7’’ Square Hotplate

12300245

User Manual

HP550-S

LED Digital 7”Square Hotplate

Please read the User Manual carefully before use, and follow all operating and

safety instructions!

We cannot be responsible to inform at real-time if the outline and specifications are

subject to change for improvement.

Contents

Preface ................................................................................. 1

Service ................................................................................. 1

Warranty .............................................................................. 1

1. Safety Instructions ....................................................... 2

2. Proper use .................................................................... 3

3. Inspection .................................................................... 3

3.1 Receiving Inspection ............................................. 3

3.2 Listing of Items ..................................................... 3

4. Control ......................................................................... 4

4.1 Control elements .................................................... 4

4.2 Display................................................................... 5

5. Trial run ....................................................................... 5

6. Working with external temperature sensor .................. 6

7. Residual heat warning ................................................. 6

8. Faults ........................................................................... 7

9. Maintenance and Cleaning .......................................... 7

10. Associated standards and regulations .......................... 8

11. Specifications .............................................................. 9

12. Ordering information ................................................. 10

1

7” Square Hotplate

Preface

Welcome to the “7” Square Hotplate User Manual”. Users

should read this Manual carefully, follow the instructions

and procedures, and be aware of all the cautions when using

this instrument.

Service

When help needed, you can always contact the Service

Department of manufacturer for technical support.

Please provide the customer care representative with the

following information:

• Serial number(on the rear panel)

• Certification

• Description of problem (i.e., hardware or software)

• Methods and procedures adopted to resolve the problems

• Your contact information

Warranty

This instrument is warranted to be free from defects in

materials and workmanship under normal use and service,

for a period of 24 months from the date of invoice. The

warranty is extended only to the original purchaser. It shall

not apply to any product or parts which have been damaged

on account of improper installation, improper connections,

misuse, accident or abnormal conditions of operation.

For claims under the warranty please contact your local

supplier. You may also send the instrument directly to

manufacturer, enclosing the invoice copy and by giving

reasons for the claim.

2

7” Square Hotplate

1. Safety Instructions

Warning!

• Read the operating instructions carefully

before use.

• Ensure that only trained staff works with the

instrument.

Risk of burn!

• Caution when touch the housing parts and

the hotplate which can reach temperature of

550°C.

• Pay attention to the residual heat after

switching off.

Protective ground contact!

• Make sure that socket must be grounded

(protective ground contact) before use.

• When working wear personal safety guards to avoid the

risk from:

- Release of toxic or combustible gases

• Set up the instrument in a spacious are on a stable, clean,

non-slip, dry and fireproof surface. Do not operate the

instrument in explosive atmospheres, with hazardous

substances or under water.

• Temperature must always be set to at least 50℃ lower

than the fire point of the media used.

• Be aware of hazards due to unsafe container.

• Process pathogenic materials only in closed vessels.

• Check the instrument and accessories prior to each use.

Do not use damaged components. Safe operation is only

guaranteed with the accessories described in the

“Accessories” chapter. Accessories must be securely

attached to the device and can not come off by themselves.

Always disconnect the plug before fitting accessories.

• When the external temperature sensor needed, the tip of

the measuring sensor must be at least 5-10mm from vessel

bottom and wall.

• The instrument can only be disconnected from the main

power supply by pulling out the main or the connector plug.

• The voltage stated on the label must correspond to the

main power supply.

• Ensure that the main power supply cable does not touch

the hotplate. Do not cover the device.

• Forbid to put pressure and over heat media on the surface

of glass ceramic, that can be caused surface broken.

• The instrument may only be opened by experts.

3

7” Square Hotplate

2. Proper use

The instrument is designed for mixing and/or heating

liquids in schools, laboratories or factories.

• Observe the minimum distances between the devices,

between the device and the wall and above the assembly

(min. 100 mm)

>100mm

>100mm

Figure 1

This device is not suitable for using in residential areas or

other constraints mentioned in Chapter 1.

3. Inspection

3.1 Receiving Inspection

Unpack the equipment carefully and check for any damages

which may have arisen during transport. Please contact

manufacturer/supplier for technical support.

Note:

If there is any apparent damage to the system,

please do not plug it into the power line.

3.2 Listing of Items

The package includes the following items:

Items

Qty

Main unit

1

Power cable

1

User Manual

1

Table 1

4

7” Square Hotplate

4. Control

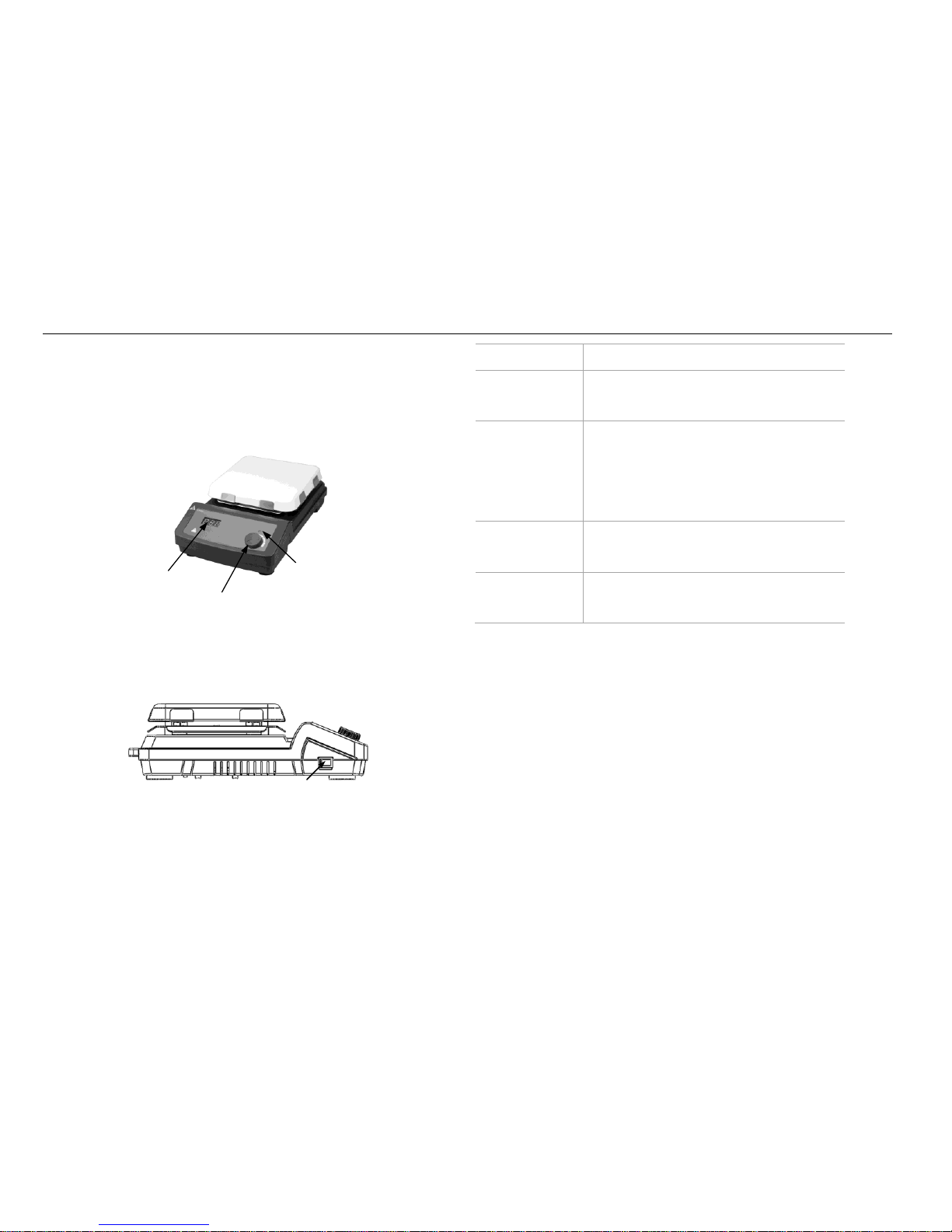

4.1 Control elements

LED Heat

Temperature Control Knob

LED Display

Figure 3

Power Switch

Figure 4

Items

Descriptions

Temperature

control knob

The heating function is switched

ON or OFF by rotating knob.

LED Display

If rotate the heating knob, LED

displays the temperature setting

value and shift to real value in the

duration of 5 seconds.

LED Heat

When the heating function is

switched ON, the LED Heat flash.

Power

Switch

Switch ON or OFF the instrument.

Table 2

5

7” Square Hotplate

4.2 Display

Display area

Figure 5

Display

Descriptions

Display

area

When the heating function is switched ON and

rotate the stirring knob, LED displays the

temperature setting value and shifts to real value

in 5 seconds.

When the heating function is switched OFF and

the hotplate temperature is still above 50℃,

LED displays Hot, otherwise LED displays 0.

5. Trial run

• Make sure the required operating voltage and power

supply voltage match.

• Ensure the socket must be properly grounded.

• Plug in the power cable,ensure the power is on and begin

initializing.

• Place vessel on the work plate.

• Set the target temperature and start heating.

• Stop the heating functions.

If these operations above are normal, the device is ready to

operate. If these operations are not normal, the device may

be damaged during transportation, please contact

manufacturer/supplier for technical support.

6

7” Square Hotplate

6. Working with external

temperature sensor

Figure 6

The external temperature sensor PT1000 is the

Manufacture’s standard accessory. If the sensor is plugged

in and rotate the heating knob, LED displays the

temperature setting value and shifts to real value in 5

seconds. Safe circuit controls hotplate temperature.

Comparing with the temperature control of the hotplate, the

external temperature sensor can control the medium’s

temperature more precisely. The heating function will be

stopped automatically under abnormal conditions. Please

operate follow the instructions below:

• Switch OFF the instrument.

• Ensure the external temperature sensors is inserted in

the media heated.

• Switch ON the instrument and run heating function.

If the heating function did not work, please contact

manufacturer/supplier for technical support.

7. Residual heat warning

In order to prevent the risk of burns from a hotplate, digital

hotplate has a residual heat warning function. When the

heating function is switched off and the heating plate

temperature is still above 50°C, “Hot” will flash to warn

that there is a hazard of burns from the hotplate. When the

hotplate temperature drops to below 50°C, the unit will

automatically switch off. If users want to turn off the LCD

or LED immediately, just pull out the plug directly. When

the plug is pulled out, the residual heat warning function

cannot be run.

7

7” Square Hotplate

8. Faults

• Instruments can’t be power ON

- Check whether the power line is unplugged

- Check whether the fuse is broken or loose

• Fault in power on self test

- Switch OFF the unit, then switch ON and reset the

instruments to factory default setting.

• Unit cannot be powered off when switched off.

If these faults are not resolved, please contact

manufacturer/supplier.

9. Maintenance and Cleaning

• Proper maintenance can keep instruments working

properly and lengthen its lifetime.

• Do not spray cleanser into the instrument when

cleaning.

• Unplug the power line when cleaning.

• Only use recommended cleansers:

Dyes

Isopropyl alcohol

Construction materials

Water containing tenside /

Isopropyl alcohol

Cosmetics

Water containing tenside /

Isopropyl alcohol

Foodstuffs

Water containing tenside

Fuels

Water containing tenside

• Wear the proper protective gloves during cleaning of

the instrument.

• Before using other method for cleaning or

decontamination, the user must ascertain with the

manufacturer that this method will not harm the

instrument.

• Send in the case of service the instrument back in the

packaging carton. Storage packing is not sufficient for

the back dispatch. Use additionally a suitable

transportation packing.

• The enamel makes the hotplate easier to care for and

more resistant to acids and bases. Because of it,

however, the hotplate is also more susceptible to

extreme fluctuations in temperature and the force of

impact. This can result in cracks forming or the

coating flaking off.

Warning!

Cut off power when maintenance and cleaning.

8

7” Square Hotplate

10. Associated standards and

regulations

Construction in accordance with the following safety

standards:

EN 61010-1

UL 3101-1

CAN/CSA C22.2(1010-1)

EN 61010-2-10

Construction in accordance with the following EMC

standards:

EN 61326-1

Associated EU guidelines:

EMC-guidelines: 89/336/EWG

Instrument guidelines: 73/023/EWG

Changes or modifications not expressly approved by the

party responsible for compliance could void the user's

authority to operate the equipment.

NOTE: This equipment has been tested and found to

comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful

interference when the equipment is operated in a

commercial environment. This equipment generates, uses,

and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may

cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to

cause harmful interference in which case the user will be

required to correct the interference at his own expense.

9

7” Square Hotplate

11. Specifications

Items

Specifications

Voltage [VAC]

100-120/200-240

Frequency [Hz]

50/60

Power [W]

1010

Plate material

Glass ceramic

Dimensions of workplate (mm)

184×184

*Heating power [W]

1000

*Temperature range [°C]

RT-550, increment:

5

*Temperature display [°C]

LED

*Temperature display accuracy [°C]

±1

*Control accuracy of heating

temperature [°C]

±10

*The safety temperature of the

hotplate [℃]

580

*Temperature sensor in medium

PT1000

*Control accuracy of heating

temperature with temperature

sensor [℃]

±0.5

*Residual heat warning

50℃

Dimensions (mm)

215×360×112

Weight [kg]

3.8

Permitted ambient temperature [°C]

5-40

Permitted relative humidity

80%

Protection class acc. to DIN 60529

IP21

Table 3

10

7” Square Hotplate

12. Ordering information

Cat No.

Descriptions

51212101xxxx

HP550-S LED Digital 7’’ Square

Hotplate, glass ceramics hotplate, USA

plug, 100-120V, 50Hz/60Hz

51212112xxxx

HP550-S LED Digital 7’’ Square

Hotplate, glass ceramics hotplate, Cn

plug, 200-240V, 50Hz/60Hz

51212122xxxx

HP550-S LED Digital 7’’ Square

Hotplate, glass ceramics hotplate, Euro

plug, 200-240V, 50Hz/60Hz

51212132xxxx

HP550-S LED Digital 7’’ Square

Hotplate, glass ceramics hotplate, UK

plug, 200-240V, 50Hz/60Hz

Accessories

18900016

PT1000-A Temperature sensor for digital

hotplate model, length of 230mm

18900136

PT1000-B Glass coated temperature

sensor for digital hotplate model, length

of 230mm

18900017

Support clamp of PT1000

SCILOGEX, LLC

1275 Cromwell Ave. Suite C6

Rocky Hill, CT 06067 USA Tel:

1-860-436-9221

Fax:1-860-436-9745

info@scilogex.com

www.scilogex.com

Loading...

Loading...