3-finger centric gripper

Original operating manual

PZH-plus 020-075

Assembly and Operating Manual

Superior Clamping and Gripping

Imprint

Dear customer,

Kindest Regards

Yours SCHUNK GmbH & Co. KG

Imprint

Copyright:

This manual remains the copyrighted property of SCHUNK GmbH & Co. KG. It is solely supplied to our customers and operators of our products and forms part of the product. This

documentation may not be duplicated or made accessible to third parties, in particular competitive companies,

without our prior permission.

Technical changes:

We reserve the right to make alterations for the purpose of technical improvement.

Document number: 0389504

Edition: 02.00 |26/10/2016|en

© SCHUNK GmbH & Co. KG

All rights reserved.

congratulations on choosing a SCHUNK product. By choosing SCHUNK, you have opted for

the highest precision, top quality and best service.

You are going to increase the process reliability of your production and achieve best

machining results – to the customer's complete satisfaction.

SCHUNK products are inspiring.

Our detailed assembly and operation manual will support you.

Do you have further questions? You may contact us at any time – even after purchase.

Spann- und Greiftechnik

Bahnhofstr. 106 – 134

D-74348 Lauffen/Neckar

Tel. +49-7133-103-0

Fax +49-7133-103-2399

www.schunk.com

2 02.00|PZH-plus 020-075|en

info@de.schunk.com

Table of contents

075|en

Table of contents

1

General .............................................................................................................................. 5

1.1

About this manual ............................................................................................................. 5

1.1.1

Presentation of Warning Labels ........................................................................... 5

1.1.2

Applicable documents........................................................................................... 6

1.1.3

Sizes ........................................................................................................................ 6

1.2

Warranty ............................................................................................................................ 6

1.3

Scope of delivery ................................................................................................................ 6

1.3.1

Accessory pack ....................................................................................................... 6

1.4

Accessories ......................................................................................................................... 7

1.4.1

Seal kit .................................................................................................................... 7

1.4.2

Mounting kit for proximity switch IN ................................................................... 7

1.4.3

Pressure piece assembly kit .................................................................................. 7

2

Basic safety notes ............................................................................................................. 8

2.1

Intended use ...................................................................................................................... 8

2.2

Not intended use ............................................................................................................... 8

2.3

Constructional changes ..................................................................................................... 8

2.4

Spare parts ......................................................................................................................... 8

2.5

Gripper fingers .................................................................................................................. 9

2.6

Environmental and operating conditions ........................................................................ 9

2.7

Personnel qualification ...................................................................................................... 9

2.8

Personal protective equipment ...................................................................................... 10

2.9

Notes on safe operation .................................................................................................. 11

2.10

Transport .......................................................................................................................... 11

2.11

Malfunctions .................................................................................................................... 11

2.12

Disposal ............................................................................................................................ 12

2.13

Fundamental dangers...................................................................................................... 12

2.13.1

Protection during handling and assembly ......................................................... 12

2.13.2

Protection during commissioning and operation ............................................. 13

2.13.3

Protection against dangerous movements ....................................................... 13

2.13.4

Protection against electric shock ....................................................................... 14

2.14

Notes on particular risks ................................................................................................. 14

3

Technical data .................................................................................................................. 16

4

Design and description .................................................................................................... 17

4.1

Configuration ................................................................................................................... 17

4.2

Description ....................................................................................................................... 17

5

Assembly ......................................................................................................................... 18

02.00|PZH-plus 020-

3

Table of contents

5.1

Connections ..................................................................................................................... 18

5.1.1

Mechanical connection ....................................................................................... 18

5.1.2

Air connection ..................................................................................................... 20

5.2

Mounting the sensor ....................................................................................................... 22

5.2.1

Overview of sensors ............................................................................................ 22

5.2.2

IN 80 inductive proximity switch ........................................................................ 23

5.2.3

MMS 22 magnetic switch ................................................................................... 25

5.2.4

MMS-P programmable magnetic switch ........................................................... 27

6

Troubleshooting .............................................................................................................. 32

6.1

Product is not moving ..................................................................................................... 32

6.2

The module does not travel through the entire stroke? .............................................. 32

6.3

Product opens or closes abruptly ................................................................................... 33

6.4

The gripping force is dropping ........................................................................................ 33

6.5

Product does not achieve the opening and closing times ............................................ 34

7

Maintenance .................................................................................................................... 35

7.1

Notes................................................................................................................................. 35

7.2

Maintenance and lubrication intervals .......................................................................... 35

7.3

Lubricants/Lubrication points ......................................................................................... 35

7.4

Disassembly of the module ............................................................................................ 36

7.4.1

Assembly tool X ................................................................................................... 37

7.4.2

Assembly tool Y ................................................................................................... 38

7.5

Servicing and assembling the module ............................................................................ 39

7.5.1

Screw tightening torques .................................................................................... 39

8

Assembly drawing ........................................................................................................... 40

9

Translation of original declaration of incorporation ........................................................ 41

10

Annex to Declaration of Incorporation ............................................................................ 42

4 02.00|PZH-plus 020-075|en

General

075|en

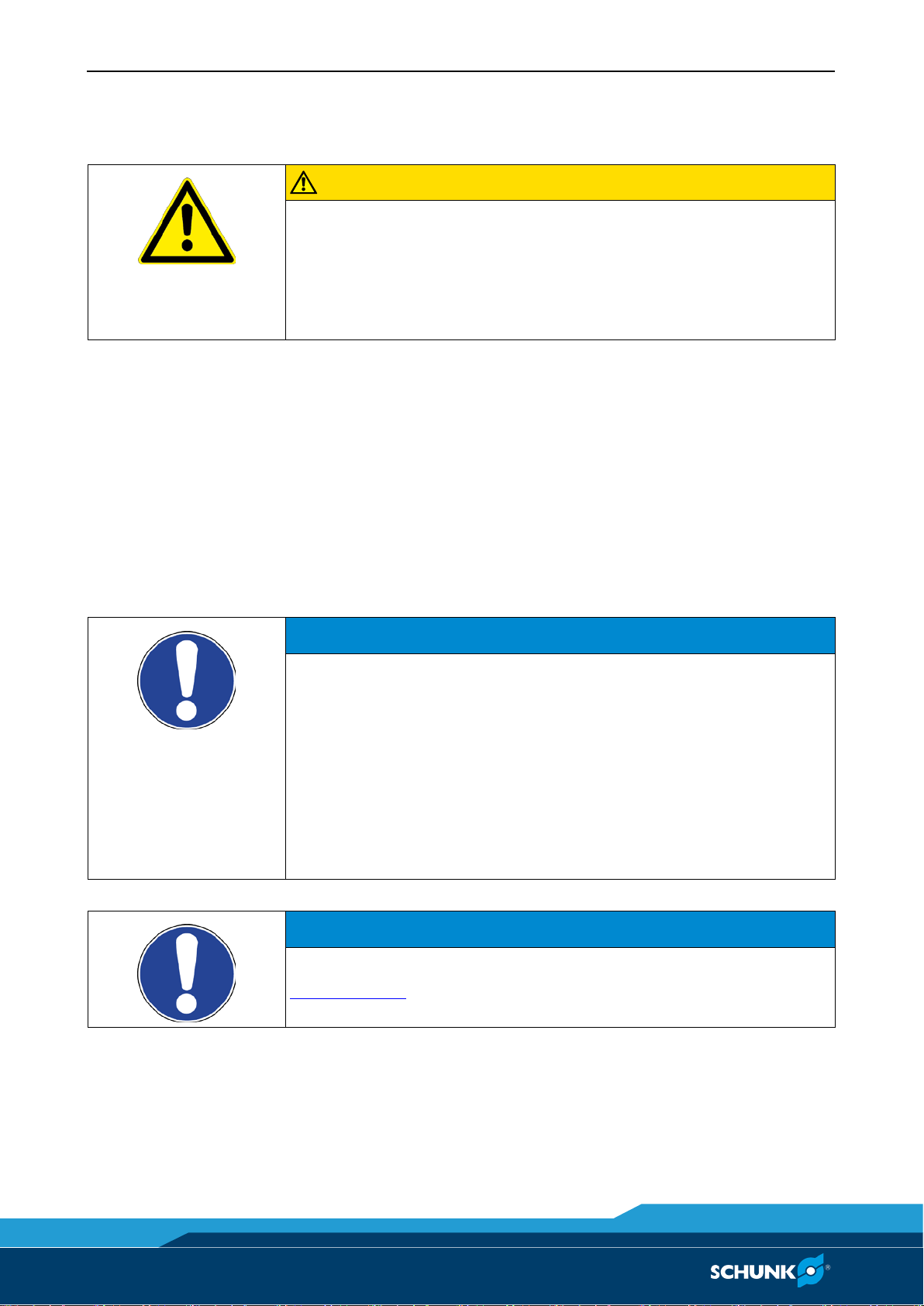

DANGER

Danger for persons!

