ENVI PRO

OPERATION MANUAL

Rev.

0 Initial Release 4933 May 2009 AM

Description of

Change

ECO Date of Issue App

2

P/N 788715 Rev. 0

SCINTREX LIMITED

222 Snidercroft Road

Concord, ON, Canada

L4K 2K1

Telephone: +1 905 669 2280

Fax: +1 905 669 6403

e-mail: scintrex@scintrexltd.com

www.scintrex.com

Copyright@SCINTREX Limited 2009. All rights reserved.

No part of this publication may be reproduced, stored in a retrieval system or

transmitted, in any form, or by any means, electronic, mechanical, photo-copying,

recording, or otherwise without prior consent from SCINTREX Limited.

ENVI MAG and WALKMAG are trademarks of SCINTREX Limited.

P/N 788715 Rev. 0 ECO 4933

3

P/N 788715 Rev. 0

Table of Contents

Chapter 1 Preface.................................................................................................1—2

Features ............................................................................................................. 1—2

Upgrades and Options .......................................................................................1—2

Chapter 2 Introduction.........................................................................................2—1

Cold Boot ...........................................................................................................2—1

Instrument Overview ..........................................................................................2—1

Chapter 3 Preparing the ENVI PRO....................................................................3—1

Unpacking ..........................................................................................................3—2

Repacking ..........................................................................................................3—2

Assembly............................................................................................................ 3—2

Connecting the magnetic sensor(s) to the cable............................................3—2

Total-field sensor............................................................................................ 3—2

Installing the terminal protective cover...........................................................3—4

Assembling the sensor / GPS staff................................................................3—5

Staff Mounted Installation............................................................................... 3—5

Back-pack Installation .................................................................................... 3—8

Battery Installation/Exchange....................................................................... 3—10

Using the external battery pack.................................................................... 3—11

Using an external power supply ................................................................... 3—12

Chapter 4 The Instrument....................................................................................4—1

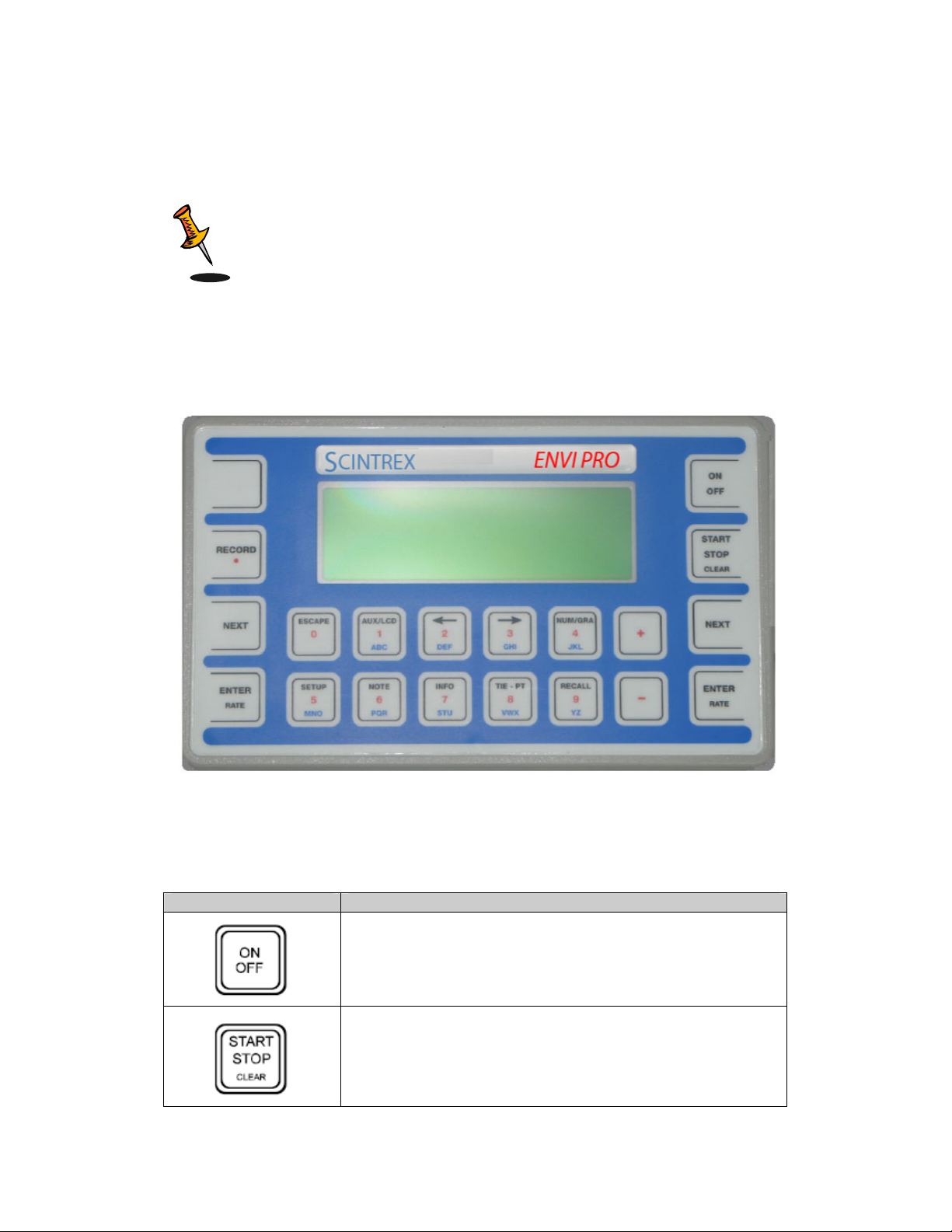

Console Description ........................................................................................... 4—2

Keypad Description ............................................................................................ 4—2

Key Functions ....................................................................................................4—3

Display Screens .................................................................................................4—5

Cursor ............................................................................................................4—6

Display Blocks................................................................................................4—6

Pop-Up Windows ...........................................................................................4—7

Help Screens.................................................................................................. 4—7

Chapter 5 Operating Displays............................................................................. 5—1

Main Operating display ..................................................................................5—1

Instrument setup display ................................................................................5—3

Magnetometer setup display .......................................................................... 5—4

Data Displays ..................................................................................................... 5—8

Numeric data display...................................................................................... 5—8

Graphic data display ....................................................................................5—11

Recall Displays............................................................................................. 5—13

Recall Setup display.................................................................................. 5—13

RECALL DATA display ................................................................................5—14

Modifying the display window....................................................................... 5—15

Auxiliary Functions display ........................................................................... 5—16

Data Output Display ..................................................................................... 5—17

Data output formats...................................................................................... 5—19

NOTES display............................................................................................. 5—19

Information / GPS Setup Display..................................................................5—20

Chapter 6 Setting Up the ENVI MAG ..................................................................6—1

First Time Operation ..........................................................................................6—1

Cold Boot .......................................................................................................6—1

Configuration Menu........................................................................................6—2

HOW TO: ...........................................................................................................6—3

Access the Main Operating Display ............................................................... 6—3

Access Display Sub-Panels/Blocks................................................................ 6—3

Access the Parameter Fields ......................................................................... 6—3

Change Parameters ....................................................................................... 6—3

Select and Enter............................................................................................. 6—4

Line and Station Setup.......................................................................................6—5

Entering the Starting Station .......................................................................... 6—6

Entering the Starting Line............................................................................... 6—6

Instrument Setup............................................................................................6—7

Sample Total-Field Setup (Walkmag or Walkgrad)........................................6—8

Sample Stop-and-Go Gradiometer Setup .................................................... 6—11

Sample Base-Station Setup ......................................................................... 6—14

Information Display ......................................................................................6—17

Note Entry .................................................................................................... 6—19

Display Intensity Control .............................................................................. 6—21

Parameter Lock............................................................................................6—21

Chapter 7 Operating the ENVI PRO....................................................................7—1

Accurate and Meaningful Measurements........................................................... 7—1

Orientation...................................................................................................... 7—1

Effects of gradient .......................................................................................... 7—1

Other sources of noise ................................................................................... 7—2

On the staff..................................................................................................... 7—2

Base-station ................................................................................................... 7—2

Repeated Surveys Lines ................................................................................ 7—3

Magnetometer Operation ................................................................................... 7—4

Walkmag Total-Field/Gradiometer Automatic Mode ......................................7—4

WALKGRAD Gradiometer Survey..................................................................7—7

Manual Mode – Total-Field/Gradiometer (Semi-Automatic)...........................7—7

Automating your measurements .................................................................. 7—11

Base Station Operation .................................................................................... 7—11

Check your setup ......................................................................................... 7—12

Survey Data Correction Procedures ................................................................7—13

Using Base-Station Data..............................................................................7—13

Tie-Point (TIE-PT) Mode .............................................................................. 7—15

Loop type – collecting data ..........................................................................7—15

Line type – collecting data............................................................................ 7—16

Tie-Point Correction Procedure....................................................................7—18

Chapter 8 Data Output.........................................................................................8—1

Output Formats ..................................................................................................8—1

Notes..............................................................................................................8—4

Operation Mode .............................................................................................8—5

Dumping Data ................................................................................................ 8—6

All data ........................................................................................................8—6

Specific data................................................................................................ 8—7

Line by Line.................................................................................................8—7

Erasing data from memory .............................................................................8—8

Operation mode...........................................................................................8—9

Chapter 9 Maintenance and Repair....................................................................9—1

Battery Charging ................................................................................................9—1

One Battery ................................................................................................. 9—1

Two Batteries ..............................................................................................9—2

Periodic Maintenance......................................................................................... 9—3

Cleaning the Sensors.....................................................................................9—3

Desiccant Exchange ......................................................................................9—3

Fuse Replacement ......................................................................................... 9—4

2

P/N 788715 Rev. 0

Console Disassembly/Assembly .................................................................... 9—4

Cable Repair .................................................................................................. 9—4

Trouble Shooting................................................................................................9—5

Chapter 10 Reference Information ...................................................................10—1

Envi Pro Technical Specifications .................................................................... 10—1

Dimensions & Weight...................................................................................10—2

Warranty & Repair............................................................................................ 10—3

Warranty....................................................................................................... 10—3

Repair........................................................................................................... 10—3

When to ship the unit................................................................................. 10—3

Description of the problem ........................................................................10—3

Shipping Instructions....................................................................................10—3

Chapter 11 Applications for the ENVI PRO......................................................11—1

Magnetic Surveying Overview.......................................................................... 11—1

Introduction ......................................................................................................11—1

Basic magnetic theory......................................................................................11—1

What is being measured? ............................................................................11—1

Anomalies ....................................................................................................11—3

Shape........................................................................................................11—4

Amplitude ..................................................................................................11—6

Variations in the Earth’s magnetic field ............................................................ 11—7

Diurnal variation ........................................................................................11—7

Micro-pulsations ........................................................................................ 11—8

Magnetic storms ........................................................................................ 11—8

Removing magnetic variations .................................................................. 11—9

Magnetic targets............................................................................................. 11—10

Induced and Remanent magnetism ........................................................... 11—10

Survey Planning ............................................................................................. 11—12

Introduction ................................................................................................11—12

Sampling intervals......................................................................................11—12

Line and Station spacing vs. Anomaly width ........................................... 11—12

Precision and Accuracy of Surveys............................................................ 11—13

Noise ....................................................................................................... 11—13

Tuning .....................................................................................................11—14

Survey mode ........................................................................................... 11—14

Field Observations .................................................................................. 11—16

Grid layout and orientation ......................................................................... 11—16

Survey procedures and a sample survey.......................................................11—17

Introduction ................................................................................................11—17

Survey do’s and don’ts...............................................................................11—17

Laying out the grid................................................................................... 11—17

Diurnal corrections vs. Survey pattern ....................................................11—19

Search mode...........................................................................................11—21

Note taking .............................................................................................. 11—21

Surveying in the WALKMAG mode .........................................................11—21

Surveying in the Stop-and-Go mode ....................................................... 11—23

Magnetic cleanliness ............................................................................... 11—23

Monitoring your data................................................................................11—24

Post-survey procedures .............................................................................11—24

Clean-up site if required .......................................................................... 11—24

Data correction ........................................................................................11—24

Data transfer............................................................................................11—24

Processing data.......................................................................................11—24

Field example.............................................................................................11—25

Columbia test site — Waterloo, Ontario .................................................. 11—25

3

P/N 788715 Rev. 0

Bibliography .............................................................................................................1

INDEX ......................................................................................................................2

4

P/N 788715 Rev. 0

Chapter 1 Preface

Congratulations on purchasing the ENVI PRO environmental

magnetometer/gradiometer from Scintrex Limited. You are in possession of one of the

most advanced magnetometers for environmental, geotechnical, archaeological and

mineral exploration uses of today.

