Page 1

CS-3

Scintrex Cesium Vapor Magnetometer Sensor

OPERATION

MANUAL

SCINTREX

CS-3 Manual - part # 762701 Revision 4.0

Page 2

Rev Description of change ECO Date of issue App

1.0 Initial Release Feb 21, 2002 G.H.

2.0 Additional information Nov 30, 2005 G.M.

3.0 Additional information Oct 30, 2006 G.M.

4.0 Additional information 4405 Jan 18, 2007 R.L.

Page 3

CS-3

Scintrex Cesium Vapor Magnetometer Sensor

Operation Manual

CS-3 Manual - part # 762701 Revision 4.0

Page 4

SCINTREX LIMITED

HEAD OFFICE

SCINTREX Limited

222 Snidercroft Road

Unit #1

Concord, Ontario

Canada, L4K 2K1

tel: +1 905 669 2280

fax: +1 905 669 6403

e-mail:

scintrex@scintrexltd.com

World-wide web: http://www.scintrexltd.com

Copyright © SCINTREX Limited 2005. All rights reserved.

No part of this publication may be reproduced, stored in a retrieval system or

transmitted, in any form, or by any means, electronic, mechanical,

photo-copying, recording, or otherwise, without prior consent from

SCINTREX Limited.

Document Part No. 762701, Revision 3.0

Printed and bound in Canada

CS-3 Manual - part # 762701 Revision 4.0

Page 5

Foreword

Getting Started

About this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Page Numbering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Type Styles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Chapter Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Understanding Instrument Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Sensor Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Sensor Electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Old version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

2nd Draft

New version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Operating the CS-3 in the Field

Setting Up the CS-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Mounting the CS-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2

Powering Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Obtaining the Larmor Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Setting the Operating Hemisphere . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Operating in the Presence of Spurious Magnetic Fields . . . . . . . . . . . . . . . . . . . . . . 2-9

2nd

Orienting Your CS-3

Understanding the Active Zone of the CS-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Using a Strapped Down CS-3 for Surveys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Calculating the Tumble Angle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Recommended Survey Orientations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Comparison with the Locked Oscillator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

Table of Contents

Maintaining Your CS-3 and Trouble-shooting

Trouble-shooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Reference Information

CS-3 Technical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Instrument Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

CS-3 Standard Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Warranty and Repair. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

CS-3 Manual - part # 762701 Revision 4.0

v

Page 6

Shipping Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Appendix A: Theory of Operation

System Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Appendix B: CS-3 Block Diagram

