Page 1

Page 1

Page 1

SERVICE MANUAL

MANUALE DI SERVIZIO

ACM 25

VERSIONE R 134 A / R 404 A

Home ice cuber

Fabbricatore di

ghiaccio a cubetti

domestico

090088.41 - REV. 03/2002

Page 2

Page 2

Page 2

TABLE OF CONTENTS PAGE

TO THE USER 3

USER’S INFORMATIONS

- INTRODUCTION 4

DESCRIPTION

• Sealed Refrigeration System 4

• Self contained Storage Bin 4

• Removable water reservoir 4

SPECIFICATIONS 5

OPERATIONS BEFORE UNIT

START-UP 6

OPERATING INSTRUCTIONS

• Start-up 6

• Cleaning and Care 8

PRINCIPLE OF OPERATIONS

• Freezing cycle 10

• Harvest cycle 10

INDICE PAGINA

PER L’UTILIZZATORE 20

INFORMAZIONI PER L’UTILIZZATORE

- INTRODUZIONE 21

DESCRIZIONE

• Sistema refrigerante 21

• Contenitore del ghiaccio 21

• Bacinella dell’acqua amovibile 21

SPECIFICHE TECNICHE 22

OPERAZIONI DA EFFETTUARE

PRIMA DELL’AVVIAMENTO 23

ISTRUZIONI DI FUNZIONAMENTO

• Avviamento 23

• Pulizia e manutenzione 25

PRINCIPIO DI FUNZIONAMENTO

• Ciclo di congelamento 27

• Ciclo di sbrinamento 27

SERVICEMAN’S INFORMATIONS

- GENERAL 11

• Service Diagnosis 11

• Wiring Diagram 13

• Adjustment & Removal & Replacement

• Procedure 14

PARTS ILLUSTRATIONS AND

PARTS LIST ACCESSORIES 15

COMPRESSOR AND ELECTRIC

COMPONENTS CHART 19

INFORMAZIONI TECNICHE

- PREMESSA 28

• Servizio analisi 28

• Schema elettrico 30

• Procedure per la rimozione e la

• sostituzione dei vari componenti 31

ILLUSTRAZIONI ED ELENCHI

DELLE PARTI DI RICAMBIO ED

ACCESSORI 32

COMPONENTI DEL COMPRESSORE

ED ELETTRICI 36

Page 3

Page 3

TO THE USER

Page 3

Your SCOTSMAN model ACM 25 Ice Maker is a

product carefully engineered and quality

constructed to provide you with many years of

faithful performance and a minimum of

maintenance costs.

Produced by the world’s leading manufacturer of

automatic ice making equipments, your

SCOTSMAN ICE CUBE MAKER incorporates

the same reliable systems already proven over

years of actual operation by thousands of users.

Many of you will have an opportunity to see and

use clear, slow melting SCOTSMAN CUBERS

for the first time.

You will quickly compare the clear, glass-like

quality of your Scotsman Cubes to the type

produced by your home refrigerator, freezer.

By comparison, cubes made in trays in your

refrigerator are very white or cloudy, they also

melt faster than clear ice.

Take the time now to review this manual and you

will see why Scotsman Cubes are solid and

clearer than ice cubes of your refrigerator.

No installation is required

Easy access for service is provided by the prompt

removal of the front panel and/or the cabinet.

Page 4

Page 4

Page 4

USER'S INFORMATIONS

INTRODUCTION

This manual provides the specifications and the

step-by-step procedures for the start-up and

operation and, the maintenance and cleaning for

the SCOTSMAN Model ACM 25 Automatic Ice

Cube Maker.

The ACM 25 Automatic Cubers are quality

designed, engineered and constructed and

throughly, tested ice making and ice storage

systems, providing the utmost in flexibility to fit

the needs of particular users.

Separate sections detail more specifically:

General Informations & Start-up Operation;

Principles of Operation; Adjustment and Removal

and Replacement Procedures; Maintenance &

Cleaning Instructions; Service Diagnosis; Wiring

Diagrams; and the illustrated Assemblies, Parts

List & Accessories.

One of the outstanding features of this series of

cubers is the easy way for starting it up.

Since it does not require any plumbing connection,

it can be placed in any location and put in

operation.

REMOVABLE WATER RESERVOIR

The most exclusive feature of the ACM 25 consists

in having a removable water sump reservoir. It

can be easily removed at any time to be washed

clean.

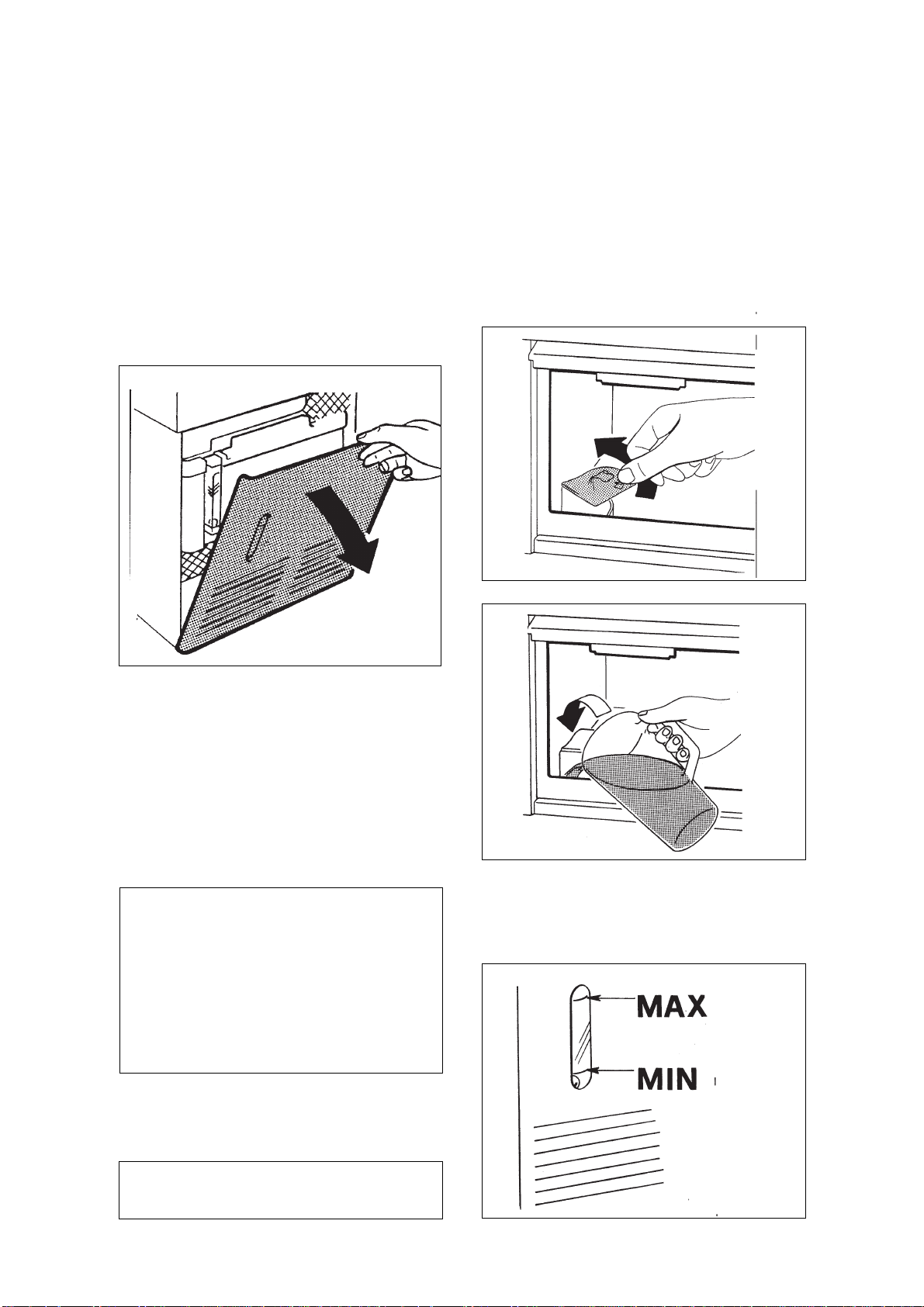

A water level indicator is provided on the front of

the reservoir alloving prompt visual inspection of

water level into reservoir.

A special funnel in comunication with the water

reservoir allows prompt and easy filling of water

reservoir itself without the need to remove it.

∂

∏

∑

DESCRIPTION

An attractive compact cabinet of textured plastic

with an almond enamel finish, makes the styling

of the ACM 25 very handsome allowing it to be in

harmony with many interior decors. The easy

removable front panel provides immediate access

to the water reservoir and to the electromechanical components.

SEALED REFRIGERATION SYSTEM

The compressor is fully hermetic and its motor is

internally spring-mounted to ensure quiet and

efficient operation of the Ice Maker.

The refrigerant circuit is entirely sealed to prevent

mishandling and refrigerant leaks.

SELF CONTAINED STORAGE BIN

The ACM 25 ICE MAKER stores its own ice

supply in a properly insulated ice storage bin.

A sensing bulb of a thermostat keeps automatic

control of the stored ice cubes level.

A sliding (recessing) plastic door located in the

upper front of the cabinet gives ample access to

the storage bin.

