12300090

Digital 7’’ Square (Hotplate) Magnetic Stirrer

User Manual

MS7-Pro Digital 7”Square Plate Magnetic Stirrer

MS7-H550-Pro Digital 7”Square Hotplate Magnetic Stirrer

Please read the User Manual carefully before use, and follow

all operating and safety instructions!

www.scilogex.com

Contents

Preface …………………………………………………… 2

Service …………………………………………………… 2

Warranty ………………………………………………… 2

1.Safety Instructions …………………………………… 3

2.Proper use ……………………………………………… 4

3.Inspection ……………………………………………… 5

3.1 Receiving Inspection …………………………… 5

3.2 Listing of Items ………………………………… 5

4.Control and Display …………………………………… 5

4.1 Control Elements ………………………………… 5

4.2 Display ………………………………………… 6

5.Trial run ……………………………………………… 7

6.Initialization …………………………………………… 8

6.1 Initializing Sequence …………………………… 8

6.2 Default Settings ………………………………… 8

7.Function: Heating ……………………………………… 8

7.1 Working with External Temperature Sensor …… 9

7.2 Residual Heat Warning(Hot) …………………… 9

7.3 Setting the Safety Temperature ………………… 10

8.Function: Stirring ……………………………………… 10

9.Remote Control ……………………………………… 10

10.Faults ………………………………………………… 11

11.Maintenance and Cleaning …………………………… 12

12.Associated Standards and Regulations ……………… 13

13.Technical Data ……………………………………… 13

14.Ordering Information ………………………………… 15

15.Main Spare Parts …………………………………… 16

15.1 Spare Parts Diagram …………………………… 16

15.2 List of Spare Parts ……………………………… 17

1

Digital 7” Square(Hotplate)Magnetic Stirrer

Preface

Welcome to the“Digital 7”Square (Hotplate) Magnetic

Stirrer User Manual ”. Users should read this Manual

carefully, follow the instructions and procedures, and be

aware of all the cautions when using this instrument.

Service

When help needed, you can always contact the Service

Department of manufacturer/supplier for technical support

in the following ways :

SCILOGEX, LLC

500 Four Rod Road

Suite 122

Berlin, CT 06037

USA

Tel:1- (860) 828-5614

Fax:1- (860) 828-5389

E-mail: info@scilogex.com

Website:Http://www.scilogex.com

Please provide the customer care representative with the

following information:

Serial number on the rear panel

•

Description of problem (i.e.,hardware or software)

•

Methods and procedures adopted to resolve the problems

•

Your contact information

•

Warranty

You have purchased a Scilogex instrument. This instrument

is warran ted to be free fro m de fects i n ma terials and

workmanship under normal use and service, for a period

of 24 months from the date of invoice. The warranty is

extended only to the original purchaser. It shall not apply to

any product or parts which have been damaged on account

of improper installation, improper connections, misuse,

accident or abnormal conditions of operation.

For claims under the warranty please contact your local

supplier. You may also send the instrument directly to

manufacturer, enclosing the invoice copy and by giving

reasons for the claim.

2

1.Safety Instructions

Warning!

Read the operating instructions carefully

•

before use.

Ensure that only trained staff works with the

•

instrument.

Risk of burn!

Caution when touch the housing parts and

•

the hotplate which can reach temperature of

550℃.

Pay attention to the residual heat after

•

switching off.

Protective ground contact!

Make sure that socket must be grounded

•

(protective ground contact) before use.

When working wear personal safety guards to avoid the

•

risk from:

Splashing and evaporation of liquids

-

Release of toxic or combustible gases

-

Set up the instrument in a spacious area on a stable,

•

clean, non-slip, dry and fireproof surface. Do not operate

the instrument in explosive atmospheres, with hazardous

substances or under water.

Digital 7” Square(Hotplate)Magnetic Stirrer

Gradually increase the speed, reduce the speed if :

•

Stirring bar breaks away due to high speed

-

The instrument is not running smoothly, or container

-

moves on the base plate

Temperature must always be set to at least 50℃ lower

•

than the fire point of the media used.