WARNING

Dangers for persons!

CAUTION

Dangers for persons!

NOTICE

Material damage!

1

1.1

1.1.1

General

About this manual

This manual contains important information for a safe and appropriate use of the product.

This manual is an integral part of the product and must be kept accessible for the personnel at all times.

Before starting work, the personnel must have read and understood

this operating manual. Prerequisite for safe working is the observance of all safety instructions in this manual.

Illustrations in this manual are provided for basic understanding and

may differ from the actual product design.

In addition to these instructions, the documents listed under

( 1.1.2, Page 6)

Presentation of Warning Labels

are applicable.

To make risks clear, the following signal words and symbols are used

for safety notes.

Non-observance will inevitably cause irreversible injury or death.

Non-observance can lead to irreversible injury and even death.

Non-observance can cause minor injuries.

Information about avoiding material damage.

02.00|PZH-plus 020-

5

General

Accessory pack for

ID number

PZH-plus 20

5522173

PZH-plus 30

5522174

PZH-plus 50

5522175

PZH-plus 75

5522176

1.1.2

1.1.3

1.2

1.3

1.3.1

Applicable documents

• General terms of business *

• Catalog data sheet of the purchased product *

• Assembly and Operating manuals of the accessories *

The documents marked with an asterisk (*) can be downloaded on

our homepage www.schunk.com.

Sizes

This operating manual applies to the following sizes:

• PZH-plus 20

• PZH-plus 30

• PZH-plus 50

• PZH-plus 75

Warranty

If the product is used as intended, the warranty is valid for 24 months

from the ex-works delivery date under the following conditions:

• Intended use in 1-shift operation

• Observe the mandatory maintenance and lubrication intervals

• Observe the environmental and operating conditions

Parts touching the work piece and wear parts are not part of the warranty.

Scope of delivery

The scope of delivery includes

• 3-finger centric gripper PZH-plus in the version ordered

• Accessory pack

Accessory pack

6 02.00|PZH-plus 020-075|en

ID.-No. of the accessory pack

Content of the accessories pack: ( 8, Page 40).

General

075|en

Seal kit for

ID number

PZH-plus 20

5522219

PZH-plus 30

5522220

PZH-plus 50

5522221

PZH-plus 75

5522222

ID number

PZH-plus

0305364

Assembly kit for

ID number

PZH-plus 20

0305363

PZH-plus 30

0305373

PZH-plus 50

0305383

PZH-plus 75

0305393

1.4

1.4.1

1.4.2

1.4.3

Accessories

A wide range of accessories are available for this product

For information about which accessories can be used with the appropriate product version see catalog.

Seal kit

ID.-No. of the seal kit

Contents of the sealing kit, ( 8, Page 40).

Mounting kit for proximity switch IN

ID no. of the mounting kit

Pressure piece assembly kit

ID no. of the assembly kit

02.00|PZH-plus 020-

7

Basic safety notes

2

2.1

2.2

2.3

2.4

Basic safety notes

Intended use

The product is designed exclusively for gripping and temporarily holding workpieces or objects.

• The product may only be used within the scope of its technical da-

ta, ( 3, Page 16)

.

• The product is intended for installation in a machine/system. The

applicable guidelines must be observed and complied with.

• The product is intended for industrial use.

• Appropriate use of the product includes compliance with all instructions in this manual.

Not intended use

It is not intended use if the product is used, for example, as a pressing

tool, stamping tool, lifting gear, guide for tools, cutting tool, clamping

device or a drilling tool.

• Any utilization that exceeds or differs from the appropriate use is

regarded as misuse.

Constructional changes

Making constructional changes

Modifications, constructional changes and subsequent work, e.g. additional threads, drill holes and safety devices may impair the operation and safety or damage the product.

• Constructional changes may only be done with SCHUNK's permission.

Spare parts

Use of unauthorised spare parts

Using unauthorised spare parts can endanger personnel and damage

the product or cause it to malfunction.

• Use only original spare parts or spares authorised by SCHUNK.

8 02.00|PZH-plus 020-075|en

Basic safety notes

075|en

Gripper fingers

2.5

2.6

2.7

Trained electrician

Requirements for the gripper fingers

Stored energy within the product creates the risk of serious injuries

and significant property damage.

• Arrange the gripper fingers in a way that the product reaches either the position "open" or "closed" in a de-energized state.

• Only exchange the gripper fingers when no residual energy remains in the product.

Environmental and operating conditions

Required ambient conditions and operating conditions

Incorrect ambient and operating conditions can make the product

unsafe, leading to the risk of serious injuries, considerable material

damage and/or a significant reduction to the product's life span.

• Make sure that the product and the top jaws are a sufficient size

for the application.

• Observe maintenance and lubrication intervals, ( 7.2, Page 35)

.

• Make sure that the environment is free from splash water and

vapors as well as from abrasion or processing dust. Exceptions are

products that are designed especially for contaminated environments.

Personnel qualification

Inadequate qualifications of the personnel

If the personnel working with the product is not sufficiently qualified,

the result may be serious injuries and significant property damage.

• All work may only be performed by qualified personnel.

• Before working with the product, the personnel must have read

and understood the complete assembly and operating manual.

• Observe the national safety regulations and rules and general

safety instructions.

The following personal qualifications are necessary for the various activities related to the product:

Due to their technical training, knowledge and experience, trained

electricians are able to work on electrical systems, recognize and

02.00|PZH-plus 020-

9

Basic safety notes

avoid possible dangers and know the relevant standards and regula-

Pneumatics specialist

Hydraulic specialist

Qualified personnel

Instructed person

Service personnel of

the manufacturer

2.8

tions.

Pneumatics specialists have been trained for this particular area of

responsibility and know the relevant standards and regulations.

Hydraulic specialists have been trained for this particular area of responsibility and knows the relevant standards and regulations.

Due to its technical training, knowledge and experience, qualified

personnel is able to perform the delegated tasks, recognize and avoid

possible dangers and knows the relevant standards and regulations.

Instructed persons were instructed by the operator about the delegated tasks and possible dangers due to improper behaviour.

Due to its technical training, knowledge and experience, service personnel of the manufacturer is able to perform the delegated tasks

and to recognize and avoid possible dangers.

Personal protective equipment

Using personal protective equipment

Not wearing personal protective equipment while working with the

product, may result in dangers that impact the personnel's safety and

health.

• While working with the product, observe the health and safety

regulations and wear the required personal safety equipment.

• Observe the valid safety and accident prevention regulations.

• In case of sharp edges and corners and rough surfaces, wear protection gloves.

• In case of hot surfaces, wear heat-resistant protection gloves.

• When dealing with hazardous substances, wear protection gloves

and goggles.

• In case of moving parts, wear tight protection clothes.

10 02.00|PZH-plus 020-075|en

Basic safety notes

075|en

Notes on safe operation

2.9

2.10

2.11

Incorrect handling of the personnel

Incorrect handling and assembly may impair the product's safety and

cause serious injuries and considerable material damage.

• Avoid any manner of working that may interfere with the function

and operational safety of the product.

• Use the product as intended.

• Observe the safety notes and assembly instructions.

• Do not expose the product to any corrosive media. This does not

apply to products that are designed for special environments.

• Eliminate any malfunction immediately.