π

∫

bin recessing door

∂

ice storage bin

∑

water vessel

∏

water level indicator

π

front panel

∫

Page 5

Page 5

Page 5

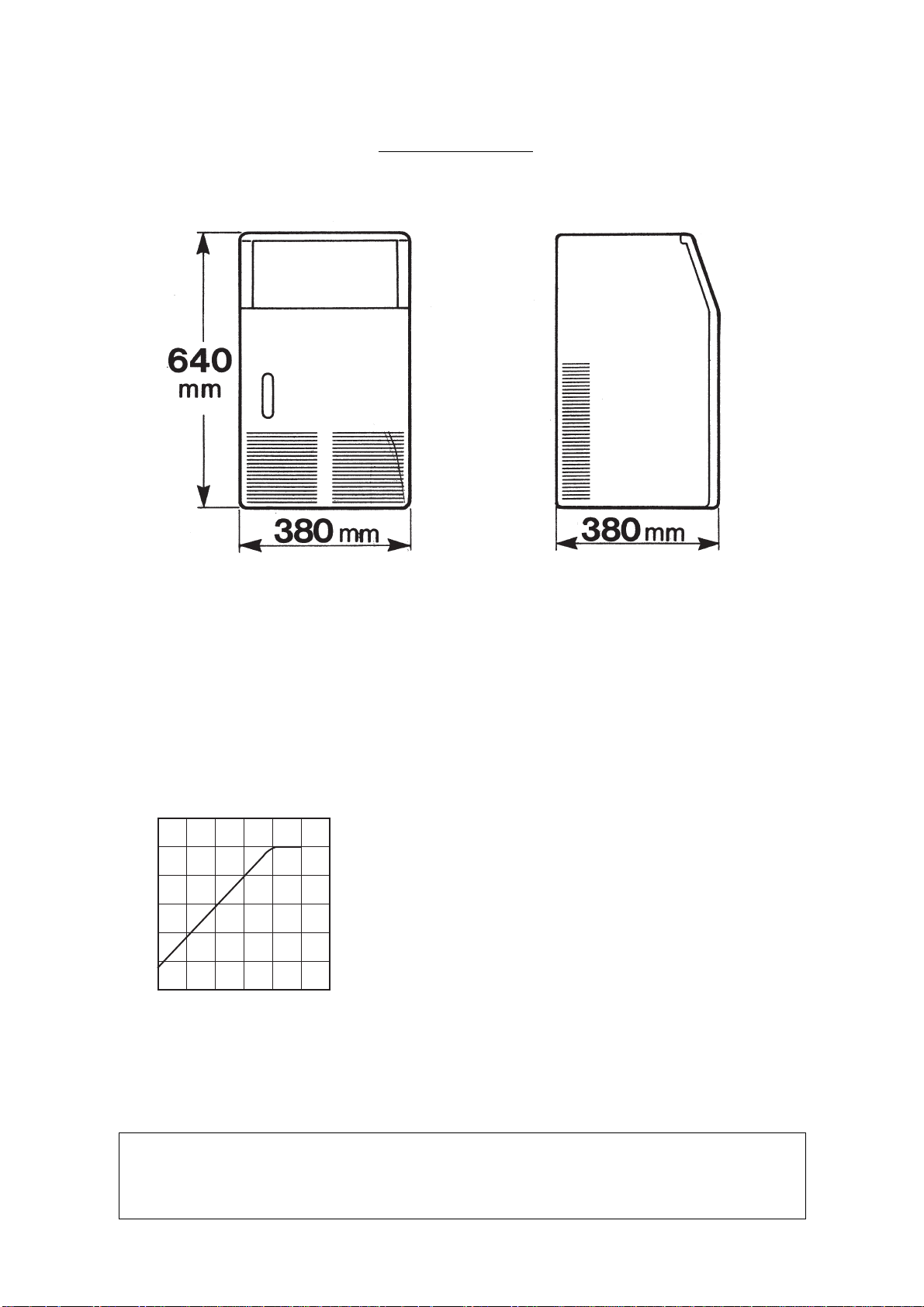

SPECIFICATIONS

AIR COOLED MODELS

Kg.

11

10

9

8

7

6

ICE PRODUCED PER 24 HRS.

5

35 30 525 20 15 10

AMBIENT TEMPERATURE

• Dimensions = m/m 380 wide-380 deep-640 high

• Weight = 29 kg (64 Ibs.)

• Cabinet = Plastic

• Finish = Enamel

• Color = Almond

• Storage bin = ABS

• Door = Sliding (recess)

• Power Requirements = 230 Volts, 50 Hz, 1 Phase

• Power Consumption = 4,5 Kwh x 24 HRS

• Wire Size = 1 m/m

2

• Fuse Size = 6 Amps

• Compressor = 1/5 HP

• Refrigerant metering

device = Capillary

• Refrigerant Charge = 220 grms FREON, R 134 A

• Harvest Means = Hot gas

o

°C

• Cubes per harvest = 8

• Storage bin capacity = 3.5 Kgs. (7.7 Ibs.)

• Water reservoir capacity = 4 liters (1.1 gl.)

°C

°F

NOTE.

When machine is “built-in” at ambient temperature of 32°C (90°F) indicated ice capacity

decreases about 10%.

To keep your SCOTSMAN CUBER performing at its maximum capacity, it is necessary to perform

periodic maintenance as outlined on page 8 of this manual.

Page 6

Page 6

Page 6

OPERATIONS TO PERFORM

BEFORE UNIT START-UP

1) After unpacking the unit, visually inspect its

exterior and make sure it does not show any

severe damage.

2) Remove Lower Compartment Panel and

inspect for concealed damage; then check if fan

blades move freely, and if compressor is snug on

all mounting pads.

OPERATING INSTRUCTIONS

START-UP

1) Locate on left side, in storage bin

compartment the funnel for pouring the water.

2) Through this funnel pour in unit water

reservoir 4 liters of fresh potable water.

3) Open the bin door and remove any

wrappings or adhesive tape that may be inside,

as well as the instruction card attached to the

control knob.

4) Use clean damp cloth or disposable paper

wiper to wipe clean the interior surface of ice

storage bin.

5) Place ice maker in its selected permanent

location and make sure that it is properly levelled.

NOTICE:

shall include:

a) Minimum room temperature 10°C

(50 degrees F); and maximum room temperature 35°C (95 degrees F)

b) Well ventiled location for efficient air

removal around the unit and maintain proper

condensing operation.

c) Service Access i.e. adequate space for

prompt service inspections.

6) Check that the location source voltage

corresponds with the voltage specified on the

nameplate of the unit.

Prior consideration for location site

3) Check to see through the water level glass

the water level obtained. (Must not exceed the

maximum level line and not below minimum level

line).

WARNING: The location power source

must have a solid earth wire connection.

Page 7

Page 7

Page 7

4) Plug the electric cable into the appropriate

socket. Make sure that the indicator on the control

knob is pointing to the “white dot”. The machine

is now working and the first cooling cycle can

begin.

5) The first freezing cycle will last about 35

minutes. During this time, make sure that the

plastic curtain that covers the water spray system

hangs down loose and no excessive water is

passing through, make sure to eliminate

eventually noises and vibration sources.

6) After about 35 minutes of operation, the

first ice cubes harvest takes place.

7) During the harvest cycle, which lasts about

3 minutes, the hot gas, circulating through the

evaporator serpentine, defrosts the ice cubes up

to the point that they are released from their mold

cups and drop into the storage bin.

