Page 1

INSTRUCTION MANUAL

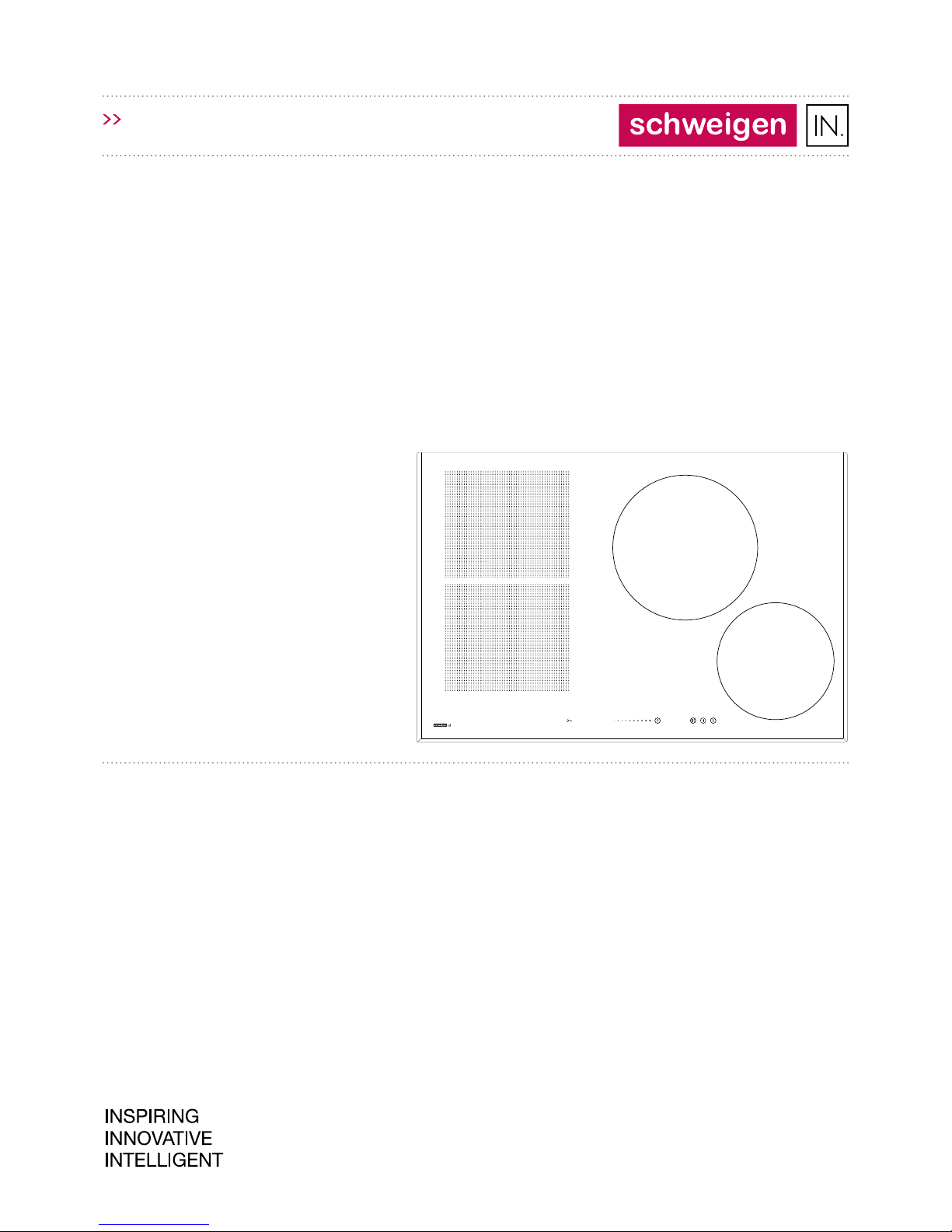

INID77

INDUCTION COOKTOP

cooktop/INDUCTION/ceran/77cm

Installation / Operation / Maintenance

Revision V1.0

INID77 (PBZ4VI527AFTB4SC)

Page 2

Thank you for purchasing this Schweigen IN

appliance.

To achieve the optimal performance from your

appliance, and to avoid the risk of accident or

damage, it is essential to read this manual before

installation and rst time use.

This guide contains important information on the

use and maintenance of the appliance, as well as

important safety notes.

Your appliance has been thoroughly checked for

safety and functionality before being packaged

and leaving the manufacturer.

Please keep this instruction manual in a safe

place so you can refer to it at any time.

IMPORTANT!

The appliance should only be operated when

you have read and understood this manual

thoroughly.

The appliance can be only used for the purpose

for which it was designed. Any other use is

improper and can be dangerous.

Installation, regulation and maintenance

of gas and electrical appliances should only

be carried out by qualied and authorised

professionals familiar with Australian

Appliance Industry regulations.

Upon collection or delivery of the appliance,

any damage or defects must be reported

within 48 hours to your retailer or

Schweigen Customer Service, in order

to recognise any claim.

The manufacturer reserves the right to

introduce changes, which do not aect the

operation of the appliance, at any time.

Page 2

WELCOME

Page 3

Page 3

INDEX

Welcome ......................................................... 2

Important Safety Information ...................... 4

How to Save Energy ....................................... 6

Unpacking ....................................................... 6

Disposal of the Appliance .............................. 7

Description of the Appliance

Control Panel ............................................................... 8

Specication .................................................. 8

Installation

Ventilation .................................................................... 9

Combustible Surfaces ................................................ 9

Requirements for the Placement of Installation ... 9

Notes for the Installer ............................................. 10

Gas Connection .......................................................... 11

Universal Gas - ULPG ................................................ 11

Natural Gas ................................................................. 11

Installing the Gas Cooktop ...................................... 13

Adapt the Cooktop to a Particular Type of Gas .... 14

Table of Burner & Injector Characteristics ........... 14

Adjust the Valves for A Reduced Flow .................. 14

Adjust the Valves ..................................................... 15

Operation

Turn on the Appliance ............................................... 16

Child Lock ................................................................... 16

Release the Child Lock ............................................. 16

Control Panel Indications ........................................ 16

Residual Heat Indicator ............................................ 17

Energy Eciency ...................................................... 17

Choice of Cookware .................................................. 17

Cookware Lids ............................................................ 17

Burner Control Dial .................................................... 17

Adjust Flame ............................................................. 18

Cleaning and Maintenance

Burners, Trivets .......................................................... 19

Regular Inspections .................................................. 19

In the Event of A Gas Leak Or Suspect Fault 20

Troubleshooting

Emergency Procedure ............................................. 21

Page 4

Page 4

SAFETY INSTRUCTIONS

Warning: The appliance and its accessible parts

become hot during use. Care should be taken to

avoid touching heating elements.

This appliance is not intended for use by anyone

(including children) with reduced physical, sensory

or mental capabilities, or lack of experience and

knowledge, unless they are supervised and/or have

been given instruction for use of the appliance.

Cleaning and user maintenance cannot be

performed by children without supervision.

Children should be supervised to ensure that they

do not play with the appliance.

Children shall not play with the appliance. Cleaning

and user maintenance shall not be made by

children.

Warning: Unattended cooking on a cooktop with

fat or oil can be dangerous and may result in re.

NEVER try to extinguish a re with water, but

switch o the appliance and then cover ame e.g.

with a lid or a re blanket.

Warning: Danger of re: do not store items on the

cooking surfaces.

Caution: The cooking process has to be

supervised. A short term cooking process has to be

supervised continuously.

Page 5

SAFETY INSTRUCTIONS

Page 5

Warning: If the surface is cracked, switch o the

appliance to avoid the possibility of electric shock.

Metallic objects, such as knives, forks, spoons and

lids should not be placed on the cooktop surface.

After use, switch o the cooktop element by its

controls and do not rely on the pan detector.

The appliance is not intended to be operated by

means of an external timer or separate remotecontrol system.

You should not use steam cleaning devices to clean

the appliance.

Page 6

Page 6

• Before using the induction cooktop for the rst

time, carefully read its user manual. This will

ensure user safety and prevent damage to the

appliance.

• If the induction cooktop is operated in immediate

vicinity to the radio, television set or other

radio-frequency-emitting device, make sure

that the cooktop’s touch sensor controls operate

correctly.

• The cooktop must be connected by a qualied

installer.

• Do not install the appliance near a refrigerator.

• Furniture, where the cooktop is installed must

be resistant to temperatures up to 100°C. This

applies to veneers, edges, surfaces made of

plastics, adhesives and paints.

• The appliance may only be used once tted in

kitchen benchtop. This will protect the user

against touching any live parts.

• Repairs to electrical appliances may only be

conducted by specialists. Improper repairs can be

dangerous to the user.

• The appliance is not connected to mains power

when it is unplugged or the main circuit breaker

is switched o.

• The power cord should be accessible after

appliance has been installed.