• Observe the care and maintenance instructions.

• Observe the current safety, accident prevention and environmental protection regulations regarding the product's application

field.

Transport

Handling during transport

Incorrect handling during transport may impair the product's safety

and cause serious injuries and considerable material damage.

• When handling heavy weights, use lifting equipment to lift the

product and transport it by appropriate means.

• Secure the product against falling during transportation and handling.

• Stand clear of suspended loads.

Malfunctions

Behavior in case of malfunctions

• Immediately remove the product from operation and report the

malfunction to the responsible departments/persons.

• Order appropriately trained personnel to rectify the malfunction.

• Do not recommission the product until the malfunction has been

rectified.

• Test the product after a malfunction to establish whether it still

functions properly and no increased risks have arisen.

02.00|PZH-plus 020-

11

Basic safety notes

2.12

2.13

2.13.1

Disposal

Handling of disposal

The incorrect handling of disposal may impair the product's safety

and cause serious injuries as well as considerable material and environmental harm.

• Follow local regulations on dispatching product components for

recycling or proper disposal.

Fundamental dangers

General

• Observe safety distances.

• Never deactivate safety installations.

• Install the provided protective product in the danger zone before

switching on the product.

• Remove energy supplies before the installation, modification,

maintenance or adjustment work. Make sure that no residual energy is remaining in the system.

• Do not move parts by hand while the energy supply is connected.

• Do not reach into the open mechanism or movement area of the

product during operation.

Protection during handling and assembly

Incorrect handling and assembly

Incorrect handling and assembly may impair the product's safety and

cause serious injuries and considerable material damage.

• Have all work carried out by appropriately qualified personnel.

• For all work, secure the product against accidental operation.

• Observe the relevant accident prevention rules.

• Use suitable assembly and transport equipment and take precautions to prevent jamming and crushing.

12 02.00|PZH-plus 020-075|en

Incorrect lifting of loads

Falling loads may cause serious injuries and even death.

• Stand clear of suspended loads and do not step into their swiveling range.

• Never move loads without supervision.

• Do not leave suspended loads unattended.

Basic safety notes

075|en

Protection during commissioning and operation

2.13.2

2.13.3

Falling or violently ejected components

Falling and violently ejected components can cause serious injuries

and even death.

• The danger zone must be cordoned off by a protective barrier.

• Never step into the danger zone during operation.

Protection against dangerous movements

Unexpected movements

Residual energy in the system may cause serious injuries while working with the product.

• Switch off the energy supply and ensure that no residual energy

remains.

• Never rely solely on the response of the monitoring function to

avert danger. Until the installed monitors become effective, it

must be assumed that the drive movement is faulty, with its action being dependent on the control unit and the current operating condition of the drive. Perform maintenance work, modifications, and attachments outside the danger zone defined by the

movement range.

• To avoid accidents and/or material damage, human access to the

movement range of the machine must be restricted. Restrict unintentional access by persons to this range e.g. via a protective

cover, protective fence or photoelectric barrier. The protective

cover and protective fence must be rigid enough to withstand the

maximum possible movement energy. EMERGENCY STOP switches must be easily and quickly accessible. Check the function of the

EMREGENCY STOP before starting up the machine or system. If

this protective equipment is not working properly, prevent the

operation of the machine.

02.00|PZH-plus 020-

13

Basic safety notes

Protection against electric shock

DANGER

Risk of fatal injury from suspended loads!

• Wear suitable protective equipment.

WARNING

Risk of injury from objects falling and being ejected!

• The danger zone must be cordoned off by a protective barrier.

2.13.4

2.14

Possible electrostatic energy

Components or assembly groups may become electrostatically

charged. When the electrostatic charge is touched, the discharge

may trigger a shock reaction leading to injuries.

• The operator must ensure that all components and assembly

groups are included in the local equipotential bonding in accordance with the applicable regulations.

• While paying particulary attention to the actual conditions of the

working environment, the equipotential bonding must be implemented by a specialist electrician according to the applicable regulations.

• The effectiveness of the equipotential bonding must be verified

by executing regular safety measurements.

Notes on particular risks

Falling loads can cause serious injuries and even death.

• Stand clear of suspended loads and do not step within their

swiveling range.

• Never move loads without supervision.

• Do not leave suspended loads unattended.

Falling and ejected objects during operation can lead to serious injury or death.

14 02.00|PZH-plus 020-075|en

Basic safety notes

075|en

WARNING

Risk of injury from uncontrolled movements!

• Make sure there is no residual energy in the system

WARNING

Risk of injury due to squeezing and bumping!

movement range.

WARNING

Risk of injury from sharp edges and corners!

• Use suitable protective equipment.

WARNING

Risk of injury due to spring forces!

• Make sure that no residual energy remains in the system.

WARNING

Risk of injury from objects falling during energy supply failure

pressure maintenance valves.

system, parts may move unexpectedly and cause serious injuries.

• Switch off energy supply.

If the energy supply is switched on or residual energy remains in the

Moving the base jaws and breaking or loosening the gripper fingers

may cause serious injuries.

• Do not reach into the product's open mechanical system or

Sharp edges and corners can cause cuts.

Parts are under spring tension on modules which clamp using spring

force or which have gripping force maintenance. While disassembling it is possible that the gripper’s parts move uncontrollably and

cause serious injuries.

• Disassemble the product cautiously.

Products with a mechanical gripping force maintenance can, during

energy supply failure, still move independently in the direction specified by the mechanical gripping force maintenance.