The ENVI PRO is a portable, proton-precession magnetometer that also is inexpensive,

lightweight and rugged. In its trademarked WALKMAG mode it is ideal for applications

where high productions, fast reading and high sensitivity are required. It is quite

versatile and can be optionally configured as a total-field magnetometer, a gradiometer

or as a base-station.

Features

The main features of the ENVI PRO include:

• Interactive menus for easy operator use

• Selectable sampling rates as fast as 2 times per second

• WALKMAG mode for rapid data acquisition

• True simultaneous gradiometer option with the WALKGRAD mode for rapid

data acquisition

• Single-frequency GPS antenna allowing the user to acquire non-differential

positional data along with the magnetometer data

• Large internal memory, expandable to 188,000 readings

• Easy to read, large LCD screen that displays data both graphically and

numerically

• Easy review of the data and Datacheck quality control

The complete ENVI PRO consists of several basic modules:

• Lightweight console with a large screen alphanumeric display and high

capacity memory

• GPS receiver antenna

• Staff or back-pack mounted sensor and sensor cable

• Rechargeable lead-acid battery and battery charger

• RS-232 cable for downloading data

Upgrades and Options

There are optional upgrade kits available for the ENVI PRO to provide the following:

1. True simultaneous gradiometer – An additional processor module is installed in

the console, a second sensor with a staff extender and a ruggedized backpack

for the WALKGRAD mode are provided in this kit.

2. Base-station applications – An accessory kit allows the sensor and staff to be

converted into a base-station sensor and the cabling allows a field ENVI PRO

or ENVI MAG to be connected for automatic magnetic operations down to

minus 40°C.

1—2

P/N 788715 Rev. 0

3. Low temperature operations – An external battery pouch along with a

thermostatically controlled display heater will permit field operations down to

minus 40°C.

4. External trigger interface – This kit provides a tool for acquiring evenly spaced

data when no survey grid has been established in advance. The kit is an

interface between the ENVI PRO and a triggering device (such as a measuring

wheel or a hip-chain that you supply). It works by triggering a station increment

at intervals in the WALKMAG mode. Detailed instructions for installation,

interfacing and usage are provided with the kit.

1—3

P/N 788715 Rev. 0

Chapter 2 Introduction

This section is the reference for the ENVI PRO instrument itself. You will find all the

information you need to know about setting up the unit for field use, its operation,

maintenance and trouble-shooting. It is divided into eleven chapters with the

information flow from chapter to chapter following a natural progression, as shown

in the following table:

Chapter Description

1. Preface Features, upgrades and options.

2. Introduction Outlines what the instrument can do.

3. Preparing Describes the assembly of the system for use.

4. The

Instrument

5. Operating

Displays

6. Setting Up

7. Operating

8. Date Output

9. Maintenance

10. Reference

11. Applications Magnetic Surveying Overview and basic magnetic theory

This chapter is about the instrument itself.

Describes the various display screens.

Describes how to initialize the ENVI PRO and program it for

different modes of operation.

Guides you through typical instrument operation using basic,

search and advanced configurations in a WALKMAG and a Stopand-go type of survey.

Shows examples of data output formats and explains how to dump

the acquired data.

Describes basic maintenance, trouble-shooting and repair.

Contains the technical specifications, instrument parts list and

warranty information.

Cold Boot

Please read the section “First time operation” on page 6—1 so that you will know

how to do a cold boot of the instrument. This is needed the first time you use it,

whenever you wish to change operating configurations or after the batteries have

been removed for more than 10 minutes.

Instrument Overview

The SCINTREX ENVI PRO is an easy-to-use, lightweight, battery-powered,

portable magnetometer. The magnetometer is a total field instrument using the

proton-precession technique to measure the local magnetic field. Optional

magnetometer upgrade kits allow the instrument to be used as a gradiometer or as

a base-station. The standard configuration has the sensor mounted in a backpack

mode permitting rapid data acquisition in the trademarked WALKMAG mode.

Measured data is stored in the ENVI PRO console memory along with the

coordinates where the measurement took place. You can

2—1

P/N 788715 Rev. 0

Introduction

also enter descriptive notes of up to 32 characters at any station. The data can be

displayed either numerically or graphically for quick inspection of the data quality

and spotting of anomalies. Data can also be recalled from memory for visual

inspection, dumped either to the serial port (RS-232) of a computer or directly to a

printer. You can also automatically correct your magnetic data for diurnal variations

when another ENVI PRO is used as a base-station or when you conduct your

survey in the TIE mode.

The operating modes of the ENVI PRO can be manual, semi-automatic or fully

automatic. In the WALKMAG (walking magnetometer) mode, data are acquired and

recorded at rates of up to two readings per second, as you walk at a steady pace

along the survey line. At desired intervals, you trigger a station marker by pressing a

single button and the co-ordinates are automatically assigned to the recorded data.

You can even introduce delays in the automatic recording to compensate for

walking over rugged terrain.

The ENVI PRO comes with a Single-frequency GPS antenna allowing the user to

acquire non-differential positional data along with the magnetometer data. Being a

non-differential receiver, the positional accuracy is of the order of a few meters,

which is sufficiently accurate for most magnetometer surveys. Should you require

more accurate position and sensitivity, you should consider our NAVMAG cesium

vapor magnetometer.

2—2

P/N 788715 Rev. 0

Chapter 3 Preparing the ENVI PRO

This chapter describes:

How the ENVI PRO is packaged, how to connect the components to get an

operational unit, the various options you may have for powering the unit

The following photographs show the basic components (less packing materials) of

the standard ENVI PRO.

3—1

The basic ENVI PRO kit

P/N 788715 Rev. 0

Unpacking

The standard ENVI PRO is shipped in a carrying/shipping case The ENVI PRO with

its accessories is packaged in cut-out sections in the case. This provides a proper

place for every item when you repack your instrument for shipping or storage. These

foam layers are disassembled in the following order, starting at the top:

Repacking

Warning: The batteries must be removed from the ENVI PRO

console prior to shipping or storage. Failure to do so

may result in damage.

Assembly

In order to make the system as compact as possible for shipment and

storage, and considering the various sensor configurations available, the

ENVI PRO requires you to connect up the external components. This

section will describe the steps required to completely assemble your

instrument.