• Ensure that children do not play with the

appliance.

• This appliance should not be used by persons

(including children) with physical, mental

or sensory handicaps, or by those who are

inexperienced or unfamiliar with the appliance,

unless under supervision or in accordance with

the instructions as communicated to them by

persons responsible for their safety.

• Persons with implanted devices, which support

vital functions (eg, pacemaker, insulin pump, or

hearing aids) must ensure that these devices

are not aected by the induction cooktop (the

frequency of the induction cooktop is 20-50 kHz).

• Once power is disconnected all settings and

indications are erased. When electric power is

restored, caution is advisable. If the cooking

zones are hot, “ ” the residual heat indicator

will be displayed. The child lock key will also

be displayed.

• Built-in residual heat indicator can be used

to determine if the appliance is on and if it

is still hot.

• If the mains socket is near the cooking zone,

make sure the power cord does not touch any

hot areas.

• When cooking using oil and fat do not leave the

appliance unattended, as there is a re hazard.

• Do not use plastic containers and aluminium

foil. They melt at high temperatures and may

damage the cooking surface.

• Solid or liquid sugar, citric acid, salt or plastic

must not be allowed to spill on the hot cooking

zone.

• If sugar or plastic is accidentally spilled onto

the hot cooking zone, rst wait for it to cool,

then wipe o the spill with a clean, damp cloth

(do not use cleaning agents as these can cause

discolouration).

• If spillage has set hard, ensure the cooktop

is cool, then gently scrape away using an

appropriate sharp scraping utensil. Wipe o

any remaining residue with a clean, damp cloth

(do not use cleaning agents as these can cause

discolouration).

SAFETY INSTRUCTIONS FOR USE

Page 7

SAFETY INSTRUCTIONS FOR USE

Page 7

• When cooking on induction cooktop only use

pots and pans with a at base having no sharp

edges or burrs as these can permanently scratch

the cooking surface.

• The induction cooktop cooking surface is

resistant to thermal shock. It is not sensitive to

cold or heat.

• Avoid dropping objects on the cooking surface. In

some circumstances, impacts such as dropping a

bottle of spices, may lead to cracks and chipping

of the cooking surface.

• If any damage occurs, food or liquids may seep

into the live parts of the induction cooktop

through damaged areas.

• If the cooking surface is cracked, switch o

power to avoid the risk of electric shock.

• DO NOT use the cooking surface as a cutting

board or work table.

• DO NOT place metal objects such as knives, forks,

spoons, lids and aluminium foil on the cooking

surface.

• DO NOT install the cooktop over a heating unit,

dishwasher, refrigerator, freezer or washing

machine.

• If the cooktop has been built into the kitchen

worktop, metal objects located in a cabinet

below can be heated to high temperatures

through the air owing from the cooktop

ventilation system. You must install a partition

(see Fig. 2).

• Please follow the instructions for care and

cleaning of induction cooktop. In the event of

misuse or mishandling warranty may be void.

Page 8

Using the electricity in a responsible manner

not only saves money, but also helps protect the

environment. So let’s save electricity! This is how

it’s done:

• Use the correct cookware.

Cookware with at and a thick base can save up

to 1/3 of electricity. Please remember to cover

cookware with the lid, otherwise electricity

consumption increased four times!

• Always keep the cooking zones and

cookware bases clean.

Dirt prevents proper heat transfer. Often burnt

stains can be removed only with agents harmful

to the environment.

• Avoiding unnecessary lifting the lid to peek into

the pot.

• Do not install the cooktop in the immediate

vicinity of refrigerator / freezer.

The electricity consumption is unnecessarily

increased.

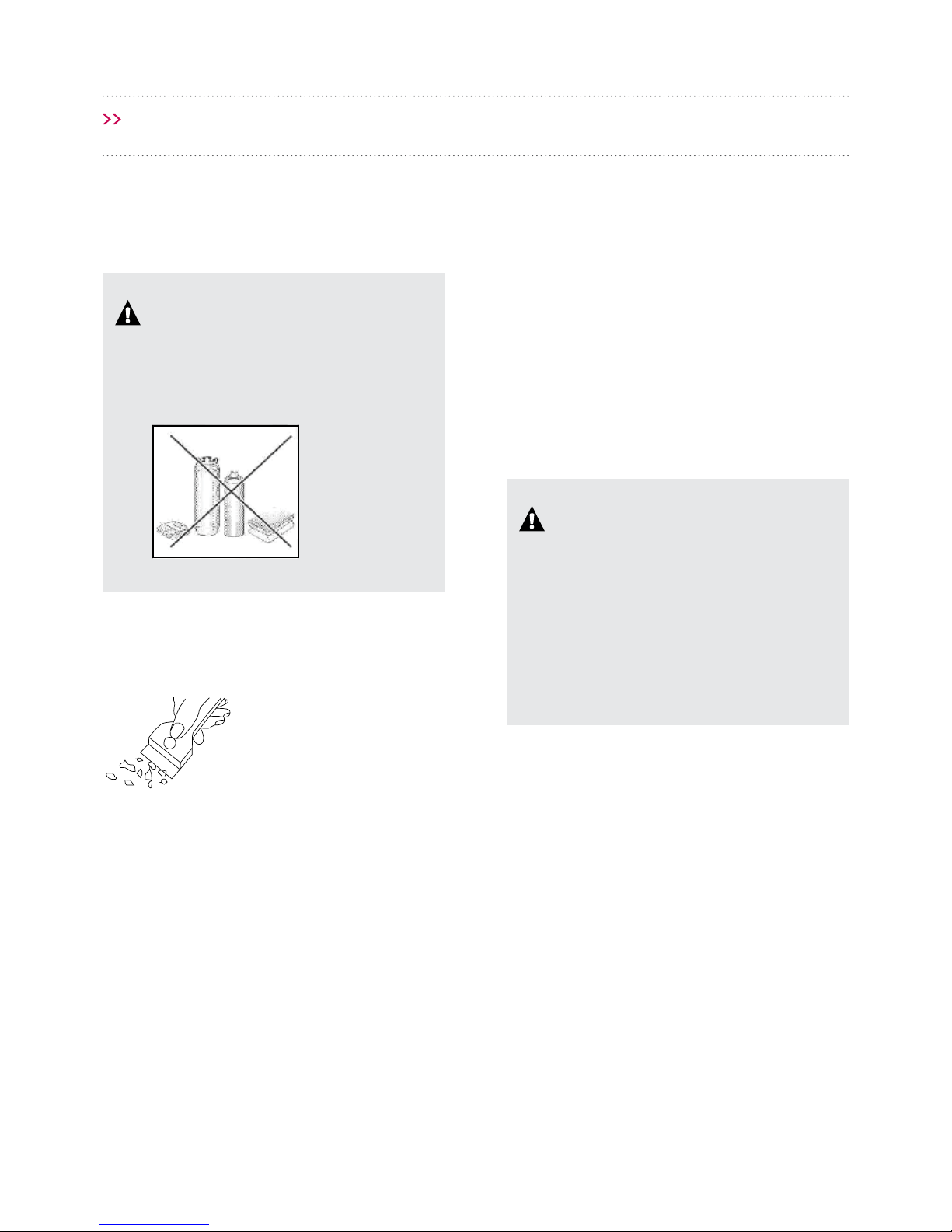

This appliance is marked with the symbol of the

crossed-out waste container.

This marking means that the appliance must not be

disposed of together with other household waste

after it has been used. The user is obliged to hand

it over to waste collection centre collecting used

electrical and electronic goods. The collectors,

including local collection points, shops and local

authority departments provide recycling schemes.

Proper handling of used electrical and electronic

goods helps avoid environmental and health

hazards resulting from the presence of dangerous

components and the inappropriate storage and

processing of such goods.

The appliance was packed to protect it from

damage at the time of transport. After unpacking,

please dispose of all elements of packaging

in a way that will not cause damage to the

environment. All materials used for packaging

the appliance are environmentally friendly; they

are 100% recyclable and are marked with the

appropriate symbol.

IMPORTANT! Keep the packaging

material (bags, styrofoam pieces, etc.) out of

reach of children during unpacking.