• Secure the end positions of the product with SCHUNK SDV-P

02.00|PZH-plus 020-

15

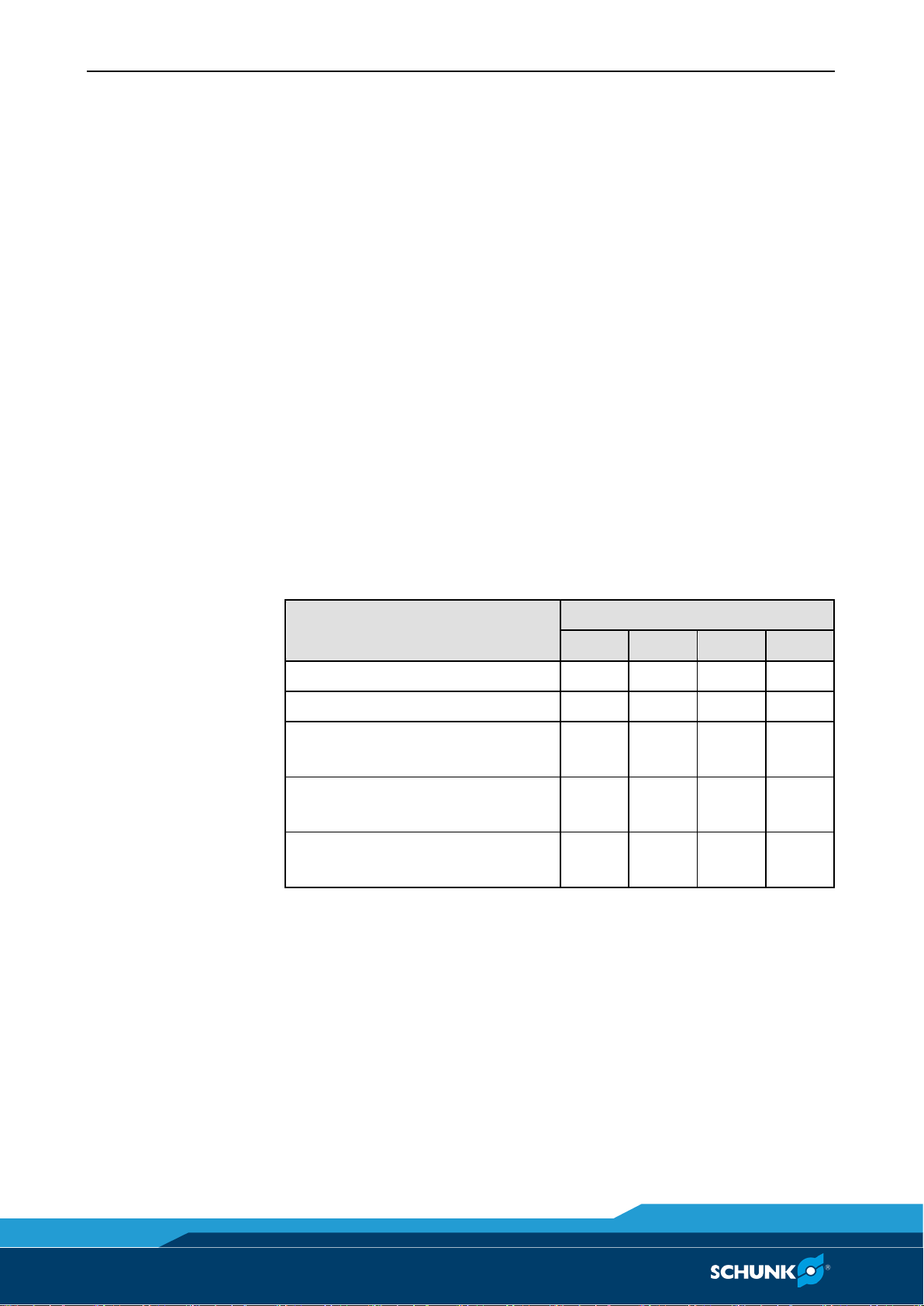

Technical data

Pressure medium

Compressed air, compressed air

1:7 4 4

Nominal working pressure [bar]

6

Min. pressure [bar]

2

Max. pressure [bar]

8

Pressure range for

air purge [bar]

0,5 – 1

Noise emission [dB(A)]

≤ 70

3

Technical data

quality according to ISO 8573-

More technical data are included in the catalog data sheet. Whichever is the latest version.

