SMARTMAG

MODELS SM–4/4G

OPERATIONS MANUAL

SCINTREX LIMITED

Head Office In the U.S.A. In Australia

222 Snidercroft Road

Concord, Ontario

Canada, L4K 1B5

Tel.: (905) 669-2280

Fax: (905) 669-6403 (Sales)

(905) 669-9899 (Service)

Telex: 06-964570

Copyright © SCINTREX Limited 1996. All rights reserved.

No part of this publication may be reproduced, stored in a retrieval

system or transmitted, in any form, or by any means, electronic,

mechanical, photo-copying, recording, or otherwise, without prior

consent from SCINTREX Limited.

SMARTMAG and WALKMAG are trademarks of SCINTREX Limited.

525 Fort Worth Drive

Suite 216

Denton, Texas 76201

Tel.: (817) 591-7755

Fax: (817) 591-1968

1031 Wellington St.

West Per t h ,

West Australia 6005

Tel: (619) 321-6934

Fax: (619) 481-1201

Document P/N 759 704

Revision 1.0

Manual designed and produced by GEO F/X.

Printed and bound in Canada.

Disclaimer

Preface

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xi

SMARTMAG versions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Type styles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Page numbering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

HELP-Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

1–Introduction

Cold boot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–2

Instrument overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–3

SMARTMAG

Table of Contents

Table of Contents

2–Preparing the SMARTMAG

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–2

Repacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–2

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–3

Installing the battery belt . . . . . . . . . . . . . . . . . . . . . . . . 2–3

Installing/exchanging the battery in the battery belt. . . . . . 2–4

Connecting the sensor(s) to the Battery Belt . . . . . . . . . . 2–4

Installing the LED display and keyboard . . . . . . . . . . . . . . . 2–5

Installing the shoulder strap . . . . . . . . . . . . . . . . . . . . . . 2–6

Installing the audio option kit . . . . . . . . . . . . . . . . . . . . . . 2–6

SMARTMAG console battery installation/exchange . . . . . . . 2–7

Using the external battery pack . . . . . . . . . . . . . . . . . . . . 2–8

Using an external power supply . . . . . . . . . . . . . . . . . . . . 2–10

i

3–Guidelines

Operator preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–1

Geometry of dead zones . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–1

Determining operating zones . . . . . . . . . . . . . . . . . . . . . . . 3–3

Adjusting the sensor head angle. . . . . . . . . . . . . . . . . . . . . 3–4

4–The SMARTMAG Model SM–4

Receiving your instrument . . . . . . . . . . . . . . . . . . . . . . . . . 4–1

The components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–2

Assembling the instrument . . . . . . . . . . . . . . . . . . . . . . . 4–2

Connecting the cables. . . . . . . . . . . . . . . . . . . . . . . . . . . 4–2

Setting up the instrument . . . . . . . . . . . . . . . . . . . . . . . . . 4–3

Turning on the instrument . . . . . . . . . . . . . . . . . . . . . . . . 4–3

Using the headphones. . . . . . . . . . . . . . . . . . . . . . . . . . . 4–4

Setting the parameters with the console . . . . . . . . . . . . . 4–4

Using the LED display and keypad . . . . . . . . . . . . . . . . . . . . 4–5

Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–5

Displays and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . 4–5

Performing a Survey . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–8

5–The SMARTMAG Model SM–4G

Receiving your instrument . . . . . . . . . . . . . . . . . . . . . . . . . 5–1

The components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–2

Assembling the instrument . . . . . . . . . . . . . . . . . . . . . . . . 5–2

Master processor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–2

Connecting the cables. . . . . . . . . . . . . . . . . . . . . . . . . . . 5–3

Setting up the instrument . . . . . . . . . . . . . . . . . . . . . . . . . 5–4

Turning on the instrument . . . . . . . . . . . . . . . . . . . . . . . . 5–4

Using the headphones. . . . . . . . . . . . . . . . . . . . . . . . . . . 5–4

Setting the parameters with the SMARTMAG console . . . 5–5

Using the LED display and keypad . . . . . . . . . . . . . . . . . . . . 5–5

Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–6

Displays and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . 5–6

Assembling the Gradiometer . . . . . . . . . . . . . . . . . . . . . . 5–9

Vertical Gradiometer . . . . . . . . . . . . . . . . . . . . . . 5–9

Horizontal Gradiometer . . . . . . . . . . . . . . . . . . . . 5–10

Performing a Survey . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–10

ii

6–The SMARTMAG Console

Pre-defined operating modes. . . . . . . . . . . . . . . . . . . . . . . . 6–1

Console description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–3

Keypad description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–4

Key Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–5

Display screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–8

General information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–8

Cursor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–9

Display blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–9

Pop-up windows . . . . . . . . . . . . . . . . . . . . . . . . . . 6–10

Help screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–11

Operating displays. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–12

Basic mode configuration displays . . . . . . . . . . . . . . . . . . 6–12

Basic mode data collection displays . . . . . . . . . . . . 6–16

Search mode configuration display . . . . . . . . . . . . . . . . . . 6–17

Search mode data collection displays . . . . . . . . . . . 6–19

Advanced mode configuration displays. . . . . . . . . . . . . . . . 6–20

Main operating display . . . . . . . . . . . . . . . . . . . . . 6–20

Instrument setup display . . . . . . . . . . . . . . . . . . . 6–22

Magnetometer setup display . . . . . . . . . . . . . . . . . 6–23

Advanced mode data displays . . . . . . . . . . . . . . . . . . . . . . 6–26

Numeric data display . . . . . . . . . . . . . . . . . . . . . . 6–26

Graphic data display . . . . . . . . . . . . . . . . . . . . . . . 6–28

Recall displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–29

Recall setup display . . . . . . . . . . . . . . . . . . . . . . . 6–29

Recall data display . . . . . . . . . . . . . . . . . . . . . . . . 6–30

Modifying the display window . . . . . . . . . . . . . . . . . 6–32

Auxiliary display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–33

Data output display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–34

Data output formats . . . . . . . . . . . . . . . . . . . . . . 6–36

Notes display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–37

Information display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–38

SMARTMAG Distance Trigger . . . . . . . . . . . . . . . . . . . . . . . 6–39

Table of Contents

7–Setting-up the SMARTMAG Console

First time operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–1

Cold Boot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–2

Configuration menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–3

General setup principles . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–4

iii

How to: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–5

Access the main operating display . . . . . . . . . . . . . . . . . . 7–5

Access display sub-panels/blocks . . . . . . . . . . . . . . . . . . . 7–5

Access the parameter fields . . . . . . . . . . . . . . . . . . . . . . 7–5

Change parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–5

Select! and Enter!. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–6

Select! . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–6

Enter! . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–6

Line and Station setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–7

Entering the starting station . . . . . . . . . . . . . . . . . . . . . 7–8

Entering the starting line . . . . . . . . . . . . . . . . . . . . . . . . 7–8

Basic Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–9

Sample total-field setup . . . . . . . . . . . . . . . . . . . . . . . . . 7–9

Starting Your Survey . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–11

Search Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–12

Sample search mode setup . . . . . . . . . . . . . . . . . . . . . . . 7–12

Advanced Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–14

Instrument setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–14

Sample total-field setup (WALKMAG or WALKGRAD) . . . . . 7–15

Sample base-station setup . . . . . . . . . . . . . . . . . . . . . . . 7–18

Information display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–21

Note entry. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–23

Display intensity control . . . . . . . . . . . . . . . . . . . . . . . . . 7–25

Parameter lock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–26

Reprogramming the operating system . . . . . . . . . . . . . . . 7–27

At the computer . . . . . . . . . . . . . . . . . . . . . . . . . 7–27

At the SMARTMAG Console . . . . . . . . . . . . . . . . . 7–27

8–Operating the SMARTMAG with the Console

Accurate and meaningful measurements . . . . . . . . . . . . . . 8–1

Determining operating zones . . . . . . . . . . . . . . . . . . . . . . 8–2

Effects of gradient . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–2

Other sources of noise . . . . . . . . . . . . . . . . . . . . . . . . . . 8–2

Base-station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–3

Repeated surveys lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–3

WALKMAG—Total-field/Gradiometer . . . . . . . . . . . . . . . . . . 8–4

Check your setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–5

Start survey . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–5

WALKGRAD gradiometer survey . . . . . . . . . . . . . . . . . . . 8–6

iv

Manual mode—Total-field/Gradiometer . . . . . . . . . . . . . . . . 8–7

Check your setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–8

Start survey. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–8

Automating your measurements . . . . . . . . . . . . . . . . . . . 8–9

Base-station operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–10

Check your setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–11

Start operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–11

Search mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–12

Basic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–12

Advanced . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–13

Survey data correction procedures. . . . . . . . . . . . . . . . . . . 8–14

Using base-station data . . . . . . . . . . . . . . . . . . . . . . . . . 8–14

Tie-point (TIE-PT) mode . . . . . . . . . . . . . . . . . . . . . . . . . . 8–15

Loop type—collecting data . . . . . . . . . . . . . . . . . . 8–15

Line type—collecting data. . . . . . . . . . . . . . . . . . . 8–16

Tie-point correction procedure . . . . . . . . . . . . . . . . . . . . . 8–18

Basic modes (Loop only) . . . . . . . . . . . . . . . . . . . . 8–18

Advanced modes . . . . . . . . . . . . . . . . . . . . . . . . . 8–19

9–Data output

Output formats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–1

XYZ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–2

XYZ+ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–3

XYZ++ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–4

PRN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–5

NOTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–6

BINARY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–7

Converting binary data with XFSMART . . . . . . . . . . 9–7

Basic mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–9

Advanced mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–10

Output setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–10

Dumping data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–12

All data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–12

Specific data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–13

Binary Dump . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–13

Line by line. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–14

Erasing data from memory. . . . . . . . . . . . . . . . . . . . . . . . 9–15

Basic mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9–15

Advanced mode . . . . . . . . . . . . . . . . . . . . . . . . . . 9–16

Table of Contents

v

10–Maintaining your SM–4/4G

General rules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10–1

Charging the battery belt batteries . . . . . . . . . . . . . . . . . 10–2

Console battery charging . . . . . . . . . . . . . . . . . . . . . . . . . 10–3

One battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10–4

Two batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10–5

Periodic maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10–6

Desiccant exchange . . . . . . . . . . . . . . . . . . . . . . . . . . . 10–6

Fuse replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10–7

Console disassembly/assembly . . . . . . . . . . . . . . . . . . . . . 10–8

Cable repair. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10–9

Sensor troubleshooting guide . . . . . . . . . . . . . . . . . . . . . . 10–10

Console troubleshooting guide . . . . . . . . . . . . . . . . . . . . . 10–11

11–Reference information

SMARTMAG Technical Specifications . . . . . . . . . . . . . . . . 11–1

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11–3

Instrument parts list . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11–4

Warranty & Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11–5

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11–5

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11–5

When to ship the unit . . . . . . . . . . . . . . . . . . . . 11–5

Description of the problem . . . . . . . . . . . . . . . . . 11–5

Shipping instructions . . . . . . . . . . . . . . . . . . . . . . . . . . 11–6

Customs documents . . . . . . . . . . . . . . . . . . . . . 11–7

A–Orienting Cesium sensors for best performance

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A–1

The active zone of the SMARTMAG. . . . . . . . . . . . . . . . . . . A–2

Calculation of the tumble angle. . . . . . . . . . . . . . . . . . . . . . A–5

Recommended sensor orientations. . . . . . . . . . . . . . . . . . . A–14

vi

DISCLAIMER

The product supplied by the vendor under this sale agreement, when

properly maintained, calibrated and operated will perform in accor-

dance with the vendor’s published specifications. The vendor disclaims

responsibility for the detection of any particular target under any par-

ticular set of circumstances, and the purchaser and or user hereby ac-

knowledges and accepts such a disclaimer.

The purchase and or user releases and agrees to hold harmless the ven-

dor, its officers, servants, employees, agents and contractors, against

any and all claims, demands, actions and liabilities whatsoever, arising

out of the use or operation of the product.

SMARTMAG

Disclaimer

It is understood and agreed that this contract shall be governed by the

laws of the Province of Ontario, Canada.

vii

Disclaimer

viii

PREFACE

SMARTMAG

Preface

Congratulations on purchasing the SMARTMAG high sensitivity, high

resolution, cesium vapour magnetometer/gradiometer from

Ltd.! You are in possession of one of the most advanced magnetometers

for environmental, geotechnical, archaeological and mineral explora-

tion uses of today.

The

SMARTMAG is a portable, cesium magnetometer that also is inex-

pensive, lightweight and rugged. In its trademarked

it is ideal for applications where high production, fast reading and high

sensitivity are required.