Page 8

SAVING ENERGY UNPACKING

DISPOSAL

Page 9

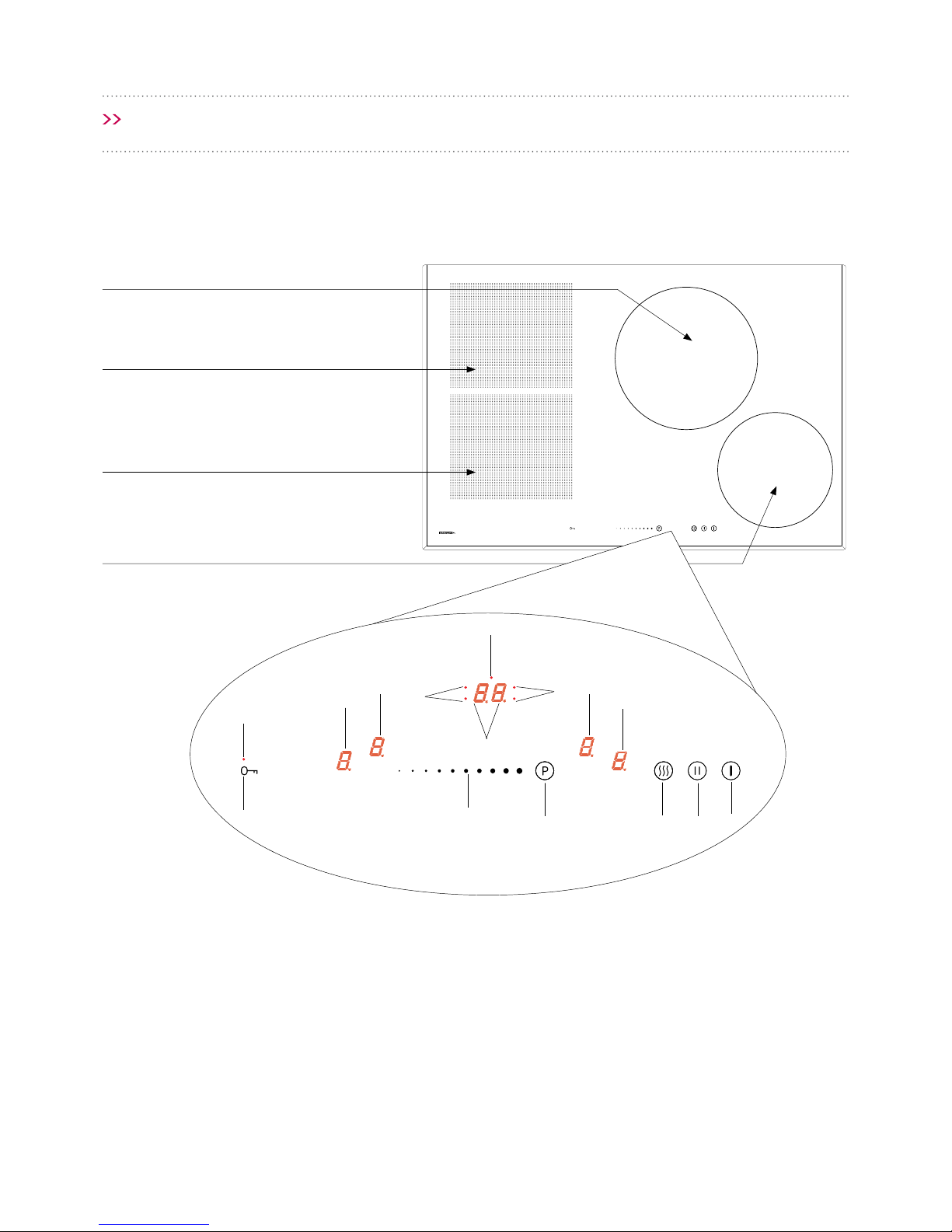

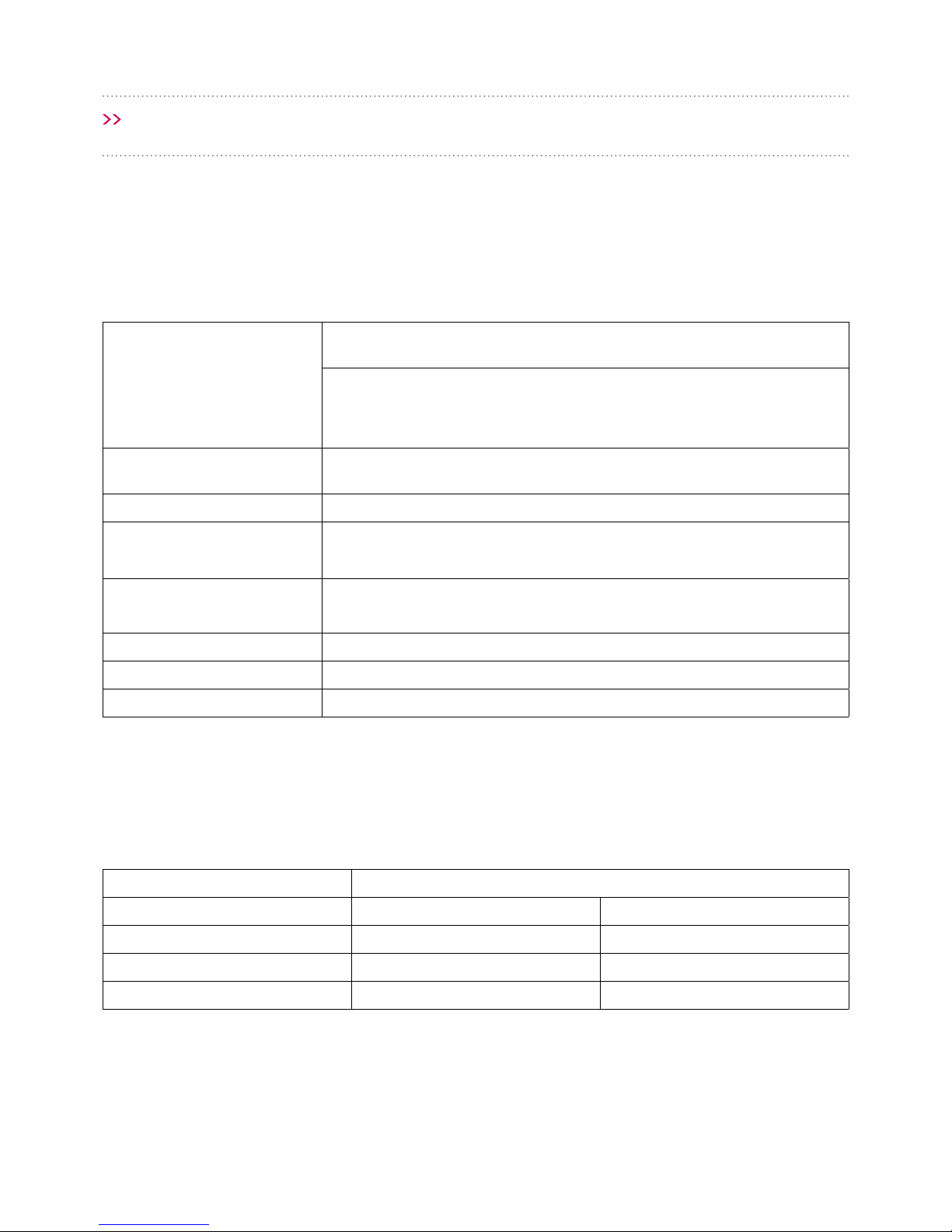

CONTROL PANEL

SENSOR FIELDS:

1. On/o sensor eld

2. Heat setting selection sensor eld

3. Cooking zone indicator

4. Timer display

5. Timer indicator light

6. Booster sensor eld

7. Stop ’n’ go function sensor eld

8. Keep Warm function sensor eld

9. Child lock sensor

10. Child lock indicator light

11. Kitchen timer indicator light

COOKTOP DESCRIPTION

CONTROL PANEL

Induction cooking zone

booster (rear right)

Induction cooking zone

booster (rear left)

Induction cooking zone

booster (front left)

Induction cooking zone

booster (front right)

