1 OF 4

www.scintex.com.au | sales@scintex.com.au

Model: SPKP12V40 & SPKP24V40

Portable Diesel Transfer Pump Kit

12V & 24V DC

User’s Manual

2 OF 4

WARNING: Read carefully and understand all

INSTRUCTIONS before operating. Failure to follow the safety

instructions and other basic safety precautions may result in

serious personal injury.

A. DECLARATION OF CONFORMITY

DECLARATION OF CONFORMITY

IN CONFORMANCE WITH THE DIRECTIVES

98/37/EEC (MACHINERY • 97/23/EEC (PRESSURE VESSELS)

89/336/EEC (ELECTOR-MAGNETIC COMPATIBILITY) AND FURTHER MODIFICATIONS

2000/14 DIRECTIVE ON LIMITATION OF NOISE

B. MACHINE DESCRIPTION

The fuel box is made from high density polyethylene material. 1PC DC pump equipped with the suction

hose, delivery hose and nozzle are fixed and installed internally to the box. For more convenient operation,

the pump and fittings are connected by rotating swivel connectors.

PUMP: self-priming, volumetric, rotating vane pump, equipped with by-pass valve.

MOTOR: Brush motor, DC, low tension with intermittent cycle, closed type in protection class IP55, directly

flanged to the pump body.

SUCTION TUBING:

- Minimum recommended nominal diameter: 3/4”

- Nominal recommended pressure: 10bar/145PSI

- Use hose suitable for suction pressure

DELIVERY TUBING:

- Minimum recommended nominal diameter: 3/4”

- Nominal recommended pressure: 10bar/145PSI

Nozzle:

- Aluminium Manual nozzle

- Connection: 3/4’’

3 OF 4

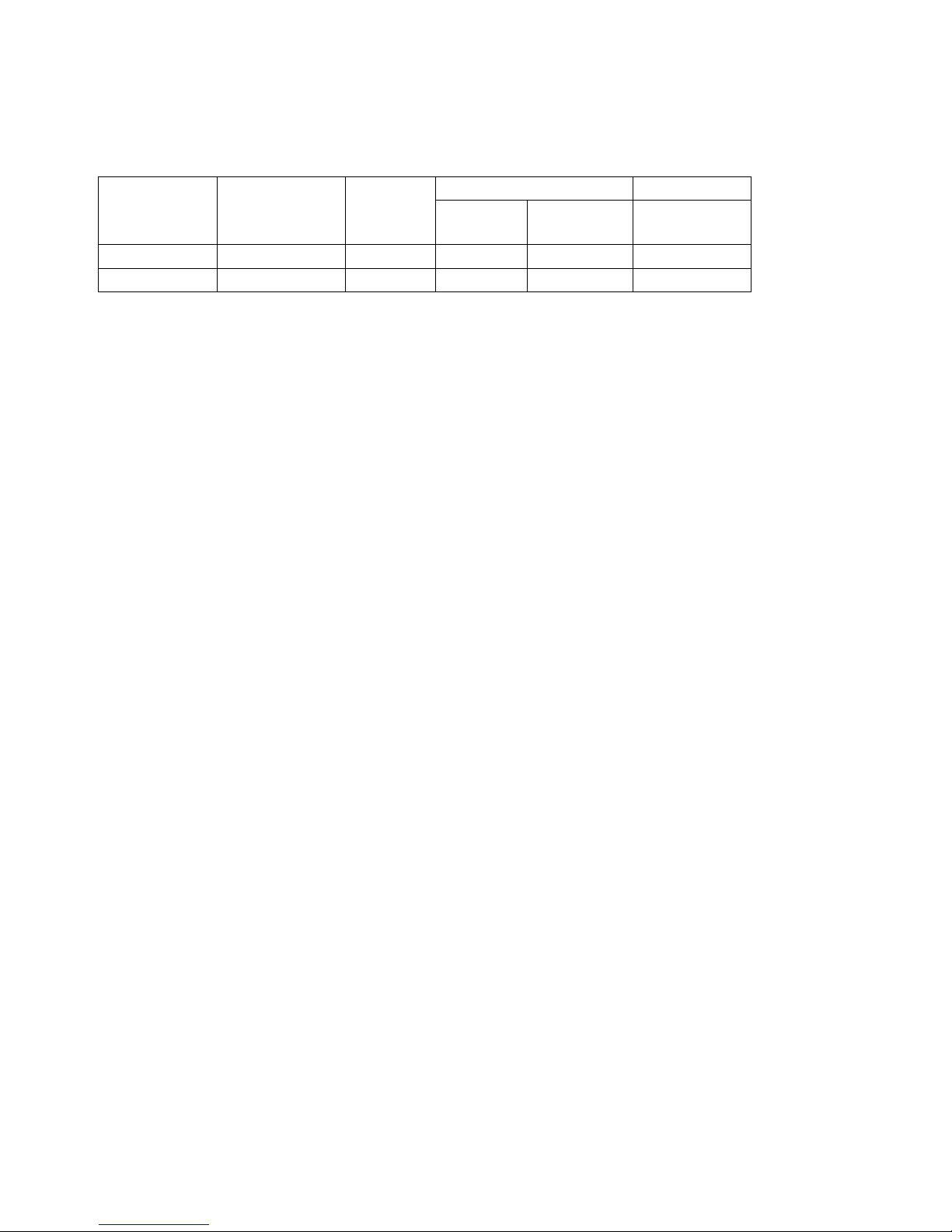

C. TECHNICAL DATA

C1. Electrical Data

Kit Model PUMP MODEL FUSES

ELECTRICAL POWER FLOW RATE

Current Voltage(V) GPM/LPM

SPKP12V40

SPT12V40LPM 25 DC 12 10/40

SPKP24V40

SPT24V40LPM 15 DC 24 10/40

D. OPERATING CONDITIONS

Refer to pump manuals for SPT12V40LPM & SPT24V40LPM

E. Installation and Operation

The pump box includes 1pc DC pump, connecters, suction hose with filter, delivery hose and manual

nozzle.

1 ) Before using, put the pump box on level footing. Then take out the nozzle and delivery hose, rotating

the hose connectors to the best operation position.

2 ) Take out the suction hose and rotating the hose connectors to best operation position put the suction

hose with filter to the drum bottom.

3 ) Check all hoses and fittings.

4 ) After using, take out the suction hose and stand for several minutes to drain fuel in the hose.

5 ) At the same time, start the pump and run dry for several seconds to drain remaining fuel.

6 ) After emptying the fuel in the hose and pump, please retract the suction hose to the box then retract

the nozzle and delivery hose for better storing and moving.

NOTE : Please refer to the Pump Manuals for applications and more details.

4 OF 4

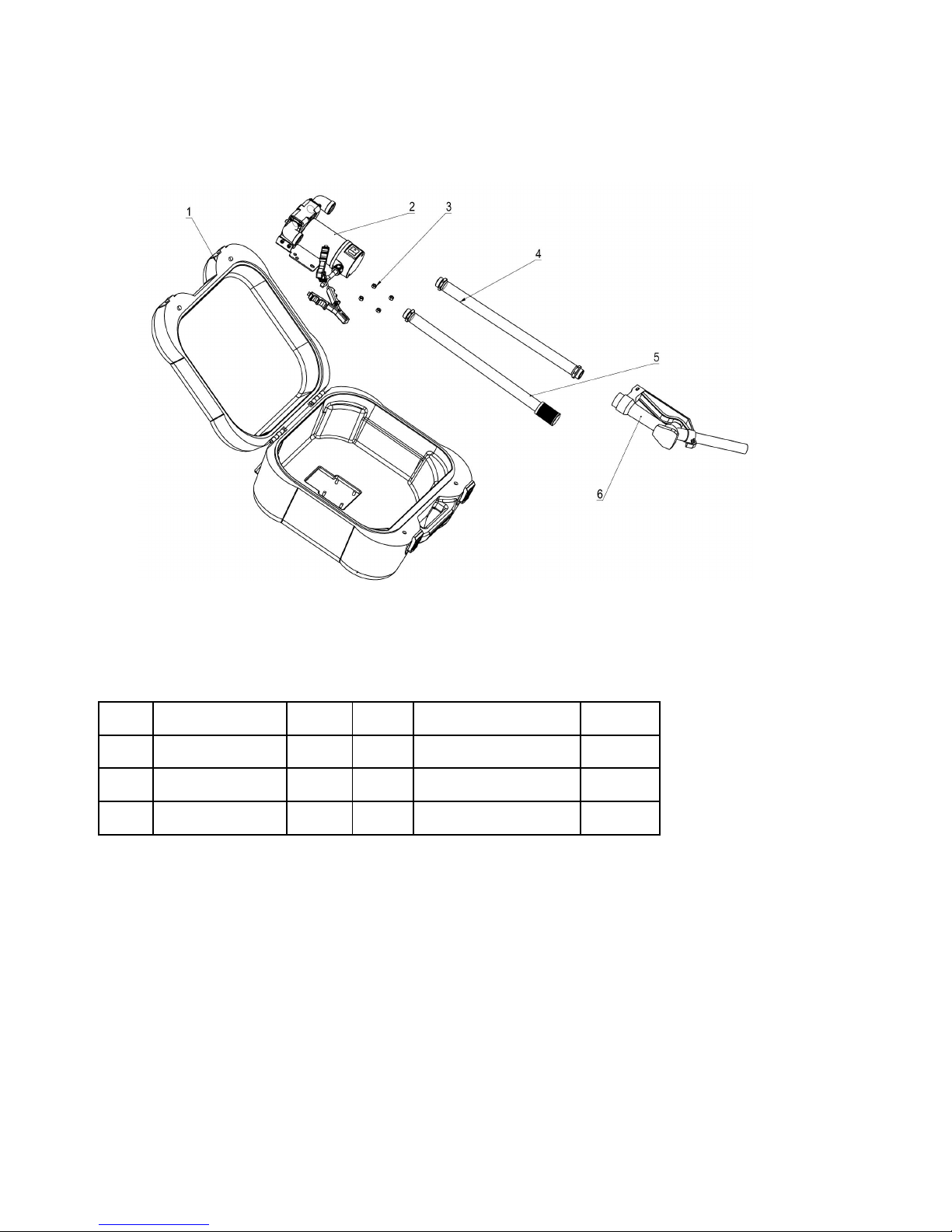

F. DIAGRAM AND PARTS LIST

1. MODELS:

SPKP24V40 & SPKP24V40

NO. Description QTY. NO. Description QTY.

1

PLASTIC BOX

1 4 DELIVERY HOSES 1

2

PUMP

1 5 SUCTION HOSES 1

3 SCREW 4 6 NOZZLE 1

Loading...

Loading...