WALKMAG mode,

SCINTREX

Preface

Your SM–4 is quite versatile and can be optionally upgraded and

configured as a gradiometer or as a base-station. To upgrade your sys-

tem to the SM–4G model, please contact your SCINTREX representative.

FEATURES

SMARTMAG The main features/options of the SMARTMAG include:

▲ integrated sensor/staff and processing electronics

▲ advanced digital signal processing for low noise 0.01nT

resolution

▲ rugged, waterproof design incorporating adjustable sensor head

▲ audio output with auto baseline tracking

▲ sunlight readable LED display and keypad

▲ RS-232/RS-422 output

▲ SMARTMAG console

ix

Preface

Console The main features of the SMARTMAG console include:

▲ real-time graphic display of magnetic field readings

▲ interactive menus for easy operator use

▲ selectable sampling rates as fast as 10 times per second

▲ WALKMAG mode for rapid data acquisition

▲ true simultaneous gradiometer option with the WALKGRAD mode

for rapid data acquisition

▲ large internal memory, expandable to over 300,000 readings

(750,000 for base station)

▲ easy to read, large LCD screen that displays data both graphically

and numerically

▲ easy review of the data and Datacheck quality control

▲ ENVIMAP software for processing and mapping of the data

SMARTMAG VERSIONS

There are five versions (factory configured) of the SMARTMAG:

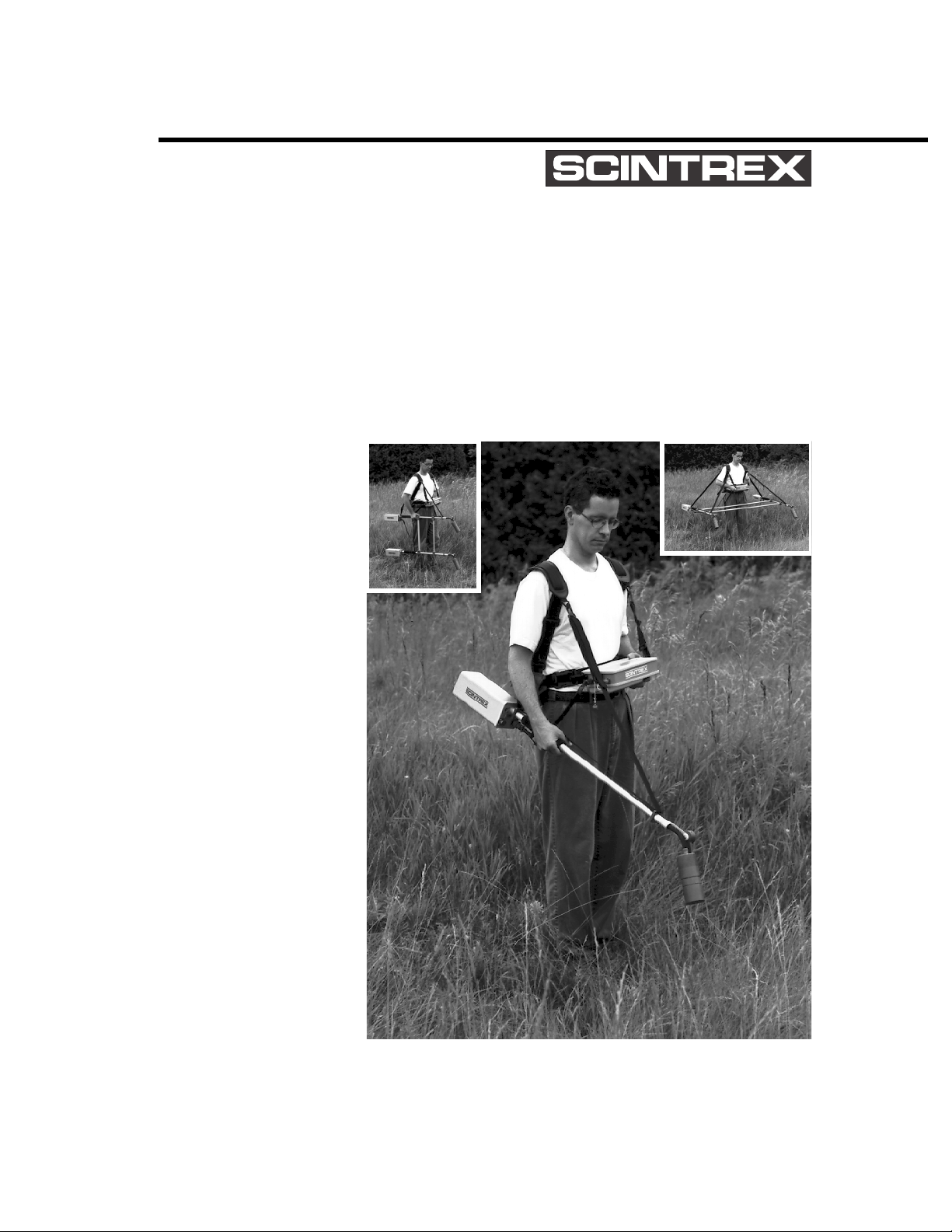

1. SMARTMAG model SM-1 (759 001):

Figure A SMARTMAG model SM-1 components

x

SMARTMAG versions

2. SMARTMAG model SM-2 (759 005):

Figure B SMARTMAG model SM-2 components

3. SMARTMAG model SM-3 (759 002):

Preface

Figure C SMARTMAG model SM-3 components

xi

Preface

4. SMARTMAG model SM-4 (759 003):

Figure D SMARTMAG model SM-4 components

xii

5. SMARTMAG model SM-4G (759 004):

Figure E SMARTMAG model SM-4G components

ABOUT THIS MANUAL

About This Manual

TYPE STYLES

The following typeface conventions will be used throughout the man-

ual. There may be additional conventions used in the specific sections.

These will be described in the introduction for the section.

PAGE NUMBERING

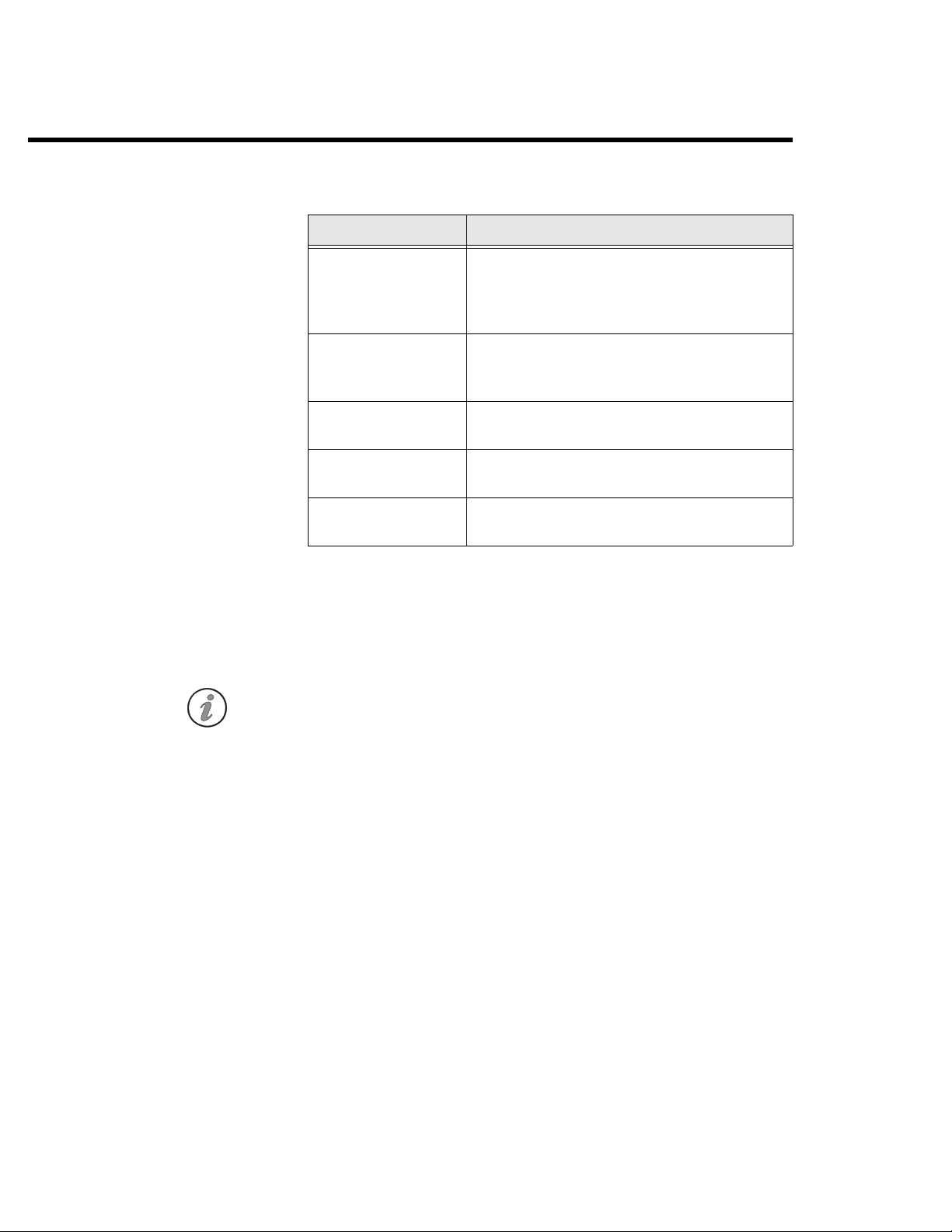

Convention Use

Bold An action you are required to perform

A proper name.

Italic A new term is being introduced

An item of importance is being emphasized.

Dot Matrix A prompt on the

Text to be input to the console.

LED

ALL CAPS

A prompt or parameter on the LED display.

A display or key on the SMARTMAG console

The name of a method, item or mode.

SMARTMAG console

Preface

SYMBOLS

The page numbering scheme used consists of two parts; the chapter

number and page number. For exa mple,

page 1.

For your convenience, each chapter in a section has a thumb-tab on the

right-hand side allowing you to quickly locate a chapter of interest. The

thumb-tabs are arranged in descending order.

The following symbols will be used to highlight specific sections of text

throughout the manual.

3-1 would refer to Chapter 3,

xiii

Preface

Symbol Meaning

▲

Indicates an item in a list/grouping or a singlestep procedure

Note:

Indicates specific information that you should

read.

Hint:

Indicates a tip, new idea or helpful hint.

Caution:

Indicates a note of caution. You should pay

special attention to this section.

Warning:

Indicates a warning. You should read this section very carefully.

xiv

Important:

Please read this! Indicates a very important

message.

HELP-LINE

In order to provide a high-degree and quality of technical support, a

special HELP-Line is available for

help with the instrument, applying the instrument to a particular prob-

lem or help with the

port at the following numbers:

In Canada:

In the U.S.A.:

SMARTMAG users. If you need any

ENVIMAP software, please contact SCINTREX sup-

Telephone: (905) 669-2280

Fax: (905) 669-6403 (Sales Department)

(905) 669-9899 (Customer Service)

Telex: 06-964570

Telephone: (817) 591-7755

Fax: (817) 591-1968

HELP-Line

Preface

In Australia:

Telephone: (619) 321-6934

Fax: (619) 481-1201

xv

Preface

xvi

SMARTMAG

INTRODUCTION

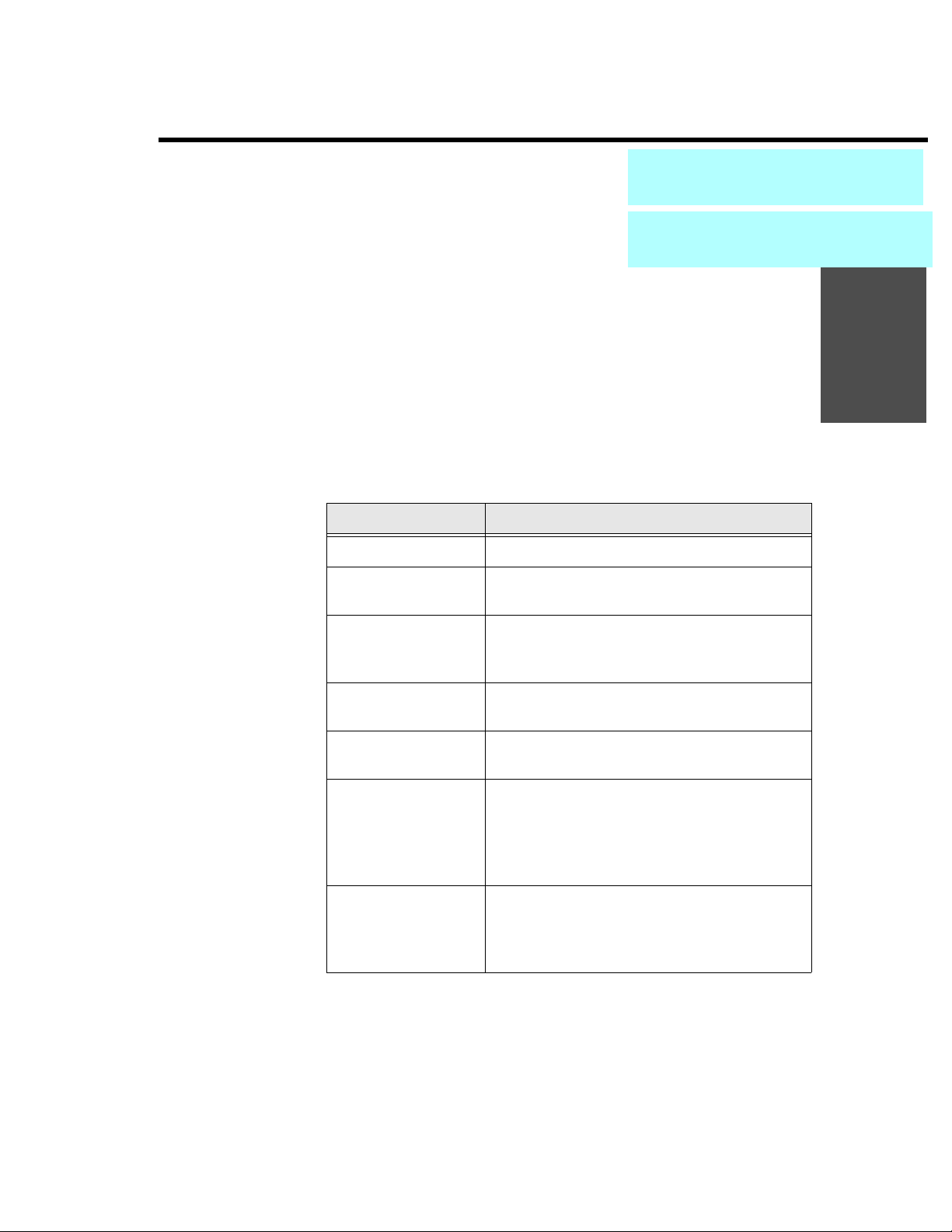

This manual is divided into twelve chapters with the information flow

from chapter to chapter following a natural progression, as shown in

the following table:

Chapter Description

Introduction

Preparation

Guidelines

Chapter

Outlines what the instrument can do.

Describes the assembly of the system in

preparation for use.

Provides guidelines, hints and basic troubleshooting information that are common to all

SMARTMAG models.

1

Introduction

SM–4 Model

SM–4G Model

Console

Setting up

Provides step by step instructions on how to

use the SM–4

Provides step by step instructions on using the

SM–4G

Describes the physical parts of the

console, keypad and display menus. It also

describes the function of each key, as well as

the various modes and parameters shown on

the display panel.

Gives step-by-step instructions on how to set

up the instrument as either a total-field magnetometer, a gradiometer or a magnetic basestation.

SMARTMAG without the console.

SMARTMAG without the console.

SMARTMAG

1-1

Introduction

Chapter Description

COLD BOOT

Operations

Data Output

Maintenance

Reference

Appendix

Note: Please read the section “First time operation” on page 7–1 so

that you will know how to do a cold boot of the instrument.

This is needed the first time you use it, whenever you wish

to change operating configurations, or after the batteries

have been removed for more than 10 minutes.

Guides you through typical instrument operation, using basic and advanced configurations, in a

survey.

Shows examples of data output formats and

explains how to dump the acquired data to a

computer.

Describes basic maintenance, trouble-shooting and repair.

Contains the technical specifications, instrument parts list and warranty information.

Gives a detailed overview of issues relating to

optimum sensor orientation.

WALKMAG and a stop-and-go type of

1-2

INSTRUMENT OVERVIEW

Instrument overview

The SCINTREX SMARTMAG is an easy-to-use, light-weight, battery-powered,

portable magnetometer. It is a total-field instrument using the Larmor

frequency of precession of cesium atoms to measure the local magnet-

ic field. Optional upgrade kits allow the instrument to be used as a gra-

diometer or as a base-station.

Measured data is stored in memory along with the coordinates where

the measurement took place. In the advanced configuration modes,

you can also enter descriptive notes of up to 32 characters at any sta-

tion. The data can be displayed either numerically or graphically for

quick inspection of the data quality and spotting of anomalies. Data

can also be recalled from memory for visual inspection, dumped to the

serial port (RS-232) of a computer or directly to a printer. You can also

automatically correct your magnetic data for diurnal variations when

another

survey in the

To m a ke th e

site characterization, drum location, archaeology, general search,

ground water, mineral, oil and gas exploration. These configurations

fall into two categories: basic (where you only need to set a few param-

eters) and advanced (where you have complete control over all oper-

ating modes).

SMARTMAG is used as a base-station or when you conduct your

TIE mode.

SMARTMAG easy to use, there are preset configurations for

Introduction

The operating modes of the

or fully automatic. In the

data are acquired and recorded at rates of up to ten readings per sec-

ond, as you walk at a steady pace along the survey line. At desired in-

tervals, you trigger a station marker by pressing a single button and the

co-ordinates are automatically assigned to the recorded data.

Note that each model of the

quire additional software and/or hardware to be converted from one

model to another, if desired. Please consult your sales representative for

further information.

SMARTMAG can be manual, semi-automatic

WALKMAG (walking magnetometer) mode,

SMARTMAG (SM–1 through SM–4G) may re-

1-3

Introduction

1-4

SMARTMAG

Chapter

PREPARING THE SMARTMAG

This chapter describes:

▲ how the SMARTMAG is packaged,

▲ how to connect the components to get an operational unit,

▲ the various options you may have for powering the unit.