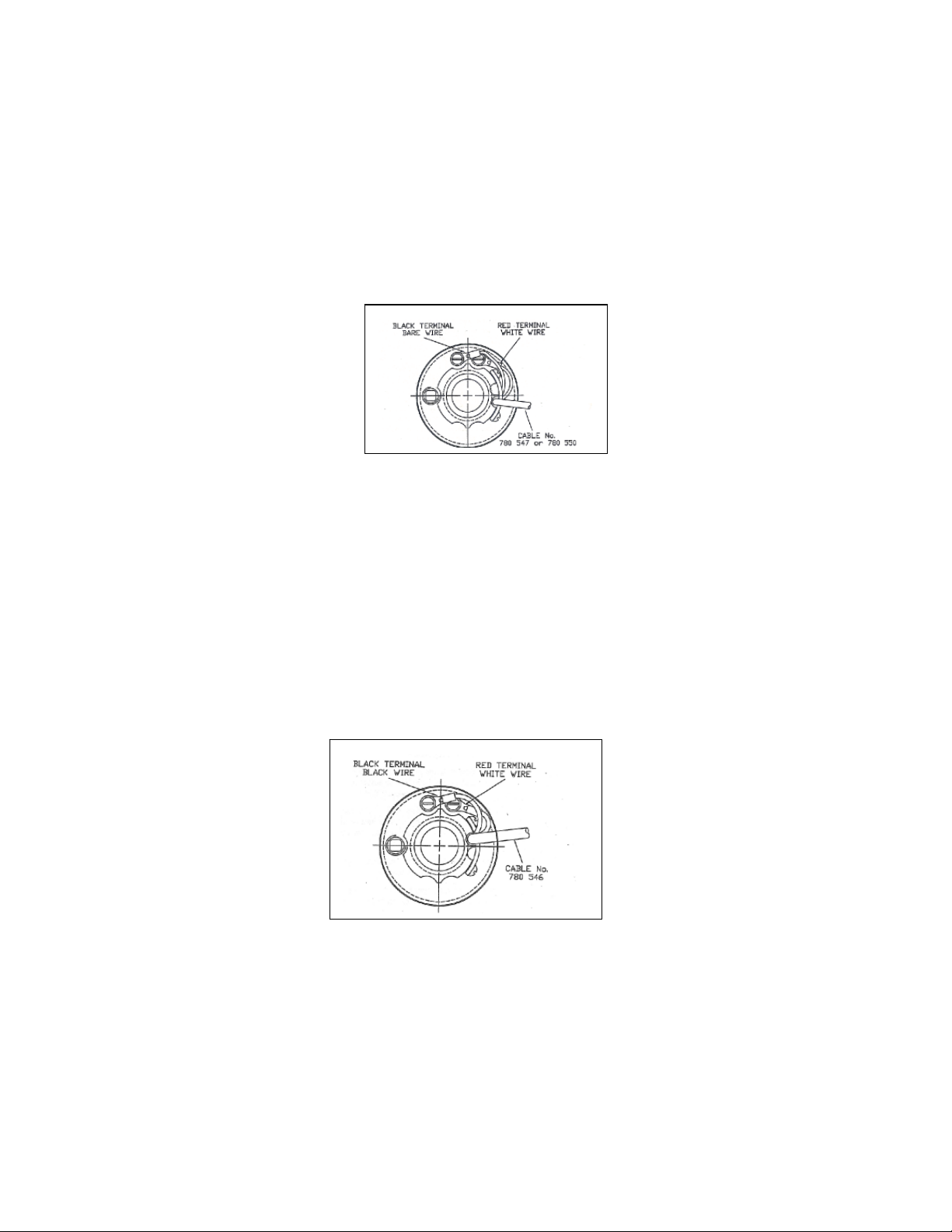

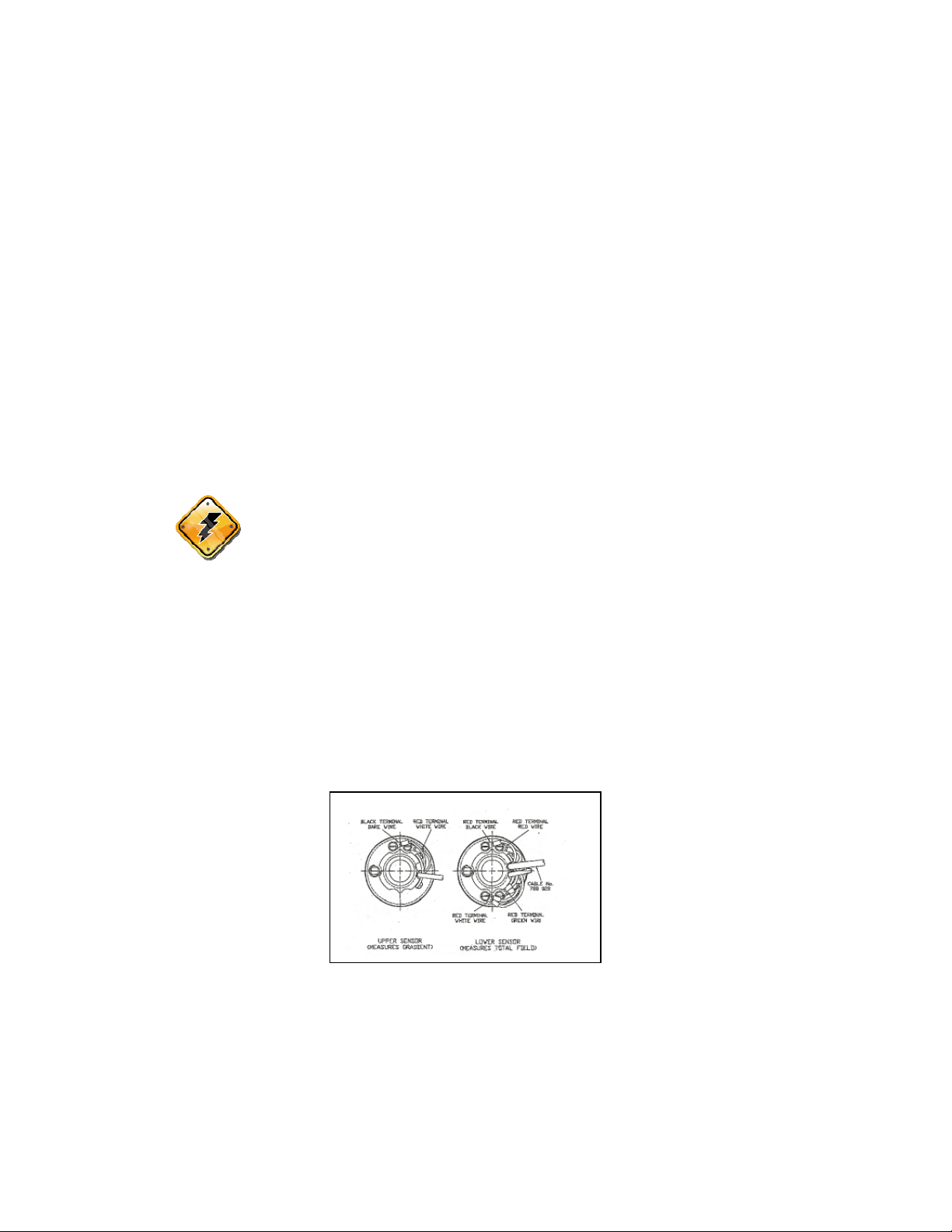

Connecting the magnetic sensor(s) to the cable

The following illustrations show the proper cable connections for each of

the different magnetic sensor configurations. The sensors are shown being

viewed from their bottoms looking at the screw terminals.

Important: All parts near the sensor are non-magnetic. It is highly

recommended that you use only the brass screws and

wire connectors supplied by Scintrex. There are

additional screws for the terminals and cable hold-down

in the minor spare parts kit (Scintrex p/n 788030). If

you ever need to replace any of these parts under field

conditions please ensure that they are made of non magnetic materials.

Total-field senso r

1. Orient the sensor so that as you look at the bottom of the sensor (the end with the

terminals), the large square plug is at the 9 o’clock position.

3—2

P/N 788715 Rev. 0

Preparing

2. Use either Scintrex cable number 780547 (the shorter one) for the backpack

configurations or cable number 780550 for the staff configuration.

3. Remove the cable hold-down plate by unscrewing the screws at the 2 o’clock and

4 o’clock positions.

4. Connect the black spade-lug on the bare wire of the cable to the terminal at the 11

o’clock position.

5. Connect the red spade-lug on the white wire of the cable to the terminal at the 11

o’clock position.

6. Place the cable in the smaller slot just below the 3 o’clock position.

7. Re-attach the cable hold down plate.

Total Field Sensor Cabling

Base-station sensor

1. Orient the sensor so that as you look at the bottom of the sensor (the end with the

terminals), the large square plug is at the 9 o’clock position.

2. Use Scintrex cable number 780546.

3. Remove the cable hold-down plate by unscrewing the screws at the 2 o’clock and

4 o’clock positions.

4. Connect the black spade-lug on the black wire of the cable to the terminal at the

11 o’clock position.

5. Connect the red spade-lug on the white wire to the terminal at the 1 o’clock

position.

6. Place the cable in the larger slot just above the 3 o’clock position.

7. Re-attach the cable hold down plate.

Base-Station Sensor Cabling

Gradiometer Sensors - Lower Sensor

1. Orient both the sensors so that as you look at the bottom of the sensors (the end

with the terminals), the large square plug is at the 9 o’clock position.

2. Use Scintrex cable number 788028 - it has four conductors.

3. Select the lower sensor - it has pairs of terminals at the 12 o’clock and 6 o’clock

positions, as well as an attached cable to the terminals at the 6 o’clock position. See

Gradiometer sensor cabling on page 3—4.

3—3

P/N 788715 Rev. 0

Preparing

4. Remove the cable hold-down plate by unscrewing the screws at the 2 o’clock and

4 o’clock positions.

5. Connect the red wire of the cable to the terminal at the 1 o’clock position.

6. Connect the black wire of the cable to the terminal at the 11 o’clock position.

7. Connect the green wire of the cable to the terminal at the 5 o’clock position.

Please ensure that the already attached bare wire of the smaller two-conductor cable

remains attached.

8. Connect the white wire of the cable to the terminal at the 7 o’clock position. Please

ensure that the already attached white wire of the smaller two-conductor cable

remains attached.

9. Place the smaller two-conductor cable into the smaller slot just below the 3 o’clock

position.

10. Place the larger four-conductor cable into the larger slot just above the 3 o’clock

position.

11. Re-attach the cable hold-down plate.

Gradiometer Sensors - Upper Sensor

12. Select the upper sensor - it only has a pair of terminals at the 12 o’clock position.

See Gradiometer sensor cabling on page 3—4.

13. Attach the upper sensor to the lower one by placing the shaft of the lower sensor

into the socket of the upper one while rotating slightly counter-clockwise. When they

are fully engaged, firmly twist them clockwise against each other.

Warning: Both sensors must have their directional marks aligned

in the same manner, i.e. the N on the top sensor must

be in-line with the N on the bottom sensor.

14. Remove the cable hold-down plate of the upper sensor by unscrewing the screws

at the 2 o’clock and 4 o’clock positions.

15. Connect the white wire of the two-conductor cable coming from the lower sensor

to the terminal at the 1 o’clock position.

16. Connect the black wire of the two-conductor cable coming from the lower sensor

to the terminal at the 11 o’clock position.

17. Re-attach the cable hold down plate.

Gradiometer sensor cabling

Installing the terminal protective cover

A plastic cup-like assembly is included to slide over the base of the sensor(s) to

protect the terminal connections from the elements.

3—4

P/N 788715 Rev. 0

Preparing

To install the cover:

1. Slide it over the sensor shaft with the widest end pointing towards the sensor.

2. Slide the supplied O-ring into the grove on the shaft to lock it into place.

To remove the cover, just reverse the above procedure. First remove the O-ring and

slide the cup away from the sensor.

Assembling the sensor / GPS staff

Note: You can disregard this section if you are going to be using the

ENVI PRO in the backpack mode.

The sensor staff is shipped in four sections. These sections are located in the

shipping case slot labeled Sensor and Staff. You should note that one of the sections

has a sealed bottom, and you should start assembling the staff with this section.

Staff sections are assembled individually and connected to the sensors as follows:

1. Insert the male end partially into the female end and rotate counter-clockwise while

gently pushing the two parts together.

