Page 1

Page 1Page 1

INSTRUCTION MANUAL

.........................................................................................................................................................

Installation / Operation / Maintenance

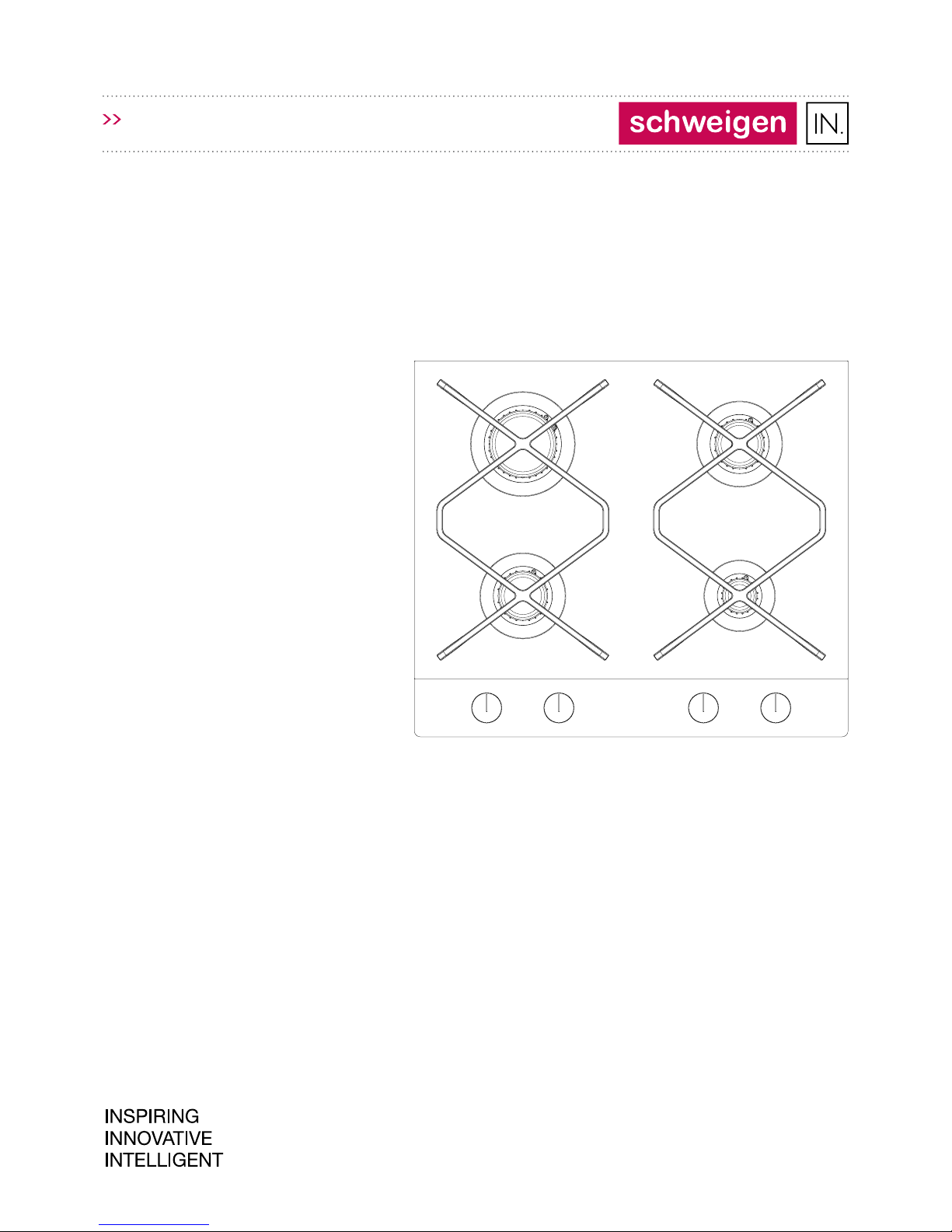

cooktop/GAS/glass/60cm

INGG60B

GAS COOKTOP

INGG60B (PGINGp4.0ZpZtAB)

(10.2017 / V2.0)

Page 2

Page 2

INDEX

Page 2

Welcome ��������������������������������������������������������� 3

Important Safety Information ���������������������� 4

How to Save Energy ��������������������������������������� 6

Unpacking ������������������������������������������������������� 6

Disposal of the Appliance ������������������������������ 7

Description of the Appliance ������������������������ 8

Control Panel ............................................................... 8

Specication �������������������������������������������������� 8

Installation ����������������������������������������������� 9-16

Ventilation .................................................................... 9

Combustible Surfaces ................................................ 9

Requirements for the Placement of Installation ... 9

Minimum Clearance Measurements ...................... 10

Notes for the Installer .............................................. 11

Gas Connection ......................................................... 12

Universal Gas - ULPG ............................................... 12

Natural Gas ................................................................ 12

Installing the Gas Cooktop ...................................... 14

Adapt the Cooktop to a Particular Type of Gas .... 15

Table of Burner & Injector Characteristics ........... 15

Adjust the Valves for a Reduced Flow .................. 15

Adjust the Valves ..................................................... 16

Glass Top Safety Warnings ..................................... 16

Operation ������������������������������������������������� 17-18

Energy Eciency ...................................................... 17

Choice of Cookware .................................................. 17

Cookware Lids ............................................................ 17

Burner Control Dial .................................................... 17

Adjust Flame ............................................................. 18

Cleaning and Maintenance ��������������������������� 19

Burners, Trivets .......................................................... 19

Regular Inspections .................................................. 19

Service Request ........................................................ 20

Faulty Installation ..................................................... 20

In the Event of A Gas Leak Or Suspect Fault ��� 21

Troubleshooting ������������������������������������������� 22

Emergency Procedure ............................................. 23

Disclaimer .................................................................. 23

Page 3

Page 3

WELCOME

Page 3

Thank you for purchasing this Schweigen IN

appliance.