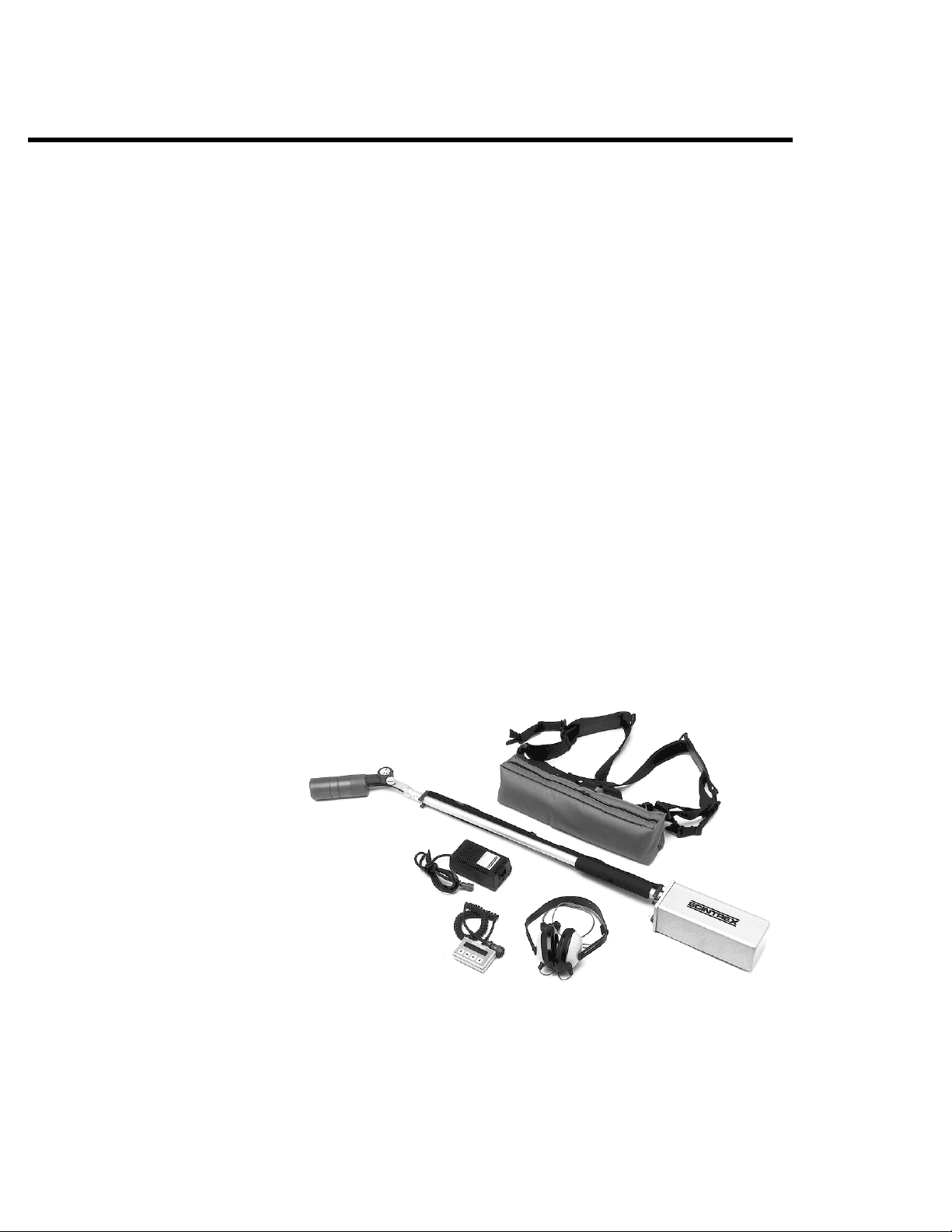

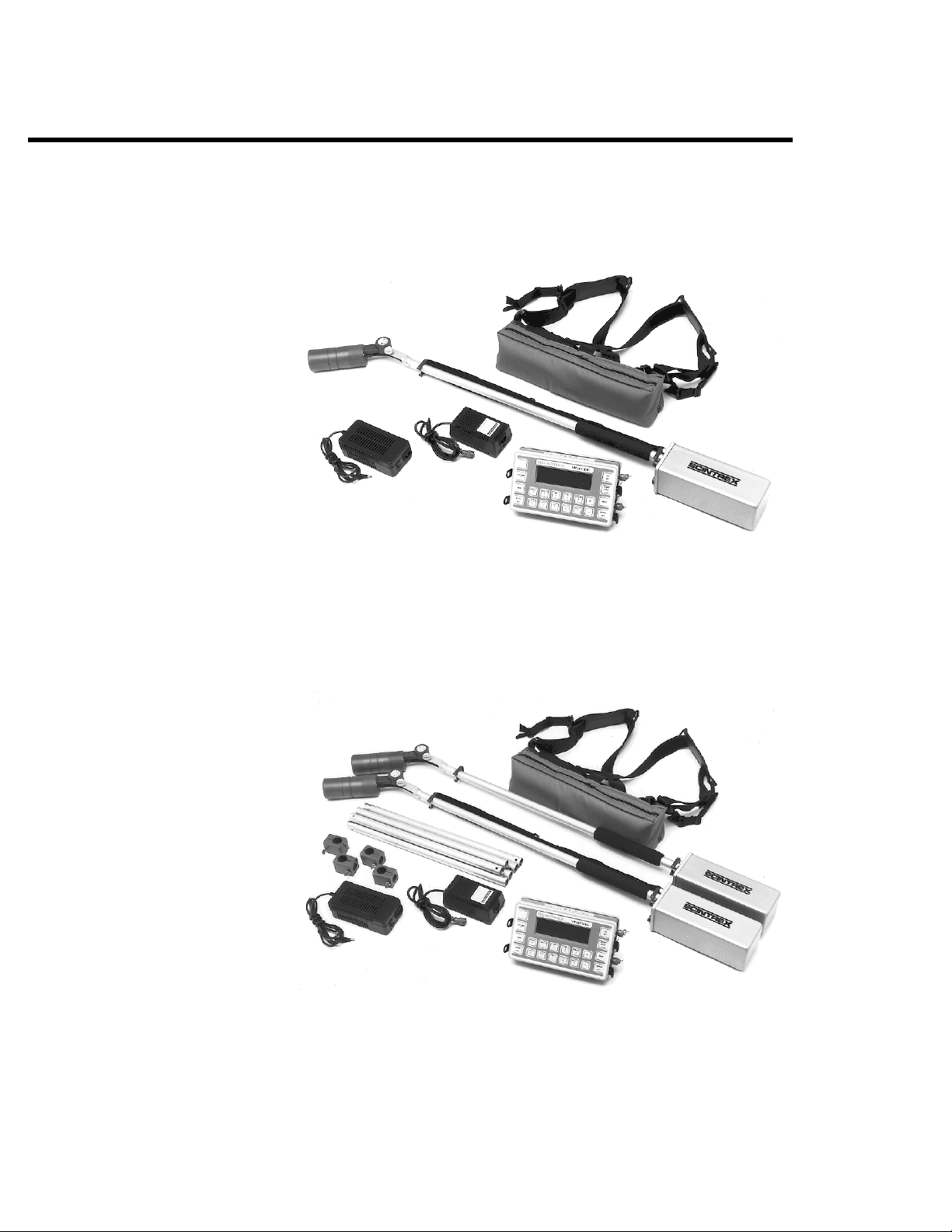

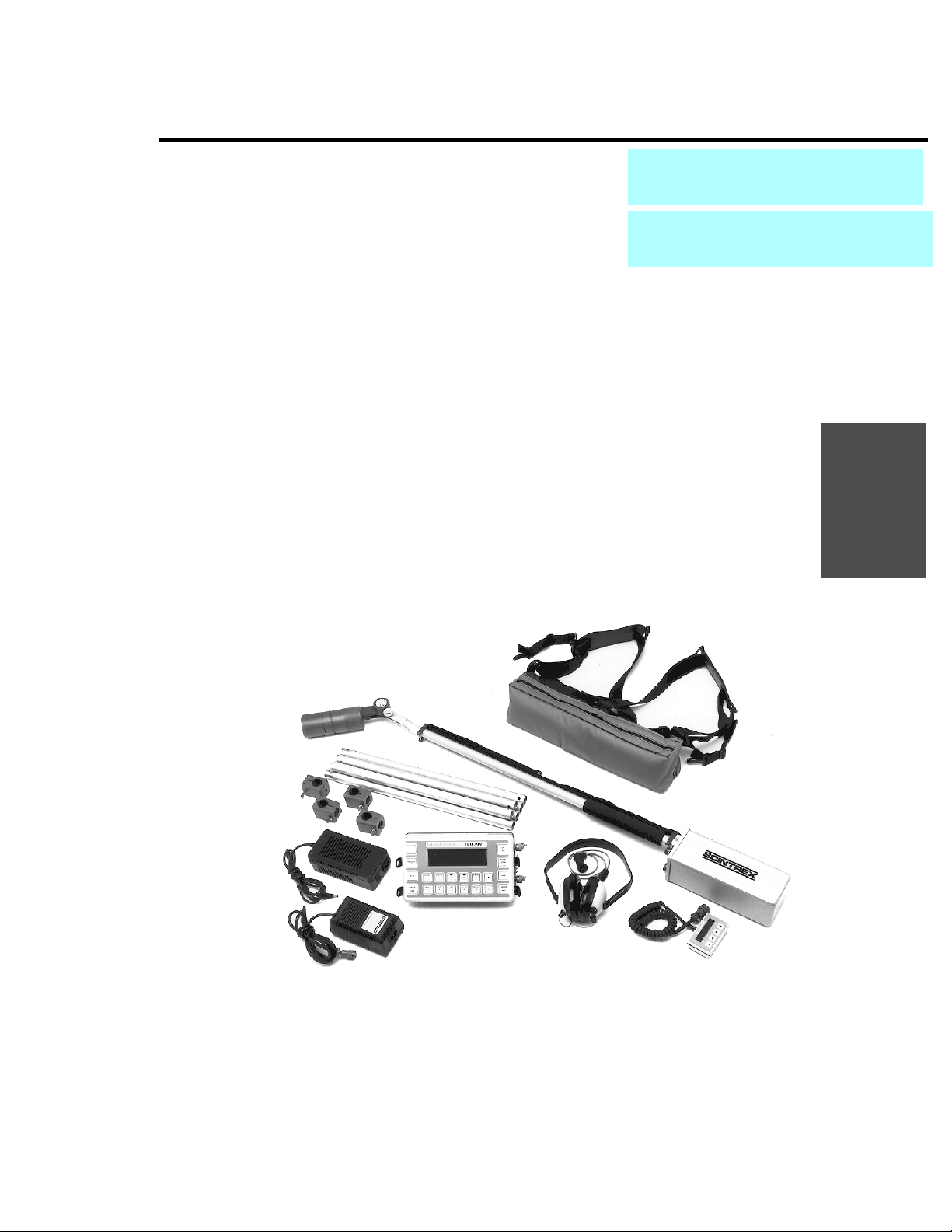

The following two photographs show all the components (less packing

materials) of the standard

SMARTMAG and the SMARTMAG Gradiometer.

2

Preparation

Figure 1 The complete SMARTMAG SM–4 kit

with optional accessories.

2-1

Preparing the SMARTMAG

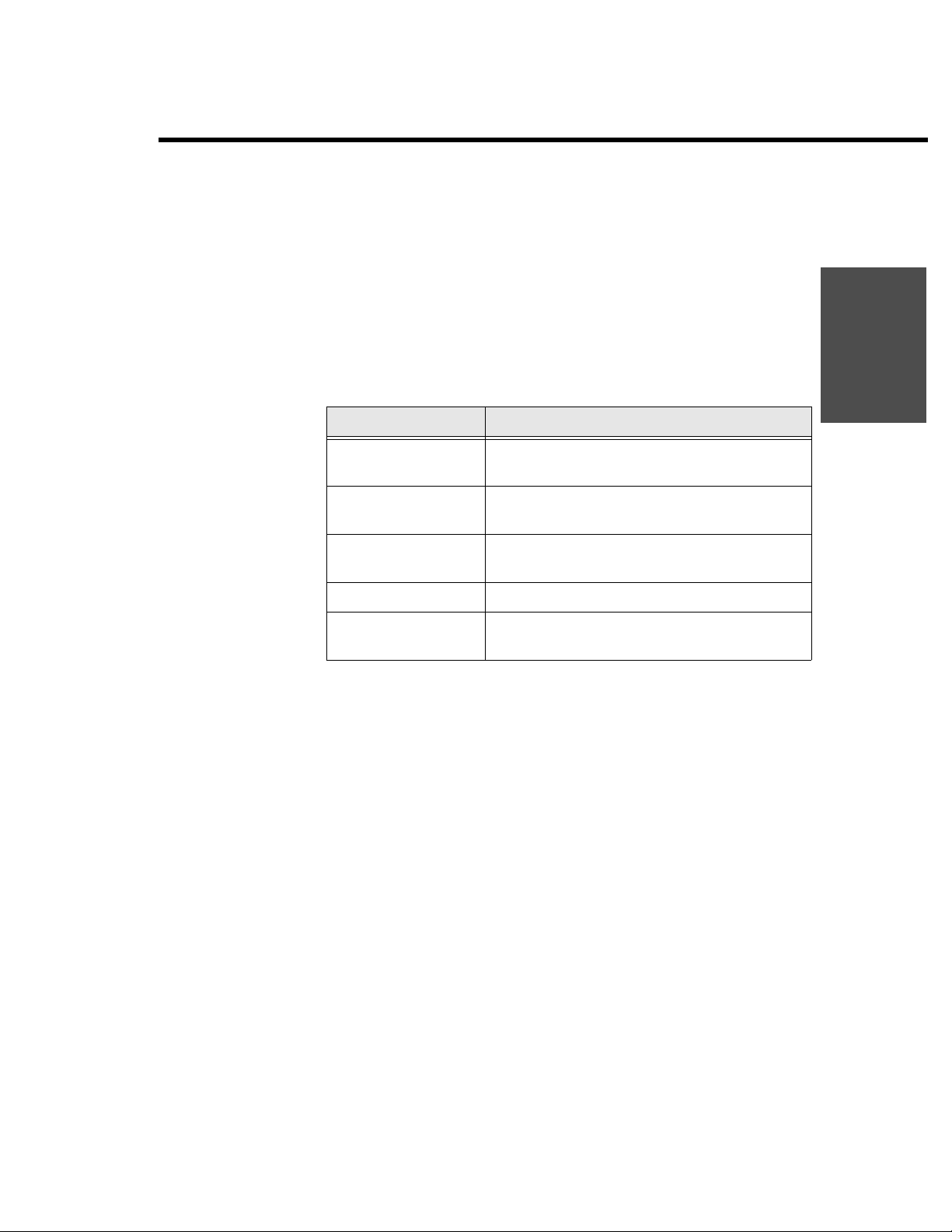

Figure 2 The complete SMARTMAG gradiometer

kit with optional accessories.

UNPACKING

The standard SMARTMAG is shipped in a durable carrying/shipping case

that should be retained for storage and shipping. This provides a proper

place for every item when you repack your instrument for shipping or

storage. Please check the components delivered against the actual order, as systems may vary

REPACKING

Please make certain that the batteries are removed and stored in the ap-

propriate places. Failing to do so may result in damaged batteries and

possibly a damaged console.

2-2

Warning: The batteries must be removed from the unit prior to

shipping or storage.

FAILURE TO DO SO MAY RESULT IN DAMAGE.

ASSEMBLY

In order to make the system as compact as possible for shipment and

storage, and considering the various sensor configurations available,

the

SMARTMAG system requires you to connect up the external compo-

nents. This section will describe the steps required to completely as-

semble your instrument.

INSTALLING THE BATTERY BELT

The battery belt contains the batteries that power up the SMARTMAG sen-

sor assembly. The

stored within the console housing and is discussed in “SMARTMAG

console battery installation/exchange” on page 2–8.

SMARTMAG console is powered by batteries that are

Assembly

Preparation

2-3

Preparing the SMARTMAG

Figure 3 The Battery Belt

INSTALLING/EXCHANGING THE BATTERY IN THE BATTERY BELT

1. When installing replacement batteries, disconnect the existing

batteries and install the new ones.

2. Adjust the battery pouch velcro compartments to secure the

batteries in the pouch.

2-4

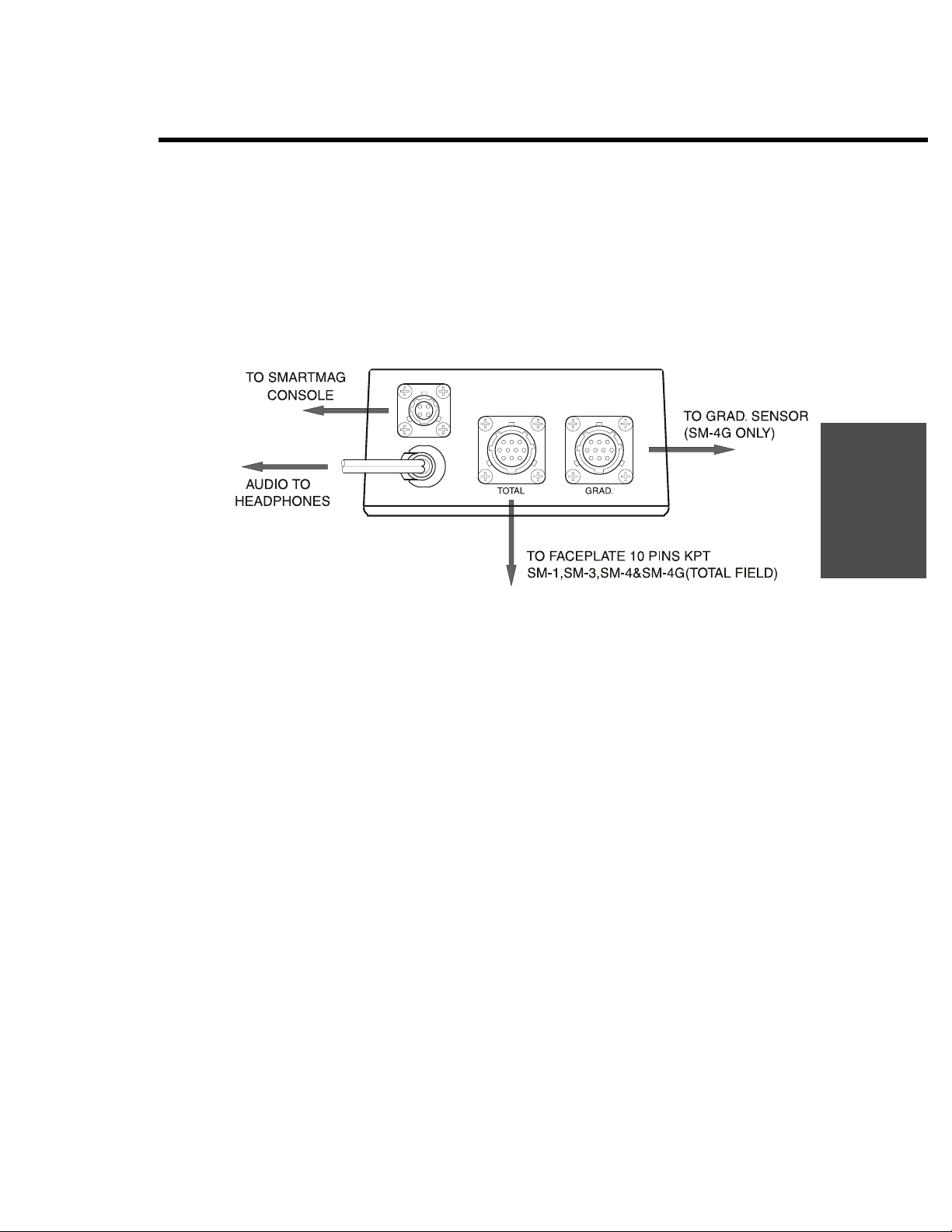

CONNECTING THE SENSOR(S) TO THE BATTERY BELT

1. Using the following diagram, connect the appropriate assemblies

to the connectors on the Battery Belt box which is located on the

underside of the Battery Belt.