2. When they are fully engaged firmly twist them clockwise against each other.

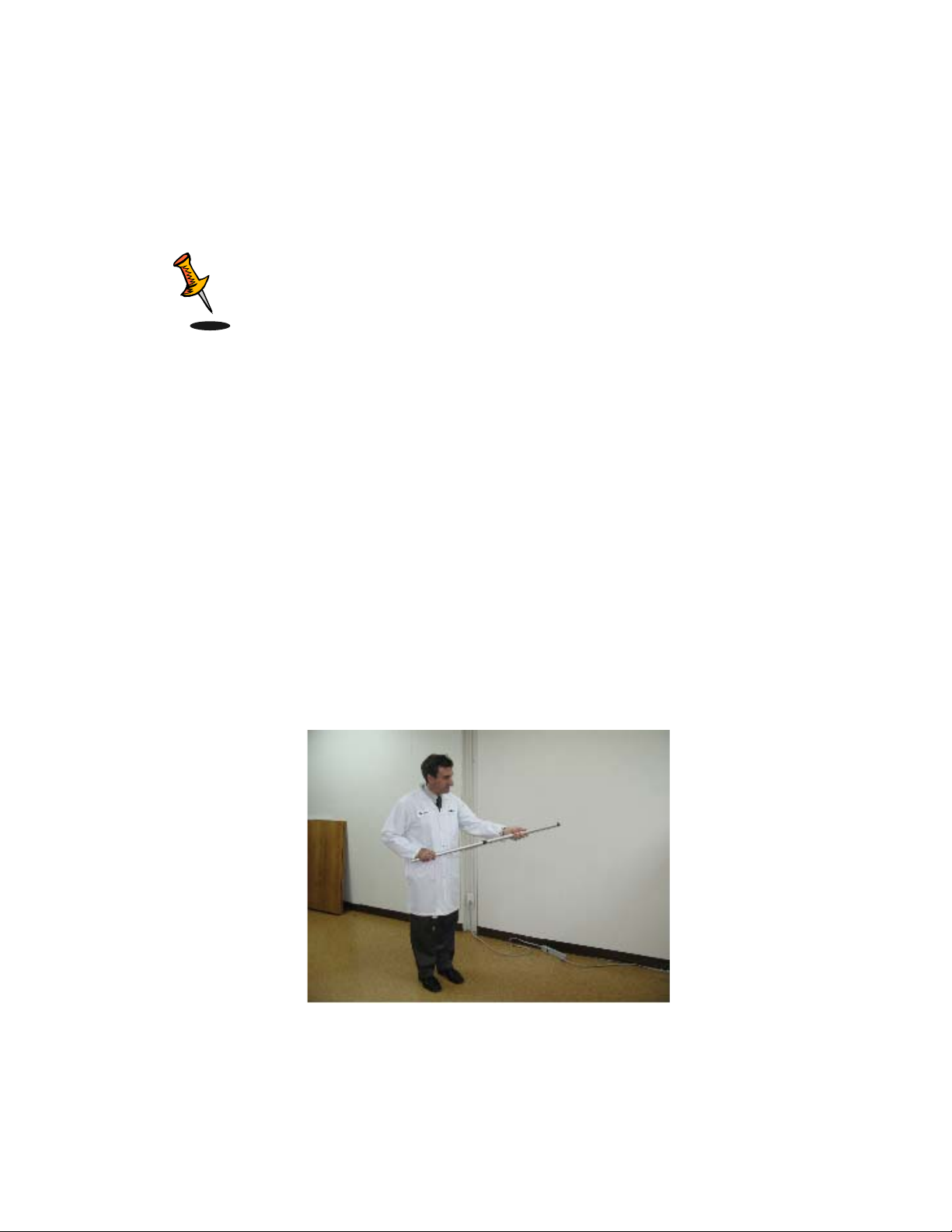

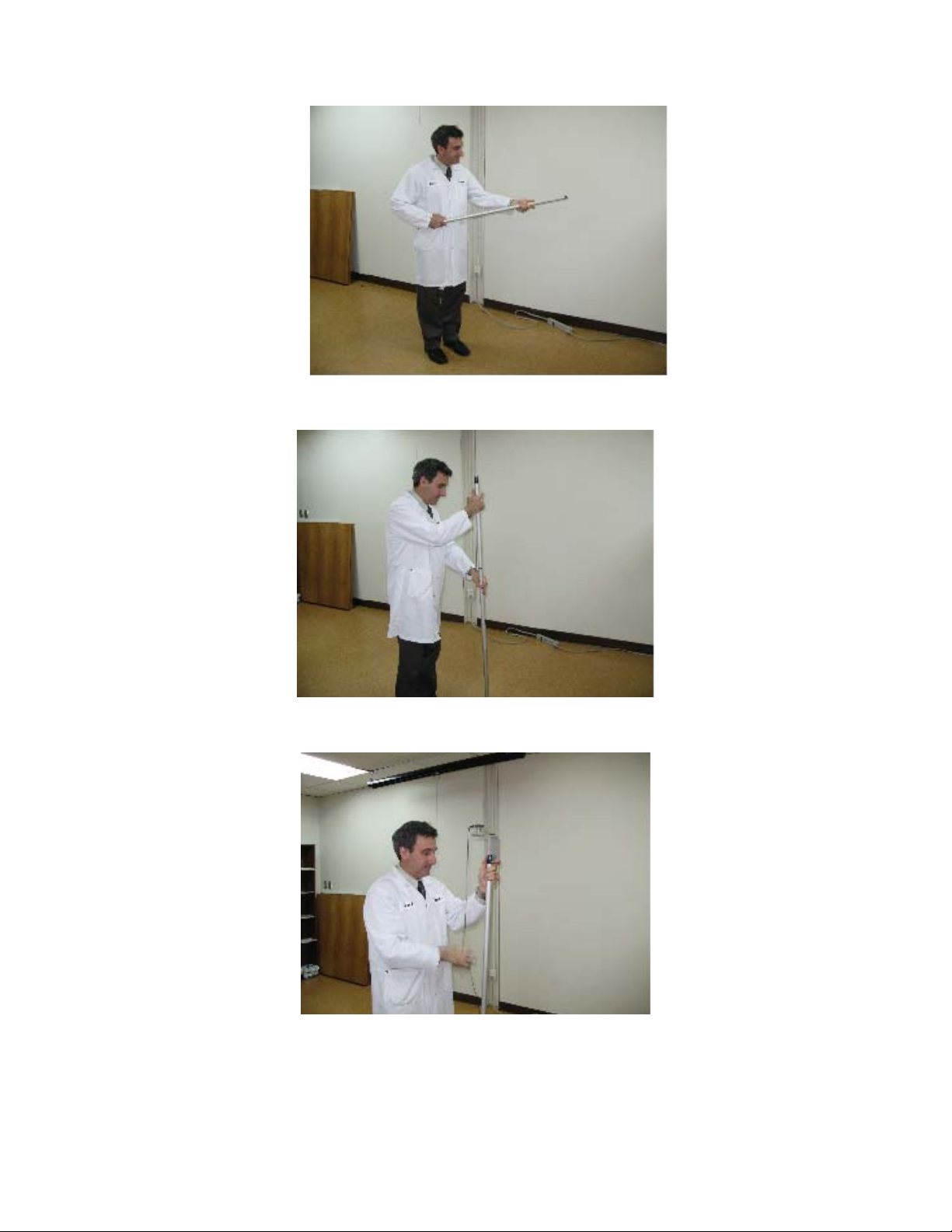

Staff Mounted Installation

A staff mounted configuration is the most convenient when carrying out a

magnetometer survey in the stop-and-go mode.

The following steps are required to properly assemble the ENVI PRO sensor and

GPS antenna in the staff mounted configuration.

1. Assemble the staff sections as illustrated.

3—5

P/N 788715 Rev. 0

Preparing

2. Insert the GPS antenna mount as illustrated.

3. Insert another staff section in order to clamp the GPS antenna mount between two

staff sections as illustrated.

3—6

P/N 788715 Rev. 0

Preparing

4. Insert the magnetometer sensor on the top section as illustrated.

3—7

P/N 788715 Rev. 0

Preparing

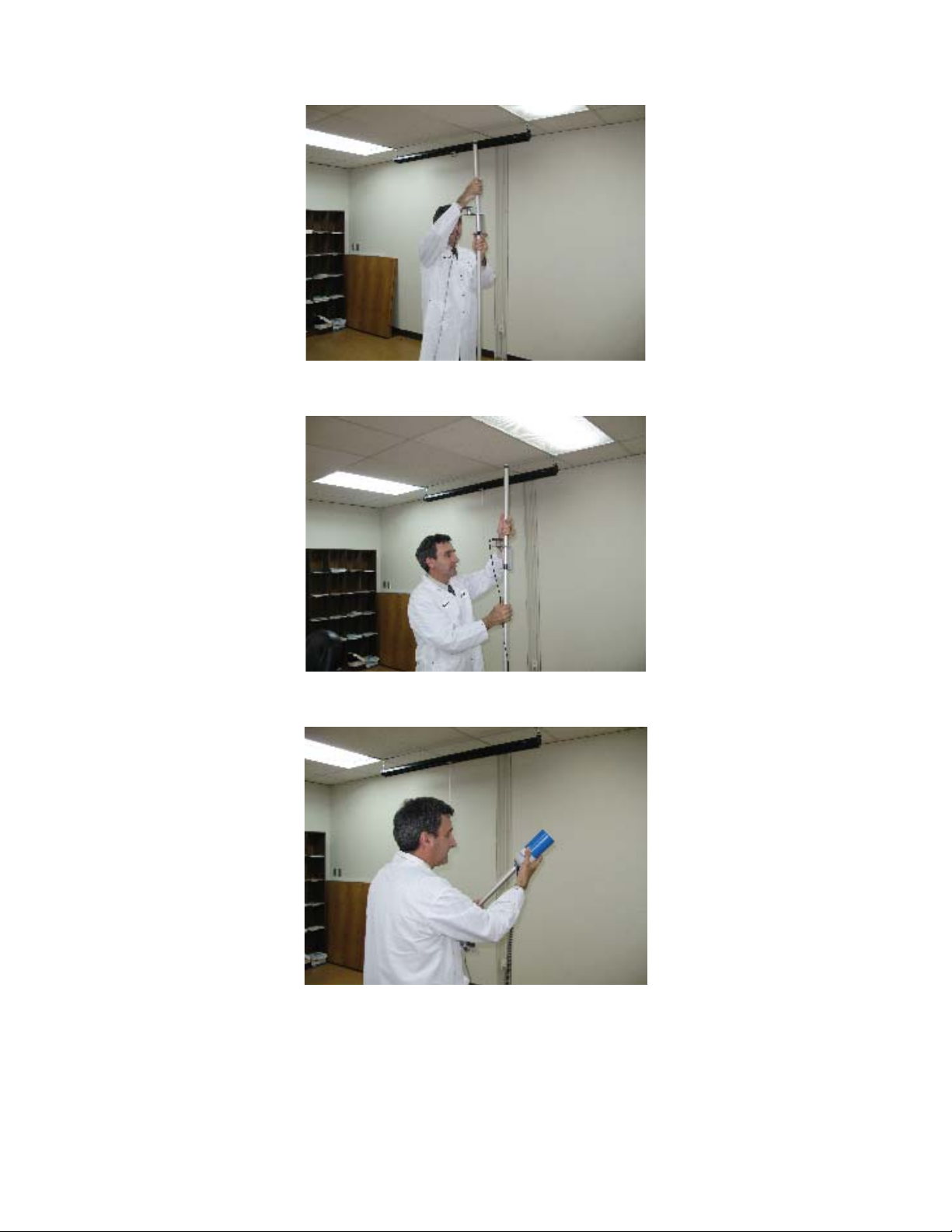

Back-pack Installation

A back-pack mounted configuration is the most convenient; providing a hands-free

operation for the ENVI PRO.

The following steps are required to properly assemble the ENVI PRO sensor and

GPS antenna in the back-pack configuration.

1. Insert a staff section in the staff mounting insert located on the back-pack as

illustrated.

2. If you are using the GPS antenna, insert the GPS antenna mount on top of

the previous staff section, as illustrated.

3. Insert a second staff section, as illustrated. The GPS antenna mount will thus

be lodged between two staff sections.

3—8

P/N 788715 Rev. 0

Preparing

4. Insert the magnetometer sensor at the top of the second staff section, as

illustrated.

3—9

P/N 788715 Rev. 0

Preparing

Complete Assembly

Warning: You need to consider your travel direction wile

surveying when you attach the sensor. The

magnetometer’s performance is a function of the

sensor’s orientation with respect to the earth’s

magnetic field. Therefore you must ensure that the N

mark on the sensor faces either magnetic north (or

south – either is allowed due to symmetry). Please

see Orientation on page 7-1.

Battery Installation/Exchange

The ENVI PRO is shipped without the battery installed. This is the proper procedure,

while shipping and storing the instrument, to prevent deep discharge of the battery.

Deep discharge can possibly cause permanent damage to the battery and will always

shorten the battery life. This situation will occur because a small current is being

drawn even if the instrument is turned off.

The following steps outline the battery installation:

1. Turn the instrument face down on a clean and even surface.

2. Unscrew both knurled screws on either side of the battery cover and lift the cover

off.

3. Place the battery into the recess in the rear panel of the instrument.

3—10

P/N 788715 Rev. 0

Preparing

4. Connect it carefully to the MAIN BATTERY connector. It is not important which

side of the plug is up, as long as the connector pins are properly aligned.

5. Replace the cover and tighten both knurled screws.

6. If this is the first time installation proceed with battery charging.

The small size and low cost of the battery makes it convenient to carry an additional

battery along as a spare.

Warning: An internal battery keeps the memory and the internal

clock alive for about 10 minutes. It is strongly advised

that the switching to the spare battery be done quickly,

to prevent the loss of your data.

Note: You need not worry about a low battery causing data loss,

since the memory power requirements are much less than

those needed to make a valid reading of the magnetic field.

ENVI PRO battery pack

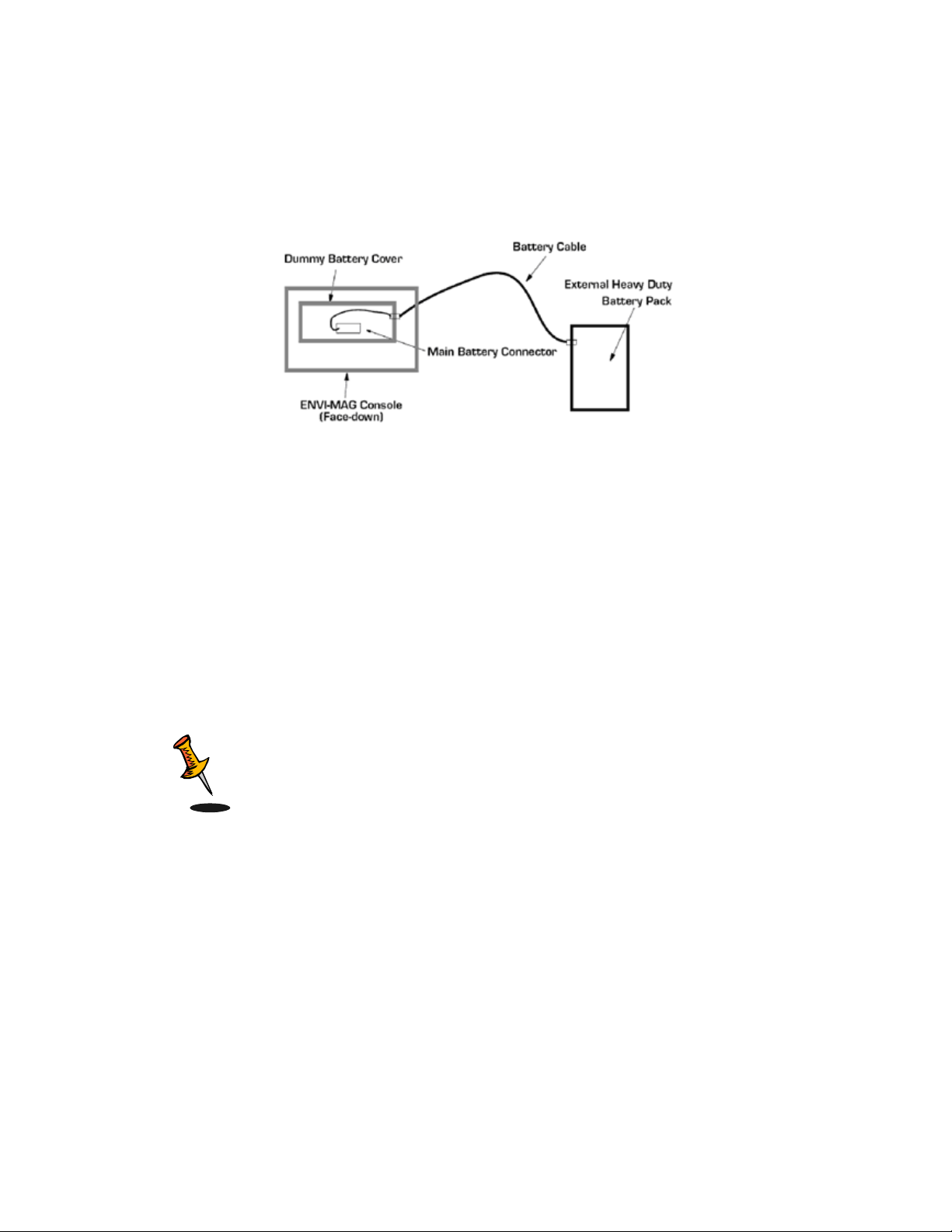

Using the external battery pack

Cold weather use and extended WALKMAG surveys may require more power than

the standard battery together with a spare can provide. To satisfy this additional