vi

CS-3 Manual - part # 762701 Revision 4.0

Page 7

Foreword

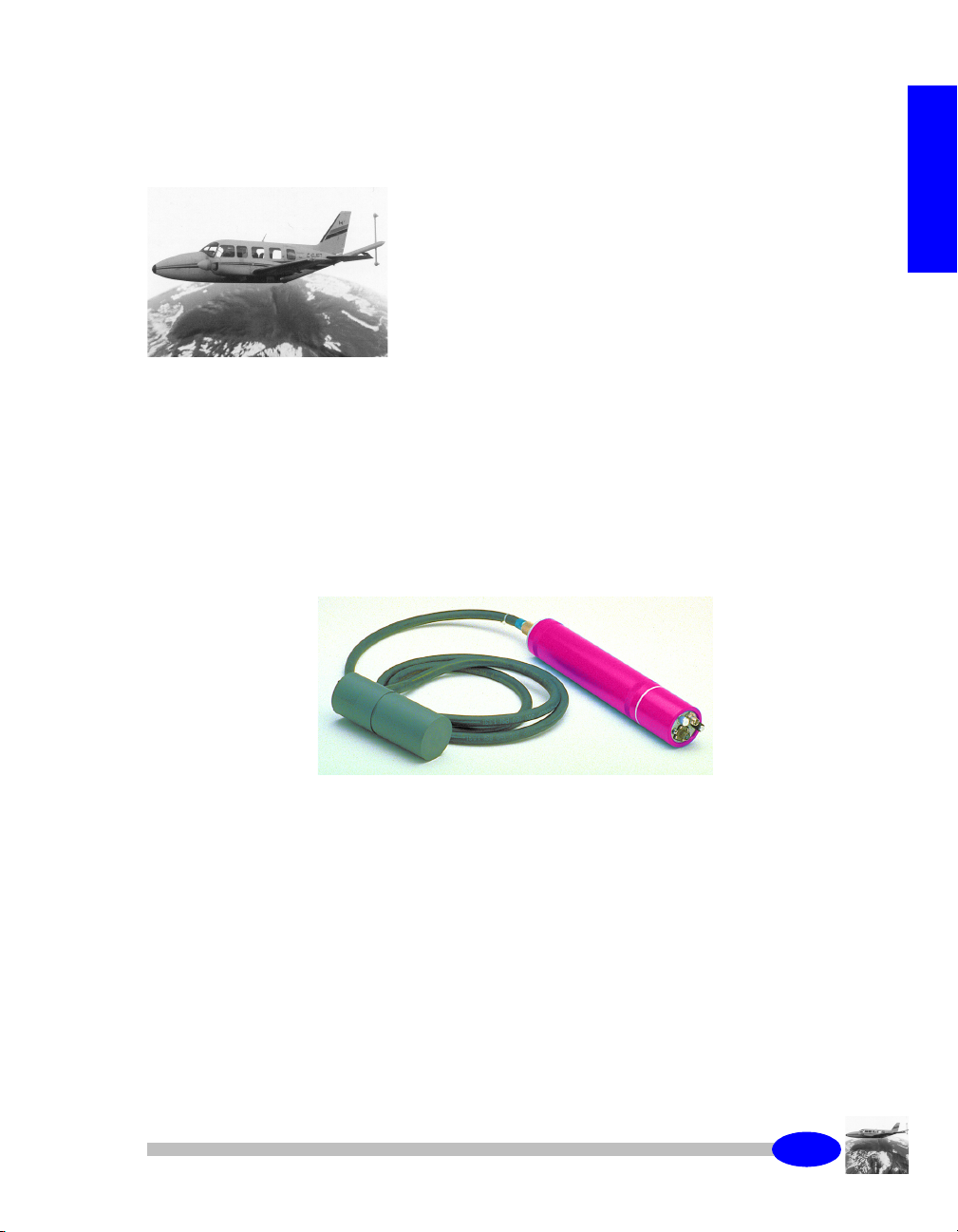

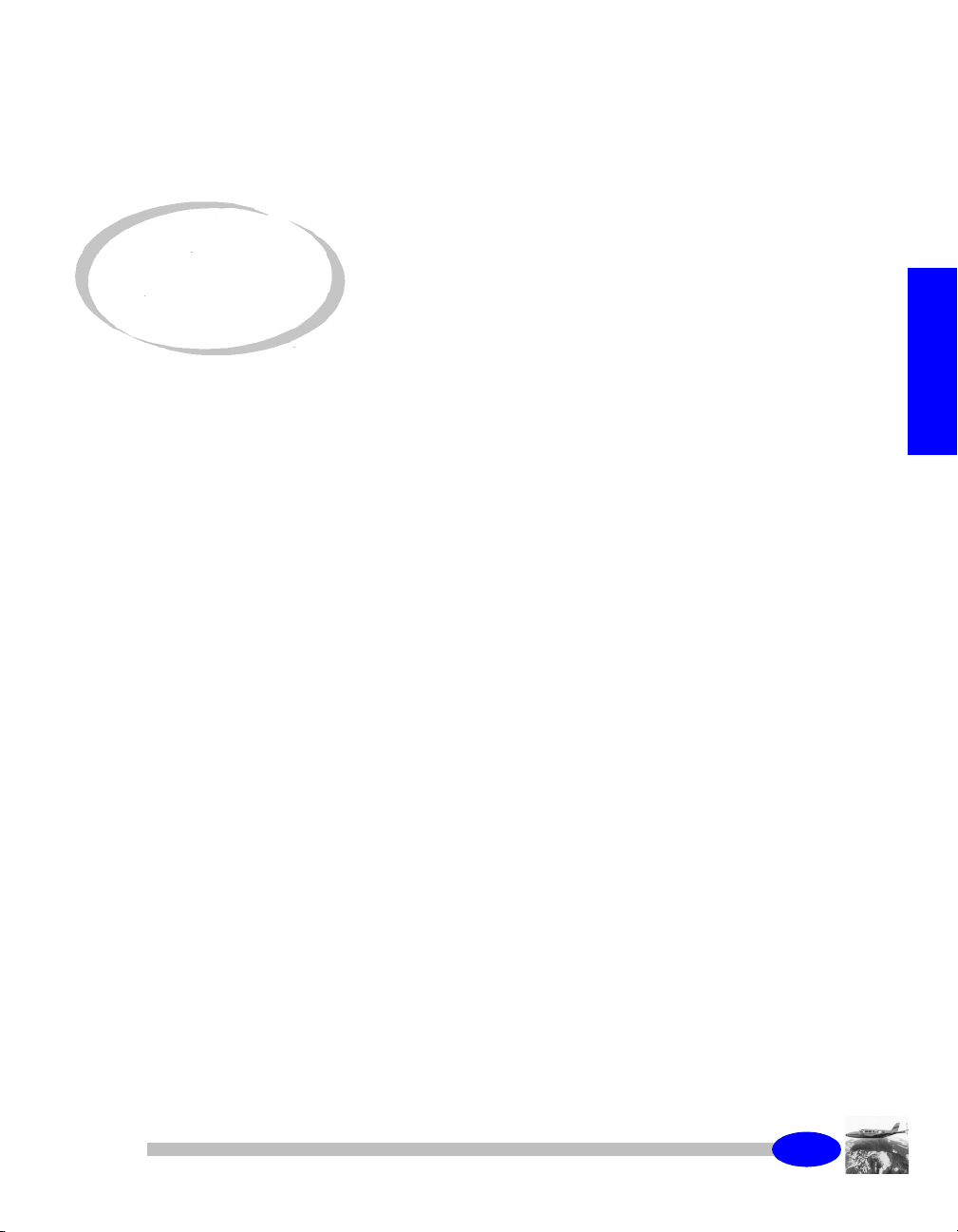

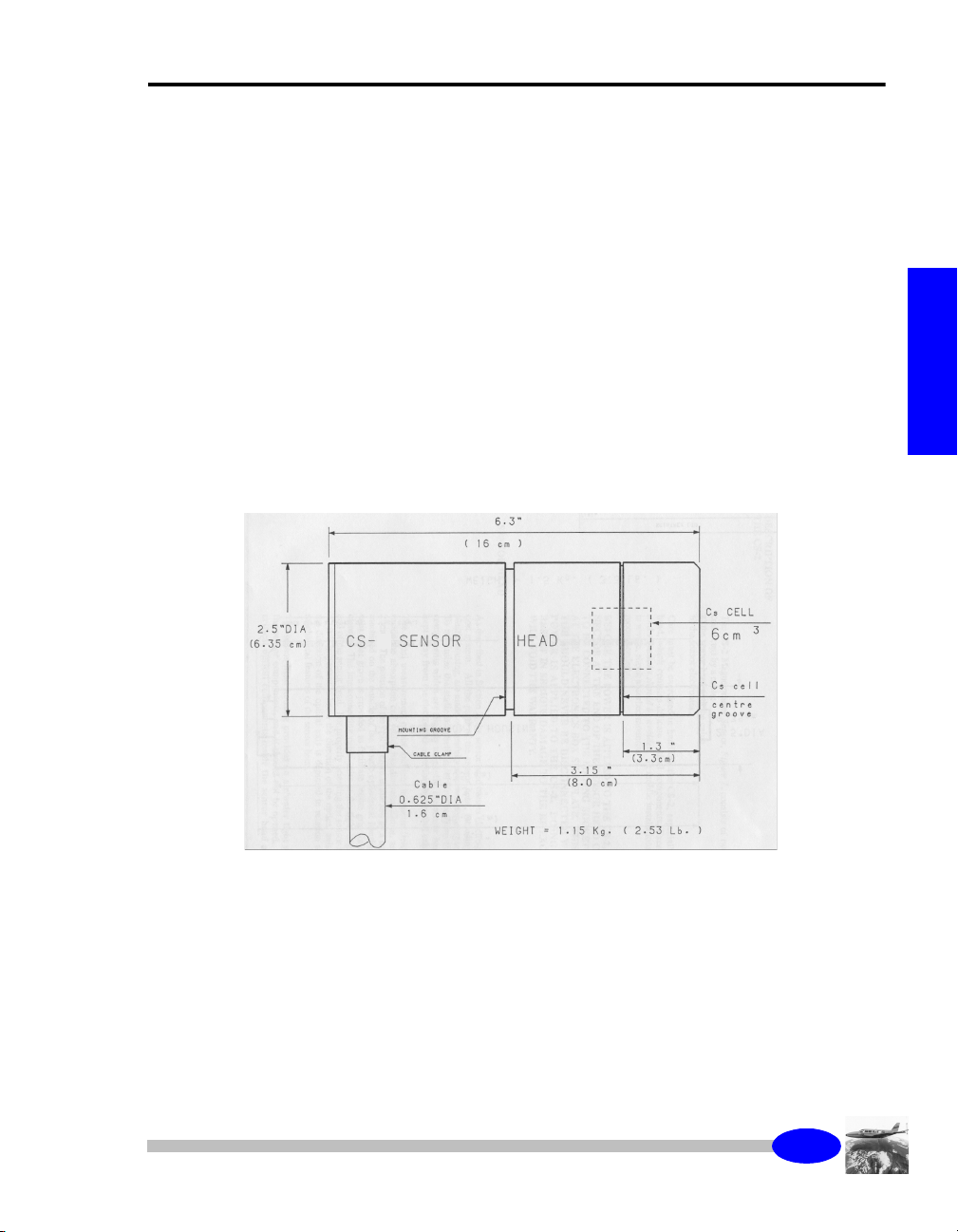

The CS-3 is an optically pumped cesium vapor magnetometer sensor used for

scalar measurement of the Earth's magnetic field. As shown below, the CS-3

sensor consists of a sensor head with cable and sensor electronics.

Foreword

Figure 1: CS-3 Magnetometer Sensor

The system excels in a variety of applications (ex. airborne, satellite, marine

and ground magnetometry or gradiometry, base station magnetometry and

ferrous ordnance location) due to its:

• high sensitivity

• high cycling rates

• excellent gradient tolerance

• continuous output

• automatic hemisphere switching

vii

CS-3 Manual - part # 762701 Revision 4.0

Page 8

• fast response

• low susceptibility to the electromagnetic interference

Magnetic field measurements performed by the CS-3 is based on quantum

mechanics principles, and the phenomena of optical pumping and

self-oscillation. When properly oriented in relation to the ambient magnetic

field, cesium vapor in the sensor oscillates continuously by itself without any

assistance. The frequency of oscillation (defined as the Larmor frequency) is

proportional to the ambient magnetic field.

The sensor outputs a signal at the Larmor frequency which is normally

processed by an external magnetometer processor linked to the system. The

magnetometer processor converts the Larmor frequency into digital magnetic

field readings and presents them for display and recording. Modern magnetic

processors have a resolution of 0.001 nT and read 10 times each second or

faster.

In summary, the CS-3 offers distinct and substantial benefits in measurement

of magnetic fields due to the principles of both optical pumping and

self-oscillation. These advantages are described in the next two sections.

Advantages of Optical Pumping

These benefits are shared by all well designed optically pumped

magnetometers regardless of which atoms (cesium, rubidium, potassium or

helium) are being pumped, and regardless which of two principles of

operation is utilized (self oscillation, or locked oscillation).

High Sensitivity

Due to the narrow resonant linewidth and good signal to noise ratio the

sensitivity of optically pumped magnetometers is in the range of few pT

(1pT=0.001nT) in the measuring bandwidth of 1Hz. In contrast to the proton

precession magnetometers, the sensitivity does not deteriorate as the

measured ambient field decreases.

Continuous Signal

The operation of the optically pumped magnetometers is not cyclic. Highly

sensitive readings could be obtained at the high repetition rate.

viii

CS-3 Manual - part # 762701 Revision 4.0

Page 9

High Gradient Tolerance

Absorption cells of the optically pumped magnetometers in which the

detection of the ambient field is taking place are normally much smaller than

the sensors of proton precession (including Overhauser) magnetometers.

Consequently, the field gradients over the sensor volume are much smaller

and the proper operation of the magnetometer is much less affected, e.g. the

volume of the CS-3 absorption cell is only 0.006 liters.

Low Radiated Electromagnetic Interference

Sensors of the optically pumped magnetometers radiate low disturbing EM

fields. The H

is well confined and of the high frequency - around 165 MHz for the CS-3.

2nd Draft

field is the order of 10 nT. The RF field for the lamp excitation

1

Insensitivity to Motion Induced Doppler Effects

Irregular motion of the platform carrying the sensor modulates (adds to) the

precession frequency and introduces noise into the measurements of the

2

magnetic field.

2nd

Proton precession (including Overhauser) magnetometers are affected to a

much greater degree by motion noise due to much lower gyromagnetic

constant, e.g. in the ambient magnetic field of 50,000nT the Larmor

frequency of the CS-3 is 175,000Hz, which is 82 times larger than 2100Hz,

the precession frequency of the proton magnetometer.

Foreword

Advantages of Self Oscillation

Use of the self-oscillating principle of operation results in the following

additional benefits not available from optically pumped magnetometers using

locked oscillator principle of operation:

Fast Start-up

If the sensor head is properly oriented inside its active operating zone, the

CS-3 will start oscillating shortly after it is turned on. The warm-up time is

determined by the time required for the electronically controlled heaters to

bring the absorption cell and the cesium lamp to the proper operating

temperature.

ix

CS-3 Manual - part # 762701 Revision 4.0

Page 10

The warm-up is over in few minutes after a cold start. However, if the

operating temperature is already established, it takes only few milliseconds

for the magnetometer to start oscillating after a turn on or after an orientation

change from a dead zone into the active zone.

In contrast, a locked oscillator magnetometer invariably contains a voltage

controlled oscillator (VCO), whose frequency in normal operation is forced

(locked) by the control electronics to follow the resonant Larmor frequency.

However, at every start-up, cold or warm, before the locking is acquired, the

VCO frequency has to be swept relatively slowly until it comes close enough

to the Larmor frequency. Then the locking takes place and the magnetometer

becomes operational.

Note that the Larmor frequency is known beforehand only coarsely and

consequently this search process takes several seconds. The same search

procedure takes place if the lock is lost because of a fast field change or a

disturbing AC magnetic field.

Fast Response and Tracking

The response of a self-oscillating magnetometer to the magnetic field

changes is extremely fast. It has been experimentally determined that the

Larmor frequency precisely changed in response to the step changes of

several thousand nT within a Larmor period. Equally, the magnetometer

followed sinusoidal field changes of the amplitude of hundreds nT at the rate

of several kHz without appreciable lag in response.

In contrast, the rate of ambient field change, which a locked oscillator

magnetometer could follow without losing lock, is much smaller. In addition,

spurious fields, either AC (50-400Hz) or pulsed, in the range of several

hundred nT cause the magnetometer to lose lock.

Low Susceptibility to Electromagnetic Fields

The susceptibility to spurious EM fields depends very much on the principle

of operation. Most widely encountered spurious fields originate from the

power lines and the airborne geophysical EM systems, and are in the

frequency range of 50Hz to several thousand Hz. In general, the

susceptibility increases greatly as the frequency of the interfering field

approaches the operating (Larmor, proton precession) frequency.

Proton precession magnetometers (including Overhauser) have low

susceptibility for two reasons:

• they use induction coils to detected proton precession

x

CS-3 Manual - part # 762701 Revision 4.0

Page 11

• the interfering EM field are normally at the frequencies close to the proton

precession frequency.

Neither of above liabilities apply for optically pumped magnetometers

because:

• signal detection is optical

• the interfering frequencies are normally far from the Larmor frequency.