Assembly

Preparation

Figure 4 Battery Belt Box Connectors

2-5

Preparing the SMARTMAG

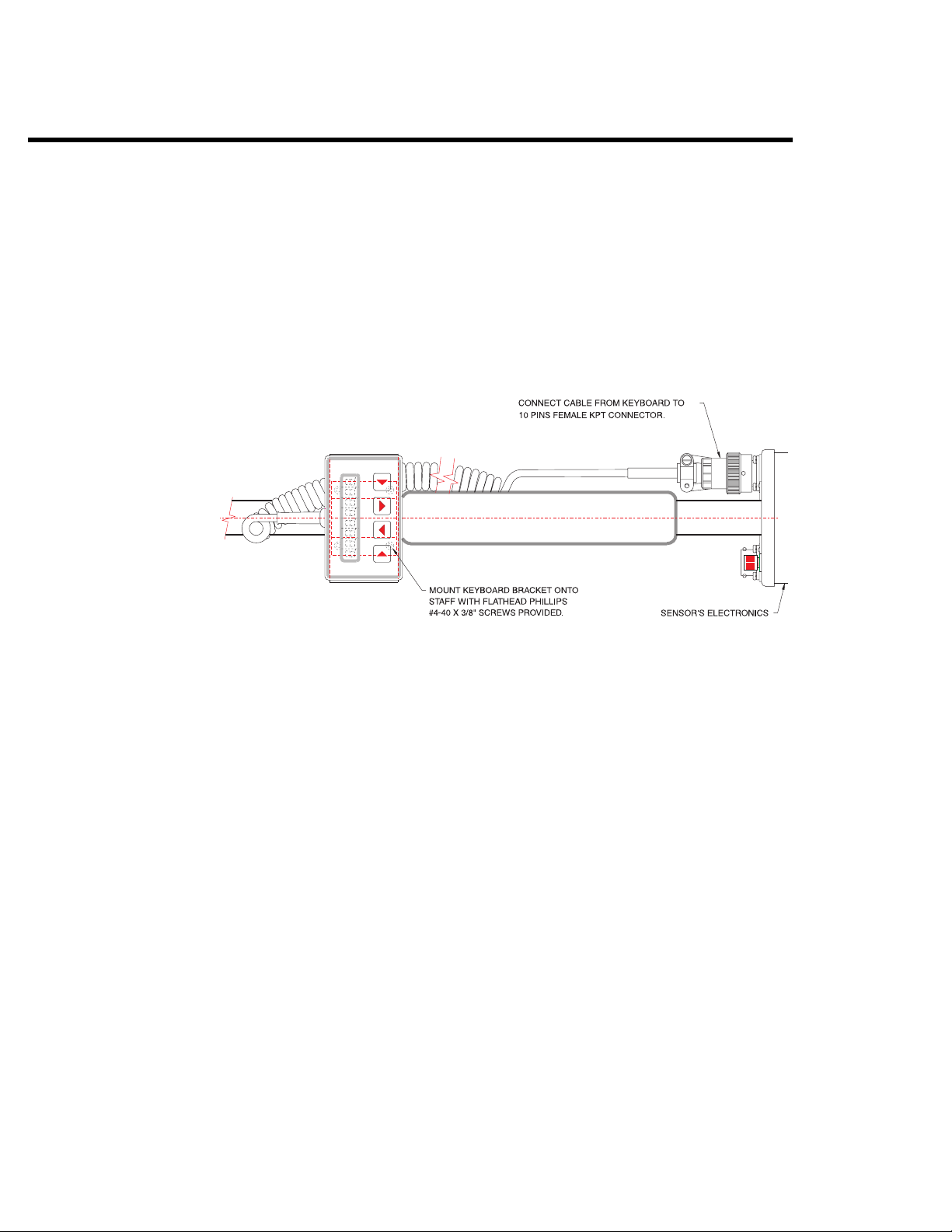

INSTALLING THE LED DISPLAY AND KEYBOARD

1. Attach the mounting brackets to the sensor staff by using the four,

#4 Philips screws that are supplied with the mounting kit as shown

below. Ensure that the mounting bracket with the velcro is

mounted on the top of the staff.

2-6

Figure 5 LED and Keyboard Mounting Kit

2. Attach the display and keyboard to the top of the mounting

bracket with the velcro.

3. Connect the display and keypad connector to the rear of the

sensor compartment as shown in the diagram.

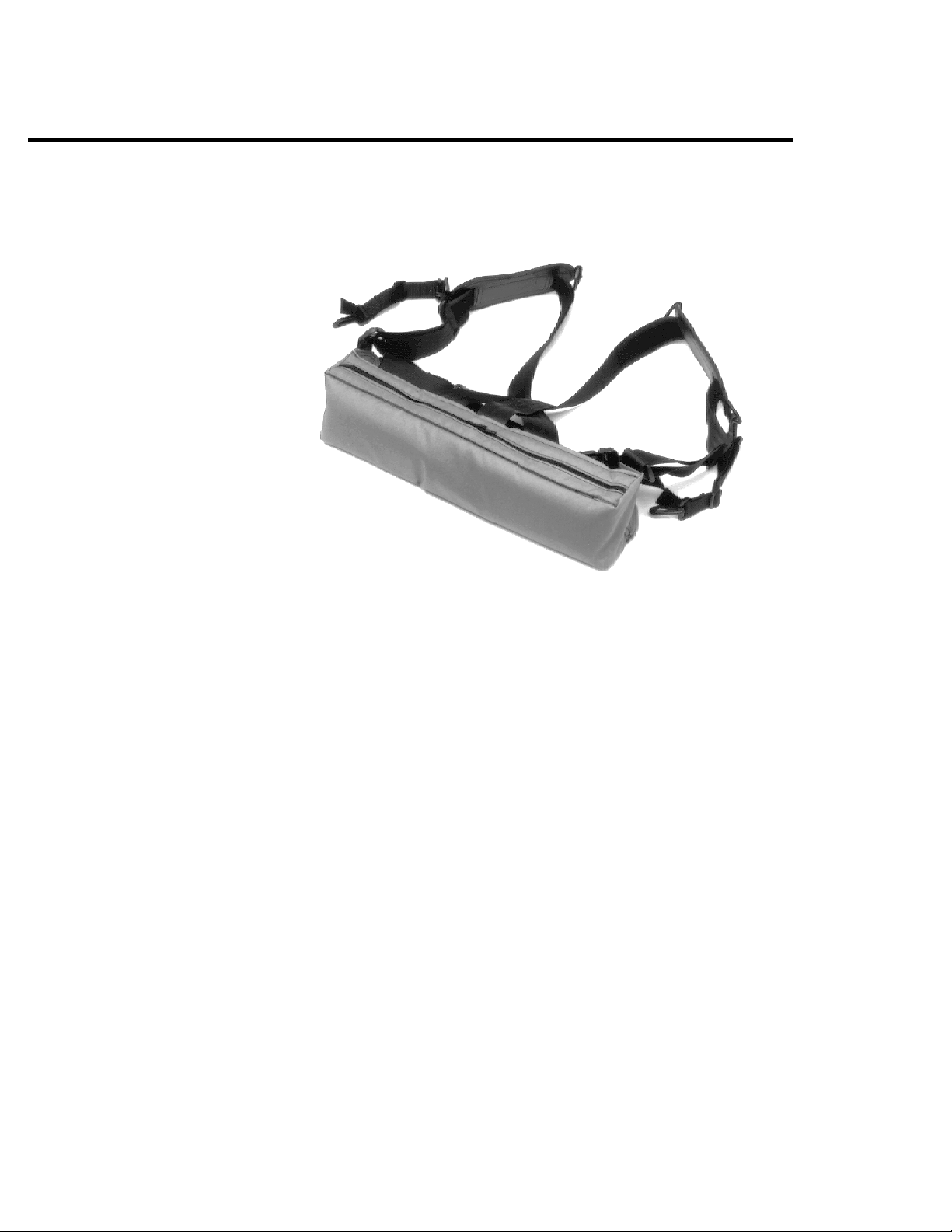

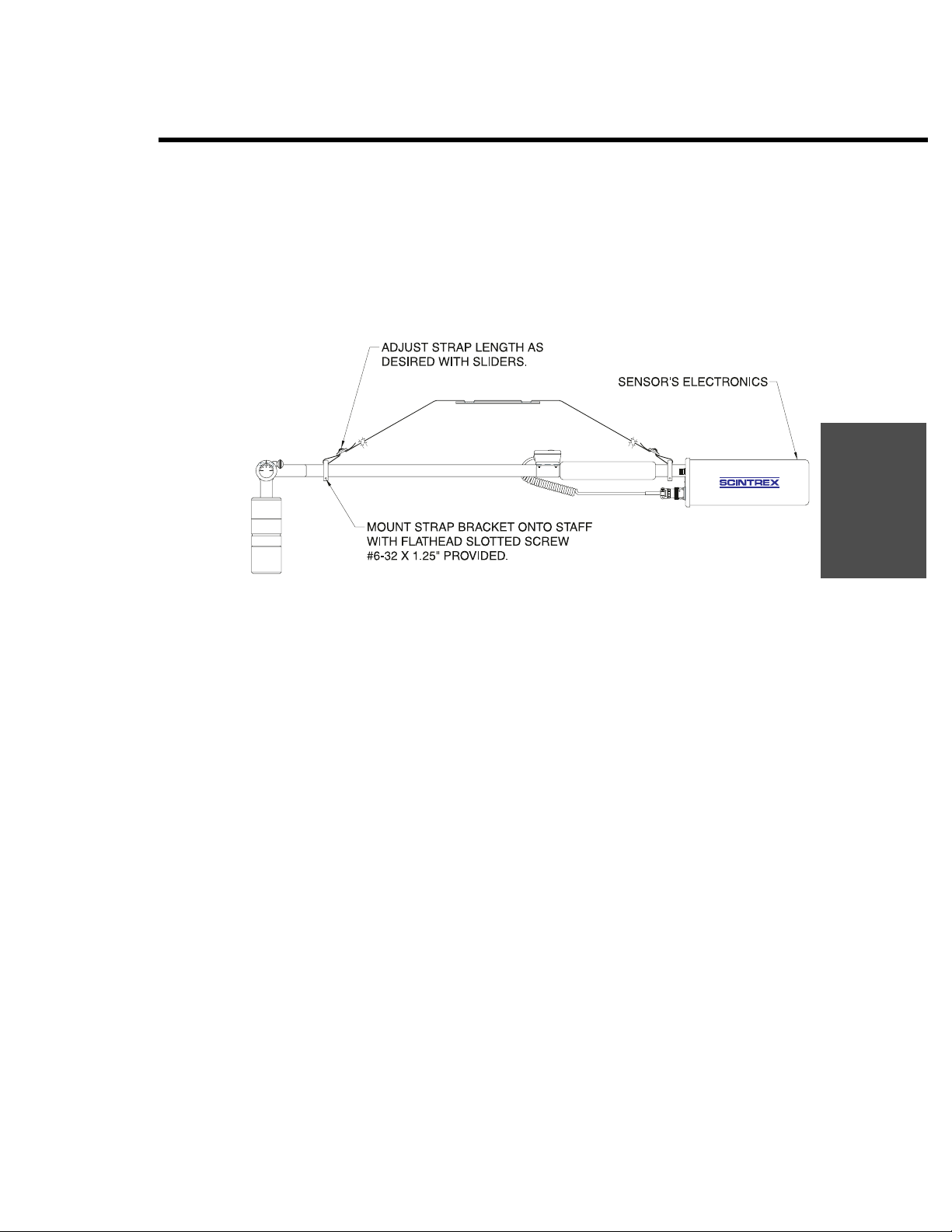

INSTALLING THE SHOULDER STRAP

1. Thread the shoulder strap through the plastic clips and attach the

strap to the sensor staff as shown in the diagram below:

Figure 6 Installing the shoulder strap

Assembly

Preparation

2. Adjust the straps in the plastic clips until the sensor staff is the

correct height and the strap comfortably fits your shoulder.