requirement, the External Heavy Duty Battery Pack (Scintrex p/n 788026) is

available. It provides about three times as much power as the standard battery. This

battery pack can be carried by the strap or attached to a belt.

To connect the external battery you must proceed as follows:

1. Turn the instrument face down on a clean and even surface.

2. Unscrew both knurled screws on either side of the battery cover.

3. Lift off the cover and store it somewhere convenient for future use with the

standard battery configuration.

4. Remove the ENVI PRO STANDARD battery.

5. Connect the connector in the dummy battery cover carefully to the MAIN

BATTERY connector. It is not important which side of the plug is up as long as the

connector pins are properly aligned.

6. Place the new cover on to the console by gently pushing it into place and tighten

the knurled screws on the both sides.

3—11

P/N 788715 Rev. 0

Preparing

7. Please check the battery voltage condition at this stage and charge the battery, if

required.

External Heavy Duty Battery Connection

Using an external power supply

More demanding applications, such as an extended base-station operation, may

require more power than can be provided with either of the Scintrex supplied battery

packs. In this case you have two options:

a) AC Power

If a source of AC power is available, the instrument can be run while the charger is

connected to it. You will also be charging the standard internal battery, if it is

installed, at the same time.

Note: Please be aware of possible magnetic noise from generators,

and ensure that all cabling and sensors are as far away as

possible from the generator.

b) 12 volt battery (car or marine)

A 12 volt car battery may be more appropriate for other applications. The special

External Power Cable (Scintrex p/n 788029) should be used for this purpose.

1. The standard internal battery may be left in place.

2. Plug in the end of the cable with the single plug into the Charger Connector at the

right-rear side of the ENVI PRO console. See item 6 in the figure on page 4—2.

3. Connect the end with the clips to the battery terminals. The red cable-clip goes to

the positive battery terminal. The black cable-clip goes to the negative battery

terminal.

3—12

P/N 788715 Rev. 0

Preparing

Important: The correct polarity must be used for the instrument to

operate properly.

3—13

P/N 788715 Rev. 0

Chapter 4 The Instrument

This chapter is about the instrument itself and fully describes:

• The ENVI PRO console

• The keypad functions

• The various display menus

• The display formats that you will encounter

4—1

P/N 788715 Rev. 0

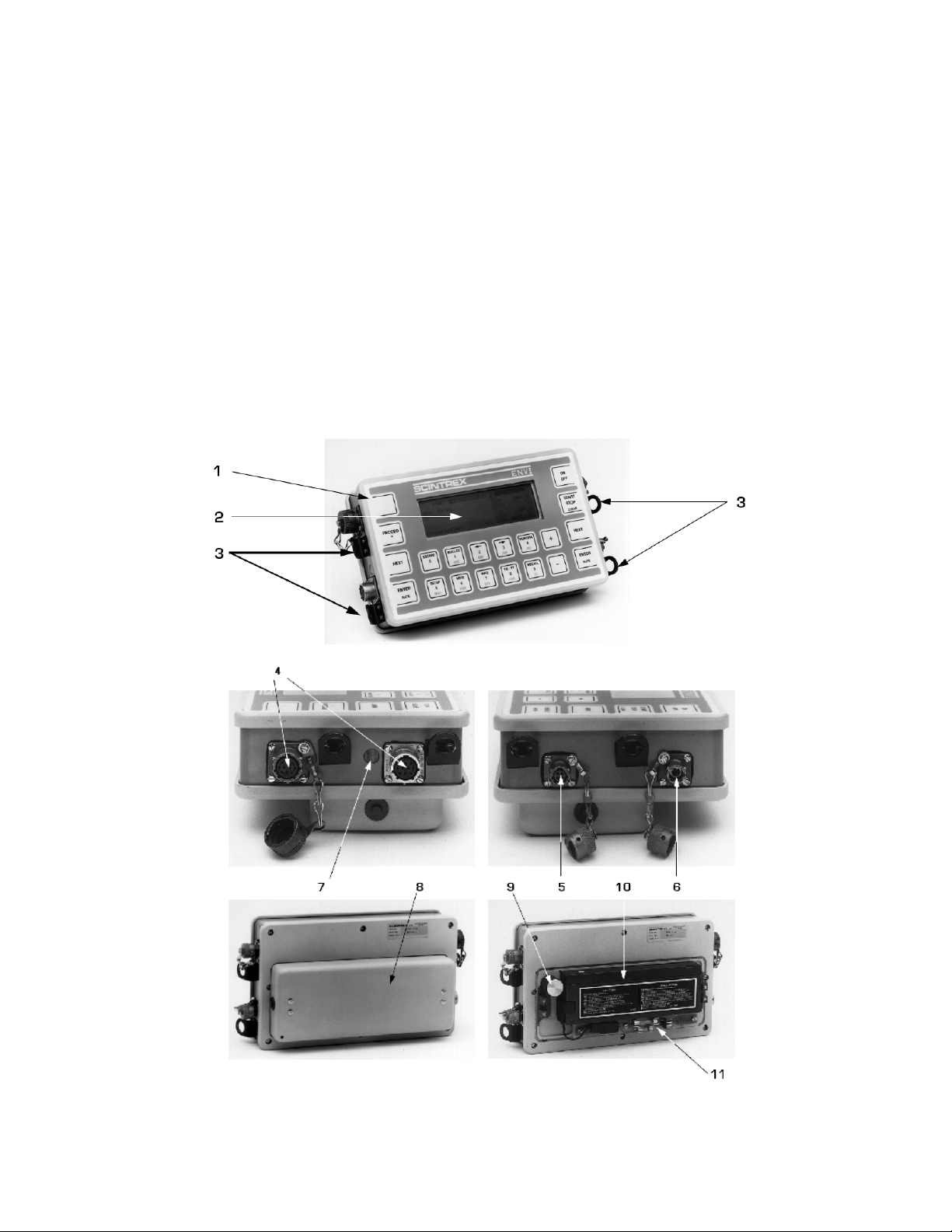

Console

Console Description

# Item Description

1 Keypad The fully sealed Keypad has 19 keys and a sound port.

Liquid Crystal

2

Display (LCD)

Carrying Strap

3

Attachment

4 Sensor Connector

Data Output

5.

Connector

Charger/External

6

Power Connector

The large 8 line by 40 character (64 x 240 dots)

Supertwist LCD (with a wide temperature range) presents

status and data in a numeric or graphic format.

Four rings at the side of the console that allow attachment

of the carrying harness.

Up to two sensor connectors may be present at the left

hand side of the console. The nearer one J102, 10 Pin

connector, is reserved for the magnetometer sensor.

The J101, 8 Pin connector is reserved for the GPS

antenna.

The data output connector carries RS-232 data dump

signals, as well as the analog signal for a strip chart

recorder and is located at the right hand side of the

console.

It has the following pin assignments:

A – common (ground) B – RS-232 receive data

C – RS-232 transmit data C – analog out 0-1 Volt

This connector accepts the charger to recharge either the

standard battery or the external heavy-duty battery pack.

It also accepts external, well filtered, 11 to 16 Volt DC

input.

The center pin is negative (-)

The shell is positive (+)

7 Charging Light

Battery

8

Compartment

9 Desiccant Cartridge

10 Battery

11 Fuse The standard 1.5A fuse to use with the standard battery.

The charging light (visible through a window on the left

side) indicates that the battery is charging at a high rate.

The battery compartment is located at the back of the

console and contains one rechargeable lead-acid battery,

the desiccant cartridge and the fuse. The battery cover is

replaced with another cover with a cable attached when

the external battery is used.

The desiccant cartridge is a cylindrical re-usable capsule

filled with a drying agent. It absorbs any moisture that

my get inside the instrument.

A rechargeable lead-acid battery in the standard ENVI –

MAG configuration.

Keypad Description

4—2

P/N 788715 Rev. 0

Console

The keypad has 19 keys. Two of the most used keys are duplicated on the right and

left sides of the console for easy access. Some keys have up to three separate

functions assigned to them. The response of these multifunctional keys depends

upon the operation in progress.

Note: The function mode of the keys has precedence over the alpha-

numeric mode of the keys.

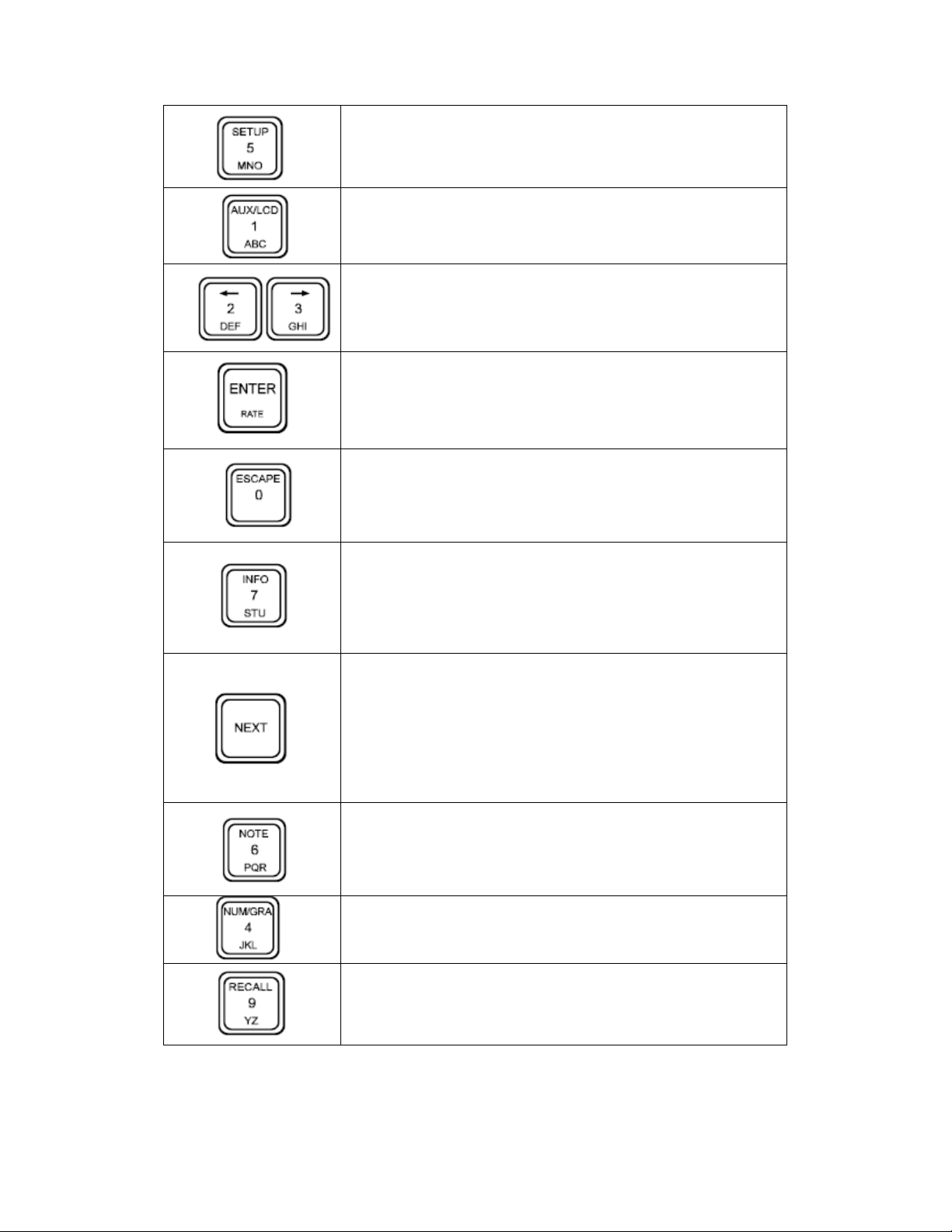

Key Functions

Key Description

4—3

The ENVI PRO keypad

Turns the instrument on and off. Turning the instrument off

during a reading abruptly terminates a reading with the loss

of the current data.

