Page 1

INSTALLATION GUIDE

Isodrive 900

Under our policy of continuous product development,

product specications may change without notice.

Please refer to the online version of the manual for the

latest updates and specications.

www.schweigen.com.auRevision V4 11/05/22

Page 2

Welcome

Thank you for purchasing your new Schweigen Isodrive system.

To get the maximum output from this unit, please read through this guide before use and installation.

This guide contains important information on the correct use and maintenance of the unit, as well as important

safety notes. This will ensure your personal safety and the lasting value of your Isodrive system.

Please always retain your proof of purchase to aid in any warranty queries.

This appliance and its packaging are produced by processes that minimise waste and respect the environment.

Please help us to continue this eort to protect the environment by using the appliance eciently and dispose

of the packaging in a responsible manner.

Page 2

Page 3

Index

1. Welcome _____________________________________________________________________________________2

2. Your Safety

Receiving your rangehood ______________________________________________________________________ 4

Before Installation ______________________________________________________________________________ 4

Electrical Cord __________________________________________________________________________________ 4

Motor Features ________________________________________________________________________________ 5

General Notes on Installation and Use ____________________________________________________________ 5

Recommended Installation Distance _____________________________________________________________ 5

Minimum Mounting Height ______________________________________________________________________ 6

Avoidance of Back Flow _________________________________________________________________________ 6

Safety of Children ______________________________________________________________________________ 6

Replacement of Supply Cord _____________________________________________________________________ 6

™

Why Schweigen SteelFlex

3. Description

Isodrive Motor _________________________________________________________________________________ 7

Safety Duct __________________________________________________________ 6

4. Installation

Roof Installation _______________________________________________________________________________ 8

Wall Installation ________________________________________________________________________________ 10

Flat Roof Installation ___________________________________________________________________________ 12

Through Wall Installation for Isodrive 900 _______________________________________________ 13

Fan Unit Shutter Assembly for Isodrive 900 (Optional) _____________________________________ 14

5. Measurements

Measurements for Isodrive 900 ______________________________________________________ 15

™

6. SteelFlex

SteelFlex

Assembling SteelFlex

Safety Duct

™

Safety Ducting __________________________________________________________ 16

™

Safety Duct ____________________________________________________ 17

Shallow Roof Space _______________________________________________________________ 18

Important Note __________________________________________________________________ 18

™

Securing SteelFlex

Safety Duct ______________________________________________________ 19

7. Parts List

Parts List for Isodrive 900 ___________________________________________________________ 20

8. Maintenance

Roof Restoration or Cleaning ________________________________________________________ 22

9. Warranty/Disclaimer ________________________________________________________________________ 23

Page 3

Page 4

2. Your Safety

RECEIVING YOUR RANGEHOOD

Please read this section thoroughly before attempting to operate the appliance.

Inspect your product upon receipt. Any damage or defects MUST be reported

within 48 hours, or no claim will be recognised.

DO NOT INSTALL THIS APPLIANCE IF YOU FIND IT DAMAGED.

If this product is installed damaged, the supplier, nor the retailer, will be responsible

for the costs associated with the repair, replacement, removal or re-installation of

the appliances.

This appliance is not intended for use by person/s (including children) with reduced physical, sensory or

mental capabilities, or lack of experience and/or knowledge. Unless the person has been given supervision

or instruction concerning the use of the appliance by a person responsible for their safety. Children should be

supervised to ensure that they do not play with the appliance, it is not a toy.

Do not install Isodrive motor to a non-Schweigen and/or non-silent rangehood. If you fail to do so, your

warranty will be voided.

The manufacturer declines all responsibility in case of failure to adopt proper safety measures.

Ensure that the location in which this appliance is installed, has good and permanent ventilation.

Please consult local laws and regulations and install in accordance.

Use an electrical connector with earth that is correct for your location.

Check that the voltage in your area corresponds to the appliance as indicated on the rating label.

Before Installation

We recommend this appliance to be installed or repaired by an experienced Home Appliances technician.

Please see our website www.schweigen.com.au for experienced installers.

It is dangerous to modify any part of this appliance. Modication of any kind, will immediately void the warranty.

Electrical Cord

Ensure the supply cord is not exposed to heat, chemicals or sharp objects. If the supply cord is damaged, it must be

replaced by the manufacturer, service agent or a similarly qualied person in order to avoid a hazard. The power

supply cord connection MUST BE installed in such a way that access is easy in case of emergency.