1

2

3

3

3

4

5

6

78

9

10

11

5

3

Page 9

DESCRIPTION OF THE APPLIANCE

Page 10

Page 10

INSTALLATION

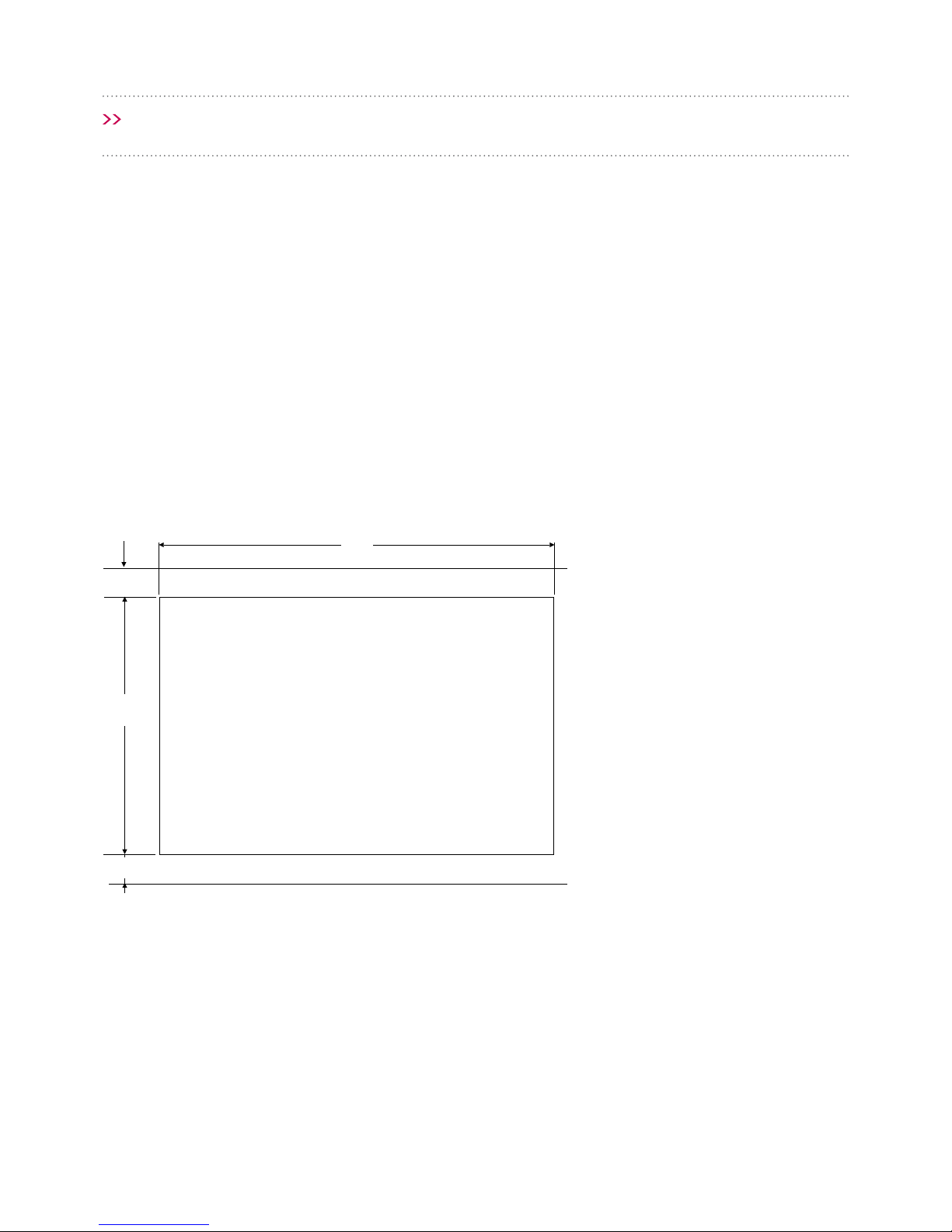

RECESSING THE BENCHTOP

Benchtop thickness should be 28 - 40 mm, with a

width of at least 600 mm. The benchtop must be

at and level, and the edge of the benchtop near

the wall must be sealed to prevent ingress of water

or other liquids.

There should be sucient spacing around the

opening in particular — at least 50 mm distance to

the wall and 60 mm distance to the front edge of

benchtop.

The distance between the edge of the opening and

the side wall of the benchtop should be a minimum

of 55 mm.

The benchtop must be made of materials –

including veneer and adhesives – resistant to

a temperature of 100°C. Otherwise the veneer

could come o or the surface of the benchtop can

become deformed.

The edge of the opening should be sealed with

suitable materials to prevent ingress of water.

The benchtop opening must be cut to dimensions

as shown in Figure 1.

Ensure there is a minimum clearance of 25 mm

below the cooktop to allow proper air circulation

and prevent overheating. See Figure 2.

750

094

nim

06

nim

05

321

Figure 1. Cutout

Measurements in mm.

Page 11

INSTALLATION

Page 11

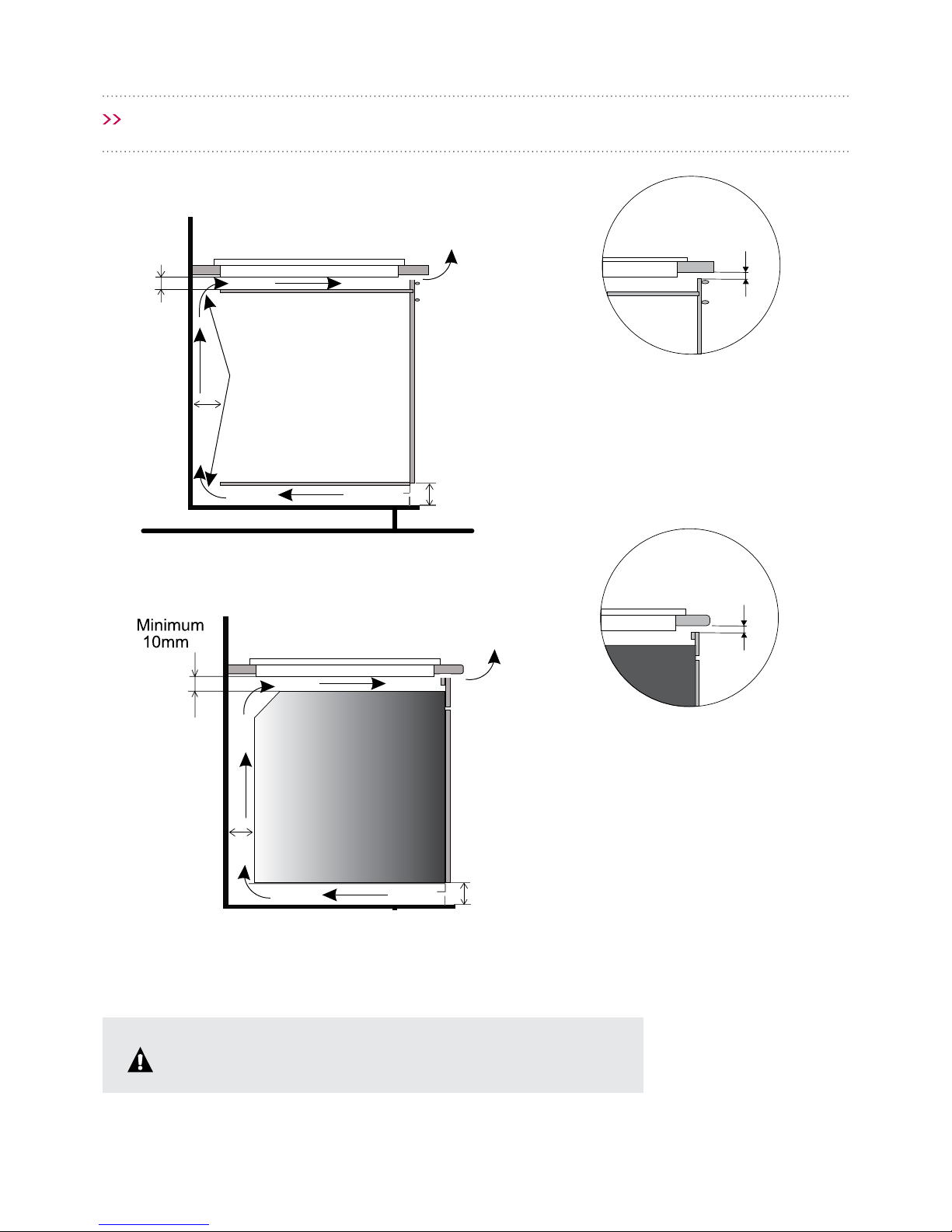

Figure 2.

750

094

06

05

Installing cooktop in kitchen

cabinet benchtop.

Installing cooktop in kitchen

benchtop above oven with

ventilation.

5 10mm-

5 10mm-

25mm

30mm

20mm

321

20mm

10mm

10mm

Do not install the cooktop above the oven without ventilation.