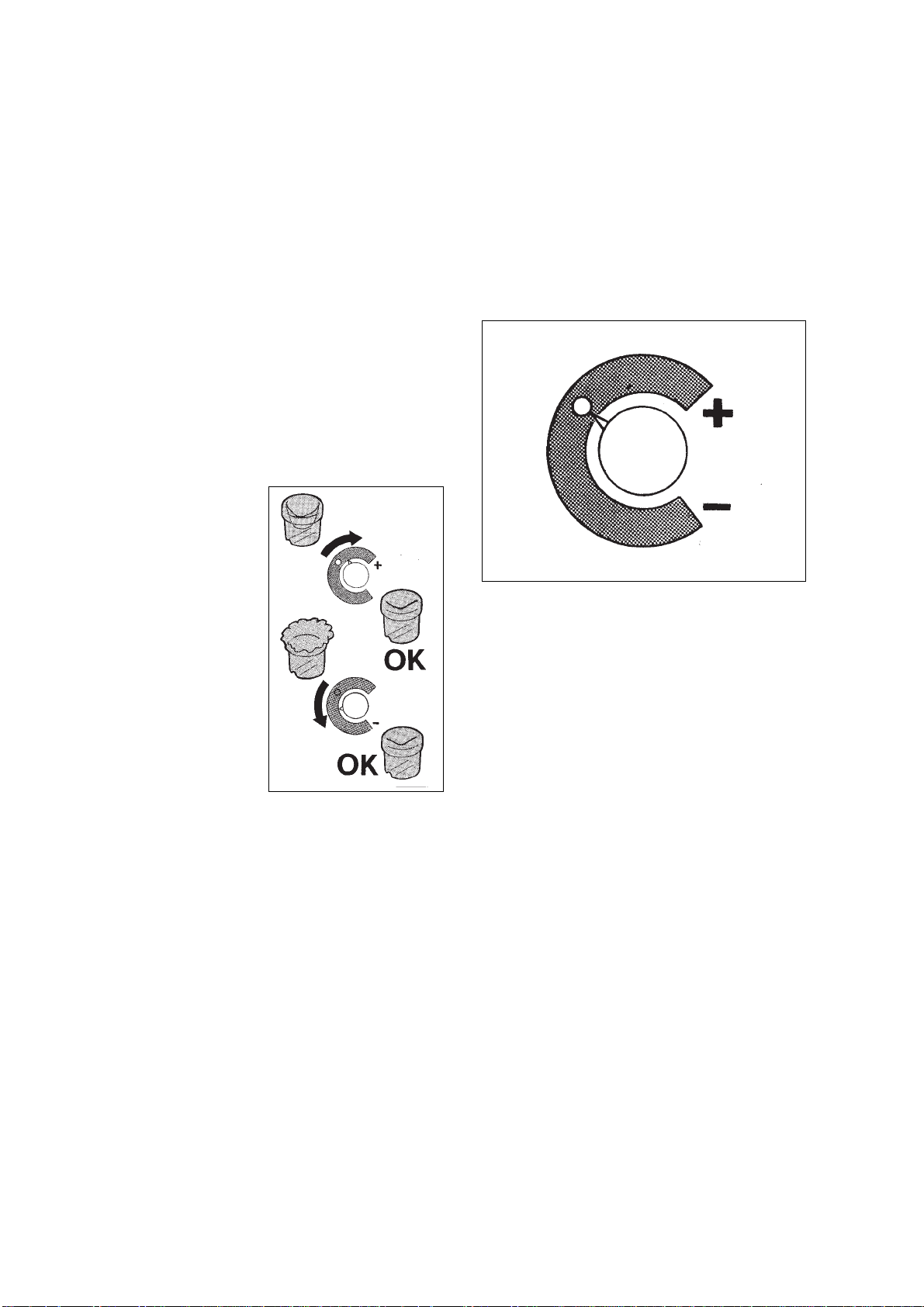

8) If the tem-

perature of the

room in which the

machine is place

is below 20°C, the

cubes will tend to

be partly hollowed out (see fig.

on right).

If, on the other

hand, the room

temperature is

above 30°C the

cubes produced

will have a jagged

rim of ice around

the crown.

9) If it is thought necessary, the above

situations can be remedied by, in the first case,

turning the control knob indicator (as little or as

much as is required) to the left of the white

marker and, in the second case, turning the knob

to the right. It should, however, be remembered

that if the room temperature returns later to the

20 ÷ 30°C range, the knob indicator must once

again be turned to point to the white dot. (see fig.

below).

10) The ice maker will automatically stop when

the ice cubes in this storage bin compartment

cover the sensing bulb of the bin thermostat and

will automatically start when the same sensing

bulb will be cleared from the ice.

11) Remember to fill up the water reservoir

before the water level in it goes below the minimum

level line of the indicator.

In any case, if for some reason the machine is left

running for a short time without water, no serious

harm will be caused.

Page 8

Page 8

CLEANING AND CARE

WARNING - Before proceeding with

any cleaning operation make sure that

the power line of the unit is disconnected.

WATER RESERVOIR AND STORAGE

BIN LINER

All commercial units that make or contain edible

produces, require a frequent throught sanitation

of all their parts that are in contact with the

produces.

It is recommendable, therefore, to perform the

cleaning and disinfecting operation once a week

as per the following indications.

Page 8

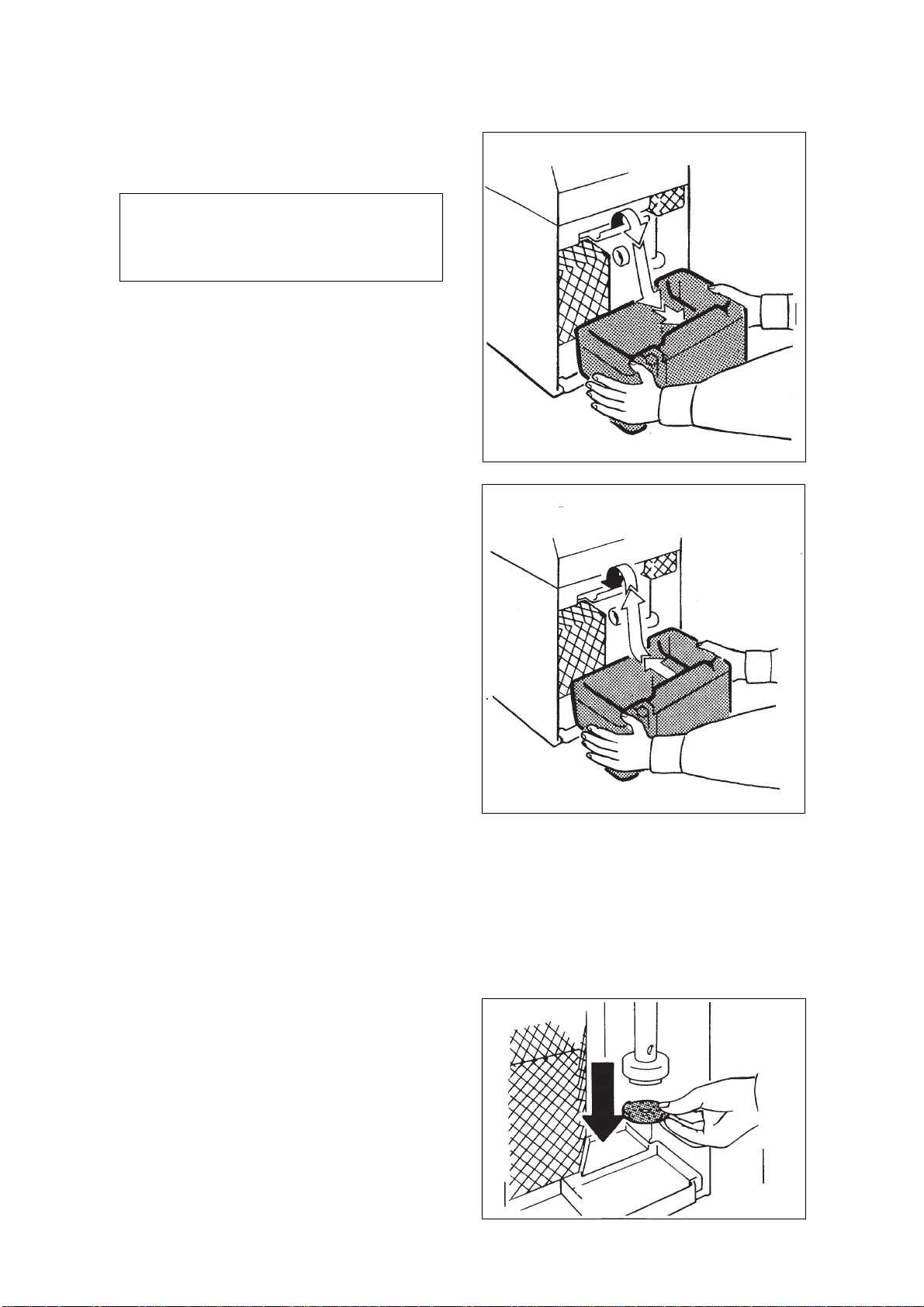

- Remove all ice cubes deposited in ice storage

bin if there are any.

- Remove the front lower panel by pulling it

from its upper edge and locate the water

reservoir.

Place one hand under the reservoir in order to

hold it and with the other grab the hooked front

edge.

- Slightly move the reservoir upward until it is

loose, than lower and tilt it a bit while

drawing out (try to avoid the pump body in

doing this).

- Make this reservoir empty and then place it back

in the unit.

- In a separate plastic pan, prepare a solution with

two liters of water and one full spoon of chlorine

water (hypochlorite).

- Pour the prepared solution into the storage bin

compartment than wipe clean its interior,

meanwhile the solution flows down into the

reservoir.

- Connect the power line and put in operation the

unit for few minutes. The bleaching solution will

be circulated by the pump through the water

pipes and nozzles.

PUMP INLET SCREEN

While the water reservoir is removed, it is

recommendable to clean the water pump inlet

screen.

Pull it down with gentle pressure and wash it

clean under a stream of tap water. Once the

screen is properly cleaned reposition it in its

original place on the pump body.

- Disconnect the power line, remove again the

plastic reservoir, make it empty then re-fit it in its

place.

- Pour through the funnel the necessary quantity

of new fresh water until the maximum water

level in the water reservoir is reached.

- The until is now sanitized and can resume

normal operations.