16 02.00|PZH-plus 020-075|en

Design and description

075|en

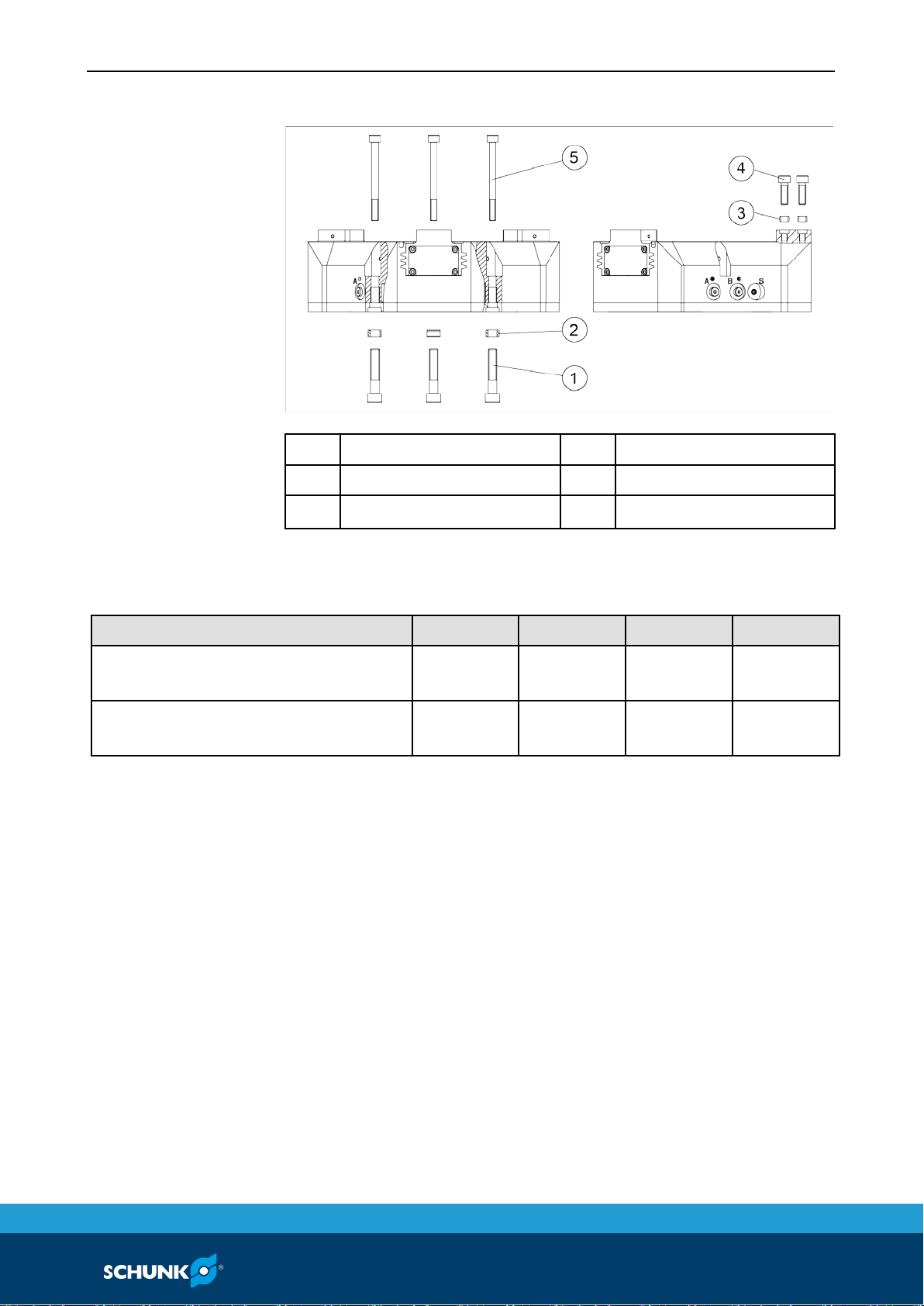

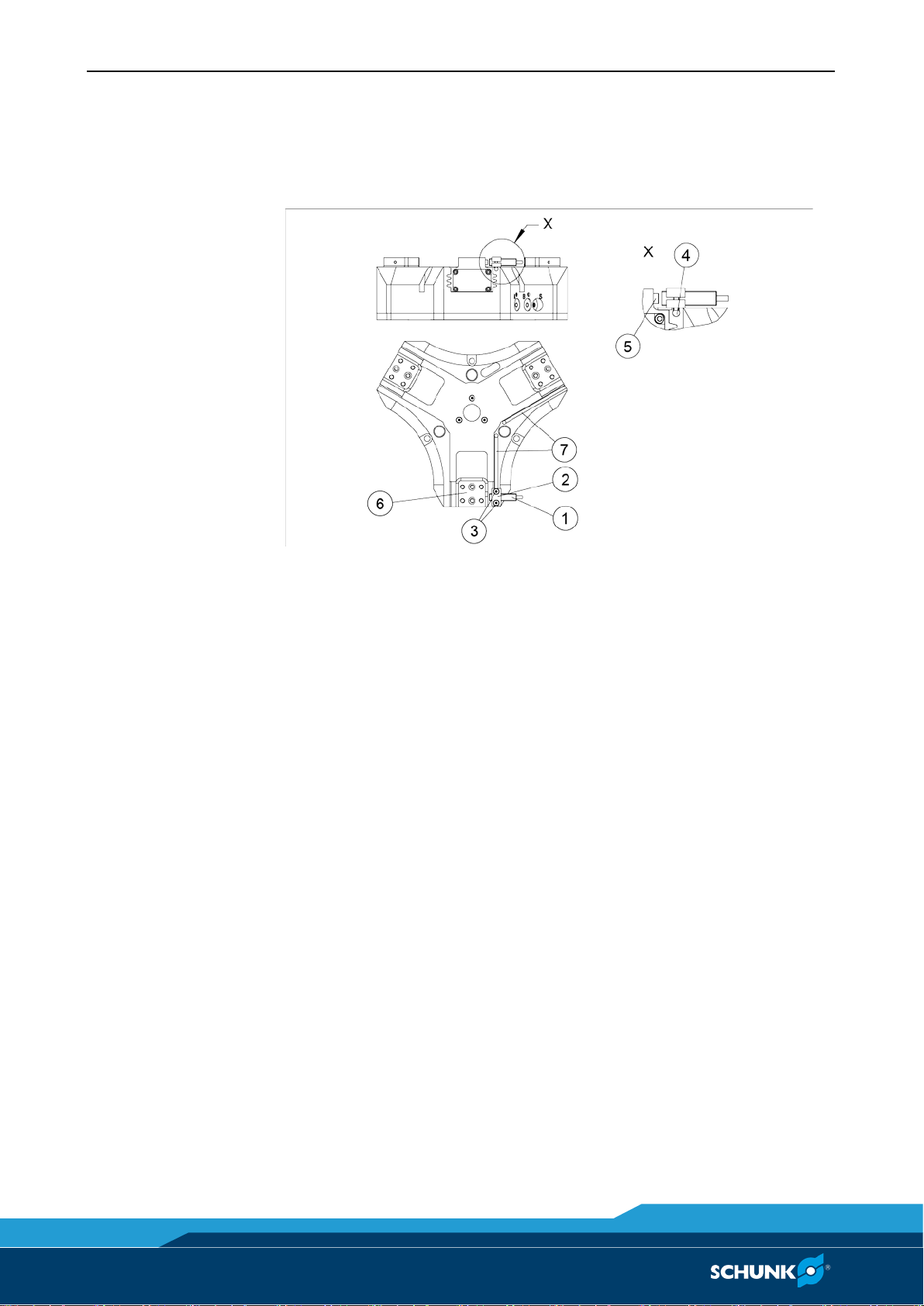

1

Housing

2

Air purge connection

3

Main air connections

4

Base jaws

4

4.1

4.2

Design and description

Configuration

3-finger centric gripper

Description

Universal centric gripper with high gripping force and maximum moments due to multi-tooth guidance

02.00|PZH-plus 020-

17

Assembly

Diameter

Permissible unevenness

< 100

< 0.02

> 100

< 0.05

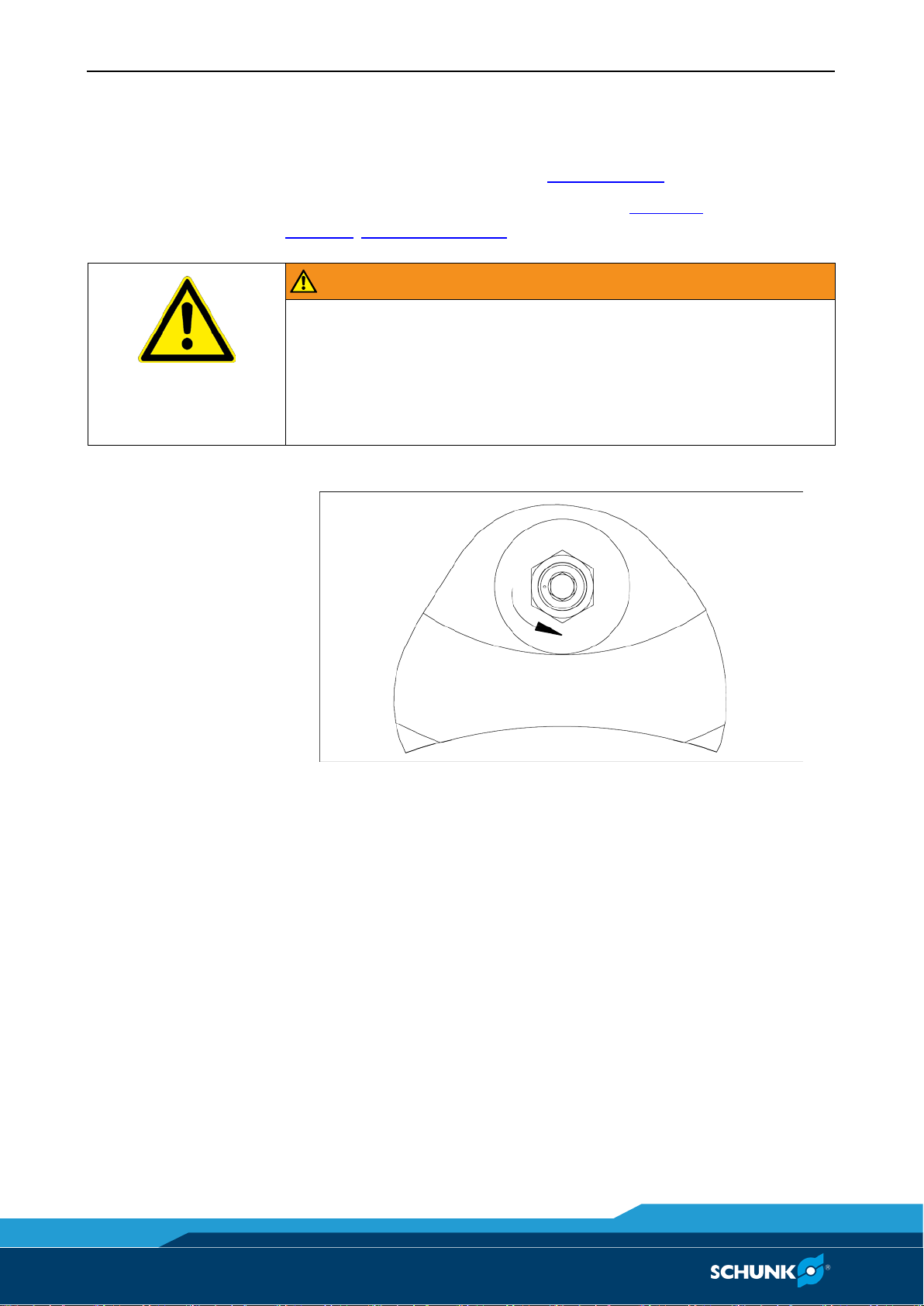

WARNING

Risk of injury if the unit falls during transport or assembly!

• The gripper is to be hoisted by the three transport threads.

5

5.1

5.1.1

Levelness of the

mounting surface

Assembly

Connections

Mechanical connection

The values apply to the whole mounting surface to which the product

is mounted.

Requirements for levelness of the mounting surface (Dimensions in mm)

• Secure the unit during transport and assembly by sufficiently

large aids.