INSTALLING THE AUDIO OPTION KIT

The Audio option can be added to the SMARTMAG after you have taken

possession of the instrument by adding the audio option kit. To install

the audio option in your

SMARTMAG, please contact the factory.

2-7

Preparing the SMARTMAG

SMARTMAG CONSOLE BATTERY INSTALLATION/EXCHANGE

The SMARTMAG console is shipped without the battery installed. This is

the proper procedure, while shipping and storing the instrument, to

prevent deep discharge of the battery. Deep discharge can possibly

cause permanent damage to the battery and will always shorten the

battery life. This situation will occur because a small current is being

drawn even if the instrument is turned off.

The following steps outline the battery installation:

1. Turn the instrument face down on a clean and even surface.

2. Unscrew both knurled screws on either side of the battery cover

and lift the cover off.

3. Place the battery into the recess in the rear panel of the

instrument.

4. Connect it carefully to the MAIN BATTERY connector. It is not

important which side of the plug is up, as long as the connector

pins are properly aligned.

2-8

5. Replace the cover and tighten both knurled screws.

6. If this is the first time installation, proceed with battery charging.

The small size and low cost of the battery makes it convenient to carry

an additional battery along as a spare.

Warning: An internal battery keeps the memory and the internal

clock alive for about

the switching to the spare battery be done

TO PREVENT THE LOSS OF YOUR DATA!

10 minutes. It is strongly advised that

quickly,

Assembly

You need not worry about a low battery causing data loss, since the

memory power requirements are much less than those needed to make

a valid reading of the magnetic field.

Preparation

Battery cover

Figure 7 SMARTMAG battery pack

Battery pack

USING THE EXTERNAL BATTERY PACK

The standard battery should provide 24 hours operation at 20°C and 8

hours of operation at -40°C. Extended cold weather

may require more power than the standard battery together with a

spare can provide. To satisfy this additional requirement, the External

Heavy Duty Battery Pack (

provides about three times as much power as the standard battery. This

battery pack can be carried by the strap or attached to a belt.

To connect the external battery you must proceed as follows:

1. Turn the instrument face down on a clean and even surface.

2. Unscrew both knurled screws on either side of the battery cover.

3. Lift off the cover and store it somewhere convenient for future

use with the standard battery configuration.

4. Remove the standard battery.

SCINTREX part number 788 026) is available. It

WALKMAG surveys

5. Connect the connector in the dummy battery cover carefully to

the

MAIN BATTERY connector. It is not important which side of the

plug is up, as long as the connector pins are properly aligned.

2-9

Preparing the SMARTMAG

6. Place the new cover on to the console by gently pushing it into

7. Please check the battery voltage condition at this stage and

Dummy Battery Cover

SMARTMAG Console

(Face-down)

its place and tighten the knurled screws on both sides.

charge the battery, if it is required.

Battery Cable

External Heavy Duty

Battery Pack

Main Battery Connector

2-10

Figure 8 External heavy duty battery connection

USING AN EXTERNAL POWER SUPPLY

More demanding applications, such as an extended base-station oper-

ation, may require more power than can be provided with the either of

the

SCINTREX supplied battery packs. In this case you have two options:

a) AC-power

If a source of AC-power is available, the instrument can be run

while the charger is connected to it. You will also be charging the

standard internal battery, if it is installed, at the same time.

Note: Please be aware of possible magnetic noise from genera-

tors, and ensure that all cabling and sensors are as far away

as possible from the generator as possible.

b) 12-volt battery (car or marine)

A 12-volt car battery may be more appropriate for other

applications. The special External Power Cable (

788 029) should be used for this purpose.

Assembly

Preparation

SCINTREX P/N

1. The standard internal battery may be left in place.

2. Plug in the end of the cable with the single plug into the

Charger Connector at the right-rear side of the

console. (See item 6 in Figure 12 on page 6–2.)

3. Connect the end with the clips to the battery terminals.

The red cable-clip goes to the positive battery terminal. The

black cable-clip goes to the negative battery terminal.

Caution: The correct polarity must be used for the instrument to

operate properly.

SMARTMAG

2-11

Preparing the SMARTMAG

2-12

SMARTMAG

GUIDELINES

OPERATOR PREPARATION

Prior to conducting a search or survey with a cesium magnetometer,

the operator must remove all offending metallic items from his/her

body (some metals are non-magnetic or have low magnetic signature;

aluminum and brass for example). Commonly worn or carried magnet-

ic items include the following: belt buckles, watches, coins, steel toed

boots/shoes, metal buttons, pocket knives, compasses and magnets. It

may not always be obvious that an item contains metallic parts, for ex-

ample some shoes may have metallic eyelets. Of course, the

can be used to test suspect items.

Chapter

3

Guidelines

SMARTMAG

GEOMETRY OF DEAD ZONES

Cesium magnetometers will operate properly only if the angle that the

sensor head makes with the earth’s magnetic field vector is within the

ranges 10–85 degrees, 95–170 degrees, 190–265 degrees and 275–355

degrees. When the sensor head is parallel (more correctly in line,

which consists of parallel and antiparallel alignment) or at right angles

to the earth’s magnetic field vector, no usable signal is available. For a

small zone about parallel and right angle alignment there is still no us-

able signal. These zones are referred to as dead zones and are illustrated

in Figure 9 on page 3–2.

3-1

Guidelines

For parallel alignment we have two dead zones, the first about 0 degrees with range –10 to +10 degrees and the second about 180 degrees

with range 170–190 degrees. These two zones are referred to as the po-

lar dead zones and form two conical solid angles in three-dimensional

space.

For right angle alignment, we have a dead zone whenever the sensor

head is in the plane perpendicular to the earth’s magnetic field vector.

This zone is encountered whenever the angle that the sensor head

makes with the earth’s magnetic field vector is in the range of 85–95 (or

265–275) degrees. This zone may be considered as a disk in threedimensional space, and is referred to as the equatorial dead zone.

3-2

Figure 9 Cesium sensor dead zones in the

northern hemisphere.

Determining operating zones

DETERMINING OPERATING ZONES

1. To determine the operating zones of the SMARTMAG, face north

and swing the sensor head to the ground and then upwards. This

will enable you to determine the angular range of operation by

either the audio or display reading. When the sensor head is out

of the operating range, the audio will vary wildy and the display

reading will go out of range (range 20,000 to 99,999 nT). Preferably, the staff should be oriented so that it lies in the center of the

angular range as just described.

2. While facing magnetic north, the range of sweep operation may

be determined by swinging the

then to the right. The usable sweep angle will depend on your

geographical position. If sweep operations are then conducted

while walking in a northerly direction, the allowable sweep

motion will be known by the previous test.

SMARTMAG staff to the left and

3. To determine the proper staff position and sweep angle for

walking south, perform the previous tests while facing south.

Guidelines

3-3

Guidelines

ADJUSTING THE SENSOR HEAD ANGLE

1. Adjust the angle of the sensor head relative to the staff by loosen-

ing the brass wing nut and then swiveling the head. The head

should be positioned so that it is in the centre of the operating

zone and that it does not enter a dead zone during a survey operation.

2. When the sensor head is in the appropriate position, tighten the

brass wing nut.

3-4

SMARTMAG

Chapter

THE SMARTMAG MODEL

SM–4

This chapter is about the SMARTMAG model SM–4 which contains a full

featured

numerical and graphical data. The SM–4 features:

▲ adjustable cesium sensor with rigid staff,

▲ SMARTMAG Console featuring:

LCD console. The SM– 4 console has full storage for recording

▲ graphics display

▲ full keyboard

▲ 310,000 Readings —Total Field

4

▲ 750,000 Reading —Base Station

▲ Non-magnetic waterproof construction

RECEIVING YOUR INSTRUMENT

On receipt of your instrument, carefully inspect the shipping or carry-

ing case for damage. Also ensure that you have received all required as-

semblies by checking against your order, as systems may vary.

SM–4

4-1

The SMARTMAG Model SM–4

THE COMPONENTS

The basic SM– 4 (part no. 759 003) consists of the following assemblies

(see “Instrument parts list” on page 11–4 for more details):

▲ SMARTMAG main assembly (759 009)

▲ Rechargeable battery belt (759 043)

▲ 110/220 VAC battery charger (400 151)

▲ Shoulder strap (759 504)

▲ SMARTMAG minor spare parts kit (759 039)

▲ SMARTMAG console (759 012)

▲ Rechargeable battery (400 078)

▲ 110/220 VAC battery charger (400 139)

▲ Console minor spare parts kit (788 030)

▲ RS-232 Cable (745 081)

▲ SMARTMAG SM–4/4G Information kit (759 534)

▲ Transit case (759 505)

ASSEMBLING THE INSTRUMENT

The shoulder strap assembly are not attached to the instrument when

shipped. The shoulder strap is attached to the staff by way of clips that

are snapped on and then screw tightened. The clamps are to be positioned on either side of the black foam handle on the staff. This will require some experimentation to find the most comfortable position for

the individual user.

CONNECTING THE CABLES

In order to operate the SMARTMAG you must provide power to the staff

assembly by connecting the cable (with 10 pin KPT connector) from

the battery belt (this connector is labeled ‘

nector on the face plate. This connector is locked by rotating the

mounting ring on the connector in a clockwise direction. (See “Connecting the sensor(s) to the Battery Belt” on page 2–5.) (Cable P/N 759

513)

4-2

TOTAL’) to the mating con-

Setting up the instrument

The optional LED display and keypad is similarly connected to the other

connector (10 pin KPT) on the face plate.

The headphones are connected to its signal cable coming from the cen-

ter of the battery belt box.

The

SMARTMAG console is connected via RS-232 cable (with dual 4-pin

KPT cable P/N 759 514) to the battery belt box. Connect the ‘Data Out-

put’ connector on the

tor on the battery belt box. This 4 pin RS-232 connector is on the bottom

of the battery belt box, and is adjacent to the 10 pin ‘

SMARTMAG console to the 4-pin RS-232 connec-

SETTING UP THE INSTRUMENT

TURNING ON THE INSTRUMENT

TOTAL’ connector.

1. Set the 3-position switch in the battery belt to the ON position. The

amber coloured

2. Press and release the RESET push-button switch on the face plate

of the

SMARTMAG.

If the 3-position switch in the battery belt is put in the center or

STBY (standby) position, the sensor head power is removed but

digital electronics remains powered. This mode may be used

when learning the display functions if you want to conserve

battery power.

Note: The instrument operates from battery power only — the

charger will not power the instrument and the charger will

not charge the batteries in any position other than the

position of the 3-position switch.

LED will then light.

OFF

4-3

SM–4

The SMARTMAG Model SM–4

USING THE HEADPHONES

The headphones are connected to the black plastic connector at the

end of the cable coming from the bottom of the battery belt. The headphones are monaural and have a single volume control on the right

hand cup.

The sensitivity of the headphone is set by the PITCH parameter on the

SMARTMAG console. Alternatively, the sensitivity of the headphones can

be set with the Audio function accessed by the

LED display and key-

board described below.

SETTING THE PARAMETERS WITH THE

CONSOLE

4-4

Prior to operating a survey, it is necessary to enter certain parameters

into the

▲ hemisphere of operation

▲ local field value

▲ audio sensitivity

▲ sample rate

▲ filter bandwidth

SMARTMAG console. These include:

These parameters are downloaded into the sensor wand from the

SMARTMAG console when the START key is first pressed on the console.

The message initializing will be displayed on the

console

the

LCD display. If a communication error results, press and release

RESE T button on the SMARTMAG faceplate.

Note: SM–4 users (and particularly SM– 4G users) will find the

SMARTMAG

LED

display and keypad useful for verifying that the sensor

wands have reset and are fully functioning. Please refer to

Chapter 6 for a full description of the

SMARTMAG console.

Using the LED display and keypad

USING THE LED DISPLAY AND KEYPAD

Note: The SM– 4 may be used as a search magnetometer using the

optional

LED display and keyboard in place of the console.

The parameters may be set from the

bly which consists of an 8 digit, sunlight readable display and a four key

keyboard. The keys are labeled with both arrows and numbers

(1,2,3,4). The functions are as follows:

KEYPAD

Function key—(1 key, right arrow) This key is used to enter and exit

!

@#

$

functions. The available functions may be viewed by using the scroll

keys.

Scroll keys—(2 key, up arrow; 3 key, down arrow) These keys are used

to scroll or scan through functions. Once a function has been selected

or entered (by pressing Key 1), the scroll keys are then used to scroll or

scan through the options provided by that function.

Auxiliary Key—(4 key, left arrow) The auxiliary key is currently re-

served for future use.

DISPLAYS AND FUNCTIONS

LED display and keyboard assem-

SM–4

Function ‘ ’

(blank display)

This display shows the total field value in nT.

1. Press the

displayed.

2. Press the

3. Press the

or # scroll key until the ‘ ’ (blank display) is

@

function key to display the total field value in nT.

!

function key to exit this parameter.

!

4-5

The SMARTMAG Model SM–4

Function

north

south

Function

Audio

Select this function to enter in the North or South hemisphere. In order

to operate properly, the hemisphere setting must be set according to the

hemisphere that the instrument is being operated in. If you are operating in the northern hemisphere, (Canada, USA, Japan etc.) select

north, Otherwise, select south. The default power up setting of

the

SMARTMAG is for northern hemisphere operation.

1. Press the

is displayed.

2. Press the

3. Press the

4. When you have selected the appropriate hemisphere, press the

function key to exit this parameter,

!

Select this function to set the sensitivity of the audio headphones. The

sensitivity can be set from 0 to 990 in increments of 10.

1. Press the

2. Press the

3. Press the

selected. The sensitivity can be set from 0 through 990 in

increments of 10. The default is 100. Use a smaller value for less

sensitivity and a larger value for greater sensitivity.

or # scroll key until the either north or south

@

function key to access the setting.

!

or # scroll key to select either north or south.

@

or # scroll key until Audio is displayed.

@

function key to access the setting.

!

or # scroll key until the appropriate sensitivity is

@

Function

LoPAS

4-6

Select this function to set the low-pass filter bandwidth in Hz of the displayed data. This function does not affect audio information. The visual

display of the total magnetic field may b e u se d to sup pl eme nt the aud io

information. The bandwidth settings are 0.5, 1.0, 2.0, 4.0 and 8.0 Hz (optionally higher bandwidths are available).

1. Press the

2. Press the

3. Press the

selected. The bandwidth can be set to 0.5, 1.0, 2.0, 4.0 or 8 Hz (or

optionally higher).

or # scroll key until the LoPAS is displayed.

@

function key to access the setting.

!

or # scroll key until the appropriate bandwidth is

@

Using the LED display and keypad

Note: Bandwidths and sample rates are independent — data may

be obtained at the highest sample rate regardless of the

bandwidth setting.

Function

fLASH

Function

rAtE

Function

FIELd

Select this function to program the FLASH memory

1. Press the

2. Press the

3. Press the

10 in increments of 1 (0, 1, 2, …10). When 10 is reached, the

SMARTMAG will be ready to receive its new operating program

from a

1. The PC program FASTCOM

2. A downloadable sys file *.SYS

3. RS-232 cable to connect the battery belt’s 4 pin KPT

connector to PC

Access this function to select the LED display update rate of 1, 2, 5 or 10

readings per second.

Access this function to set the local field strength in 1,000’s of nT to the

nearest 5,000 nT. This parameter does not have to be correctly set for the

SMARTMAG to function, so you can determine the correct value of the

field by measuring the field with the

field settings are:

or # scroll key until FLASH is displayed.

@

function key to access the setting.

!

key to increment the displayed number from 0 to

@

PC via RS-232 at 19,200 baud. This requires:

SMARTMAG. Some examples of

SM–4

Local Field: Set FIELd to:

23,000 nT 25 (for 25,000 nT)

57,000 nT 55 (for 55,000 nT)

90,000 nT 90 (for 90,000 nT)

The field parameter may be set ±10 without effect. If the field is grossly

out of setting, bandwidth settings will not be correct. To set the field:

4-7

The SMARTMAG Model SM–4

1. Press the

2. Press the

3. Use the

strength by 5 (5,000 nT).

Warning: Users who operate with both the

and

the operating parameters in the

Changes made to the operation parameters such as

bandwidth via the

process of data collection will be recognized by the sensor

wand processor but will not be recorded in the

console header information.

or # scroll key until FIELd is displayed.

@

function key to access the setting.

!

or # scroll key to increment or decrement the field

@

SMARTMAG console simultaneously should configure

PERFORMING A SURVEY

LED display and keypad

SMARTMAG console only.

LED display and keypad while in the

SMARTMAG

4-8

See the SMARTMAG Applications booklet for details on how to perform

a survey.

SMARTMAG

HE SMARTMAG MODEL

T

SM–4G

This chapter is about the SMARTMAG model SM–4G which contains a

full featured

sole has full storage for recording numerical and graphical data. The

SM–4G features:

▲ gradiometer interconnect poles.

▲ two cesium sensors with adjustable sensor orientation,

▲ SMARTMAG Console featuring:

LCD console and the gradiometer option. The SM– 4G con-

▲ graphics display

▲ non-magnetic water proof construction

Chapter

5

▲ storage for 190,000 gradiometer readings

▲ full keyboard

RECEIVING YOUR INSTRUMENT

On receipt of your instrument, carefully inspect the shipping or carry-

ing case for any damage. Also, please ensure that you have received all

required assemblies by checking against your order, as systems may

vary.

SM–4G

5-1

The SMARTMAG Model SM–4G

THE COMPONENTS

The basic SM– 4G SMARTMAG (part no. 759 004) consists of the following assemblies (see also “Instrument parts list” on page 11–4):

▲ SMARTMAG main assembly (759 009)

▲ Rechargeable battery belt (759 043)

▲ 110/220 VAC battery charger (400 151)

▲ Shoulder harness (759 504)

▲ SMARTMAG minor spare parts kit (759 039)

▲ SMARTMAG console (759 012)

▲ Rechargeable battery (400 078)

▲ 110/220 VAC battery charger (400 139)

▲ Console minor spare parts kit (788 030)

▲ RS-232 Cable (745 081)

▲ Gradiometer mounting kit (759 082)

▲ SMARTMAG SM–4/4G Information kit (759 534)

▲ Transit case (759 505)

ASSEMBLING THE INSTRUMENT

The shoulder strap assembly is not attached to the instrument when

shipped. The shoulder strap is attached to the staff by means of clips

that are snapped on and then screw tightened. The clamps are to be positioned on either side of the black foam handle on the staff. This will

require some experimentation to find the most comfortable position for

the individual user.

MASTER PROCESSOR

When operating in the Gradiometer configuration with two sensor

wands, the wand connected to the battery belt

pin

KPT) will process both the Total and Gradiometer signals. The

5-2

TOTAL connector (10

Assembling the instrument

TOTAL sensor wand transmits both total and gradiometer data to the

SMARTMAG console via the 4 pin KPT connector on the bottom of the

battery box (this connector is adjacent to the

TOTAL connector).

Note: The

erate as a master processor. The

internally jumpered to operate as a slave processor.

When receiving a SM–4G system, the

slave) sensor wands will be labelled.

Warning: Please consult the

changing these configurations. Note that both master and

slave processor wands may be used as is for performing

total field surveys.

CONNECTING THE CABLES

In order to operate the SMARTMAG you must provide power to the staff

assembly by connecting the cable (with 10 pin

the battery belt (this connector is labeled

nector on the face plate. This connector is locked by rotating the

mounting ring on the connector in a clockwise direction. (See “Con-

necting the sensor(s) to the Battery Belt” on page 2–5.). (Cable P/N 759

513)

TOTAL sensor wand must be internally jumpered to op-

GRAD sensor must be also

TOTAL (or master) and GRAD (or

SCINTREX factory for information on

KPT connector) from

TOTAL) to the mating con-

Similarly, the gradiometer sensor is connected to the battery belt con-

nector labelled

The optional

connector (10 pin

GRAD.

LED display and keypad is similarly connected to the other

KPT) on the face plate.

The headphones are connected to its signal cable coming from the cen-

ter of the battery belt box.

The

SMARTMAG console is connected via RS-232 cable (with dual 4-pin

KPT cable P/N 759 514) to the battery belt box. Connect the ‘Data Out-

put’ connector on the

SMARTMAG console to the 4 pin RS-232 connector

on the battery belt box. This 4 pin RS-232 connector is on the bottom

of the battery belt box and is adjacent to the 10 pin

TOTAL connector.

5-3

SM–4G

The SMARTMAG Model SM–4G

SETTING UP THE INSTRUMENT

TURNING ON THE INSTRUMENT

1. Set the 3-position switch in the battery belt to the ON position. The

amber coloured

2. Press and release the RESET push-button switch on the face plate

of the

SMARTMAG. (Gradiometer: press both buttons on each of

the face plates.)

If the 3-position switch in the battery belt is put in the center or

STBY (standby) position, the sensor head power is removed but

digital electronics remains powered. This mode may be used

when learning the display functions if you want to conserve

battery power.

Note: The instrument operates from battery power only — the

charger will not charge the batteries in any position other

than the

LED will then light.

OFF position of the 3-position switch.

USING THE HEADPHONES

The headphones are connected to the black plastic connector at the

end of the cable coming from the center of the battery belt. The headphones are monaural and have one volume control on the right hand

cup.

The sensitivity of the headphones is set by the PITCH parameter in the

SMARTMAG console. Alternatively, the sensitivity of the headphones can

be set in the Audio function accessed by the

board described in the following sections.

5-4

LED display and key-

Setting the parameters with the SMARTMAG console

SETTING THE PARAMETERS WITH THE

SMARTMAG CONSOLE

Prior to operating a survey, it is necessary to enter certain parameters

into the

▲ sample rate

▲ local field value

▲ hemisphere of operation

▲ filter bandwidth

▲ audio sensitivity

These parameters are downloaded into the sensor wand from the

SMARTMAG console when the START key is first pressed on the console.

The message initializing will be displayed on the

console LCD display. If a communication error results, press and release

the

the SM–4G.

SMARTMAG console. These include:

SMARTMAG

RESET button on the SMARTMAG faceplate (or both RESET buttons for

Note: SM–4 users (and particularly SM– 4G users) will find the

display and keypad useful for verifying that the sensor

wands have reset and are fully functioning. Refer to Chapter

6 for a full description of the

SMARTMAG console.

USING THE LED DISPLAY AND KEYPAD

The SM – 4G may be used as search magnetometer/gradiometer using

the optional

The parameters may be set from the

bly which consists of an eight digit, sunlight readable display and a four

key keyboard. The keys are labeled with both arrows and numbers

(1,2,3,4). The functions are as follows:

LED display and keyboard in place of the LCD console.

LED display and keyboard assem-

LED

SM–4G

5-5

The SMARTMAG Model SM–4G

KEYPAD

Function key—(1 key, right arrow) This key is used to enter and exit

!

@#

$

functions. The available functions may be viewed by using the scroll

keys

Scroll keys—(2 key, up arrow; 3 key, down arrow) These keys are used

to scroll or scan through functions. Once a function has been selected

or entered (by pressing Key 1), the scroll keys are then used to scroll or

scan through the options provided by that function.

Auxiliary Key—(4 key, left arrow) The auxiliary key is currently reserved for future use.

DISPLAYS AND FUNCTIONS

Function ‘ ’

(blank display)

Function

north

south

This display shows the total field value in nT.

1. Press the

displayed.

2. Press the

3. Press the

Select this function to enter in the North or South hemisphere. In order

to operate properly, the hemisphere setting must be set according to the

hemisphere that the instrument is being operated in. If you are operating in the northern hemisphere, (Canada, USA, Japan etc.) select

north, Otherwise, select south. The default power up setting of

the

SMARTMAG is for northern hemisphere operation.

1. Press the

is displayed.

2. Press the

3. Press the

4. When you have selected the appropriate hemisphere, press the

function key to exit this parameter,

!

or # scroll key until the ‘ ’ (blank display) is

@

function key to display the total field value in nT.

!

function key to exit this parameter.

!

or # scroll key until the either north or south

@

function key to access the setting.

!

or # scroll key to select either north or south.

@

5-6

Using the LED display and keypad

Function

Audio

Function

LoPAS

Select this function to set the sensitivity of the audio headphones. The

sensitivity can be set from 0 to 990 in increments of 10.

1. Press the

2. Press the

3. Press the

selected. The sensitivity can be set from 0 through 990 in

increments of 10. The default is 100. Use a smaller value for less

sensitivity and a larger value for greater sensitivity.

Select this function to set the low-pass filter bandwidth in Hz of the dis-

played data. This function does not affect audio information. The visual

display of the total magnetic field may b e u se d to sup pl eme nt the aud io

information. The bandwidth settings are 0.5, 1.0, 2.0, 4.0 and 8.0 Hz (op-

tionally higher bandwidths are available).

1. Press the

2. Press the

3. Press the

selected. The bandwidth can be set to 0.5, 1.0, 2.0, 4.0 or 8 Hz (or

optionally higher).

or # scroll key until Audio is displayed.

@

function key to access the setting.

!

or # scroll key until the appropriate sensitivity is

@

or # scroll key until the LoPAS is displayed.

@

function key to access the setting.

!

or # scroll key until the appropriate bandwidth is

@

Function

fLASH

Note: Bandwidths and sample rates are independent — data may

be obtained at the highest sample rate regardless of the

bandwidth setting.

Select this function to program the FLASH memory

1. Press the

2. Press the

3. Press the

10 in increments of 1 (0, 1, 2, …10). When 10 is reached, the

SMARTMAG will be ready to receive its new operating program

from a

or # scroll key until FLASH is displayed.

@

function key to access the setting.

!

key to increment the displayed number from 0 to

@

PC via RS-232 at 19,200 baud. This requires:

SM–4G

5-7

The SMARTMAG Model SM–4G

1. The PC program FASTCOM

2. A downloadable sys file *.SYS

3. RS-232 cable to connect the battery belt’s 4 pin KPT

connector to

PC

Function

rAtE

Function

FIELd

Access this function to select the LED display update rate of 1, 2, 5 or 10

readings per second.

Access this function to set the local field strength in 1,000’s of nT to the

nearest 5,000 nT. This parameter does not have to be correctly set for the

SMARTMAG to function, so you can determine the correct value of the

field by measuring the field with the

SMARTMAG. Some examples of

field settings are:

Local Field: Set FIELd to:

23,000 nT 25 (for 25,000 nT)

57,000 nT 55 (for 55,000 nT)

90,000 nT 90 (for 90,000 nT)

The field parameter may be set ±10 without effect. If the field is grossly

out of setting, bandwidth settings will not be correct. To set the field:

1. Press the

2. Press the

3. Use the

strength by

or # scroll key until FIELd is displayed.

@

function key to access the setting.

!

or # scroll keys to increment or decrement the field

@

5 (5,000 nT).

5-8

Warning: Users who operate with both the

and

SMARTMAG console simultaneously should configure

the operating parameters in the

Changes made to the operation parameters such as

bandwidth via the

LED display and keypad while in the

process of data collection will be recognized by the sensor

wand processor but will not be recorded in the

console header information.

LED display and keypad

SMARTMAG console only.

SMARTMAG

ASSEMBLING THE GRADIOMETER

The gradiometer option can be assembled either horizontally or verti-

cally. The gradiometer kit has six 0.5 metre inter-connecting poles.

Vertical Gradiometer

The vertical gradiometer is configured by using two 0.5 metre inter-

connecting poles to attain a vertical separation between the two sensor

staff assemblies, as shown in the diagram below:

Using the LED display and keypad

Figure 10 Assembling the Vertical Gradiometer

SM–4G

5-9

The SMARTMAG Model SM–4G

Horizontal Gradiometer

In the horizontal gradiometer assembly, there are two options. The gradiometer separation in the horizontal position can be 0.5, 1.0 or 1.5

metres. The separation is achieved by the number of inter-connecting

polesused in the configuration. For example, if you require a 1.5 metre

separation, all of the poles would be used. See the diagram below for

a typical horizontal configuration.

5-10

Figure 11 Assembling the Horizontal

Gradiometer

PERFORMING A SURVEY

See the SMARTMAG Applications booklet for details on how to perform

a survey.

Performing a Survey

5-11

SM–4G

The SMARTMAG Model SM–4G

5-12

SMARTMAG

Chapter

6

THE SMARTMAG CONSOLE

This chapter is about the the SMARTMAG console and fully describes:

▲ the keypad functions,

▲ the various display menus,

▲ the display formats that you will encounter.

PRE-DEFINED OPERATING MODES

To ma ke the SMARTMAG easier to use, it has a menu of seven predefined

configurations, in three modes, to choose from. The menu is obtained

by pressing the “SETUP + ON” keys simultaneously.

BASIC ▲ used for site characterization, buried ordnance detection, drum

location and archaeology

▲ operates in the WALKMAG mode (continuous reading)

▲ does not have on-line data recall features; you have to dump the

data to a computer to inspect it—you can still see a graphical

display of the data

▲ data correction is from a base-station or the TIE-PT Loop mode

▲ real-time graphic display of the data

Console

SEARCH ▲ operates in a continuous reading mode, but the data is not

stored in memory

▲ you can see a graphical display of the data as it is collected

▲ real-time graphic display of the data

ADVANCED ▲ used for ground water, mineral, oil and gas exploration or

detailed site characterization, drum location, archaeology, etc.

▲ allows you to adjust all possible parameters of the SMARTMAG

▲ real-time graphic display of the data

6-1

The SMARTMAG Console

1

2

3

3

4

5

6

7 8 9 10

6-2

Figure 12 The SMARTMAG console.

11

Console description

*

CONSOLE DESCRIPTION

# Item Description

1 Keypad The fully sealed Keypad has 19 keys and a sound port.

Console

2 Liquid Crystal

Display (LCD)

3 Carrying Strap

Attachment

*Sensor

4

Connectors

5 Data Output

Connector

6 Charger/

External Power

Connector

7 Charging Light The charging light is visible through a window at the left side of

The large 8 line by 40 character (64 x 240 dots) Supertwist

LCD (with a wide temperature range) presents status and data

in numeric or graphic format.

Four rings at the side of the console allow attachment of the

carrying harness.

Up to two sensor connectors may be present at the left hand

side of the console. The nearer one (J102) is reserved for the

magnetometer.

The data output connector carries RS-232 data dump signals,

as well as the analog signal for a strip chart recorder and is located at the right hand side of the console.

It has the following pin assignments:

A - common (ground), C - RS-232 transmit data,

B - RS-232 receive data. D - analog out O - 1 Volt,

This connector accepts the charger to recharge either the

standard battery or the external heavy-duty battery pack. It

also accepts external, well filtered, 11 to 16 Volt DC input.

The center pin is negative (–).

The shell is positive (+).

the console. It is lit while the battery is charging at a high rate.

8 Battery

Compartment

9 Desiccant

Cartridge

10 Battery A rechargeable lead-acid battery in the standard

11 Fuse The standard 1.5A fuse to use with the standard battery.

*

The number of sensor connectors may vary depending upon configuration

The battery compartment is located at the back of the console

and contains one rechargeable lead-acid battery, the desiccant

cartridge and the fuse. The battery cover is replaced with another cover with a cable attached when the external battery is

used.

The desiccant cartridge is a cylindrical re-usable capsule filled

with a drying agent. It absorbs any moisture that may get inside the instrument.

SMARTMAG configuration.

6-3

The SMARTMAG Console

KEYPAD DESCRIPTION

The keypad has 19 keys. Two of the most used keys are duplicated on

the right and left sides of the console for easy access. Some keys have

up to three separate functions assigned to them. The response of these

multi-function keys depends upon the operation in progress.

Note: The function mode of the keys has precedence over the

alphanumeric mode of the keys

.

6-4

Figure 13 The SMARTMAG console keypad.

KEY FUNCTIONS

Key Description

q

Keypad description

Console

Turns the instrument on and off. Turning the instrument off during a reading abruptly terminates a reading with the loss of the

current data.

Starts or stops an operation, such as data acquisition, data

dumping, data recall, etc.

w

5

1

23

e

*When the instrument is in the Notes operation, this button

acts as a “backspace” key to delete entries.

*Accesses the various setup displays. The actual setup menu

that will be displayed depends upon the display screen in which

this key is pressed.

*Accesses the Auxiliary Functions display allowing:

▲ setting of the LCD intensity,

▲ data output,

▲ locking of the setup parameters,

▲ reprogramming of the main system software (EEPROM).

Moves the cursor to the left or up; to the right or down,

▲ scrolls sequentially through graphic display pages (online),

▲ scrolls sequentially through graphic display pages (recall).

Two identical keys:

▲ opens and closes the parameter fields during setups,

▲ opens and closes the scaling option field for the graphics display,

▲ toggles the sample rate in the walking type survey.

0

Allows escape from a deeper level in a program to a higher level,

ultimately to the top level, which is signified by the

Main operating display.

Aborts a data dump.

6-5

The SMARTMAG Console

Key Description

*Accesses the Info. Display, which allows:

7

t

6

4

9

▲ setting of date and time,

▲ entering of serial and job numbers and operator identification,

▲ observation of memory availability.

Two identical keys:

▲ moves the cursor from one sub-page to the next sub-page,

▲ moves the cursor to the next character location during note entry,

▲ advances the station number by station separation in the

walking mode.

*Accesses the Note Entry display, which allows:

▲ the entry of five common notes (macros) to be recorded

repeatedly with selected readings,

▲ the entry of unique notes to be recorded with a particular

reading.

Toggles the data display between numerical and graphic data

presentation during data acquisition only.

*Presents the Recall display for selection of:

▲ data item to be recalled,

▲ setting of the starting location or time of the recall.

6-6

r

8

*Manually records measured data and notes in internal

memory.

Acts as the START key at a Tie-point. This is used for the

Tie-point line and loop mode corrections.

Keypad description

Key Description

Facilitates the scrolling forward or backward through a list of

items:

=-

1-9, ., A-Z *Allows alpha-numeric entry for setups and notes.

BEEPER PORT

+

q

1

▲ allows sign entry to numbers,

▲ allows panning along a line of data during recall,

▲ increments or decrements the line and station number in the

Stop-and-Go mode.

This blank “key” in the upper left corner of the console is not actually a key, but a flexible membrane to enhance the loudness of

the beeper.

Pressing the “ON” and “AUX/LCD” keys simultaneously performs the COLD BOOT operation, resetting the instrument to

factory defaults.

Console

q

+

5

Pressing the “ON” and “SETUP” keys simultaneously allows you

to select between Basic, Search or Advanced modes.

*These items/key functions are only operational when you

select the advanced operating modes (options 5 to 7) from the

initial configuration menu.

6-7

The SMARTMAG Console

DISPLAY SCREENS

The SMARTMAG currently has seven preset configurations. Depending

upon which of the configurations you choose to survey with, you may

not see all of the various types of displays:

▲ configuration selection menus

▲ help screens

▲ confirmation screens

▲ parameter selection screens

▲ note entry screens

▲ numeric data displays

▲ graphical data displays

▲ pop-up options and confirmations

GENERAL INFORMATION

Most of the screens contain three bands of information as shown below:

Title Line

Specific

Display

Info.

Prompts

6-8

WELCOME TO SMARTMAG APPLICATIONS

MENU

1-Buried Ordnance Det.

2-Drum Location

3-Archaeology

4-Search Magnetometer

more +-

Please Select Your Application #:

Figure 14 General display information bands

1. The Title Line at the top indicates the current operating func-

tions.

2. The middle six lines contain specific display information

consisting of either instrument and survey parameters or data.

3. The bottom line usually contains prompts for actions, such as

pressing the key required to start an operation. Miscellaneous

23

Display screens

messages may also appear here. The battery voltage (a value

between 100 and 140) is also shown on the right-side of this line.

Note: The instrument automatically turns off (blank display) to

conserve battery power, if there is no reading or key stroke

detected for one minute.

Cursor

A large, blinking cursor (❚) indicates the specific parameter that can

be altered to change setups, starting station value, station or line spac-

ing, and so on. The cursor is moved from parameter to parameter or

line to line by pressing the arrow (← →) keys to move in the desired di-

rection. The prompt on the bottom line will let you know which key to

press to make any changes.

Display blocks

Some displays are divided into two or more blocks or sub-panels. The

blocks are separated by solid partition lines as shown in the following

figure.

Console

Cursor

Prompt

t

Separator

BlockBlock

START

locationsmeasurement

of:

MAG: mmmm ST: sss.s d

SEP: ppp.p

DIVBY: 0.

LN:llll.l d

SEP: pppp.p

Figure 15 Instrument display showing information

blocks (sub-panels)

To move the cursor from one block to another, press the “NEXT” key.

6-9

The SMARTMAG Console

Some measured data is displayed on more than one page (display

screen). Switching between pages is also done by pressing the “NEXT”

key. The display screens are designed so that these multi-page displays

do not have separate sub-blocks. All of this is discussed in detail under

“Advanced mode data displays” on page A6–27.

Pop-up windows

Some displays will have pop-up windows (either on the right or left side

of the main display) that will contain:

▲ prompts for selecting or changing parameters

▲ confirmations and warnings of impending operations requiring

▲ status indication of an operation under way, such as data output

a Y (yes) or N (no) entry from the keypad

MODE: t-fld

locations

BW: 8Hz

PITCH: 100 ST: 10. E

LOCAL FLD. 50000 SEP: 25.

TM/DT: OUTPUT: DIVBY: 0.

BASE: TIE: LN: 1. N

HEM:N ERASE MEM.: SEP: 10.

Chg?:ENT. 000 help:INFO BATT:134

locations

TIME: 13:40:35

DATE: 94/10/02 ST: 0. +

SEP: 0.

DIVBY: 0.

Main Menu: ESC LN: 0. +