Page 12

INSTALLATION

Page 12

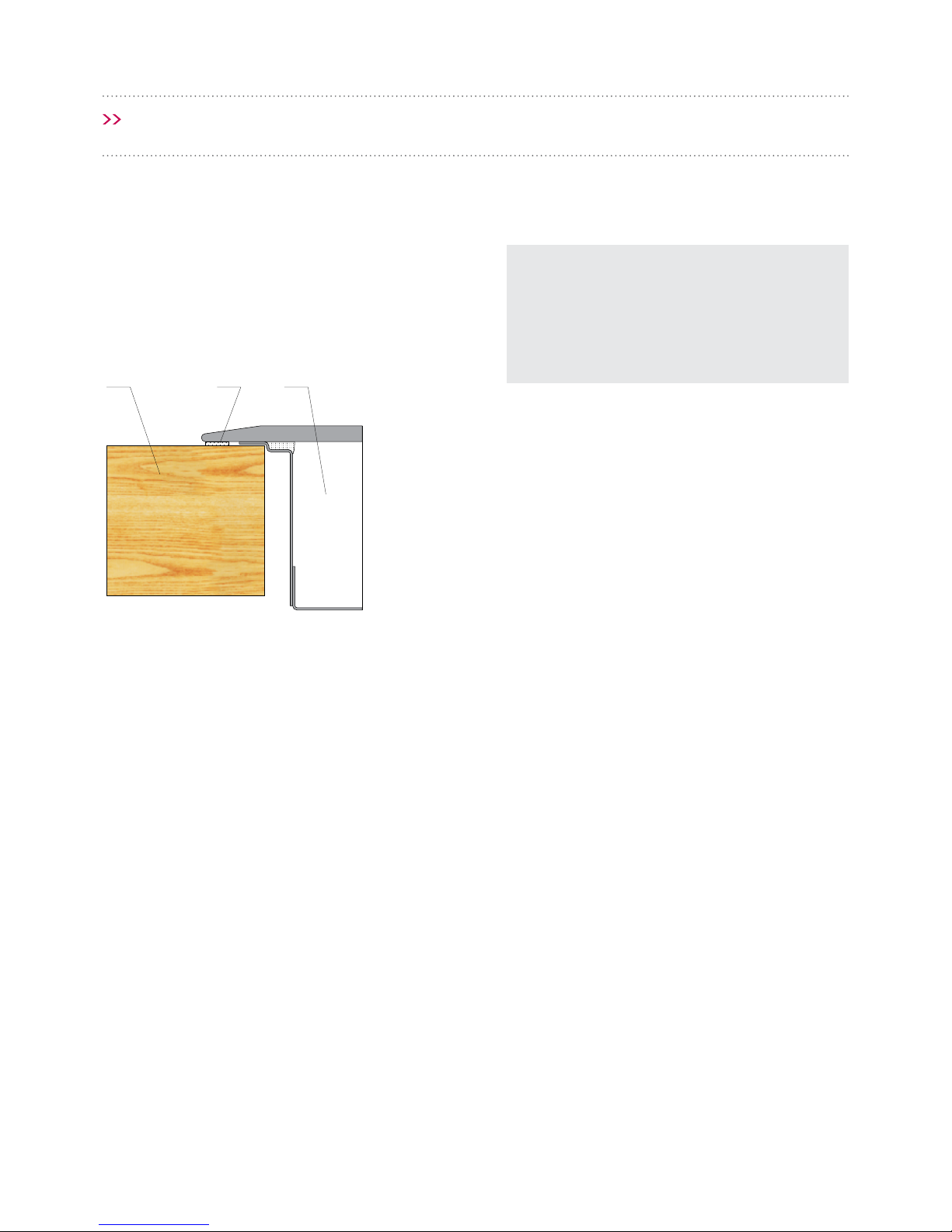

INSTALLING THE COOKTOP

• Using an electrical cord, connect the cooktop

according to electrical diagram provided.

• Remove dust from the worktop, insert cooktop

into the opening and press in rmly (Fig. 3).

CONNECTING TO ELECTRICAL MAINS

321

IMPORTANT

Electrical connection must be made by an

authorised qualied installer. Do not make

any alterations to the cooktop’s electrical

system.

Figure 3.

1. Benchtop

2. Flange Gasket

3. Induction cooktop

Page 13

INSTALLATION

Page 13

TIPS FOR THE INSTALLER

The cooktop is equipped with a terminal block

allowing dierent connections appropriate for a

specic type of power supply.

Terminal block allows the following connections:

Single-phase 220-240 V ~

Two-phase 400 V 2N~

The cooktop can be adapted to a specic type

of power supply by bridging the appropriate

terminals according to wiring diagram. The wiring

diagram is placed on the cooktop’s underside. The

terminal block can be accessed by removing the

lid on cooktop’s underside. Remember to match

the power cord to the type of connection and the

cooktop’s power rating.

IMPORTANT

Remember to connect the Earth lead to the correct terminal block clamp, marked with . The electrical

system supplying the cooktop must be protected by a appropriate tripping device or a circuit breaker

allowing to disconnect the power supply in an emergency.

When connecting to xed wiring a means for an all pole disconnection with at least 3mm contact

separation must be incorporated in the xed wiring in accordance with the wiring rules. This appliance

should only be installed by qualied persons.

Before connecting the appliance to power, carefully

read the information provided on the rating plate

and wiring diagram.

Connecting the cooktop other than shown on

the wiring diagram will cause damage.

Page 14

INSTALLATION

Page 14

WIRING DIAGRAM

IMPORTANT: Heating elements operate at 220-240 V ~

Important! For each connection the protective conductor must be

connected to the terminal marked

.

Type / Conductor

cross section

Fuse protection

1 For a 230 V single phase

connection with a neutral lead,

terminals L1, L2 are bridged,

neutral lead is connected to

terminal N, and the protective

conductor to

.

1N~

NL1

HO5VV-FG

3 x 4mm

2

min.30A

2* For a 230/400 V two phase

connection with a neutral lead,

neutral lead is connected to

terminal N, and the protective

conductor to

.

2N~

NL1L2

HO5VV-FG

4 x 2.5mm

2

min.16A

L1 = R, L2 = S, L3 = T; N = neutral lead connection;

= protective lead terminal

* For domestic 3-phase 230/400 V electrical system, connect the remaining wire to the terminal:L3, which is not

connected to the cooktop internal electrical system.

* NN terminals are internally connected, they need not be bridged

Page 15

BEFORE USING THE APPLIANCE

FOR THE FIRST TIME

• Thoroughly clean your induction cooktop rst.

The induction cooktop should be treated with

the same care as a glass surface.

• Switch on the ventilation in the room or open

a window, as the appliance could emit odours

during rst use.

• Operate the cooktop observing all safety

guidelines.

INDUCTION COOKING OPERATION PRINCIPLE

An electric oscillator powers a coil placed inside

the appliance. This coil produces a magnetic eld,

which induces eddy currents in the cookware.

These eddy currents induced by the magnetic eld

cause the cookware to heat up.

This requires the use of pots and pans a

ferromagnetic base — in-other-words susceptible

to magnetic elds.

Overall, induction technology is characterised by

two advantages:

• The heat is only emitted by the cookware,

• There is no thermal inertia, since the cooking

starts immediately when the pot is placed on the

cooktop and ends once it is removed.

Certain sounds can be heard during normal use

of the induction cooktop, which do not aect its

correct operation.

Low-frequency humming. This noise arises when

the cookware is empty and stops when water is

poured or food is placed in the cookware.

• High-frequency whiz. This noise arises in

cookware made of multiple layers of dierent

materials at maximum heat setting. The noise

intensies when using two or more cooking

zones at maximum heat setting. The noise will

stop or reduce when the heat setting is reduced.

• Creaking noise. This noise arises in cookware

made of multiple layers of dierent materials.

The noise intensity depends on how the food is

cooked.

• Buzzing. Buzzing can be heard when the

electronic cooling fan operates.

The noises that can be heard during the normal

appliance operation are the result of the cooling

fan operation, cooking method, cookware

dimensions, cookware material and the heat

setting. These noises are normal and do not

indicate a fault.

Page 15

OPERATION

Page 16

OPERATION

Page 16

Protective device: If the cooktop has been

installed correctly and is used properly, any

protective devices are rarely required.

Fan: protects and cools controls and power

components. It can operate at two dierent speeds

and is activated automatically. Fan runs until the

electronic system has suciently cooled down

regardless of the appliance or the cooking zones

being turned on or o.

Temperature sensor: The temperature of the

electronic circuits is continuously monitored by

a temperature sensor. If temperature is raised

beyond a safe level, the protection system will

reduce the cooking zone heat setting or shut down

the cooking zones adjacent to the overheated

electronic circuits.

Pan detection: sensor allows the cooktop to

detect pans placed on a cooking zone. Small objects

placed on the cooking zone (eg, spoon, knife, ring,

etc.) will not be recognised as pans and the cooktop

will not operate.

PAN DETECTOR

A pan detector sensor is installed in this induction

cooktop. The pan detector starts heating

automatically when a pan is detected on a cooking

zone and stops heating when it is removed. This

helps save electricity.

When a suitable pan is placed on a cooking zone,

the display shows the heat setting.

IMPORTANT

If a pan is not placed on a cooking zone or

the pan is unsuitable, the symbol is

displayed. The cooking zone will not operate.

If a pan is not detected within 90 seconds,

the cooking zone will be switched o.

Switch o the cooking zone using the touch

control sensor eld rather than by removing

the pan.

Pan detector is not an on/o operation.

The induction cooktop is equipped with electronic

touch control sensor elds, which are operated by

touching the marked area with a nger.

Each time a sensor eld is touched, an acoustic

signal can be heard.

IMPORTANT

When switching the appliance on or o, or

changing the heat setting, touch only one sensor

eld at a time.

When two or more sensor elds are touched at

the same time, the appliance ignores the control

signals and may trigger a fault indication (with

the exception of Bridging, Timer, and Child Lock

operations).