Page 4

Page 5

2. Your Safety

This guide is for the installation of the motor used in the Isodrive systems after the canopy/rangehood or

bathroom extraction grill has been mounted on the wall or ceiling. (Refer to canopy/rangehood or bathroom

extraction unit installation manual).

™

NOTE: All PVC pipe and SteelFlex

ducting measurements are referring to inside measurements, unless

otherwise mentioned..

Motor Features

• Roof and wall mounting with IPX4 degree of weather protection.

• Patented anti water intrusion system.

• Super quiet, long vane, backward curved centrifugal fan.

• Airow is dependant on installation and the ducting used. Using a single 200mm SteelFlex

3

should attain up to 900m

/hr depending on the ducting installation. The use of a smaller than 200mm

ducting would result in a loss of airow.

• Simple installation: The motor mounts onto a 150mm PVC pipe for ultimate strength and allows for easy

Dektite roof sealing.

• Industrial quality motor and fan made in Germany and rated at 40,000 hours.

• Motor is a high eciency PSC type and rated at 57W.

• WARRANTY 10 YEARS return to manufacturer. Covers faulty manufacturing or components. It does not

cover normal wear and tear, chemical or storm damage etc. (see warranty card for more information).

™

duct, you

General Notes on Installation and Use

This fan unit is designed to be installed using 150mm (ISD) PVC pipe as the initial connection duct to the fan

™

module, and is supplied with a 150mm (ISD) PVC pipe to 200mm SteelFlex

This fan is suitable for connection to ducting runs with a minimum inlet area of 22,000mm

8 metres maximum (check with supplier if longer duct length required). SteelFlex

duct bell-mouth adaptor.

2

and length up to

™

ducting must be extended

suciently to present a smooth air passage with bends of at least the radius of twice the diameter of the duct.

Excessive bends in the ducting will compromised extraction.

WARNING: The rangehood must not be ducted into a wall cavity or a ceiling space, where a build up of grease

can occur and become a potential re risk. This will void your warranty.

™

NOTE: Fan module and Steelex

in increased noise and may void warranty. See installation instruction notes ‘Why Schweigen SteelFlex

duct are acoustically matched. Use of semi-rigid or rigid ducting will result

™

Safety Duct’.

Recommended Installation Distance

Isodrive 900 motor, recommended 4 metres of SteelFlex™ ducting and with at least two bends.

NOTE: Installation closer than this distance may result in higher noise level. Maximum duct length is 8 metres.

Check with supplier if longer duct length is required. Do not reduce the duct size at any time and avoid

sharp bends.

Page 5

Page 6

2. Your Safety

Minimum Mounting Height

This fan unit is intended for mounting at a minimum height of 2.1 metres (measured to the lower part of the

fan impeller) above a oor or the ground.

Avoidance of Back Flow

Care should be taken to avoid the back ow of gases into the room from the open ue of gas or other open re

appliances.

Safety of Children

This fan is not intended for use by young children or inrm persons without supervision.

Replacement of Supply Cord

If the supply cord is damaged, it must be replaced by a service agent or suitably qualied person in order to

avoid a hazard.

Why Schweigen SteelFlex™ Safety Duct

Schweigen SteelFlex™ is an ultra-strong and exible high-performance safety ducting made

®

of Shirikon Firemesh

Schweigen – the Silent Rangehood specialists, for quiet and ecient high-volume transfers

of temperature-sensitive air. Engineered to enhance the health and safety of your home,

Schweigen SteelFlex

It is reproof, pest and crush proof with a treated surface that prevents the build-up of grease

and bacteria.

Schweigen’s unique Isodrive system works in the opposite way to conventional rangehoods, pulling air through

the hood and acoustically matched ducting, producing almost silent high volume ow. The use of a complete

rigid or semi-rigid ducting system will allow an organ piping eect to occur; like a didgeridoo where a noise is

produced at one end of a hollow rigid pipe and the noise is amplied out the other.

– a tri-layer tear-resistant UV-treated sleeve. Both are developed by

™

is antimicrobial treated, thermally insulated and acoustically dampened.

The Isodrive system places the noise outside the house.

WARNING: Installation without the use of at least the minimum recommended length of acoustically matched

™

SteelFlex

to Schweigen. Call outs relating to incorrect installation will result in a service fee direct to the customer.