In addition, the susceptibility of the self-oscillating magnetometer is low,

because its feedback loop is very simple and fast, allowing it to respond with

little lag to the fast changing fields.

In contrast, the locked oscillator response is much slower because its control

loop frequency bandwidth is limited to few hundred Hz. Furthermore, the

2nd Draft

feedback control is achieved by monitoring a modulating signal, which

frequency is in the range of one hundred Hz, and which detection could be

readily upset by the interfering EM fields.

For either of above reasons, the locked oscillator may lose lock and become

temporary non-functional for few seconds in presence of a spurious EM field.

2

Superior Worldwide Orienting Capabilities

2nd

The analysis presented in Chapter 3, “Orienting Your CS-3” proves that,

contrary to the widely accepted belief, a well designed self-oscillating

magnetometer is as easy to orient as the locked oscillator. Even more

important, it offers wider safety margins to the boundaries of operating zone,

than the locked oscillator.

Foreword

xi

CS-3 Manual - part # 762701 Revision 4.0

Page 12

xii

CS-3 Manual - part # 762701 Revision 4.0

Page 13

1

Getting Started

About this manual

Page Numbering

The numbering scheme used consists of two parts: the chapter number and

page number. For example,

For your convenience, each chapter has a thumb-tab on the right-hand side

allowing you to quickly locate a chapter of interest. The thumb-tabs are

arranged in descending order, with Chapter 1 always starting at the top.

3-1 would refer to chapter 3, page 1.

Startup

1-1

CS-3 Manual - part # 762701 Revision 4.0

Page 14

Getting Started

Type Styles

The following typeface conventions will be used throughout the manual.

Convention Use

Bold Italic Indicates an action to be taken

Italic Denotes a new term being introduced

ALL CAPS Denotes the name of a screen, key or mode (function)

1-

2

CS-3 Manual - part # 762701 Revision 4.0

Page 15

Chapter Layout

This manual is divided into six chapters and four appendices with the

information flow detailed in the following table.

Chapter Description

1. Getting Started Gives an overview of the manual and describes the

2. Operations Tells how to set up your CS-3 for a survey, including how

3.Orientation Gives a detailed theoretical and practical review of the

4. Maintenance Gives a brief overview of how to maintain and

5.Reference Contains the technical specifications, instrument parts

A.Theory of

Operation

About this manual

instrument’s components.

to mount and operate the system.

considerations for orienting the instrument to obtain best

results.

trouble-shoot your system.

list and warranty information.

Explains the scientific and instrumentation theory for the

CS-3 instrument.

Startup

1-3

CS-3 Manual - part #762701 Revision 4.0

Page 16

Getting Started

Symbols

The following symbols will be used to highlight specific sections of text

throughout the manual.

Symbol Meaning

Warning:

Denotes an important point concerning safety

Important:

Indicates a important topic, particular attention should be

paid to this section

Note:

Denotes a point of interest, or information you should read

Tip:

Denotes an interesting hint for smoother operation

Question:

Indicates a relevant question concerning an important

topic

1-

4

CS-3 Manual - part # 762701 Revision 4.0

Page 17

Understanding Instrument Basics

Understanding Instrument Basics

The CS-3 Magnetometer Sensor consists of a sensor head and sensor

electronics that are interconnected by a cable. This section provides

schematics and descriptions for each of these components and their

subsystems.

Sensor Head

The sensor head houses electro-optical detection system. All the parts of the

sensor head, including the outside plastic housing, are made of carefully

screened nonmagnetic materials. The following figure shows a schematic of

the sensor head.

Startup

3

Figure 2 - Schematic of the sensor head

CS-3 Manual - part #762701 Revision 4.0

1-5

Page 18

Getting Started

The actual measurement of the ambient magnetic field takes place inside the

absorption cell which has diameter 22mm, and the length 25mm. The

position of the cell's centre is marked by a narrow groove, machined on the

outside of the plastic cylindrical housing. The adjacent wider grove is

provided to facilitate secure grip for the mounting clamps.

The interconnecting cable exits at the right angle on the top end of the sensor

head. For properly orienting the sensor head as described in

“Orienting Your CS-3”, it is important to know the direction of the optical

axis. In Figure 1 on page

relation to the outside mechanical features of the sensor head.

The sensor head housing provides an air/water tight enclosure for the sensor

components, and it should not be opened. In addition, critical optical

components inside the sensor head are carefully aligned in order to minimize

the orientation errors, and opening the sensor head by unqualified people

may upset the alignment.

Important:

To minimize the static magnetic interference from

the electronic components which are slightly

magnetic, the sensor head should be kept away from

the electronics assembly by the full cable length.

Chapter 3,

vii, the direction of the optical axis is depicted in

1-

6

CS-3 Manual - part # 762701 Revision 4.0

Page 19

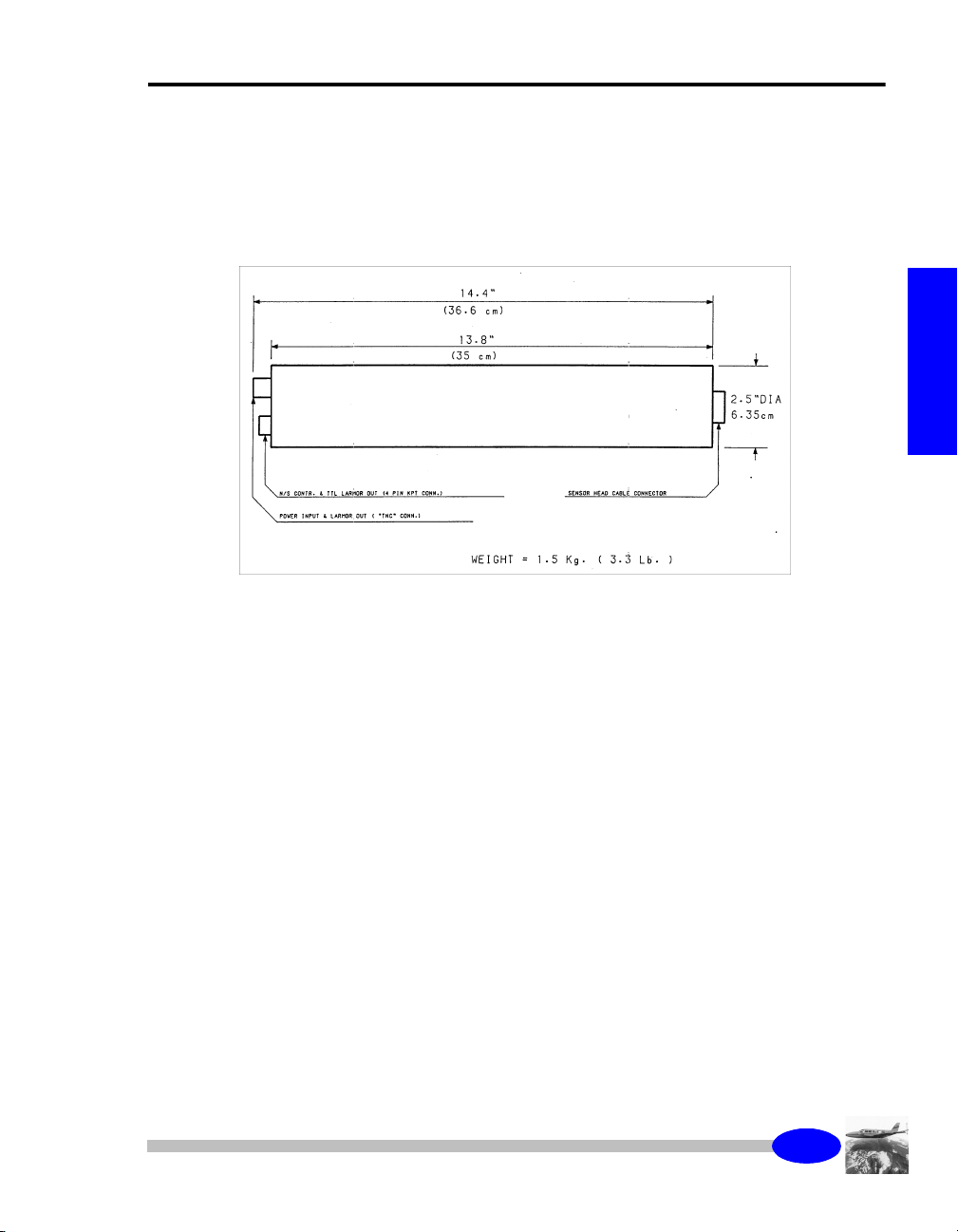

Sensor Electronics

CS-3 ELECTRONIC HOUSING

The sensor electronics are housed in a cylindrical container as shown in the

following schematic.

Understanding Instrument Basics

Startup

Figure 3 - Schematic of the electronics housing

The electronics consist of three major subsystems:

• Larmor amplifier

• Lamp and absorption cell heaters

• RF lamp exciter

The RF exciter generates few watts of RF power at the frequency of about

165MHz. In order to keep the radiated electromagnetic interference low, the

exciter is located inside a metallic enclosure. In addition, all the sensor

electronic systems are enclosed inside a cylindrical, metal box.

Electronic Housing

Internally, the sensor electronic housing is connected to the negative line of

the input supply voltage. If the negative side of the power supply, which

provides the power for the CS-3, is grounded to the frame of the vehicle, and

if the electronic box of the CS-3 makes an electrical contact to the same

frame, then the return current could flow partially through the frame instead

of being confined to the return line inside the supply cable.

1-7

CS-3 Manual - part #762701 Revision 4.0

Page 20

Getting Started

The stray magnetic field created by this current could corrupt the

measurement of the ambient field. To prevent that happening, the outside of

the electronics box is covered with a thin, plastic insulating sleeve.

The sensor head connector is mounted on one side panel of the electronic

box. On the opposite side, following components are mounted on the control

panel, see Figure 4.