Page 9

Page 9

Page 9

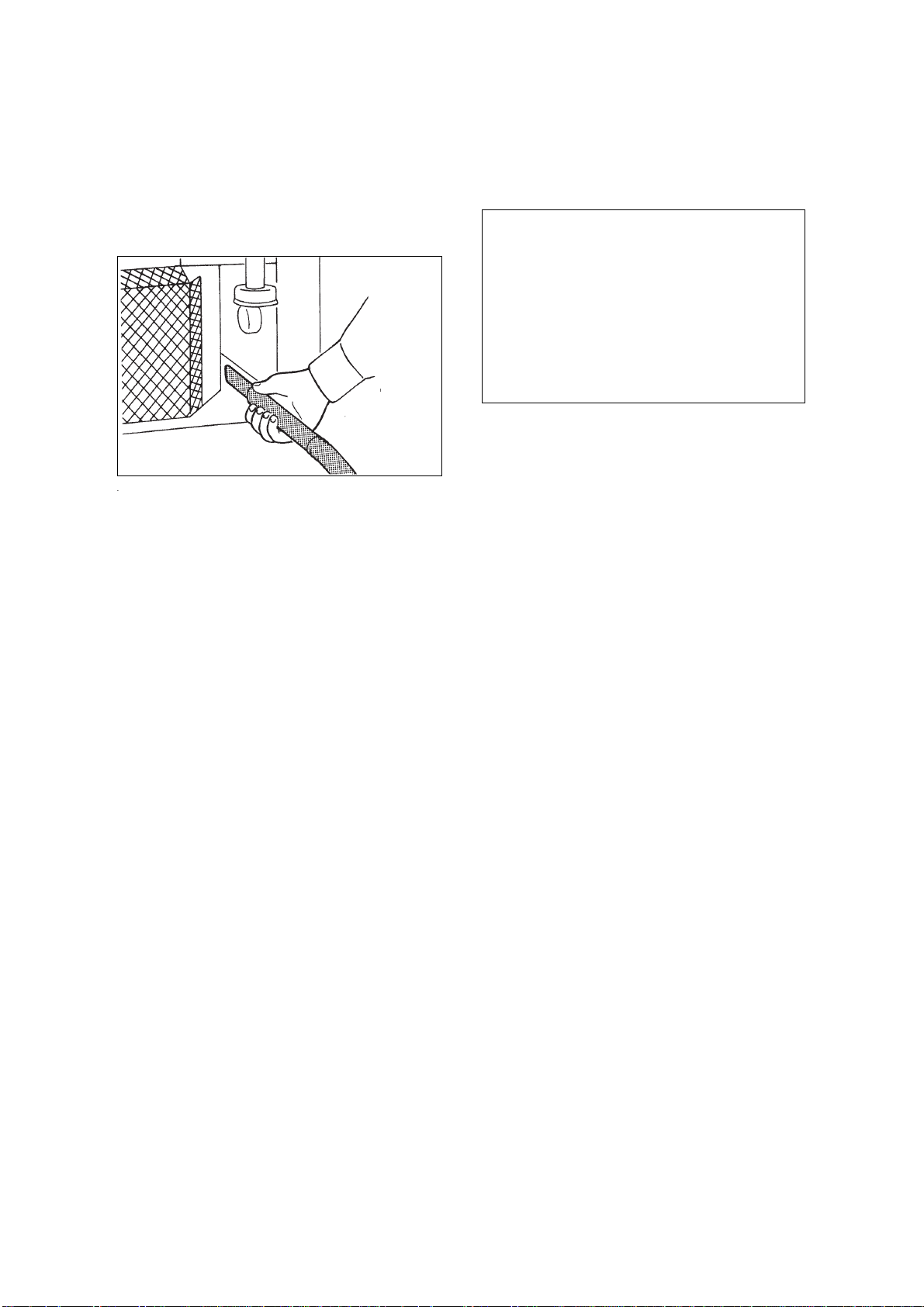

AIR COOLED CONDENSER

It is very important to clean the condenser

regularly. A dirty or blocked condenser, will

drastically reduce ice production.

Use a vacuum cleaner to remove dust from the

front of the condenser.

CABINET EXTERIOR

Clean with warm water. Do not apply wax.

Note.

When cleaning the floor in the immediate front the unit, try to do not move much

dust that could be easily sucked inside the

units through the panel louvers.

Eventually, for few seconds, you can place

in front of the louvers a piece of paper or

cardboard to prevent that the brushed

dust panetrates into the machine

compartment.

Page 10

Page 10

Page 10

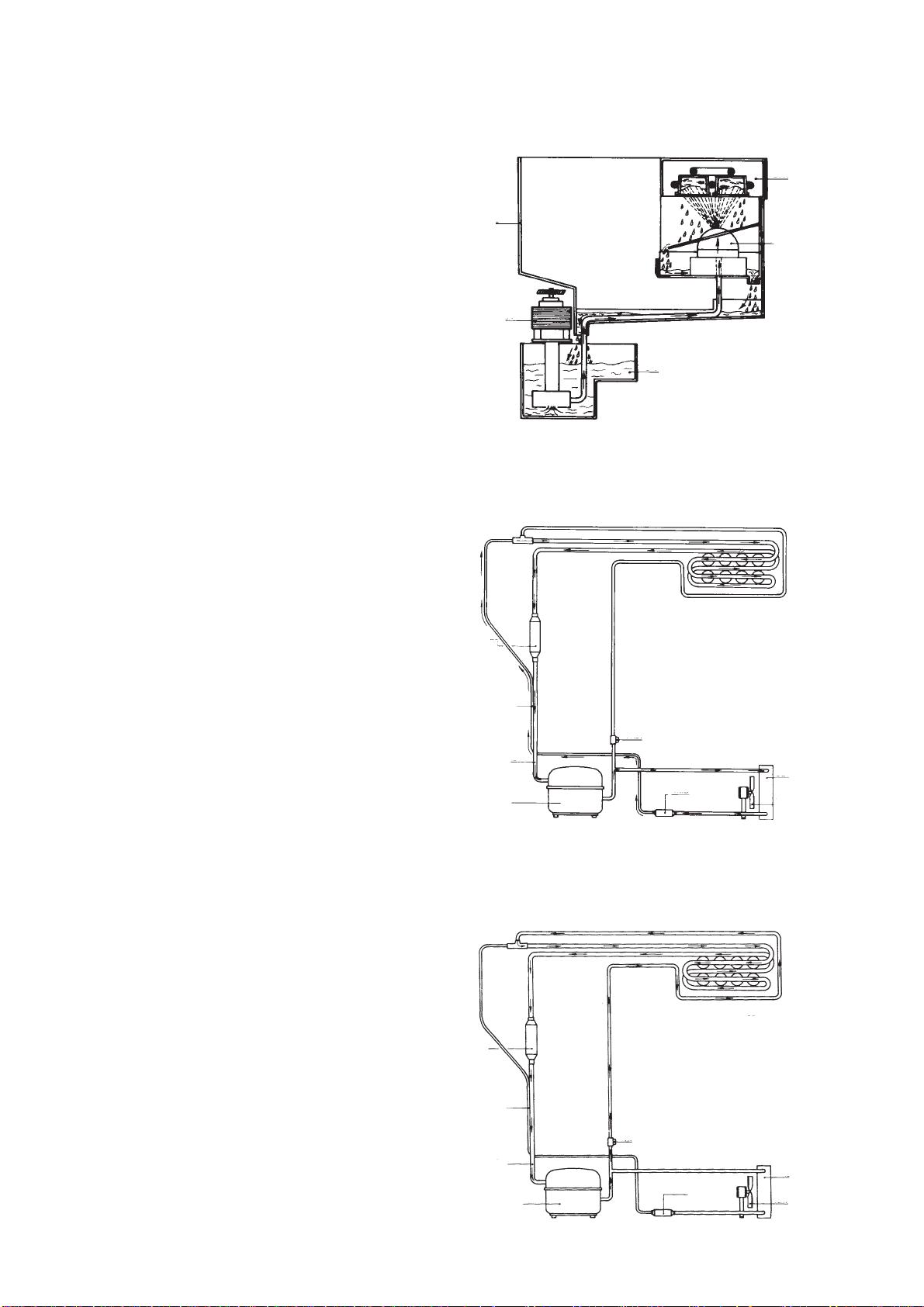

PRINCIPLE OF OPERATION

In the Scotsman ACM 25, the water to make ice

is continually moved or circulated by a small

electric pump that sprays the water under gentle

pressure through the two spray jets into the eight

inverted cube molds.

Part of the water that hits the cold refrigerated

molds freezes, building gradually into full ice

cubes bell shaped.

FREEZING CYCLE (How it works)

The hot gas refrigerant, pumped and discharged

by the compressor, passes through the condenser

where the fan blowing air causes the changing of

it into liquid.

The liquid line takes the refrigerant from the

condenser to the capillary tube. During the travel

into the capillary tube, the liquid refrigerant looses

gradually its temperature and pressure, then it

reaches the evaporator coils.

Because of the water sprayed against the

evaporator molds and coil, the liquid refrigerant

senses the heat of this water and starts boiling,

changing, as a consequence, from liquid into

vapor state.

The vapor refrigerant is sucked back to the

compressor through the suction line.

The freezing cycle is controlled by a temperature

control which determines as well the length of the

cycle and consequently the size of the ice cube.

During this phase, the contact point of the temperature control maintains closed the circuit of the

water pump which constantly sprays the water

under the evaporator mold cups up to the point

that the ice cubes reach their full size.

∑

∑

WATER CIRCUIT

∂

∏

π

① EVAPORATOR

≠ BIN

∫

③ SPRAY TUBE

④ WATER PUMP

∞ WATER RESERVOIR

FREEZING CYCLE

∂

① EVAPORATOR

≠ ACCUMULATOR

③ CAPILLARY TUBE

④ SUCTION LINE

∞ COMPRESSOR

± HOT GAS SOLENOID

∏

❻

± VALVE CLOSED

≤ CONDENSER

≥ FAN MOTOR

⑨ DRIER

π

❼

∫

❾

Ω

HARVEST CYCLE (How it works)

As soon as the temperature control senses the

temperature in the evaporator corresponding to

the full size cubes, the contact moves to close the

circuit of the Hot Gas Valve Coil and consequently

to open the circuit of the water pump which

momentarily stops.