Schweigen takes no responsibility for problems caused by faulty installation, this may void warranty.

An experienced installer list can be obtained from Schweigen website www.schweigen.com.au or by

calling 1300 881 693.

Page 6

in the system will void performance expectations. Any installation problem must be reported

Page 7

NOTE

For more SteelFlex™ ducting instructions, refer page 16.

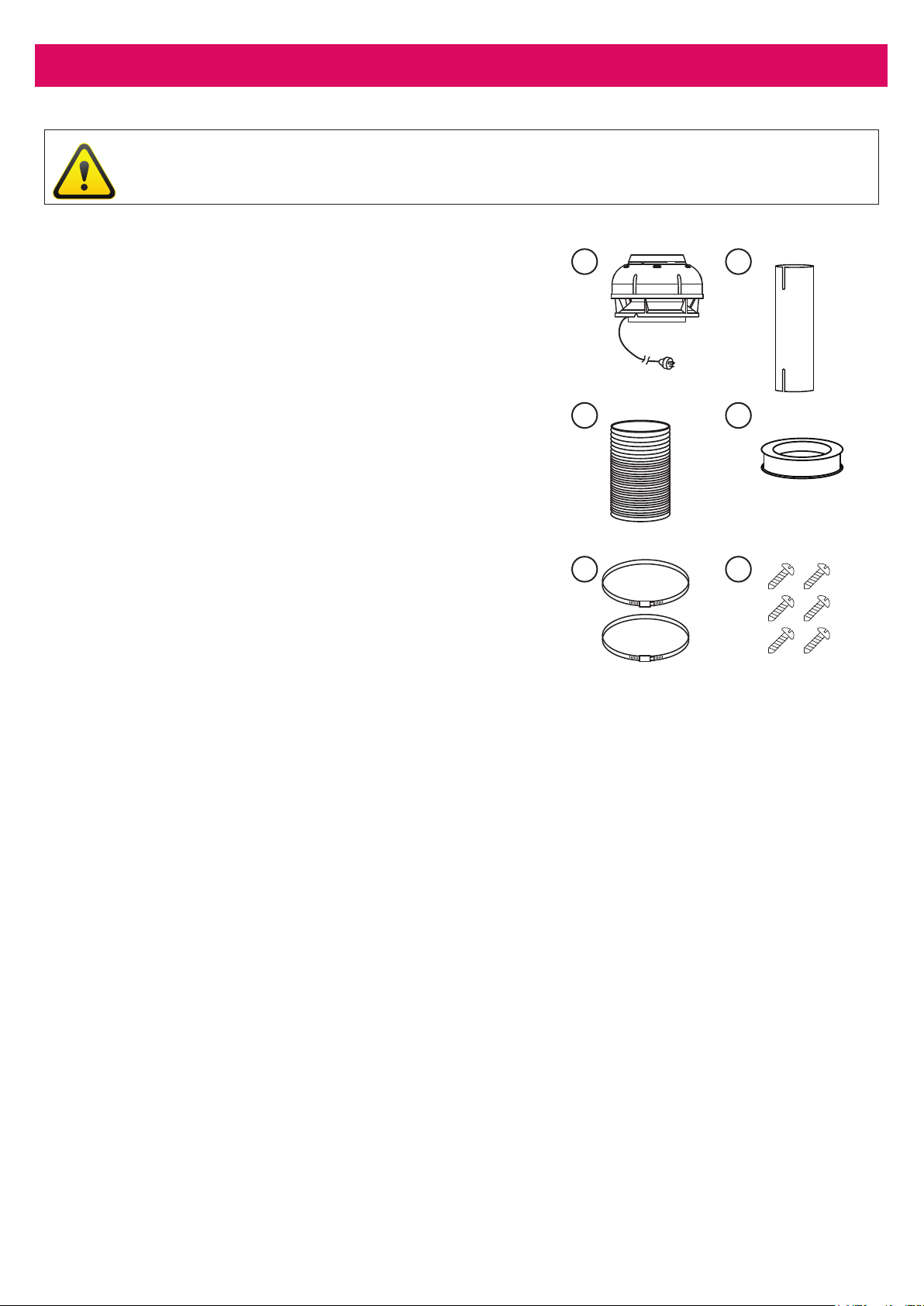

3. Description

Isodrive Motor

Included in the box:

1. Isodrive 900 motor (280W x 200H mm approx.)

Approx. 3 metre, 10amp cable and standard plug

2. Fire resistant 150mm (160mm outside dimension)

PVC riser pipe

3. SteelFlex

200mm (210mm outside dimension) diameter

4. Bell-mouth adapter ring

200mm duct to 150mm riser

5. 2 x Steel ring clamps

(for attaching ducting to rangehood and motor)

6. 6 x 20mm self-drilling button head screws

Not included in the box:

• Roof seal kit / Dektite

• Support straps for poly pipe which connects to the

roof truss

™

safety ducting. Approx. 4 metres,

1

3 4

5

2

6

• Aluminium foil tape

• Wall Cover Plate (wall mount only) – optional

Part number P1108

• Mounting Flange (wall mount only) – optional

Part number P40113MF

• Backdraft Shutter – optional

Part number 200MMBDSSBUILD

Page 7

Page 8

4. Installation

Roof Installation

Recommended duct length: 900 motor — minimum 4 metres.

Mount 150mm (ISD) rigid PVC pipe securely to beams, trusses or other appropriate structures: refer gure 1.

The pipe should be mounted vertically with the roof penetration being sealed using a Dektite or other appropriate

sealing membrane or device.

Ensure that the PVC pipe protrudes a minimum of 50mm past the top of the Dektite, checking that the fan

assembly clears the roof cladding at upper edge as shown in gure 1 — Roof Mount Option.

Pass power cord and plug through mounting ange and pipe, then out the slotted PVC pipe for connection to the

socket coming from the canopy/rangehood. Refer to gure 4.

Do not insert plug into socket outlet or switch on until installation has been completed. Fit fan module to pipe and

x in position using side locking screw.

Certain external installation congurations may cause audible levels of noise to be heard due to the air being

expelled from the motor. To minimize external noise disturbance you can use between 4 to 8 metres of SteelFlex

duct to place the Isodrive motor in an appropriate position.

3

Please be aware that the 900 motor is capable of expelling air at 900m

/hr.

For more information on environmental noise limit and conditions please contact your local Council. We have a list

of experienced installers available on the Schweigen website.

™

Do not install the SteelFlex

in a straight line and minimum of two gentle bends in the ducts is required.

™

Page 8

Page 9

Backdraft shutter (optional)

Power Cord

150mm PVC Pipe

(Locking holes fan end)

Dektite

900 motor

50mm

4. Installation

Pipe protrusion above dektite

Fix fan module using side

locking screw

Bell-mouth Adaptor

NOTE: Prevent any cord bunching by

pulling cord through from plug top end

Connect to power supply

Figure 1: Roof mount option

Fit side supports to locate pipe

Strap to supports

Connect to

rangehood

NOTE: Minimum ducting length

4 metres. Fully extend SteelFlex

ducting, cut to length.

™

IMPORTANT

For more SteelFlex™ ducting instructions, refer page 16.

Page 9

Page 10

4. Installation

Wall Installation

This type of installation is similar to roof mounting, ensuring that the pipe extends at least 50mm past the wall

surface refer gure 2. If the pipe length is shortened, reproduce the power cord exit slot on the inside of the

wall.

™

NOTE: By decreasing the length of the SteelFlex

there will be an increase in airow and noise levels as a result. This increase in airow can cause movement of

air to be heard through the system and inhibit the system to run silently.

duct from which specied (refer to installation instructions)

Optional Mounting Flange

(P40113MF*)

Optional Backdraft Shutter

900

motor

Locking screws to be fully

tightened engaging in holes

From outside face of ange to end of pipe (or

wall if mounting ange not used)

50

Wall

150mm PVC Stormwater Pipe

Locking screws

Locking holes at 4 and 10 o’clock

Wall Optional

Fitment Pipe

50

Seal with silicone or

urethane

*Optional wall mounting ange (P40113MF) is available

from Schweigen, please contact 1300 881 693.

Fill gap between pipe

and wall or t second

wall mount ange if

required

Power cord to

240V supply

Page 10

Figure 2: Wall installation

IMPORTANT

For more SteelFlex™ ducting instructions, refer page 16.

