reservoir mounting

bracket to the cabinet.

8. Lift the reservoir up & away from the top of the

auger drive motor.

9. Remove the 4 bolts holding the auger motor

cover to the gear reducer case.

10. Lift the plastic switch housing off the auger

drive motor.

11. Hold the centrifugal switch and remove the

screw holding it to the rotor of the motor.

12. Lift the centrifugal switch up and off the motor.

13. Lift the motor cover up and off the motor.

14. Pull the fan up and off the rotor.

August 1994

Page 23

Gear Reducer

Page 23

Motor Cover & Top

Rotor Bearing

Fan

AFE325

Shaft Seals, 2 are

used per shaft as

shown

Stator

Woodruff

Key

Rotor

Spacer Washer,

Use To Adjust

Height of Gears to

Avoid Rubbing

First Gear

August 1994

Loading...

Loading...