To achieve the optimal performance from your

appliance, and to avoid the risk of accident or

damage, it is essential to read this manual before

installation and rst time use.

This guide contains important information on the

use and maintenance of the appliance, as well as

important safety notes.

Your appliance has been thoroughly checked for

safety and functionality before being packaged

and leaving the manufacturer.

Please keep this instruction manual in a safe

place so you can refer to it at any time�

IMPORTANT!

The appliance should only be operated when

you have read and understood this manual

thoroughly.

The appliance can be only used for the purpose

for which it was designed. Any other use is

improper and can be dangerous.

Installation, regulation and maintenance

of gas and electrical appliances should only

be carried out by qualied and authorised

professionals familiar with Australian

Appliance Industry regulations.

Upon collection or delivery of the appliance,

any damage or defects must be reported

within 48 hours to your retailer or

Schweigen Customer Service, in order

to recognise any claim.

The manufacturer reserves the right to

introduce changes, which do not aect the

operation of the appliance, at any time.

Page 4

Page 4Page 4

The appliance and its accessible parts become hot

during use. Care should be taken to avoid touching

heating elements.

This appliance is not intended for use by anyone

(including children) with reduced physical, sensory

or mental capabilities, or lack of experience and

knowledge, unless they are supervised and/or have

been given instruction for use of the appliance.

Cleaning and user maintenance cannot be

performed by children without supervision.

Children should be supervised to ensure that they

do not play with the appliance.

• Unattended cooking on a cooktop with fat or oil

can be dangerous and may result in re.

• NEVER attempt to extinguish re with water.

Unplug the appliance and cover ame with lid or

non-combustible re blanket.

• DO NOT store anything on the cooking surface.

The appliance is not intended to be operated by

means of an external timer or separate remotecontrol system.

• DO NOT use steam cleaning equipment to clean

the cooktop or its parts.

• DO NOT USE OR STORE FLAMMABLE MATERIALS

IN OR NEAR THIS APPLIANCE.

• DO NOT SPRAY AEROSOLS IN THE VICINITY OF

THIS APPLIANCE WHILE IT IS IN OPERATION.

• DO NOT MODIFY THIS APPLIANCE.

• DO NOT PLACE ARTICLES ON OR AGAINST THIS

APPLIANCE.

• WHERE THIS APPLIANCE IS INSTALLED IN

MARINE CRAFT OR IN CARAVANS, IT SHALL NOT

BE USED AS A SPACE HEATER.

• Not suitable for use with aftermarket lids or

covers.

• DO NOT place anything, e.g. ame tamer or

griddle plate between pan and pan support.

• DO NOT remove the pan support and enclose

the burner with a wok stand.

• DO NOT use large pots or heavy weights which

can bend the pan support or deect ame onto

the hotplate. Locate pan centrally over the

burner so that it is stable and does not overhang

the appliance.

This appliance must be installed in accordance

with the applicable regulations and used only

in a well-ventilated room� Before you install

and use the appliance, carefully read the

operating instructions�

• DO NOT let children play with the appliance - hot

burners, trivet, pots with hot liquids may cause

burns.

• Make sure that the power cords of other equipment

do not touch any hot surfaces of the appliance.

• The power cord wall plug must be accessible after

appliance has been installed.

• DO NOT install the appliance near any cooling

equipment such as an air conditioning unit.

• DO NOT leave the appliance unattended while

cooking. Oils and fats may catch re due to

overheating.

• Make sure that liquids do not boil over onto the

burners.

• DO NOT open the valve on the gas connection or

the valve on the gas cylinder before you make sure

that all valves are closed.

• DO NOT allow liquids to boil over onto the burners

and avoid burner contamination. Soiled burners

must be cleaned & dried immediately after cooling.

• DO NOT place pots directly on the burners.

• DO NOT place pots weighing more than 5kg on

the trivet over one burner or more than 25kg on

the entire trivet. Do not place one pot on two

burners.

• DO NOT hit the control dials or burners.

• Persons without proper qualications and training

must not make any alterations or repair the

appliance.

• DO NOT extinguish the ame by blowing.

• DO NOT alter the appliance to allow it to be used

with a dierent type of gas, or move the appliance

to another place nor make any modications in the

gas supply system. These must be carried out by a

qualied installer only.

• DO NOT allow young persons who have not read

the operating instructions to use the appliance.

IMPORTANT SAFETY INFORMATION

Page 5

Page 5Page 5

• IF YOU SUSPECT A GAS LEAK, DO NOT:

light matches, smoke, turn on or o any electrical

devices (door bell, light switch, etc.) and use

other electrical or mechanical equipment that

can produce an electrical spark or impact spark.

In such a case, immediately close the valve on

the gas cylinder or the gas system shut-o valve,

ventilate the room and call a qualied person to

remove the cause of the leak.

• In the event of any technical fault, immediately

unplug the appliance (following the above rule)

and report the fault to the service centre or

qualied gas technician to be repaired.

• DO NOT connect any antenna cables, e.g. radio

receivers to the gas system

• In the event of ignition of gas escaping from a

leaking system, immediately shut o the gas

supply using the shut-o valve.

• In the event of ignition of gas escaping from

a leaking gas cylinder valve: cover the cylinder

with a wet blanket to cool it and close the valve

on the cylinder. Once cooled, move the gas

cylinder out to the open air. Do not reuse the

damaged gas cylinder. This procedure should be

carried out by a qualied gas technician.

• If you do not use the appliance for a few days,

close the gas system main valve, and after each

use in case of a gas cylinder.

CAUTION!

If the power cord is damaged, it must be

replaced by the manufacturer, its service

agent or a qualied person in order to

avoid a hazard.

Cooking with this appliance results in the emission

of heat and moisture in the room in which it is

installed. Make sure that kitchen is well ventilated.

Natural ventilation openings or forced mechanical

ventilation (rangehood) should be available.

• Prolonged intensive use of the appliance may

require additional ventilation, for example,

opening a window or a more eective

ventilation, such as increasing eciency of

mechanical ventilation rangehood, if applicable.

GAS & ELECTRICAL CONNECTION

This appliance must be installed only by authorised

persons and in accordance with this instruction

manual, AS/NZS 5601 — Gas Installations

(installations and pipe sizing), local gas tting

regulations, local electrical regulations, local water

regulations, local health regulations, Building Code

of Australia and any other government authority.

WARNING: This appliance must be earthed.

VENTILATION

The use of a gas cooking appliance results in the

production of heat and moisture in the room in

which it is installed. Ensure that the kitchen is well

ventilated; keep natural ventilation holes open or

install a mechanical ventilation device (mechanical

extractor hood). Prolonged intensive use of the

appliance may call for additional ventilation, e.g.

opening of a window or, more eective ventilation,

increasing the level of mechanical ventilation

where present.

IMPORTANT SAFETY INFORMATION

Page 6

Page 6Page 6

Using energy responsibly not only saves money but

also helps the environment. So let’s save energy!

And this is how you can do it:

• Use quality pans for cooking� Pans with thick,

at bases can save up to 1/3 on electric energy.

Remember to cover pans if possible, otherwise

you will use four times as much energy!

• Match the size of the saucepan to the

surface of the heating zone� Cookware base

should never be smaller than cooking zone.

• Ensure that heating zones and pan bases

are clean� Dirt can prevent heat transfer, and

repeatedly burnt-on spillages can often only be

removed by products which cause damage to the

environment.

• Do not uncover the pan too often

(a watched pot never boils!)

• Turn o the appliance in time and use the

residual heat� For long cooking times, turn o

heating zones 5 to 10 minutes before nishing

cooking. This saves up to 20% on energy.

• Do not install the cooktop in the immediate

vicinity of refrigerator / freezer, otherwise

energy consumption increases unnecessarily.

The appliance was packed to protected it from

damage during transport. After unpacking, please

dispose of all elements of packaging in a way that

will not cause damage to the environment.

All materials used for packaging the appliance are

environmentally friendly; they are 100% recyclable

and are marked with the appropriate symbol.

Important! During unpacking, keep the packaging

material (polyethylene bags, polystyrene pieces,

etc.) out of reach of children.

HOW TO SAVE ENERGY UNPACKING

Page 7

Page 7Page 7

This appliance is marked with the symbol of the

crossed-out waste container.

This marking indicates that the appliance must

not be disposed of together with other household

waste after it has been used.

The user is obliged to hand it over to waste

collection centre collecting used electrical and

electronic goods. The collectors, including local

collection points, shops and local authority

departments provide recycling schemes.

Proper handling of used electrical and electronic

goods helps avoid environmental and health

hazards resulting from the presence of dangerous

components and the inappropriate storage and

processing of such goods.

DISPOSAL OF THE APPLIANCE

Page 8

Page 8Page 8

....................................................................................................................................................

....................................................................................................................................................

>>

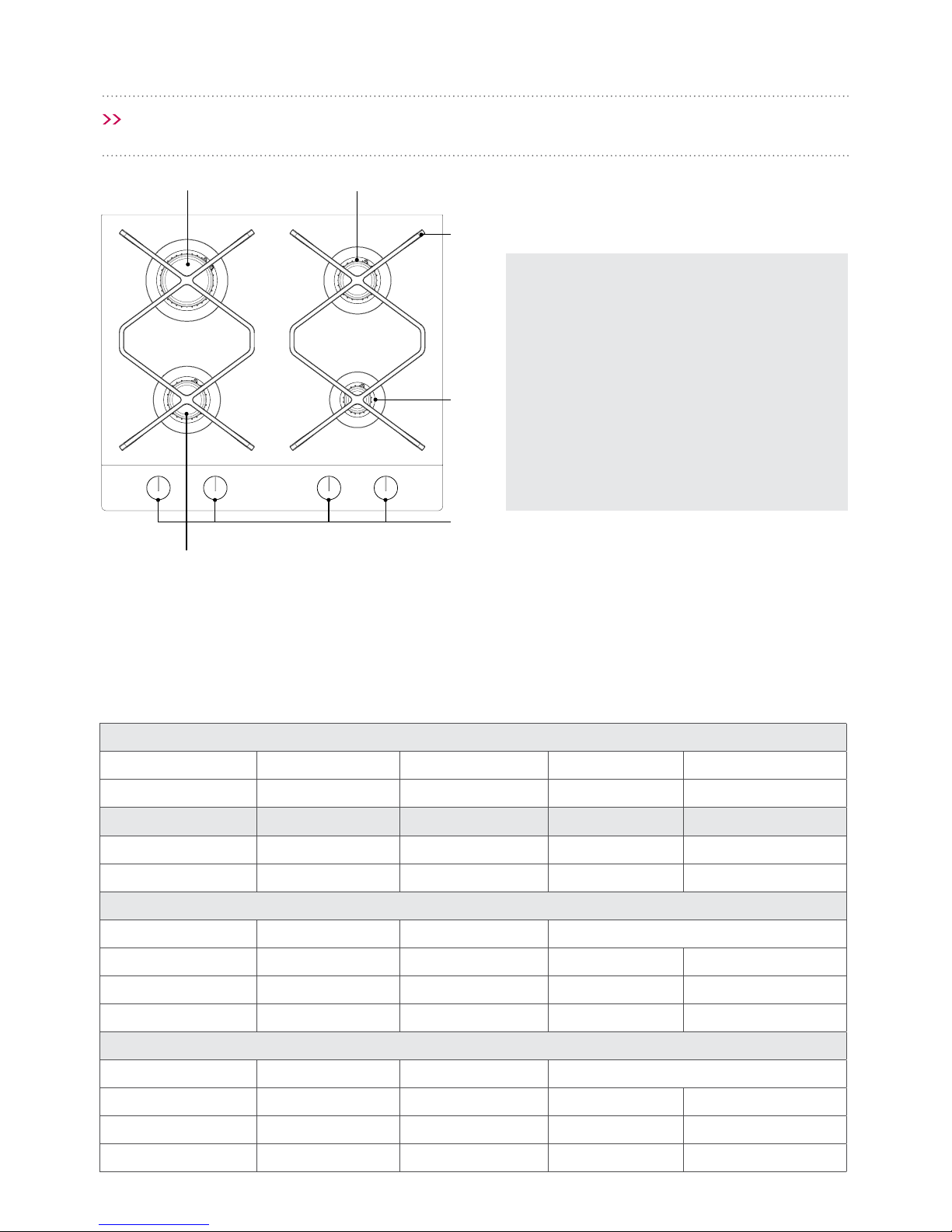

SPECIFICATION

LEGEND

AUX - Auxiliary Burner

SR - Semi-Rapid Burner

R - Rapid Burner

1 – Control Dials with incorporated

auto-ignition

2 – Trivets (cast iron pan supports)

DESCRIPTION OF THE APPLIANCE

Packaged Weight - 12kg

Overall Dimensions - 48mm (H) x 520mm (D) x 600mm (W)

Total Nominal Gas Consumption

Model Natural Gas Universal LPG

4 Burner INGG60B 30.8 MJ/h 30.2 MJ/h

Test Point Pressure

Natural Gas 1.0 kPa

Universal LPG 2.75 kPa

Burner Conguration - Natural Gas

Burner Main Injector By-Pass (mm) Nominal Gas Consumption (MJ/h)

Auxiliary 0.85 0.29 3.8

Semi-Rapid 1.20 0.29 7.7

Rapid 1.48 0.39 11.6

Burner Conguration - Universal LPG

Burner Main Injector By-Pass (mm) Nominal Gas Consumption (MJ/h)

Auxiliary 0.55 0.29 3.8

Semi-Rapid 0.79 0.29 7.6

Rapid 0.93 0.39 11.2

3

4

1 2

6

5

AUX

R

2

1

SR

SR

Page 9

Page 9Page 9

The following instructions are intended for a

qualied professional installer. These instructions

are intended to provide the most professional

installation and maintenance of the appliance.

• Before you install the appliance, make sure

that the local distribution conditions (gas

type and pressure) and conguration is

appropriate.

• Conguration details are given on the

appliance nameplate.

• This appliance is not to be connected to

ues. The appliance must be installed and

connected in accordance with the current

regulations. In particular, consideration

must be given to the applicable

requirements for ventilation.

REGULATIONS AND STANDARDS

This appliance must be installed by an authorised

persons in accordance with this instruction manual,

AS/NZS 5601 — Gas Installations (installation and

pipe sizing), local gas tting regulations, local

electrical regulations, local water regulations, local

health regulations, Building Code of Australia and

any other government authority.

• MUST NOT be installed in a marine craft,

caravan or mobile home, unless each

burner is tted with a ame safeguard.

VENTILATION

Ventilation must be in accordance with AS/NZS

5601 - Gas Installations. In general, the appliance

should have adequate ventilation for complete

combustion of gas, proper ueing and to maintain

temperature of immediate surroundings within

safe limits.

COMBUSTIBLE SURFACES

The wall and benchtop surfaces must be capable

of sustaining temperature of 90˚C. All laminates,

xing adhesive and surfacing materials should be

certied suitable for this temperature.

Requirements for the placement

of installation

• The kitchen should be dry, airy and well

ventilated according to the applicable technical

regulations.

• The room should be equipped with a ventilation

system to extract the combustion gases outside

the room. The ventilation system must include a

ventilation grille or a rangehood.

• The room should also allow air supply which is

necessary for the correct combustion of gas.

The air supply should be not less than 2 m³/h

per 1 kW of the burners power. Natural airow

from the outside may be provided or through a

duct with a cross-section of at least 100 cm²,

or indirectly from the adjacent rooms that have

ventilation ducts leading outside.

• The distance between the burners and the

rangehood exhaust should be at least 600 mm.

• The rangehood must be installed in accordance

with your rangehood installation guide, as

compliance with state and federal laws.

INSTALLATION

Page 10

Page 10

INSTALLATION

Page 10

MINIMUM CLEARANCE MEASUREMENTS

A� OVERHEAD CLEARANCE — (Measurement A)

Rangehoods and exhaust fans must be installed

in accordance with the manufacturer’s relevant

instructions.

However, in no case should the clearance

between the highest part of the hob of the

gas cooking appliance and a rangehood be less

than 600mm or, for an overhead exhaust fan,

750mm.

B & C� SIDE CLEARANCE

— (Measurements B & C) Where B, measured

from the periphery of the nearest burner to

any vertical combustible surface, or vertical

combustible surface covered with toughened

glass or sheet metal, is less than 200mm,

the surface shall be protected to a height C of

not less than 150mm above the hob for the

full dimension (width or depth) of the cooking

surface area.

Where the gas cooking appliance is tted with

a ‘splashback’, protection of the rear wall is not

required.

C

B

A

Page 11

Page 11

INSTALLATION

Page 11

This appliance shall be installed only by authorised

persons and in accordance with the manufacturer’s

installation instructions, local gas tting

regulations, municipal building codes, electrical

wiring regulations, local water supply regulations,

AS 5601 - Gas Installations and any other statutory

regulations.

NOTES FOR THE INSTALLER

The installer must:

- Have appropriate qualication,

- Read the information on the nameplate or

information sticker concerning the type of

gas, for which the appliance is intended.

This information must be compared with

the gas supply specication at the place of

installation.

Check:

- eectiveness of ventilation, i.e. exchange of

air in the room,

- tightness of gas ttings,

- proper operation all the functional

components.

For proper operation of igniters and ame failure

cut-o device, adjust the position of the gas dials

with the supplied washers.

- Check the operation of igniters and ame

failure cut-o device.

- In the event of faulty operation, remove the

dials, make adjustments by inserting a washer

(washers) on the valve pin.

- Once adjusted, protect the system with a

clamping washer and replace the cooktop.

PROVIDE THE USER WITH THE GAS COOKTOP

INSTALLATION CERTIFICATE AND GIVE

INSTRUCTIONS ON THE APPLIANCE OPERATION.

The appliance has an G 1/2” threaded pipe

connector to connect it to the gas system.

The gas supply hose should not touch the metal

parts of the cooktop.

Carefully read the operating instructions

supplied and follow all guidelines�

CAUTION!

Only a qualied person must install and

connect the appliance.

CAUTION!

Ensure all the connections are tight�

Once you install the appliance, check all

connections for leaks, for example using

soapy water. DO NOT use re to check

the connections.

IMPORTANT: You are dealing with

gas. The appliance must be supplied

with the type of gas specied by the

manufacturer.

Information on the type of gas for which

the appliance is designed is given on the

nameplate, which can be located on the

base of the cooktop.

Page 12

Page 12

INSTALLATION

Page 12

GAS CONNECTION

To perform these operations the qualied installer

will follow the indications given in the “Adaptation

to the various types of gas” section (see pg. 15). For

safer operation make sure that the supply pressure

respects the values given in the “Table of burner

and injector characteristics” (see pg. 15).

The appliance must be connected to the gas supply

or the cylinder according to the specications of

the standards and after checking that it is adjusted

for the type of gas available.

The gas connection is male 1/2” BSP and is

situated 55mm from the right and 565mm from

the oor. There are two ways to carry out the

connection to the main gas line:

A. The cooktop can be connected with rigid pipe

as specied in AS5601 - table 3.1.

B. The cooktop can be connected with a Flexible

Hose, which complies with AS/NZS 1869 (AGA

Approved), 10mm ID, class B or D, no more than

1.2m long and in accordance with AS5601.

Ensure that the Hose does not contact the

hot or sharp surfaces of the hotplate, oven,

dishwasher or other appliance that may be

installed underneath or next to the cooktop.

The isolating manual shut-o valve

connection point must be accessible when

the appliance is installed�

WARNING: Ensure that the hose assembly is

restrained from accidental contact with a ue

or ue outlet of an underbench oven. The gas

hose should not be subjected to abrasion, kinking

or permanent deformation and should be able

to be inspected along its entire length. Unions

compatible with the hose ttings must be used

and connections tested for gas leaks. The supply

connection point shall be accessible with the

appliance installed.

The appliance is factory set for Natural Gas. The

test point pressure should be adjusted to 1.00kPa

with 50% of the burners burners operating at

maximum.

The appliance is set up to operate with the gas

specied on the gas type label placed on the back

of the appliance.

When the type of gas available does not

correspond to that for which the appliance is set

up, replace the corresponding injectors (provided),

being careful to put on the new label (provided)

and remove the old one.

UNIVERSAL GAS - ULPG

When converting from Natural Gas to Universal

LPG ensure that the NG regulator is removed

and replaced with the Test Point Assembly. An

AGA Approved gas regulator suitable for a supply

pressure of 2.75kPa should be part of the gas

tank supply and the test point pressure should be

adjusted to 2.75kPa.

Before Leaving - Gas leakage and operation of the

appliance must be tested by the installer before

leaving. Check burner ames are blue in colour,

stable and completely ignite at both high and low

ame setings with no appreciable yellow tipping,

carbon deposition, lifting, oating, lighting back

or objectionable odour. Test burners individually

and in combination. When satised with the

operation of the cooker, please instruct the user

on the correct method of the operation in case

the appliance fails to operate correctly after all

checks have been carried out, call the Schweigen

Customer Service Team.

NATURAL GAS

Natural Gas installation requires the connection

of a gas regulator. Only use the Natural Gas

regulator supplied with this appliance. Assemble

the regulator (noting the gas ow direction) and

transition pieces (supplied with the appliance),

in accordance with Figure 1 below. The transition

piece on the supply side of the regulator must be

provided by the installer. The appliance has been

tted with injectors for natural gas. Universal ULPG

gas injectors (if required) have been included with

the cooktop. Gas pressure must be adjusted to

1.0kPa when approximately 50% of the burners

are on high ame, the appliance test point is

located on the regulator.

Test point

Fig� 1

Page 13

Page 13

INSTALLATION

Page 13

Cooktop installation must be in accordance

with state and federal laws�

When installing the cooktop in the kitchen

benchtop, install a partition panel, (see Fig.2A).

If the cooktop is to be installed above a built-in

oven, installation of the partition panel is not

required (see Fig. 2B).

If the cooktop is installed in the kitchen benchtop

above a drawer, the bottom cover of the cooktop

must be covered with a wooden panel or protective

board, provided it is capable of withstanding the

appliance temperature.

The rear edge of the cooktop opening should be

located at least 60 mm from the rear kitchen wall.

Min. 130mm

Fig� 2A Installation above a drawer

130mm

Oven

Cooktop

Fig� 2B Installation above an oven

WARNING!

DO NOT x the cooktop into the

benchtop with sealant, ie. sillicon, as this

will void the warranty.

IMPORTANT: DO NOT install the

cooktop above the oven without

ventilation; inadequate ventilation will

damage the cooktop and void warranty.

Position electrical lead so that it does

not touch the lower guard.

NOTE: Where the data plate is obstructed by

cabinetry when the cooktop is in the installed

position, attach the supplied dupolicate data

plate to a suitable adjacent surface or within the

instruction manual for future reference.

Page 14

Page 14

INSTALLATION

Page 14

4

321

4

321

555

484

01

32

170

170

170

30 30

135

30

20

242

600

520

84

INSTALLING THE GAS COOKTOP

1. Prepare an opening in the kitchen benchtop, as

per the installation measurements (see Fig. 3)

2. Ensure a minimum clearance of 130 mm below

the gas or gas-electric cooktop (see Fig. 2B on

previous page).

3. Connect the cooktop to a gas and electrical

system in accordance with the instructions

supplied.

4. Loosely attach xing brackets to the bottom of

the cooktop (see Fig. 4A and 4B).

5. To properly secure the cooktop on 38mm thick

benchtops use four xing brackets (see Fig. 4A)

6. To properly secure the cooktop on 28mm thick

benchtops use four xing brackets (see Fig.4B).

7. Fit the cooktop into the benchtop opening.

8. Check the adhesive seal is properly applied to

the under side of the cooktop ange.

9. Remove dust from the benchtop, insert cooktop

into the opening and press in rmly.

10. Position xing brackets (see Fig. 4)

perpendicular to the cooktop edge and tighten

rmly.

11. Once you install the cooktop in the benchtop,

check if it operates, especially the ame failure

cut-o and igniter.

Fig� 4

Fig� 4A

Fig� 4B

Fig� 3

1. Benchtop

2. Screw

3. Bracket

4. Cooktop

Page 15

Page 15

INSTALLATION

Page 15

TABLE OF BURNER & INJECTOR CHARACTERISTICS�

Type of gas

BURNER

Auxiliary Semi-Rapid Rapid

Natural Gas 0.85 1.20 1.48

ULPG 0.55 0.79 0.93

REPLACE BURNER NOZZLE

Unscrew the nozzle using a special wrench no. 7 and replace with a new one suitable

for the new gas type (see table above).

Once converted, place a sticker indicating the gas type for which the appliance

is intended. Replacing the burner nozzle is only to be carried out by a licensed,

qualied technician.

ADJUST THE VALVES FOR A REDUCED FLOW�

Burners Flame Convert the appliance from

LPG to Natural Gas

Convert the appliance from

Natural Gas to LPG

TOP BURNERS

Full ame Replace burner nozzle with the

appropriate nozzle according to

the table.

Replace burner nozzle with the

appropriate nozzle according to

the table.

Economic ame Gently loosen the adjusting screw

and adjust the ame.

Slightly tighten the adjusting

screw, check the ame stability

and size.

ADAPT THE COOKTOP TO A PARTICULAR

TYPE OF GAS

If the cooktop is set up with a gas type dierent

to the gas type specied by the manufacturer, i.e.

natural gas, replace the burner nozzles and adjust

the ame.

CAUTION

Cooktops supplied by the manufacturer are tted

with burners designed for the gas specied on the

nameplate and in the warranty.

Nameplate is located on the bottom of the housing

and lists information on the type of gas the

appliance is intended for.

In order to adapt the cooktop to another gas type:

- replace the nozzles (see table),

- adjust the valves for a reduced ow.

NOTE� This cooktop is for use with Natural Gas or

ULPG only.

Any other type of gas connection will void warranty

and the manufacturer will take no responsibility for

damages or accidents that may occur.

Page 16

ADJUST THE VALVES

To adjust the valves turn the control dial to

“economic ame” position and ignite the ame.

Remove the control dial and adjust the size of an

economic ame with a screwdriver.

In order to check the ame, heat up the burner on

a full ame for about 10 minutes, and then turn

the burner dial to an economic ame position. The

ame should not go out or jump on the nozzle.

However, if it does, re-adjust the valves.

WARNINGS FOR THE SAFETY OF

THE GLASS TOP

DO NOT place anything, e.g. ame tamer, asbestos

mat, between pan and pan suport, as serious

damage to the appliance may result.

DO NOT remove the pan support and enclose the

burner with a wok stand as this will concentrate

and deect heat onto the hotplate.

DO NOT use large pots or heavy weights which

can bend the pan support or deect ame onto the

hotplate.

Page 16

INSTALLATION

Page 16

Page 17

Page 17

OPERATION

Page 17

ENERGY EFFICIENCY

To achieve signicant energy savings, use the

appliance as per these operating instructions, make

the appropriate adjustments and use suitable pots.

Potential energy savings:

• up to 60%, when using appropriate pots,

• up to 60%, when using the appliance according

to the instructions and correctly adjusting the

ame when cooking.

Keeping the burners clean is crucial to an ecient

energy consumption by the appliance (especially

the ame outlets and nozzles).

CHOICE OF COOKWARE

Make sure that the diameter of the bottom of the

pot is always slightly larger than the crown of the

burner ame, and the pot itself is covered with

a lid. It is recommended that the pot diameter is

approximately 2.5 - 3 times larger than the burner:

• Auxiliary (Small) burner

— pot diameter of 90 to 150 mm,

• Semi Rapid (Medium) burner

— pot diameter of 160 to 220 mm,

• Rapid (Large) burner

— pot diameter of 220 to 240 mm

Note: The pot height should NOT be greater than

its diameter.

wrong

right

COOKWARE LIDS

Placing a lid on top prevents heat from escaping

and thus reduces heating time.

Do not use cookware that protrudes over

the edges of the cooktop.

BURNER CONTROL DIAL

"burner off" position

sition

position

CORRECT

INCORRECT

Page 18

Page 18

OPERATION

Page 18

Using the cooktop equipped with igniter dials

• push down the dial of a selected burner until

you feel resistance and turn left to the “large

ame”position

• hold the dial until gas ignites

• once ame ignites, release the dial and adjust

ame size.

The cooktop is equipped with a ame failure

cut-o device

In cooktops equipped with a ame-failure cut-o

device, hold the pushed down dial in the “large

ame” position for approximately 10 seconds to

activate the ame-failure device .

Repeat the above step if ame does

not ignite�

If ame is extinguished, the ame

failure device will cut o gas supply

within about 60 seconds�

You can open and control the gas

supply to the burners using dials with

ame-failure cut-o device�

ADJUST FLAME

Flame from a properly adjusted burner is pale blue

with a clearly outlined inner cone. You can adjust

the ame by setting the dial to dierent positions.

large ame

small ame (“economic”)

• burner o (no gas supply)

INCORRECT CORRECT

This example shows you how to operate the dial

and adjust ame size.

To optimise cooking, set the dial to “large ame”

initially to boil your food, then set it to “small

ame” to continue the cooking process. Adjust the

ame size depending on your needs.

Do not leave the dial positioned

between the • burner o and

large ame�

Igniter Flame failure

device

Flame spreader

Burner cap

Page 19

Page 19

CLEANING AND MAINTENANCE

Page 19

Proper routine maintenance and cleaning

of the appliance can signicantly extend

its trouble-free operation.

Before cleaning or other

maintenance work, always unplug

the appliance or use the main

electrical system circuit breaker to

cut o power�

DO NOT begin cleaning until the cooktop

has cooled.

DO NOT use abrasive scouring powders.

DO NOT use steam cleaning equipment

for cleaning.

BURNERS, TRIVETS

If the burners or trivets become soiled, remove

them from the cooktop and wash in warm water

with some dishwashing liquid.

Once the trivets are removed, thoroughly clean the

area under the burner and wipe it dry with a soft

cloth.

Flame outlets and burner head must be clean at

all times (see gure below). Clean the gas nozzles

using a thin copper wire. Do not use steel wire or

try to ream the holes.

Make sure that burner is correctly reassembled

after cleaning.

CORRECT

INCORRECT

• Use mild detergents to wash enamel surfaces.

When cleaning do not use abrasive cleaners such

as scouring powders, pastes, abrasive stones,

pumice, metal scrubbers, etc.

• Thoroughly clean the cooktop before use.

Especially make sure to remove any adhesive

residue or self-adhesive tape applied when the

appliance was packaged.

• Clean the cooktop after each use. Do not allow

the cooktop to get heavily stained; particularly

from burnt–on spillages from boiled over liquids.

REGULAR INSPECTIONS

In addition to normal cleaning and maintenance:

• carry out periodic checks of burner dials and

other elements. After the warranty expires, have

authorised service inspect the appliance every

two years,

• repair any operational faults,

• carry out periodic maintenance of the cooktop.

All burner parts must be dry�

Water droplets may block the gas

ow and cause the burner to operate

incorrectly.

Igniter Flame failure

device

Flame spreader

Burner cap

Page 20

Page 20Page 20

Page 20

CLEANING & MAINTENANCE

Page 20

Calling the Technical Assistance Service

Hotline

In the event that the failure is not due to the

faults mentioned in Trouble Shooting, contact

Schweigen’s Customer Service Team.