Handling with large weight for PZH-plus 75

Eye bolts in the transport threads

18 02.00|PZH-plus 020-075|en

Assembly

075|en

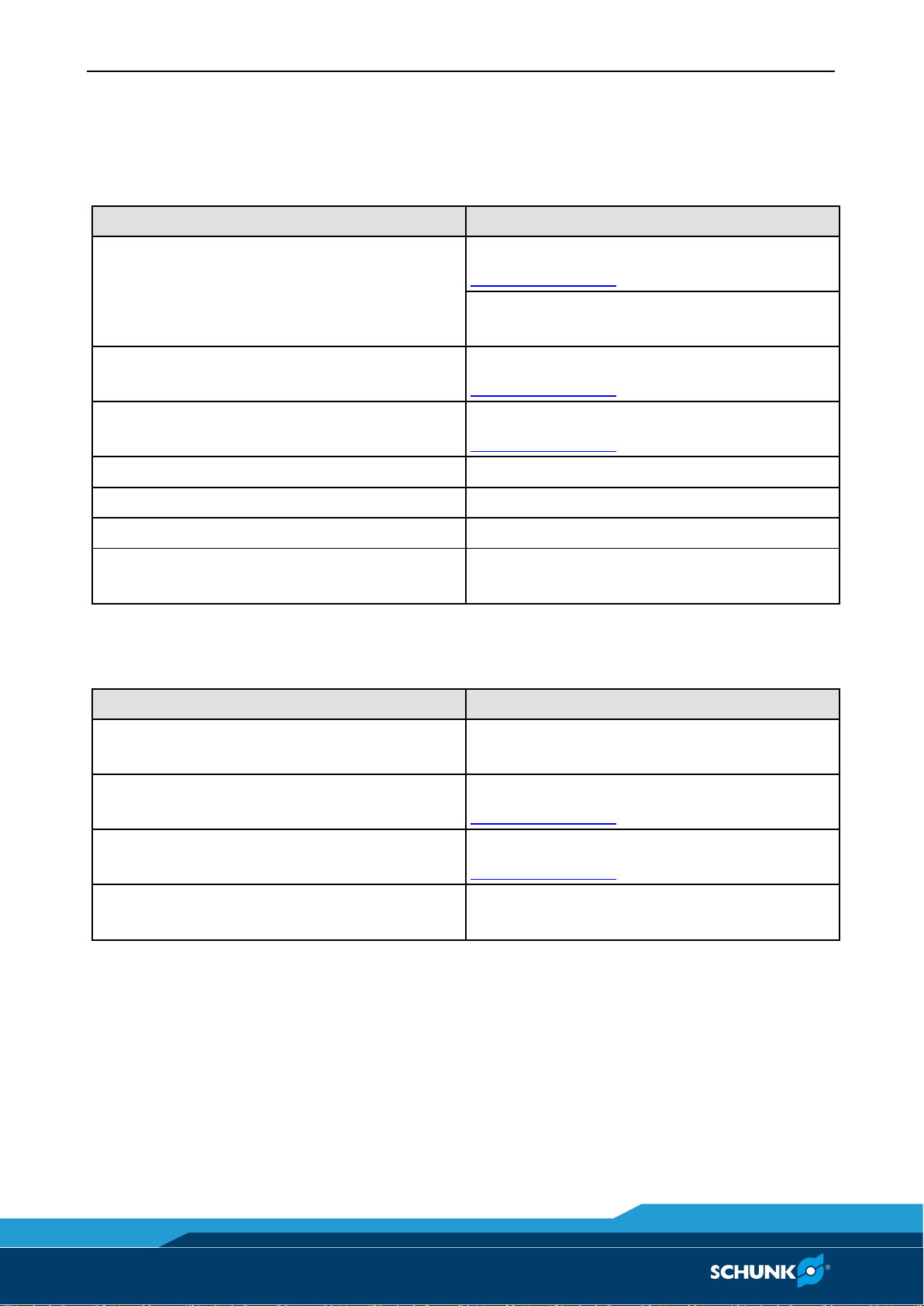

1

Mounting from the rear

4

Finger mounting

2

Centering sleeves

5

Mounting from the front

3

Centering sleeves

Size

20

30

50

75

Thread diameter and max. depth of

engagement for rear mounting

M6

15 deep

M8

22 deep

M10

24 deep

M12

34 deep

Thread diameter and max. depth of

engagement for finger mounting

M4

10 deep

M5

10 deep

M5

10 deep

M10

17 deep Mounting

The module can be mounted from the front or the rear.

Mounting material

The centering sleeves (2 / 3) are included in the accessory pack.

02.00|PZH-plus 020-

19

Assembly

CAUTION

The spring-loaded pressure piece is under spring tension.

springs.

NOTICE

Damage to the gripper is possible!

• Observe the diagrams and information in the catalog data sheet.

NOTICE

Observe the requirements for the air supply

5.1.1.1

5.1.2

Mounting of the gripper by using a spring loaded pressure-piece

contusions.

• During assembly or disassembly, be especially careful with the

The pressure piece can fly out in an uncontrolled fashion and cause

When mounting the gripper from the side of the gripper fingers, the

assembly of the pressure piece must be done after the mounting of

the gripper.

Mounting the pressure piece is described in the insert "Installation

instructions - pressure piece", which is included in the pressure

piece's scope of delivery.

Air connection

If the maximum permissible finger weight or the permissible mass

moment of inertia of the fingers is exceeded, the gripper can be

damaged.

• A jaw movement always has to be without jerks and bounce.

• You must therefore implement sufficient reduction and/or

damping.

( 3, Page 16).

20 02.00|PZH-plus 020-075|en

Assembly

075|en

Item

Connection

1

Hose connection (A = open, B = close)

2

Air purge connection

3

Hose-free direct connection (a = open, b = close)

4

Direct connection for air purge

Air connection

• Only open the air connections required.

• For hose-free direct connections, use the O-rings from the accessory pack.

• If the maximum permitted finger weight is exceeded, a reduction

is imperative so that the jaw movement occurs without any hitting or bouncing.

Further information on the hose-free direct connection contains the

catalog data sheet.

02.00|PZH-plus 020-

21

Assembly

Mounting the sensor

NOTE

Observe the assembly and operating manual of the sensor for

mounting and connecting.

Designation

PZH-plus

20

30

50

75

Inductive Proximity Switch IN 80

x x x

x

Magnetic Switch MMS 22

x x x

x

Programmable Magnetic Switch

MMS-22 PI1

x x x

x

Programmable Magnetic Switch

MMS-22 PI2

x x -

-

Programmable Magnetic Switch

MMS-P 22

x x -

-

5.2

5.2.1

The product is prepared for using sensors

• Exact type designation of the compatible sensors, see catalog.

• Technical data of the matching sensors, see assembly and operating manual and data sheet.

– The assembly and operating manual and the catalogue data

sheet are included in the scope of delivery and can be downloaded from www.schunk.com.

• If you require further information on sensor operation, contact

your SCHUNK contact person or download information from our

homepage.