When you nish cooking switch o the

cooking zone using the touch control sensor

elds and do not rely solely on the pan

detector.

Page 17

OPERATION

Page 17

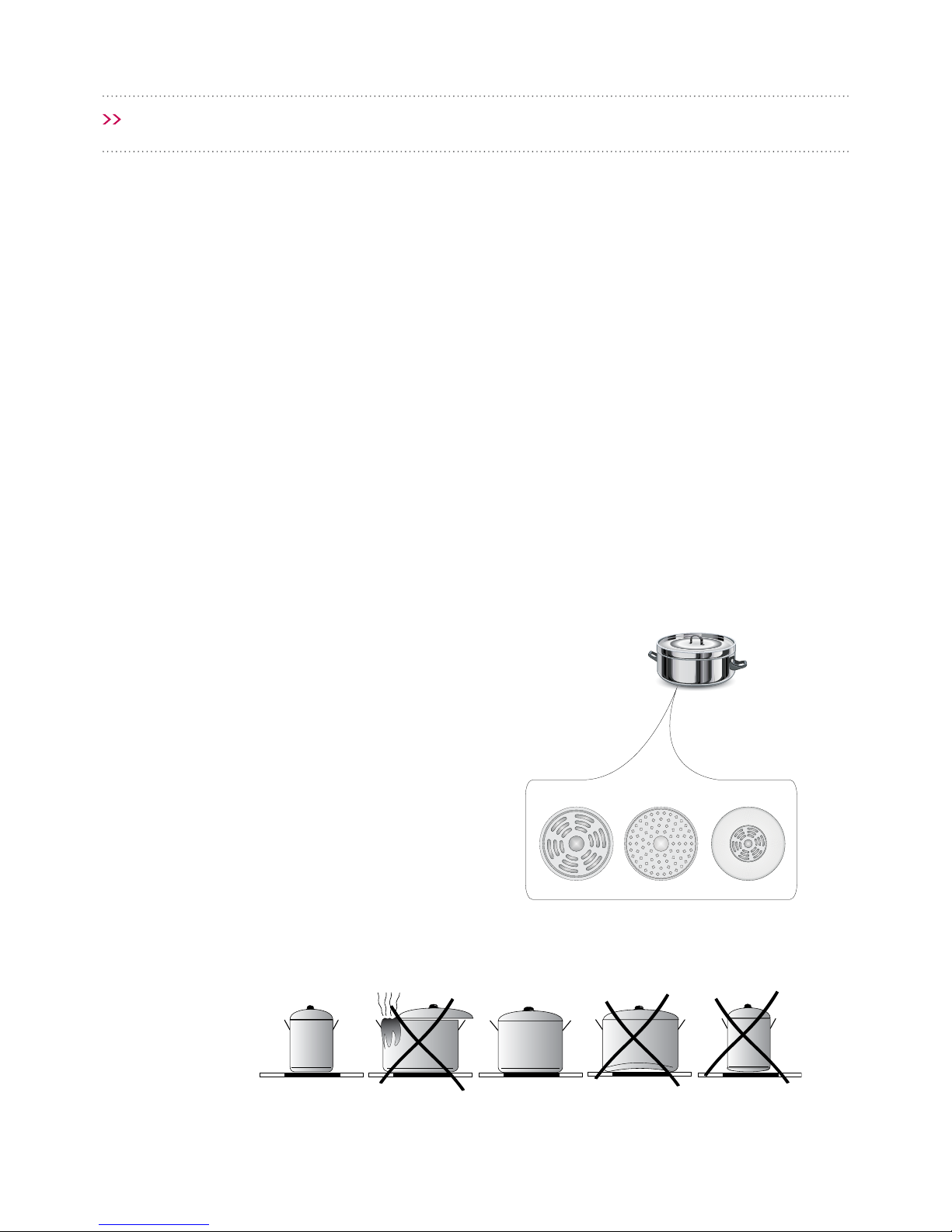

COOKWARE CHARACTERISTICS

• To determine if cookware is suitable, make sure

that its base attracts a magnet.

• Always use high quality cookware, with perfectly

at base. This prevents the formation of local

hot spots, where food might stick. Pots and

pans with thick steel walls provide superior heat

distribution.

• Make sure that cookware base is dry: when

lling a pot or when using a pot taken out of the

refrigerator, make sure its base is completely dry

before placing it on the cooking zone. This is to

avoid soiling the surface of the cooktop.

• A lid prevents heat from escaping and

reduces heating time as well as lowers energy

consumption.

• Cookware base has to be at for optimal

temperature control by the induction

module.

• A concave base or deep-embossed

manufacturer’s logo (Fig. 1) may interfere

with the temperature induction control

module and can cause overheating of the

pot or pan.

• Do not use damaged cookware such as

cookware with a deformed base due to

excessive heat.

• Ensure cookware is placed on the cooking

zone correctly (Fig. 2).

• When you use large ferromagnetic base

cookware, whose diameter is less than the

total diameter of the cooking zone, only the

ferromagnetic base heats up. This results in a

situation where it is not possible to uniformly

distribute the heat in the cookware. If the

ferromagnetic area is reduced due to inclusion of

aluminium parts then the eective heated area

can be reduced. Problems with the detection of

the cookware could arise or cookware may not be

detected at all. To achieve optimum cooking

results, the diameter of the ferromagnetic

base should match that of the cooking

zone. If cookware is not detected in a given

cooking zone, it is advisable to try it in a smaller

cooking zone.

SELECTING COOKWARE TO USE WITH YOUR INDUCTION COOKTOP

High-quality cookware is essential for optimal induction cooking.

Figure 1.

Figure 2.

Page 18

OPERATION

Page 18

For induction cooking us only ferromagnetic base materials such as:

• Enamelled steel

• Cast iron

• Special stainless steel cookware designed for induction cooking.

How will I know my cookware

is suitable for use on the

induction cooktop?

Check for markings on the cookware indicating that the cookware is

suitable for induction cooking.

Use magnetic cookware (enamelled steel, ferrite stainless steel, cast iron).

The easiest way to determine if your cookware is suitable is to perform the

“magnet test”. Find a generic magnet and check if it sticks to the base of the

cookware.

About Stainless Steel

Cookware

Stainless steel cookware will not be detected; with the exception of the

ferromagnetic steel cookware.

Aluminium Cookware Aluminium cookware will not be detected.

Cast Iron Cookware

High eciency.

CAUTION: Cast Iron Cookware can scratch the cooktop surface.

Enamelled Steel Cookware High eciency.

Cookware with a at, thick and smooth base is recommended.

Glass Cookware Glass cookware will not be detected.

Porcelain Cookware Glass cookware will not be detected.

Cookware with copper base Glass cookware will not be detected.

COOKWARE SIZE

• Energy is transferred best when cookware size corresponds to the size of the cooking zone. The smallest and

largest possible diameters are indicated in the following table and depend on the quality of the cookware

used.

• When using cookware smaller than the minimum diameter, the induction cooktop may not work.

Induction cooking zone The base diameter of induction cookware

Diameter (mm) Minimum (mm) Maximum (mm)

2 x 220 x 190 120 220

1 x 260 160 260

1 x 210 140 210

Page 19

OPERATION

Page 19

1

2

3

3

3

4

5

6

78

9

10

11

5

3

CONTROL PANEL

Immediately after the appliance is connected to

electrical mains, all displays will light up briey.

Your induction cooktop is then ready for use.

The induction cooktop is equipped with electronic

touch control sensor elds, which are operated by

touching with a nger for at least 1 second.

Touching the sensor eld is accompanied by an

acoustic signal to acknowledge.

No objects should be placed on

the sensor elds (this could cause

an error). Touch sensor elds

should always be kept clean.

If none of the sensor elds are

touched within 10 seconds of

switching on the appliance,

the cooking zone switches o.

A cooking zone is active when its

display shows a digit or a letter.

This indicates the cooking zone

is ready for the heat setting to be

set or changed.

If none of the sensor elds are

touched within 10 seconds, the

appliance switches itself o.

SWITCH ON THE APPLIANCE

• To switch on the appliance touch and hold the

on/o sensor eld (1) for at least 1 second.

• The appliance is switched on when all heat

setting displays (3) show “ ” and decimal point

is ashing.

SWITCH ON THE COOKING ZONE

Once the appliance is switched on using the on/o

touch sensor (1), select a cooking zone (3) within

the next 10 seconds.

1. When a cooking zone selection sensor eld (3) is

touched, “ ”on the corresponding heat setting

indicator display will pulsate.

2. To select the desired heat setting, slide your

nger across the setting selection sensor eld (2).