In Australia,

Customer Service 1300 829 066

In New Zealand,

Customer Service 0800 200 510

Lodging an Online Service Request

In the event that failure is not due to reason(s)

listed in the Troubleshooting section, you can lodge

an Online Service Request.

To lodge an Online Service Request, visit our

website www.schweigen.com.au/pages/support/

servicewarranty and click on the link to download

the service request form.

A Service Request will require the following

information:

• The purchase date.

• The appliance model number and type,

e.g. Gas Cooktop.

• The serial number or batch number — located on

the sticker under the cooktop, on the cover of

the User Manual or included separately with the

User Manual.

• A copy of the purchase receipt (without a receipt

our service request cannot be processed)

FAULTY INSTALLATION

It is not the responsibility of Schweigen to rectify

any incorrect installations. A service call out fee

will be charged for any Schweigen technician

that attends a call, whereby it is established that

the fault is due to an incorrect installation or

non-manufacturing fault. Should the appliance

be installed insuch a way that the service agent

is unable to gain access to the appliance, the

person/s who own the premises where the

appliance resides – will be responsible to provide

access to the appliance at their expense.

Page 21

Page 21Page 21

Page 21

IN THE EVENT OF A GAS LEAK OR SUSPECTED FAULT

Page 21

IN THE EVENT OF A GAS LEAK OR

SUSPECTED FAULT

• turn o the at burner dials (see Fig.1 below)

• close the gas system shut-o valve

• ventilate the room

• report the fault to a service centre or a qualied

gas tter to have it repaired

• do not use your gas cooktop until the fault has

been repaired.

Burner Control Dials

Fig� 1

Fig� 2

A� valve “open” B. valve “closed”

BURNER DOES NOT IGNITE, I CAN SMELL

LEAKING GAS

• turn o the burner dials (see Fig.1)

• close the gas system shut-o valve (see Fig.2)

• ventilate the room

• remove the burner

• clean and purge the ame outlets

• replace the burner

• retry to ignite the burner

WARNING!

If You Suspect a Gas Leak, DO NOT:

Light matches, smoke, turn on or o

any electrical devices (door bell, light

switch, etc.) and use other electrical

or mechanical equipment that can

produce an electrical or impact spark.

NO FLAME? HAVE THE APPLIANCE SERVICED!

Burner Control

Dials

Page 22

Page 22Page 22

Page 22

TROUBLESHOOTING

Page 22

In the event of any fault:

• turn o the appliance

• disconnect the power supply

• based on the instructions given in the table

below, some minor issues can be corrected by

the user.

Please check the consecutive points in the table

before you refer the repair to customer service.

Problem Possible Cause Remedy

1. The appliance does not work. No power. Check the Mains Power connection

is on.

2. Burner does not ignite. Soiled ame outlet. Close the gas shut-o valve, close

the burners dials, ventilate the room,

remove the burner, clean and clear

out the ame outlets.

3. Igniter does not work. No power. Check the power supply.

No power. Open the gas supply valve.

Soiled (greasy) igniter. Clean the igniter.

The burner dial was not pushed

down for long enough.

Hold down the dial until you see a full

ame around the burner crown.

4. The ame goes out when

igniting the burner.

Burner dial released too soon. Hold the dial down for longer in a

“large ame” position.

DISCLAIMER

Under our policy of continuous product development, product specications may change without notice. Prospective

purchasers should therefore check with the retailer to ensure this publication correctly describes the products being

oered for sale. All information supplied is to be used for general reference purposes only and is on the understanding that

Schweigen will not be liable for any loss, liability or damage of whatever kind arising as a result of any reliance upon such

information. All pictures used in the guide are for illustrative purposes only.

EMERGENCY PROCEDURE

If an emergency situation occurs you

should:

• turn o the appliance,

• disconnect the power supply,

• Call the Schweigen Customer Service

Centre or a qualied gas technician.

NOTE: Annual service by an authorised person is

recommended, or if any of the following conditions

are noticed:

- Incomplete ignition

- Appreciable yellow tipping

- Carbon deposition

- Lifting

- Floating

- Lighting back

- Objectionable odour

Page 23

Page 23Page 23

Page 23

NOTES

Page 23

.........................................................................................................................................................

.........................................................................................................................................................

.........................................................................................................................................................

.........................................................................................................................................................

.........................................................................................................................................................

.........................................................................................................................................................

.........................................................................................................................................................

.........................................................................................................................................................

.........................................................................................................................................................

.........................................................................................................................................................

.........................................................................................................................................................

.........................................................................................................................................................

.........................................................................................................................................................

.........................................................................................................................................................

.........................................................................................................................................................

.........................................................................................................................................................

.........................................................................................................................................................

.........................................................................................................................................................

.........................................................................................................................................................

.........................................................................................................................................................

.........................................................................................................................................................

Page 24

Schweigen Pty Ltd.

8/3-4 Anzed Court, Mulgrave, Victoria 3170.

Sales: 1300 881 693.

Email: sales@schweigen.com.au.

All Service, Warranty & Technical Enquiries

Ph: 1300 829 066 (Lines Open Weekdays 9AM - 5.30PM AEST)

Fax: 1300 881 639

Email: service@schweigen.com.au.

www.schweigen.com.au

© Schweigen Pty Ltd. 2017.

Loading...

Loading...