Starts or stops an operation, such as data acquisition, data

dumping, data recall, etc.

*When the instrument is in the Notes operation, this button

acts as a “backspace” key to delete entries.

P/N 788715 Rev. 0

Console

*Accesses the various setup displays. The actual setup

menu that will be displayed depends upon the display

screen in which this key is pressed.

*Accesses the Auxiliary Functions display allowing:

- setting of the LCD intensity

- data output

- locking of the setup parameters

Moves the cursor to the left or up; to the right or down.

2 identical keys:

- opens and closes the parameter fields during setups

- opens and closes the scaling option field for the graphics

display

- toggles the sample rate in the walking type survey.

Allows escape from a deeper level in a program to a higher

level, ultimately to the top level, which is signified by the

Main operating display.

Aborts a data dump.

*Accesses the Info. Display, which allows:

- setting of data and time

- enabling and selecting GPS coordinates

- entering of serial and job numbers, and operator

identification

- observation of memory availability.

2 identical keys:

- scrolls sequentially through numeric data display pages

- scrolls sequentially through graphic data display pages

- moves the cursor from one sub-page to the next sub-page

- moves the cursor to the next character location during note

entry

- advances the station number by station separation in the

walking mode.

*Accesses the Note Entry display, which allows:

- the entry of five common notes (macros) to be recorded

repeatedly with selected readings

- the entry of unique notes to be recorded with a particular

reading.

4—4

Toggles the data display between numerical and graphic

data presentation during data acquisition only.

*Presents the Recall display for selection of:

- data item to be recalled

- setting of the starting location or time of the recall.

P/N 788715 Rev. 0

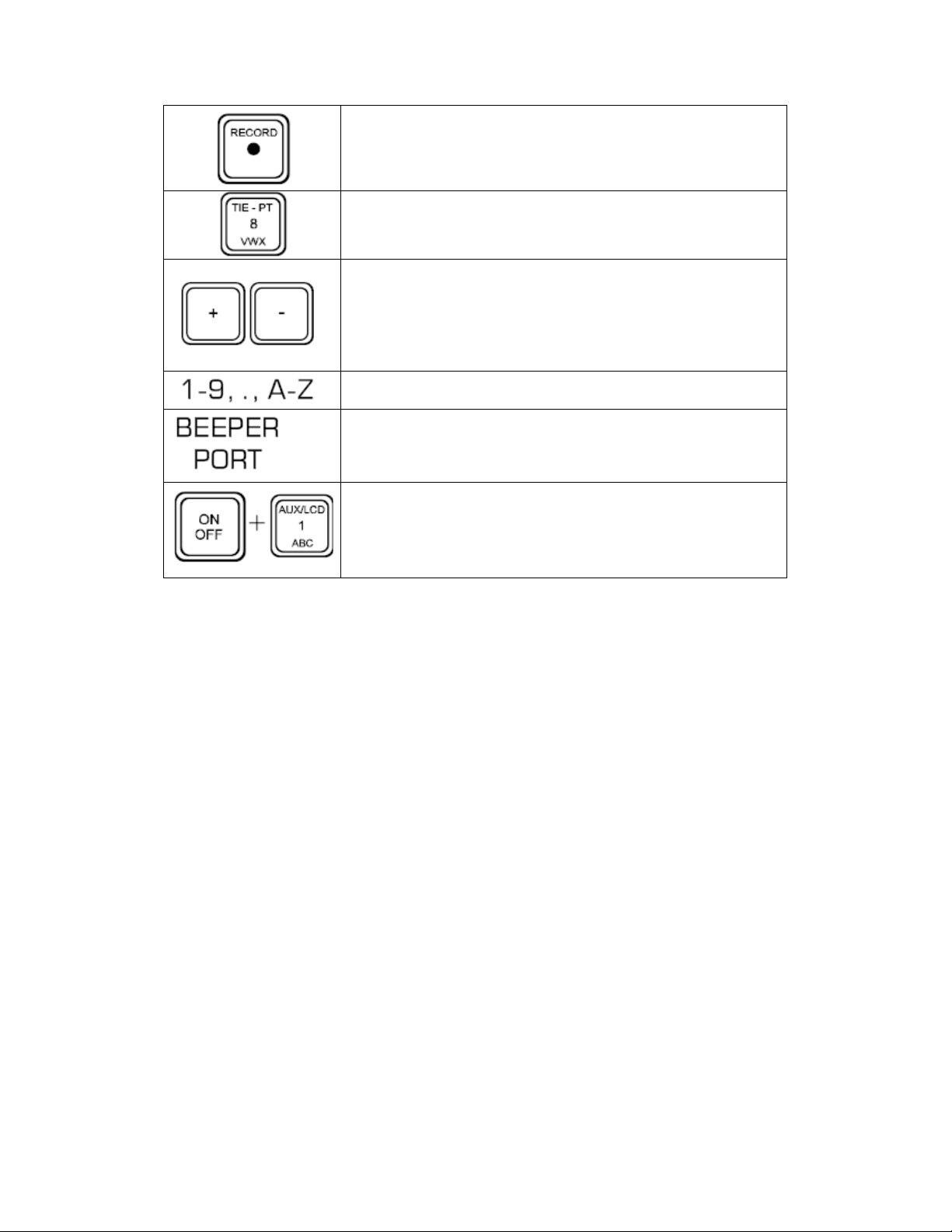

Console

*Manually records measured data and notes in internal

memory.

Acts as the START key at a Tie-point. This is used for the

Tie-point line and loop mode corrections.

Facilitates the scrolling forward or backward through a list of

items:

- allows sign entry to numbers

- allows panning along a line of data during recall

- increments or decrements the line and station number in

the Stop-and-Go mode.

*Allows alpha-numeric entry for setups and notes.

This blank “key” in the upper left corner of the console is not

actually a key, but a flexible membrane to enhance the

* These items/key functions are only operational when you select the advanced

operating modes (options 5 to 7) from the initial configuration menu.

loudness of the beeper.

Pressing the “ON” and “AUX/LCD” keys simultaneously

performs the COLD BOOT operation, resetting the

instrument to factory defaults.

Display Screens

The ENVI PRO currently has the following types of displays:

• Help screens

• Confirmation screens

• Parameter selections screens

• Note entry screens

• Numeric data displays

• Graphical data displays

• Pop-up options and confirmations

General Information

Most of the screens consist of three bands of information as shown below:

4—5

P/N 788715 Rev. 0

Console

General display information bands

The Title Line at the top indicates the current operating functions.

The middle six lines contain specific display information consisting of either

instrument and survey parameters or data.

1. The bottom line usually contains prompts for actions, such as pressing the

key required to start an operation. Miscellaneous messages may also appear

here. The battery voltage (values between 100 and 140) is also shown on the

right-side of this line.

Note: The instrument automatically turns off (blank display) to

conserve battery power, if there is no reading or key stroke

detected for 30 minutes.

Cursor

A large, blinking cursor indicates the specific parameter that

can be altered to change setups, starting station value, station or line spacing, and so

on. The cursor is moved from parameter to parameter or line to line by pressing the

arrow keys to move in the desired direction. The prompt on the bottom line will let

you know which key to press to make any changes.

Display Blocks

Some displays are divided into two or more blocks or sub-panels. The blocks are

separated by solid partition lines as shown in the following figure.

4—6

P/N 788715 Rev. 0

Console

Instrument display showing information blocks (sub-panels)

To move the cursor from one block to another, press the “NEXT” key.

Some measured data is displayed on more than one page (display screen).

Switching between pages is also done by pressing the “NEXT” key. The display

screens are designed so that these multi-page displays do not have separate subblocks. All of this is discussed in detail under “Advanced mode data displays” on

page 5—8.

Pop-Up Windows

Some displays will have pop-up windows (either on the right or left side of the main

display) that will contain:

• Prompts for selecting or changing parameters

• Confirmations and warnings of impending operations requiring a Y(yes) or N

(no) entry from the keypad

• Status indication of an operation under way, such as data output

• Synchronization of the Real Time Clock of the ENVI PRO console with the

GPS time signal

Sample pop-up windows

Help Screens

4—7

P/N 788715 Rev. 0

Console

On line help is also available. There are three screens of information providing a

quick reference on how to do most operations and which buttons to push. The

screens are as follows:

4—8

Help screens available

The help screens are displayed when you press the

“INFO” button. Whenever you see the text “help: INFO” in

the bottom prompt line of a display, you can activate the

help screens.

To toggle to another help screen, press the “+” or “–“ key.

The screens change in a cyclical manner.

To return to the MAIN OPERATING menu, press the

“ESC” key.

P/N 788715 Rev. 0

Operating Displays

4—0

P/N 788715 Rev. 0

Operating Displays

Chapter 5 Operating Displays

The various display screens with and without GPS will be discussed in this chapter.

Main Operating display

MAIN OPERATING display with and without GPS appears as follows:

Main operating display without GPS

Main operating display with GPS in Lat/Lon coordinate

5—1

Main operating display with GPS in UTM coordinate

P/N 788715 Rev. 0

Operating Displays

The configurable parameters of the MAIN OPERATING display are:

Parameter Description

MAG

ST

SEP

DIVBY

LN

LON

LAT

EASTING

mmm shows which type of magnetometer measurement is

currently enabled, and therefore ready to be started.

The station number for this measurement.

It consists of the numeric part (ssss.s) and the directional part (d).

The range is from 0 to 99999 with a decimal point as required.

The direction allows the entry of the geographical direction or the

Cartesian co-ordinates. The allowed entries are N,E,S,W, + or -.

The line or station separation.

The range is from 0 to 99999 with a decimal point, as required,

and can either be positive (+) or negative (-). It may not

necessarily represent the reading separation.

See the “NEXT” key and AUTO. St. INC. for more information.

When the separation is positive, the station number gets

incremented by the separation.

When the separation is negative, the station number gets

decremented by the separation.

NOTE: a negative (W,S,-) station, when incremented, becomes

less negative, and vice versa.

Trigger switch closure counter.

The line number, along which the measurements take place.

It consists of the numeric part (1111.1) and the directional part (d).

The range is from 0 to 99999 with a decimal point as required.