Page 11

™

SteelFlex

200mm ducting

Min 150mm long

150mm PVC pipe

Bell-mouth Adaptor

4. Installation

IMPORTANT: When

mounting pipe fan

locking holes to be in

outside end of pipe

(fan end)

Locking holes at

10 and 4 o’clock

900 motor

Min 50mm

Backdraft shutter

(optional)

NOTE: Ensure that power cord is fed through exit slot and

is not allowed to double back restricting fan inlet.

900 motor

Backdraft shutter

(optional)

Cord slots at bottom

(6 o’clock position)

NOTE: Prevent any cord

bunching by pulling cord

through from plug top end

Fix fan module using side locking

screw at 4 & 10 o’clock

Figure 3: Wall mount option

Page 11

Page 12

4. Installation

Flat Roof Installation

Flat roof mounting using optional mounting ange*.

Engage locking

screws in holes

Backdraft shutter

(optional)

900 motor

Optional mounting ange

P40113MF*

Seal top edge of ange

Seal 3 holes in

stepped surface

Seal between mounting

ange and cover

Up-stand and

capping

Power supply cord

passing through

pipe slots

NOTE: Cut 150mm PVC storm

water pipe to length and reslot

ducting end. Ensure that fan end

locking holes remain

Protrusion of pipe above

50

mounting ange

Bond ange to pipe using

silicone, urethane or type ‘N’

PVC solvent cement

Dektite

Roof Cladding

200mm SteelFlex

Ducting

™

Page 12

*Optional wall mounting ange (P40113MF) is available

from Schweigen, please contact 1300 881 693.

Figure 4: Flat roof installation

IMPORTANT

For more SteelFlex™ ducting instructions, refer page 16.

Page 13

Through Wall Installation for Isodrive 900

Fan Unit

Optional Shutter Assembly

(200mm BDSS BUILD ASS)*

4. Installation

Ensure that power cable

passes through the cover

plate notched recess and is

clear of cut edges

Optional wall cover plate with

notch at bottom P1108*

Minimum pipe protrusion from

wall surface

Wall

47mm

Wall cover plate

(optional part)

Figure 5: Wall installation

Power cord

Slot in pipe at bottom (6 O’Clock)

*Optional parts are available from Schweigen, please contact 1300 881 693.

Page 13

Page 14

4. Installation

Fan Unit Shutter Assembly for Isodrive 900 (Optional)

1. Assemble by tting shutter assembly into fan inlet shroud moulding, ensuring that attaching screws align

with holes. Alignment can be checked visually by folding in shutter aps.

2. Fully tighten both screws and re-check tment into holes.

3. Fit assembly to duct pipe as per installation instructions supplied.

Attaching screws

Attaching hole

Page 14

Inlet shroud moulding

Shutter Assembly

(optional)

NOTE: With through wall installations ap

shaft will be close to vertical

Figure 6: Shutter assembly

Page 15

5. Measurements

Measurements for Isodrive 900

198mm

515mm

Dektite

130mm

242mm

(Not to Scale)

270mm

160mm

50mm

50mm

160mm

Backdraft shutter

(optional)

Figure 7: Measurements for Isodrive 900

Page 15

Page 16

6. SteelFlex™ Safety Duct

SteelFlex

SteelFlex™ safety ducting must be fully extended and cut to the required length upon installation. Maximum

fan performance will not be achieved unless the ducting is fully extended. Failure to fully extend ducting

results in a smaller air passage and lower airows. Incorrect installation may reduce airow or increase noise

levels. Call outs relating to incorrect installation will result in a service fee directed to the customer. Schweigen

will take no responsibility for problems caused by faulty installation. A list of experienced installers can be

obtained from the Schweigen website www.schweigen.com.au.

™

Safety Ducting

900 motor

Please keep the SteelFlex™ ducting

taut, 4 metres in length with two

gentle bends.

NOTE: In shallow roof spaces extend

™

SteelFlex

ducting horizontally

Figure 8: SteelFlex™ Safety Ducting

Page 16

Page 17

6. SteelFlex™ Safety Duct

Assembling SteelFlex

SteelFlex™ safety duct must be secured to either the bell-mouth adapter ring or a 200mm mounting pipe.