Overview of sensors

22 02.00|PZH-plus 020-075|en

Assembly

075|en

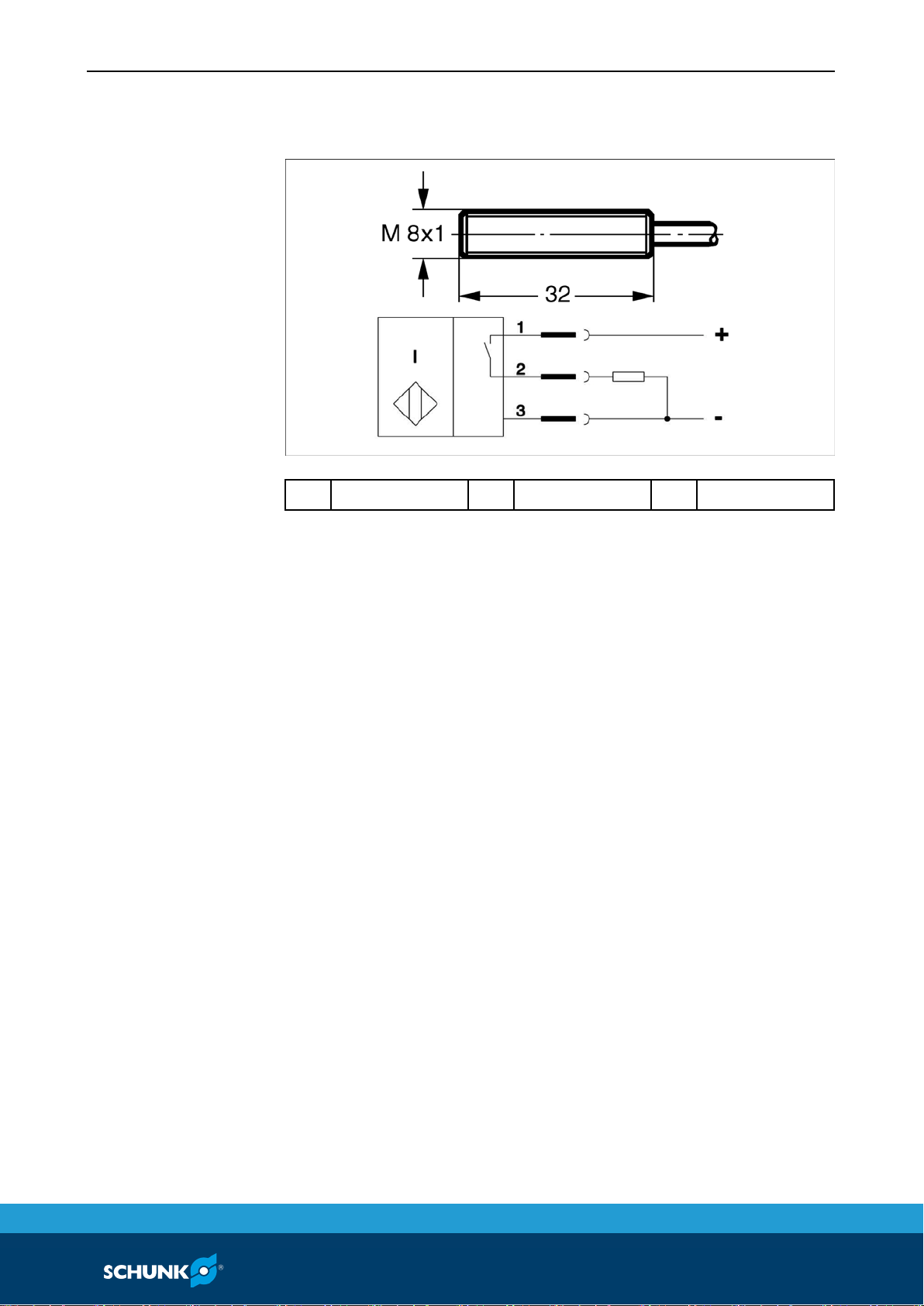

1

brown

2

black

3

blue

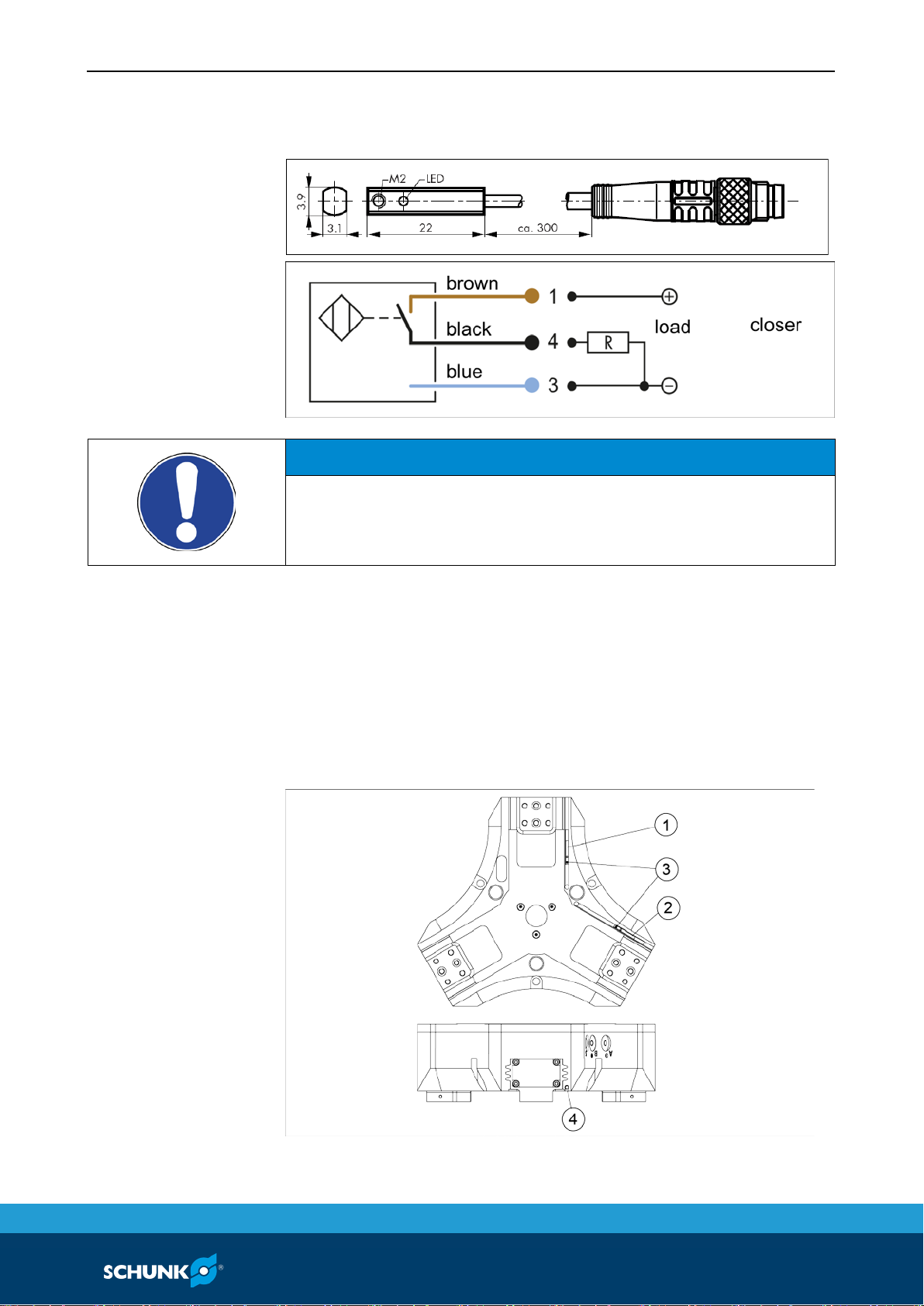

5.2.2

IN 80 inductive proximity switch

Connection example for IN 80

The inductive proximity switches used are equipped with reverse polarity protection and are short-circuit-proof.

Make sure that you handle the proximity switches properly:

• Do not pull on the cable.

• Do not allow the sensor to dangle from the cable.

• Do not overtighten the mounting screw or mounting clip.

• Please adhere to a permitted bend radius of the cable. (☞ catalog)

• Avoid contact of the proximity switches with hard objects and

with chemicals, in particular nitric acid, chromic acid and sulphuric

acid.

The inductive proximity switches are electronic components, which

can react sensitively to high-frequency interference or electromagnetic fields.

• Check to make sure that the cable is fastened and installed correctly. Provide for sufficient clearance to sources of highfrequency interference and their supply cables.

• Parallel switching of several sensor outputs of the same type

(npn, pnp) is permissible, but does not increase the permissible

load current.

• Note that the leakage current of the individual sensors (ca. 2 mA)

is cumulative.

02.00|PZH-plus 020-

23

Assembly

Mounting kit

Installation of the

proximity switch

To use the inductive sensor, the gripper has to be retrofitted with a

special mounting kit. This mounting kit is available from SCHUNK for

the models below.

1 Push the T-nut (4) into the gripper slot (7).

2 Fasten the bracket (2) by tightening the screws (3) at the T-nut

(4). Apply the screws only enough that the bracket (2) can still be

moved in the gripper slot (7).

3 Screw in and tighten the screw (5) in the base jaw (6).

4 Put the gripper in the position to be monitored (opened / closed

/ part grasped).

5 Position the bracket (2) in such a way that the gripper slot (7) is

aligned with the position of the screw (5).

6 Insert the proximity switch (1) in the bracket (2) and push it as

close as possible to the screw (5).

7 Fasten the proximity switch (1) by tightening the screws (3).

8 Open and close the gripper to test its functioning.

24 02.00|PZH-plus 020-075|en

Assembly

075|en

MMS 22 magnetic switch

NOTICE

Risk of damage to the sensor during assembly!

screws.

NOTE

Ferromagnetic material changes the switching positions of the sensor. For example: Adapter plate made of ordinary steel.

At ferromagnetic adapter plates:

• Then, the positions of the magnetic switch have to be set

5.2.3

Positioning the

magnetic switch

• Observe a maximum tightening torque of 10 Ncm for the set-

• The module must firstly be mounted on the adapter plate

02.00|PZH-plus 020-

25

Assembly

Gripper open:

1 Set the gripper to the "Open" position.

2 Push the magnetic switch 1 (1) into the groove until it stops at

the end of the groove.

3 Pull the magnetic switch 1 (1) back again slowly until it switches.

4 Tighten the set-screw (3) to clamp the magnetic switch 1 (1) in

this position in the groove.

5 Close and close the gripper to test its function.

Gripper closed:

1 Set the gripper to the "Closed" position.

2 Push the magnetic switch 2 (2) into the groove towards the mid-

dle of the gripper until it switches.

3 Tighten the set-screw (3) to clamp the magnetic switch 2 (2) in

this position in the groove.

4 Open and close the gripper to test its function.

Part gripped (O.D. gripping):

1 Clamp the part to be gripped.

2 Push the magnetic switch 2 (2) into the groove towards the mid-

dle of the gripper until it switches.