CONTROL PANEL

SENSOR FIELDS:

1. On/o sensor eld

2. Heat setting selection sensor eld

3. Cooking zone indicator

4. Timer display

5. Timer indicator light

6. Booster sensor eld

7. Stop ’n’ go function sensor eld

8. Keep Warm function sensor eld

9. Child lock sensor

10. Child lock indicator light

11. Kitchen timer indicator light

Page 20

OPERATION

Page 20

SELECTING THE COOKING ZONE HEAT

SETTING

When the cooking zone display (3) shows pulsating

“ ” start setting the desired heat setting by sliding

your nger across the setting selection sensor eld

(2).

DEACTIVATE COOKING ZONES

• A given cooking zone must be active. Heat

setting display pulsates.

• To switch o a cooking zone touch the on/

o sensor eld or touch the sensor (3) for

3 seconds. Slide your nger across the heat

selection sensor eld (2) to reduce the heat

setting to “ ”.

SWITCH OFF THE APPLIANCE

• The appliance operates when at least one

cooking zone is on.

• To switch o the appliance touch the on/o

sensor (1).

If a cooking zone is still hot, the relevant display (3)

will show the letter “ ” to indicate residual heat.

BOOSTER FUNCTION

“

”

The Booster Function increases the nominal power

of individual cooking zones from

ø 220 x 190mm cooking zone from 2200W to 3700W,

ø 260mm cooking zone from 2100W to 3400W,

ø 210mm cooking zone from 2000W to 3000W,

Bridge from 3600W to 5500W.

In order to activate the Booster function, select

the cooking zone and then using sensor (6) set the

heat setting to “ ”. The letter “ ” will be shown on

the display (3).

To switch o the Booster function, touch the heat

setting selection sensor eld (2) and reduce the

heat setting, or lift the pot from the cooking zone.

For Ø 220x190 cooking zone, operation

of the Booster function is limited to 10

minutes. Once the Booster function is

automatically deactivated, the cooking

zone continues to operate at its nominal

power.

The Booster function can be reactivated,

provided the appliance electronic

circuits and induction coils are not

overheated.

When the pot is lifted from the

cooking zone when the Booster function

is in operation, it remains active and the

countdown continues.

If the cooktop’s electronic circuits or

induction coils overheat when

the Booster function is in operation,

it is automatically deactivated. The

cooking zone then continues to operate

at its nominal power.

Page 21

OPERATION

Page 21

BOOSTER FUNCTION CONTROL

You can use booster function on two vertically or

horizontally arranged cooking zones at the same

time.

THE CHILD LOCK FUNCTION

The Child Lock function protects the appliance from

inadvertent operation by children. The appliance

can be operated once the child lock function has

been released.

The Child Lock function can be set when the

appliance is turned on or o.

TURN CHILD LOCK ON/OFF

Touch and hold sensor (9) for 5 seconds to turn

Child Lock on/o. Indicator light (10) is on when the

Child Lock function is on.

The Child Lock function remains set until

it is released even after the appliance

has been switched o and then

switched on again.

Disconnecting the appliance from the

electrical mains deactivates the Child Lock.

RESIDUAL HEAT INDICATOR

Heat energy that remains

accumulated in the cooking zone

after cooking is called the residual

heat. The appliance displays two

dierent levels of residual heat.

When a cooking zone temperature

is above 60°C and the cooking

zone or the appliance is switched o, the relevant

cooking zone display will show the letter “ ”.

Residual heat indication is displayed as long as the

cooking zone temperature exceeds 60°C. When a

cooking zone temperature is between 45°C and

60°C, the relevant cooking zone display will show

the letter “ ” indicating low residual heat. When

a cooking zone temperature is below 45°C the

residual heat indication is turned o.

When the residual heat indicator is on,

do not touch the cooking zone as there

is a risk of burns. Do not place any items

that are sensitive to heat on the zone.

The “ ” residual heat indicator is not

displayed during a power outage.

However, cooking zones may still be hot!

Page 22

OPERATION

Page 22

If a pot is lifted from the cooking zone

and replaced before the warm-up

countdown is completed, the warm-up

function will resume and countdown will

continue until completed.

LIMITING THE OPERATING TIME

In order to increase eciency, the induction

cooktop is tted with an operating time limiter for

each of the cooking zones. The maximum operating

time is set according to the last heat setting

selected.

If you do not change the heat setting for a long

time (see table) then the associated cooking zone

is automatically switched o and the residual heat

indicator is activated. However, you can switch on

and operate individual cooking zones at any time in

accordance with the operating instructions.

AUTOMATIC WARMUP FUNCTION

• Touch sensor eld (3) to activate the selected

cooking zone.

• Then sliding your nger across the setting

selection sensor eld (2) set the desired heat

setting in the 1-8 range and then touch sensor

eld (3) again.

• The display will alternate between the letter

“ ” and the heat setting.

After a certain time of operation at boosted power,

the cooking zone switches back to the heat setting

set, which will be shown on the display.

Cooking Heat Setting Maximum Operating

Time (hours)

8

1 8

2 8

3 5

4 5

5 5

6 1.5

7 1.5

8 1.5

9 1.5

P 0.16

Cooking Heat Setting Duration of the

Automatic Warm-up

(minutes)

1 0.8

2 1.2

3 2.3

4 3.5

5 4.4

6 7.2

7 2

8 3.2

Page 23

OPERATION

Page 23

SETTING THE TIMER

The timer function makes cooking easier by setting

the cooking duration. The timer function can only

be set when a cooking zone is operating (heat

setting is greater than “ ” ). The timer function

can be set independently for all individual cooking

zones. Timer countdown can be set from 1 to 99

minutes.

To set the timer:

• Select a cooking zone by touching cooking the

zone selection sensor eld (3) and select the

desired heat setting from 1 to 9 by sliding your

nger across the heat setting selection sensor

eld (2). The display will show the selected heat

settings from 1 to 9.

• Then, during the next 10 seconds, touch the

Timer selection sensor eld (4). “

” will

be shown on the Timer display (4) and the

appropriate Timer activation indicator light (5)

will light up to indicate activation of the Timer

function for the relevant cooking zone.

• Now, select the desired Timer setting by sliding

your nger across the setting selection sensor

eld (2). The second digit is set rst and the rst

digit is set next. Once the second digit is set,

touch the sensor (4) again to set the rst digit. If

you do not set any value for the rst digit within

10 seconds, the value will be set to “ ” (eg.

“

”). The countdown starts when the Timer

activation indicator light (5) starts ashing.

CHANGING TIMER DURATION

Programmed Timer setting can be changed at any

time.

To change the programmed Timer setting, select

a cooking zone by touching the cooking zone

selection sensor eld (3), and then touch the Timer

selection sensor eld (4).

CHECK TIMER DURATION

To check progress of Timer countdown at any time,

touch the timer sensor eld (4). Timer indicator

light (5) for the relevant cooking zone will ash.

STOP THE TIMER

When the set time has elapsed an acoustic signal

is sounded, which can be muted by touching any

sensor eld. If no sensor eld is touched, the

acoustic signal will stop automatically after 2

minutes.

To stop the timer countdown before the set

cooking duration has elapsed:

• Touch cooking zone selection sensor eld (3) to

select a cooking zone. The display will become

bright.

• Then touch and hold sensor eld (4) for 3

seconds or adjust duration using the sensor eld

(2) sliding your nger down to “

” .

Timer countdown can be set

independently for all cooking zones.

If more than one timer is set the shortest

duration is displayed. Timer indicator

light (5) of a relevant cooking zone will

ash.

Page 24

OPERATION

Page 24

KITCHEN TIMER

When no cooking zones are in use, the Timer

function can be used as a regular Kitchen Timer.

SET KITCHEN TIMER

When the appliance is o:

• Touch the on/o sensor (1) to turn on the

appliance. “ ” will be shown on cooking zone

displays (3).

• Then, during the next 10 seconds, touch the

Kitchen timer selection sensor eld (4). Kitchen

timer display (4) will show “

”.

• Now, select the desired Timer setting by sliding

your nger across the setting selection sensor

eld (2). The second digit is set rst and the rst

digit is set next. Once you set the second digit,

the appliance will automatically allow you to set

the rst digit. If you do not set any value for the

rst digit within 10 seconds, the value will be

set to “ ” (eg.“

”). The kitchen timer starts

countdown when the indicator lamp (11) starts

ashing.

STOP KITCHEN TIMER

When the set duration has elapsed an acoustic

intermittent signal is sounded (beeping), which

can be muted by touching any sensor eld. If no

sensor eld is touched, the acoustic signal will stop

automatically after 2 minutes.

To stop the timer countdown before the set

duration has elapsed:

• Touch and hold sensor eld (4) for 3 seconds or

adjust duration using the sensor eld (2) sliding

your nger down to “

”

• Kitchen Timer function does not aect cooking

zone operation.

Kitchen timer is reset when the timer

function is activated.

Page 25

OPERATION

Page 25

KEEP WARM FUNCTION

The Keep Warm function allows you to set any zone

to one of three preset ‘ideal’ cooking temperatures:

• 42°C - butter or chocolate melting; keeps readyto-serve food warm, retaining taste, and prevent

contents from sticking to the bottom of the pan .