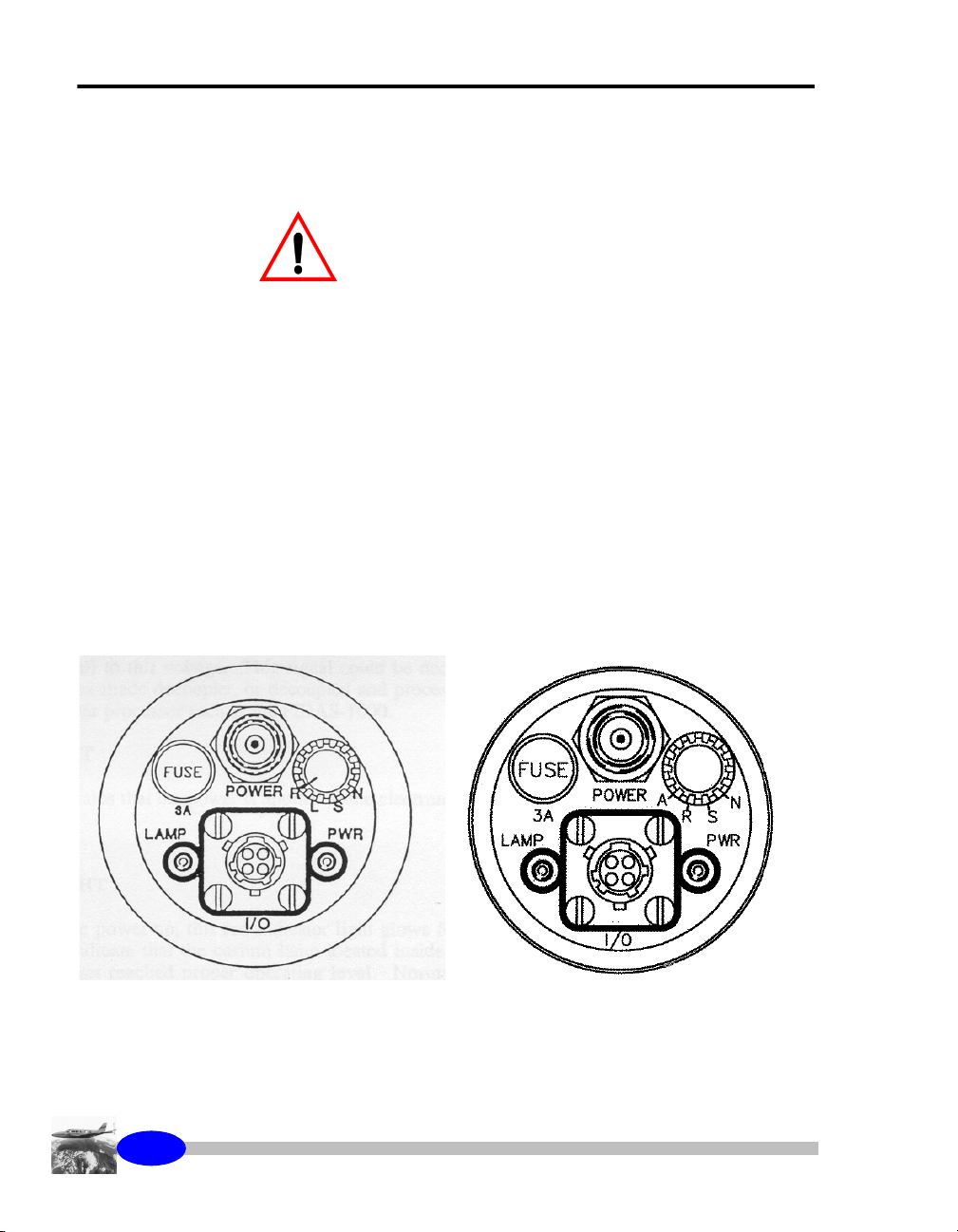

Hemisphere Control Switch

The hemisphere control switch is a four-position rotary switch as shown

below. Please note that depending upon the version of your Cs-3, you will

have either version.

Important:

Please, make sure that this plastic sleeve is not

damaged to such an extent that the metal part of the

CS-3 electronics housing is making contact to a

metal part of the airplane or vehicle frame.

OLD VERSION

Figure 4 - Schematic of the hemisphere control switch

1-

8

CS-3 Manual - part # 762701 Revision 4.0

NEW VERSION

Page 21

Old version

The swich settings perform the following functions:

N - Manually sets the CS-3 to operate in northern operating hemisphere.

S - Manually sets the CS-3 to operate in southern operating hemisphere.

L - Local setting allows the operation of the CS-3 to be controlled by the

TTL voltage level at the pin D of the four pin connector (pin A is ground):

open circuited or high level voltage for operation in southern hemisphere,

low level voltage or short connected to pin A for operation in northern

operating hemisphere.

R - (JP3 - OFF, JP2 - ON). Remote setting allows the operation of the CS-3

to be controlled remotely by superimposing on the supply voltage an 80Hz

sine signal. In the absence of the signal, the CS-3 is set to operate in the

northern hemisphere.

R - (JP3 - ON, JP2 - OFF). Automatic hemisphere switch.

Understanding Instrument Basics

Startup

Note:

JP2 and JP3 refer to jumpers on the Larmor board.

New version

The swich settings perform the following functions:

N - Manually sets the CS-3 to operate in northern operating hemisphere.

S - Manually sets the CS-3 to operate in southern operating hemisphere.

R - Remote setting allows the operation of the CS-3 to be controlled by the

TTL voltage level at the pin D of the four pin connector (pin A is ground):

open circuited or high level voltage for operation in southern hemisphere,

low level voltage or short connected to pin A for operation in northern

operating hemisphere.

A - Automatic hemisphere switch.

I/O Connector

Four pins of the I/O connector carry following signals:

1-9

CS-3 Manual - part #762701 Revision 4.0

Page 22

Getting Started

A - ground level

B - positive input of the supply voltage +24 to 35 V; this input is connected in

parallel to the centre pin of the coaxial TNC power connector on the same

panel

C - Larmor output signal, TTL compatible square voltage signal at Larmor

frequency

D - TTL compatible input: high level or open for operation in the southern

operating hemisphere, low level or connected to pin A for operation in the

northern hemisphere. This input is effective only if the Hemisphere Control

switch is in the Remote (R) position.

1-10

CS-3 Manual - part # 762701 Revision 4.0

Page 23

2

Operating the CS-3 in the Field

By now you have familiarized yourself with your CS-3. This chapter reviews

the basic steps required to carry out a survey. They include the following:

• setting up the CS-3

• mounting the CS-3

• powering up

• obtaining the Larmor frequency

• setting the operating hemisphere

• operating in the presence of spurious magnetic fields

Operations

2-1

CS-3 Manual - part # 762701 Revision 4.0

Page 24

Operating the CS-3 in the Field

Setting Up the CS-3

The basic procedure for setting up the CS-3 is as follows:

• mount the sensor in the vehicle according to the mounting instructions (see

below)

• connect the sensor head to the electronics via the supplied cable

Note:

To minimize the static magnetic interference from

the electronic components which are slightly

magnetic, the sensor head should be kept away from

the electronics assembly by the full cable length. If

the electronics is kept at 3 meters away from the

sensor head, its magnetic signature is less than

0.1nT.

• make sure that you have between 24 and 35V of power to the device

• connect the CS-3 to the power connector (i.e. link to your power supply, data

acquisition unit or coupler)

• turn on the power

Warning:

BEFORE THE POWER IS APPLIED TO THE

CS-3, THE CONNECTOR AT THE END OF THE

SENSOR HEAD CABLE HAS TO BE

CONNECTED TO THE MATING SOCKET

LOCATED AT THE ELECTRONICS BOX SIDE

PLATE. THIS CONNECTOR SHOULD NEVER

BE DISCONNECTED WHILE THE POWER IS

APPLIED TO THE CS-3. DOING SO WILL

RESULT IN SERIOUS DAMAGE TO THE RF

EXCITER AND WILL VOID THE WARRANTY.

• let the unit warm up for a designated warm up period to enable the lamp and

heaters to stabilize (i.e. stabilize the optics)

The remainder of this chapter provides more details that will help you with

installation and start-up.

2-

2

CS-3 Manual - part # 762701Revision 4.0

Page 25

Mounting the CS-3

The quality of data depends greatly on the quality of the installation. Our

advice is to obtain the services of a highly skilled systems engineer for the

installation of all magnetometer sensors and associated survey

instrumentation. There are numerous factors related to aircraft,

instrumentation and custom modifications that may be required to achieve a

successful installation.

In general, when mounting a high sensitivity sensor such as the CS-3, you

should consider the following guidelines:

• Secure the sensor so that it is rigid during aircraft motion. The use of a

proper gimbal is highly recommended. The gimbal makes changing the

orientation easier and also provides a secure base for operating the sensor.

• Keep the sensor as far as possible away from moving surfaces or magnetic

inducing objects.

• Screen all hardware used in proximity of the sensor for ferrous

contamination.

• Minimize the amount of conductive hardware, such as brass screws and

aluminum, as they will introduce a secondary field when they are in motion

through the earth field.

Setting Up the CS-3

Operations

• Although the sensor electronics have a minimal magnetic signature, keep the

electronics as far away as possible from the sensor.

• Always ensure that the cable between the sensor and electronics is physically

secured.

• Do not coil the cable to take up slack. If necessary, all slack should be at the

preamplifier electronics end of the installation.

• Always ensure that there is adequate ventilation at both the sensor head and

the preamplifier electronics. This is especially critical when operating in hot

climates.

• Keep the sensor away from direct exposure to weather elements and keep it

clean from debris.

• Ensure that there is adequate static discharge available along the surrounding

surfaces of the aircraft installation. In dry conditions, static will build along

the flying surfaces and create noticeable “pop” noise in the data during

discharges.

• Do not place secondary sensors, such as a fluxgate magnetometer, in very

close proximity to the cesium sensor.

2-

3

CS-3 Manual - part #762701 Revision 4.0

Page 26

Operating the CS-3 in the Field

Powering Up

The power for the CS-3 should be supplied from a DC supply 24-35V, 2A

minimum supply capability. The power can be connected either through

either:

• the coaxial TNC connector by a 50 ohm coaxial cable (centre pin positive

wire)

• the four pin I/O connector, on pins B (positive wire) and A (negative wire).