Be aware of hazards due to:

•

Flammable materials or media with a low boiling

-

temperature

Overfilling of media

-

Unsafe container

-

Process pathogenic materials only in closed vessels.

•

Check the instrument and accessories prior to each

•

use. Do not use damaged components. Safe operation

is only guaranteed wit h the acc esso ries des crib ed

in the“ Accessories”chapter. Accessories must be

securely attached to the device and can not come off by

themselves. Always disconnect the plug before fitting

accessories.

Ensure that the external temperature sensor is inserted in

•

the media to a depth of at least 20 mm.

When using metal vessels, do not place the temperature

•

sensors on the bottom of the vessel. This can cause

excessively high temperatures to be measured especially

in media with poor conductivity.

3

Digital 7” Square(Hotplate)Magnetic Stirrer

The tip of the measuring sensor must be at least 5 mm

•

from vessel bottom; a distance of 10 mm is ideal.

The instrument can only be disconnected from the main

•

power supply by pulling out the main or the connector

plug.

The voltage stated on the label must correspond to the

•

main power supply.

Ensure that the main power supply cable does not touch

•

the hotplate. Do not cover the device.

The instrument may only be opened by experts.

•

Keep away from high magnetic field.

•

2.Proper use

The instrument is designed for mixing and/or heating liquids

in schools, laboratories or factories.

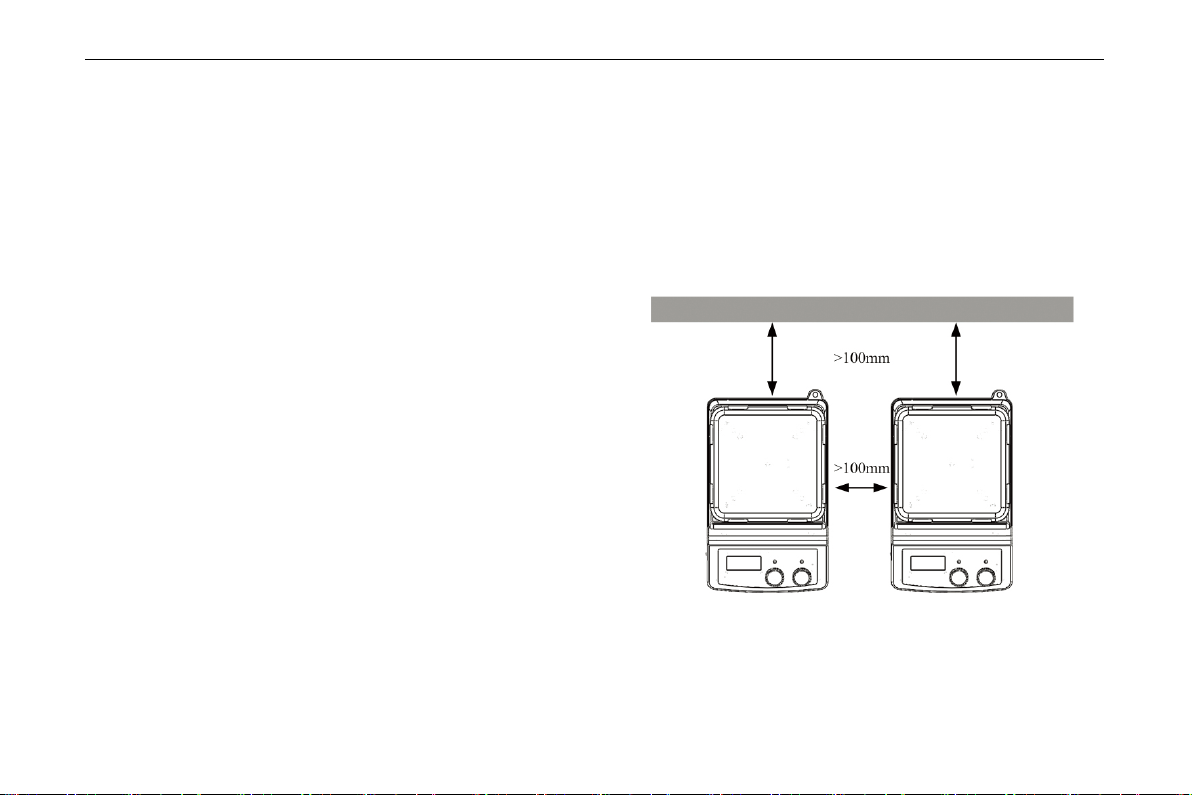

Observe the minimum distances between the devices,

•

between the device and the wall and above the assembly

(min. 100 mm).

Figure 1

This device is not suitable for using in residential areas or

other constraints mentioned in Chapter 1.

4

Digital 7” Square(Hotplate)Magnetic Stirrer

3.Inspection

3.1 Receiving Inspection

Unpack the equipment carefully and check for any damages

which may have arisen during transport. Please contact

manufacturer/supplier for technical support.

Note:

If there is any apparent damage to the system,

please do not plug it into the power line.

3.2 Listing of Items

Items Qty

Main unit 1

Power cable 1

User Manual 1

Table 1

4.Control and Display

4.1 Control elements

LED Heat

(Hotplate model)

LCD

Temperature Control Knob

(Hotplate model)

Speed Control Knob

Figure 2

Safe Temperature Control Knob

LED Stir

Figure 3

5

Power Switch

Digital 7” Square(Hotplate)Magnetic Stirrer

Items Descriptions

Speed control Knob Stir

Temperature control

knob Heat (Hotplate)

LCD

LED Heat(Hotplate)

LED Stir

Safe temperature

control Knob

Power Switch

Set the rated rotary speed. The

stirring function is switched ON

or OFF by pushing the knob.

Set the rated temperature. The

heating function is switched ON

or OFF by pushing the knob.

LCD displays the real working

state and all settings.

When the hea ting functi on i s

switched

When the sti rring funct ion is

switched ON, the LED Stir is lit.

Set safety temperat u r e , stop

heating when exceed sec

ure

temperature.

S w i t c h O N o r O F F t h e

instrument.

Table 2

4.2 Display

Figure 4

Character Descriptions

Temp and ℃

Mot

Hot

Probe Display when using external probe.

Display temperature when the heating

function is switched ON.

Display stirring state when the stirring

function is switched ON.

Display hot warning if the hotplate

te m p e ra t u r e is abo v e 50℃ af t e r

switching OFF the heating function.

6

Digital 7” Square(Hotplate)Magnetic Stirrer

Remote Display in case of remote control.

Err Display in case of error happening.

Rated value/Real

value

Note:

If both heating and stirring functions have been

st art ed a t th e sa me t ime, heatin g fu nction

always has higher priority. If in this case speed

is changed via the stirrin g knob, it displays

stirring speed and reverses to temperature in

the duration of 5 seconds.

Display value in case of heating or

stirring function switching ON.

Table 3

5.Trial run

Make sure the required operating voltage and power

•

supply voltage match.

Ensure the socket must be properly grounded.

•

Ensure the power is off.

•

Plug in the power cable,ensure the power is on and begin

•

initializing.

Add the medium into the vessel with a stirring bar.

•

Place vessel on the work plate.

•

Set the rated stirring speed and begin.

•

Observe the stirring bar and LCD display.

•

Set the rated temperature and start heating.

•

Observe the real temperature on LCD display.

•

Stop the heating and stirring functions.

•

If these operations above are normal, the device is ready

to operate. If these operations are not normal, the device

may be damaged during transportation, please contact

manufacturer for technical support.

7

Digital 7” Square(Hotplate)Magnetic Stirrer

6.Initialization

6.1 Initializing sequence

Turn on instrument by the power switch.

•

The“Heat”and“Stir”LEDs and the LCD display

•

flash about 3 times.

LCD displays the work plate, safe temperature limit in

•

“SAFE xxx℃”.

LCD displays residual heat warning“rES On/OFF”.

•

LCD displays stirring bar breakaway monitoring“br

•

On/OFF”.

LCD displays the“Probe” c h a r a cters in case of

•

connecting with external temperature sensors.

6.2 Default settings

The following table is supplied with default settings:

Items Default settings

Setting temperature (℃ ) 25

Setting rotary speed (rpm) 100

Table 4

7.Function: Heating

The device is controlled by digital temperature control

technology, which has two separate safe circuits. The

hotplate is kept at a constant temperature by a digital control

circuit. The hotplate temperature can also be monitored

from a separate, adjustable safe circuit. The two temperature

sensors (PT1000) internal for temperature control are built

into the hotplate. The single external PT1000 can monitor

the temperature of sample.

If external temperature sensors needed, it must be plugged in

before the device is switched ON.

Ensure the external temperature sensor connect firmly

•

before heating.

Set the temperature via turning the temperature control

•

knob slowly to the ideal value.

When the heating function is switched on, the LED

•

“Heat”will light up and the LCD will display the real

temperature.

The rated temperature will be displayed on the right-hand

•

side of the LCD as well as Temp and℃ characters.

The heating function is switched on or off by pushing

•

heating knob.

Instrument is turned on for the setting zone temperature

setting when the last shutdown temperature, the common

8

Digital 7” Square(Hotplate)Magnetic Stirrer

cas e , set the heating tem p e rature disp l a y the act u a l

temperature may have the following differences:.

Hotplate center and outer edge.

-

The sample container and the container.

-

In order to ensure the accuracy of the temperature inside

the container, please use the external temperature sensor

PT1000.

7.1 Working with external temperature

sensor

Figure 5

T h e e x t e r n a l te m p e r a t u r e s e n s o r P T 1 0 00 is t h e

Manufacture’s standard accessory. If the sensor is not

plugged in,“Probe”will flash. If plugged in,“Probe”

will be shown on the digital display to indicate the sensor is

operating. The setting value of external temperature sensors

and actual temperature are displayed. Safe circuit controls

hotplate temperature.

Comparing with the temperature control of the hotplate,

the external temperature sensor can control the medium’s

temperature more precisely.

Warning

Do not insert or remove sensor while heating.

!

7.2 Residual heat warning (Hot)

In order to prevent the risk of burns from a hotplate, digital

hotplate model has a residual he at w arni ng f unction.

When the heating function is switched off and the hotplate

temperature is still above 50℃,“Hot”will flash to warn

that there is a hazard of burns from the hotplate (Figure

6).When the hotplate temperature drops to below 50℃, the

unit will automatically switch off. If users want to turn off

the LCD immediately, just pull out the plug directly. When

the plug is pulled out, the residual heat warning function can

not be run.

9

Digital 7” Square(Hotplate)Magnetic Stirrer

Figure 6

7.3 Setting the safety temperature

The safety temperature can be set as follows:

Adjust the temperature setting key to set the safety

•

temperature.

8.Function: Stirring

The function“stirring”is switched on or off via rotating

stirring knob. The speed is set on the knob (100 to 1500 rpm

in steps of 10 rpm ).

When both of function heating and stirring are switched on

and those above operations are done, the LCD will shift to

the speed value and come back to the temperature value in

about 5 seconds.

9. Remote control

10

Figure 7

Digital 7” Square(Hotplate)Magnetic Stirrer

The unit can be controlled from an external PC (using the

dedicated software) via the RS232 C serial interface fitted to

the unit. Data communication from laboratory instrument to

computer is only possible on demand of the computer.

The functions of the interface lines between laboratory

•

instrument and automation system are selected from

the specified signals of the EIA-standard RS232C,

corresponding with DIN66020 Part 1. The allotment of

the bushing can be taken from Figure 7.

Transmission method: Asynchronous signal transmission

•

in start-stop-operation.

Mode of transmission:Fully Duplex.1start bit; 7 character

•

bits; 1stop bit.

Transmission speed: 9600 bit/s.

•

Start remote control knob LED display “Remote”.

•

Note:

F o r b i d t o in s e r t or r e m o v e t h e R S 2 3 2 C

communication line when switch on!

10.Faults

Instruments can not be power ON

•

Check whether the power cable is plugged in

-

Check whether the fuse is broken or loose

-

Fault in power on self test

•

Switch OFF the unit, then switch ON and reset the

-

instruments to factory default setting.

Temperature can switched on not reach set point

•

Check whether the safety temperature value is set too

-

low.

Stir speed can not reach set point

•

Check whether the stirring bar breakaway monitoring

-

is ON.

Excessive medium viscosity may cause abnormal

-

speed reduction of the motor.

Heating or stirring function do not start when knob is

•

pressed.

Check whether the unit is in the mode setting program,

-

Exit from the mode setting and restart the heating/

-

stirring functions.

Unit do not power down when switched off.

•

Check if the residual heat warning function is still ON

-

and hotplate temperature is above 50℃(the LCD still

works and“Hot”flashes).

If these faults are not resolved,please set the instruments

to factory default setting or take the unit to technical service

center.

11

Digital 7” Square(Hotplate)Magnetic Stirrer

11.Maintenance and Cleaning

Proper maintenance can kee p instruments working

•

properly and lengthen its lifetime.

Do not spray cleanser into the instrument when cleaning.

•

Unplug the power line when cleaning.

•

Only use recommended cleansers:

•

Dyes Isopropyl alcohol

Construction materials

Cosmetics

Foodstuffs Water containing tenside

Fuels Water containing tenside

Wear the proper protective gloves during cleaning of the

•

instrument.

B e fo r e u s in g o t he r m e t h o d f o r c l ea n i n g o r

•

decontami nation, the use r must as certain with the

man u f a cturer that this method will not harm the

instrument.

Send in the case of service the instrument back in the

•

Water con tai ning te nsid e / Isopro pyl

alcohol

Water con tai ning te nsid e / Isopro pyl

alcohol

packaging carton. Storage packing is not sufficient for the

back dispatch. Use additionally a suitable transportation

packing.

Th e ename l make s the h otplat e easi er to c a re for

•

and more resistant to acids and bases. Because of it,

however, the hotplate is also more susceptible to extreme

fluctuations in temperature and the force of impact. This

can result in cracks forming or the coating flaking off.

Warning

Cut off power when maintenance and cleaning.

!

12

Digital 7” Square(Hotplate)Magnetic Stirrer

1 2 . A s s o c i a t e d s t a n d a r d s a n d

regulations

Construction in accordance with the following safety

standards:

EN 61010-1

UL 3101-1

CAN/CSA C22.2(1010-1)

EN 61010-2-10

Construction in accordance with the following EMC

standards:

EN 61326-1

Associated EU guidelines:

EMC-guidelines: 89/336/EWG

Instrument guidelines: 73/023/EWG

The above standards will be available from July 2011.

*

13.Technical data

Voltage [VAC] 100-120/200-240

Frequency [Hz] 50/60

Power [W]

Stirring point position quantity 1

Max. stirring quantity (H2O) [L] 20

Max. magnetic bar [mm] 80×10

Motor type Brushless motor

Max. power input of motor [W] 18

Max. power output of motor [W] 10

Speed range[rpm] 100-1500

Rotary speed display LCD

Speed display accuracy [rpm] 1

Hotplate material Glass ceramic

1050(hotplate model)

50

Dimensions of workplate (mm) 184×

13

184

Digital 7” Square(Hotplate)Magnetic Stirrer

Dimensions of heating (mm) 176×176

Heating power[W] 1000(hotplate model)

Temperature range [℃]

RT-550

(hotplate model)

Temperature display[℃] LCD(hotplate model)

Temperature display accuracy [℃] 0.1(hotplate model)

Control accuracy of heating

temperature [℃]

The safety temperature range

of the hotplate [℃]

Temperature sensor in medium

1(100℃ below)/

±1%(100℃ above)

(hotplate model)

100-580

(hotplate model)

PT1000

otplate model)

(h

Control accuracy of heating

temperature with temperature

0.2(hotplate model)

sensor [℃]

Residual heat warning 50℃(hotplate model)

