SCHUNK ROTA TPS 125-26 K, ROTA TPS 160-38 K, ROTA TPS 160-38 Z, ROTA TPS 200-52 K, ROTA TPS 200-52 Z Assembly And Operating Manual

...

Translation of the original manual

Stationary 3-Jaw-Power-Chuck

ROTA TPS-K, ROTA TPS-Z

Assembly and operating Manual

Superior Clamping and Gripping

Imprint

2

03.00|ROTA TPS-K, ROTA TPS-Z |en

Imprint

Copyright:

This manual is protected by copyright. The author is SCHUNK GmbH & Co. KG. All rights

reserved. Any reproduction, processing, distribution (making available to third parties),

translation or other usage - even excerpts - of the manual is especially prohibited and

requires our written approval.

Technical changes:

We reserve the right to make alterations for the purpose of technical improvement.

Document number: 0889145

Version: 03.00 |19/09/2018|en

© H.-D. SCHUNK GmbH & Co.

All rights reserved.

Dear Customer,

thank you for trusting our products and our family-owned company, the leading

technology supplier of robots and production machines.

Our team is always available to answer any questions on this product and other solutions.

Ask us questions and challenge us. We will find a solution!

Best regards,

Your SCHUNK team

H.-D. SCHUNK GmbH & Co.

Spanntechnik KG

Lothringer Str. 23

D-88512 Mengen

Tel. +49–7572-7614-0

Fax +49-7572-7614-1099

info@de.schunk.com

schunk.com

Table of contents

03.00|ROTA TPS-K, ROTA TPS-Z |en

3

Table of contents

1

General .................................................................................................................... 5

1.1

About this manual .................................................................................................... 5

1.1.1

Presentation of Warning Labels .................................................................... 5

1.1.2

Applicable documents ................................................................................... 6

1.1.3

Sizes ............................................................................................................... 6

1.2

Warranty ................................................................................................................... 6

1.3

Scope of delivery ...................................................................................................... 6

1.4

Accessories ............................................................................................................... 6

2

Basic safety notes .................................................................................................... 7

2.1

Intended use ............................................................................................................. 7

2.2

Not intended use ...................................................................................................... 7

2.3

Constructional changes ............................................................................................ 7

2.4

Spare parts ................................................................................................................ 8

2.5

Chuck jaws ................................................................................................................ 8

2.6

Environmental and operating conditions ................................................................. 8

2.7

Personnel qualification ............................................................................................. 9

2.8

Personal protective equipment .............................................................................. 10

2.9

Notes on safe operation ......................................................................................... 10

2.10

Transport ................................................................................................................ 10

2.11

Malfunctions ........................................................................................................... 11

2.12

Disposal ................................................................................................................... 11

2.13

Fundamental dangers ............................................................................................. 11

2.13.1

Protection during handling and assembly .................................................. 12

2.13.2

Protection during commissioning and operation ....................................... 12

2.13.3

Protection against dangerous movements ................................................. 12

2.13.4

Notes on particular risks ............................................................................. 13

3

Technical data ......................................................................................................... 16

4

Torques per screw ................................................................................................... 17

5

Functional testing .................................................................................................... 17

6

Maintenance ........................................................................................................... 18

6.1

Pre-assembly measures .......................................................................................... 18

6.2

Connection of the stationary 3-Jaw-Power-Chuck................................................. 18

6.3

Assembly of the TPS on the machine table ............................................................ 19

7

Commissioning and maintenance ............................................................................ 20

7.1

Initial operation ...................................................................................................... 20

Table of contents

4

03.00|ROTA TPS-K, ROTA TPS-Z |en

7.2

Hardened Reversible Jaws and Soft Top Jaws........................................................ 20

7.3

Maintenance and Lubrication ................................................................................ 21

7.4

Control of thightness .............................................................................................. 21

7.5

Disassembly and assembly ..................................................................................... 22

7.5.1

Disassembly and cleaning ........................................................................... 22

7.5.2

Assembly ..................................................................................................... 23

8

Trouble shooting ..................................................................................................... 25

8.1

The chuck jaws do not move .................................................................................. 25

8.2

The Clamping System does not move the full stroke? ........................................... 25

8.3

Clamping force getting weaker .............................................................................. 25

8.4

Clamping system movement jerky ......................................................................... 25

9

Spare parts .............................................................................................................. 26

10

Drawing................................................................................................................... 27

11

Translation of original declaration of incorporation ................................................. 28

General

03.00|ROTA TPS-K, ROTA TPS-Z |en

5

General

About this manual

This manual contains important information for a safe and

appropriate use of the product.

This manual is an integral part of the product and must be kept

accessible for the personnel at all times.

Before starting work, the personnel must have read and

understood this operating manual. Prerequisite for safe working is

the observance of all safety instructions in this manual.

Illustrations in this manual are provided for basic understanding

and may differ from the actual product design.

In addition to these instructions, the documents listed under

( 1.1.2, Page 6) are applicable.

Presentation of Warning Labels

To make risks clear, the following signal words and symbols are

used for safety notes.

DANGER

Danger for persons!

Non-observance will inevitably cause irreversible injury or death.

WARNING

Dangers for persons!

Non-observance can lead to irreversible injury and even death.

CAUTION

Dangers for persons!

Non-observance can cause minor injuries.

NOTICE

Material damage!

Information about avoiding material damage.

1

1.1

1.1.1

General

6

03.00|ROTA TPS-K, ROTA TPS-Z |en

Applicable documents

• General terms of business*

• Catalog data sheet of the purchased product *

The documents marked with an asterisk (*) can be downloaded on

our homepage schunk.com

Sizes

This operating manual applies to the following sizes:

• ROTA TPS 125-26; 160-38; 200-52; 250-68; 315-90; 315-105

Warranty

The warranty period is 24 months after delivery date from factory

or 300 000 cycles*, if it is used as intended, under the following

conditions:

• Observe the applicable documents ( 1.1.2, Page 6)

• Observe the ambient conditions and operating conditions,

( 2.6, Page 8)

• Observe the specified maintenance and lubrication intervals,

( 7, Page 20)

Parts touching the workpiece and wear parts are not included in

the warranty.

* A cycle consists of a complete clamping process

("Open" and "Close").

Scope of delivery

stationary 3-jaw chuck ROTA TPS (without top jaws)

2

Elbow unions

2

Straight fittings

6

T-nuts

6

Cylindrical screws for top jaws

1

Assembly tool

only for TPS-Z:

6

Studs

6

Hexagon nuts

Accessories

(see catalog or data sheets when ordering separately)

• Top jaws

(also available from SCHUNK in a workpiece-specific design)

• Gripping force maintenance device with pressure maintenance

valve

1.1.2

1.1.3

1.2

1.3

1.4

Basic safety notes

03.00|ROTA TPS-K, ROTA TPS-Z |en

7

Basic safety notes

Intended use

This product is intended for clamping workpieces on machine tools

and other suitable technical devices.

• The product may only be used within the scope of its technical

data, ( 3, Page 16).

• The product is intended for industrial and industry-oriented

use.

• Appropriate use of the product includes compliance with all

instructions in this manual.

Not intended use

The power chuck for stationary use/application is not being used

as intended if, for example:

• It is used as a lathe chuck.

• It is used as a press, a punch, a chuck, a load-handling device or

as lifting equipment.

• It is used in working environments that are not permissible.

• Workpieces are not clamped properly, paying particular

attention to the clamping forces specified by the manufacturer.

• People work on machines or technical equipment that do not

comply with the EC Machinery Directive 2006/42/EC,

disregarding the applicable safety regulations.

• The technical data specified by the manufacturer for using the

chuck are exceeded.

Constructional changes

Implementation of structural changes

By conversions, changes, and reworking, e.g. additional threads,

holes, or safety devices can impair the functioning or safety of the

product or damage it.

• Structural changes should only be made with the written

approval of SCHUNK.

2

2.1

2.2

2.3

Basic safety notes

8

03.00|ROTA TPS-K, ROTA TPS-Z |en

Spare parts

Use of unauthorized spare parts

Using unauthorized spare parts can endanger personnel and

damage the product or cause it to malfunction.

• Use only original spare parts or spares authorized by SCHUNK.

Chuck jaws

Requirements of the chuck jaws

Stored energy can make the product unsafe and risk the danger of

serious injuries and considerable material damage.

• Only replace chuck jaws if no residual energy can be released.

• Do not use welded jaws.

• The chuck jaws should be designed to be as light and as low as

possible. The clamping point must be as close as possible to the

chuck face (clamping points at a greater distance lead to

greater surface pressure in the jaw guidance and can

significantly reduce the clamping force).

• Screw the jaw mounting bolts into the bore holes furthest

apart.

• After a collision, the lathe chuck and the chuck jaws must be

subjected to a crack test before being used again. Damaged

parts must be replaced with original SCHUNK spare parts.

• Replace the chuck jaw mounting bolts if there are signs of wear

or damage. Only use bolts with a quality of 12.9.

Environmental and operating conditions

Required ambient conditions and operating conditions

Incorrect ambient and operating conditions can make the product

unsafe, leading to the risk of serious injuries, considerable material

damage and/or a significant reduction to the product's life span.

• Make sure that the product is used only in the context of its

defined application parameters, ( 3, Page 16).

• Make sure that the product is a sufficient size for the

application.

• Only use high-quality cooling emulsions with anti-corrosive

additives during processing.

• Lubricating intervals must be adhered to ( 7.3, Page 21).

2.4

2.5

2.6

Basic safety notes

03.00|ROTA TPS-K, ROTA TPS-Z |en

9

Personnel qualification

Inadequate qualifications of the personnel

If the personnel working with the product is not sufficiently

qualified, the result may be serious injuries and significant

property damage.

• All work may only be performed by qualified personnel.

• Before working with the product, the personnel must have read

and understood the complete assembly and operating manual.

• Observe the national safety regulations and rules and general

safety instructions.

The following personal qualifications are necessary for the various

activities related to the product:

Due to their technical training, knowledge and experience, trained

electricians are able to work on electrical systems, recognize and

avoid possible dangers and know the relevant standards and

regulations.

Due to its technical training, knowledge and experience, qualified

personnel is able to perform the delegated tasks, recognize and

avoid possible dangers and knows the relevant standards and

regulations.

Instructed persons were instructed by the operator about the

delegated tasks and possible dangers due to improper behaviour.

Due to its technical training, knowledge and experience, service

personnel of the manufacturer is able to perform the delegated

tasks and to recognize and avoid possible dangers.

2.7

Trained electrician

Qualified personnel

Instructed person

Service personnel of

the manufacturer

Basic safety notes

10

03.00|ROTA TPS-K, ROTA TPS-Z |en

Personal protective equipment

Use of personal protective equipment

Personal protective equipment serves to protect staff against

danger which may interfere with their health or safety at work.

• When working on and with the product, observe the

occupational health and safety regulations and wear the

required personal protective equipment.

• Observe the valid safety and accident prevention regulations.

• Wear protective gloves to guard against sharp edges and

corners or rough surfaces.

• Wear heat-resistant protective gloves when handling hot

surfaces.

• Wear protective gloves and safety goggles when handling

hazardous substances.

• Wear close-fitting protective clothing and also wear long hair in

a hairnet when dealing with moving components.

Notes on safe operation

Incorrect handling of the personnel

Incorrect handling and assembly may impair the product's safety

and cause serious injuries and considerable material damage.

• Avoid any manner of working that may interfere with the

function and operational safety of the product.

• Use the product as intended.

• Observe the safety notes and assembly instructions.

• Do not expose the product to any corrosive media. This does

not apply to products that are designed for special

environments.

• Eliminate any malfunction immediately.

• Observe the care and maintenance instructions.

• Observe the current safety, accident prevention and

environmental protection regulations regarding the product's

application field.

Transport

Handling during transport

Incorrect handling during transport may impair the product's

safety and cause serious injuries and considerable material

damage.

2.8

2.9

2.10

Basic safety notes

03.00|ROTA TPS-K, ROTA TPS-Z |en

11

• When handling heavy weights, use lifting equipment to lift the

product and transport it by appropriate means.

• Secure the product against falling during transportation and

handling.

• Stand clear of suspended loads.

Malfunctions

Behavior in case of malfunctions

• Immediately remove the product from operation and report

the malfunction to the responsible departments/persons.

• Order appropriately trained personnel to rectify the

malfunction.

• Do not recommission the product until the malfunction has

been rectified.

• Test the product after a malfunction to establish whether it still

functions properly and no increased risks have arisen.

Disposal

Handling of disposal

The incorrect handling of disposal may impair the product's safety

and cause serious injuries as well as considerable material and

environmental harm.

• Follow local regulations on dispatching product components for

recycling or proper disposal.

Fundamental dangers

General

• Observe safety distances.

• Never deactivate safety devices.

• Before commissioning the product, take appropriate protective

measures to secure the danger zone.

• Disconnect power sources before installation, modification,

maintenance, or calibration. Ensure that no residual energy

remains in the system.

• If the energy supply is connected, do not move any parts by

hand.

• Do not reach into the open mechanism or movement area of

the product during operation.

2.11

2.12

2.13

Basic safety notes

12

03.00|ROTA TPS-K, ROTA TPS-Z |en

Protection during handling and assembly

Incorrect handling and assembly

Incorrect handling and assembly may impair the product's safety

and cause serious injuries and considerable material damage.

• Have all work carried out by appropriately qualified personnel.

• For all work, secure the product against accidental operation.

• Observe the relevant accident prevention rules.

• Use suitable assembly and transport equipment and take

precautions to prevent jamming and crushing.

Incorrect lifting of loads

Falling loads may cause serious injuries and even death.

• Stand clear of suspended loads and do not step into their

swiveling range.

• Never move loads without supervision.

• Do not leave suspended loads unattended.

Protection during commissioning and operation

Falling or violently ejected components

Falling and violently ejected components can cause serious injuries

and even death.

• Take appropriate protective measures to secure the danger

zone.

• Never step into the danger zone during operation.

Protection against dangerous movements

Unexpected movements

Residual energy in the system may cause serious injuries while

working with the product.

• Switch off the energy supply, ensure that no residual energy

remains and secure against inadvertent reactivation.

• Never rely solely on the response of the monitoring function to

avert danger. Until the installed monitors become effective, it

must be assumed that the drive movement is faulty, with its

action being dependent on the control unit and the current

operating condition of the drive. Perform maintenance work,

modifications, and attachments outside the danger zone

defined by the movement range.

• To avoid accidents and/or material damage, human access to

the movement range of the machine must be restricted.

2.13.1

2.13.2

2.13.3

Basic safety notes

03.00|ROTA TPS-K, ROTA TPS-Z |en

13

Limit/prevent accidental access for people in this area due

through technical safety measures. The protective cover and

protective fence must be rigid enough to withstand the

maximum possible movement energy. EMERGENCY STOP

switches must be easily and quickly accessible. Before starting

up the machine or automated system, check that the

EMERGENCY STOP system is working. Prevent operation of the

machine if this protective equipment does not function

correctly.

Notes on particular risks

DANGER

Risk of fatal injury to operating personnel due to the workpiece

falling down or being flung out in the event of a power failure

In the event of a power failure, the lathe chuck's clamping force

may fail immediately and the workpiece may be released in an

uncontrolled manner. This poses a risk of death or injury to the

operating personnel and can result in serious damage to the

automated system.

• The machine manufacturer and the operator of the machine

must carry out and document a hazard assessment and risk

analysis to ensure that suitable measures are taken to

maintain the lathe chuck's clamping force until the machine

comes to a standstill and the workpiece can be secured (e.g.

using a crane or suitable lifting equipment).

• The machines and equipment must fulfill the minimum

requirements of the EC Machinery Directive; specifically, they

must have effective technical measures to protect against

potential mechanical hazards.

2.13.4

Basic safety notes

14

03.00|ROTA TPS-K, ROTA TPS-Z |en

DANGER

Possible risk of fatal injury to operating personnel if a jaw

breaks or if the lathe chuck fails because the technical data have

been exceeded and a workpiece is released or parts fly off

• The technical data specified by the manufacturer for using the

lathe chuck must never be exceeded.

• The lathe chuck may only be used on machines and facilities

that fulfill the minimum requirements of the EC Machinery

Directive; specifically, they must have effective technical

measures to protect against possible mechanical hazards.

WARNING

Risk of injury due to dropping the chuck during transport,

installation or removal.

• Take special care in the danger zone when transporting,

installing or removing the chuck.

• Note the relevant load securing regulations for working safely

with cranes, ground conveyors, lifting gear and load-handling

equipment.

CAUTION

Danger of slipping and falling in case of dirty environment

where the chuck is used (e.g. by cooling lubricants or oil).

• Ensure that the working environment is clean before starting

assembly and installation work.

• Wear suitable safety shoes.

• Follow the safety and accident-prevention regulations when

operating the chuck, especially when working with machine

tools and other technical equipment.

Basic safety notes

03.00|ROTA TPS-K, ROTA TPS-Z |en

15

CAUTION

Danger of limbs being crushed by opening and closing of the

chuck jaws during manual loading and unloading or when

replacing moving parts.

• Do not reach between the jaws.

• Wear safety gloves.

• Observe the safety and accident prevention regulations during

operation of the chuck, especially in connection with

machining centers and other technical equipment.

CAUTION

Risk of burns due to workpieces with high temperatures.

• Wear protective gloves when removing the workpieces.

• Automatic loading is preferred.

CAUTION

Risk of damage due to incorrect choice of clamping position for

chuck jaws on workpiece.

If an incorrect clamping position is chosen for the chuck jaws on

workpiece, the base and top jaws may become damaged.

• The T-nuts for connecting the top jaws to the base jaws must

not protrude beyond the base jaws in the radial direction.

• The diameter of the workpiece may not be bigger than the

chuck diameter.

CAUTION

Danger from noise generation

Physical and mental stress by noise generation during the

working process.

• Wear hearing protection.

Technical data

16

03.00|ROTA TPS-K, ROTA TPS-Z |en

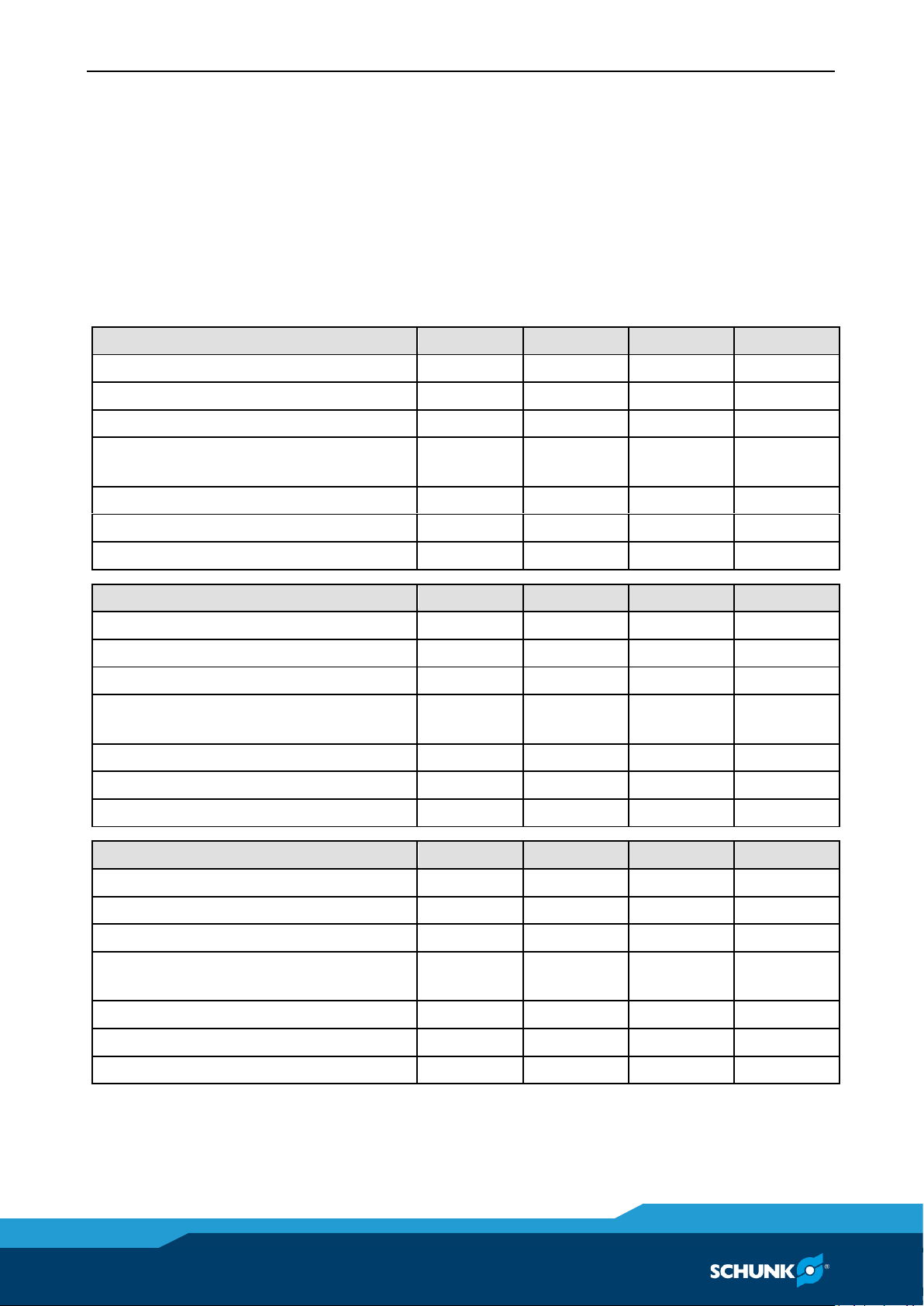

Technical data

Actuation pressure

6 bar

Pressure medium

Compressed air, compressed air quality according to

ISO 8573-1:7 4 4

Operating temperature

+ 5°C to + 60°C

Noise emission

≤ 70 dB (A)

Installation position

Any

ROTA TPS

125-26 / K

125-26 / Z

160-38 / K

160-38 / Z

ID no.

0816127

0816126

0816137

0816136

Stroke per jaw [mm]

3 3 4.2

4.2

Max. clamping force* [kN]

22

22

39

39

Air consumption per double stroke

[cm3]

2200

2200

4800

4800

Closing/opening time at 6 bar [s]

0.35

0.35

0.39

0.39

Weight [kg]

12

12

23

23

Max. jaw stroke [mm]

40

40

40

40

ROTA TPS

200-52 / K

200-52 / Z

250-68 / K

250-68 / Z

ID no.

0816147

0816146

0816157

0816156

Stroke per jaw [mm]

4.2

4.2 5 5

Max. clamping force* [kN]

68

68

105

105

Air consumption per double stroke

[cm3]

7800

7800

13200

13200

Closing/opening time at 6 bar [s]

0.85

0.85

0.89

0.89

Weight [kg]

34

34

60

60

Max. jaw stroke [mm]

54

54

70

70

ROTA TPS

315-90 / K

315-90 / Z

315-105 / K

315-105 / Z

ID no.

0816167

0816166

88000779

88000785

Stroke per jaw [mm]

5 5 5 5 Max. clamping force* [kN]

140

140

80

80

Air consumption per double stroke

[cm3]

16400

16400

10800

10800

Closing/opening time at 6 bar [s]

1.2

1.2

1.5

1.5

Weight [kg]

82

82

72

72

Max. jaw stroke [mm]

76

76

70

70

* Clamping force is the arithmetic sum of the individual forces

occurring at the chuck jaws at a distance of "H" at 6 bar

3

Functional testing

03.00|ROTA TPS-K, ROTA TPS-Z |en

17

Torques per screw

Tightening torques for mounting screws used to clamp the chuck

on lathes or other suitable technical equipment (screw quality

10.9)

Screw size

M6

M8

M10

M12

M14

M16

M18

M20

M22

M24

M27

M30

Admissible torque

MA (Nm)

13

28

50

88

120

160

200

290

400

500

1050

1500

Tightening torques for mounting screws used to attach top jaws

onto the chuck (screw quality 12.9)

Screw size

M6

M8

M10

M12

M14

M16

M20

M24

Max. admissible torque MA (Nm)

16

30

50

70

130

150

220

450

Functional testing

Functional test

After installation of the chuck, its function must be checked prior

to start-up. Make sure there are no leaks in the line system.

Two important points are:

• Clamping force! At max. actuating force/pressure, the clamping

force specified for the chuck must be reached.

• Stroke control The stroke of the clamping piston must have a

margin of safety at the front and back end positions. The

machine tool must not start up until the clamping piston has

passed through the safety margin Only limit switches that meet

the requirements for safety limit switches specified in DIN EN

60204-1 may be used to monitor the clamping path.

If the chuck jaws are changed, adjust the stroke control to the new

situation.

4

5

Maintenance

18

03.00|ROTA TPS-K, ROTA TPS-Z |en

Maintenance

NOTICE

The power supply must be switched off during assembly and

connection of the clamping system.

Pre-assembly measures

Carefully lift the product (e.g. using suitable lifting gear) from the

packaging.

CAUTION

Danger of injury due to sharp edges and rough or slippery

surfaces

Use personal protective gear, especially safety gloves.

Check the delivery for completeness and for transport damage.

Connection of the stationary 3-Jaw-Power-Chuck

ROTA TPS has 2 air connections for OPEN and CLOSED.

1

CLOSED

2

OPEN

6

6.1

6.2

Maintenance

03.00|ROTA TPS-K, ROTA TPS-Z |en

19

Thread for air connections

ROTA TPS 125

G1/8"

ROTA TPS 160

G1/4"

ROTA TPS 200

G1/4"

ROTA TPS 250

G1/4"

ROTA TPS 315

G1/4"

NOTICE

Always make sure the connections are tight, and protect the

pneumatic hoses from hot chips and falling parts by using a

suitable metal hose.

NOTICE

When actuating the clamping device (clamping or releasing), a

short pause for ventilation must be maintained between each

shifting operation. This ventilation pause must be at least 0.5

seconds, depending on the length of the hose. A 4/3 or 5/3-way

valve is recommended for this purpose (center position

depressurized).

Assembly of the TPS on the machine table

Adjustment grooves are provided on both locating surfaces of all

stationary, pneumatically operated power clamping units of type

ROTA TPS-K, which enable mounting on the work table by means

of T-nuts. The T-nuts must be made or ordered according to the

width of the groove of the table.

Corresponding devices must be made by the customer for types

ROTA TPS-Z which ensure secure mounting and enable adjustment

of the power chucks.

6.3

Commissioning and maintenance

20

03.00|ROTA TPS-K, ROTA TPS-Z |en

Commissioning and maintenance

Initial operation

Check whether the jaw guides and the piston of the ROTA TPS

power chuck are sufficiently lubricated at the lubricating nipples

embedded in the base jaws.

If required, lubricate the chuck with the base jaws retracted, by

using LINOMAX special grease from SCHUNK.

NOTICE

An insufficiently lubricated chuck will result in a significantly

reduced clamping force.

Turning, facing or skimming of the front-end power chuck is not

permitted.

Drilling of the chuck on the front face side may be performed only

after consulting the SCHUNK technical sales department.

Hardened Reversible Jaws and Soft Top Jaws

Fine serration of the base and top jaws is 1/16" x 90°. The

adjusting stroke from tooth to tooth is approximately 1.6 mm.

NOTICE

It must be ensured that the top jaws are fixed on the fine

serration in such a way that a maximum of 2/3 the jaw stroke is

extended for clamping.

Hardened reversible jaws should only be used in sets in

accordance with the packaging, as they are manufactured on the

device in sets. 1 set of hardened reversible jaws is normally

ordered for a power chuck.

When installing and removing the reversible jaws numbered 1 - 3,

make sure that the individual jaws are installed/removed on/from

the base jaws with the same designation to ensure a high level of

accuracy of the clamping center.

The fine serration of the base jaws and top jaws should always be

cleaned when the top jaws are adjusted, because otherwise the

true running accuracy will be reduced.

The screws of the hardened reversible jaws and soft top jaws must

be tightened with the specified torque.

7

7.1

7.2

Commissioning and maintenance

03.00|ROTA TPS-K, ROTA TPS-Z |en

21

Maintenance and Lubrication

• A maintenance unit consisting of filter, water separator and

oiler should be connected upstream of the power chuck. The

air enriched with oil supplies all sliding parts of the cylinder

chamber with an oil film. Check the oil level of the oil tank on a

daily basis and refill if necessary. If the oil consumption is too

low, i.e. if the oil level does not visibly drop over a period of 2

to 3 days, the oil adjustment screw must be opened slightly.

Depending on the accumulation of condensation, the

condensation drain screw must be opened occasionally.

The uniform clamping force, accuracy, and life span of a chuck

depend greatly on regular cleaning and sufficient lubrication. Rust,

scale, casting dust, and chips produce friction and reduce motion.

• The chuck must be lubricated with SCHUNK LINOMAX special

grease at the base jaw lubrication nipples by means of a grease

gun after every 20 – 30 operating hours. The chuck should be

actuated two to three times here without a workpiece to

achieve optimum grease distribution by means of the

completely extended jaw stroke.

• The fine serration of the base jaws and top jaws should always

be cleaned when the top jaws are adjusted, because otherwise

the true running accuracy will be reduced.

Even though there is optimum sealing provided by the hardened

guide bushing in the through-hole and by the closed base jaws,

foreign matter, such as dust, scale, casting dust, and fine chips can

penetrate into the chuck. In addition, the coolant also washes

away the lubricant of the chuck.

• The chuck must be completely disassembled, cleaned and

relubricated from time to time. When doing this, replace the

sealing rings if necessary. ( 7.5, Page 22)

The time until complete maintenance depends on the presence

of dirt and the clamping frequency, so a generally applicable

rule cannot be provided.

Control of thightness

NOTE:

Temperature fluctuations must be avoided during the leak test.

The following components are required to check for leaks:

pressure gauge, shut-off valve and quick coupler.

The leak test should only be conducted when the chuck is in the

"CLOSED" position.

Leak test sequence:

7.3

7.4

Commissioning and maintenance

22

03.00|ROTA TPS-K, ROTA TPS-Z |en

1 Seal the "OPEN" air connection so it is air-tight.

2 Connect the components to the open "CLOSED" air connection

in the following order:

pressure gauge – shut-off valve – coupling – supply line.

3 Pressurize the clamping system with compressed air until the

pressure gauge displays 6 bar.

4 Disconnect the supply line.

5 Let the clamping system sit clamped for 24 hours.

6 After 24 hours, the clamping block is:

sealed – if the pressure gauge indicates a pressure of ≥ 5.5

bar.

leaking – if the pressure gauge indicates a pressure of < 5.5

bar.

If the clamping system is leaking, check the screws first (e.g. with

Metaflux leak detection spray).

Seal any leaking screws.

Once the screws are sealed, the seals must be checked and

replaced if necessary.

Disassembly and assembly

The item numbers specified for the corresponding individual

components relate to chapter drawings.( 10, Page 27)

Disassembly and cleaning

1 On the chuck mount (item 7) with O-ring (item 48, 52),

unscrew the hexagon socket screws (item 39) and screw 3 of

these screws into the threaded extraction holes to push off

the mount.

2 Loosen the radial set screw (item 34) in the fixing nut (item

40). The clamping by the copper bolt (item 33) slows down

and the nut can be loosened with the enclosed assembly tool

(item 80).

3 Screw three hexagon socket screws into the threaded holes of

the piston cover (item 6) and force the piston cover (item 6)

from the piston (item 3).

4 On the front side of the chuck, loosen the socket screws (item

36) of the sleeve (item 4) and pull out the sleeve (item 4)

7.5

7.5.1

Commissioning and maintenance

03.00|ROTA TPS-K, ROTA TPS-Z |en

23

toward the front by lightly knocking from the back side of the

chuck.

5 Remove the sealing disk (item 5) fastened by socket screws

(item 37) and take out the O-ring (item 43).

6 The piston (item 3) can be pulled out of the chuck body (item

1) and the base jaws (item 2) can be pulled out of the base jaw

guides inwardly through the piston bore hole of the chuck

body. The base jaws (item 2) as well as the base jaw guides in

the chuck body (item 1) and the hardened reversible jaws are

numbered 1, 2, and 3. This ensures the same position, and

thus the same true-running accuracy, is achieved during

assembly.

7 Degrease and clean all parts and check them for damage.

8 Check all O-rings for possible damage and wear, replace them

if necessary, grease with Renolit HLT 2 or a equivalent grease,

and carefully reinstall them.

9 Lubricate the cylinder chamber of the chuck with oil.

Jaw guides in the chuck body, base jaws and piston at the

wedge hooks are greased with SCHUNK LINOMAX special

grease.

Assembly

NOTE:

All parts of the ROTA TPS power chuck are smooth-running

components. Therefore, do not strike the chuck hard with a

hammer during assembly.

1 Insert the designated base jaws (item 2) into the

corresponding guides, let the piston with the O-ring (item 47)

engage in the splines of the base jaws (item 2) and insert the

piston up to the end of the stroke.

2 Insert the O-ring (item 51) and sealing disk (item 5) with O-ring

(item 50) and screw them securely and air-tight to the chuck

body by means of the hexagon socket screws (item 37).

3 ROTA TPS 160-38, ROTA TPS 200-52, ROTA TPS 250-68, ROTA

TP 315-90: Insert the piston cover with the O-ring (item 6, 53)

and use the enclosed assembly tool (item 80) to mount the

lock nut (item 40). Lock the nut radially with the copper bolt

(item 33) and setscrew (item 34).

ROTA TPS 125-26: Use the enclosed assembly tool (item 80) to

assemble the lock nut (item 40). Securing the nut with safety

cord (item 33).

7.5.2

Commissioning and maintenance

24

03.00|ROTA TPS-K, ROTA TPS-Z |en

ROTA TPS 315-105: Assemble screws (item 40) and tighten

alternately.

4 Put on the chuck mount with O-rings (item 48, 52) and fasten

it with hexagon socket screws (item 39).

5 Insert the guide bushing (item 4) from the front side of the

chuck and tightly fasten it with the screws (item 36).

Trouble shooting

03.00|ROTA TPS-K, ROTA TPS-Z |en

25

Trouble shooting

The chuck jaws do not move

Possible cause

Corrective action

Air supply interrupted

Connections mixed up.

Check compressed air lines.

Piston will not move:

- Compressed air is not oiled.

- Maintenance unit with oiler is too far from

the chuck.

- The seal in the cover is not properly

inserted.

Install maintenance unit with oiler.

Position the maintenance unit with oiler

closer to the chuck.

Check the seal in the cover and insert

correctly.

The Clamping System does not move the full stroke?

Possible cause

Corrective action

Chips or dirt between guide bushing and

base jaws.

Completely disassemble, clean and

relubricate the chuck. ( 7.5, Page 22)

Clamping force getting weaker

Possible cause

Corrective action

The clamping system is leaking:

- Connection and/or sealing screws leaking.

- Seals damaged.

- Steel guide rollers on sliding surfaces not

greased.

Seal any leaking screws.

Disassemble chuck and replace seals

. ( 7.5, Page 22)

Lubricate the chuck with SCHUNK LINO MAX

special grease at the base jaw lubrication

nipples by means of a grease gun.

Clamping system movement jerky

Possible cause

Corrective action

Steel guide rollers on sliding surfaces not

greased.

Lubricate the chuck with SCHUNK LINO MAX

special grease at the base jaw lubrication

nipples by means of a grease gun.

8

8.1

8.2

8.3

8.4

Spare parts

26

03.00|ROTA TPS-K, ROTA TPS-Z |en

Spare parts

When ordering spare parts, it is imperative to specify the type,

size and above all the serial no. of the chuck.

Seals, sealing elements, screw connections, springs, bearings,

screws and wiper bars plus parts coming into contact with the

workpiece are not covered by the warranty.

Item

Designation

1

Chuck body

2

Base jaw

3

Piston

4

Bushing

5

Sealing disk

6

Piston cover

7

Bracket plate/Z-mount

8

T-nut

17

Sealing plug

33

Copper bolts

Safety lanyard (TPS 125)

34

Set-screw, DIN EN ISO 34827

36

Screws, DIN EN ISO 7984

37

Screws, DIN EN ISO 4762

39

Screws, DIN EN ISO 4762

40

Locking nut

Screws (ROTA TP 315-105)

41

Funnel lubrication nipple

43

Stud DIN 938 8.8 (Z-version)

44

Hexagon nut DIN 934-10 (Z-version)

45

Swivel fitting

46

Straight screw connection

47

O-ring

48

O-ring

49

O-ring

50

O-ring

51

O-ring

52

O-ring

53

O-ring

65

Copper sealing ring DIN 7603

67

Fiber seal

80

Assembly tool

9

Drawing

03.00|ROTA TPS-K, ROTA TPS-Z |en

27

Drawing

10

Translation of original declaration of incorporation

28

03.00|ROTA TPS-K, ROTA TPS-Z |en

Translation of original declaration of incorporation

in terms of the Directive 2006/42/EG, Annex II, Part 1.B of the European Parliament and of

the Council on machinery.

Manufacturer/

Distributor

H.-D. SCHUNK GmbH & Co. Spanntechnik KG

Lothringer Str. 23

D-88512 Mengen

We hereby declare that the following product:

Product designation:

Stationary 3-jaw chuck ROTA TPS-K, ROTA TPS-Z

ID number

0816127, 0816126, 0816137, 0816136, 0816147, 0816146,

0816157, 0816156, 0816167, 0816166, 88000779, 88000785

meets the applicable basic requirements of the Machinery Directive (2006/42/EC).

The partly completed machine may not be put into operation until conformity of the

machine into which the partly completed machine is to be installed with the provisions of

the Machinery Directive (2006/42/EC) is confirmed.

Applied harmonized standards, especially:

EN ISO 12100:2010

Safety of machinery - General principles for design Risk assessment and risk reduction

DIN EN 1550

Machine-tools safety – Safety requirements for the design and

constructions of workholding chucks

DIN 55028

Machine-tools – holding fixtures for clamping devices

The manufacturer agrees to forward on demand the special technical documents for the

partly completed machine to state offices.

The special technical documents according to Annex VII, Part B, belonging to the partly

completed machine have been created.

Person responsible for documentation: Mr. Alexander Koch, Adress: see adress of the

manufacturer

Mengen, February 2018

p.p. Alexander Koch; Director for Development / Design

11

Loading...

Loading...