The sensor electronics is protected from an accidental polarity reversal on

both power inputs.

The green light on the side panel indicates that the power is applied to the

sensor electronics. Initially, after the power-up, the red indicator light glows

for a short while to indicate that the cesium lamp located inside the sensor

has not yet reached proper operating level.

Normally, this indicator light will go off completely indicating that the

cesium lamp is radiating sufficient light. At 25°C it takes normally only few

seconds for this light to go off. At a low ambient temperature, it may take

longer for the lamp exciter to warm up and for the lamp to start to operate

properly.

At the beginning of the cold start-up, the power supply current will be

highest, approximately 1.5A, as the cell and the lamp heater are operating at

the full output capacity. As the cell and the lamp are approaching the required

stabilized operating temperature, the supply current will decrease and it will

reach steady level which is ambient temperature dependent.

At the 20°C the supply current will be approx. 0.5A, at -40°C it is approx.

0.7A. The warm-up time is less than 5 minutes at 20°C, increasing to less

than 15 minutes at -40°C.

Warning:

Make sure that power line voltage is in the specified

range and clean without transients. Under voltage

will cause interruptions or loss of larmor signal.

Over voltage will cause serious permanent damages

to your CS-3 and warranty will be void.

2-

4

CS-3 Manual - part # 762701Revision 4.0

Page 27

Obtaining the Larmor Signal

Obtaining the Larmor Signal

If the sensor head is properly oriented inside its active operating zone, as

described in

shortly after it is turned on, as soon as the absorption cell and the cesium

lamp reach the operating temperature.

Chapter 3, “Orienting Your CS-3”, the CS-3 will start oscillating

Note:

If the operating temperature is already established, it

takes only few milliseconds for the magnetometer to

start oscillating after a warm power-up or after an

orientation change from a dead zone into the active

zone.

The frequency of oscillation is called the Larmor frequency. The Larmor

frequency is proportional to the magnitude of the ambient magnetic field.

The constant of proportionality, which relates the magnitude of the ambient

magnetic field to the Larmor frequency, is known as the gyromagnetic

constant and for the cesium 133 it equals 3.498577Hz/nT.

The amplitude of the output signal of the CS-3 is kept nearly constant

(+/-15% variation is due to the transformer frequency characteristic) by

electronic means for magnetometer orientations inside the active zone, in

spite of:

• the amplitude changes of the light modulation (original Larmor signal) with

the magnetometer orientation and

• the amplitude versus frequency dependence of the Larmor amplifier

electronics.

Output Signals

The output signals at the Larmor frequency are available in two formats:

• square wave signal with TTL/CMOS logical levels is available at the I/O

connector, pin C, with the ground at pin A. Fast transitions of the square

wave make this output much less susceptible than the sinewave output to the

system noises like ground line noise. The output driving capability of this

output restricts the maximum cable length of the RG-58 coaxial cable to 8

meters. An external line driver is required if the signal is to be transmitted

over the longer distance.

Operations

2-

5

CS-3 Manual - part #762701 Revision 4.0

Page 28

Operating the CS-3 in the Field

• sinewave Larmor signal is transformer coupled inside the sensor electronics

box on to the D.C. power supply line. This is done in a similar way as in the

older models of Varian and Scintrex cesium vapor magnetometers. The only

difference that the output amplitude of the CS-3 is electronically stabilized to

be independent of the sensor orientation or slightly dependent of the Larmor

frequency over the range of 50-350kHz. This additional feature will prevent

the sensitivity of the magnetometer to deteriorate more than necessary in

presence of the power supply noise. The power supply noise affects more the

signal with the lower amplitude.

Couplers, Processors and Power Supplies

In older magnetometers the output amplitude was varying as much as 10:1.

The CS-3 magnetometer could easily replace, as far as the power and signal

conditioning is concerned, the older models without any changes to the

existing equipment such as sensor couplers, magnetometer processors, power

supplies.

The only incompatibility is in the control of the operating hemisphere, as it

will be explained in the next section. The Larmor signal coupled on the

coaxial power cable could be transmitted to the processor (decoupler) over

the distance of up 100 meters before it is decoupled by a transformer.

Many of modern magnetometer processors, such as Scintrex MEP series of

processors, incorporate the power and signal conditioning circuits such as the

regulated power supply and the sensor decoupler. One has to just connect the

coaxial power cable to the appropriate power output connector and the

installation is complete. The supply current is measured and displayed, as

well.

For more detailed information, please, refer to the specific processor

operating manual. The MEP series of processors obsoletes the older

generation of Scintrex self standing sensor couplers such as VIW2340A1 or

VIW2340D4, but they still could be used in existing installations to decouple

the Larmor signal from the CS-3.

2-

6

CS-3 Manual - part # 762701Revision 4.0

Page 29

Setting the Operating Hemisphere

Setting the Operating Hemisphere

It has been briefly explained why the operation of the CS-3 is divided in two

operating hemispheres in

Chapter 3, “Orienting Your CS-3” defines the operating hemispheres in more

detail, and provides instructions on how to orient the sensor head.

Here, we explain how the operator can control the setting of the operating

hemisphere. The Hemisphere Control switch is used to select the mode of

control. FOUR modes of control of the operating hemisphere setting are

available:

Manual Control

Two positions of the Hemisphere Control switch are used for the manual

control:

• in position "N" the CS-3 is set manually to operate in the northern operating

hemisphere.

• in position "S" the CS-3 is set manually to operate in the southern operating

hemisphere.

Chapter 1, “Getting Started with the CS-3”.

Operations

Electronic Control "R"

In the position "R" of the Hemisphere switch, the setting of the operating

hemisphere is actuated by the TTL compatible control voltage level at the pin

D of the four pin I/O connector: open circuited or high level voltage for

setting the operation in southern hemisphere, low level voltage or short

connection to the pin A for operation in northern operating hemisphere.

The control voltage could be supplied to the connector pins D and A through

a coaxial cable or a pair of twisted wires. The length of the cable or the wires

is not critical, as the control voltage is D.C. signal.

“A” - Automatic Hemisphere Switch

In the position “A” of the hemisphere switch, the CS-3 is operating in

automatic hemisphere switching mode.

2-

7

CS-3 Manual - part #762701 Revision 4.0

Page 30

Operating the CS-3 in the Field

Summary

If the CS-3 is properly oriented inside the active zone, defined by equations

(1) and (2) in

hemisphere is not set properly either of following will happen:

• There will be no Larmor signal at the output. By setting the operation to the

proper operating hemisphere, the Larmor signal will appear.

• There will be signal at the output, but not at the Larmor frequency. The false

magnetic field reading will be higher than the true reading, obtained when

the operating hemisphere setting is correct (about 60nT higher if the ambient

field is 60,000nT). In addition, it will be much noisier.

The reason for this is the existence of another resonant line, smaller in

amplitude and opposite in phase from the desired resonant signal. The

self-oscillation based on this signal can take place if the operating

hemisphere is wrongly selected. By setting the operation to the proper

operating hemisphere, the true, lower value and less noisier, magnetic field

reading will be obtained.

The described alternative modes of controlling the operating hemisphere of

the CS-3 are incompatible with the optional electronic control used in older

models of Varian and Scintrex magnetometers.

Chapter 3, “Orienting Your CS-3”, and the operating

The reversing of the magnetometer power supply polarity, used in these older

magnetometer models, had certain disadvantages and it was abandoned in the

CS-3. It is not difficult to change the existing installations by rewiring the

switch used for the power supply reversal and to make it perform level

control required by the electronic control mode "R", as described in this

section, or by automatic hemisphere switching.

2-

8

CS-3 Manual - part # 762701Revision 4.0

Page 31

Operating in the Presence of Spurious Magnetic Fields

Operating in the Presence of

Spurious Magnetic Fields

It is not uncommon for magnetometers to be required to operate in presence

of higher magnitude (over 50nT) alternating magnetic fields. These fields are

present close to the power lines, and in the survey airplanes equipped with

EM transmitters.

Before it is explained how the AC magnetic fields could upset the operation

of a real magnetometer, specifically the CS-3, it is worth mentioning that

readings of an ideal scalar magnetometer can be affected by an AC field. The

alternating field adds vectorially to the D.C. field to be measured.

Due to the nonlinearity of the vector addition (squaring and taking square

root) one observes an error. If the AC field b(coswt) has a component

b

(coswt) at right angle to the D.C. field B, one measures effectively the

p

mean value equal to B

For gaining more insight, the effective mean value is tabled for B=50000nT

and several values of b

=B[1+(bp/2B)2].

e

:

p

Operations

bp[nT] 0 100 200 500 10000

Be[nT] 50000.00 50000.05 50000.20 50001.25 50005.00

If the magnitude or the orientation of the AC field changes, the effective

mean value will change as well.

The CS-3, as explained the “Foreword” of this manual, is much less sensitive to

the spurious AC fields than either the proton precession (including

Overhauser) magnetometers or the locked oscillator optically pumped

magnetometers.

In the CS-3, the spurious AC field affects the precession of the magnetic

moment similarly to the H

A, “Theory of Operation”. If the AC field is large enough it will provoke

considerable light modulation at its own frequency. Further away the

spurious field frequency is from the Larmor frequency larger magnitude is

required to cause trouble. If this light modulation becomes comparable in

amplitude to the normal modulation induced by the feedback field H

operation of the CS-3 may be seriously affected.

field. More information is provided in Appendix

1

, the

1

2-

9

CS-3 Manual - part #762701 Revision 4.0

Page 32

Operating the CS-3 in the Field

It is important to mention that the disturbing effect is reduced, if the direction

of the spurious AC field is perpendicular to the sensor optical axis. It has

been experimentally determined that in this case the tested magnetometer

operated satisfactory in presence of the disturbing field with magnitude

3500nT peak at the frequency 3kHz.

The operating range of the tumble angle, in the plane perpendicular to the

direction of the spurious field, was reduced from 10°-85° (without the AC

field) to 25°-65° (with the AC field).

2-10

CS-3 Manual - part # 762701 Revision 4.0

Page 33

3

An ideal magnetometer placed in a constant field should produce a constant

frequency. A real optically pumped magnetometer, regardless of which

element it uses for its operation (cesium, rubidium, potassium or helium), and

regardless of which principle of operation it employs (self oscillating, locked

oscillator), produces a frequency which varies because:

• the unavoidable sensor noise makes the frequency jitter around the correct

• the output frequency is somewhat dependent on the magnetometer

The later dependency gives rise to the so-called heading error. Both, the

magnetometer noise and the heading error, are low due to proper design and

careful alignment of the magnetometer. Precautions should be taken that they

are sustained low by properly orienting the magnetometer sensor inside the

operating active zone.

Orienting Your CS-3

Orientation

frequency

orientation

The purpose of this section is to recommend how to achieve the proper

orientation without restricting established survey practices.

3-1

CS-3 Manual - part # 762701 Revision 4.0

Page 34

Orienting Your CS-3

Understanding the Active Zone of the CS-3

The sensor head assembly has a so called optical axis. The angle between the

positive direction of the optical axis and the direction of the magnetic field,

H

, is called the tumble angle, q.

o

As explained in Appendix A, “Theory of Operation”, there is no Larmor

signal generated in a self-oscillating magnetometer such as the CS-3 if

the optical axis is parallel to the magnetic field (the polar orientation,

q=0° or q=180°) or perpendicular to the field (the equatorial orientation,

q=90°).

The optical signal amplitude increases quite rapidly outside those two

orientations, and it has a broad maximum around

Note:

The Larmor signal amplitude generated inside the

sensor head is not to be confused with the signal

output of the CS-3 available either inside the

electronics assembly or at the output of the

PDAS-1000A Power Signal Coupler. The Larmor

signal amplitude at these outputs is electronically

kept constant, in spite of the variations of Larmor

signal itself and the amplitude variation of the

detection and amplification circuits.

q=40° or q=140°.

Experimental results confirm that the CS-3 will perform satisfactorily when

the angle

q is from:

10° < q < 85° (1)

and from

95° < q < 170° (2)

Equation (1) covers the magnetometer's active zone in the northern operating

hemisphere. This active zone is depicted in Figure A-2. The measured

magnetic field could be anywhere inside the space bound by the northern

polar dead zone cone and the equatorial dead zone "disk".

Note, that the polar sensor orientation occurs when the sensor optical axis is

parallel with the ambient magnetic field. In the northern polar orientation the

magnetic field and the sensor optical axis point in the same direction (

3-2

CS-3 Manual - part # 762701 Revision 4.0

q=0°),

Page 35

in the southern polar orientation they point in the opposite directions

(

q=180°). The equatorial orientation occurs when the optical axis is

perpendicular to the ambient magnetic field (

q=90°).

Equation (2) covers the magnetometer's active zone in the southern operating

hemisphere. This active zone is depicted in Figure A-3 on page A-4. The

magnetic field could be anywhere inside the space bound by the southern

polar dead zone and the equatorial dead zone.

The Earth's magnetic field vector is pointing into the ground in the Earth's

northern magnetic hemisphere, and out from the ground in the Earth's

southern magnetic hemisphere. It is parallel with the ground at the Earth's

magnetic equator. Note, that neither the Earth's geographic and magnetic

poles nor the equators exactly coincide, as it can be seen in Figure 5.

Orientation

Figure 5 - Earth magnetic field inclination angle (degrees)

The Hemisphere switch located on the CS-3 control panel allows setting of

the electronics for the proper operation in either northern or southern

operating hemisphere. The operating hemisphere setting could be either

manually controlled locally or electronically remotely controlled, as

explained in

Chapter 2, “Operating the CS-3 in the Field” and the topic

“Operating in the Presence of Spurious Magnetic Fields” on page 2-9.

3-3

CS-3 Manual - part #762701 Revision 4.0

Page 36

Orienting Your CS-3

Inside its operating range the CS-3 performance is acceptable, in regard to

measurement noise and heading errors. The measurement noise starts to

increases appreciably only when the magnetometer orientation comes close

to the boundary of the operating range given by equations (1) and (2). It is

about three times larger at the boundary of the operating range than it is at a

broad minimum centered around the middle of the operating zone. It is about

twice as large 5° away from the boundary of the operating zone.

Equally, the heading errors are low inside most of the operating zone, and

increase somewhat faster close to the polar dead zones, as shown on the

typical plot of the tumble heading error curve, Figure 6. Note that the actual

dead zones are very narrow: the polar and equatorial dead zones are

approximately 8° and 4° respectively. The actual operating zone is several

degrees larger than indicated by relationships (1) and (2).

The records in Figure 6a and b were made during the alignment of a CS-3

sensor at the Scintrex test facility 50 km north of Metro Toronto. The test

facility is constructed to have low magnetic signature and to be away from

man made magnetic interferences. The test facility consists of two buildings

separated 35 meters apart and well away from a rural road. The instrument

building contains all the test equipment and in the test building there are only

the magnetometer to be aligned and the reference magnetometer.

The test building is constructed of wood, fastened by aluminum nails. The

magnetometer sensor under test is mounted on a gimbal system, which is

remotely operated from the instrument building. The gimbal system

facilitates the rotation of the sensor around:

• the axis which passes through the center of the absorption cell and it is

perpendicular to both, the sensor optical axis and to the direction of the

ambient magnetic field - this arrangement is used for the tumble heading

error tests, and around

• the optical sensor axis - this arrangement is used for the spin heading error

tests.

3-4

CS-3 Manual - part # 762701 Revision 4.0

Page 37

Figure 6a - Plot of tumble heading error curve (northern hemisphere).

lot shows magnetic field (readout difference between a specific

sensor under test and an immobile reference) against tumble angle.

3-5

CS-3 Manual - part #762701 Revision 4.0

Orientation

Page 38

Orienting Your CS-3

Figure 6b - Plot of tumble heading error curve (southern hemisphere).

Plot shows magnetic field (readout difference between a specific

sensor under test and an immobile reference) against tumble angle.

3-6

CS-3 Manual - part # 762701 Revision 4.0

Page 39

Using a Strapped Down CS-3 for Surveys

Wherever a magnetic survey is conducted, the CS-3 Cesium Magnetometer

can be strapped rigidly to a survey vehicle, such as an airplane, a ship or an

automobile. It is convenient to use a simple, nonmagnetic gimbal platform

made by Scintrex, as this allows the magnetometer sensor to be precisely and

quickly oriented in azimuth and inclination.

The vehicle conducts a magnetic survey by moving on the well defined

survey grid consisting of parallel survey lines. If the survey lines are oriented

in the NW direction, for example, the survey vehicle may travel either in the

NW or SE directions shown in Figure 7

on page 3-9.

Several times during a survey day, a tie line may be used as shown in Figure

7. The tie line is generally flown at 90° to the survey line, which would be in

our example either in the NE or SW direction. The magnetometer sensor

orientation must be selected so that it performs well on the direction parallel

or antiparallel to the survey line, and parallel or antiparallel to the tie line,

which is perpendicular to the survey line.

Calculating the Tumble Angle

CS-3 sensor orientation is determined by two angles:

• the sensor azimuth, a, defined as the angle in the horizontal plane between

the horizontal projection of the sensor optical axis direction and the direction

of the magnetic north

Orientation

• the magnetometer sensor inclination, b, defined as the angle in the vertical

plane between the horizontal line and the magnetometer optical axis.

• The ambient magnetic field inclination, g, is defined as the angle between the

horizontal and the field direction. The Earth's magnetic field inclination is a

positive angle in the range from 0° to 90° in the Earth's Northern Magnetic

Hemisphere and negative in the Southern Hemisphere. Its dependence on the

geographic location is shown in Figure 5

on page 3-3.

For a given sensor orientation and magnetic field inclination, the angle

between the sensor and the magnetic field, i.e. the tumble angle,

q, can be

calculated from the following equation:

q = arccos(cosa x cosb x cosg + sinb x sing ) (3)

3-7

CS-3 Manual - part #762701 Revision 4.0

Page 40

Orienting Your CS-3

This equation can be used to find out whether the magnetometer sensor is

inside its active zones specified by equations (1) and (2). It is a good idea to

reduce the operating active zone by the amount of the anticipated aircraft

motion. In general, airborne magnetic surveys are conducted in calmer

weather to keep the aircraft motion to within 5° in pitch, roll and yaw.

In this case, with the additional allowance we must orient the magnetometer

sensor so that the tumble angle,

hemisphere the relationship:

15° > q > 80° (4)

and in the southern operating hemisphere the relationship

100° > q > 165° (5)

Inside this operating zone the magnetometer noise will increase by about a

factor of two from the minimum value at

error will be inside the specified limits of +/-0.25nT.

As it will be seen in the next section, orienting the CS-3 is simple: with

only two settings one can survey the entire Earth's surface. However, in

order to gain more insight, the tumble angle, equation (3), is evaluated, over

the entire range of the magnetic field inclinations, for two sets of sensor

azimuths, and five values of sensor inclinations. The results are shown on

graphs, Figures 7 to 16.

q, satisfies in the northern operating

q=40° or q=140°, and the heading

Tumble angles from 0° to 90° indicate that the magnetometer has to be set for

operation in the northern operating hemisphere. Tumble angles from 90° to

180° indicate that the magnetometer has to be set for operation in the

southern operating hemisphere. As indicated in

Chapter 1, “Getting Started”,

the operating hemisphere setting is performed manually or electronically.

In accordance with the equations (4) and (5), the polar dead zones are from

0° to 15° and from 165° to 180°. The equatorial dead zones are from 80° to

100°. The azimuth values in each set differ by 90°, to comply with the

requirement that both, the flight lines and the perpendicular tie lines, are

flown in two opposite directions.

The sensor inclination should be selected so that the sensor will not be in any

of dead zones for either one of these four azimuths and over the range of

magnetic field inclinations expected in the surveyed area. Comments on

advantages and disadvantages of five representative sensor orientations

follow.