Parts required:

1. SteelFlex

2. Steel ring clamp

3. Bell-mouth adapter ring 200mm duct to

150mm riser

4. 150mm PVC riser pipe

5. 20mm self-drilling button head screws

™

safety ducting

™

Safety Duct

1

3 4 5

2

1. Slide the steel ring clamp over the end of

the duct then insert the bell-mouth adapter

ring into the duct end

3. Slide the steel ring clamp back up and

tighten to secure the bell-mouth adapter

and the duct

2. Secure duct to the bell-mouth adapter at

regular intervals with 4 x 20mm button

head screws

x4

4. Attach the mounting pipe to the bell-mouth

adapter and secure with 1 x 20mm button

head screw

x1

Figure 9: Duct assembling

NOTE: Do not use duct tape to fasten the duct – the screws and hose clamp are adequate to secure the duct

to the bell-mouth adapter ring.

Page 17

Page 18

6. SteelFlex™ Safety Duct

Shallow Roof Space

In shallow roof spaces, do not crush or kink SteelFlex™ ducting, as it will reduce air ow severely. 90 degree

curve made of PVC or galvanise can be used as a substitute for the bend, refer to gure 12.

90 degree curve PVC or

galvanise curve

Figure 10: Shallow roof space

Important Note

Please do not crush or kink SteelFlex™ ducting, as it will reduce air ow and may cause noise to occur through

the system. Ducting needs to be kept taut at all times.

Page 18

Figure 11: SteelFlex

™

duct recommended installation

Page 19

6. SteelFlex™ Safety Duct

Securing SteelFlex

SteelFlex™ safety duct must be installed with supports at maximum intervals of 1.5 metres. SteelFlex™ safety

ductwork can be supported by using good quality gaer or aluminium foil tape. Provided that it does not

restrict the internal diameter of the ducting. Ducting installed looped over hanging beams should be installed

in such a manner as to ensure the changes of direction are gradual. Support of the ducting with the use of

hangers may be required, see option 2.

NOTE: Ducting should be kept taut at all times.

Option 1

™

Secure the SteelFlex

duct to the beam

™

Safety Duct

Aluminium foil

tape

Option 2

™

Support SteelFlex

duct by using hangers.

NOTE: Care shall be

taken to minimize

sagging or snaking

of the duct between

supports.

Hanger

Aluminium foil tape

Figure 12: Securing SteelFlex™ Safety Duct

Page 19

Page 20

7. Parts List

Parts List for Isodrive 900

3

11

Page 20

12

10

Page 21

Parts List for Isodrive 900

7. Parts List

Number Part

Number

1 P40100 Terminal Block Cover 1

2 P40121 Wire Insulator Cap 1

3 P1061 O Ring 4¼” ID 1

4 P1059 Capacitor 2μF 1

5 P807 Terminal Block 1

6 P40102 Fan Plate – Motor Mount 1

8 P40122 900 Inlet Shroud Mount 1

9 P1069 150mm Slotted Pipe 1

10 P40114 Bell Mouth Adaptor 1

11 P40101 Fan Shroud 1

Description Quantity

12 P301 Power Cable 1

Page 21

Page 22

8. Maintenance

Roof Restoration or Cleaning

Before doing your roof restoration or cleaning, please completely cover the outside motor system and avoid all

chemical contact.

IMPORTANT

Any damages caused by the

use of chemical products are

not covered by warranty.

Figure 13: Avoid chemical contact to motor system

Page 22

Page 23

9. Warranty / Disclaimer

Warranty

Isodrive motor has a 10-Year replacement product warranty.* The consumer is responsible for any charges

associated with removal of the faulty unit and installation of the new unit. The customer is also responsible

for any freight charges incurred in this change over process. Schweigen SteelFlex

Warranty*.

(See warranty for more information)

™

comes with a Lifetime

Disclaimer

Under our policy of continuous product development, product specications may change without notice.

Prospective purchasers should therefore check with the retailer to ensure this publication correctly describes

the products being oered for sale. All information supplied is to be used for general reference purposes only

and is on the understanding that Schweigen Home Appliances will not be liable for any loss, liability or damage

of whatever kind arising as a result of any reliance upon such information. All pictures used in the guide are for

illustrative purposes only.

*Terms and conditions apply.

Page 23

Page 24

Australia Unit 4/1-5 Lake Drive, Dingley Village, Victoria 3172. Phone 1300 881 693

Email sales@schweigen.com.au Web www.schweigen.com.au

New Zealand 5 Tolich Place, Henderson, Auckland 0610. Phone 0800 200 510

Email info.parex@emerson.com Web www.parex.co.nz

Loading...

Loading...