The direction allows you to enter the geographical direction or the

Cartesian co-ordinates as one of: N,E,S,W, + or -.

The GPS longitude of this measurement in lat_lon coordinate.

It consists of the positive numeric part (ll.llllll) and the directional

part (W or E).

The GPS latitude of this measurement in lat_lon coordinate.

It consists of the positive numeric part (ll.llllll) and the directional

part (N or S).

The GPS easting of this measurement in UTM coordinate.

It consists of the positive numeric part (eeeeeee.e).

5—2

P/N 788715 Rev. 0

Operating Displays

The GPS easting of this measurement in UTM coordinate.

NORTHING

It consists of the positive numeric part (nnnnnnn.n).

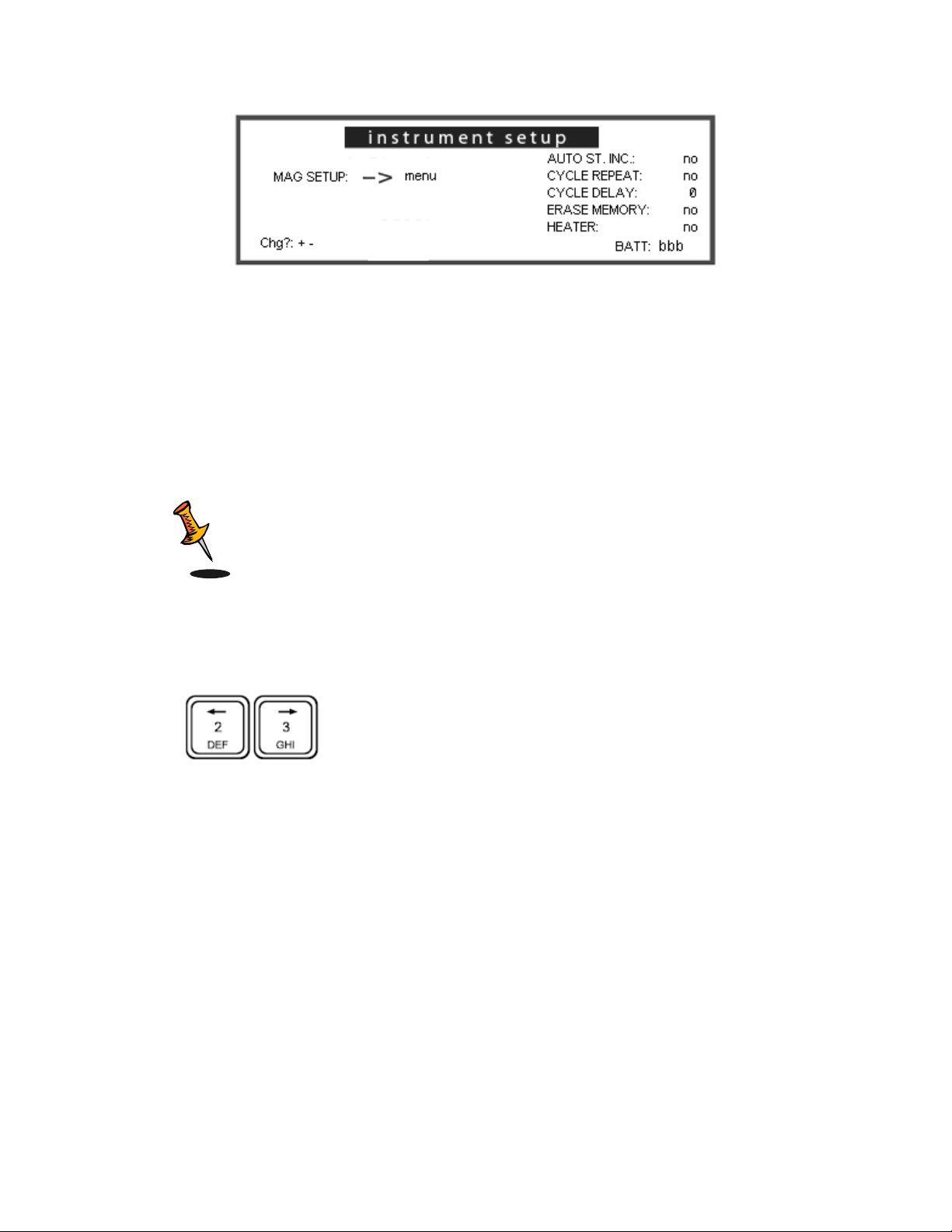

Instrument setup display

This display enables you to configure the basic data acquisition

portion of the ENVI PRO and is accessible with the “SETUP” key.

ENVI PRO instrument setup display

Parameter Description Default

Displays the magnetometer specific

MAG

SETUP

AUTO

ST. INC.

CYCLE

REPEAT

setup menu.

Pressing the “ENTER” key gets the

next menu.

A “yes/no” toggle that controls the

automatic station increment

(decrement).

no - for the base station, walking or

manual type of operation.

yes – for semi-automatic operation.

Determines whether the

magnetometer will take one reading

only, or will continuously take

readings at the time interval specified

by the DURATION parameter I the

Mag. Setup.

This is not applicable for Base

Station operation, which is set in the

Mag Setup.

No

No

5—3

P/N 788715 Rev. 0

Operating Displays

The delay between readings when

the cycle repeat feature is enabled.

CYCLE

DELAY

ERASE

MEMORY

HEATER

It affects the total-field magnetometer

or gradiometer only.

The base-station repetition rate is

controlled in the Mag. Setup under

Cycle Time.

Allows clearing of the data memory.

A request for confirmation will be

displayed before the actual erasure

takes place.

NOTE: The setup parameters remain

intact.

Enables or disables the LCD display

heater.

If the temperature is above – 15° C,

enabling this parameter has no

effect.

0

No

No

Magnetometer setup display

This display is different depending on if GPS is enabled or

not.

This display provides access to the parameters affecting

the operation of the magnetometer portion of the ENVI.

This display is accessible from either the Instrument setup display, or

from the Main operating display (by using the short-cut, i.e. pressing

the “ENTER” key).

5—4

P/N 788715 Rev. 0

Operating Displays

Magnetometer setup display with GPS disabled

Magnetometer setup display with GPS enabled

Parameter Description Default

Allows the selection of:

- Total Field

Magnetometer

MODE:

DURATION

(default)

- Gradiometer

- Base Station

- Off (will disable the

ENVI PRO)

The measurement duration.

A choice of 0.5, 1 or 2 seconds is

available.

The correct selection depends on the

desired measurement accuracy and

the spacing of the stations when

using the WALKMAG mode of

operation.

The duration also controls the

repetition rate if CYCLE REPEAT

with a CYCLE DELAY of 0 (zero) was

chosen in the ENVI instrument setup.

The longest duration results in the

highest precision.

Tfld

0.5

5—5

P/N 788715 Rev. 0

Operating Displays

The value of the Earth’s ambient

magnetic field in the survey area.

For best performance, the tuning field

should match the ambient field as

closely as possible, at least to within

+/- 1000 nT.

TUNE

FIELD

BASE

CORRECT

TIE

CORRECT

CYCLE

TIME

A map showing the approximate field

intensity on the Earth’s surface can

be found in Section B: Applications.

The values shown can be used as a

starting point, and applied equally to

the Total-field sensor or the

Gradiometer sensor.

See also AUTO TUNE.

A “yes/no” toggle that applies a

BASE-STATION correction using

data supplied from a base-station

ENVI PRO.

You must press the “+” key to toggle

the YES on.

You need to have the base-station

connected as described in “Using

base-station data”.

A request for confirmation will be

displayed in a pop-up window before

your data is corrected. You must

press the “9/YZ” (Yes) key to begin or

the “5/MNO” (No) key to abort.

NOTE: The original raw data is

changed.

A “yes/no” toggle that applies a tiepoint correction using data collected

in the TIE mode.

Selecting this opens a window

indicating which tie-point (loop or

line) correction mode is in effect. You

must enter “Y” to start the correction.

NOTE: The original raw data is

changed.

The reading interval of the base

station.

The allowable range is 0 to 99999

seconds.

0

No

No

0

5—6

P/N 788715 Rev. 0

Operating Displays

Entering 0 (zero) results in a reading

interval equal to the reading time.

The instrument goes to “sleep”

between readings, for 4 seconds and

up.

The sensitivity for the analog output

CHART

SCALE

AUTO

TUNE

BASEFIELD

for the strip chart recorder.

The following choices are available:

1, 10, 100, 1000, 10000 nT.

A “yes/no” toggle that controls the

automatic tuning function.

It is independent for the Total-field

sensor and the Gradiometer sensor.

The tuning value is updated after

each reading in preparation for the

next one.

Auto tuning is particularly applicable

if large variations of the ambient field

are encountered over longer

distances.

Fixed tuning may be more

appropriate in areas of large cultural

electrical noise or very narrow, large

amplitude anomalies. These may

pull the tuning away from the desired

frequency to that of the interfering

frequency or to tuning field values

greatly different from the background.

As the setting of this parameter

depends upon your particular survey

conditions, it is not possible to

suggest the best setting. The mode

should therefore be established by

experimenting. In general it is more

applicable to use fixed tuning for the

site characterization and drum

location modes.

The base field is used in conjunction

with the base-station correction

procedure.

The base-station correction

technique removes variation in the

ambient field during the time that the

base station is running. However,

variations taking place from day to

day are not corrected. The base field

1

No

0

5—7

P/N 788715 Rev. 0

Operating Displays

value is used for this purpose.

The actual value is not critical, as

long as it is the same for all

instruments in the survey. It is

important that this value not be

changed during the entire survey. A

logical value is the first reading of the

base-station on the first survey day.

Allows you to select either the Line or

Loop type of tie-line correction.

TIE MODE

AUTO

RECORD

NOTE: The Tie-line correction

method is substantially less precise

than the base-station correction

method.

A “yes/no” toggle.

This function is used in the semiautomatic mode to save you from

having to press another key.

Auto Record is always in effect in the

base-station operation or if the Cycle

Repeat function is selected in the

ENVI PRO Instrument Setup.

Line

No

Data Displays

Data is displayed on a page by page basis in either numeric or

graphic form. There are up to two pages each. The “NUM/GRA”

key toggles between the two display forms. This display is different

depending on if GPS is enabled or not.

Numeric data display

Numeric displays are only available when the instrument is recording data, i.e. you

cannot “recall” the data in a tabular format as shown in the figure below.

The displays shown in the examples that follow are Pages 1 and 2 of the numeric

data display for the gradiometer. The difference between the two display pages is

that Page 2 shows the signal precession as a bar graph. This allows you to monitor

the quality of each reading.

The total-field and the base-station displays differ in that the gradient column is

absent.

5—8

P/N 788715 Rev. 0

Operating Displays

The following table shows the availability of a numeric display after pressing the

“NEXT” key.

* You will have to use the “RECALL” function, if you have pushed the

“ESCAPE” key.

Page 1 of the numeric data display with GPS disabled

5—9

Page 2 of the numeric data display with GPS disabled – signal strength

P/N 788715 Rev. 0

Operating Displays

Page 1 of the numeric data display with GPS enabled

in lat_lon coordinate

Page 2 of the numeric data display with GPS enabled

in lat_lon coordinate – signal strength

Page 1 of the numeric data display with GPS enabled

in UTM coordinate

Page 2 of the numeric data display with GPS enabled

in UTM coordinate – signal strength

Display Item Description

The magnitude measured by the lower total-field sensor in

nanoTeslas (nT).

TOTAL

5—10

The most current reading is the top most followed by preceding

readings.

P/N 788715 Rev. 0

Operating Displays

NOISE

GRADIENT

TIME

LN

ST

LON

LAT

EASTING

NORTHING

A number indicating the quality of the reading.

It is based on the noisiness of the individual periods of the

precession signal. The smaller the value the better the quality of

the reading.

The magnetic gradient between the two sensors.

Expressed in nT/m.