The hot gas refrigerant discharged by the

compressor is now diverted through the opened

hot gas valve to the evaporator coil.

The hot gas circulares through the evaporator

coil raising the temperature around the cube

cups sufficiently to release the ice cubes.

The released ice cubes drop by gravity into the

storage bin.

The temperature control bulb, due to the warm

temperature in the evaporator moves again the

contact de-energizing the hot gas valve and

energizing the water circulating pump starting a

new freezing cycle.

∑

π

∏

HARVEST CYCLE

❻

❾

∂

① EVAPORATOR

≠ ACCUMULATOR

③ CAPILLARY TUBE

④ SUCTION LINE

∞ COMPRESSOR

± HOT GAS SOLENOID

± VALVE OPENED

≤ CONDENSER

≥ FAN MOTOR

⑨ DRIER

❼

Ω∫

Page 11

Page 11

Page 11

SERVICEMAN’S INFORMATIONS

GENERAL

perature.

It gradually pulls down to 7 atm at the end of the

Models ACM 25 Ice Cube Makers have been

designed for little service and maintenance

requirements.

Average head pressure is 10 atm at the start-up

of the freezing cycle at 21°C ambient tem-

cycle.

Suction pressure at the start-up of the freezing

cycle will be around 3 atm then it pulls down

gradually to approximately 0 atm at the end of

freezing cycle.

SERVICE ANALYSIS

The following Service Analysis Section is for use in aiding the serviceman in diagnosing a particular

problem for pin-pointing the area in which the problem lies, thus an ever available reference for proper

corrective action.

SYMPTOM POSSIBLE CAUSE CORRECTION

Machine does not make ice. Fuse in Power Line Blown. Check fuses in the house fuse

box. Other loads on the same

line may have caused fuse

to blow. Use a 10 amp circuit

and fuse.

Water reservoir empty. Re-fill water reservoir.

Temp. control out of setting. Check for proper setting.

Wiring broken or connection off. Check electrical circuitry.

Compressor does not run. Any of the following may be

Water pump not operating. Clean or replace pump.

Bin thermostat not operating Check thermostat by warming

correctly. with hand and cooling with ice

Restricted Capillary Tube. Purge and recharge.

Moisture and air in system. Purge - recharge - replace drier.

Shortage of refrigerant. Charge unit properly.

Low ice capacity. High Room Temperature. Provide ventilation to the unit.

High head pressure. Dirty condenser. Clean.

the cause. Starting relay,

overload, or defective compressor.

cube. Replace if necessary.

Decrease temperature as much

as possible.

Cubes too large. Cube Size Control set Check and adjust for proper

improperly. operation.

Page 12

Page 12

SYMPTOM POSSIBLE CAUSE CORRECTION

Cubes cloudy. Spray jets Dirty. Clean.

Page 12

Shortage of Water. Check water level in water

Dirty water supply, accumulator Wipe clean water reservoir

of dirty in water system. and re-fill with new fresh water.

Cubes too small. Shortage of water. Check water level in reservoir.

Cube size control set Check and adjust for proper

improperly. operation.

Water leaking from pump Check clamp and hoses.

hoses. Replace if necessary.

Compressor cycles Low voltage. Minimum voltasge to be 10%

intermittently. Iess than normal rating.

Air in the system. Purge and recharge.

Poor harvest cycle. Too short defrost time. Check temperature control -

Hot gas not passing through Check hot gas valve coil,

valve. replace if necessary.

reservoir and re-fill.

Clean water pump screen.

replace if necessary.

Shortage of refrigerant. Charge unit properly.

Ice cubes too big. Set control knob correct shape

of ice cubes.

Page 13

Page 13

Page 13

WIRING DIAGRAM

A BLUE

M BROWN

N BLACK

G-V YELLOW-GREEN

PUMP MOTOR

BIN. TEMP. CONTROL

FAN MOTOR

MOTOR SOLENOID VALVE

6

MOTOR COMPRESSOR

THERMOSTAT

THERMOSTAT

6

BIN. TEMP. CONTROL

2

4

2

4

COMPRESSOR MOTOR

HOT SOLENOID VALVE

PUMP MOTOR

FAN MOTOR

Page 14

Page 14

Page 14

REMOVAL & REPLACEMENT PROCEDURE

WARNING: DISCONNECT THE ELECTRICAL SUPPLY BEFORE PERFORMING

ANY OF THE FOLLOWING OPERATIONS

Cabinet Removal

1. Remove lower panel by pulling forwand at

both top corners.

2. Remove water reservoir.

3. Disconnect the electrical cord and pass it

through the rear side of the cabinet into the unit

compartment.

4. Unloose and remove the two screws

secuting the front door trim to the side walls of

cabinet.

5. Through the interior of the compressor

compartment reach the three screws securing

the cabinet to the chassis and unloose them.

(See indicating arrows).

6. Remove the bottom drip tray.

7. Remove the cabinet by pulling it forward

from the rear side.

7. Locate the thermostat bulb on the evaporator

and push it out from its well.

8. The control is now entirely removed.

9. Re-assemble the new control by

proceeding on reserve.

NOTE:

Seal both the ends of bulb holder

after the introduction of the new evaporator

thermostat capillary tube to avoid that some

water freezes inside.

Bin thermostat replacement

1. Follow step 1 thru 7 for cabinet removal.

2. Follow step 1 thru 4 for temperature control

replacement.

3. Unloose and remove the nut securing the

bin control to the panel.

4. Remove the end of bin control capillary

tube from the interior of the bin.

5. Remove the spade connection from the

Temp. Control.

6. The control is now completely free.

Proceed to re-assemble acting on reserve.

Temperature control replacement

(Evaporator)

1. Follow step 1 thru 7 for cabinet removal.

2. Remove temperature control knob by pulling

it.

3. Unloose the screw securing the control box

panel.

4. Pull forward the control box panel.

5. Unloose and remove the nut securing the

temperature control to the panel.

6. Remove the spade connections from the

control.

Water pump Replacement

1. Follow step 1 thru 7 for cabinet removal.

2. Remove the screw which holds the water

pump in place.

3. Remove the two water pump electrical

leads.

4. Remove the hose from pump bottom

housing.

5. Lift out the pump.

6. To small the replacement pump, follow

previous steps in reverse.

Page 15

Page 15

THE PARTS ILLUSTRATIONS AND PARTS LIST

CONTROL PANEL ASSY

Page 15

④

±

≤

≥

Pos. Part. N. Description

4 630070.04 Terminal board

6 620264.10 Evaporator thermostat

7 660321.01 Panel

8 620263.00 Bin control

Page 16

Page 16

FRONT - VIEW

Page 16

Pos. Part. N. Description

3 620433.00 Water pump assy

18 650330.00 Plug

22 660321.00 Control panel

24 784169.03 Curtain

25 660330.00 Funnel cover

Page 17

Page 17

SIDE - VIEW

Page 17

Pos. Part. N. Description

44 741049.02 Evaporator cover

46 650331.01 Insulation

47 660326.00 Cabinet assy

49 660340.02 Evap. bulb holder

660386.00 Clip

50 783130.00 Evap housing

51 640093.00 Seal ring

52 660320.00 Water spray tray

53 610139.00 Plastic hose

(pump to spray system)

54 660336.00 Cover

57 660325.00 Water drip tray

58 781284.00 Bin door

59 782053.00 Ice storage bin

60 660339.00 Bulb holder

* Not shown

Pos. Part. N. Description

61 781285.00 Front lower panel

62 793114.00 Water reservoir assy

63 781335.00 Reservoir holder

65 784234.00 Evaporator platen assy

66 784252.02 Suction accumulator

67* 660359.00 Funnel insert

68 660335.00 Upper separator

69 660343.00 Lower separator

70 660338.00 Rubber fitting

71 660337.00 Sight glass

72* 783141.00 Reservoir cover

660424.00 Reservoir cover - Pump

73 660341.00 Rubber plug

Page 18

Page 18

COMPRESSOR & CONDENSING UNIT

Page 18

Pos. Part. N. Description

1 670097.08 Compressor cpl. Electrolux

670066.09 Compressor cpl. U.H.

2 620306.48 Hot gas valve coil

620306.14 Hot gas valve body

3 620419.00 Fan motor only

7 620058.65 Protector for Electrolux

620058.64 Protector for U.H.

Pos. Part. N. Description

8 620057.35 Relay for Electrolux

620057.32 Relay for U.H.

23 630003.05 Dryer

35 620285.00 Condenser

36 781283.00 Chassis assy

Page 19

Page 19

Page 19

ACM 25 - COMPRESSOR AND ELECTRIC COMPONENTS CHART

Model Volts Compr. Model Compr. Cpl.

ACM 25-2 230/60/1 U.H. AE Z4425Y 670066.08 620057.40 620058.74 620167.45

ACM 25-6 230/50/1 Cubigel GL 80PB 670097.08 620057.35 620058.65 –

U.H. AE Z4425Y 670066.09 620057.32 620058.64 –

Model Water pump

ACM 25-2 620306.48 620433.01 620419.00

ACM 25-6 620306.48 620433.00 620419.00

Hot gas valve Fan motor

coil only

Compr. Compr. Start

relay protector Capacitor

Page 20

Page 20

PER L’UTILIZZATORE

Pagina 20

Page 20

Il vostro fabbricatore di ghiaccio SCOTSMAN

modello ACM 25 è un prodotto accuratamente

progettato e costruito per assicurarvi anni di

ottime prestazioni con costi di esercizio e manutenzione minimi.

Costruita dalla maggiore industria mondiale del

settore, la vostra SCOTSMAN impiega lo stesso

principio per la fabbricazione del ghiaccio lungamente sperimentato su decine di migliaia di

apparecchi in funzione in tutte le parti del

mondo.

Molti di voi avranno per la prima volta l’opportunità di vedere ed utilizzare i cubetti di ghiaccio

SCOTSMAN caratterizzati da una elevata solidità e trasparenza e, molto importante, da una

lenta fusione, fattori non riscontrabili in quelli

formati nel vostro frigorifero domestico che in

genere sono opachi e di rapida fusione.

Vorremmo ora suggerirvi di dedicare un po’ del

vostro tempo alla lettura del presente manuale;

potrete così sincerarvi delle ragioni per cui i

cubetti di ghiaccio SCOTSMAN sono molto

più trasparenti e solidi di quelli del vostro

frigorifero.

Non è richiesto nessun allacciamento idraulico

Togliendo il pannello frontale e/o l’intero mantello si può facilmente accedere ai vari componenti

del fabbricatore di ghiaccio ACM 25.

Page 21

Pagina 21

Page 21

INTRODUZIONE

Page 21

INFORMAZIONI PER L’UTILIZZATORE

Il presente manuale è stato emesso per fornire

tutte le informazioni utili onde agevolare il compito di chi è preposto all’avviamento ed alla

riparazione dei fabbricatori di ghiaccio; infatti,

oltre alle specifiche tecniche contiene numerose

indicazioni per il posizionamento, l’avviamento,

il funzionamento, la manutenzione e la pulizia

del fabbricatore di ghiaccio a cubetti SCOTSMAN

modello ACM 25.

I fabbricatori di ghiaccio a cubetti ACM 25 sono

stati progettati e costruiti con un elevato standard

qualitativo; essi vengono collaudati interamente

per diverse ore e sono in grado di assicurare il

massimo rendimento relativamente ad ogni particolare uso e situazione.

Un notevole numero di informazioni è esposto

minuziosamente nei diversi capitoli, che sono:

Informazioni Generali; Avviamento e Marcia;

Principi di Funzionamento; Procedure per la

Regolazione, la Rimozione e la Sostituzione;

Schemi Elettrici; Istruzioni per la Manutenzione e

la Pulizia e le illustrazioni dei componenti e Parti

di Ricambio.

Una delle caratteristiche principali di questa serie di apparecchi consiste nel loro avviamento

estremamente semplice.

Non richiedendo alcun collegamento idraulico,

possono essere collocati e messi in funzione in

qualsiasi luogo.

Lo sportello scorrevole, posto nella parte frontale

superiore del mobile, permette un agevole accesso al contenitore stesso.

BACINELLA DELL’ACQUA AMOVIBILE

Caratteristica esclusiva dell’ACM 25 consiste

nell’avere una bacinella contenente l’acqua, agevolmente rimovibile dall’apparecchio per facilitare la sua pulizia periodica.

L’indicatore di livello, situato nella parte frontale,

permette una pronta verifica del livello dell’acqua.

Uno speciale imbuto, posto nell’angolo sinistro

del contenitore del ghiaccio, consente il ripristino

del livello d’acqua nella bacinella senza il bisogno di rimuovere la stessa.

∂

∏

∑

DESCRIZIONE

Grazie ad un mobile di design sobrio e gradevole, in plastica smaltata color avorio, il fabbricatore

di ghiaccio a cubetti ACM 25 può essere armoniosamente inserito in qualunque ambiente. Il

pannello frontale, di facile rimozione, permette

un immediato accesso alla bacinella dell’acqua

ed ai componenti elettrici dell’apparecchio.

SISTEMA REFRIGERANTE

Il compressore impiegato è del tipo ermetico,

quindi particolarmente efficace e silenzioso durante il funzionamento; il circuito frigorifero è

completamente ermetico onde prevenire delle

perdite di refrigerante dal medesimo.

CONTENITORE DEL GHIACCIO

Il fabbricatore di ghiaccio ACM 25 è in grado di

stivare la propria produzione in un contenitore

propriamente isolato.

Il bulbo sensibile del termostato contenitore

mantiene automaticamente il livello del ghiaccio

in esso stivato.

π

∫

∂

∑

∏

π

∫

Page 22

Page 22

SPECIFICHE TECNICHE

Pagina 22

Page 22

RAFFREDDAMENTO AD ARIA

Kg.

11

10

9

8

7

6

GHIACCIO PRODOTTO IN 24 ORE

5

35 30 525 20 15 10

TEMPERATURA AMBIENTE

• Dimensioni = larghezza mm. 380

== profondità-380 altezza-640

• Peso = 29 kg.

• Mobile = Plastica

• Finitura = Verniciato

• Colore = Avorio

• Contenitore ghiaccio = ABS

• Sportello = Scorrevole

• Alimentazione elettrica = 230/50/1

• Consumo di energia

elettrica = 4,5 Kwh x 24 ore

• Dimensione cavo di

alimentazione = 1 mm

2

• Fusibile = 6 Amps

• Compressore = 1/5 HP

• Dispositivo espansione

refrigerante = Tubo capillare

• Carica refrigerante = 220 gr. FREON R 134 A

• Scongelamento = Tramite gas caldo

• Cubetti per ciclo = 8

• Capacità contenitore

o

°C

ghiaccio = 3.5 Kg.

• Capacità bacinella acqua = 4 litri

°C

°F

NOTA

. Con l’apparecchio incassato la produzione di ghiaccio è ridotta rispetto a quanto indica il

diagramma, sino a raggiungere un massimo del 10% a temperatura ambiente superiore a 32°C.

Per mantenere la produzione del vostro fabbricatore di ghiaccio a cubetti al massimo della sua

condizione è necessario eseguire la manutenzione periodica come illustrato a pagina 25 di questo

manuale.

Page 23

Pagina 23

Page 23

Page 23

OPERAZIONI DA EFFETTUARE

PRIMA DELL’AVVIAMENTO

1) Sballare l’apparecchio e controllare che

non abbia subito alcun danno durante il trasporto.

2) Togliere il pannello frontale inferiore ed

asportare il serbatoio acqua per meglio controllare l’interno dell’apparecchio; assicurarsi che il

ventilatore giri liberamente e che il compressore

sia ben posizionato sui supporti.

ISTRUZIONI DI

FUNZIONAMENTO

AVVIAMENTO

1) Localizzare nella parte sinistra del contenitore l’imbuto di riempimento acqua alla macchina.

2) Versare attraverso l’imbuto 4 litri di acqua

potabile.

3) Aprire lo sportello del contenitore e togliere

eventuali involucri o nastri adesivi all’interno

dello stesso, nonchè il cartellino d’istruzioni fissato sul volantino di comando.

4) Pulire l’interno del contenitore con un panno umido e pulito.

5) Sistemare l’apparecchio nella sua posizione definitiva ed assicurarsi che sia ben livellato.

NOTA:

nare la macchina occorre tener presente

che:

a) Minima temperatura ambiente

b) Luogo ben ventilato per una efficiente

c) Spazio adeguato per una facile ispezione

6) Accertarsi che l’alimentazione elettrica disponibile corrisponda a quanto indicato sulla

targhetta dell’apparecchio.

nella scelta del luogo in cui posizio-

10°C (50°F);

Massima temperatura ambiente

35°C (95°F)

ventilazione intorno all’apparecchio e

quindi corretto funzionamento del condensatore.

dell’apparecchio e delle sue parti.

3) Controllare attraverso l’indicatore di livello

la posizione raggiunta dall’acqua. (Non deve superare il massimo nè essere inferiore al minimo).

ATTENZIONE: la presa elettrica di collegamento all’apparecchio deve essere

provvista di un buon collegamento a terra.

Page 24

Page 24

Pagina 24

Page 24

4) Inserire la spina nella relativa presa di corrente. Accertarsi che il volantino di comando

abbia l’indicatore posto in corrispondenza del

“punto bianco”. L’apparecchio entra in funzione

ed ha inizio il primo ciclo di refrigerazione.

5) Per il primo completamento di questo ciclo

occorreranno circa 30/35 minuti. Durante questo

tempo accertarsi che la tendina paraspruzzi sia

ben posizionata e non lasci passare acqua in

eccesso. Eliminare eventuali cause di rumori o

vibrazioni.

6) Dopo circa 30/35 minuti si avrà il primo ciclo

di sbrinamento che consentirà il distacco e la

caduta dei primi 8 cubetti.

7) Il distacco e la conseguente caduta degli 8

cubetti è causata dal gas caldo pompato dal

compressore che, circolando nella serpentina

dell’evaporatore, scalda le sedi dei cubetti provocando quindi un leggero scioglimento dei

cubetti stessi che, non essendo più trattentuti

dall’effetto congelante, cadono nel contenitore di

raccolta.

8) Se la tempe-

ratura del locale

in cui è posto l’apparecchio è inferiore a 20°C, i

cubetti prodotti

possono avere un

incavo pronunciato al loro intervento (Vedi figura a lato).

Se invece la temperatura ambiente sarà superiore

a 30°C i cubetti

prodotti tenderanno ad avere

delle frastagliature di ghiaccio

attorno alla corona.

9) Chi lo ritenesse necessario, potrebbe migliorare le sopra illustrate situazioni di cubetti,

portando, nel primo caso, l’indicatore del volantino di comando più o meno leggermente a

sinistra del punto bianco di riferimento, nel secondo caso più o meno leggermente a destra.

Occorre però tener presente che, qualora la

temperatura ambiente rientrasse entro i

20 ÷ 30°C, l’indicatore del volantino andrà ripor-

tato in corrispondenza del punto bianco (Vedi

illustrazione sotto).

10) L’apparecchio si fermerà automaticamente quando il contenitore sarà pieno di ghiaccio ed

i cubetti toccheranno il bulbo del termostato

contenitore, e si rimetterà automaticamente in

funzione una volta prelevato il ghiaccio.

11) Ricordarsi di riempire di acqua il contenitore dell’apparecchio ogni qualvolta il livello dell’acqua sarà inferiore al minimo .

Comunque, se l’apparecchio verrà lasciato in

funzione senz’acqua per brevi periodi, per dimenticanza od altro, non avverrà alcunchè di

grave.

Page 25

Pagina 25

Page 25

PULIZIA E MANUTENZIONE

ATTENZIONE. Prima di procedere a qualsiasi operazione di pulizia accertarsi che

la corrente elettrica dell’apparecchio sia

staccata.

BACINELLA CONTENITORE ACQUA E

RISERVA GHIACCIO

Tutte le apparecchiature commerciali che producono o preservano dei prodotti commestibili richiedono una pulizia ed una disinfezione frequente delle loro parti che sono in contatto con il

prodotto.

Per tale motivo si raccomanda di effettuare sul

produttore di ghiaccio una pulizia e disinfezione

settimanale secondo le indicazioni seguenti:

- Togliere tutto il ghiaccio eventuale contenuto

nella riserva di ghiaccio.

- Togliere il pannello frontale inferiore tirandolo

dal bordo superiore e localizzare la bacinella

acqua.

- Mettere una mano sotto alla bacinella per sostenerla e con l’altra prendere la sua parte

superiore.

- Muovere lentamente la bacinella verso l’alto

finché sia liberata dall’incastro, quindi verso il

basso piegandola leggermente in avanti mentre la si estrae. (Evitare di toccare il corpo della

pompa durante questa operazione).

-Svuotare completamente la bacinella e

rimetterala di nuovo al suo posto.

- In un recipiente a parte preparare una soluzione di due litri di acqua ed un cucchiaio di

varechina.

- Versare tale soluzione così preparata nella

riserva di ghiaccio e pulirne bene il suo interno

nel mentre la soluzione discende nella bacinella sottostante.

- Ricollegare la corrente elettrica all’apparecchio

e mettere in funzione la macchina per pochi

minuti. La soluzione pulente verrà fatta circolare dalla pompa attraverso i tubi dell’acqua e gli

spruzzatori.

- Staccare la corrente elettrica all’apparecchio,

togliere di nuovo la bacinella contenitore acqua, svuotarla completamente e rimetterla nella sua posizione originale.

- Versare attraverso l’imbuto di riempimento la

quantità di acqua potabile necessaria al riempimento del contenitore fino alla posizione massima indicata sull’indicatore di livello.

- L’apparecchio è adesso disinfettato e può riprendere il suo normale funzionamento.

Page 25

FILTRO ENTRATA POMPA

Quando si procede alla pulizia della bacinella è

consigliabile pulire anche il filtro di entrata della

pompa.

Togliere il filtro dal corpo pompa mediante una

leggera pressione e pulirlo sotto un getto di

acqua corrente. Indi rimetterlo nella sua posizione originale.

Page 26

Page 26

Pagina 26

Page 26

CONDENSATORE AD ARIA

E’ molto importante pulire periodicamente il condensatore ad aria. Un condensatore sporco o

bloccato riduce drasticamente la produzione di

ghiaccio. Usare un aspirapolvere per togliere lo

sporco accumulatosi sulla parte frontale del condensatore.

ESTERNO DELL'APPARECCHIO

Pulire con acqua tiepida. Non usare cera.

NOTA.

Quando si pulisce il pavimento nelle

immediate vicinanze dell’apparecchio, fare

in modo di non sollevare molta polvere che

potrebbe facilmente essere aspirata all’interno dell’apparecchio attraverso le feritoie del

pannello frontale.

Eventualmente per pochi secondi si potrebbe mettere davanti alle feritoie un foglio di

carta o di cartone per evitare che la polvere

sollevata possa penetrare all’interno

dell’apparechio.

Page 27

Page 27Pagina 27

Page 27

PRINCIPIO DI

FUNZIONAMENTO

Nel fabbricatore di ghiaccio SCOTSMAN modello ACM 25 l’acqua usata per la produzione del

ghiaccio è tenuta costantemente in movimento

tramite una pompa elettrica che spruzza l’acqua

a pressione moderata, attraverso gli spruzzatori,

all’interno dei bicchierini rovesciati

dall’evaporatore.

CICLO DI CONGELAMENTO

Il refrigerante allo stato gassoso pompato dal

compressore passa attraverso il condensatore

dove si trasforma in refrigerante allo stato liquido. La linea del liquido permette al refrigerante di

fluire dal condensatore al tubo capillare attraverso il filtro deumidificatore. Durante il passaggio

attraverso il tubo capillare il refrigerante allo stato

liquido perde gradualmente la sua pressione e

temperatura raggiungendo successivamente la

serpentina dell’evaporatore. L’acqua spruzzata

nei bicchierini rovesciati dell’evaporatore cede

del calore al refrigerante circolante all’interno

della serpentina, causandone l’evaporazione

quindi cambiandone di conseguenza il suo stato

fisico che da liquido diviene vapore.

Il refrigerante allo stato vaporoso dopo essere

passato attraverso l’accumulatore viene aspirato nuovamente dal compressore tramite la linea

di aspirazione.

Il ciclo di congelamento è regolato da un controllo della temperatura (termostato evaporatore)

che determina la durata dello stesso e di conseguenza la dimensione dei cubetti.

Durante il ciclo di congelamento i contatti elettrici

del termostato evaporatore mantengono chiuso

il circuito elettrico della pompa la quale spruzza

costantemente l’acqua nei bicchierini rovesciati

fino a che i cubetti di ghiaccio raggiungono le

giuste dimensioni.

∑

∑

CIRCUITO IDRAULICO

∂

∏

π

① EVAPORATORE

∫

CICLO DI CONGELAMENTO

≠ CONTENITORE

③ SPRUZZATORE

④ POMPA

∞ BACINELLA ACQUA

∂

∏

❻

π

❼

∫

❾

Ω

CICLO DI SBRINAMENTO

Al momento in cui il termostato evaporatore

sente la temperatura corrispondente ai cubetti di

ghiaccio di dimensione piena, i contatti dello

stesso cambiano posizione chiudendo il circuito

della bobina del gas caldo ed allo stesso tempo

si aprono i circuiti della pompa e del ventilatore i

quali cessano di funzionare.

Il refrigerante allo stato gassoso, pompato dal

compressore, è ora dirottato dalla valvola del gas

caldo aperta, direttamente alla serpentina

dell’evaporatore, seguendo il percorso più diretto cioè non passando attraverso il condensatore.

Il gas caldo, che circola all’interno della serpentina

dell’evaporatore, fa aumentare la temperatura

dei bicchierini facendo quindi distaccare i cubetti

di ghiaccio dai medesimi.

I cubetti staccatisi cadono per gravità sopra lo

scivolo da dove vengono convogliati all’interno

del contenitore del ghiaccio.

Grazie al fluire del gas caldo nella serpentina

dell’evaporatore, la temperatura dello stesso sale

e conseguentemente sale anche la temperatura

del bulbo sensibile del termostato evaporatore il

CICLO DI SBRINAMENTO

∂

∑

∏

❻

π

❾

quale inverte i suoi contatti disattivando la bobina della valvola gas caldo ed attivando la pompa

di circolazione dell’acqua iniziando così un nuovo ciclo di congelamento.

❼

Ω∫

Page 28

Page 28

INFORMAZIONI TECNICHE

Pagina 28

Page 28

PREMESSA

ad una temperatura ambiente di 21°C per poi

abbassarsi gradatamente attorno alle 7 atm alla

I fabbricatori di ghiaccio a cubetti ACM 25 sono

così semplici da ridurre la loro assistenza e

manutenzione a poche operazioni.

In media la pressione di mandata (alta pressione) è di 10 atm all’inizio del ciclo di congelamento

fine dei ciclo di congelamento.

La pressione di aspirazione (bassa pressione)

sarà di circa 3 atm all’inizio del ciclo di

congelamento per poi calare gradualmente at-

torno alle 0 atm alla fine del ciclo di congelamento.

SERVIZIO ANALISI

Il seguente capitolo serve come aiuto al tecnico riparatore nel diagnosticare un particolare problema,

individuare la sua possibile causa e suggerire le operazioni da intraprendere per porvi rimedio.

GUASTO POSSIBILE CAUSA RIMEDI SUGGERITI

L’unità non produce Fusibile sulla linea elettrica Sostituire il fusibile e cercare la

ghiaccio. bruciato. causa per cui è bruciato.

Bacinella contenitore acqua Ripristinare il livello.

vuota.

Cictuito elettrico interrotto. Controllare circuito elettrico.

Compressore non funziona. Verificare ognuna delle seguenti

possibili cause. Relè

d'avviamento, protettore, o

compressore difettoso.