• 70°C - reheating food to ready-to-serve

temperature

• 94°C - maintain rolling boil.

For the Keep Warm function to operate correctly,

use a at base pot or frying pan, so that the

base temperature is accurately measured by the

temperature sensor tted in the cooking zone.

The Keep Warm function can be activated for any

cooking zone.

To activate a Keep Warm function:

• 42°C: Touch sensor (3) to select the cooking

zone, then touch Keep Warm function sensor

eld (8) and the display will show the “ ” symbol

indicating the temperature of 42°C is selected.

• 70°C: Touch Keep Warm function sensor eld (8)

again and the second “ ” symbol will be shown

indicating the temperature of 70°C is selected.

• 94°C: Touch Keep Warm function sensor eld

(8) again and the third “ ” symbol will be shown

indicating the temperature of 94°C is selected.

To turn o the Keep Warm function:

• To turn o the Keep Warm function at any time

touch sensor (3), and then slide across the

sensor (2) to reduce heat setting to “ ” .

STOP ‘N’ GO FUNCTION

“

”

Stop ‘n’ go function acts like a ‘pause button’. It

simultaneously suspends operation of all cooking

zones and then resumes at the heat settings that

were previously set.

To activate the Stop ‘n’ go function:

In order to activate the Stop ‘n’ go function, at least

one cooking zone must be in use.

Next, touch the Stop ‘n’ go function sensor eld (7).

“ ” will be shown on all cooking zone displays (3).

When a cooking zone is still hot, the “ ” symbol will

alternate between “ ” and “ ” indicating residual

heat in a given cooking zone.

To activate the Stop ‘n’ go function:

To deactivate the Stop ‘n’ go function, touch the (7)

sensor eld again. The cooking zone displays (3)

will show the heat setting that was previously set

before activation of the Stop ‘n’ go function.

BRIDGE FUNCTION

The Bridge function allows pairing of two cooking

zones into a single combined cooking zone. The

Bridge function is very convenient, especially when

cooking with very large pots, grill skillets or baking

pans.

Note: The two left cooking zones can be bridged.

In order to activate the Bridge function, touch

the cooking zone sensor eld (3) and then

simultaneously touch two sensors of both left side

cooking zones (3). The rear cooking zone will display

“ ” , while the front cooking zone will display “ ” .

The desired heat setting is selected by sliding your

nger across the setting selection sensor eld (2).

Both cooking zones can now be controlled at

the same time.

In order to deactivate the Bridge function, touch

and hold the cooking zone sensor (3) with symbol

“

” for 3 seconds. The respective cooking zone

displays will show “ ” .

Both cooking zones can now be controlled

independently.

Page 26

Page 26

CLEANING AND MAINTENANCE

Proper routine maintenance and cleaning of the

appliance can signicantly extend its trouble-free

operation.

Cleaning After Each Use

Wipe light stains with a damp cloth without

detergent. The use of dishwashing liquid may

cause a bluish surface discolouration. These

persistent stains cannot always be removed right

away, even using a special cleaner.

Spills that have set hard can be carefully removed

with a scraper. Then wipe the cooking surface with

a damp cloth.

REMOVING STAINS

Bright stains of pearl colour (residual

aluminium) can be removed from the cool cooktop

using a special cleaning agent. Limestone residue

(eg. after evaporated water) can be removed by

vinegar or a special cleaning agent.

Turn o the cooking zone before removing sugar,

food containing sugar, plastic and aluminium foil.

Immediately and thoroughly scrape the leftovers

o the hot cooking zone using a sharp scraper.

Once the bulk of the stain is removed, the cooktop

can only be cleaned with water or an appropriate

specially designed cleaning agent*.

When cleaning your induction cooktop,

the same principles apply as for

glass surfaces. Do not use under any

circumstances any abrasive or caustic

cleaners or scouring powders or pads. Do

not use steam or pressure cleaners.

DO NOT use any descaling agents to

clean the cooktop.

Special cleaners designed especially for

induction cooktop surfaces are available in

supermarkets, electrical and home appliance

stores, and the Schweigen kitchen showroom.

Scrapers can be purchased in hardware

stores, as well as in shops carrying painting

accessories.

Page 27

CLEANING AND MAINTENANCE

Page 27

PERIODIC INSPECTIONS

In addition to normal cleaning and

maintenance:

• Carry out periodic checks of touch controls. After

the warranty expires, have an authorised service

technician inspect the appliance every two

years.

• Repair any identied problems.

• Carry out periodic maintenance of the cooktop.

IMPORTANT

All repairs and adjustments must be

performed by a qualied technician or by an

qualied installer.

Never apply a detergent on the hot cooking zone.

Any traces of the detergent should be wiped

o clean with a damp cloth before re-heating.

Otherwise, it can be corrosive.

Warranty will be void if you do not follow the

above guidelines!

IMPORTANT

If the cooktop controls do not respond for

whatever reason, turn o the main circuit

breaker or disconnect the power and contact

customer service.

In the event of breakage or chipping of the

cooktop cooking surface, turn o and unplug

the appliance. To do this, disconnect the

power or unplug the appliance. Then refer

the repair to Customer Service or a qualied

technician.

Page 28

Page 28

TROUBLESHOOTING

In the event of any fault:

• Turn o the appliance

• Disconnect the power supply

• Based on the instructions given in the table

below, some minor issues can be corrected by

the user. Please check the consecutive points in

the table before you refer the repair to customer

service or qualied technician.

Problem Possible Cause Remedy

1. The appliance does not

work

- No power - Check the power is connected

2. Sensor elds do not

respond when touched

- Appliance is not turned on - Turn on the appliance

- Sensor eld touched too briey

(less than one second)

- Touch the sensor eld longer

- Multiple sensors touched at the

same time

- Always touch only one sensor eld

(except when a cooking zone is

switched o)

3. The appliance does not

respond and emits and

extended beep

- Improper use (wrong sensor eld

touched or sensors touched too

briey)

- Reconnect the cooktop

- sensor elds are covered or dirty - Uncover or clean the sensor elds

4. The appliance switches

itself o

- No sensor eld is touched within 10

seconds of activating the appliance

- Switch on the appliance and set heat

setting without delay

- Sensor elds covered or dirty - Uncover or clean the sensor elds

5. A single cooking zone

switches o and residual

heat indicator “

” is shown.

- Limited cooking time - Switch on the cooking zone again

- Sensor elds covered or dirty - Uncover or clean the sensor elds

- Electronic components overheated

6. Residual heat indicator

extinguished even though

the cooking zones are hot

- A power outage or the appliance has

been disconnected from power

- Residual heat indicator will be shown

again the next time the appliance is

turned on and o again

Page 29

TROUBLESHOOTING

Page 29

Problem Possible Cause Remedy

7. The cooktop cooking

surface is cracked.

Danger! Immediately unplug the appliance or switch o the main

circuit breaker. Contact Customer Service or a qualied technician.

8. When the problem is still

not remedied.

Immediately unplug the appliance or switch o the main circuit breaker. Refer

the repair to Customer Service or a qualied technician.

IMPORTANT

You are responsible for operating the appliance correctly and maintaining

its good condition. If you call service as a result of operating the appliance

incorrectly you will be responsible for the costs incurred even under warranty.

The manufacturer shall not be held liable for damage caused by failure to follow

this manual.

9. Induction cooktop makes

buzzing sound.

This is normal. Cooling fan is operating to cool down internal electronics.

10. Induction cooktop

makes hissing and whistling

sounds.

This is normal. When using several cooking zones at full power, the cooktop makes

hissing and whistling sounds due to the frequencies used to power the coils.

11. The cooktop does not

work. The cooking zones will

not operate.

- Faulty electronics - Reset the appliance, unplug it for a

60 seconds (disconnect the power).

Page 30

770mm

518mm

Page 30

SPECIFICATION

Rated voltage 400V 2N~50 Hz

Rated power 7.4kW

Model INID77

Induction cooking zone:

- Ø 220 x 190mm

- Ø 210mm

- Ø 260mm

- Ø 210mm

- Ø 260mm

2200W

2000W

2100W

2000/3000W

2100/3400W

Booster induction cooking zone:

- Ø 220 x 190mm

- Ø 210mm

- Ø 260mm

2200/3700W

2000/3000W

2100/3400W

Dimensions 770 x 518 x 59mm

Weight 15kg

Page 31

Page 31

NOTES

Page 32

© Schweigen Home Appliances Pty Ltd. 2017.

8/3-4 Anzed Court, Mulgrave, Victoria 3170.

Phone: 1300 881 693.

Email: sales@schweigen.com.au.

www.schweigen.com.au

© Schweigen Pty Ltd. 2017.

Loading...

Loading...