The current time in hours: minutes:seconds.

It is used to time stamp each reading.

The line number on which this measurement took place.

The value consists of the numeric and directional parts.

The station number to which the respective magnetic data applies.

The value consists of the numeric and directional parts.

GPS longitude in lat-lon coordinate on which this measurement

took place.

The value consists of the numeric and directional parts

GPS latitude in lat-lon coordinate on which this measurement took

place.

The value consists of the numeric and directional parts.

GPS easting in UTM coordinate on which this measurement took

place.

The value consists of the numeric only.

GPS northing in UTM coordinate on which this measurement took

place.

The value consists of the numeric only.

Graphic data display

The display shown below is page two of the graphic data for the gradiometer. Page

one appears identical, except that the word ‘GRADIENT” is changed to “TOTAL” and

a plot of the total field is shown. This display is different depending on if the GPS is

enabled or not.

The following table shows the availability of graphic displays after pressing the

“NEXT” keys.

5—11

P/N 788715 Rev. 0

Operating Displays

* You will have to use the “RECALL” function, if you have pushed the

“ESCAPE” key.

** Depends upon the status before “STOP” was pressed.

Graphic data display of Page 2 – without GPS

5—12

Graphic data display of Page 2 – GPS Lat/Lon

Graphic data display of Page 2 – GPS UTM

P/N 788715 Rev. 0

Operating Displays

Display Item Description

The display title indicating the data shown by the graph.

GRADIENT

LN

ST

LON

LAT

EASTING

NORTHING

The numeric value indicated by ggg.g is the respective gradient, at

the indicated Line and Station number

The line number along which this measurement took place,

consisting of the numeric and directional parts.

The station number, at the cursor position, to which the respective

magnetic data applies (consisting of the numeric and directional

parts).

GPS longitude in lat-lon coordinate on which this measurement

took place.

The value consists of the numeric and directional parts

GPS latitude in lat-lon coordinate on which this measurement took

place.

The value consists of the numeric and directional parts.

GPS easting in UTM coordinate on which this measurement took

place.

The value consists of the numeric only.

GPS northing in UTM coordinate on which this measurement took

place.

The value consists of the numeric only.

Recall Displays

The “RECALL” function is useful to view the collected and stored data. But the

RECALL function is disabled when GPS enabled.

Recall Setup display

This display allows you to select the type, location or time and date

of the data when GPS is disabled. This display is accessed by

pressing the “RECALL” key.

The RECALL SETUP display with GPS disabled

5—13

P/N 788715 Rev. 0

Operating Displays

The RECALL SETUP display with GPS enabled

Display Item Description

MAG

LN

ST

TM

DT

Warning: GPS must be disabled in order to recall t-fld and grad. data.

The station number is the starting location for the recall, consisting

This parameter is only present when the Base Station is selected.

This parameter is only present when the Base Station is selected.

Either one of Total Field, Gradient or Base Station.

The line number whose data is to be recalled, consisting of the

Not only the Time and Date, but the Line and Station numbers

must also be correct to successfully recall Base Station data.

The mode of the data collected.

numeric and directional parts.

of the numeric and directional parts.

The starting time of the recall.

The data of the data to be recalled.

RECALL DATA display

Note: Only Data collected and saved with GPS disabled can

5—14

be recalled, but only in graphic form and with GPS

disabled. Up to 178 readings can be shown at one

time. The display window can be moved sideways

(called panning) in steps of one half of its width (i.e. up

to 89 readings) to view adjacent data with the aid of the

P/N 788715 Rev. 0

Operating Displays

“+” or “-“keys. It is also possible to adjust the vertical

scale and bring any point to the vertical center of the

window.

Exact values can be read off the numerical section at the left hand side of the

display.

The Total Field display is shown and explained. The Gradient display differs in title

only. The Base Station display shows Time and Date instead of Line and Station.

Note that there are two pages of data for the gradiometer.

These displays are accessible with the “START” key when in the

RECALL SETUP display.

The RECALL DATA display

Display Item Description

The title of the display indicating the data shown by the graph.

TOTAL

LN

ST

The numeric value indicated by MMMMM.M is the respective totalfield value, at the indicated line and station number.

The line number along which this measurement took place,

consisting of the numeric and directional parts.

The station number to which the respective magnetic data applies,

consisting of the numeric and directional parts, at the cursor

position.

Modifying the display window

The graph can be altered by changing the vertical scale or by centering any point

vertically in the window. A smaller window can be opened up using the “ENTER”

key to allow changes. The changes take effect after you press “ENTER”.

5—15

P/N 788715 Rev. 0

Operating Displays

The RECALL Display ready for customizing

Display Item Description

Shown after the “ENTER” key is pressed.

SCL

It indicates the vertical full scale.

Scrolling using the +/- keys allows the full scale values of 1, 10,

100, 1000, 10000 nT.

This is the cursor, which is normally at the left edge of the window.

It can be moved with the aid of the ← and → cursor keys.

Numerical data at the left hand side of the display represents the

data at the cursor position.

Pressing the “0” key adjusts the display such that the point at the

cursor position becomes the center value of the graph.

Auxiliary Functions display

The Auxiliary Functions display is accessible by pressing the

“AUX/LCD” key. It provides additional functions which are not

directly accessible from the keyboard. You will need to press the

appropriate key to get to the function.

5—16

P/N 788715 Rev. 0

Operating Displays

The auxiliary functions display

Key Pressed

These keys allow you to adjust the intensity of the

LCD screen for better viewing under a variety of

lighting conditions.

This option allows you to access the Data Output

menu to transfer information to you computer or

printer.

This function is reserved for production and service

tests. It has no functions for you to use.

The lock option allows you to lock the ENVI PRO

setup parameters so that they are not accidentally

changed. To make any changes, you will have to

toggle this option first.

Action under

Auxiliary functions

Data Output Display

This display allows the selection of:

• Communication parameters between the ENVI console and the output device

such as a computer or printer.

• The data format of the output

• And possibly the Line number, if a line by line data dump is desired.

Data can be dumped in its entirety at once, or selectively on a mode basis.

This display is accessible from the AUXILIARY FUNCTIONS display. Depending on if

GPS is enabled or not, the display is different.

The data output display with GPS disabled

5—17

P/N 788715 Rev. 0

Operating Displays

The data output display with GPS enabled

Parameter Description Default

With the cursor placed after the

: all data

recorded

MAG

BY LN

LN

BAUD

DL

colon, all the data in the instrument

would be dumped sequentially into

one, possibly very large, file.

Lists the modes available for the

ENV-MAG. As shown, only the

gradiometer data would be dumped

as indicated by the cursor position.

yes/no

Directs the instrument to dump the

data on a line by line basis, in

addition to a method by method

basis.

This is usually left at no.

The line number whose data has to

be dumped, consisting of the numeric

and directional parts.

The Baud rate of communication with

the output device.

The following choices are available

by scrolling: 600, 1200, 2400, 4800,

9600, 19200, 38400, 57600 Baud.

A delay which may be added after

each carriage return/linefeed (CR/LF)

to accommodate slow peripherals

such as some printers.

The range is 0 to 999 ms.

This value is normally left at 0 for

dump to computers.

The proper setting has to be

established experimentally for other

equipment. Problems usually are

indicated by the loss of a few

characters.

No

9600

0

5—18

P/N 788715 Rev. 0

Operating Displays

The number of data bits.

The default value is 8 bits, which

usually works properly.

BIT

FMT

The proper setting has to be

established experimentally. For

example, on some printers, 7 or 8 bits

results in either normal or italic print.

The output data format.

8

Data output formats

The following table shows the available output formats for dumping the data to a

computer or printer.

Data output

format

XYZ

XYZ+

XYZ++

PRN

NOTES

XYZ is the simplest format.

It contains no heading or comments.

The individual data items are separated by a single space

character.

X and Y represent the Cartesian coordinates (N and E are positive

while S and W are negative).

Z is one or more items of magnetic data.

There is one set of data per printed line, including the time of the

measurement.

CAUTION: Due to the lack of header information, you should label

the files clearly.

XYZ+ is identical to XYZ but a header and user entered NOTES

are added.

XYZ++ is identical to XYZ+ but the data is now placed into

columns.

PRN is a format used with software for the Scintrex MP-3/4

Magnetometer.

NOTES outputs a report of all user entered NOTES, crossreferenced with the Line and Station number, or GPS coordinate

value.

Description

NOTES display

The notes display is useful for the entry of comments, which are stored with the data

at the particular Line and Station number.

5—19

P/N 788715 Rev. 0

Operating Displays

Macros (pre-recorded messages) provide a quick entry for repetitive notes which can

be entered while measuring. This display is accessible with the “NOTE” key.

The NOTES display

Parameter Description

Alpha-numeric characters, including “+”, “.” and “-“ up to 32

characters.

NOTES

MACROS

1:

…

5:

A note can be saved as one of five macros in a separate memory

for re-use.

MACROS are pre-recorded messages of up to 15 characters.

These are used to speed up note entry.

It is most advantageous to enter frequently encountered items,

such as road, fence, and so on.

Information / GPS Setup Display

This display screen is used for the entry of ancillary information and

GPS setup. You can also see how much free memory is available.

This screen is accessed from the main display by pressing the “INFO”

key. Fig. 1 shows the default display or with GPS disabled. In order to

enable or disable GPS, move the cursor to GPS and press “+” or “-“, a pop-up

window comes out as shown in Fig. 2. By selecting 2 or 3 to enable GPS and

configure it to either Lat/Lon or UTM coordinate. At this point, the real time clock

(RTM) is synchronizing with GPS time, as shown in Fig. 3. Fig. 4 and 5 show the

INFO screen with GPS lat/lon and UTM coordinate, respectively.

5—20

P/N 788715 Rev. 0

Operating Displays

Fig. 1 The default INFO display

Fig. 2 GPS setup display

Fig. 3 RTC synchronizing display

5—21

Fig. 4 The INFO display with GPS enabled (LAT/LON)

P/N 788715 Rev. 0

Operating Displays

Fig. 5 The INFO display with GPS enable (UTM)

Parameter Description

Vx.x The version number of the ENVI PRO internal software.

TIME The current time of day.

DATE The present data.

GPS

GPS

INTERVAL

SER.*

JOB *

OPERATOR This is the operator’s name or number.

MEMF The percentage of free memory available for further use.

HDOP This is the qualities of GPS reading.

SAT. This is the number of satellites.

LON. This is the GPS longitude value.

LAT. This is the GPS latitude value.

EAST. This is the GPS UTM easting value.

NORT. This is the GPS UTM northing value.

Enable or disable of GPS.

Configure GPS to LAT/LON coordinate or UTM coordinate.

This is the GPS reading intervals when taking measurement.

This is usually the serial number of the instrument.

No use is made of this number by the instrument, therefore it also

could represent the users inventory number.

Up to 8 digits are accepted.

This may be the survey project number.

Up to 6 digits are accepted.

Warning: The TIME and DATE must

match between the base-station and the portable

magnetometer(s) for the base-station style of

correction to work properly.

5—22

P/N 788715 Rev. 0

Operating Displays

5—23

P/N 788715 Rev. 0

Chapter 6 Setting Up the ENVI MAG

This chapter describes the process of how to:

• Initialize the ENVI PRO for first time operation

• Program it for the different modes of operation

• Enter line and station numbers

Step by step procedures are given in Chapter 7 on how to perform:

• A total-field survey in the WALKMAG mode

• A gradiometer survey in the stop-and-go mode

• Base-station operation

First Time Operation

A special procedure has to be followed to get the ENVI-PRO software set up

properly. This procedure is called a cold boot. This assures that all setup

parameters are initialized properly and that the memory is cleared.

Warning: First time operation procedures (cold boot) have to be

carried out every time the instrument has had its

battery disconnected for more than 10 minutes. You

may also need to cold boot if the screen stays blank or

is scrambled.

Cold Boot

To perform a cold boot, proceed as follows: