COMMISSIONING MANUAL

for

MODEL 6290

TANK GAUGING SYSTEM

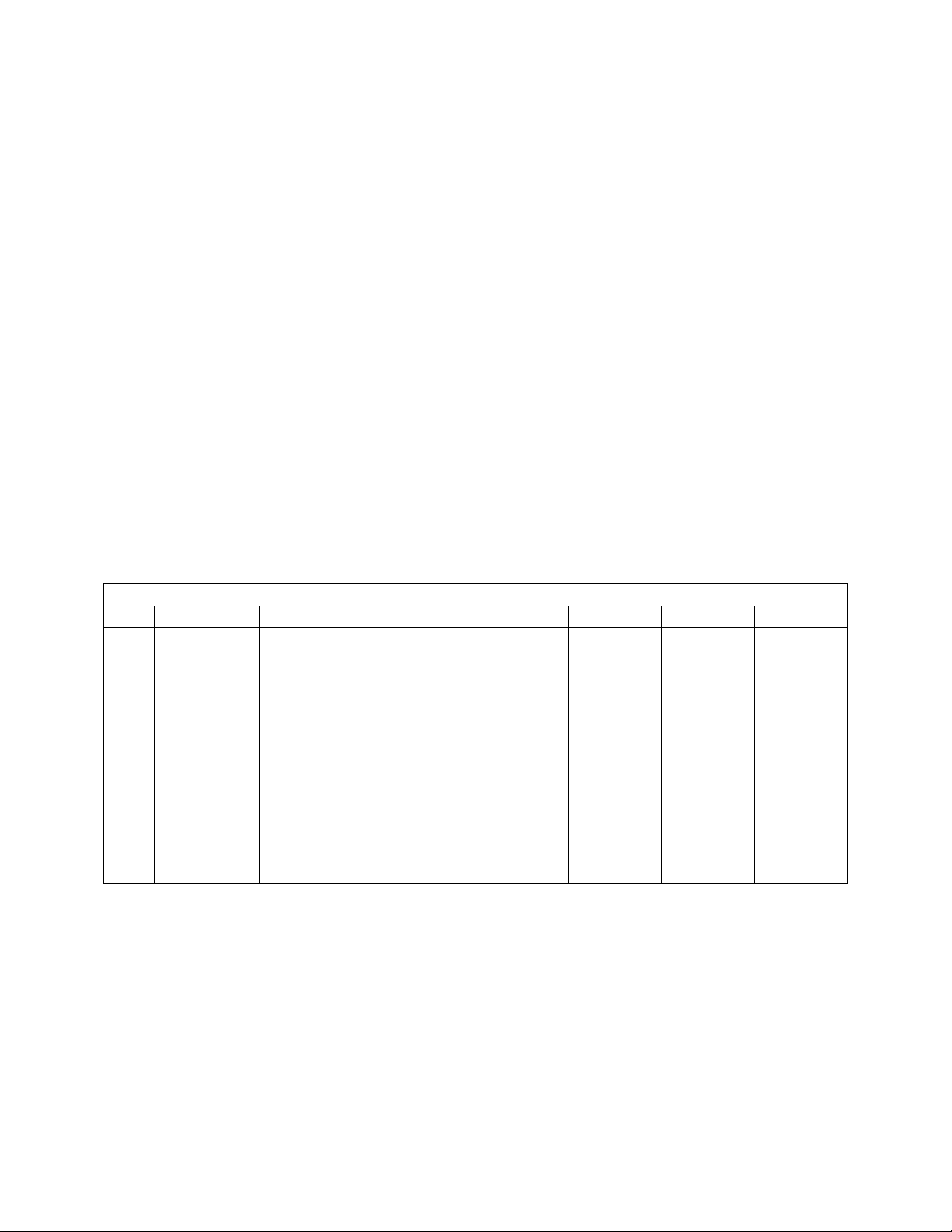

Record of Revisions

Rev RFEA # Description Rev by Date Appr by Date

−

Initial Release

SCIENTIFIC INSTRUMENTS, INC.

090-254

TABLE OF CONTENTS

1 INTRODUCTION .................................................................................................... 1-1

2 INSTALLATION VERIFICATION ............................................................................ 2-1

2.1 Mechanical Installation .................................................................................. 2-1

2.2 Electrical Wiring............................................................................................. 2-1

3 INITIAL SYSTEM TESTING ................................................................................... 3-1

3.1 System Preparation....................................................................................... 3-1

3.2 Application of Power...................................................................................... 3-1

3.2.1 Control Room........................................................................................... 3-1

3.2.2 Tank Top.................................................................................................. 3-1

3.3 Motor Drive.................................................................................................... 3-2

3.4 Temperature.................................................................................................. 3-3

3.5 Density .......................................................................................................... 3-3

4 SYSTEM TESTING IN LIQUID ............................................................................... 4-1

4.1 Liquid Level ................................................................................................... 4-1

4.2 Temperature.................................................................................................. 4-2

4.3 Density .......................................................................................................... 4-2

5 COMMUNICATIONS TESTING.............................................................................. 5-1

APPENDIX A: M6290 SITE COMMISSIONING CHECKOFF SHEET .........................A-1

i

1 INTRODUCTION

The Model 6290 (M6290) Tank Gauging System monitors the level, temperature, and

density of the cryogenic liquid in a large storage tank. This manual details the normal

start-up procedures to be followed before the equipment is put into use on a regular

basis.

A separate manual documents the installation procedures to be carried out for this

system. It is assumed that these procedures have already been accomplished. If they

have not, then reference should be made to the Installation Manual for the Model 6290

Tank Gauging System (090-249-XX), and all procedures called for in that manual

should be completed prior to continuing with commissioning activities.

The Hand Held PC (HHPC) supplied with the M6290 is an integral part of system

operation. Some instructions on using the HHPC are given here, but for more details,

please refer to the Hand Held PC User Interface Manual (090-252).

It is also assumed that at least one meter of liquid is available in the tank. Although

power may be applied to the equipment, and certain functions may be tested without

liquid, it is not possible to test all features and properly commission this system in the

absence of liquid.

A site-specific mechanical installation drawing and a site-specific field-wiring diagram

are provided with the systems manual. Additional standard documents are provided for

clarification of details where necessary. This documentation should be located and

available for reference during the commissioning activities.

A check-off sheet is included in Appendix A for those sites requiring a sign-off. Each

step should be initialed upon completion.

090-254 Rev −

1-1

2 INSTALLATION VERIFICATION

Prior to application of power, the entire system should be inspected for proper

installation. Special attention should be given to verification of field wiring to minimize

the potential damage of electronics due to improper voltages being applied.

2.1 Mechanical Installation

As already mentioned, the mechanical installation should have already been

completed. The entire installation should be checked for integrity with special

attention being given to the following:

• Mechanical unit is level.

• Support legs are properly installed and adjusted to share the weight evenly.

• All flange bolts are installed and tight.

• Cabling is attached with proper flameproof fittings.

• All cabling is properly supported.

• Working platform is secure and safe per site requirements.

WARNING: The flameproof integrity of the system can only be maintained by

using approved flameproof fittings at all cable entry points and following

proper assembly procedures at these points.

2.2 Electrical Wiring

All wiring internal to the control unit is completed and tested at the factory. Thus, the

wiring that must be verified is the field wiring. Referring to the site-specific fieldwiring diagram (040-237-XX), perform the following checks using a digital ohmmeter

and standard “loop check” procedures. Be sure to check that all screw terminals are

properly tightened.

• Verify that the AC wiring to the control unit is properly connected.

• Verify that the wiring from the control unit to the Tank Gauge Interface Module

(TGIM) in the control room is correct.

• Verify that 24 volts is properly wired to the TGIM module.

• If the optional user interface is installed, verify that wiring to that unit is

correct.

• If the system is connected to a host DCS, verify that wiring is correct.

090-254 Rev −

2-1

3 INITIAL SYSTEM TESTING

NOTE: Initial application of power to the equipment should only be made after all wiring

has been verified. It is recommended that personnel be positioned both in the control

room and on the top of the tank with proper communications established.

3.1 System Preparation

The probe may have been shipped secured inside the mechanical enclosure, or it

may have been shipped in the probe enclosure and secured with packing material.

This packing material should have been removed during the installation process.

The location of the probe should be verified at this time. If the probe is still located in

the housing, the housing cover must be removed and the probe positioned into the

probe enclosure. If this is necessary, refer to the Calibration and Corrective

Maintenance Manual (090-251) for access procedures. After the probe has been

properly positioned, the mechanical enclosure cover should be replaced.

The pinch valve is normally left closed during installation. If it is not closed, it should

be closed at this time and remain closed for initial testing. Be sure that the pinch

valve is not closed on the probe itself.

3.2 Application of Power

WARNING: Power should not be applied to the control unit on top of the tank if

the cover is off and explosive gas is present. Be sure to follow site safety

procedures to ensure explosive gas is not present during the following startup procedures.

3.2.1 Control Room

Make sure the system power switch is off. Also, verify that 24 VDC is not

applied to the Tank Gauge Interface Module (TGIM). Remove the TGIM card,

apply 24 VDC to the TGIM and measure the voltage at the card block to verify

proper voltage and polarity according to the site-specific wiring diagram. After

verifying this voltage at the correct pins, remove power, reinsert the card and

apply 24 VDC again. The LED (D8) on the TGIM card should be lighted at this

point. Leave the power switch in the off position.

3.2.2 Tank Top

With the control unit box open and both power switches off (TGIM power switch

and tank-top manual override switch), apply AC power with the circuit breaker.

Measure power at the AC terminal block to verify proper voltage and

connections.

On the control module, plug the HHPC into the RJ11 socket on the left (marked

System Control). Using the manual override switch, apply power to the unit. The

signal conditioning card finishes booting up first and will cause the LED labeled

SCC-CPU to start blinking. After a brief delay (10 – 15 seconds), the control

module CPU card also finishes booting and the LED labeled CM-CPU will blink.

090-254 Rev −

3-1

The rate of the LED’s blinking indicates whether certain parts of the system are

working properly or not. The signal conditioning card CPU (SCC-CPU) causes

its LED to blink once per second. The normal rate of the control module CPU

(CM-CPU) is a little slower. A fast blink rate on either LED indicates a problem

that should be investigated further using the Calibration and Corrective

Maintenance Manual.

The HHPC should also power on, and after it finishes its boot process, it will

attempt to establish communication with the control module. After the control

module CPU card finishes booting and communication is established, the HHPC

will display current temperature, density, and other system quantities. The motor

drive system should not move if the system is still set to its factory defaults. (If

the system indicates “Cal” after power up and starts to move following an audible

beeping sound, press “STOP” on the HHPC.)

In summary, the following conditions should be observed at this point:

• The LED labeled SCC-CPU is blinking once per second.

• The LED labeled CM-CPU is blinking at a rate slightly slower than the SCC-

CPU LED.

• The Display on the HHPC shows current temperature, density, and other

system quantities. Current drive mode is Manual Stop.

• The 28 VDC indicator on the TGIM in the control room should be on,

indicating the control unit is powered up.

To test the power control wiring to the control room, turn off the power at the tank

top by pressing the switch control rod in. Then apply power by turning on the

switch in the control room. Note that the unit powers up properly as before. The

system is normally left in this state so that power can be controlled from the

control room.

3.3 Motor Drive

Using the keys on the HHPC, drive the probe down until it rests on the pinch valve

boot. This will activate the bottom reference switch and stop the drive. Verify that

the bottom reference switch indicator shows on the HHPC display.

Again, using the HHPC, drive the probe up approximately 0.4 meters. Be sure to

stop the drive before the top of the probe reaches the base plate. If this happens,

the drive motor will “slip” and make a chattering noise. After a few seconds, the reel

alarm will stop the movement. This will not hurt anything, but should not be done as

a normal course of action.

Repeat this up and down movement several times. Verify that the entire system is

driving smoothly, and that the bottom reference switch is functioning properly.

090-254 Rev −

3-2

3.4 Temperature

Note that the temperature on the HHPC display is reading the ambient temperature.

If the ambient temperature is reasonable, this is the only test required at this time.

3.5 Density

In air, the density meter typically reads a value just above zero. A much better way

to tell if the meter is reading accurately is to go into the Basic Units display on the

HHPC. This can be done by pressing “ESC” and then selecting option 2. Verify that

the period of the density signal matches the “T

” value found on the density

air

calibration data sheet and on the configuration worksheet. It should be

approximately 176 microseconds in air. If the reading is close to this, the density

meter is functioning properly. This is the only test that can be performed at this time.

090-254 Rev −

3-3

4 SYSTEM TESTING IN LIQUID

The system is now ready for testing in liquid. Operation of the system may be

controlled either from the tank top or from the control room as desired. If operation is

continued from the tank top, no change to the connections is required. If it is desired to

perform the final test from the control room, then the HHPC should be removed and the

control unit cover closed at this time. The HHPC should then be reconnected in the

control room.

NOTE: If AC power has been switched on by using the local manual power override

switch, it should be turned off by pushing in on the control rod prior to closing the

cover. System power should be reapplied by turning the power switch on in the

control room. Note also that there is a service switch reset actuator attached to the

lid of the control unit which, if adjusted properly, will automatically push the power

switch in, thereby removing power when the lid is closed.

At this time, the pinch valve should be opened to allow the probe to be driven into the

tank. If the tank isolation gate valve (or ball valve) has not been opened, it should be

opened at this time as well. If site procedures require it, the mechanical unit should be

purged of air at this time.

WARNING: It is strongly recommended that the tank isolation gate valve (or ball

valve) be locked in the open position at this time. Closing this valve on the drive

cable will severely damage or possibly sever the drive cable, allowing the probe

to fall into the tank.

4.1 Liquid Level

Using the HHPC, drive the probe to the bottom of the tank. If other instrumentation

is available to indicate the approximate liquid level, it will help in determining that the

system is functioning properly. Since the level sensors have not yet been calibrated

in liquid, they may not indicate when liquid level has been reached.

Aside from the level sensors, there are two ways to determine when the probe is

entering liquid. While the probe is descending through the vapor, temperature will

be decreasing steadily. When the temperature sensor enters the liquid, the

temperature will drop immediately to the temperature of the liquid.

Before entering liquid, the density will be at a value just above zero. When the

density meter begins to enter liquid, the liquid around the meter will begin to boil,

and the density readings will increase and begin to vary widely. After the meter

cools to the temperature of the liquid, readings will stabilize. It will take

approximately ½ hour for the readings to stabilize completely.

When it has been determined that the probe has entered the liquid, it will be useful

to stop and make a note of the position. If the approximate liquid level is already

known, then it will be possible to determine when the probe should hit the bottom of

the tank.

090-254 Rev −

4-1

After making a note of the probe position at liquid level, put the system in the

calibration mode by pressing “CMND” and then choosing option 2. The probe will

drive to the bottom of the tank and then start to drive back up to liquid level. Stop

the probe after this occurs.

When the probe first reaches the bottom, the probe position will be reset to the

bottom reference value and the difference between the previous bottom reference

(at the pinch valve above) and the new bottom reference will be calculated. To

display this value, press ESC to return to the main menu and select option 3, Motor

Diagnostics. This value should be shown as “BREF diff1”. Record this value on the

configuration worksheet as the distance from the tank floor to the top of the pinch

valve for future reference during maintenance activities.

After the probe has initially reached the bottom of the tank, drive the probe up about

one meter and then down several times, noting that the probe stops at the same

point each time. This verifies proper operation of the bottom reference switch.

With the probe about ½ meter from the bottom, calibrate the level sensors. The

option to perform this function is found in the Maintenance Menu under Maintenance

Functions. After calibrating the level sensors, initiate a system calibration by putting

the system in the calibration mode, as described above. The probe should drive to

the bottom, and then drive up to find the liquid level. Observe that the liquid level is

the level that is expected.

The drive system has been calibrated at the factory and an initial level scale value

established. If an accurate benchmark is available for calibrating the level,

performing an on-site level calibration may increase the system accuracy. Refer to

the Calibration and Corrective Maintenance Manual for the procedure to perform this

level calibration.

4.2 Temperature

With the probe in the liquid, observe that the temperature is reading correctly. The

temperature probe has been calibrated at the factory with a standard traceable to

the National Institute of Standards and Technology (NIST), thus no further

calibration on site should be necessary. If it is desired to adjust the temperature to

agree with on-site standards, the resistance of the sensor at liquid nitrogen should

be adjusted accordingly. Refer to the HHPC User Interface Manual for further

instructions on how to do this.

4.3 Density

With the probe in the liquid, observe that the density is reading correctly. The

density meter has been calibrated by the manufacturer with standards traceable to

NIST, thus no further calibration on site is necessary. In the event that it is desired

to adjust the density meter calibration to agree with on-site standards, the T0 value in

the density calculation parameters should be adjusted until the desired value is

obtained. Refer to the HHPC User Interface Manual for further instructions on

setting this value.

090-254 Rev −

4-2

5 COMMUNICATIONS TESTING

If the system is connected to the optional user interface or a host computer, the

communications to those units should be checked at this time. The HHPC may be used

to check the communications to the TGIM by configuring each link to be compatible with

the HHPC. Instructions for doing this are included in the HHPC User Interface Manual.

The operation of the optional user interface and the operation of the host computer are

checked by verifying that all of the displayed data is correct, and that the system

responds to all commands.

Since normal system operation will not exercise all alarm conditions and status

indications, a simulation mode has been provided to simulate these conditions. This is

activated with the HHPC on a particular tank. This simulation mode is intended

primarily to verify the software on a DCS that is using the MODBUS data link. Care

should be taken to cancel the simulation mode at the end of the software verification,

returning the entire system to normal operation. For further details on how to complete

this test, please refer to the HHPC User Interface Manual.

090-254 Rev −

5-1

APPENDIX A M6290 SITE COMMISSIONING CHECKOFF SHEET

Customer: ____________________________ Location: _______________________

System S/N: _______________ Date: __________________

ITEM INITIAL

1. Mechanical Installation __________

2. Electrical Wiring __________

3. Control Room Power __________

4. Tank Top Power __________

5. Motor Drive __________

6. Liquid Level __________

7. Temperature __________

8. Density __________

9. Communications __________

Tests Accomplished by:__________________________ Date:____________

Verified by:____________________________________ Date:____________

Customer Acceptance:___________________________ Date:____________

090-254 Rev –

A-1

Loading...

Loading...