SCHUNK PZN-plus 64, PZN-plus 100, PZN-plus 125, PZN-plus 160, PZN-plus 200 Assembly And Operating Manual

...

Translation of the original manual

Assembly and Operating Manual

PZN-plus

3-Finger Centric Gripper

Imprint

2

08.00 | PZN-plus | Assembly and Operating Manual | en | 0389374

Imprint

Copyright:

This manual is protected by copyright. The author is SCHUNK GmbH & Co. KG. All rights reserved. Any reproduction, processing, distribution (making available to third parties),

translation or other usage - even excerpts - of the manual is especially prohibited and requires our written approval.

Technical changes:

We reserve the right to make alterations for the purpose of technical improvement.

Document number: 0389374

Version: 08.00|11/01/2018|en

© SCHUNK GmbH & Co. KG

All rights reserved.

Dear Customer,

thank you for trusting our products and our family-owned company, the leading techno-

logy supplier of robots and production machines.

Our team is always available to answer any questions on this product and other solutions.

Ask us questions and challenge us. We will find a solution!

Best regards,

Your SCHUNK team

SCHUNK GmbH & Co. KG

Spann- und Greiftechnik

Bahnhofstr. 106 – 134

D-74348 Lauffen/Neckar

Tel. +49-7133-103-0

Fax +49-7133-103-2399

info@de.schunk.com

schunk.com

Table of contents

08.00 | PZN-plus | Assembly and Operating Manual | en | 0389374

3

Table of contents

1 General.................................................................................................................... 5

1.1 About this manual ................................................................................................5

1.1.1 Presentation of Warning Labels ...............................................................5

1.1.2 Applicable documents ..............................................................................6

1.1.3 Sizes ..........................................................................................................6

1.1.4 Variants..................................................................................................... 6

1.2 Warranty .............................................................................................................. 7

1.3 Scope of delivery ..................................................................................................7

1.3.1 Accessories kit ..........................................................................................7

1.4 Accessories ........................................................................................................... 8

1.4.1 Sealing kit ................................................................................................. 8

2 Basic safety notes ................................................................................................... 9

2.1 Intended use......................................................................................................... 9

2.2 Not intended use.................................................................................................. 9

2.3 Constructional changes ........................................................................................9

2.4 Spare parts ........................................................................................................... 9

2.5 Gripper fingers ................................................................................................... 10

2.6 Environmental and operating conditions ...........................................................10

2.7 Personnel qualification....................................................................................... 10

2.8 Personal protective equipment.......................................................................... 11

2.9 Notes on safe operation ..................................................................................... 11

2.10 Transport ............................................................................................................ 12

2.11 Malfunctions....................................................................................................... 12

2.12 Disposal .............................................................................................................. 12

2.13 Fundamental dangers......................................................................................... 12

2.13.1 Protection during handling and assembly ..............................................13

2.13.2 Protection during commissioning and operation ...................................13

2.13.3 Protection against dangerous movements.............................................14

2.13.4 Protection against electric shock............................................................14

2.14 Notes on particular risks..................................................................................... 15

3 Technical data.........................................................................................................17

4 Design and description............................................................................................18

4.1 Design ................................................................................................................. 18

4.2 Description ......................................................................................................... 18

5 Assembly ................................................................................................................19

5.1 Installing and connecting.................................................................................... 19

5.2 Connections........................................................................................................ 20

5.2.1 Mechanical connection...........................................................................20

5.2.2 Pneumatic connection............................................................................23

Table of contents

4

08.00 | PZN-plus | Assembly and Operating Manual | en | 0389374

5.3 Mounting the sensor .......................................................................................... 24

5.3.1 Overview of sensors ...............................................................................24

5.3.2 Switch-off hysteresis...............................................................................25

5.3.3 Turn control cam ....................................................................................25

5.3.4 Setting dimensions .................................................................................26

5.3.5 Mounting MMS 22 magnetic switch.......................................................27

5.3.6 Mounting MMS 22-PI1 programmable magnetic switch........................28

5.3.7 Mounting programmable MMS 22-PI2 magnetic switch........................29

5.3.8 Mounting programmable MMS-P 22 magnetic switch...........................30

5.3.9 Mounting the reed switch RMS 80 .........................................................30

5.3.10 Mounting inductive proximity switch IN 80 ...........................................32

5.3.11 Mounting flexible position sensor FPS ...................................................34

5.3.12 Mounting the analog position sensor APS-M1 .......................................35

5.3.13 Mounting the analog position sensor APS-Z80.......................................37

5.3.14 Mounting the radio system RSS-R1/T2...................................................38

5.3.15 Mounting FMS force-measuring jaw ......................................................39

6 Troubleshooting .....................................................................................................40

6.1 Product is not moving......................................................................................... 40

6.2 Product is not executing the complete stroke ................................................... 40

6.3 Product opens or closes abruptly ....................................................................... 40

6.4 Gripping force is dropping.................................................................................. 41

6.5 Product does not achieve the opening and closing times.................................. 41

7 Maintenance ..........................................................................................................42

7.1 Notes .................................................................................................................. 42

7.2 Maintenance intervals........................................................................................ 43

7.3 Lubricants/greasing areas (basic lubrication)..................................................... 44

7.4 Disassembly and assembly .................................................................................45

7.4.1 Variant with dust cover ..........................................................................45

7.4.2 Version without gripping force maintenance.........................................45

7.4.3 Version with gripping force maintenance O.D. ......................................46

7.4.4 Version with gripping force maintenance I.D. ........................................48

7.4.5 Version with force amplification cylinder (KVZ) .....................................50

7.4.6 Notes for assembly ................................................................................. 52

7.4.7 Screw tightening torques........................................................................53

7.4.8 Spring force information for assembly ...................................................53

7.5 Drawings............................................................................................................. 53

7.5.1 Basic module ..........................................................................................54

7.5.2 Variant with dust cover ..........................................................................55

7.5.3 Variant with force amplification cylinder ...............................................56

8 Translation of original declaration of incorporation ................................................57

9 Annex to Declaration of Incorporation....................................................................58

General

08.00 | PZN-plus | Assembly and Operating Manual | en | 0389374

5

1 General

1.1 About this manual

This manual contains important information for a safe and appropriate use of the product.

This manual is an integral part of the product and must be kept accessible for the personnel at all times.

Before starting work, the personnel must have read and understood this operating manual. Prerequisite for safe working is the

observance of all safety instructions in this manual.

Illustrations in this manual are provided for basic understanding

and may differ from the actual product design.

In addition to these instructions, the documents listed under Ap-

plicable documents [}6] are applicable.

1.1.1 Presentation of Warning Labels

To make risks clear, the following signal words and symbols are

used for safety notes.

DANGER

Danger for persons!

Non-observance will inevitably cause irreversible injury or death.

WARNING

Dangers for persons!

Non-observance can lead to irreversible injury and even death.

CAUTION

Dangers for persons!

Non-observance can cause minor injuries.

NOTICE

Material damage!

Information about avoiding material damage.

General

6

08.00 | PZN-plus | Assembly and Operating Manual | en | 0389374

1.1.2 Applicable documents

• General terms of business*

• Catalog data sheet of the purchased product *

• Assembly and operating manuals of the accessories *

• For ATEX versions: Supplementary sheet "Installation and operating instructions - EX" *

The documents marked with an asterisk (*) can be downloaded on

our homepage schunk.com

1.1.3 Sizes

This operating manual applies to the following sizes:

• PZN-plus 40

• PZN-plus 50

• PZN-plus 64

• PZN-plus 80

• PZN-plus 100

• PZN-plus 125

• PZN-plus 160

• PZN-plus 200

• PZN-plus 240

• PZN-plus 300

• PZN-plus 380

1.1.4 Variants

This operating manual applies to the following variations:

• PZN-plus

• PZN-plus with gripping force maintenance O.D. gripping

• PZN-plus with gripping force maintenance I.D. gripping

• PZN-plus Force intensified version (KVZ)

• PZN-plus Dust-tight

• PZN-plus ATEX-Version (EX)

• PZN-plus Anti-corrosion version

• PZN-plus Precision version

General

08.00 | PZN-plus | Assembly and Operating Manual | en | 0389374

7

1.2 Warranty

If the product is used as intended, the warranty is valid for 36

months from the ex-works delivery date under the following conditions:

• Intented use in 1-shift operation

• Observe the specified maintenance and lubrication intervals

• Observe the ambient conditions and operating conditions

Parts touching the workpiece and wear parts are not included in

the warranty.

1.3 Scope of delivery

The scope of delivery includes

• 3-Finger Centric Gripper PZN-plus in the version ordered

• Assembly and Operating Manual

• Accessory pack

1.3.1 Accessories kit

Content of the accessory pack:

• 6 x Centering sleeves for mounting

• 2 x O-ring for hose-free direct connection

• 2 x screw plug for hose connection

• 2 x Cylindrical pin

ID.-No. of the accessory pack

Accessory pack for PZN-plus PZN-plus-

High-temperature

(HT)

PZN-plus 40 5521694 5521695

PZN-plus 50 5520796 5520797

PZN-plus 64 5512728 395512728

PZN-plus 80 5512729 395512729

PZN-plus 100 5512730 395512730

PZN-plus 125 5512731 395512731

PZN-plus 160 5512732 395512732

PZN-plus 200 5512733 395512733

PZN-plus 240 5514005 395514005

PZN-plus 300 5514240 395514240

PZN-plus 380 5520730 -

General

8

08.00 | PZN-plus | Assembly and Operating Manual | en | 0389374

1.4 Accessories

A wide range of accessories are available for this product

For information regarding which accessory articles can be used

with the corresponding product variants, see catalog data sheet.

1.4.1 Sealing kit

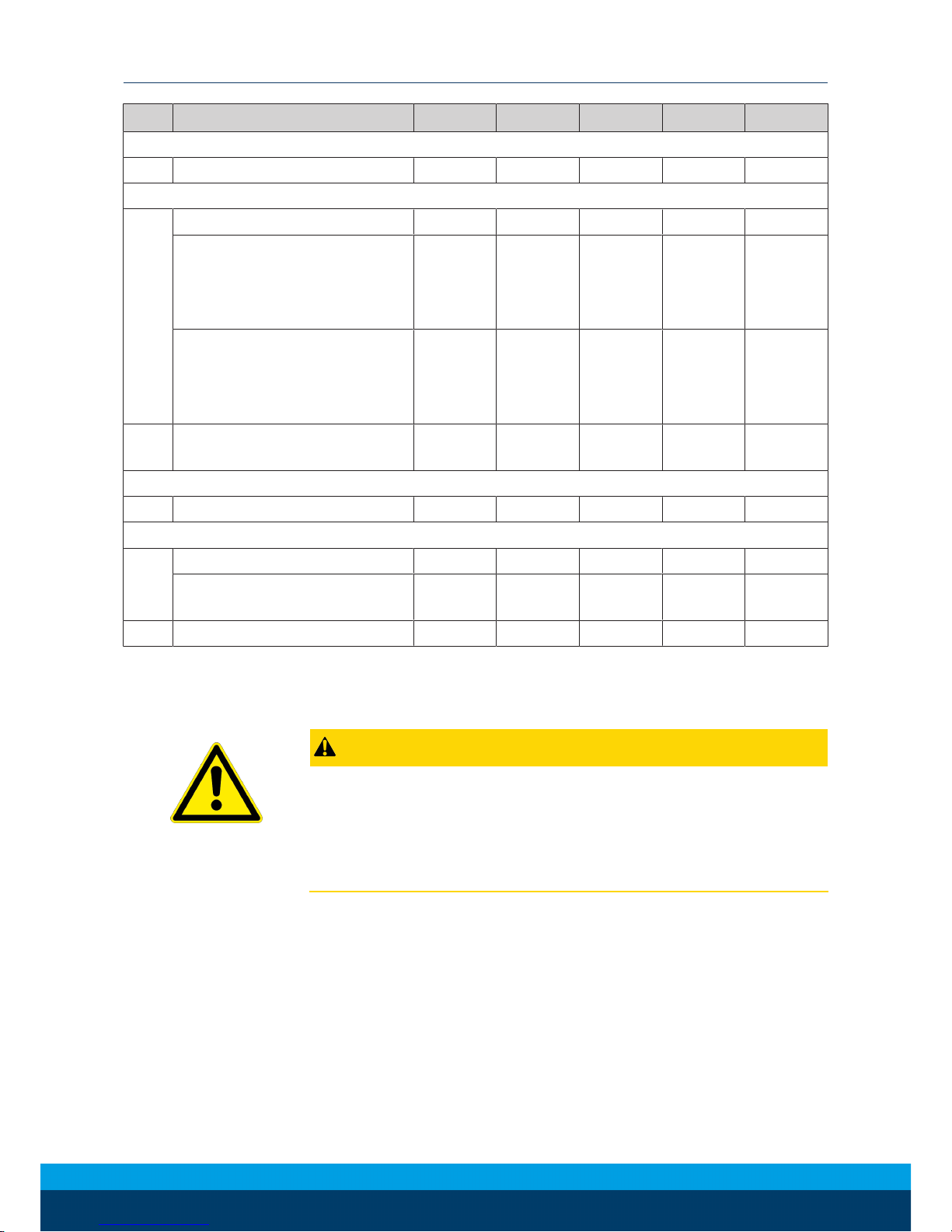

Seal kit for PZN-plus PZN-plus-

High-

temperature

(HT)

PZN-plus-

Dust-tight

PZN-plus-

Force

intensified

version

(KVZ)

PZN-plus 40 5516815 395516815 5518720 PZN-plus 50 5516816 395516816 5518721 PZN-plus 64 0303450 39303450 5518722 5515869

PZN-plus 80 0303451 39303451 5518723 5515870

PZN-plus 100 0303452 39303452 5518724 5515871

PZN-plus 125 0303453 39303453 5518725 5515872

PZN-plus 160 0303454 39303454 5518726 5515873

PZN-plus 200 0303455 39303455 5518727 PZN-plus 240 0303456 39303456 5518728 PZN-plus 300 0303457 39303457 5518729 PZN-plus 380 0303458 39303458 5511513 -

Contents of the sealing kit, Drawings [}53].

Basic safety notes

08.00 | PZN-plus | Assembly and Operating Manual | en | 0389374

9

2 Basic safety notes

2.1 Intended use

The product is designed exclusively for gripping and temporarily

holding workpieces or objects.

• The product may only be used within the scope of its technical

data, Technical data [}17].

• When implementing and operating components in safety-related parts of the control systems, the basic safety principles in

accordance with DIN EN ISO 13849-2 apply. The proven safety

principles in accordance with DIN EN ISO 13849-2 also apply to

categories 1, 2, 3 and 4.

• The product is intended for installation in a machine/system.

The applicable guidelines must be observed and complied with.

• The product is intended for industrial and industry-oriented use.

• Appropriate use of the product includes compliance with all instructions in this manual.

2.2 Not intended use

It is not intended use if the product is used, for example, as a

pressing tool, stamping tool, lifting gear, guide for tools, cutting

tool, clamping device or a drilling tool.

• Any utilization that exceeds or differs from the appropriate use

is regarded as misuse.

2.3 Constructional changes

Implementation of structural changes

By conversions, changes, and reworking, e.g. additional threads,

holes, or safety devices can impair the functioning or safety of the

product or damage it.

• Structural changes should only be made with the written approval of SCHUNK.

2.4 Spare parts

Use of unauthorized spare parts

Using unauthorized spare parts can endanger personnel and damage the product or cause it to malfunction.

• Use only original spare parts or spares authorized by SCHUNK.

Basic safety notes

10

08.00 | PZN-plus | Assembly and Operating Manual | en | 0389374

2.5 Gripper fingers

Requirements for the gripper fingers

Stored energy within the product creates the risk of serious injuries and significant property damage.

• Arrange the gripper fingers in a way that the product reaches

either the position "open" or "closed" in a de-energized state.

• Only exchange the gripper fingers when no residual energy remains in the product.

• Make sure that the product and the top jaws are a sufficient

size for the application.

2.6 Environmental and operating conditions

Required ambient conditions and operating conditions

Incorrect ambient and operating conditions can make the product

unsafe, leading to the risk of serious injuries, considerable material

damage and/or a significant reduction to the product's life span.

See also Technical data [}17].

2.7 Personnel qualification

Inadequate qualifications of the personnel

If the personnel working with the product is not sufficiently qualified, the result may be serious injuries and significant property

damage.

• All work may only be performed by qualified personnel.

• Before working with the product, the personnel must have read

and understood the complete assembly and operating manual.

• Observe the national safety regulations and rules and general

safety instructions.

The following personal qualifications are necessary for the various

activities related to the product:

Trained electrician

Due to their technical training, knowledge and experience, trained

electricians are able to work on electrical systems, recognize and

avoid possible dangers and know the relevant standards and regulations.

Qualified personnel

Due to its technical training, knowledge and experience, qualified

personnel is able to perform the delegated tasks, recognize and

avoid possible dangers and knows the relevant standards and regulations.

Instructed person

Instructed persons were instructed by the operator about the delegated tasks and possible dangers due to improper behaviour.

Service personnel of

the manufacturer

Due to its technical training, knowledge and experience, service

personnel of the manufacturer is able to perform the delegated

tasks and to recognize and avoid possible dangers.

Basic safety notes

08.00 | PZN-plus | Assembly and Operating Manual | en | 0389374

11

2.8 Personal protective equipment

Use of personal protective equipment

Personal protective equipment serves to protect staff against

danger which may interfere with their health or safety at work.

• When working on and with the product, observe the occupational health and safety regulations and wear the required personal protective equipment.

• Observe the valid safety and accident prevention regulations.

• Wear protective gloves to guard against sharp edges and

corners or rough surfaces.

• Wear heat-resistant protective gloves when handling hot surfaces.

• Wear protective gloves and safety goggles when handling hazardous substances.

• Wear close-fitting protective clothing and also wear long hair in

a hairnet when dealing with moving components.

2.9 Notes on safe operation

Incorrect handling of the personnel

Incorrect handling and assembly may impair the product's safety

and cause serious injuries and considerable material damage.

• Avoid any manner of working that may interfere with the function and operational safety of the product.

• Use the product as intended.

• Observe the safety notes and assembly instructions.

• Do not expose the product to any corrosive media. This does

not apply to products that are designed for special environments.

• Eliminate any malfunction immediately.

• Observe the care and maintenance instructions.

• Observe the current safety, accident prevention and environmental protection regulations regarding the product's application field.

Basic safety notes

12

08.00 | PZN-plus | Assembly and Operating Manual | en | 0389374

2.10 Transport

Handling during transport

Incorrect handling during transport may impair the product's

safety and cause serious injuries and considerable material damage.

• When handling heavy weights, use lifting equipment to lift the

product and transport it by appropriate means.

• Secure the product against falling during transportation and

handling.

• Stand clear of suspended loads.

2.11 Malfunctions

Behavior in case of malfunctions

• Immediately remove the product from operation and report the

malfunction to the responsible departments/persons.

• Order appropriately trained personnel to rectify the malfunction.

• Do not recommission the product until the malfunction has

been rectified.

• Test the product after a malfunction to establish whether it still

functions properly and no increased risks have arisen.

2.12 Disposal

Handling of disposal

The incorrect handling of disposal may impair the product's safety

and cause serious injuries as well as considerable material and environmental harm.

• Follow local regulations on dispatching product components for

recycling or proper disposal.

2.13 Fundamental dangers

General

• Observe safety distances.

• Never deactivate safety devices.

• Before commissioning the product, take appropriate protective

measures to secure the danger zone.

• Disconnect power sources before installation, modification,

maintenance, or calibration. Ensure that no residual energy remains in the system.

• If the energy supply is connected, do not move any parts by

hand.

• Do not reach into the open mechanism or movement area of

the product during operation.

Basic safety notes

08.00 | PZN-plus | Assembly and Operating Manual | en | 0389374

13

2.13.1 Protection during handling and assembly

Incorrect handling and assembly

Incorrect handling and assembly may impair the product's safety

and cause serious injuries and considerable material damage.

• Have all work carried out by appropriately qualified personnel.

• For all work, secure the product against accidental operation.

• Observe the relevant accident prevention rules.

• Use suitable assembly and transport equipment and take precautions to prevent jamming and crushing.

Incorrect lifting of loads

Falling loads may cause serious injuries and even death.

• Stand clear of suspended loads and do not step into their swiveling range.

• Never move loads without supervision.

• Do not leave suspended loads unattended.

2.13.2 Protection during commissioning and operation

Falling or violently ejected components

Falling and violently ejected components can cause serious injuries

and even death.

• Take appropriate protective measures to secure the danger

zone.

• Never step into the danger zone during operation.

Basic safety notes

14

08.00 | PZN-plus | Assembly and Operating Manual | en | 0389374

2.13.3 Protection against dangerous movements

Unexpected movements

Residual energy in the system may cause serious injuries while

working with the product.

• Switch off the energy supply, ensure that no residual energy remains and secure against inadvertent reactivation.

• Never rely solely on the response of the monitoring function to

avert danger. Until the installed monitors become effective, it

must be assumed that the drive movement is faulty, with its action being dependent on the control unit and the current operating condition of the drive. Perform maintenance work, modifications, and attachments outside the danger zone defined by

the movement range.

• To avoid accidents and/or material damage, human access to

the movement range of the machine must be restricted. Limit/

prevent accidental access for people in this area due through

technical safety measures. The protective cover and protective

fence must be rigid enough to withstand the maximum possible

movement energy. EMERGENCY STOP switches must be easily

and quickly accessible. Before starting up the machine or automated system, check that the EMERGENCY STOP system is

working. Prevent operation of the machine if this protective

equipment does not function correctly.

2.13.4 Protection against electric shock

Possible electrostatic energy

Components or assembly groups may become electrostatically

charged. When the electrostatic charge is touched, the discharge

may trigger a shock reaction leading to injuries.

• The operator must ensure that all components and assembly

groups are included in the local potential equalisation in accordance with the applicable regulations.

• While paying attention to the actual conditions of the working

environment, the potential equalisation must be implemented

by a specialist electrician according to the applicable regulations.

• The effectiveness of the potential equalisation must be verified

by executing regular safety measurements.

Basic safety notes

08.00 | PZN-plus | Assembly and Operating Manual | en | 0389374

15

2.14 Notes on particular risks

DANGER

Risk of fatal injury from suspended loads!

Falling loads can cause serious injuries and even death.

• Stand clear of suspended loads and do not step within their

swiveling range.

• Never move loads without supervision.

• Do not leave suspended loads unattended.

• Wear suitable protective equipment.

WARNING

Risk of injury from objects falling and being ejected!

Falling and ejected objects during operation can lead to serious

injury or death.

• Take appropriate protective measures to secure the danger

zone.

WARNING

Risk of injury due to unexpected movements!

If the power supply is switched on or residual energy remains in

the system, components can move unexpectedly and cause serious injuries.

• Before starting any work on the product: Switch off the power

supply and secure against restarting.

• Ensure that no residual energy remains in the system.

WARNING

Risk of injury from crushing and impacts!

Serious injury could occur during the base jaw procedure and

when breaking or loosening the gripper fingers.

• Wear suitable protective equipment.

• Do not reach into the open mechanism or the movement area

of the product.

WARNING

Risk of injury from sharp edges and corners!

Sharp edges and corners can cause cuts.

• Use suitable protective equipment.

Basic safety notes

16

08.00 | PZN-plus | Assembly and Operating Manual | en | 0389374

WARNING

Risk of injury due to spring forces!

Parts are under spring tension on products which clamp using

spring force or which have gripping force maintenance. While disassembling components can move unexpectedly and cause serious injuries.

• Disassemble the product cautiously.

• Make sure that no residual energy remains in the system.

WARNING

Risk of injury from objects falling during energy supply failure

Products with a mechanical gripping force maintenance can, during energy supply failure, still move independently in the direction specified by the mechanical gripping force maintenance.

• Secure the end positions of the product with SCHUNK SDV-P

pressure maintenance valves.

Technical data

08.00 | PZN-plus | Assembly and Operating Manual | en | 0389374

17

3 Technical data

Designation PZN-plus

Pressure medium Compressed air, compressed

air quality according to ISO

8573-1:7 4 4

Nominal working pressure [bar] 6

Minimum pressure [bar]

without gripping force maintenance

with gripping force maintenance

2.5

4

Max. pressure [bar]

without gripping force maintenance

with gripping force maintenance

Force intensified version (KVZ)

8

6.5

6

Pressure range for air purge [bar] 0.5 - 1

More technical data is included in the catalog data sheet.

Whichever is the latest version.

Environmental and operating conditions

Designation PZN-plus

Ambient temperature [°C]

min.

max.

+5

+90 / (V/HT: +130)

IP protection class * 40 / (SD: 64)

Noise emission [dB(A)] ≤ 70

* For use in dirty ambient conditions (e.g. sprayed water, vapors,

abrasion or processing dust) SCHUNK offers corresponding

product options as standard. SCHUNK also offers customized

solutions for special applications in dirty ambient conditions.

Design and description

18

08.00 | PZN-plus | Assembly and Operating Manual | en | 0389374

4 Design and description

4.1 Design

3-Finger Centric Gripper

1 Housing

2 Base jaw

3 Compressed air main connection

4.2 Description

Universal 3-finger centric gripper with high gripping force and high

maximum moments due to multi-tooth guidance.

Assembly

08.00 | PZN-plus | Assembly and Operating Manual | en | 0389374

19

5 Assembly

5.1 Installing and connecting

DANGER

Danger of explosion in potentially explosive areas!

• Observe supplementary sheet for products with explosion-res-

istant versions "PZN-plus -...-EX".

WARNING

Risk of injury due to unexpected movements!

If the power supply is switched on or residual energy remains in

the system, components can move unexpectedly and cause serious injuries.

• Before starting any work on the product: Switch off the power

supply and secure against restarting.

• Ensure that no residual energy remains in the system.

NOTICE

Damage to the gripper is possible!

If the maximum permissible finger weight or the permissible

mass moment of inertia of the fingers is exceeded, the gripper

can be damaged.

• A jaw movement always has to be without jerks and bounce.

• You must therefore implement sufficient reduction and/or

damping.

• Observe the diagrams and information in the catalog data

sheet.

Ø Check the evenness of the mounting surface, Mechanical con-

nection [}20].

Ø Only open the required air connections (main connection or dir-

ect connection), Pneumatic connection [}23].

Ø Connect the product via the hose-free direct connection.

✓ Use O-rings from the accessory pack.

✓ Seal main air connections which are not required with locking

screws.

Ø OR: Connect compressed air lines to the main air connec-

tions"A" and"B".

✓ Screw in air connections (plug connections).

OR: Screw on throttle valve in order to be able to perform

sufficient throttling and/or dampening.

Assembly

20

08.00 | PZN-plus | Assembly and Operating Manual | en | 0389374

Ø Screw the product to the machine/system, Mechanical connec-

tion [}20].

✓ When mounting from the rear: use cylindrical pins for fixing

the product in place.

✓ If necessary, use appropriate connection elements (adapter

plates).

✓ Observe requirements for the adapter plate, Mechanical con-

nection [}21].

✓ Observe the maximal tightening torque, admissible screw-in

depth and, if necessary, strength class.

Ø Secure the gripper fingers to the base jaws, Mechanical connec-

tion [}20].

✓ Use centering sleeves from the enclosed accessory pack.

Ø If necessary, fit a pressure piece for spring-supported position-

ing of the workpiece against a stop, Mounting of the gripper by

using a spring loaded pressure-piece [}22].

Ø Connect the sensor, see assembly and operating manual of the

sensor.

Ø Mount the sensor, Mounting the sensor [

}

24].

5.2 Connections

5.2.1 Mechanical connection

Evenness of the

mounting surface

The values apply to the whole mounting surface to which the

product is mounted.

Requirements for evenness of the mounting surface (Dimensions in mm)

Edge length Permissible unevenness

< 100 < 0.02

> 100 < 0.05

Assembly

08.00 | PZN-plus | Assembly and Operating Manual | en | 0389374

21

Requirements for

customer adapter

plates

If the adapter plate has bores or recesses and therefore the

product is not fully flush, the minimum support surface must be

adhered to. The recess/bore in the adapter plate may not exceed

the dimension "A"; for dimensions, see the following table.

The product can be assembled from two sides.

Connections at the

housing and on the

base jaws

Assembly options

Item 40 50 64 80 100 125

Mounting the product from the front (side A)

1 Mounting screw (3 x) M3 M3 M5 M6 M6 M8

Mounting the product from the rear (side B)

2 Mounting screw (3 x) - M4 M6 M8 M8 M10

Max. depth of engagement

from locating surface [mm]

• without gripping force

maintenance

- 10 13 17 18 21

Max. depth of engagement

from locating surface [mm]

• with gripping force maintenance (AS / IS)

- 20.5 26 32 38 45.5

3 Fitting bore for cylindrical

pins *

Ø2H7 Ø3H7 Ø4H7 Ø5H7 Ø5H7 Ø6H7

Possible recess in the adapter plate

A Max. recess [mm] Ø24 Ø32 Ø40 Ø55 Ø70 Ø85

Affixing the gripper fingers

4 Mounting screw(2x) M2.5 M3 M4 M5 M6 M6

Max. depth of engagement

from locating surface [mm]

6 8 10 10 13 13

5 Centering sleeve* [mm] Ø4 Ø5 Ø6 Ø8 Ø10 Ø10

*) Contained in accessory pack.

Assembly

22

08.00 | PZN-plus | Assembly and Operating Manual | en | 0389374

Item 160 200 240 300 380

Mounting the product from the front (side A)

1 Mounting screw (3 x) M8 M10 M12 M16 M20

Mounting the product from the rear (side B)

2 Mounting screw (3 x) M10 M12 - - -

Max. depth of engagement

from locating surface [mm]

without gripping force

maintenance

21.5 25 - - -

Max. depth of engagement

from locating surface [mm]

with gripping force

maintenance (AS / IS)

51.5 61 - - -

3 Fitting bore for cylindrical

pins *

Ø6H7 Ø8H7 Ø8H7 Ø10H7 Ø12H7

Possible recess in the adapter plate

A Max. recess [mm] Ø115 Ø150 Ø196 Ø236 Ø292

Affixing the gripper fingers

4 Mounting screw(2x) M10 M12 M12 M16 M20

Max. depth of engagement

from locating surface [mm]

17 17 20 26 30

5 Centering sleeve * [mm] Ø14 Ø16 Ø16 Ø22 Ø28

*) Contained in accessory pack.

5.2.1.1 Mounting of the gripper by using a spring loaded pressure-piece

CAUTION

The spring-loaded pressure piece is under spring tension.

The pressure piece can fly out in an uncontrolled fashion and

cause contusions.

• During assembly or disassembly, be especially careful with the

springs.

When mounting the gripper from the side of the gripper fingers,

the assembly of the pressure piece must be done after the mounting of the gripper.

Mounting the pressure piece is described in the insert "Installation

instructions - pressure piece", which is included in the pressure

piece's scope of delivery.

Assembly

08.00 | PZN-plus | Assembly and Operating Manual | en | 0389374

23

5.2.2 Pneumatic connection

NOTE

• Observe the requirements for the compressed air supply, Tech-

nical data [}17].

• In case of compressed air loss (cutting off the energy line), the

components lose their dynamic effects and do not remain in a

secure position. However, the use of a SDV-P pressure maintenance valve is recommended in this case in order to maintain the

dynamic effect for some time. Product variants are also offered

with mechanical gripping force via springs, which also ensure a

minimum clamping force in the event of a pressure drop.

Air connections

1 Main connections (Hose connection)

(A = open, B = close)

2 Hose-free direct connection

(a = open, b = close)

3 Air purge connection

Hose-free direct connection

4 Product 5 O-ring 6 Attachment

Thread diameter of the air connections

Item Mounting 40 50 64 80

100/

125

160 200 240 300/

380

1 Main connections

(Hose connection)

M3 M5 M5 M5 G1/8" G1/4"

2 Hose-free direct

connection

M3 M3 M4 M4 M5 M4

M5

M5

M8

3 Air purge

connection

M3 M5

Assembly

24

08.00 | PZN-plus | Assembly and Operating Manual | en | 0389374

5.3 Mounting the sensor

NOTE

Observe the assembly and operating manual of the sensor for

mounting and connecting.

The product is prepared for the use of sensors.

• For the exact type designations of suitable sensors, please see

catalog datasheet and Overview of sensors [}24].

• For technical data for the suitable sensors, see assembly and

operating manual and catalog datasheet.

– The assembly and operating manual and catalog datasheet

are included in the scope of delivery for the sensors and are

available at schunk.com.

• Information on handling sensors is available at schunk.com or

from SCHUNK contact persons.

5.3.1 Overview of sensors

Designation PZN-plus

40 50 64 80 100 125 160 200 240 300 380

Magnetic switch MMS 22 X X X X X X X X X X X

Programmable magnetic

switch MMS-22 PI1

X X X X X X X X X X X

Programmable magnetic

switch MMS-22 PI2

X X X X X X X

Programmable magnetic

switch MMS-P 22

X X X X X X X

Reed switch RMS 80 X X X X X X X X X

Inductive proximity switch

IN 80

X X X X X X X X X

Flexible position sensor

FPS-S M8

X X X X X X X X

Analog position sensor APS-M1 X X X X X X X X X

Analog position sensor APS-Z80 X X X X X X X X X

Radio system RSS R1/T2 with

Reed switch RMS 80

X X X X X X X X X

Force-measuring jaw FMS X X X X X X X X

Assembly

08.00 | PZN-plus | Assembly and Operating Manual | en | 0389374

25

5.3.2 Switch-off hysteresis

Sensors MMS 22, MMS-P 22, MMS 22-PI1 and MMS 22-PI2

The smallest detectable difference in stroke is defined in the following table:

The smallest detectable difference in stroke based on the nominal stroke

For grippers with X mm

nominal stroke per jaw

Min. query range per jaw/

min. queried stroke difference per jaw

X ≤ 5 mm 30% of the nominal stroke per jaw

X > 5 mm to X ≤ 10 mm 20% of the nominal stroke per jaw

X > 10 mm 10% of the nominal stroke per jaw

Example: Product with 7 mm nominal stroke per jaw

7 mm * 20 % = 1.4 mm

5.3.3 Turn control cam

Turn control cam, example control cam for inductive monitoring

Depending on the jaw stroke, it may be necessary to change the

alignment of the control cam for the sensors IN 80 and RMS 80.

In the image, the installation situation (A) shows the control cam

in the delivery state of the product and the installation

situation (B) shows the turned control cam.

In order to change the alignment of the control cam, proceed as

follows:

Ø Undo the screw (2).

Ø Remove control cam (1) from the product, turn and re-insert it

into the product.

Ø Turn the screw (3) to push the position of the control cam (1).

Assembly

26

08.00 | PZN-plus | Assembly and Operating Manual | en | 0389374

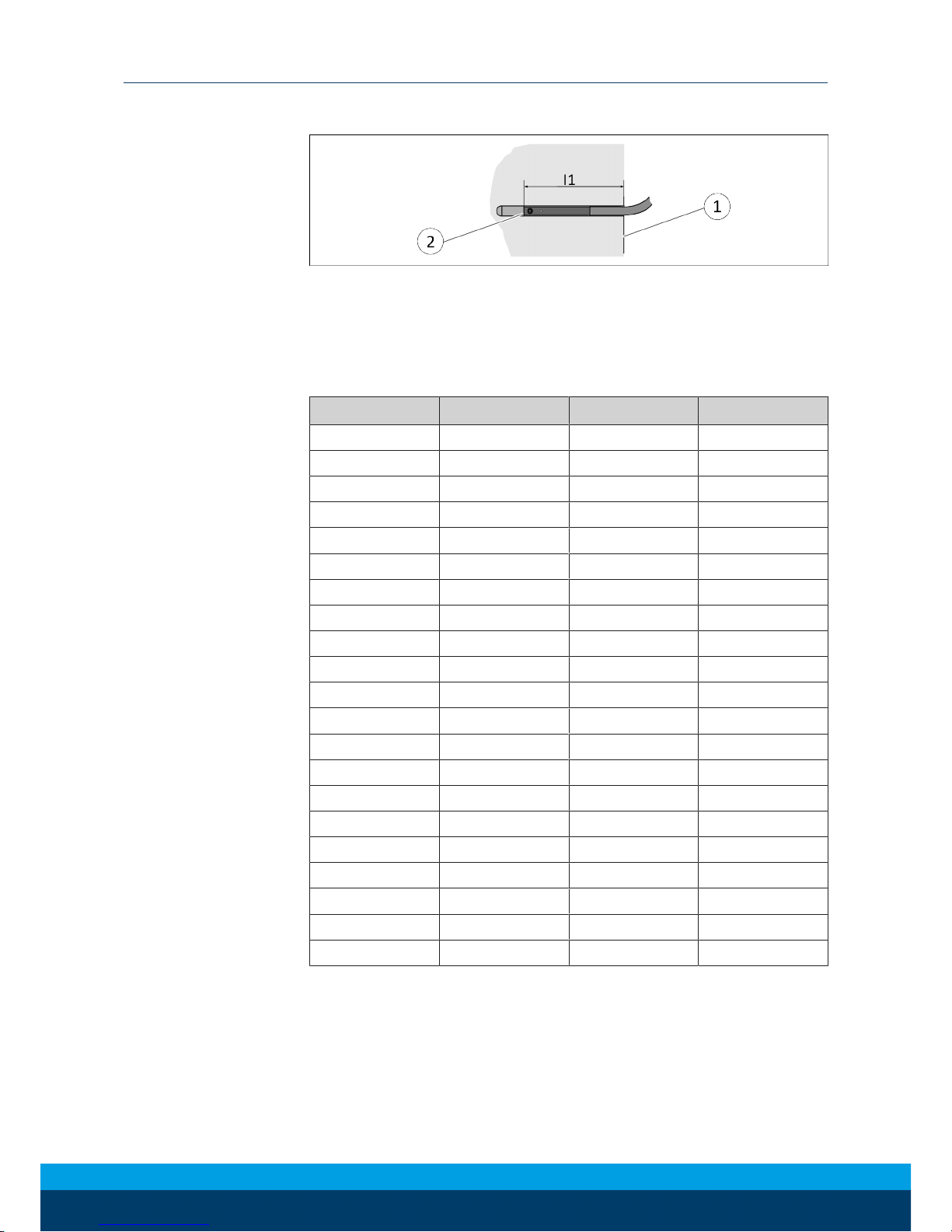

5.3.4 Setting dimensions

* Setting dimension I1, from product bottom edge (1) to front sensor (2)

The setting dimension applies for the following sensors:

• Programmable magnetic switch MMS-22 PI1

• Programmable magnetic switch MMS-22 PI2

• Programmable magnetic switch MMS-P 22

Size l1* [mm] Size l1* [mm]

40 20.3 80-KVZ 51.9

40 AS 28.2 80 AS-KVZ 66.9

40 IS 28.3 80 IS-KVZ 66.9

40-KVZ 34.8 100 29.8

40 AS-KVZ 42.8 100 AS 49.9

40 IS-KVZ 42.8 100 IS 49.8

50 21.7 100-KVZ 59.8

50 AS 32.2 100 AS-KVZ 79.8

50 IS 32.1 100 IS-KVZ 79.8

50-KVZ 39.7 125 32.5

50 AS-KVZ 50.1 125 AS 56.8

50 IS-KVZ 50.1 125 IS 57.0

64 24.5 125-KVZ 67.5

64 AS 38.0 125 AS-KVZ 92.0

64 IS 38.0 125 IS-KVZ 92.0

64-KVZ 45.5 160 35.9

64 AS-KVZ 59.0 160 AS 66.2

64 IS-KVZ 59.0 160 IS 65.9

80 26.9 160-KVZ 75.9

80 AS 42.5 160 AS-KVZ 105.9

80 IS 41.9 160 IS-KVZ 105.9

Assembly

08.00 | PZN-plus | Assembly and Operating Manual | en | 0389374

27

5.3.5 Mounting MMS 22 magnetic switch

NOTICE

Risk of damage to the sensor during assembly!

• Observe the maximal tightening torque.

Positioning the magnetic switches

Position "Gripper open" or "Part gripped (I.D. gripping)"

Ø Bring product in the position to be set.

Ø If necessary remove T-nut (3).

Ø Turn the sensor 1 (1) into the groove (2).

OR: Slide the sensor 1 (1) into the groove (2) until the sensor 1

(1) stops at the end of the groove.

Ø Pull the sensor 1 (1) back again slowly until it switches.

Ø Secure the sensor 1 (1) using the set-screw (4).

Tightening torque: 10 Ncm

Ø Bring product into the "Gripper open" or "Part gripped" position

and test the function.

Position "Gripper closed" or "Part gripped (O.D. gripping)"

Ø Bring product in the position in which it is to be set.

Ø If necessary remove T-nut (3).

Ø Turn the sensor 2 (1) into the groove (2).

OR: Slide sensor 2 (1) into the groove (2) in the direction of the

housing middle (3), until the sensor 2 (1) switches.

Ø Secure the sensor 2 (1) using the set-screw (4).

Tightening torque: 10 Ncm

Ø Bring product into the "Gripper closed" or "Part gripped" posi-

tion and test the function.

Assembly

28

08.00 | PZN-plus | Assembly and Operating Manual | en | 0389374

5.3.6 Mounting MMS 22-PI1 programmable magnetic switch

NOTICE

Risk of damage to the sensor during assembly!

• Observe the maximal tightening torque.

NOTE

If there is no T-nut available, slide the sensor according to dimension I1 into the groove (2), Setting dimensions [}26].

Sizes 40 - 160

Ø Turn the sensor 1 (1) into the groove (2).

OR: Slide the sensor 1 (1) into the groove (2) until the sensor 1

(1) stops at the T-nut (3).

Ø Secure the sensor 1 (1) using the set-screw (4).

Tightening torque: 10Ncm

Ø Adjust sensor 1 (1), see sensor assembly and operating manual.

Ø Repeat steps for sensor 2.

Sizes 200–380

Ø Bring gripper in the position in which it is to be set.

Ø Hold teaching tool to the sensor 1 (1) until the sensor flashes.

Ø Slide sensor 1 (1) into the groove (2), until the sensor 1 flashes

rapidly.

✓ The optimal position is displayed.

Ø Secure the sensor 1 (1) using the set-screw (4).

Tightening torque: 10Ncm

Ø Hold teaching tool to the sensor 1 (1), to confirm the position.

✓ The sensor 1 (1) has been taught in.

Ø Repeat steps for sensor 2.

Assembly

08.00 | PZN-plus | Assembly and Operating Manual | en | 0389374

29

5.3.7 Mounting programmable MMS 22-PI2 magnetic switch

NOTICE

Risk of damage to the sensor during assembly!

• Observe the maximal tightening torque.

NOTE

If there is no T-nut available, slide the sensor according to dimension I1 into the groove (2), Setting dimensions [}26].

Ø Turn the sensor (1) into the groove (2).

OR: Slide the sensor (1) into the groove (2) until the sensor (1)

stops at the T-nut (3).

Ø Secure the sensor (1) using the set-screw (4).

Tightening torque: 10Ncm

Ø Adjust sensor (1), see sensor assembly and operating manual.

Assembly

30

08.00 | PZN-plus | Assembly and Operating Manual | en | 0389374

5.3.8 Mounting programmable MMS-P 22 magnetic switch

NOTICE

Risk of damage to the sensor during assembly!

• Observe the maximal tightening torque.

NOTE

If there is no T-nut available, slide the sensor according to dimension I1 into the groove (2), Setting dimensions [}26].

Ø Turn the sensor (1) into the groove (2).

OR: Slide the sensor (1) into the groove (2) until the sensor (1)

stops at the T-nut (3).

Ø Secure the sensor (1) using the set-screw (4).

Tightening torque: 10Ncm

Ø Adjust sensor (1), see sensor assembly and operating manual.

5.3.9 Mounting the reed switch RMS 80

NOTICE

Blockade of the gripper after setting or replacing of the switching cam!

The switching cam can be tilt in the guide, if it was not fixed exactly in the base jaw.

• Apply the switching cam in the direction of the base jaw, so

that the cam does not contact the housing of the gripper.

Assembly

08.00 | PZN-plus | Assembly and Operating Manual | en | 0389374

31

NOTE

The screws (4) and (5) differ in length. With size PZN-plus 380,

these screws on sensor 3(1)are the same length.

Variant Dust-tight:

Before attaching the sensor, remove the sealing bolts from the

bracket. Before adjusting the control cam, unscrew the set-screw

from the side cover.

Position "Gripper open" or "Part gripped (I.D. gripping)"

Ø Slide the sensor 1(1)or sensor 2 (1) to the stop into the bracket

(2).

Ø Tighten the screw (3) on the bracket (2).

Tightening torque: 0.2 Nm

Ø Open gripper or grip part.

Ø Undo the screw (4).

Ø Turn the screw (5) to push the position of the control cam (6).

✓ Slide control cam (6) inwards until the sensor 1 (1) no longer

responds.

Move the control cam (6) back towards the outside until the

sensor 1 (1) begins to switch.

Ø Tighten screw (4) and in doing so press the control cam in the

direction of the gripper fingers. NOTICE!The control cam may

tilt in the guide if it has not been tightened properly.

✓ Switching point is set.

Ø Bring product into the "Gripper open" or "Part gripped" position

and test the function.

Assembly

32

08.00 | PZN-plus | Assembly and Operating Manual | en | 0389374

NOTE

If the switching position cannot be queried, it may be that the

alignment of the control cam has to be changed, Turn control

cam [}25].

Position "Gripper closed" or "Part gripped (O.D. gripping)"

Ø Slide the sensor 3(1)to the stop into the bracket (2).

Ø Tighten the screw (3) on the bracket (2).

Tightening torque: 0.2 Nm

Ø Close gripper or grip part.

Ø Undo the screw (4).

Ø Turn the screw (5) to push the position of the control cam (6).

✓ Slide control cam (6) outwards until the sensor 3 (1) no

longer responds.

Move the control cam (6) back towards the inside until the

sensor 3 (1) begins to switch.

Ø Tighten screw (4) and in doing so press the control cam in the

direction of the gripper fingers. NOTICE!The control cam may

tilt in the guide if it has not been tightened properly.

✓ Switching point is set.

Ø Bring product into the "Gripper closed" or "Part gripped" posi-

tion and test the function.

NOTE

If the switching position cannot be queried, it may be that the

alignment of the control cam has to be changed, Turn control

cam [}25].

Variant Dust-tight:

Screw in set-screw into the side cover.

5.3.10 Mounting inductive proximity switch IN 80

NOTICE

Blockade of the gripper after setting or replacing of the switching cam!

The switching cam can be tilt in the guide, if it was not fixed exactly in the base jaw.

• Apply the switching cam in the direction of the base jaw, so

that the cam does not contact the housing of the gripper.

Assembly

08.00 | PZN-plus | Assembly and Operating Manual | en | 0389374

33

NOTE

The screws (4) and (5) differ in length. With size PZN-plus 380,

these screws on sensor 3(1)are the same length.

Variant Dust-tight:

Before attaching the sensor, remove the sealing bolts from the

bracket. Before adjusting the control cam, unscrew the set-screw

from the side cover.

Position "Gripper open" or "Part gripped (I.D. gripping)"

Ø Slide the sensor 1(1)or sensor 2 (1) to the stop into the bracket

(2).

Ø Tighten the screw (3) on the bracket (2).

Tightening torque: 0.2 Nm

Ø Open gripper or grip part.

Ø Undo the screw (4).

Ø Turn the screw (5) to push the position of the control cam (6).

✓ Slide control cam (6) inwards until the sensor 1 (1) no longer

responds.

Move the control cam (6) back towards the outside until the

sensor 1 (1) begins to switch.

Ø Tighten screw (4) and in doing so press the control cam in the

direction of the gripper fingers. NOTICE!The control cam may

tilt in the guide if it has not been tightened properly.

✓ Switching point is set.

Ø Bring product into the "Gripper open" or "Part gripped" position

and test the function.

Assembly

34

08.00 | PZN-plus | Assembly and Operating Manual | en | 0389374

NOTE

If the switching position cannot be queried, it may be that the

alignment of the control cam has to be changed, Turn control

cam [}25].

Position "Gripper closed" or "Part gripped (O.D. gripping)"

Ø Slide the sensor 3(1)to the stop into the bracket (2).

Ø Tighten the screw (3) on the bracket (2).

Tightening torque: 0.2 Nm

Ø Close gripper or grip part.

Ø Undo the screw (4).

Ø Turn the screw (5) to push the position of the control cam (6).

✓ Slide control cam (6) outwards until the sensor 3 (1) no

longer responds.

Move the control cam (6) back towards the inside until the

sensor 3 (1) begins to switch.

Ø Tighten screw (4) and in doing so press the control cam in the

direction of the gripper fingers. NOTICE!The control cam may

tilt in the guide if it has not been tightened properly.

✓ Switching point is set.

Ø Bring product into the "Gripper closed" or "Part gripped" posi-

tion and test the function.

NOTE

If the switching position cannot be queried, it may be that the

alignment of the control cam has to be changed, Turn control

cam [}25].

Variant Dust-tight:

Screw in set-screw into the side cover.

5.3.11 Mounting flexible position sensor FPS

The flexible position sensor FPS consists of an evaluation unit and

the sensor FPS-S-M8.

NOTICE

Risk of damage to the sensor during assembly!

• Observe the maximal tightening torque.

To be able to mount the sensor, the gripper has to be retrofitted

with a special mounting kit.

Assembly

08.00 | PZN-plus | Assembly and Operating Manual | en | 0389374

35

Variant Dust-tight:

Before attaching the sensor, remove the sealing bolts from the

bracket. Before adjusting the control cam, unscrew the set-screw

from the side cover.

Ø Move product to the "gripper open" position.

Ø Loosen screw (4) and remove control cam (6) for the inductive

monitoring from the base jaw.

Ø Remove screw (5) from the base jaw.

Ø Slide control cam (7) out of the mounting kit with the recess at

the front into the base jaw.

Ø Screw the control cam (7) to the base jaw using the screw (8).

Ø Slide spacer shim (9) into the bracket (2) to the stop.

Ø Slide the sensor (1) to the stop into the bracket (2).

Ø Tighten the screw (3) on the bracket (2).

Tightening torque: 0.2 Nm

Ø Adjust sensor (1), see Translation of Sensor Assembly and Oper-

ating Manual.

Variant Dust-tight:

Screw in set-screw into the side cover.

5.3.12 Mounting the analog position sensor APS-M1

To be able to mount the sensor, the gripper has to be retrofitted

with a special mounting kit.

Assembly

36

08.00 | PZN-plus | Assembly and Operating Manual | en | 0389374

NOTICE

Blockade of the gripper after setting or replacing of the switching cam!

The switching cam can be tilt in the guide, if it was not fixed exactly in the base jaw.

• Apply the switching cam in the direction of the base jaw, so

that the cam does not contact the housing of the gripper.

Variant Dust-tight:

Before attaching the sensor, remove the sealing bolts from the

bracket. Before adjusting the control cam, unscrew the set-screw

from the side cover.

Ø Move product to the "gripper open" position.

Ø Loosen screw (4) and remove control cam (6) for the inductive

monitoring from the base jaw.

Ø Apply adhesive to the top and sides of the control cam (6) from

the mounting kit.

✓ Make sure that there is no adhesive on the bottom of the

control cam (6), which comes into contact with the sensor.

✓ SCHUNK recommends the adhesive Loctite 290 or 638.

Ø Slide control cam (6) out of the mounting kit front into the base

jaw.

✓ Ensure that the higher front side of the control cam(6) is

pointing outwards.

Ø Tighten screw (4) slightly.

Ø Turn the screw (5) to push the position of the control cam (6).

Ø Tighten screw (4) and in doing so press the control cam (6) in

the direction of the gripper finger.

Ø Slide the sensor (1) to the stop into the bracket (2).

Assembly

08.00 | PZN-plus | Assembly and Operating Manual | en | 0389374

37

Ø Tighten the screw (3) on the bracket (2).

Tightening torque: 0.2 Nm

Ø Adjust sensor (1), see Translation of Sensor Assembly and Oper-

ating Manual.

Variant Dust-tight:

Screw in set-screw into the side cover.

5.3.13 Mounting the analog position sensor APS-Z80

To be able to mount the sensor, the gripper has to be retrofitted

with a special mounting kit.

NOTICE

Blockade of the gripper after setting or replacing of the switching cam!

The switching cam can be tilt in the guide, if it was not fixed exactly in the base jaw.

• Apply the switching cam in the direction of the base jaw, so

that the cam does not contact the housing of the gripper.

Variant Dust-tight:

Before attaching the sensor, remove the sealing bolts from the

bracket. Before adjusting the control cam, unscrew the set-screw

from the side cover.

Ø Move product to the "gripper open" position.

Ø Loosen screw (4) and remove control cam (6) for the inductive

monitoring from the base jaw.

Ø Remove screw (5) from the base jaw.

Assembly

38

08.00 | PZN-plus | Assembly and Operating Manual | en | 0389374

Ø Apply adhesive to the top and sides of the control cam (6) from

the mounting kit.

✓ Make sure that there is no adhesive on the bottom of the

control cam (6), which comes into contact with the sensor.

✓ SCHUNK recommends the adhesive Loctite 290 or 638.

Ø Slide control cam (6) into the base jaw to the stop.

✓ Ensure that the higher front side of the control cam(6) is

pointing outwards.

Ø NOTICE!The control cam (6) must no longer move after it is

screwed on.

Screw the control cam (6) to the base jaw using the screw (5).

✓ Secure the screw (5) with medium-strength locking liquid.

Ø Slide the sensor (1) to the stop into the bracket (2).

Ø Tighten the screw (3) on the bracket (2).

Tightening torque: 0.2 Nm

Ø Adjust sensor (1), see Translation of Sensor Assembly and Oper-

ating Manual.

Variant Dust-tight:

Screw in set-screw into the side cover.

5.3.14 Mounting the radio system RSS-R1/T2

The radio system RSS-R1/T2 can be used with the following

sensors:

• Reed switch RMS 80

Assembly

Ø Install the sensor, Mounting the reed switch RMS 80 [

}

30].

Ø Adjust the sensor, see the Assembly and Operating Manual for

the sensor.

Ø Connect the radio system, see the Assembly and Operating

Manual for the radio system.

Assembly

08.00 | PZN-plus | Assembly and Operating Manual | en | 0389374

39

5.3.15 Mounting FMS force-measuring jaw

Ø Screw passive force-measuring jaw (1) and active force-measur-

ing jaw (3) onto the base jaw (2).

✓ Use centering sleeves between force-measuring jaw and in-

termediate jaw.

Ø Screw gripper fingers onto the force-measuring jaws (1, 3).

✓ Use centering sleeves between force-measuring jaw and grip-

per finger.

Ø Connect the evaluation unit, see the Assembly and Operating

Manual for the sensor.

Troubleshooting

40

08.00 | PZN-plus | Assembly and Operating Manual | en | 0389374

6 Troubleshooting

6.1 Product is not moving

Possible cause Corrective action

Base jaws jam in housing, e.g. mounting surface is not sufficiently even.

Check the evenness of the mounting surface.

Mechanical connection [}20]

Loosen the mounting screws of the product

and actuate the product again.

Pressure drops below minimum. Check air supply.

Pneumatic connection [}23]

Compressed air lines switched. Check compressed air lines.

Pneumatic connection [}23]

Proximity switch defective or set incorrect. Readjust or change sensor.

Unused air connections open. Close unused air connections.

Flow control valve closed. Open the flow control valve.

Component part defective. Replace component or send it to SCHUNK

for repair.

6.2 Product is not executing the complete stroke

Possible cause Corrective action

Dirt deposits between cover and piston. Clean and if necessary re-lubricate.

Maintenance [}42]

Dirt deposits between basic jaws and guidance.

Disassemble and clean the product.

Pressure drops below minimum. Check air supply.

Pneumatic connection [}23]

Mounting surface is not sufficiently flat. Check the evenness of the mounting surface.

Mechanical connection [}20]

Component part defective. Replace component or send it to SCHUNK

for repair.

6.3 Product opens or closes abruptly

Possible cause Corrective action

Too little grease in the mechanical guiding

areas.

Clean and lubricate product.

Maintenance [}42]

Compressed air lines blocked. Check compressed air lines of damage.

Mounting surface is not sufficiently flat. Check the evenness of the mounting surface.

One-way flow control valve is missing or ad-

justet incorrectly.

Install and adjust one-way flow control

valve.

Loading too large. Check permissible weight and length of the

gripper fingers.

Troubleshooting

08.00 | PZN-plus | Assembly and Operating Manual | en | 0389374

41

6.4 Gripping force is dropping

Possible cause Corrective action

Compressed air can escape. Check seals, if necessary, disassemble the

product and replace seals.

Too much grease in the mechanical

movement space.

Clean and lubricate product.

Maintenance [}42]

Pressure drops below minimum. Check air supply.

Pneumatic connection [}23]

Component part defective. Replace component or send it to SCHUNK

for repair.

6.5 Product does not achieve the opening and closing times

Possible cause Corrective action

Compressed air lines are not installed

optimally.

If present: Open the flow control couplings

on the product to the maximum that the

movement of the jaws occurs without boun-

cing and hitting.

Check compressed air lines.

Inner diameters of compressed air lines are

of sufficient size in relation to compressed

air consumption.

Keep compressed air lines between the

product and directional control valve as

short as possible.

Flow rate of valve is sufficiently large relat-

ive to the compressed air consumption.

NOTICE!The throttle check valve must not

be removed, even if the product has not

reached the opening and closing times.

If you still cannot achieve the open and close

times mentioned in the latest catalog, we re-

commend the use of quick-air-vent-valves

directly at the product.

Loading too large. Check permissible weight and length of the

gripper fingers.

Maintenance

42

08.00 | PZN-plus | Assembly and Operating Manual | en | 0389374

7 Maintenance

7.1 Notes

DANGER

Danger of explosion in potentially explosive areas!

• Observe supplementary sheet for products with explosion-res-

istant versions "PZN-plus -...-EX".

WARNING

Risk of burns through contact with hot surfaces!

Surfaces of components can heat up severely during operation.

Skin contact with hot surfaces causes severe burns to the skin.

• For all work in the vicinity of hot surfaces, wear safety gloves.

• Before carrying out any work, make sure that all surfaces have

cooled down to the ambient temperature.

Original spare parts

Use only original spare parts of SCHUNK when replacing spare and

wear parts.

Exchange of housing and base jaws

The base jaws and the guidance in the housing are matched. To exchange these parts, send the product with a repair order to

SCHUNK or order the housing with the base jaws as a set.

Maintenance of version with gripping force maintenance I.D.

gripping and O.D. gripping

The pistons have to be aligned using an assembly device. Therefore we recommend to have the module serviced and the seals replaced by SCHUNK.

Maintenance

08.00 | PZN-plus | Assembly and Operating Manual | en | 0389374

43

7.2 Maintenance intervals

NOTICE

Material damage due to hardening lubricants!

Lubricants harden more quickly at temperatures above 60°C,

leading to possible product damage.

• Reduce the lubricant intervals accordingly.

Interval (million cycles)

for PZN-plus

Maintenance work

40 - 160 200 - 300 380

10 5 0.05 Clean all parts thoroughly, check for

damage and wear, if necessary replace

seals and wearing parts,

Disassembly and assembly [}45].

The seals are in the enclosed sealing

kit., Sealing kit [}8].

10 5 0.05 Treat all grease areas with lubricant,

Lubricants/greasing areas (basic lubrication) [}44].

Oil or grease bare outside steel parts.

Maintenance

44

08.00 | PZN-plus | Assembly and Operating Manual | en | 0389374

7.3 Lubricants/greasing areas (basic lubrication)

SCHUNK recommends the lubricants listed.

During maintenance, treat all greased areas with lubricant. Thinly

apply lubricant with a lint-free cloth.

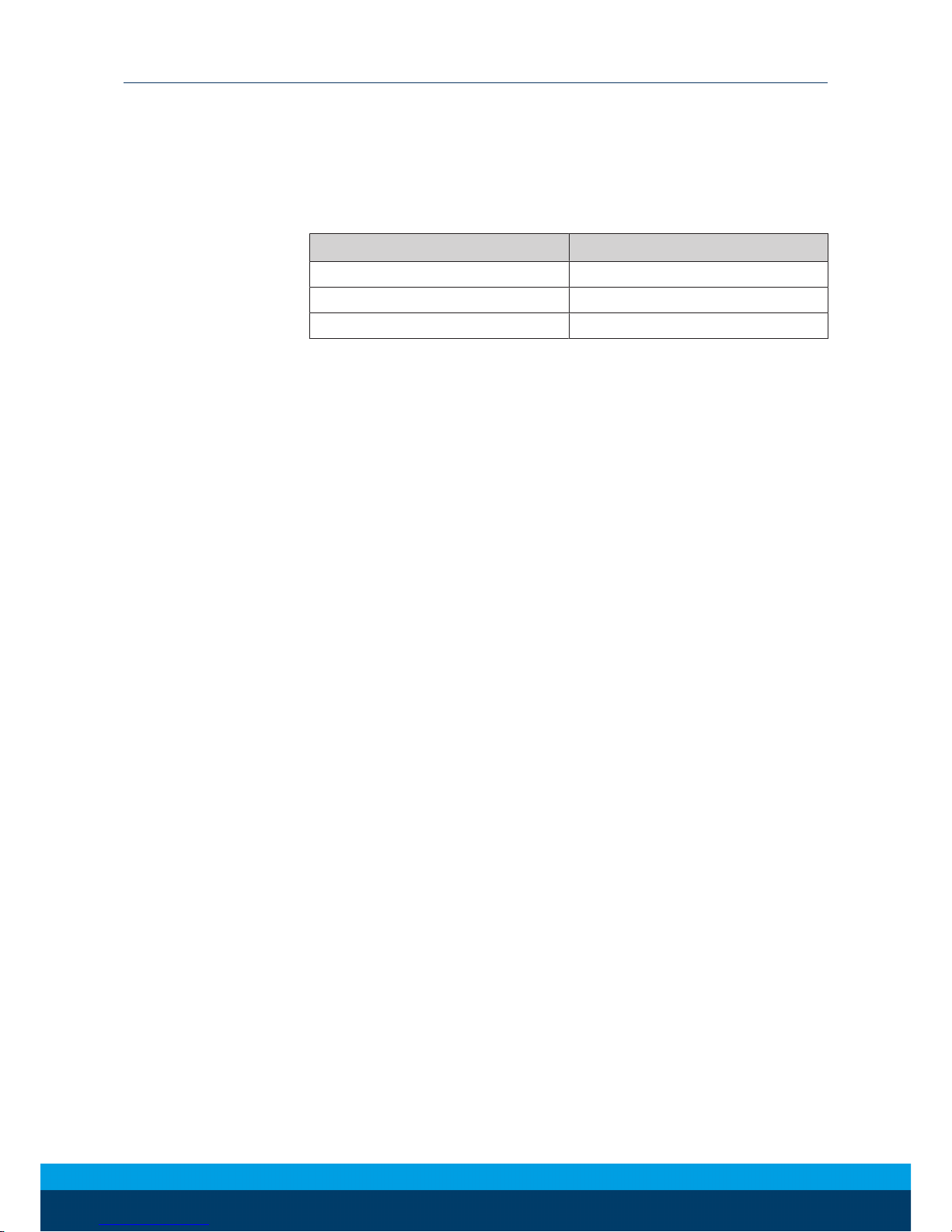

Lubricant point Lubricant

Metallic sliding surfaces microGLEIT GP 360

All seals Renolit HLT 2

Bore hole at the piston Renolit HLT 2

PZN-plus 40 - 300

Depending on the load, the guides in the housing can be

re-lubricated.

PZN-plus 380

The lubrication is made via the lubricating nipples on the lubricating hole. The other lubricating holes must be closed with a grub

screw. Therefore 15 ml of the lubricant have to be pumped in the

gripper using the lubricating nipples. After the lubricating process,

remove the lubricating nipples and close the lubricating hole with

a grub screw.

All other lubrication points like seal and hole at the piston must be

relubricated every 1 million cycles. Therefore the gripper must be

disassembled.

Maintenance

08.00 | PZN-plus | Assembly and Operating Manual | en | 0389374

45

7.4 Disassembly and assembly

7.4.1 Variant with dust cover

Position of the item numbers Variant with dust cover [}55]

The dust cover has to be removed in advance for versions with a

dust cover

Ø Unscrew and remove the screws (92) and remove the washers

(93) and the centering sleeves (86). Items 92 and 93 are only

used for securing devices for transportation.

Ø Pull out the intermediate jaws (84) upwards and remove the O-

rings (87) and the intermediate plates (83).

Ø Undo the countersunk screws (89) and remove the

cover plate (82).

Ø Unscrew the screws (90) and remove the covers (81).

7.4.2 Version without gripping force maintenance

Position of the item numbers Drawings [}53]

WARNING

Risk of injury due to unexpected movements!

If the power supply is switched on or residual energy remains in

the system, components can move unexpectedly and cause serious injuries.

• Before starting any work on the product: Switch off the power

supply and secure against restarting.

• Ensure that no residual energy remains in the system.

WARNING

In the case of the version with the pressure piece, the pressure

piece is spring-loaded!

Ø Remove air pressure lines.

Ø Carefully undo the set-screw (74) and pull out the pressure

piece.

Ø Undo the screws (47) and then remove the cover plate (5).

Ø Mark the installation position for the piston (3/8) and the base

jaw in the housing.

Ø Undo the screws (41) and then remove the cover (4).

Ø Mark the installation position between the cylinder piston (60)

and the housing (1). Fully undo the screw (40) and remove the

cylinder piston (60) from the housing (1).

Maintenance

46

08.00 | PZN-plus | Assembly and Operating Manual | en | 0389374

Ø Push the piston (3 / 8) upwards and out of the housing (1).

Ø Pull the base jaw (2 / 7) out of the housing (1).

7.4.3 Version with gripping force maintenance O.D.

Position of the item numbers Drawings [}53]

WARNING

Danger due to very high spring forces!

• With regard to size PZN-plus 240, 300 and 380 with gripping

force maintenance, we urgently recommend that you get

SCHUNK to disassemble the gripper for the purpose of maintenance and seal replacement

WARNING

Risk of injury due to spring forces!

When disassembling, the cover and the cylinder piston can be

thrown out by high spring forces.

• Secure the cover from being ejected during disassembly (e.g.

in a press)

WARNING

Risk of injury due to unexpected movements!

If the power supply is switched on or residual energy remains in

the system, components can move unexpectedly and cause serious injuries.

• Before starting any work on the product: Switch off the power

supply and secure against restarting.

• Ensure that no residual energy remains in the system.

Maintenance

08.00 | PZN-plus | Assembly and Operating Manual | en | 0389374

47

Ø Remove the compressed air lines.

Ø Unscrew the screws (47) and remove the cover plate (5).

Ø Mark the installation position of the piston (3) and the base

jaws (2) in the housing (1).

Ø Clamp the gripper with suitable plastic base (101) between the

base jaws (2) and the cover (9) in a press (100), so that the 8

screws (46) still can be removed.

Ø Unscrew the screws (46).

Ø Open press (100) carefully.

Ø Remove the cover (5).

Ø Remove centering pins (55).

Maintenance

48

08.00 | PZN-plus | Assembly and Operating Manual | en | 0389374

Ø Mark the installation position of the piston (60) and housing (1)

(observe position of the magnet).

Ø Clamp the gripper between the base jaws (2) an the cylinder

piston (60) in a press (100) with compression die (102) (mounting force F: Spring force information for assembly [}53]).

Ø Undo the screw (45) and then carefully open the press (100) un-

til the compression spring is fully extended.

Ø Remove the cylinder piston (60) and the compression springs

(25) from the housing (1).

Ø Push the piston (3) upwards and out of the housing (1).

Ø Pull the base jaws (2) out of the housing (1).

7.4.4 Version with gripping force maintenance I.D.

WARNING

Danger due to very high spring forces!

• With regard to size PZN-plus 240, 300 and 380 with gripping

force maintenance, we urgently recommend that you get

SCHUNK to disassemble the gripper for the purpose of maintenance and seal replacement!

Maintenance

08.00 | PZN-plus | Assembly and Operating Manual | en | 0389374

49

WARNING

Risk of injury due to spring forces

When disassembling, the cover can be thrown out by high spring

forces.

• Secure the cover from being ejected during disassembly (e.g.

in a press)

WARNING

Risk of injury due to unexpected movements!

If the power supply is switched on or residual energy remains in

the system, components can move unexpectedly and cause serious injuries.

• Before starting any work on the product: Switch off the power

supply and secure against restarting.

• Ensure that no residual energy remains in the system.

Ø Remove the compressed air lines.

Ø Undo the screws (47) and then remove the cover plate (5).

Ø Mark the installation position for the piston (3) and the base

jaw (2) in the housing (1).

Maintenance

50

08.00 | PZN-plus | Assembly and Operating Manual | en | 0389374

Ø Clamp the gripper with suitable plastic base (101) between the

base jaws (2) and the cover (9) in a press (100), so that the

screws (46) still can be removed.

Ø Unscrew the screws (46).

Ø Open press (100) carefully. until the compression spring is no

longer under tension.

Ø Remove cover and compression springs.

Ø Mark the installation position for the piston (60) an the housing

(1).

Ø Undo the screws (40)

Ø Remove the cylinder piston (60) out of the housing (1).

Ø Push the pistons (3) upwards out of the housing (1).

Ø Pull the base jaws (2) out of the housing (1).

7.4.5 Version with force amplification cylinder (KVZ)

WARNING

Danger due to very high spring forces!

• With regard to size PZN-plus 240, 300 and 380 with gripping

force maintenance, we urgently recommend that you get

SCHUNK to disassemble the gripper for the purpose of maintenance and seal replacement

WARNING

Risk of injury due to spring forces

When disassembling, the cover can be thrown out by high spring

forces.

• Secure the cover from being ejected during disassembly (e.g.

in a press)

WARNING

Risk of injury due to unexpected movements!

If the power supply is switched on or residual energy remains in

the system, components can move unexpectedly and cause serious injuries.

• Before starting any work on the product: Switch off the power

supply and secure against restarting.

• Ensure that no residual energy remains in the system.

Maintenance

08.00 | PZN-plus | Assembly and Operating Manual | en | 0389374

51

WARNING

For the version with pressure piece, the spring-loaded pressure

piece is under spring tension!

Ø Remove air pressure lines.

Ø Undo the screws (47) and then remove the cover plate (5).

Ø Mark the installation position for the piston (3) and the base

jaw (2) in the housing (1).

Ø Version with gripping force maintenance (A.D.) or (O.D.): As

described in the previous chapters Version with gripping force

maintenance O.D. [}46]/Version with gripping force mainten-

ance I.D. [}48], clamp the gripper into a press and remove the

screws (54).

Version without gripping force maintenance: Remove the

screws (54) and then remove the cover (4).

Ø Unscrew the screw (51) and remove the cylinder piston (6) and

the spacer piston (66) from the intermediate housing (65).

Ø Remove the intermediate housing (65).

Maintenance

52

08.00 | PZN-plus | Assembly and Operating Manual | en | 0389374

Ø Mark the installation position between the cylinder piston (60)

and the housing (1). Remove the cylinder piston (60) from the

housing (1).

Ø Push the piston (3) upwards and out of the housing (1).

Ø Pull the base jaws (2) out of the housing (1).

7.4.6 Notes for assembly

Assembly takes place in the opposite order to disassembly. Observe the following:

• Unless otherwise specified, secure all screws and nuts with Loctite no. 243 and tighten with the appropriate tightening torque.

Screw tightening torques [}53]

• For variant with gripping force maintenance: assemble cylinder

piston using a press, Version without gripping force mainten-

ance [}45].

• During assembly, observe the spring forces, Spring force inform-

ation for assembly [}53]

Maintenance

08.00 | PZN-plus | Assembly and Operating Manual | en | 0389374

53

7.4.7 Screw tightening torques

Position of the item numbersDrawings [}53]

Tightening torque [Nm]

Item

Size

40 50 64 80 100 125 160 200 240 300 380

40 2.2 5.9 12 12 20 49 96 150 150 250 415

41 0.45 1.2 1.2 1.3 1.3 2.9 8.5 20 20 35 58

45 4.9 10 14 14 29 57.5 96 200 200 250 692

46 0.45 1.2 1.2 1.3 2.9 6 10 25 25 50 50

51 - - 12 12 20 49 96 - - - -

7.4.8 Spring force information for assembly

Size

40 50 64 80 100 125 160 200 240 300 380

with gripping force maintenance O.D. gripping

preload [mm] 14 6 15 27 24 29 47 55 25 90 47

spring force [N] 174 132 261 496 875 1253 2372 4982 5016 9465 1013

0

with gripping force maintenance I.D. gripping

preload [mm] 10 14 46 36 46 71 96 100 48 100 63

spring force [N] 111 183 388 701 1389 2037 3927 7373 6267 134641416

3

7.5 Drawings

The following figures are example images.

They serve for illustration and assignment of the spare parts.

Variations are possible depending on size and variant.

Maintenance

54

08.00 | PZN-plus | Assembly and Operating Manual | en | 0389374

7.5.1 Basic module

Assembly of the variants "O.D. gripping" / "I.D. gripping" / without gripping force maintenance

1*

Wearing part, replace during maintenance.

Included in the seal kit. Seal kit can only be ordered completely.

2* Positions are adapted to each other and can not be replaced by the customer.

3* not for PZN-plus 40 - 125

4* from size PZN-plus 125

Maintenance

08.00 | PZN-plus | Assembly and Operating Manual | en | 0389374

55

7.5.2 Variant with dust cover

Maintenance

56

08.00 | PZN-plus | Assembly and Operating Manual | en | 0389374

7.5.3 Variant with force amplification cylinder

1* Wearing part, replace during maintenance.

Included in the seal kit. Seal kit can only be ordered com-

pletely.

2* not for PZN-plus 64 - 125

3* from size PZN-plus 125

4* from size PZN-plus 160

Translation of original declaration of incorporation

08.00 | PZN-plus | Assembly and Operating Manual | en | 0389374

57

8 Translation of original declaration of incorporation

in terms of the Directive 2006/42/EG, Annex II, Part 1.B of the European Parliament and of

the Council on machinery.

Manufacturer/

Distributor

SCHUNK GmbH & Co. KG Spann- und Greiftechnik

Bahnhofstr. 106 – 134

D-74348 Lauffen/Neckar