Weight [kg] 5.3

Permitted ambient temperature[℃] 5-40

Permitted relative humidity 80%

Protection class acc. to DIN 60529 IP21

RS232 interface Yes

Table 5

Dimensions (mm) 215×360×112

14

Digital 7” Square(Hotplate)Magnetic Stirrer

14.Ordering information

Cat No. Descriptions

MS 7 - H 5 5 0 - P r o Di g i t a l 7” S q u a r e

813223009999

813223019999

813223029999

813223039999

813213009999

813213019999

Hotplate Magnetic Stirrer, glass ceramics

hotplate, USA plug, 110V/50Hz/60Hz

MS 7 - H 5 5 0 - P r o Di g i t a l 7” S q u a r e

Hotplate Magnetic Stirrer, glass ceramics

hotplate, Cn plug, 220V/50Hz/60Hz

MS 7 - H 5 5 0- P ro Dig i t al 7” Sq ua r e

Hotplate Magnetic Stirrer, glass ceramics

hotplate, Euro plug, 220V/50Hz/60Hz

MS 7 - H 5 5 0 - P r o

H o tp l a t e Ma g n e ti c S t ir r er, gl a s s

ceramics hotplate, UK plug, UK plug,

220V/50Hz/60Hz

M S 7 - P r o Di g i t a l 7” S q u a r e Pl a t e

Magnetic Stirrer, glass ceramics plate,

USA plug, 110V/50Hz/60Hz

M S 7 - P r o Di g i t a l 7” S q u a r e Pl a t e

Magnetic Stirrer, glass ceramics plate, Cn

plug, 220V/50Hz/60Hz

Di g i t a l 7” Sq u a r e

MS 7 -P r o Dig i ta l 7” Sq u a r e Pl a t e

813213029999

Magnetic Stirrer, glass ceramics plate,

Euro plug, 220V/50Hz/60Hz

MS 7 -P r o Dig i ta l 7” Sq u a r e Pl a t e

813213039999

Magnetic Stirrer, glass ceramics plate, UK

plug, 220V/50Hz/60Hz

Accessories

18900016

18900084

PT1000 Temperature sensor for digital

hotplate model, length 230mm

PT1000 Temperature sensor for digital

hotplate model, length 100mm

18900017 Support clamp of

18900002

18900003

18900004

MS135.2 Red quarter pie, 11 holes, 4 ml

reaction vessel, Ø15.2mm, 20mm depth

MS135.3 Purple quarter pie, 4 holes, 20

ml reaction vessel, Ø28mm, 24mm depth

MS135.4 Blue quarter pie, 4 holes,30 ml

reaction vessel, Ø28mm, 30mm depth

PT1000

15

Digital 7” Square(Hotplate)Magnetic Stirrer

18900005

18900048

18900049

18100319

Note:The software StirPC-V2 can be freely downloaded

from our website www.

MS135.5 Black quarter pie, 4 holes,40 ml

reaction vessel, Ø28mm, 43mm depth

MS135.6 Green quarter pie, 6 holes, 8ml

reaction vessel, Ø17.75mm, 26mm depth

M S 1 3 5. 7 G o ld e n q ua r t er p i e , 4

holesØ16ml reaction vessel, Ø21.6mm,

31.7mm depth

9-Pin interface line, suitable for StirPC-V2

software.

Table 6

scilogex.com.

15.Main spare parts

15.1 Spare parts diagram

Figure 8

16

15.2 List of spare parts

Item Spare parts Item Spare parts

1 Work plate 9 Main circuit board

Hole for external

2

temperature

sensor

3 Mains switch 11 Heating parts

10 Driver circuit board

Digital 7” Square(Hotplate)Magnetic Stirrer

4 Housing 12

5 Control panel 13

External temperature

6

sensors’ socket

Direct-current

brushless motor

Internal temperature

sensor

14 Permanent magnet

7 Remote control socket 15 Protective plate

8 Main socket 16 Rubber foot

17

SCILOGEX, LLC

500 Four Rod Road

Suite 122

Berlin, CT 06037

USA

Tel:1- (860) 828-5614

Fax:1- (860) 828-5389

E-mail: info@scilogex.com

Website:Http://www.scilogex.com

Loading...

Loading...