3-8

CS-3 Manual - part # 762701 Revision 4.0

Page 41

Sensor Inclination 90°

From the graph in Figure 8, you can determine the value of the tumble angle

(the angle between the magnetic field and the sensor optical axis) for all

possible values of the magnetic field inclination. Because the sensor is

vertical, the tumble angle is independent of the sensor azimuth (one curve is

valid for all azimuths).

The operating range of the magnetic field inclinations, for which the tumble

angle is inside the active operating zone, is indicated by horizontal arrows in

the graph. The sensor orientation shown in the Figure 7 is very useful

because it covers most of the Earth's surface with the exception of polar and

equatorial regions.

Orientation

Figure 7 - Plot of tumble angle versus magnetic field

inclination. Sensor inclination is 90°. Any sensor azimuth

can be used.

CS-3 Manual - part #762701 Revision 4.0

3-9

Page 42

Orienting Your CS-3

Sensor Inclination 67.5°

Sensor azimuth values used in Figure 8 are 0, 90, 180 and 270 degrees.

Please note, that the sensor azimuth may differ from the flight direction

azimuth, as the sensor axis may have to be set out of the airplane axis. For

example, if the line (flight) direction is NE, and the sensor azimuth is to be

90°, then the sensor axis is to be rotated by 45° clockwise from the airplane

axis. The particular sensor orientation shown in Figure 8 does not offer any

advantages.

Figure 8 - Plot of tumble angle versus magnetic field

inclination. Sensor inclination is 67.5°. Sensor azimuths are

0, 90, 180 and 270 degrees.

A more advantageous orientation is one with the same sensor inclination, but

different azimuths, Figure 9. Large areas extending from either pole down to

the field inclination of 25° could be surveyed using this orientation.

However, the operation is at the edge of the active zone for the magnetic field

inclinations around +/-75°.

3-10

CS-3 Manual - part # 762701 Revision 4.0

Page 43

Figure 9 - Plot of tumble angle versus magnetic field

inclination. Sensor inclination is 67.5°. Sensor azimuths are

45, 135, 225 and 315 degrees.

Sensor Inclination 47.5°

Tumble angles for the sensor azimuths parallel or perpendicular to the

magnetic field direction could be determined from the graph in Figure 10.

This orientation could be used in surveying polar regions. If the azimuth of

90° and 270° are used for flying normal survey lines, the tumble angle is

same for both up-the-line and down-the-line flying, and it is well inside the

active zone. The sensor orientation shown in Figure 11 offers the advantage

of use for surveys in ether polar or equatorial regions.

3-11

CS-3 Manual - part # 762701 Revision 4.0

Orientation

Page 44

Orienting Your CS-3

Figure 10 - Plot of tumble angle versus magnetic field

inclination. Sensor inclination is 47.5°. Sensor azimuths are

0, 90, 180 and 270 degrees.

Please note, that, when flying in equatorial regions, the sensor operating

hemisphere has to be changed from north to south when the flight direction,

on either normal or tie survey lines, is changed. The same applies for any

other orientation used for surveying in equatorial magnetic field regions.

3-12

CS-3 Manual - part # 762701 Revision 4.0

Page 45

Figure 11 - Plot of tumble angle versus magnetic field

inclination. Sensor inclination is 47.5°. Sensor azimuths are

45, 135, 225 and 315 degrees.

For completeness, the orientation with azimuths between those shown in

Figures 10 and 11 is shown in Figure 12. As it can be seen, it does not offer

any additional advantages.

3-13

CS-3 Manual - part # 762701 Revision 4.0

Orientation

Page 46

Orienting Your CS-3

Figure 12 - Plot of tumble angle versus magnetic field

inclination. Sensor inclination is 47.5°. Sensor azimuths are

23, 113, 203 and 293 degrees.

3-14

CS-3 Manual - part # 762701 Revision 4.0

Page 47

Sensor Inclination 22.5°

The orientation shown in Figure 13 does not offer any advantages.

Figure 13 - Plot of tumble angle versus magnetic field

inclination. Sensor inclination is 22.5°. Sensor azimuths are

0, 90, 180 and 270 degrees.

Orientation

The orientation in Figure 14 offers, in comparison with the orientation in

Figure 11, an extension of surveying into regions well away from the

magnetic equator at the expense of reduction in the polar regions.

3-15

CS-3 Manual - part # 762701 Revision 4.0

Page 48

Orienting Your CS-3

Figure 14 - Plot of tumble angle versus magnetic field

inclination. Sensor inclination is 22.5°. Sensor azimuths are

45, 135, 225 and 315 degrees.

3-16

CS-3 Manual - part # 762701 Revision 4.0

Page 49

Sensor Inclination 0°

The orientation in Figure 15 is not acceptable, as the tie lines are in dead

zones.

Orientation

Figure 15 - Plot of tumble angle versus magnetic field

inclination. Sensor inclination is 0°. Sensor azimuths are

0, 90, 180 and 270 degrees.

The orientation shown in Figure 16 has the advantage of covering the entire

Earth except the polar regions. For large area, up to the field inclination of

+/-45°, the sensor operates far from the dead zones, but the sensor operating

hemisphere has to be changed when the flight direction is reversed.

3-17

CS-3 Manual - part # 762701 Revision 4.0

Page 50

Orienting Your CS-3

Figure 16 - Plot of tumble angle versus magnetic field

inclination. Sensor inclination is 0°. Sensor azimuths are

45, 135, 225 and 315 degrees.

Recommended Survey Orientations

Only two orientations are sufficient for surveying along two sets of

perpendicular lines over the entire Earth's surface:

1. The orientation in Figure 11, with the sensor inclination 45° and azimuths

45, 135, 225, 315 degrees, for polar and equatorial regions, and

2. The orientation in Figure 7 on page 3-9 with sensor inclination 90 degrees,

for the regions between polar and equatorial regions. These orientations

provide enough overlap at both ends: regions with field inclinations N/S

from 53° to 75° and inclinations N/S from 10° to 22° could be surveyed by

either sensor orientation setting 1) or 2).

3-18

CS-3 Manual - part # 762701 Revision 4.0

Page 51

In the overlap regions the tumble angle comes close to boundary of the dead

zones.

For a larger safety margin following alternate orientation is strongly

recommended:

3. The operation around the magnetic equator, extending well into the regions

with the magnetic field inclinations up to 45°, could be covered with the

sensor inclination 0° and azimuths 45, 135, 225, 315 degrees (see Figure

17).

If the above three orientations are used in both Earth's magnetic hemispheres

as follows:

• the orientation a) for the field inclinations from 60° to 90°

• the orientation b) for the field inclinations from 35° to 60°

• the orientation c) for the field inclinations from 0° to 35°

then:

1. the minimum safety margin to the boundary of the operating range is 14°

and it will occur for the field inclination 62°

2. the safety margin less than 15° will occur only for the range of the field

inclinations from 60° to 65°

3. the safety margin less than 20° will occur for the range of the field inclina-

tions from 55° to 78°.

Note:

The additional allowance of 5° has been already

subtracted from the essential operating range

specified by relationships (1) and (2) to arrive to the

reduced operating range, relationships (4) and (5)

for which the above analysis applies.

3-19

CS-3 Manual - part # 762701 Revision 4.0

Orientation

Page 52

Orienting Your CS-3

Comparison with the Locked Oscillator

Optically pumped magnetometers using the locked oscillator principle of

operation exhibit two distinct features as far as the operating range is

concerned:

• there is no polar dead zone, only the equatorial dead zone is present

• the magnetometer operates in both magnetic hemispheres of the ambient

field without any adjustment.

Modern self-oscillating magnetometers, like the CS-3 have overcome the

shortcoming of two operating hemispheres by incorporating an effective

electronic control of the operating hemisphere selection.

The asset of having only one dead zone was claimed to be a valuable

operational advantage "without orientation problems associated with

self-oscillating alkali vapor magnetometers" (e.g. EG&G brochure for the

G-833 Helium Magnetometer). The following rigorous analysis will prove

that the CS-3 has superior orienting capabilities.

The operating range of the locked oscillator extends 65° from the polar

orientations according to the relationships:

0° < q< 65° (4)

and from

115° < q< 180° (5)

It has been experimentally determined by impartial evaluators that inside this

operating zone the magnetometer noise will increase by about a factor of

three from the minimum value at

q=0° or q=180°. Passed this range, noise

increases rapidly, e.g. at 70° from the polar orientation the noise is 7-8 times

larger than in the polar orientation.

The graphs shown in Figures 7 to 16 apply for the locked oscillator as well

while taking into the account the operating range specified by relationship (4)

and (5).

3-20

CS-3 Manual - part # 762701 Revision 4.0

Page 53

Only two orientations are useful and they are sufficient for surveying along

two sets of perpendicular lines over the entire Earth's surface:

1. the orientation in Figure 7, with sensor inclination 90 degrees, for the

ambient field inclinations from 25° to 90°.

2. the operation around the magnetic equator, extending well into the regions

with the magnetic field inclinations up to 55°, is covered with the sensor

inclination 0° and azimuths 45, 135, 225, 315 degrees, Figure 16.

If the above orientations are used in both Earth's magnetic hemispheres as

follows:

• the orientation 1) for the field inclinations from 35° to 90°

• the orientation 2) for the field inclinations from 0° to 35°

then:

i) the minimum safety margin to the boundary of the operating range is 10°

and it will occur for the field inclination 35°

ii) the safety margin less than 15° will occur only for the range of the field

inclinations from 25° to 40°

iii) the safety margin less than 20° will occur for the range of the field

inclinations from 0° to 45°.

• By comparing the criteria i) to iii) above with the same criteria for the CS-3,

one can see that the CS-3 offers superior worldwide orienting capabilities.

Orientation

3-21

CS-3 Manual - part # 762701 Revision 4.0

Page 54

Orienting Your CS-3

3-22

CS-3 Manual - part # 762701 Revision 4.0

Page 55

4

No maintenance is required. Both, the sensor head and the sensor electronics

are enclosed in sealed, splashproof housings.

Maintaining Your CS-3 and Trouble-shooting

Important:

Care must be exercised in handling the CS-3,

especially the sensor head, which contains delicate

optical components.

vibrations should be avoided.

