Schwank SEM 200-60, IT 200-60, SEM 200-50, IT 200-50, SEMU 200-30 Installation And Owner's Manual

...

INSTALLATION / OWNER’S MANUAL

SEM(U) IT(U) &

SERIES

LOW INTENSITY TUBE TYPE

INFRA RED HEATERS

FOR YOUR SAFETY:

Do not store or use gasoline or other flammable vapours and liquids in the vicinity of this or any other

appliance.

If you smell Gas:

>Extinguish any open flames

>Don’t touch electrical switches

>Call your Gas supplier immediately

FIELD CONVERTIBILITY:

“The conversion shall be carried out in accordance

with the requirements of the provincial authorities

having jurisdiction and in accordance with the

requirements of the B149.1 (latest edition)

INSTALLATION CODE” in Canada, and the ANSI

Z223.1 (latest edition) in the U.S.A.

GP-MSEM-BX-03B

SEM(U) / IT(U) Manual

RD: Sept, 2005

RL: 03B

KH

NOTICE:

The Manufacturer reserves the right to make changes to

equipment and specifications without obligation or notification.

This publication, or parts thereof, may not be reproduced

in any form, without prior written consent from The Manufacturer. Unauthorized use or distribution of this publication is strictly prohibited.

Schwank Inc.

5285 Bradco Boulevard

Mississauga, Ontario,

L4W 2A6

Phone: (905) 712-4766

Fax: (905) 712-8336

1-866-361-0417

PO Box 988, 2 Schwank Way

Waynesboro, Georgia,

USA 30830

Phone: (706) 554-6191

Fax: (706) 554 9390

1-877-446-3727

e-mail: info@schwankheaters.com

http://www.schwankheaters.com

InfraSave Inc.

Mississauga, Ontario,

Waynesboro,Georgia,

Phone: 1-866-INFRASV (463-7278)

Fax: 1-866-724-9265

http://www.infrasave.com

e-mail: info@infrasave.com

GP-MSEM-BX-03B

SEM(U) / IT(U) Manual

RD: Sept, 2005

RL: 03B

KH

SEM(U) / IT(U)

INFRA-RED GAS TUBE HEATERS

TA BLE OF CONT ENTS

TOPIC PAGE NUMBER

1. GENERAL ................................................1

2. INSTALLATION IN AIRCRAFT

HANGARS................................................1

2.1 INSTALLATION IN COMMERCIAL

GARAGES............................................... 1

3. INSTALLATIONS OTHER THAN

SPACE HEATING ...................................1

4. HEATERS AND TUBE KITS .................2

TUBE KIT MATRIX ...............................3

5. PRE-INSTALLATION SURVEY ............5

6. MOUNTING CLEARANCES .................5

7. SYSTEMS INCORPORATING 90

DEGREE ELBOWS .................................7

8. SUSPENSION SYSTEM .........................8

9. BURNER AND TUBE

INSTALLATION ...................................10

10. REFLECTOR INSTALLATION ..........11

TOPIC PAGE NUMBER

11. FLUE VENTING ...................................14

12. COMBUSTION AIR DUCT ..................16

13. GAS SUPPLY INSTALLATION .........16

14. HEATER EXPANSION .........................18

15. ELECTRICAL AND THERMOSTAT

WIRING .................................................18

16. HIGH ALTITUDE INSTALLATIONS .19

17. OPERATING SEQUENCE ....................20

18. LIGHTING INSTRUCTIONS ..............21

19. RECOMMENDED MAINTENANCE ...21

20. WIRING DIAGRAM .............................22

21. TROUBLE SHOOTING GUIDE ..........23

22. SPARK IGNITION CIRCUIT ...............25

23. START UP SHEET ................................26

24. OPTIONAL COMPONENTS................ 28

25. ALTITUDE CONVERSION CHART ...32

26. LIMITED WARRANTY ........................33

GP-MSEM-BX-03B

SEM(U) / IT(U) Manual

RD: Sept, 2005

RL: 03B

KH

GP-MSEM-BX-03B

SEM(U) / IT(U) Manual

RD: Sept, 2005

RL: 03B

KH

1. GENERAL

GAS INFRA-RED TUBE HEATER

SEM(U) / IT(U) SERIES

INSTALLATION INSTRUCTIONS

It is recommended that this heater be installed

by a professional gas heating equipment service person. Installation of the SEM(u)/IT(u)

Series gas-fired tube heaters must conform to

all manufacturers heating installation design

procedures including ventilation. All local,

provincial and national code requirements including the current latest edition B149.1-00

INSTALLATION CODE” in Canada, and

ANSI Z223.1 in the U.S.A. for gas burning

appliances and equipment. The latest edition

Electrical Code PART 1 CSA C22.1 in Can-

must also be observed. Due to ever changing

standards and requirements, revision to our

equipment and installation procedures may be

necessary. In case of discrepancies, the latest

installation manual will take priority. The

SEM(u)/IT(u) heater may be installed for

heating of non-residential indoor spaces. It is

beyond the scope of these instructions to embrace all conditions that will be encountered.

All system piping must be supported in accordance with acceptable practice, local

codes, and applicable standards.

ada and ANSI/NFPA N0 70 in the U.S.A.

2. INSTALLATION IN COMMERCIAL AIRCRAFT HANGARS

The SEM(U) / IT(U) Infra red Heaters are

suitable for use in aircraft hangars when installed in accordance with the following.

A. A minimum clearance of 10 ft from bot-

tom of the heater above the highest surface of the highest aircraft which may occupy the hangar.

B. A minimum clearance of 8 ft must be

maintained from the bottom of the heater

in other sections of the aircraft hangar

such as offices and shops, which communicate with areas for servicing or storage.

Refer to the proper mounting clearances

to combustibles.

C. Heaters must be located so as to be pro-

tected from damage by aircraft and other

objects, such as cranes and movable scaffolding.

D. Heaters must be located so as to be acces-

sible for servicing and adjustment.

2.1 INSTALLATION IN COMMERCIAL GARAGES

The SEM(U) / IT(U) Infra red Heaters are

suitable for use in commercial garages when

installed in accordance with minimum clearances to combustible construction or material

in storage, from heater and vent, to standard

ANSI Z223.1 latest edition, in the U.S.A. and

CSA B149.1-00, in Canada. “Overhead heat-

3. INSTALLATIONS OTHER THAN SPACE HEATING

Use for process applications will void the C.S.A certification and may require field inspection

and/or certification.

ers shall be installed at least (8) feet above

the floor”. In addition, they shall be located

high enough to maintain the minimum distance to combustibles, as shown on the heater

rating plate, between the heater and any vehicles parked below the heater

Page 1

SEM(U) / IT(U) Manual

GP-MSEM-BX-03B

RD: Sept, 2005

RL: 03B

KH

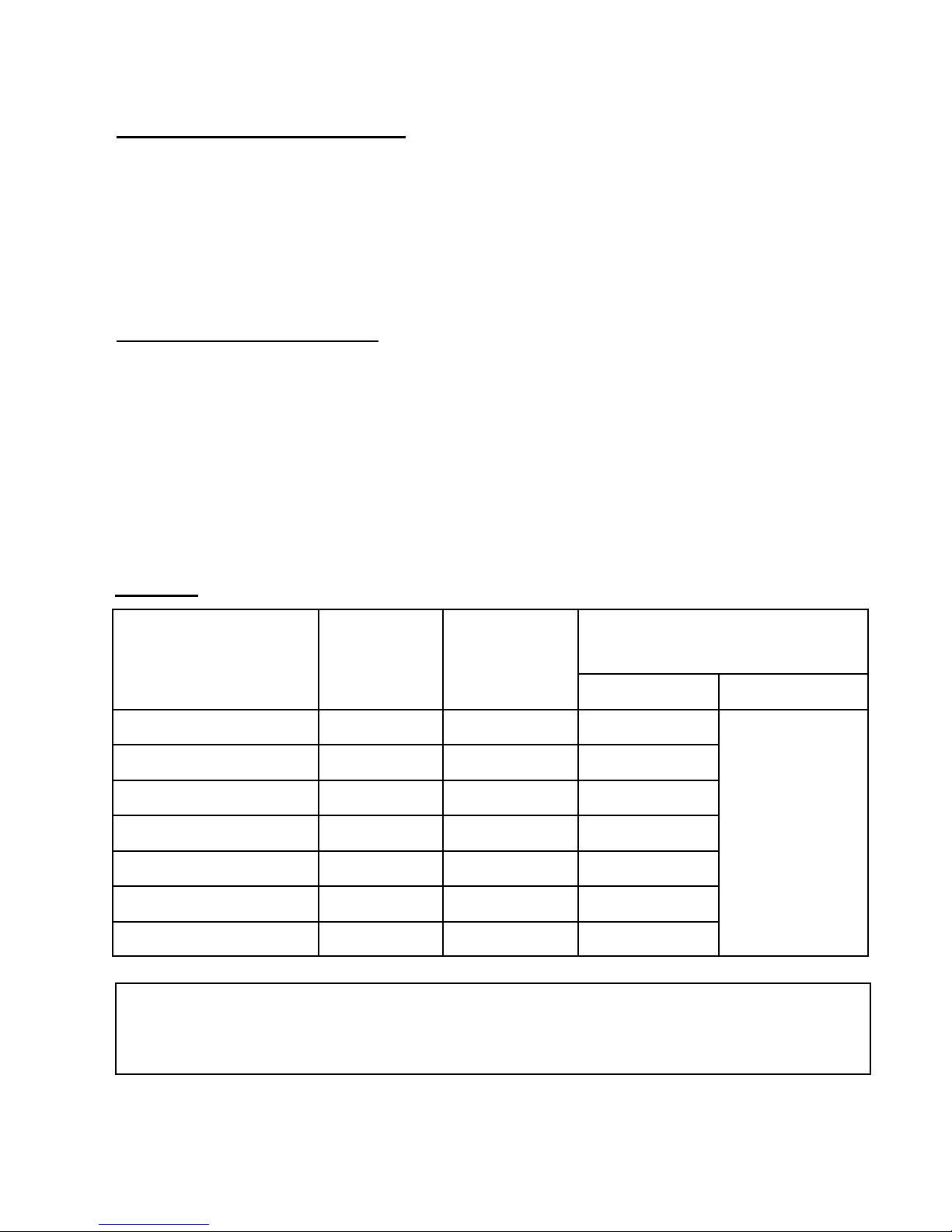

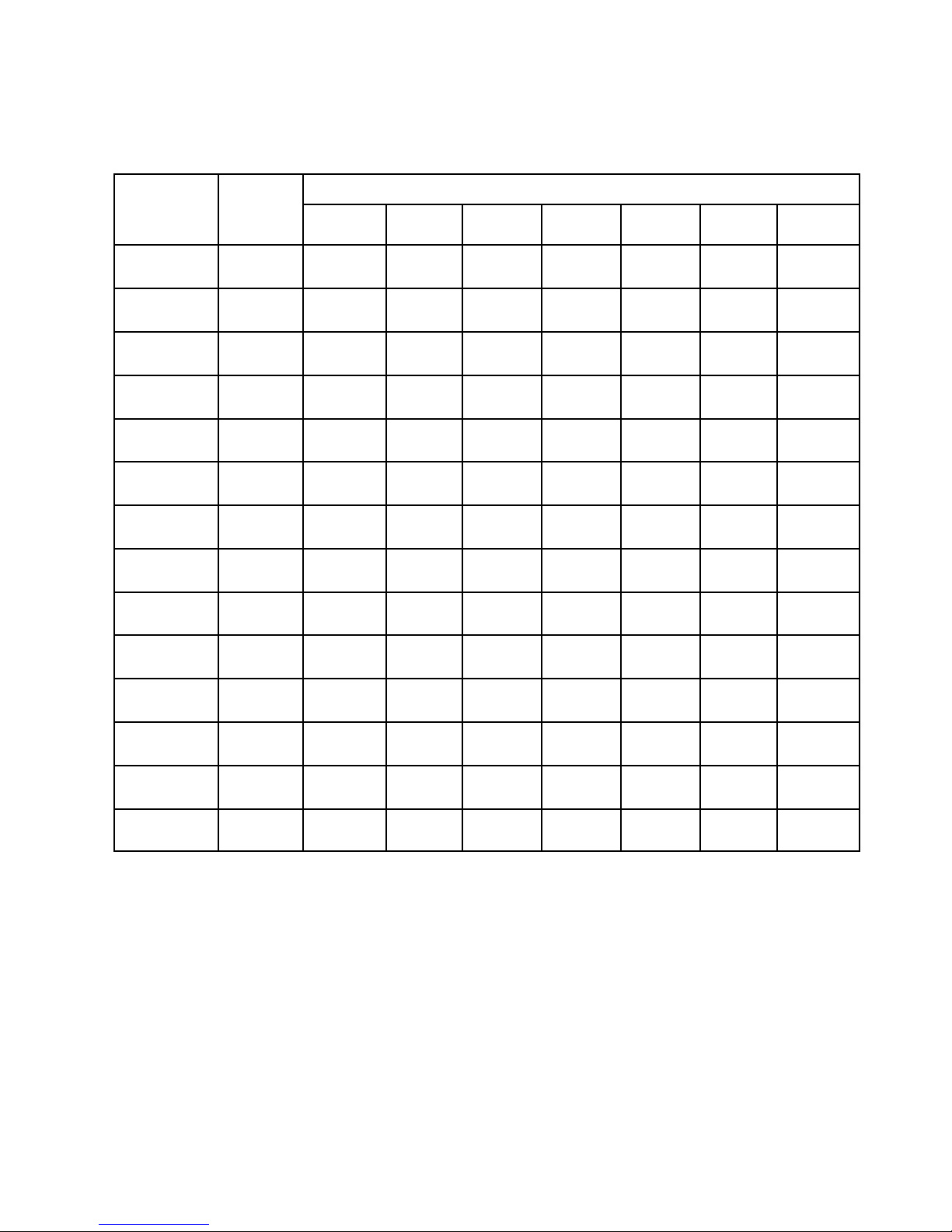

TABLE 1: MODEL

CONFIGURATIONS

OVERALL

HEATER

LENGTH

BTU/HOUR INPUT

0 TO 4500 FT ABOVE

SEA LEVEL

TURBULATOR

REQUIRED

LENGTH

GAS

PRESSURE &

ELECTRICAL

SHIPPING

WEIGHT

(LBS.)

SEM / IT 200-70

SEM / IT 200-60

SEM / IT 200-50

69’ 4”

59’ 8” 10’ 283

50’ 0” 10’ 239

SEMU/ITU 200-30 31’ 11”

SEM / IT 175-70

SEM / IT 175-60

SEM / IT 175-50

69’ 4”

59’ 8” 10’ 283

50' 0” 10’ 239

SEMU/ITU 175-30 31’ 11”

SEM / IT 155-60

SEM / IT 155-50

SEM / IT 155-40

59’ 8”

50’ 0”' Not Required 239

40' 4” 10' 195

SEMU/ITU 155-30 31’11”

SEMU/ITU 155-20 22' 3”

SEM / IT 130-50

SEM / IT 130-40

SEM / IT 130-30

50' 0”

40’ 4” 10' 195

30’ 8” 14' 150

SEMU/ITU 130-20 22’ 3”

SEMU/ITU 130-15 17’ 3”

SEM / IT 110-50

SEM / IT 110-40

SEM / IT 110-30

50’ 0”

40’ 4” 10' 195

30’ 8” 14' 150

SEMU/ITU 110-20 22’ 3”

SEMU/ITU 110-15 17’ 3”

200,000

175,000

155,000

130,000

110,000

10’ LINE

MINIMUM

328

5" W.C. N.G.

11" W.C. L.P.

10’ 287

10’ 240

LINE

10’ 287

Not Required 283

MAXIMUM

14" W.C. N.G.

14" W.C. L.P.

Not Required 287

10' 199

MANIFOLD

3.5" W.C. N.G.

Not Required 239

10" W.C. L.P.

½" INLET

10' 199

14’ 154

Not Required 239

ELECTRICAL

120V, 60 HZ

10' 199

14’ 154

SEM / IT 80-40

SEM / IT 80-30

SEM / IT 80-20

40’ 4”

30’ 8” 14' 150

21’ 0” 14' 106

SEMU/ITU 80-15 17’ 3”

SEMU/ITU 80-10 12’ 7”

SEM / IT 60-30

SEM / IT 60-20

30’ 8”

21’ 0” 14' 106

SEMU/ITU 60-10 12’ 7”

NOTE: Where required, the series SEMU/ITU heaters will be supplied with the turbulators, installed into the end tube(s) of the system

configurations.

** 2000 feet above sea level for the USA – see Orifice Altitude Conversion Chart on page 35

80,000

60,000

Page 2

10’ 195

14' 154

14' 106

14’ 150

14’ 90

GP-MSEM-BX-03B

SEM(U) / IT(U) Manual

RD: Sept, 2005

RL: 03B

KH

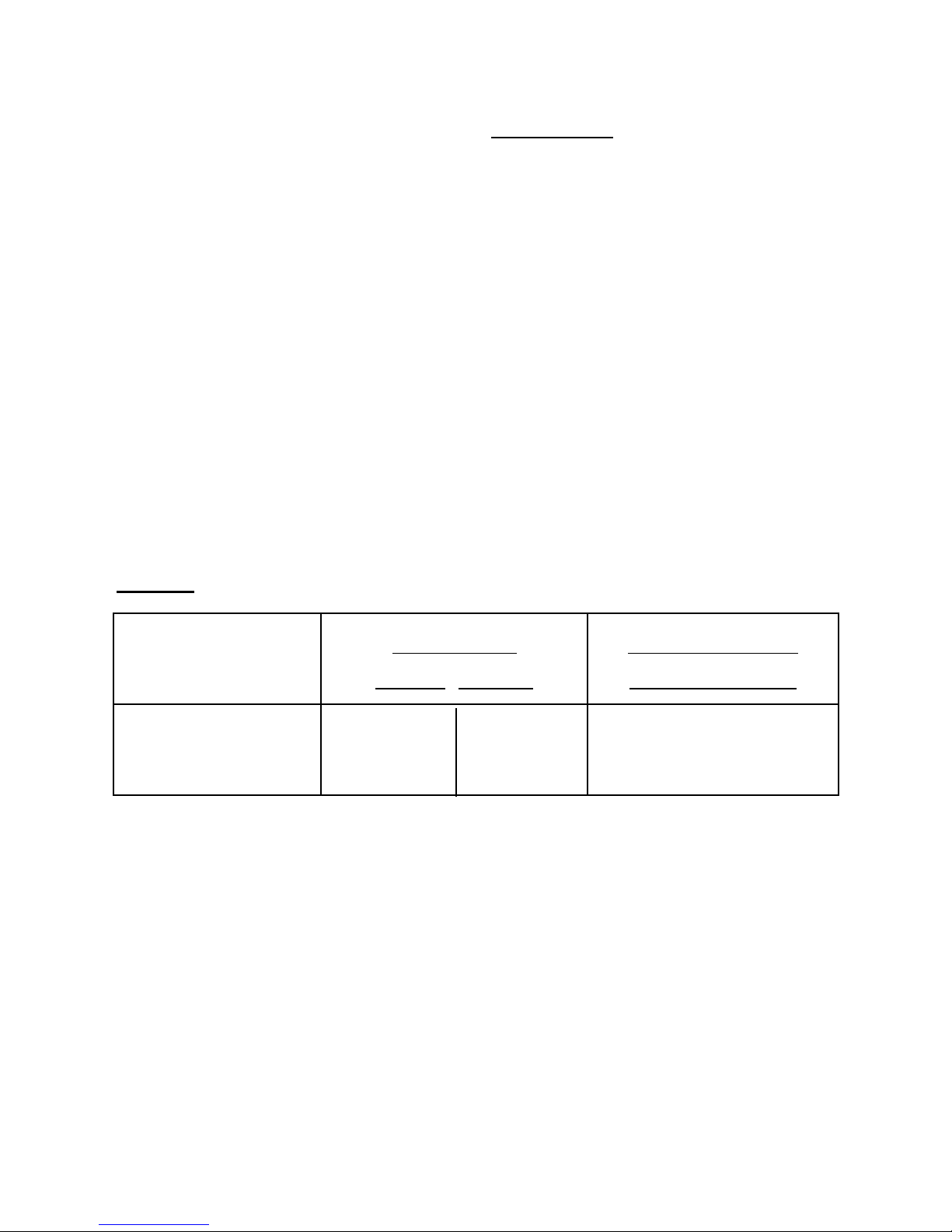

BURNER & TUB E K IT ASSEMBLY CH ART

T

MODELS:

SEM, IT: Commercial / Industrial Applications

TUBE KIT PART # & Q U A NTITY R EQ U IR ED

Stand-Alone Kits Primary Kits Secondary Kits

BURNER KIT

FIRING RATE

60,000

80,000

110,000

130,000

155,000

175,000

200,000

Stand-Alone Tube Kits require no additional tube kits.

Primary Tube Kits require at least one additional Secondary Tube Kit.

Secondary Tube Kits require a Primary Tube Kit.

Secondary Tube Kit TM-1010-SX can also be used as a 10 ft extension kit; the installer

will

need to remove the tu rbu lator

20'

30'

20'

30'

40'

30,

40'

50'

30,

40'

50'

40'

50'

60'

50'

60'

70'

50'

60'

70'

TM-1420-SXTM-1430-SXTM-1040-SXTM-F030-SXTM-1030-SXTM-1010-SXTM-0020-

1

1

(refer to Turbulator Chart in the I&O Manual).

1

1

1

1

1

1

1

1

or 1+ 1

or 1+ 1

1+ 1

or 1+ 1

1+ 1

or 1+

1+ 1

1+ 1

MODELS: SEMU / ITU

TUBE KIT SELECTION CHA R T

Tube Lengths ->

Tube Kit # ->

INPUT (Btuh)

60,000

80,000

110,000

130,000

155,000

175,000

Length

10' U 1

10' U 1

15' U 1

15 'U 1

20' U 1

15 'U 1

20' U 1

20' U 1

30' U 1 + 1

30' U 1 + 1

TUBE KIT PART # & QU AN TITY REQ U IRED

Stand-Alone Kits* Primary Kits*

2 x 10' 2 x 15' 2 x 20' 2 x 20' 2 x 20' 2 x 10'

TM-1410-SUTM-1415-SUTM-1020-

TM-0020-SUTM-A120-SUTM-0010-

SU

SX

M-0030-

1

1+ 1

1+ 1

1+ 2

1+ 1

1+ 1

1+ 2

2ndary

SU

SX

200,000

30' U 1 + 1

* Stand-Alone & Prima ry Kits include JS-0513 -BU 180° Turn B ox

packed and shipped in a separate carton.

Page 3

GP-MSEM-BX-03B

SEM(U) / IT(U) Manual

RD: Sept, 2005

RL: 03B

KH

5. PRE-INSTALLATION SURVEY

The SEM(U) / IT(U) heating system must

have gas piping of the correct diameter,

length, and arrangement to function properly.

Carefully survey area to be heated, and for

best results, whenever possible, place burner

and combustion chamber in coldest area.

For this reason, a layout drawing is necessary.

6. MOUNTING CLEARANCES

This heater must be mounted and positioned

to maintain the minimum clearance to combustible materials as shown in FIGURE 1

(PAGE 6) TABLE 3 (PAGE 6). For recommended heater placement refer to TABLE 2

(below). Heaters should also be located and

installed with respect to building construction

and equipment to provide a minimum clear-

ance of 24 inches from the end of burner

housing for servicing and cleaning of burner,

blower and controls. A minimum horizontal

clearance of 4 ft. from electrical meters, gas

meters, regulators and relief equipment is re-

quired by ANSI Z223.1.& CSA B149.1-00.

TABLE 2 RECOMMENDED HEATER PLACEMENT

MODEL

MOUNTING

HEIGHTS

(FEET)

MAXIMUM

DISTANCE

BETWEEN

HEATERS

(FEET)

DISTANCE-OUTSIDE WALL

TO HEATER LONG AXIS

PARALLEL TO WALL (FEET)

HORIZONTAL ANGLE

SEMU/ITU 200 18 – 25 50 17 – 25

SEMU/ITU 175 18 – 25 50 17 – 25

SEMU/ITU 155 16 – 21 45 15 – 20

COMBUSTIBLE

CLEARANCE

SEMU/ITU 130 15 – 21 40 15 – 20

SEMU/ITU 110 13 – 19 35 13 – 18

SEMU/ITU 80 10 – 16 30 12 – 16

SEMU/ITU 60 8 – 14 25 11 – 15

IMPORTANT: Continuous operation of single or multi-heater placement must

not cause any combustible material in storage to reach a

O

temp erature in excess of 160

Page 4

F.

GP-MSEM-BX-03B

SEM(U) / IT(U) Manual

RD: Sept, 2005

RL: 03B

KH

TABLE 3 MINIMUM CLEARANCES TO COMBUSTIBLES

MODEL

SEM/IT 200

SEM/IT 175

SEM/IT 155

SEM/IT 130

SEM/IT 110

SEM/IT 80

SEM/IT 60

SEMU/ITU 200

SEMU/ITU 175

SEMU/ITU 155

SEMU/ITU 130

SUSPENDED HORIZONTALLY

SUSPENDED AT AN ANGLE

UP TO 45 DEGREES

TOP SIDE BELOW TOP REAR FRONT BELOW

A B C D E F G

7" 22" 68" 7" 1" 57" 68"

6.5" 20" 68" 6.5" 1" 47" 68"

6" 19" 64" 6" 1" 44" 64"

4" 11" 60" 5" 1" 35" 56"

3" 9.5" 60" 4.5" 1" 26" 54"

2.5" 6" 42" 3.5" 1" 23" 38"

2.5" 5.5" 34" 3" 1" 17" 34"

7" 22" 68" 7" 1" 57" 68"

6.5" 20" 68" 6.5" 1" 47" 68"

6" 19" 64" 6" 1" 44" 64"

4" 11" 60" 5" 1" 35" 56"

SEMU/ITU 110

SEMU/ITU 80

SEMU/ITU 60

3" 10" 60" 4.5" 1" 26" 54"

2.5" 6" 42" 3.5" 1" 23" 38"

2.5" 5.5" 33" 3" 1" 17" 34"

FIGURE 1 MINIMUM CLEARANCES TO COMBUSTIBLES

SEM / IT

SEMU / ITU

A

F

D

E

B

C

Page 5

up to 45

0

G

GP-MSEM-BX-03B

SEM(U) / IT(U) Manual

RD: Sept, 2005

RL: 03B

KH

7. SYSTEMS INCORPORATING 90O ELBOWS

The SEM(U) / IT(U) Series radiant tube

heater can be installed in configurations as

illustrated in Fig:2 (below) with a maximum

of two 900 elbows per heater. The use of radiant elbows reduces the total maximum vent

The 900 elbows are shipped as a kit with one

clamp and two end caps to close off the reflector ends each side of the elbow (s). The

Reflectors must be secured with four screws

to each of the end caps. (see FIG 10 Page 11)

allowable. (See SECTION: 11 PAGE 13)

Flue Venting.

IMPORTANT: * (STRAIGHT TUBE MODEL ONLY) *

On Models SEM(U) / IT(U), 175 a minimum of 30´ of straight radiant tube must be connected to the burner before any elbow. On Models SEM(u)/IT(u) 155, 130, and 110 a

minimum of 20´ of straight radiant tube must be connected to the burner before any elbow. And on Models SEM/IT 80 and 60, a minimum of 10´ of straight radiant tube

must be connected to the burner before any elbows. Not applicable to SEMU/ITU model

FIGURE 2 SYSTEM CONFIGURATIONS

E

D

G

1

A

C

2

F

3

G

G

4

System Configuration

1 Straight line

2 “U” tube with Turn Box

3 “L” tube with 90

0

elbow kit

4 Twinned tubes into common TEE flue vent

* Note: Both heaters must be connected

with a single common thermostat

Venting Options

A Flue vent through wall 4”

B Flue vent through wall or roof 6”

Page 6

B

C Flue vent through roof

D Flue vent into building, exhaust fan inter

locked with heater

E Combustion air intake from outside

through wall.

F Combustion air intake from outside

through roof

G Combustion air intake from inside

building

GP-MSEM-BX-03B

SEM(U) / IT(U) Manual

RD: Sept, 2005

RL: 03B

KH

8. SUSPENSION SYSTEM

The system configuration and available

support locations must be considered in order

to locate the radiant tubes correctly. Labour

and material can be reduced by locating

(system configuration permitting) directly

under structural members such as joists, steel

or wood beams, etc.

Chain is recommended for hanging the tube

system, connecting the hangers to beam

support as illustrated in FIGURE 3 (below).

To support burner and keep it level, a

separate suspension chain must be attached

to the eye hook at flange end of burner angled

slightly back over burner, FIGURE 4

(below). This will permit normal expansion

and contraction of the tube system. (If rigid

devices such as rods are used in place of

chain, swing joints or other means of

sufficient length must be provided to

compensate for expansion.)

FIGURE 3 SUGGESTED MOUNTING HARDWARE

EYE BOLT THROUGH

HOLE IN BEAM

BEAM CLAMP

WITH EYE SCREW

EYE

SCREW

PIPE RING

OR CLEVIS

BAR-JOIST

CLAMP

FIGURE 4 SEM TYPICAL HANGER & SUPPORT SPACING

4”

11

4

3

ALL TUBES MUST BE SUSPENDED BY TWO (2) HANGERS PER 10’ LENGTH, MOUNTED APPROXIMATELY 6” TO 12”

IN FROM EACH TUBE END.

1- End Cap

2- Wire Hanger

3- Burner Assembly

4- Combustion Air Intake

(optional-c/w FAI adapter)

3"

12

1

6

5

"ALL TUBES MUST BE SUSPENDED BY TWO (2) HANGERS PER 10' LENGTH,

MOUNTED APPROXIMATELY 6" TO 12" IN FROM EACH TUBE END.

2

8

13

5- Sight Glass

6- Aluminized Tube with Flange

7– Tube Coupler

8- Steel Tube(s)

9– Reflector

10- Flue Vent terminal

11- Burner Support Chain

12- Hanger Support Chains

9

7

10

4"

1

* Distances shown are recommendations and may be varied to match field requirements.

Page 7

GP-MSEM-BX-03B

SEM(U) / IT(U) Manual

RD: Sept, 2005

RL: 03B

KH

FIGURE 5 SEM(U) / IT(U) TYPICAL HANGER & SUPPORT SPACING

3"

11

4

3

ALL TUBES MUST BE SUSPENDED BY TWO (2) HANGERS PER 10’ LENGTH, MOUNTED APPROXIMATELY 6” TO 12”

IN FROM EACH TUBE END.

1– Double End Cap

2– Hanging Bra cket

3- Burner Assembly

4- Combustion Air Intake

(optional-c/w FAI adapter)

4”

12

1

6

5

"ALL TUBES MUST BE SUSPEND ED BY TWO (2) HANGERS PER 10' LENGTH,

MOUNTED APPROXIMATE LY 6" TO 12" IN FROM EACH TUBE END.

5- Sight Glass

6- Aluminized Tube with Flange

7- Tube Coupler

8- Steel Tube(s)

2

8

13

9- Reflector

10- Turn Box

11- Burner Support Chain

12– Bracket Support Chain

9

7

4"

1

10

FIGURE 6

BOLTING BURNER TO FLANGED TUBE

1

3

2

4

1 Eye Hook

2 Fifth Nut (Holding Inner Burner to

Housing)

3 Lock Washers (4) Four

4 Nuts (4) Four

Note: Nuts may be shipped c/w

lock-washers as one piece

• Align the four burner bolts through the

tube flange, secure tightly with lock

washers and nuts.

• Note: A Flange Gasket is not required

for this application

• Do not loosen or remove fifth nut (#2)

directly below burner cup

• Secure suspension chain to eye hook

in order to stabiliz e burn er

FIGURE 7 COUPLER KIT

4

2

5

3

Page 8

1

.

1 Tube

2 Tube Coupler

3 Swaged section of tube

4 Point at which the Swaged tube

slides into other section of tube

5 Once the two tubes are joined

together, place the centre of

the Coupling over the line of

the joint and tighten.

GP-MSEM-BX-03B

SEM(U) / IT(U) Manual

RD: Sept, 2005

RL: 03B

KH

FIGURE 8 TURN BOX

9. BURNER AND TUBE INSTALLATION

With all hangers suspended at the same

height, insert first aluminized tube section,

through 4" hole into first two wire hangers.

Bolt burner to flange on first tube section,

SEE FIGURE 6 (page 9). Subsequent lengths

of tube can then be installed, by joining them

together one inside the other and locking the

joints using the aluminized steel clamp. SEE

FIGURE 7 (page 9). Models SEM(U) / IT(U)

200 & 175 have alumatherm as the first section with a welded Flange, the second section

is aluminized, and subsequent lengths are

steel painted.

Slacken the bolts and slip the coupler over

Page 9

the end of the pipe to be joined, making sure

the swaged end of the tube is fully inserted

into the plain end of the tube before repositioning the coupler. The coupler should

then be centred across the joint before tightening up.

If a turbulator is necessary it will be factory

installed into the tube(s). The tube(s) will be

marked stating where it must be installed in

the system, see TABLE 4 (page 12) for the

models which do require turbulators.

Note: Turbulators are ALWAYS

installed at the vent end of the heater .

GP-MSEM-BX-03B

SEM(U) / IT(U) Manual

RD: Sept, 2005

RL: 03B

KH

10. REFLECTOR INSTALLATION

After burner and tubes have been installed,

slide the focus shield reflectors one at a time

into the wire hangers. As each successive

focus shield reflector is installed on an in-line

installation, the ends of the focus shield

reflectors will overlap to provide continuous

coverage over the entire tube system. The

overlapping joints MUST BE FASTENED

together.

Note that for both horizontal and angle

mounting, the tube must be level. Improper

mounting can result in overheating of

controls and combustible materials. Use only

non-combustible mounting hardware.

Side reflectors can be added to the heaters as

an option. They should be secured directly to

the focus shield reflector using "S" hooks or

chain. Drill three holes into the focus shield

reflector flange along side, matching up with

three holes already in side reflector. Mount

side reflector as close as possible to the focus

shield reflector.

FIGURE 9 90 DEGREE ELBOW INSTALLATION

4

1

7

2

6

4

2

1 End-Cap

2 Reflector

3 End Cap Flange OVER

4 End Cap Flange UNDER

3 3

5

5900 Elbow

6 Tube Coupler

Reflector

Reflector

7 P oint at which Swaged tube is fully

inserted into elbow and Swaged end

of elbow is fully inserted into tube.

Page 10

GP-MSEM-BX-03B

SEM(U) / IT(U) Manual

RD: Sept, 2005

RL: 03B

KH

FIGURE 10 MOUNTING REFLECTOR END CAP

2

1

TABLE 4

3

4

1 Reflector End Cap Flange

protruding over and under

the Reflector

2 Screws securing Reflector

to End Cap

3 Opening for Tube

4 Focus Shield Reflector

MODEL

SEM/IT 200-70/60/50

SEM/IT 175-70/60/50

SEM/IT 155-60/50

SEM/IT 155-40

SEMU/ITU 155-30

SEMU/ITU 155-20

SEM/IT 130-50

SEM/IT 130-40

SEM/IT 130-30

SEMU/ITU 130-20

SEMU/ITU 130-15

SEM/IT 110-50

TURBULATOR

LENGTH

(IF REQUIRED)

10’

10’

not required

10'

not required

10’

not required

10'

14'

10’

14’

not required

MODEL

SEM/IT 110-40

SEM/IT 110-30

SEMU/ITU 110-20

SEMU/ITU 110-15

SEM/IT 80-40

SEM/IT 80-30

SEM/IT 80-20

SEMU/ITU 80-15

SEMU/ITU 80-10

SEM/IT 60-30

SEM/IT 60-20

SEMU/ITU 60-10

TURBULATOR

LENGTH

(IF REQUIRED)

10'

14'

10’

14’

10’

14'

14'

14’

14’

14’

14’

14’

NOTE: Where required the SEMU/ITU Series Heaters will be supplied with the turbulators,

snugly installed into the vent end tube (s) of the system configuration.

FIGURE 11 REFLECTOR ARRANGEMENTS

VENT RUN

(TOP)

TUBES

BURNER MUST

BE LOWER

Page 11

GP-MSEM-BX-03B

SEM(U) / IT(U) Manual

RD: Sept, 2005

RL: 03B

KH

FIGURE 16 REFLECTOR EXTENSIONS - JS-0509-XX-P

(OPTIONAL - IF REQUIRED )

10”

• Using “S” Hooks attach the two

Reflectors.

• Make sure “S” Hooks are closed

Page 12

GP-MSEM-BX-03B

SEM(U) / IT(U) Manual

RD: Sept, 2005

RL: 03B

KH

11. FLUE VENTING

THIS SEM(U) / IT(U) SERIES IS APPROVED FOR BOTH DIRECT AND INDIRECT

VENTING APPLICATIONS. THE SYSTEM MUST NOT BE OPERATED WITHIN A

NEGATIVE AIR CONDITION, UNLESS COMBUSTION AIR IS BROUGHT IN FROM

OUTSIDE DIRECTLY TO THE BURNER.

F A SEVERE NEGATIVE PRESSURE IS EXPERIENCED OR ANTICIPATED, THE SEC-

I

PORT (BARB) ON THE BLOCKED FLUE SWITCH SHOULD BE CONNECTED DI-

OND

RECTLY

SWITCH TO OUTSIDE OF BUILDING (HOSE KIT NOT SUPPLIED – OPTIONAL EX-

TRA

INDIRECT VENTED APPLICATION

TO OUTSIDE AIR USING 1/4” PLASTIC HOSE FROM BLOCKED FLUE

).

A length of ‘C’ Vent is to be installed on the

swaged end of the last tube before any Elbow

or Vent Cap is fitted. When the heater is installed and indirectly vented, it is required in

Canada that the heater be electrically interlocked to an independent exhaust fan by

means of an Air Proving Switch. The exhaust

fan must be sized to create 3CFM for every

1000 Btu/hr or fraction thereof, of total input

of installed equipment. Consult CSA.B149.100 latest edition for requirements.

DIRECT VENTED APPLICATION

A length of ‘C’ Vent is to be installed on the

swaged end of the last tube before any Elbow

is fitted. All venting must be single wall "C"

vent except that portion of vent passing

through a combustible wall or roof then type

"B" vent may be used as per CSA's interim

requirement. When venting horizontally, the

flue vent system must slope downwards approximately 1/4" per foot toward the vent terminal, starting at the termination of the radiant tube. For horizontal through the wall

In the USA when a heater is installed unvented the system requires consideration of

normal infiltration and introduction of outside

air by natural or mechanical means, and/or

electrically interlocked to an independent exhaust fan. Consult your local codes and ANSI

Z223.1 latest edition. for all venting requirements, and practices.

venting, the approved 4" or 6" horizontal wall

vent terminal should be used and mounted

18" from the outside wall to the inside edge

of terminal opening. The flue vent terminal

used must be of the approved type supplied

by the manufacturer or by an approved "B"

vent manufacturer. It is the responsibility of

the installer to be familiar with current local

codes or ANSI Z223.1 / CSA.B149.1-00 latest editions for all venting requirements, and

practices.

Page 13

GP-MSEM-BX-03B

SEM(U) / IT(U) Manual

RD: Sept, 2005

RL: 03B

KH

The heater is designed to operate with single

wall 4” diameter 26 gauge minimum exhaust

vent.

When venting horizontally, the flue vent system should slope downwards approximately

1/4" per foot toward the vent terminal, start-

ing at the termination of the radiant tube.

When vent and combustion air are taken

through the roof, the exhaust vent should always terminate higher than the combustion

air intake, to prevent recycling the products

of combustion back into the heater.

The total maximum allowable combined

length of vent and combustion air duct is 80'

for SEM / IT 200, 175, 155 and 130, and 50'

for SEM / IT 110, 80, 60 and 45. Total maximum allowable combined vent and duct is

reduced by ten feet for every 90o elbow installed in the vent or duct. Should the tube

system be installed with a 90o elbow in the

radiant tube, 10 ft must be deducted from the

length of vent and duct. Should the tube system be installed with a 180o elbow or an SEM

(U) / IT(U) turn box in the radiant tube, 20 ft

must be deducted from the length of vent and

duct. Neither the individual flue vent nor the

combustion air duct is to exceed 50 ft in

length. Exceeding the allowable lengths may

create condensation problems and will void

CSA Design Certification. The horizontal

flue vent shall not terminate less than the following guidelines except where indicated in

brackets:

• One feet above grade level, unless its lo-

cation is adjacent to public walkways,

then it has to be not less than seven feet.

• Must be installed to prevent blockage by

snow and protect building materials from

Page 14

degradation by flue gases.

• Directly below a soffit or over- hang.

• Directly above a gas utility meter or ser-

vice regulator.

• Twelve inches from combustion air inlet

of any heater with input up to 100,000

Btu/hr.

• Three feet from combustion air inlet of

any heater over 100,000 BTU.

• Within six feet of a mechanical air supply

inlet to any building.

• Twelve inches from sides and bottom and

eighteen inches from top when installed

close to the corner of a building.

• All vent pipe with a slip fit connection

must be mechanically secured. A length

of ‘C’ Vent is to be installed on the

swaged end of the last tube before any

Tee is fitted.

• As an Option, two heaters may be vented

through an approved common 4"x4"x6"

Vent Tee, supplied by the manufacturer.

The two heaters must then be controlled

by a single common thermostat or “ON/

OFF” switch.

GP-MSEM-BX-03B

SEM(U) / IT(U) Manual

RD: Sept, 2005

RL: 03B

KH

Where the vent pipe passes through areas

where the ambient temperature is likely to

produce condensation of the flue gases, the

vent pipe shall be insulated with a suitable

material as approved and specified by the insulation manufacturer.

FIGURE 18 FLUE VENT CONNECTION

Check with the manufacturers Technical Support as to the maximum vent temperature requirements.

The vent system must always be adequatel y

supported to prevent sagging.

FLUE VENT END

OF TUBE

For Direct and Indirect Venting it is recommended to install a length of ’C’ Vent onto the

end of the last tube before any fittings are installed. The “C” Vent connection should be

slipped onto the tube and positioned approx 6” beyond the swaged portion of the 4” tube

and must be secured with sheet metal screws.

12. COMBUSTION AIR DUCT

Where heater is operated in a negative air

condition or in contaminated air atmosphere

such as woodworking shops, air for combustion must be ducted from outside to intake

flange on blower. The total maximum combined length of vent and combustion air duct

130, and 50' for SEM(U) / IT(U) 110, 80, 60

and 45. Neither the individual flue vent or

combustion air duct is to exceed 50'. The total maximum allowable combined vent /air

duct is reduced by ten feet for every 90o vent

elbow installed.

is 80' for SEM(U) / IT(U) 200, 175, 155 and

Order Optional Parts:

Air Intake Flange:.... Heater Model Reqd.

Air Intake Vent Cap:............JS-0532-VC

Page 15

GP-MSEM-BX-03B

SEM(U) / IT(U) Manual

RD: Sept, 2005

RL: 03B

KH

Do not install filters on the combustion air

intake.

For ease of installation, this heater has an optional fresh air intake duct hood. It can be

used as an outdoor intake hood to bring combustion air to the heater from outside. If

drawing in fresh air from outside, it is recommended as per common Engineering practice,

that any single wall pipe exposed to cold air

must be insulated to prevent condensation. If

heater is being vented horizontally through

Minimum air intake inlet distances:

the wall and combustion air is ducted in from

outside to the Burner, it is advisable to create

a trap at the Burner. The trap is created by

dropping the pipe below the level of the tube

(much like a plumbing trap using elbows or a

flexible connector) before connecting it to the

fresh air intake on top of the Burner box, Do

not use flexible dryer hose for air inlet duct,

the corrugated sides of this tubing add too

much restriction to the air flow. A good quality industry approved insulated flex is allowed.

Three feet above grade

Twelve inches from flue vent terminal of

Three feet from flue vent terminal of any

heaters over 100,000 Btu/hr.

heaters with input up to 100,000 Btu’s/hr.

CAUTION:

In installations where chlorinated Hydrocarbons are in use, such as Trichloroethylene or

Chloroethylene Nu it is essential that combustion air be brought in from

non-contaminated areas. Burning the fumes from these gases will create Hydrochloric

acid fumes, which are detrimental to humans, equipment and buildings. Typical sources

of other contaminants are paint removers, paints, refrigerants, solvents, adhesives,

degreasers, lubricants, pesticides, etc.

13. GAS SUPPLY INSTALLATION

It is recommended that a locally approved

flexible connector supplied by the distributor,

be installed between the heater and gas piping. The heater must be isolated from the gas

supply piping system by closing its individual

manual shut off valve (supplied by installer)

during any pressure testing of the gas supply

piping system.

CAUTION:

If a rigid gas pipe connection is made, then compensation for normal gas

supply pipe expansion, and radiant tube expansion must be provided. All

piping must conform to local codes.

Page 16

GP-MSEM-BX-03B

SEM(U) / IT(U) Manual

RD: Sept, 2005

RL: 03B

KH

DO NOT use pressures greater than 1/2 psig.

to pressure check the heater.

TEST FOR LEAKS: All gas piping and

connections must be tested for leaks after the

installation is completed.

Apply soap suds solution to all connections

and joints and if bubbles appear, leaks have

been detected and must be corrected. DO

NOT USE A MATCH OR OPEN FLAME

OF ANY KIND TO TEST FOR LEAKS.

NEVER OPERATE THE HEATER WITH

LEAKING CONNECTIONS.

The supply system should be checked first

with heater turned "OFF" followed by another

check with heater turned "ON".

IMPORTANT:

The minimum supply-line pressure at the

inlet to the heater regulator must not, in

any instance, be lower than 5.5 inches of

water column pressure for natural gas and

11.0 inches of water column pressure for

propane gas. The supply line gas pressure

must be checked with all the heater (s) operating.

Installation of a gas line (trap) “drip leg"

is required at the inlet connection tee following the pipe drop to the heater. Failure

to provide a “drip leg” could result in condensation and foreign matter passing into

the gas valve. Failure to install a “drip leg”

in the gas line will void the warranty.

TABLE 5

GAS TYPE

Natural Gas

Propane

LINE PRESSURE

INCH WATER COLUMN

MINIMUM

5.0 14.0

11.0 14.0

MAXIMUM

NOTE: Access to the manifold pressure test

port is on the top of the valve. A 3/16" Allen

Wrench is necessary to check this. When

checking or setting the manifold pressure, a

water manometer should be used. Gauges

MANIFOLD PRESSURE

INCH WATER COLUMN

AT-TAP IN GAS VALVE

3.5

10.0

which measure in ounces per square inch or

pounds per square inch are not accurate

enough to properly measure or set the pressure. PLEASE SEE NEXT SECTION ON

HEATER EXPANSION.

Page 17

GP-MSEM-BX-03B

SEM(U) / IT(U) Manual

RD: Sept, 2005

RL: 03B

KH

14. HEATER EXPANSION

Due to the characteristics of tube heaters, the

installer must allow for 1” expansion for

every 10’ length of tube. In order to address

this characteristic, it is suggested that the

gas line, flue vent, and combustion air

intake (if used) be installed in such a manner,

that normal expansion of the heater will be

accommodated.

FIGURE 13 ALLOWANCE FOR HEATER EXPANSION

TOP VIEW

FLUE VENT

Air Intake

FLANGED TUBE

Page 18

GP-MSEM-BX-03B

SEM(U) / IT(U) Manual

RD: Sept, 2005

RL: 03B

KH

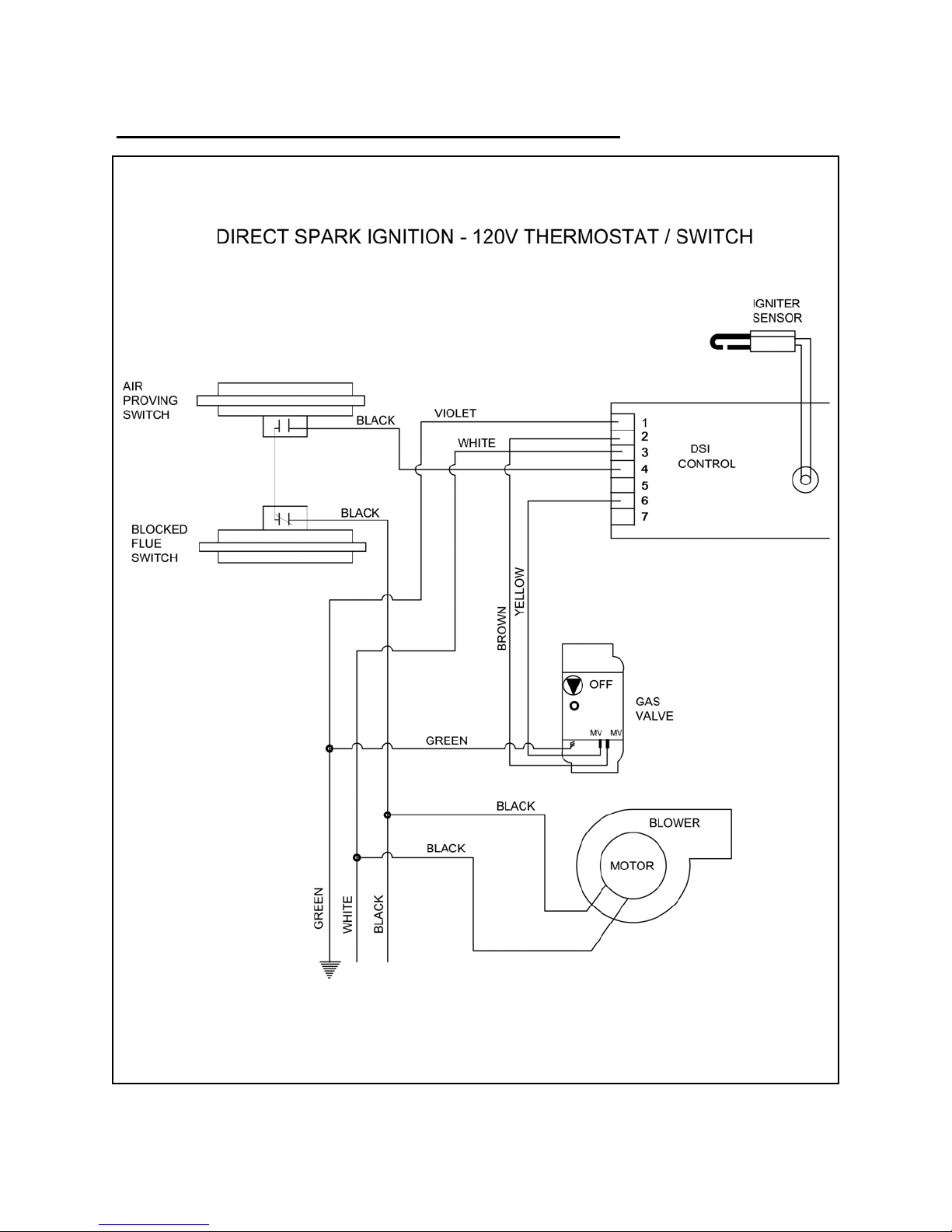

15. ELECTRICAL AND THERMOSTAT WIRING

(SEE WIRING DIAGRAMS PAGE 22)

Wiring must be done in accordance with

local codes. The total load of all heaters must

be considered in determining the required

Each individual tube heater requires 120

Volts 60 Hz electrical power sized for

145VA. The heater can be controlled by

a line voltage thermostat or "ON/OFF"

switch.

IMPORTANT:

Do not install the thermostat in the direct

radiant stream.

The voltage at the spark ignition control

is 110V. Note that proper functioning

of the heater will be adversely affected if

the input voltage varies by more than +/10%

contact rating of the controlling thermostat

or switch.

WARNING:

The heater must be electrically grounded

in accordance with the current Electrical

Code.

It is good wiring practice and the installers

responsibility to ensure that correct wiring

polarity is maintained throughout installation.

The Fenwal DSI control is polarity sensitive

and WILL malfunction if the polarities are

reversed. The black wire MUST be wired to

Hot, and the white wire MUST be wired to

Neutral. If the polarity is reversed the module

will not function correctly and will eventually

burn out.

16. HIGH ALTITUDE INSTALLATIONS

Canada: All of the SEM(U) / IT(U ) radiant

tube heaters are approved for altitudes zero

to 4500 feet above sea level and do not require de-rating.

USA: If a heater is to be installed at altitudes above 2000 ft, the input must be reduced by 4% per 1000 ft. If your local utility de-rates the heat content in the gas supply, no modification of the heater is required. If the gas supply is not de-rated, the

orifice must be changed according to the

chart on page 31. Check with your local

utility regarding de-rating of this appliance.

Page 19

GP-MSEM-BX-03B

SEM(U) / IT(U) Manual

RD: Sept, 2005

RL: 03B

KH

17. SEQUENCE OF OPERATION / FLAME RECOVERY/ SAFETY LOCKOUT

Start up - Heat Mode

When the thermostat is set above the ambient

temperature, 120 VAC is supplied to the L1

terminal. When this occurs the control

will power up and perform a self-check routine and begin a prepurge*, if selected. Following the pre-purge, the gas valve is energized and sparks commence until flame is detected or the Trial For Ignition (TFI) period

expires.

When flame is detected, the spark is shut off

and the gas valve remains energized. The

thermostat and burner flame are constantly

monitored to ensure that the system is functioning properly. When the thermostat is satisfied and the demand for heat ends, the gas

valve is de-energized immediately and the

flame is extinguished.

Flame Failure During TFI Period

Should the burner fail to light or flame is not

detected during the first trial for ignition period, the gas valve is de-energized and the

control starts the inter-purge sequence before

another ignition attempt. After inter-purge,

the control will attempt two additional ignition trials. If these attempts are unsuccessful

the control will go into lockout mode.

Flame Failure of Established Flame

Re -Ignition

If the established flame signal is lost while

the burner is operating, the control responds

and begins sparking within 0.8 seconds. The

spark will be energized for the duration of the

trial-for-ignition period in an attempt to relight the burner. If flame is re-established,

normal operation resumes.

If the Burner does not light after the first attempt, the inter-purge sequence is completed

between attempts to re-light the burner. If the

burner fails to light after the

third try, the control will de-energize the gas

valve and go into lockout mode. See

Lockout Recovery

Lockout Mode (On-Board Safety System)

After single or multiple attempts to light the

burner have failed or flame is not established,

the control automatically enters lockout The

control will not open the gas valve unless

there is intervention by the user. See Lockout

Recovery.

Lockout Recovery

For lockout recovery, reset the thermostat

below ambient temperature or remove the

120 VAC power supply for 5 seconds

Page 20

GP-MSEM-BX-03B

SEM(U) / IT(U) Manual

RD: Sept, 2005

RL: 03B

KH

18. LIGHTING INSTRUCTIONS

LIGHTING SEQUENCE:

Refer to the lighting instructions on the outside cover of the burner housing. Again, if

the unit goes off on safety, main power to the

unit must be manually interrupted for a 30

second reset period before the heater can be

restarted.

NOTE:

On initial installation, the unit may lock

out on safety owing to the length of time

required to bleed air from the gas piping

system.

19. RECOMMENDED MAINTENANCE

1. Inspect the venting system each heating

season and repair or replace worn parts

as required.

2. Check the inlet air opening and the

blower periodically, cleaning off any lint

or foreign matter, as it is important that

the flow of combustion and ventilation

• Rotate gas valve knob to ON position.

• Set Thermostat to the desired setting.

• Turn Power ON to heater.

• This should start the Blower, sending the

DSI Control into its pre-purge cycle, then

into ignition, and light off.

• If heater fails to light, shut down heater

and wait 5 minutes before relighting it

• To shut down the heater just reverse the

previous steps..

must not be obtructed. In addition we

recommend the entire system be checked

once a year by a qualified service techni

cian.

3. Lubricate Blower motor, by adding sev

eral drops of oil to oil ports located on

the left hand side of the motor.

THE TUBE HEATER BURNER IS COMPLETELY FACTORY ASSEMBLED AND

TESTED. ANY ALTERATION VOIDS THE CSA CERTIFICATION AND MANUFACTURERS WARRANTY. FOR ADDITIONAL INFORMATION, CONTACT YOUR LOCAL DISTRIBUTOR.

Each 10’ section of the SEM(U) / IT(U) Series Heater is hung by 4 chains, supporting 2 brackets, 2 tubes and one reflector. The heater may be hung at an angle up to 45 providing the Burner

Tube is in the lower position and the flue end in the upper position.

Page 21

GP-MSEM-BX-03B

SEM(U) / IT(U) Manual

RD: Sept, 2005

RL: 03B

KH

20. CA SERIES WIRING DIAGRAM 12OV THERMOSTAT

Page 22

GP-MSEM-BX-03B

SEM(U) / IT(U) Manual

RD: Sept, 2005

RL: 03B

KH

21. CA SERIES: TROUBLESHOOTING GUIDE - 120v THERMOSTAT

SET THERMOSTAT TO CALL FOR HEAT

CHECK FOR LINE VOLTAGE POWER SUPPLY.

CHECK FOR VOLTAGE AT BLOWER MOTOR

IF VOLTAGE IS PRESENT, REPLACE MOTOR.

COMBUSTION AIR BLOWER STARTS

YES

NO

AIR PROVING SWITCH CLOSED

110 VOLTS AT IGNITION CONTROL

YES

NO

SPARK ACROSS IGNITER OR

IGNITER/SENSOR GAP

YES

NO

NO VOLTAGE AT PIN 4 - CHECK THERMOSTAT

CHECK WIRING CONNECTION, FUSE / CIRCUIT

BREAKER.

ENSURE THAT THE AIR INTAKE AND FLUE

ARE NOT BLOCKED

ENSURE PRESSURE TUBE IS CONNECTED AND

NOT BLOCKED

CHECK AIR PRESSURE WITH MANOMETER

CHECK AIR PROVING SWITCH IS CLOSING

WHEN B L OWER IS RUNNING

REPLACE DEFECTIVE SWITCHES

SEE SPARK IGNITION CIRCUIT (on Page 24)

PULL IGNITION LEAD AND CHECK SPARK

CHECK SPARK GAP, ADJUST TO 1/8” TO 3/16” IF

NEEDED USING THE GROUND PRONG ONLY

SPARK OK?

cont’d

YES

NO

REPLACE IGNITION CONTROL

CHECK IGNITION CABLE, GROUND WIRING

CERAMIC INSULATOR AND CAP.

CHECK BOOT OF THE IGNITION CABLE FOR

SIGNS OF MELTING OR BUCKLING.

TAKE PROTECTIVE ACTION TO SHIELD CABLE

AND BOOT FROM EXCESSIVE TEMPERATURES.

Page 23

GP-MSEM-BX-03B

SEM(U) / IT(U) Manual

RD: Sept, 2005

RL: 03B

KH

CONTINUED FROM PREVIOUS PAGE

MAIN BURNER LIGHTS

YES

NO

SPARK STOPS WHEN

BURNER LIGHTS

YES

NO

SYSTEM RUNS UNTIL CALL

FOR HEAT ENDS

YES

NO

SPARK IGNITER MAY BE OUT OF POSITION

CHECK ELECTRICAL CONNECTION FROM IGNI

TION CONTROL PIN #2 TO GAS VALVE.

CHECK FOR 110 VAC ACROSS GAS VALVE IF

OKAY, REPLACE GAS VALVE.

CHECK GROUND WIRE, IGNITER AND HT CABLE.

CHECK THAT BURNER FLAME COVERS ELECTRODE

IF CHECKS ARE OKAY, REPLACE IGNITION CONTROL

NOTE: IF IGNITION CONTROL GOES INTO LOCKOUT, MODE

RESET THE SYSTEM.

NOTE: IF GROUND IS POOR OR ERRATIC, SHUTDOWNS

MAY OCCUR OCCASIONALLY EVEN THOUGH OPERA-

TION IS NORMAL AT THE TIME OF CHECKOUT.

CHECK GROUND WIRE NECTIONS AND CONTINUITY.

IF CHECKS ARE OKAY, REPLACE IGNITION CONTROL

CALL FOR HEAT ENDS:

SYSTEM SHUTS OFF

YES

NO

TROUBLESHOOTING ENDS

CHECK FOR PROPER TEMPERATURE CONTROLLER

OPERATIONS

REMOVE VALVE LEAD AT IGNITION CONTROL, IF VALVE

CLOSES, RECHECK TEMPERATURE CONTROLLER AND

WIRING, IF NOT, REPLACE GAS CONTROL OPERATOR

Page 24

GP-MSEM-BX-03B

SEM(U) / IT(U) Manual

RD: Sept, 2005

RL: 03B

KH

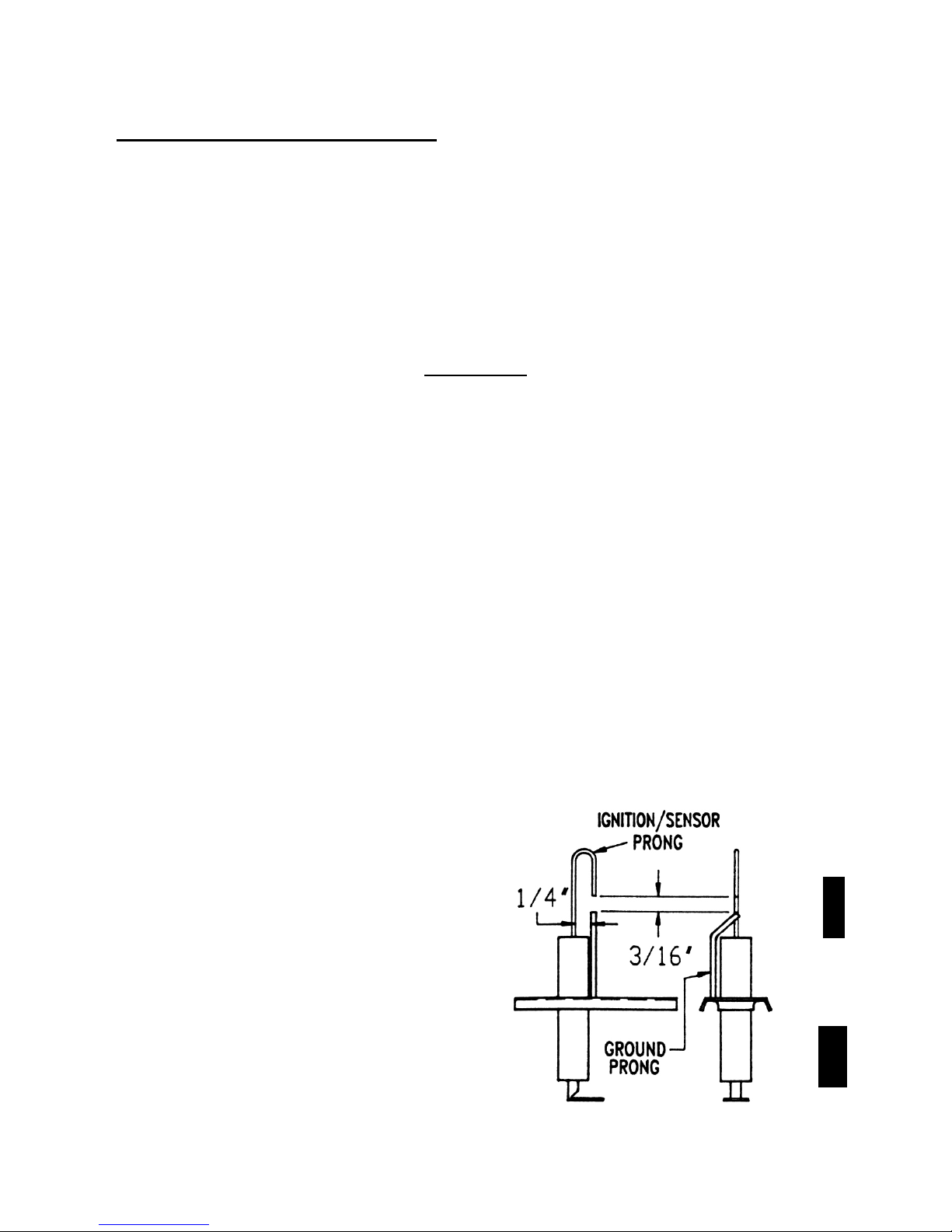

22. SPARK IGNITION CIRCUIT

The step-up transformer in the ignition control provides spark ignition at 30,000 volts (open

circuit). To check the spark ignition circuit, proceed as follows.

1 Shut off gas supply to the gas control

2 Disconnect the ignition cable at the ignition control stud terminal to isolate the circuit from

the spark igniter or igniter/sensor

3 Prepare a short jumper lead, using heavily insulated wire such as ignition cable

CAUTION

In the next step, DO NOT allow fingers to touch either the stripped

end of the jumper or the stud terminal. This is a very high voltage circuit and

electrical shock can result.

1 Perform this test immediately upon energizing the system before the ignition control goes

into safety lockout and interrupts the spark circuit. Touch one end of the jumper firmly to

the ignition control GND terminal. (DO NOT remove the existing ground lead.) Slowly

move the other end of the jumper wire toward the stud terminal on the ignition control to

establish a spark.

2 Pull the wire away from the stud and note the length of gap at which spark discontinues.

3 A spark length of 1/8 in. (3mm) or more indicates satisfactory voltage output. If no arc can

be established, or the maximum spark is less than 1/8 in. (3mm), and power to the ignition

control input terminals was proved, replace the ignition control.

SPARK IGNITER SET UP

Please use the following diagram for checking

the Igniter gap.

If the gap is incorrect all adjustments should

be made with the GROUND PRONG/PIN

ONLY!

DO NOT BEND THE IGNITER

PRONG!!!!

The black bars located at the lower right corner can be used as a guide for adjustment.

Page 25

3/16”

1/4”

GP-MSEM-BX-03B

SEM(U) / IT(U) Manual

RD: Sept, 2005

RL: 03B

KH

23. START-UP SHEET

.

.

COMMISSIONING REPORT

AS PER I&O MANUAL AND LOCAL C OD ES

CONTRACTOR NAME: ................................................................................DATE................................

ADDRESS:............................................................................................................................................

............................................................................................................................................................

CITY:........................................................................................

PHONE:...................................................................................

CELL: .....................................................................................

JOB SITE......................................................................................................CITY................................

HEATER MODEL NUMBER:................................................................................

HEATER SERIAL NUMBER: ...............................................................................

THIS EQUIPMENT HAS BEEN FACTORY FIRED AND TESTED BEFORE DELIVERY, NEVERTHELESS

IT IS NOT A PLUG IN APPLIANCE..IT DOES REQUIRE COMMISSIONING AND FIELD ADJUSTMENTS

TO ENSURE THAT SITE CONDITION S ARE COMPATIBLE WITH THIS HEATER, AND TO

ALLEVIATE NUISANCE CALL BACKS FOR THE CONTRACTOR, THE FOLLOWING

START-UP NEEDS TO BE COMPLETED

BY THE LICENSED GAS INSTALLER.

A CONTRACTOR IS CALLING FOR TECHNICAL SUPPORT,

MUST PROVIDE THE FOLLOWING INFORMATION

FROM HIS COMPLETED COMMISSIONING REPORT ON NEXT PAGE

FAX COMPLETED FORM TO TECHNICAL SERVICES: CANADA - 905-712-8336 USA - 706-554-9390

Page 26

GP-MSEM-BX-03B

SEM(U) / IT(U) Manual

RD: Sept, 2005

RL: 03B

KH

TO BE COMPLETED BY THE LICENSED INSTALLER

TUBE HEATER COMMISSIONING REPORT

TYPE OF GAS: NG LP

DOES BUILDING HAVE A NEGATIVE CONDITION: YES NO

IF THIS IS A HIGH ALTITUD E AR EA WHAT IS THE ALTITUDE ABOVE SEA LEVEL

Feet

DOES APPLICATION REQUIRE FRESH AIR TO BURNER YES NO

IS HEATER EXPOSED T O CHEMICAL OR COR R OSIVE ATMOSPHERE: YES NO

ARE ACTUAL MINIMUM CLEAR AN C ES AS PER TABLE 3 YES NO

CAN HEATER BE AFFECTED BY OVERHEAD CRANES / VIBRATION YES NO

ARE GAS SUPPLY LINES ADEQUATELY SIZED FO R SYST EM YES NO

GAS LINES AND BRANCHES HAVE BEEN PU R GED OF AIR: YES NO

THIS HEATER FIRED WITHOUT ANY MALFUNCTION: YES NO

INLET GAS SUPPLY PRESSURE WITH HEATER OPERATING : W C "

GAS VALVE OUTLET (M anifold) PRESSURE WITH H EATER OPERATING: W C "

W H AT IS THE LINE VOLTAG E R EAD ING AT THE HEATER VOLTS

W H AT IS THE VOLTAG E R EAD ING AT THE IGNITION M ODULE VOLTS

W H AT IS THE FLAME SIGNAL ST R EN GTH IN uA FROM SENSOR: uA (microamps)

IS HEATER CONT R O LLED BY A T H ER M OSTAT YES NO

IS THE THERMO STAT STRAT EGICALY LOCATED YES NO

WHAT IS TOTA L L E NGTH OF INSTALLED THERMOSTAT WIRE FEET

W H AT IS THE GAUGE O F THE THERMOSTAT WIRE GAUGE

W H AT IS THE HEATER TUBE LENGTH (10ft per Tube section) FEET

W H AT IS THE TOTAL LENGTH O F THE VENT (add 10ft for each bend) FEET

W H AT LENGTH IS COM BU STION AIR INTAKE (add 10ft for each bend) FEET

IF REQU IRED....WHAT IS THE L E NGTH OF TH E TURBU L A TOR(S) FEET

IF INSTA L L E D....IS TUR BULATOR AT FLUE END OF SYST EM YES NO

THIS HEATER MUST HAVE GOOD ELECTRICAL GROUNDING

* FAX COMPLETED FORM TO T ECHNICAL SERVICES: CANADA - 905-712-8336 OR USA - 706-554-9390

Page 27

GP-MSEM-BX-03B

SEM(U) / IT(U) Manual

RD: Sept, 2005

RL: 03B

KH

24. OPTIONAL COMPONENTS: FOR SEM / IT SERIES TUBE HEATERS

Flue Vent Terminals

4” wall horizontal

6” wall horizontal

Flue Vent Terminals

4” roof vertical

6” roof vertical

JA-0528-XX

JA-0529-XX

JA-0530-XX

JA-0531-XX

Torctite Coupler (c/w 2 bolts)

JA-0516-SW

Vent Tee 4” X 4” X 6”

(2 couplers optional)

JA- 0514-XX

Page 28

GP-MSEM-BX-03B

SEM(U) / IT(U) Manual

RD: Sept, 2005

RL: 03B

KH

90 degree Aluminized Steel Elbow Kit*

(*Kit includes: elbow, coupler, and two

end plate hangers)

180 degree Aluminized Steel Elbow Kit*

(*Kit includes: elbow, coupler, and two

end plate hangers)

Line Voltage Thermostat

10’ Tube & Reflector Extension Kit

(1-10’ Steel Tube, l-l0’Reflector, 2 Wire

Hangers, 1 Coupler.

Side Reflector Extension -

l0” deep l0ft long Each

JS-0508-SM

JS-0513-SM

JL-0772-XX

TM-1010-SX

JS-0509-XX-P

Page 29

GP-MSEM-BX-03B

SEM(U) / IT(U) Manual

RD: Sept, 2005

RL: 03B

KH

TruTemp Thermostat

(Do Not use in wet or

corrosive environments)

Low Voltage Thermostat

(24 Volts)

Transformer / Relay

(for 1 to 7 heaters per zone)

Fresh Air Intake Adapter

JM-0150-XX

JS-0569-XX

JM-0303 –KT

JS-0532-SE

Page 30

GP-MSEM-BX-03B

SEM(U) / IT(U) Manual

RD: Sept, 2005

RL: 03B

KH

Hanging Chain - (box of 50 ft)

Touch Up Paint - High Temp,

369g aerosol can

Tube Protection Screen -5 feet long

Fresh Air Intake Cap

JL-0798-XX

JA-0587-XX

JA-0780-XX

JS-0532-VC

Page 31

GP-MSEM-BX-03B

SEM(U) / IT(U) Manual

RD: Sept, 2005

RL: 03B

KH

25. ORIFICE A LTITUDE CONVERSION CHART: USA ONLY

MODEL NO

SEM/IT-60N JS-0725-

SEM/IT-60L JS-0742-

SEM/IT-80N JS-0718-

SEM/IT-80L JS-0736-

SEM/IT-110N JS-0752-

SEM/IT-110L JS-0731-

SEM/IT-130N JS-0758-

SEM/IT-130L JS-0729-

STD

ORIFICE

DM

DM

DM

DM

MM

DM

MM

DM

2000 3000 4000 5000 6000 7000 8000

JS-0726-

DM

JS-0742-

DM

JS-0719-

DM

JS-0738-

DM

JS-0751-

MM

JS-0732-

DM

JS-0757-

MM

JS-0729-

DM

SEM/IT-155N JS-0725-IN JS-0764-

MM

JS-0727-

DM

JS-0743-

DM

JS-0719-

DM

JS-0739-

DM

JS-0750-

MM

JS-0732-

DM

JS-0756-

MM

JS-0730-

DM

JS-0763-

MM

FOR USE AT ALTITUDES ABOVE (FEET)

JS-0727-

DM

JS-0743-

DM

JS-0720-

DM

JS-0739-

DM

JS-0709-

DM

JS-0732-

DM

JS-0755-

MM

JS-0730-

DM

JS-0762-

MM

JS-0728-

DM

JS-0743-

DM

JS-0721-

DM

JS-0740-

DM

JS-0711-

DM

JS-0733-

DM

JS-0703-

DM

JS-0730-

DM

JS-0761-

MM

JS-0728-

DM

JS-0744-

DM

JS-0722-

DM

JS-0741-

DM

JS-0719-

IN

JS-0734-

DM

JS-0704-

DM

JS-0730-

DM

JS-0760-

MM

JS-0729-

DM

JS-0744-

DM

JS-0723-

DM

JS-0742-

DM

JS-0713-

DM

JS-0735-

DM

JS-0705-

DM

JS-0731-

DM

JS-0759-

MM

JS-0729-

DM

JS-0745-

DM

JS-0724-

DM

JS-0742-

DM

JS-0714-

DM

JS-0736-

DM

JS-0720-IN

JS-0731-

DM

JS-0758-

MM

SEM/IT-155L JS-0714-IN JS-0735-

MM

SEM/IT-175N JS-0767-

MM

SEM/IT-175L JS-0721-

DM

JS-0766-

MM

JS-0723-

DM

SEM/IT-200N JS-0730-IN JS-0774-

MM

SEM/IT-200L JS-0719-

DM

JS-0720-

DM

JS-0729-

DM

JS-0766-

MM

JS-0723-

DM

JS-0773-

MM

JS-0720-

DM

JS-0734-

MM

JS-0765-

MM

JS-0724-

DM

JS-0773-

MM

JS-0721-

DM

JS-0733-

MM

JS-0765-

MM

JS-0725-

DM

JS-0772-

MM

JS-0722-

DM

JS-0733-

MM

JS-0764-

MM

JS-0726-

DM

JS-0728-

IN

JS-0723-

DM

JS-0730-

DM

JS-0763-

MM

JS-0727-

DM

JS-0771-

MM

JS-0725-

DM

JS-0713-IN

JS-0763-

MM

JS-0728-

DM

JS-0770-

MM

JS-0726-

DM

Page 32

GP-MSEM-BX-03B

SEM(U) / IT(U) Manual

RD: Sept, 2005

RL: 03B

KH

LIMITED WARRANTY CE R TIF ICATE

FOR GAS-FIRED INFRA-RED LOW INTENSITY TUBE TYPE HEATERS : SEM(U) / IT(U) & SER / IR SERIES

The Manufacturer warrants that this product is free from defects in material or workmanship under normal use and service subject to

the terms of this d ocum ent.

TWO YEAR WARRANTY

Subject to the conditions and limita tions stated he r e i n, during the term of this limited war r anty, w e will s up ply any compon ent part

(at our option a n ew or repair ed component part) of the heater, as defi ned below, exc luding any labor, which the Manufacture r’s examination deter mines to be defectiv e in workmanship or material for a period of two years (2 yea r s) from the da te of installation,

unless otherwise specified below. This warranty applies to the hea ter’s original ow ner , and s ub sequen t transferees and on ly if the

unit is installed and operated in accordance with the printed instructions accompanying the unit and in compliance with all applicable installation, building codes and good trade practices. Warranty is only applicable to Schwank components, other parts are limited

to their own Manufacturers warranty. (1 year)

FIVE YEAR WARRANTY

The Manufacturer warrants the burner sub-assembly comprising of ceramic and immediate metal tubing, and the radiating tubes

(excluding couplings) for a period of five years. (5 years)

WHAT IS NOT COVERED

The Manufacturer shall not be responsible for any expenses, including service, labor, diagnosis, analysis, material or transportation

cha r ge s incurred during remova l or reinstallation of this product, or a ny of its comp on ents or parts. All labor or service charges shall

be paid by the owner. This warranty does not cover heating products improperly installed, misused, exposed to or damaged by negligence, accident, corrosive or contaminating atmosphere, water, excessive thermal shock, impact, abrasion, normal wear due to use,

alteration or ope ration con tr ary to the owne r’ s ma nual or if th e ser ial number has be en altered, defac ed or removed. This war r an ty

sha ll not apply if the in put to the heating product e xceeds by more th an 2% of the r ated input on the rating plate. The Ma nufa cturer

shall not be liable for any default or delay in performance by its warranty caused by any contingency beyond its control, including

war, government restrictions, or restraints, strikes, fire, flood, ac t s of God, or sh or t or reduced supply of raw m aterials or products.

WARRANTY PROCEDURE

To es tablish the in s talla tion date for any purpose un der this Limited Warranty , you must retain the origin al records that c an establish

the installation d ate of your unit. If you do not provide suc h documents , th e start date of the term of this Limited Warranty w ill be

bas ed upon the date of un it manufacture, plus thirty (30) days. Fa ilure to m aintain th e equipmen t through r egular annual service

maintenance by a qualified service technic i a n shall void the warranty.

LIMITATIONS AND EXCLUSIONS

This document contains all warranties made by the Manufacturer and may not be varied, altered or extended by any person. There

are no promises, or agreements extending from the Manufacture other than the statements contained herein. THIS WARRANTY IS

IN LIEU OF ALL WARRANTIES EXPRESSED OR IMPLIED, TO THE EXTENT AUTHORIZED BY THE LAWS OF THE

JURISDICTION, INCLUDING SPECIFICALLY THE WARRANTIES OR MERCHANTIBILITY OF FITNESS FOR A PARTICULAR PURPOSE.

It is understood and agreed that the Manufacturer’s obligation hereunder is limited to repairing or replacing parts determined to be

defective as stated above. In no event shall the Manufacturer be responsible for any alleged personal injuries or other special, incidental or consequential damage s. A s to prope r ty damag es, contract, tort or other cla im the Manufa cturer’s responsibility shall not

exceed the purchase priced paid for the product.

All r eplacement parts w ill be warrante d for th e unused portion of the warranty coverag e p eriod remaining on the applic able unit.

Some A uthorities do not allow c ertain warr a nty ex clusions or limitations on how long a w arranty lasts or the exclusions or limi tations of incidental or c onsequential damages. In suc h c ases, the above limitations or e xclusions may not apply to you and are not

intended to do so where prohibited by law. This warranty gives you specific legal rights. You may also have other rights which

vary by each jurisdiction.

5285 BRADCO BLVD. MISSISSAUGA, ON, L4W 2A6

2 SCHWANK WAY, WAYNESBORO, GEORGIA. 30830-8336

SCHWANK INC. Ph: 905-712-4766 Fax: 905-712-8336

INFRASAVE IN C. Ph: 1-866– INFRASV (463 7278) Fax: 1-866-724 –9265

GP-DSEX-BX-02A

SE Series WARRANTY

AUGUST 2005

GP-MSEM-BX-03B

SEM(U) / IT(U) Manual

RD: Sept, 2005

RL: 03B

KH

RL: 2

KH

Loading...

Loading...