Pompa non funziona. Pulire o sostituire la pompa.

Termostato contenitore non Controllare il suo funzionamento

funziona correttamente. scaldandolo con una mano e

Restrizione nel tubo Scaricare e ricaricare.

capillare.

Umidità e aria nel sistema. Scaricare - sostituire il filtro

Mancanza di refrigerante. Caricare correttamente

Bassa produzione di ghiaccio. Temperatura ambiente Provvedere a ventilare

elevata. l'apparecchio. Ridurre la

Alta pressione di mandata. Condensatore sporco. Pulire.

raffreddandolo con del ghiaccio.

Sostituire se necessario.

deumidificatore - ricaricare.

l’apparecchio.

temperatura quanto possibile.

Cubetti troppo grossi. Termostato evaporatore Controllare e regolare

regolato impropriamente. propriamente (vedi pag. 23).

Page 29

Pagina 29

Page 29

GUASTO POSSIBILE CAUSA RIMEDI SUGGERITI

Cubetti opachi. Spruzzatori otturati. Pulire.

Mancanza d’acqua. Controllare il livello dell’acqua

nella bacinella.

Acqua di alimentazione torbida, Pulire la bacinella dell’acqua e

accumulo di depositi nel sistema riempire con acqua pulita.

idraulico. Pulire il filtro della pompa.

Cubetti troppo piccoli. Mancanza d’acqua. Controllare il livello dell’acqua

nella bacinella e riempire.

Termostato evaporatore regolato Controllare e regolare

impropriamente. propriamente (vedi pag. 23)

Perdita d’acqua dal tubo della Controllare la fascetta ed il tubo.

pompa. Sostituire se necessario.

Page 29

Il compressore fa dei cicli ad Basso voltaggio. Il minimo voltaggio deve essere

intermittenza. al max. del 10% minore del

normale.

Aria nel sistema. Scaricare e ricaricare.

Ciclo di sbrinamento Ciclo di sbrinamento troppo Controllare il termostato

insufficiente. corto. evaporatore. Sostituire se

Il gas caldo non fluisce attraverso Controllare la bobina della valvola

la valvola. gas caldo.Sostituire se necessario.

Mancanza di refrigerante. Caricare propriamente

Cubetti di ghiaccio troppo grossi. Regolare il termostato

necessario.

l’apparecchio.

evaporatore (vedi pag. 23).

Page 30

Page 30

SCHEMA ELETTRICO

A AZZURRO

M MARRONE

N NERO

G-V GIALLO - VERDE

Pagina 30

Page 30

POMPA

TERMOSTATO

CONTENITORE

VENTILATORE

VALVOLA GAS CALDO

6

COMPRESSORE

TERMOSTATO

EVAPORATORE

6

2

4

TERMOSTATO

EVAPORATORE

TERMOSTATO

CONTENITORE

2

4

COMPRESSORE

POMPA

VENTILATORE

VALVOLA GAS CALDO

Page 31

Page 31

Pagina 31

Page 31

PROCEDURE PER LA RIMOZIONE E LA SOSTITUZIONE

DEI VARI COMPONENTI

ATTENZIONE: prima di procedere ad una

qualunque delle seguenti procedure di

rimozione e di sostituzione onde prevenire possibili danni sia fisici che all'apparecchio, accertarsi che la corrente elettrica sia staccata.

Rimozione del mobile esterno

1. Togliere il pannello frontale tirandolo dal

bordo superiore.

2. Rimuovere la bacinella contenente l’acqua.

3. Far passare il cavo di alimentazione attraverso la parete posteriore.

4. Svitare e togliere le due viti che fissano la

parte frontale della cornice sportello alle pareti

del mobile.

5. Nella parte interna del compartimento compressore localizzare le tre viti che assicurano il

mobile al telaio dell’unità e svitarle.

6. Togliere la bacinella raccogligocce.

7. Svitare le due viti che fissano, nella parte

posteriore, il mobile al basamento dell’apparecchio.

8. Togliere l’intero mobile tirandolo dalla parte

posteriore.

6. Scollegare i cavetti elettrici dal termostato

evaporatore.

7. Localizzare il bulbo sensibile del termostato evaporatore posto nel portabulbo fissato alla

parte superiore dell’evaporatore ed estrarlo; rimuovere quindi l’intero controllo.

8. Montare il nuovo termostato evaporatore

seguendo le voci precedenti a ritroso.

NOTA.

Sigillare le due estremità del

portabulbo, dopo aver introdotto il bulbo sensibile del termostato evaporatore, onde evitare che dell’acqua congeli nel suo interno.

Sostituzione del termostato contenitore

1. Seguire le procedure per la rimozione dell’intero mobile.

2. Seguire le procedure dal punto 1 al punto 4

della sostituzione del termostato evaporatore.

3. Svitare e togliere il dado che fissa il termostato contenitore al coperchio della scatola elettrica.

4. Togliere il bulbo sensibile del termostato

contenitore dall’interno del contenitore stesso.

5. Scollegare i cavi elettrici dal termostato

stesso. Il termostato è ora libero.

6. Procedere al montaggio del nuovo termostato contenitore seguendo le voci al contrario.

Sostituzione del termostato evaporatore

1. Seguire le procedure dal punto 1 al punto 8

per la rimozione dell’intero mobile.

2. Togliere la manopolina del termostato

evaporatore facendo leva alla base.

3. Svitare la vite di fissaggio del coperchio

della scatola elettrica.

4. Rimuovere, prestando una certa attenzione, l’intero coperchio della scatola elettrica.

5. Togliere svitando il dado che fissa il termostato evaporatore al coperchio della scatola elettrica.

Sostituzione della pompa

1. Seguire le procedure dal punto 1 al punto 7

per la rimozione dell’intero mobile.

2. Svitare e rimuovere la vite che fissa la

pompa al supporto metallico.

3. Scollegare i cavetti elettrici dalla pompa.

4. Togliere il tubo in gomma dal corpo pompa,

quindi rimuoverla dalla sua sede.

5. Seguire le procedure al contrario per l’installazione della nuova pompa.

Page 32

Page 32

ILLUSTRAZIONI ED ELENCHI DELLE PARTI DI RICAMBIO

SCATOLA ELETTRICA

Pagina 32

Page 32

④

±

≤

≥

Pos. Codice Descrizione

4 630070.04 Morsettiera

6 620264.10 Termostato evaporatore

7 660321.00 Coperchio

8 620263.00 Termostato contenitore

Page 33

Pagina 33

Page 33

VISTA FRONTALE

Page 33

Pos. Codice Descrizione

3 620433.00 Ass. pompa

18 650330.00 Tappo

22 660321.00 Coperchio

24 784169.03 Tendina

25 660330.00 Coperchio imbuto

Page 34

Page 34

VISTA LATERALE

Page 34

Pagina 34

Pos. Codice Descrizione

44 741049.02 Coperchio evaporatore

46 650331.01 Isolamento

47 660326.00 Ass. mantello

49 660340.02 Tubo portabulbo

660386.00 Molletta

50 783130.00 Allogg. evaporatore

51 640093.00 Guarnizione

52 660320.00 Vaschetta raccogli acqua

53 610139.00 Tubo

54 660336.00 Coperchio

57 660325.00 Vaschetta raccogli gocce

58 781284.00 Sportello

59 782053.00 Contenitore ghiaccio

60 660339.00 Porta bulbo

* Non mostrato

Pos. Codice Descrizione

61 781285.00 Pannello frontale

62 793114.00 Bacinella acqua

63 781335.00 Supporto vaschetta

65 784234.00 Piastra evaporatore

66 784252.02 Linea aspirazione

67* 660359.00 Imbuto

68 660335.00 Parte sup. separatore

69 660343.00 Parte inf. separatore

70 660338.00 Raccordo in gomma

71 660337.00 Spia di livello

72* 783141.00 Coperchio bacinella

660424.00 Coperchio bacinella - pompa

73 660341.00 Tappo in gomma

Page 35

Pagina 35

Page 35

COMPARTIMENTO COMPRESSORE

Page 35

Pos. Codice Descrizione

1 670097.08 Compressore cpl. Electrolux

670066.09 Compressore cpl. U.H.

2 620306.48 Bobina valvola gas caldo

620306.14 Corpo valvola gas caldo

3 620419.00 Motore ventilatore

7 620058.65 Protettore Electrolux

620058.64 Protettore U.H.

Pos. Codice Descrizione

8 620057.35 Relè Electrolux

620057.32 Relè U.H.

23 630003.05 Deumidificatore

35 620285.00 Condensatore

36 781283.00 Ass. telaio

Page 36

Page 36

ACM 25 - COMPONENTI DEL COMPRESSORE ED ELETTRICI

Page 36

Pagina 36

Modello Voltaggio Modello Compr. Compr. Cpl.

ACM 25-2 230/60/1 U.H. AE Z4425Y 670066.08 620057.40 620058.74 620167.45

ACM 25-6 230/50/1 Cubigel GL 80PB 670097.08 620057.35 620058.65 –

U.H. AE Z4425Y 670066.09 620057.32 620058.64 –

Modello Ass. pompa

ACM 25-2 620306.48 620433.01 620419.00

ACM 25-6 620306.48 620433.00 620419.00

Bobina valvola Ass.

gas caldo ventilatore

Relé Protettore Start

Compr. Compr. Capacitor

Loading...

Loading...