Warning :

BEFORE THE POWER IS APPLIED TO THE

CS-3, THE CONNECTOR AT THE END OF THE

SENSOR HEAD CABLE HAS TO BE

CONNECTED TO THE MATING SOCKET

LOCATED AT THE ELECTRONICS BOX SIDE

PLATE. THIS CONNECTOR SHOULD NEVER

BE DISCONNECTED WHILE THE POWER IS

APPLIED TO THE CS-3. DOING SO WILL

RESULT IN SERIOUS DAMAGE TO THE RF

EXCITER AND WILL VOID THE WARRANTY.

Excessive shocks and

Maintenance

4-

1

CS-3 Manual - part # 762701 Revision 4.0

Page 56

Maintaining Your CS-3 and Trouble-shooting

Trouble-shooting

Despite the fact that your CS-3 is a very reliable instrument, there can be two

circumstances where problems may occur. The following table lists some of

these problems and their attempted solution. However, please do not hesitate

to contact your nearest Scintrex office. See

page 5-3 for the office nearest you.

Problem Possible cause Possible solution

No Larmor signal

output

The indication that the

CS-3 is receiving

power is glowing of the

green light. If the light

is not glowing, and the

power is supplied, then

the fuse may be blown.

The power is not

supplied to the sensor

electronics.

Power supply as

measured at points

indicated above is not

in the range of 24V to

35V DC.

“Warranty and Repair” on

Check that power is supplied by

measuring the voltage at either the

I/O connector (pin B positive, pin A

negative) or the power TNC coaxial

connector (center positive), and

then replace the fuse by undoing

the fuse cover.

The fuse used is Littlefuse type

Micro 273 003, 125V AC/DC, 3A.

Check power supply.

Check power supply. Note, a lower

supply voltage is insufficient for

proper operation, while a higher

supply voltage will result in

excessive dissipation of the internal

voltage regulators, and may cause

permanent damage.

Larmor output

(readings) are

noisy.

4-

2

CS-3 Manual - part # 762701 Revision 4.0

Current supply not in

range.

Sensor head oriented

in the active zone.

Possible conditions as

noted for no Larmor

signal output.

The supply current after 15 minutes

warm-up is in the range 0.5 A

(ambient temperature close to

50°C) to 0.8A (ambient temperature

close to -40°C).

Refer to the Orienting the CS-3

chapter.

Refer to above solutions.

Page 57

Trouble-shooting

There are large

spurious AC fields

present.

Excessive field

gradients across

sensor head.

Ambient magnetic

noise is low.

Check for possible sources of local

AC fields.

Check for possible sources of

gradients.

Check Power supply and

Orientation.

If all of the above conditions are met and Larmor output continues to be

either not present or noisy, ship back the CS-3 to Scintrex for repair.

4-

3

CS-3 Manual - part #762701 Revision 4.0

Maintenance

Page 58

Maintaining Your CS-3 and Trouble-shooting

4-

4

CS-3 Manual - part # 762701 Revision 4.0

Page 59

Reference

5

Reference Information

CS-3 Technical Specifications

Measurement Range 15,000nT to 100,000nT

Orientation Range

Northern Operating Hemisphere Sensor optical head axis 10° to 85° to the

ambient field direction

Southern Operating Hemisphere Sensor optical head axis 95° to 170° to the

ambient field direction

Heading Error +/- 0.25nT inside the optical axis to the field

direction angle range 15° to 75° and 105° to

165°

Noise Envelope 0.002nT peak-to-peak in 0.01 to 1 Hz

bandwidth

Gradient Tolerance 40,000 nT/meter

5-1

CS-3 Manual - part # 762701 Revision 4.0

Page 60

Reference Information

Outputs Continuous signals at the Larmor frequency

which is proportional to the magnetic field

(proportionality constant 3.498577 Hz/nT)

Squarewave signal at the I/O connector TTL,

CMOS compatible

Sinewave signal amplitude modulated on the

power supply voltage

Information Bandwidth Limited by the magnetometer processor used

Operating Temperature -40°C to +50°C

Humidity Up to 100% splashproof

Supply Voltage 24 to 35 Volts DC

Supply Current Approximately 1.5A at start-up, decreasing

to 0.5A at 20°C, larger at lower temperatures

Power Consumption 15W at 20°C, more at lower temperature or

during warm-up

Warm-up Time Approximately 15 minutes at -40°C

Control of the Operating

Hemisphere

• Automatic

• Manual switch control

• Electronic control actuated by control

voltage level (TTL/CMOS) at the I/O

connector Sensor Head to Electronics

Interconnecting Cable (standard length

3m and optional 1 to 10 m) with

connector at the sensor electronics side.

Signature of electronics less than 0.1nT

in any orientation at 3m away from the

sensor head

Sensor Head Diameter: 63mm (2.5”) and Length: 160mm

(6.3”)

Weigh t 1.15 kg (2.6 lb.)

Sensor Electronics Diameter: 63 mm. (2.5”) and Length: 350

mm (1.8”)

Weigh t 1.5 kg (3.3 lb.)

5-

2

CS-3 Manual - part # 762701 Revision 4.0

Page 61

Instrument Parts List

Instrument Parts List

CS-3 Standard Accessories

Item Description

CS-3 Magnetometer (includes:) 762-010

Case

Sensor

Electronic processing unit

Warranty and Repair

Warranty

Reference

SCINTREX

Part Number

All Scintrex equipment, with the exception of consumable items, is

warranted against defects in materials and workmanship for a period of one

year from the date of shipment from our plant. Should any defects become

evident under normal use during the warranty period, Scintrex will make the

necessary repairs free of charge.

This warranty does not cover damage due to misuse or accident and may be

voided if the instrument console is opened or tampered with by persons not

authorized by Scintrex.

5-3

CS-3 Manual - part #762701 Revision 4.0

Page 62

Reference Information

Repair

When To Ship the Unit

Please do not ship your instrument for repair until have communicated the

nature of the problem to our Customer Service Department by e-mail,

telephone, facsimile or correspondence. Our Customer Service Department

may suggest certain simple tests or steps for you to do which may solve your

problem without the time and expense involved in shipping the instrument

back to Scintrex for repair. If the problem cannot be resolved, our personnel

will request that you send the instrument to our plant for the necessary

repairs.

Description of the Problem

When you describe the problem, please include the following information:

• the symptoms of the problem,

• how the problem started,

• if the problem is constant, intermittent or repeatable,

• if constant, under what conditions does it occur,

• any printouts demonstrating the problem

Shipping Instructions

No instrument will be accepted for repair unless it is shipped prepaid. After

repair, it will be returned

with Scintrex. Please mention the instrument’s serial number in all

communications regarding equipment leased or purchased from Scintrex.

Head Office

Instruments within Canada should be shipped to:

SCINTREX Limited

222 Snidercroft Road

5-

4

CS-3 Manual - part # 762701 Revision 4.0

collect, unless other arrangements have been made

Page 63

Warranty and Repair

Unit #1

Concord, Ontario

L4K 2K1

tel: +1 905 669 2280

fax: +1 905 669 9899

e-mail: service@scintrexltd.com

Reference

5-5

CS-3 Manual - part #762701 Revision 4.0

Page 64

Reference Information

5-

6

CS-3 Manual - part # 762701 Revision 4.0

Page 65

Theory of

A

System Overview

As shown below, the CS-3 sensor consists of a sensor head with cable and

sensor electronics.

Theory

Operation

Figure A-1 CS-3 Sensor Head and Electronics

The sensor head has an electrodeless discharge lamp (containing cesium

vapor) and absorption cell. Electrical heaters bring the lamp and the cell to

optimum operating temperatures with control and driving circuits located in

the electronics console. Heating currents are supplied to the sensor head

through the interconnecting cable.

A-1

CS-3 Manual - part #762701 Revision 4.0

Page 66

When operating, an RF oscillator in the electronics console provides RF

power to a lamp exciter in the sensor head and the radio frequency (RF) field

produces a corresponding resonant optical radiation (light).

The light radiating from the cesium lamp is collimated by a lens. The light

propagates in the direction of the sensor optical axis (as shown in Figure A-1)

and passes through an interference filter which selects only the cesium D1

spectral line. The light is subsequently polarized in a split, right/left hand

circular polarizer before it is allowed to optically excite cesium vapor in the

absorption cell.

The narrow bandwidth resonant light causes momentary alignment

(polarization) of the atomic magnetic moments to the direction of the

ambient magnetic field. The resonant light "optically pumps" the cesium

atoms to a higher energy state. (Note that the polarizing light beam has to be

oriented in the general direction of the ambient field to be effective.)

Large numbers of cesium atoms can be polarized by optical pumping and

then induced to precess coherently in phase around the ambient field by

means of a small magnetic field, H

. This small magnetic field is transverse

1

to the ambient field and alternating at the Larmor frequency.

The H1 field is produced by a coil in the CS-3. The coil is coaxial with the

sensor optical axis and wound around the absorption cell. Polarized resonant

light perpendicular to the ambient magnetic field detects the precession. This

light is alternately more or less absorbed, depending on the instantaneous

orientation of the polarization.

In the CS-3, this probing light is the perpendicular component of the resonant

light beam. If the modulation of through-the-absorption-cell transmitted light

is detected with the photosensitive detector, and the resulting Larmor signal

is sufficiently amplified and phase-shifted before being fed back to the H

coil, then a closed loop self-oscillating circuit results.

The resonance occurs at the Larmor frequency, which in weak fields, e.g. the

Earth's magnetic field, is precisely linear with the field in which the

absorption cell is located. For the cesium 133 the proportionality constant

(gyromagnetic constant) is 3.498577 Hz per nT.

As indicated, different components of the same resonant light beam perform

two functions:

• the component parallel to the ambient field performs the optical pumping

• the perpendicular component detects the coherent precession.

A-

2

CS-3 Manual - part # 762701 Revision 4.0

1

Page 67

Therefore, no pumping is taking place if the light beam (the optical axis) is

perpendicular to the ambient field (the equatorial orientation) and

consequently the sensor is not operating. Equally, no light modulation is

taking place if the light beam is parallel with the ambient field (the polar