3 Tighten the set-screw (3) to clamp the magnetic switch 2 (2) in

this position in the groove.

4 Open and close the gripper to test its function.

Part gripped (I.D. gripping):

1 Clamp the part to be gripped.

2 Push the magnetic switch 1 (1) into the groove until it stops at

the end of the groove.

3 Pull the magnetic switch 1 (1) back again slowly until it switches.

4 Tighten the set-screw (3) to clamp the magnetic switch 1 (1) in

this position in the groove.

5 Close and close the gripper to test its function.

26 02.00|PZH-plus 020-075|en

Assembly

075|en

NOTE

The MMS-P can only cover the whole range of stroke in the PZH-plus

series for PZH-plus 20 and 30.

1

Mounting screw

4

Teach-button

2

Center sensor elements

5

LED display

3

LED display

6

Ribs for cable tires

5.2.4

MMS-P programmable magnetic switch

Magnetic switch MMS-P 22

Connection diagram PNP-4 conductor (MMS-P 22)

Types available for order (see catalog):

• MMS-P 22-S-M8-PNP

• MMSK-P 22-S-PNP

• V2-M8-4-2XM8-3

The MMSK-P 22-S-PNP features a cable with open strands so that it

can be connected via terminal contacts.

The V2-M8-4-2XM8-3 distributor is used to convert the 4-pin connector plug of the MMS-P 22-S-M8-PNP sensor to two standard M8

plugs with 3 pins each.

02.00|PZH-plus 020-

27

Assembly

NOTICE

Sensor can be damaged during assembly.

the set screws!

NOTE

Ferromagnetic material changes the switching positions of the sensor

(e.g. Adapter plate made of ordinary steel).

For ferromagnetic adapter

Mounting of the

sensor

• Do not exceed the maximum tightening torque of 10 Ncm for

plates:

• The module must be first mounted on the adapter plate.

• Then, the position of the magnetic switchs has to be set.

1 To relieve the cable, the electronics have to be fixed in place us-

ing cable ties (7).

There are ribs (6) in place on the electronics for mounting purposes.

2 Turn in the sensor (1 - 4).

OR

Push the sensor axially into the slot until it contacts the stop (5).

3 Fix the sensor with an Allen wrench (6).

28 02.00|PZH-plus 020-075|en

Assembly

075|en

Size

l1 [mm]

l2 [mm]

PZH-plus 20

49.1

58.0

PZH-plus 30

62.8

71.7

Setting up the swit-

ching points

Insert the magnetic switch in accordance with dimension l2 (outer

edge of gripper up to the front side of the sensor) or in accordance

with dimension l1 (outer edge of gripper up to the double arrow on

the sensor) and then mount with an Allen key.

Dimensions I1 / I2

1 Press the Teach button (4) for 2 seconds.

After 2 seconds LED 1 (3) is flashing.

2 Move the gripper into position 1 (e.g. "open").

3 Press the Teach-Button (4) briefly.

LED 1 (3) lights up and LED 2 (5) is flashing.

4 Move the gripper into position 2 (e.g. „-2mm“).

LED 1 (3) should turn out as soon as the switching point 1 is

left.

5 Press the Teach-Button (4) briefly.

LED 2 (5) lights up.

The switching points are set.

02.00|PZH-plus 020-

29

Assembly

For Grippers with X mm

nominal stroke per jaw

Min. query range per jaw /

min. queried stroke difference per jaw

X ≤ 5 mm

30% of the nominal stroke per jaw

X = 5to 10 mm

20% of the nominal stroke per jaw

X ≥ 10 mm

10% of the nominal stroke per jaw

Example: Product with 7 mm nominal stroke per jaw

7 mm * 20% = 1.4 mm

Adjusting the

hysteresis

The hysteresis to both switching points will be adjusted automatically

corresponding to the characteristics of the magnetic field.

The user can set the switching and trigging points of each position a

little bit closer than for the automatic mode. The trigging point is

closer to the switching point. At the same time the susceptibility to

trouble and damage increases. In the mode of the lowest hysteresis,

an error signal (such as jitter or untimely switch off) can be avoided, if

the sensor is protected against all types of disturbances (i.e. by

shielding). Frequent types of disturbances are change in temperature

and electro-magnetic influences.

Within the closest fine-teach mode, SCHUNK cannot guarantee EMCcompatibility any more.

The hysteresis adjustment is used for the manual adjustment of the

switching points (if necessary).

In case that the hysteresis automatically determined by the sensor

should be too high or too low after “the adjustment of the switching

points”, you may correct the value as follows.

The sensor avoids a too small hysteresis during hysteresis adjustment.

Sensors MMS 22, MMS-P 22, MMS 22-PI1 and MMS 22-PI2

The smallest detectable difference in stroke is defined in the following table:

The smallest detectable difference in stroke based on the nominal stroke

30 02.00|PZH-plus 020-075|en

Assembly

075|en

1 Press the "Teach" button (4) for 5 seconds.

LED 1 (3) flashes from 2nd to 5th second.

LED 1 goes off after 5 sec.

2 Release the "Teach" button.

3 Move the gripper to the "switch-off point for switching point 1"

position.

4 Briefly press the "Teach" button (4). LED 1 (3) flashes twice.

5 Move the gripper to the "switch-off point for switching point 2"

position.

6 Briefly press the "Teach" button (4).

LED 2 (5) flashes twice.

The assembly of the MMS-P sensor is completed.

02.00|PZH-plus 020-

31

Troubleshooting

Possible cause

Corrective action

Base jaws jam in housing, possible cause: bolt-

Check the evenness of the bolting surface.

(

5.1.1, Page 18)

Loosen the mounting screws of the product

and actuate the product again.

Pressure drops below minimum.

Check air supply.

(

5.1.2, Page 20)

Compressed air lines switched.

Check compressed air lines.

( 5.1.2, Page 20)

Proximity switch defective or set incorrect.

Readjust or change sensor.

Unused air connections open.

Close unused air connections.

Flow control valve closed.

Open the flow control valve.

Component part defective.

Replace component or send it to SCHUNK for

repair.

Possible cause

Corrective action

Dirt deposits between basic jaws and guidance.

Disassemble and clean the product.

Pressure drops below minimum.

Check air supply.

(

5.1.2, Page 20)

Screw-on surface is not sufficiently flat.

Check the evenness of the bolting surface.

(

5.1.1, Page 18)

Component part defective.

Send product with a SCHUNK repair order or

dismantle product.

6

6.1

6.2

Troubleshooting

Product is not moving

ing surface not sufficiently level.

Product does not travel through the entire stroke

32 02.00|PZH-plus 020-075|en

Troubleshooting

075|en

Product opens or closes abruptly

Possible cause

Corrective action

Too little grease in the mechanical guiding

areas.

Clean and lubricate product.

(

7, Page 35)

Compressed air lines blocked.

Check compressed air lines of damage.

Screw-on surface is not sufficiently flat.

Check the evenness of the bolting surface.

One-way flow control valve is missing or adjustet incorrectly.

Install and adjust one-way flow control valve.

Loading too large.

Check permissible weight and length of the

gripper fingers.

Possible cause

Corrective action

Compressed air can escape.

Check seals, if necessary, disassemble the

product and replace seals.

To much grease in the mechanical movement

space.

Clean and lubricate product.

(

7, Page 35)

Pressure drops below minimum.

Check air supply.

Link Pneumatischer Anschluss

Component part defective.

Replace component or send it to SCHUNK for

repair.

6.3

6.4

The gripping force is dropping

02.00|PZH-plus 020-

33

Troubleshooting

Product does not achieve the opening and closing times

Possible cause

Corrective action

Compressed air lines are not installed optimal-

If present: Open the flow control couplings on

ment of the jaws occurs without bouncing and

hitting.

Check compressed air lines.

Inner diameters of compressed air lines are of

consumption.

Keep compressed air lines between the prod-

possible.

Flow rate of valve is sufficiently large relative

to the compressed air consumption.

NOTICE! The throttle check valve must not be

reached the opening and closing times.

If you still cannot achieve the open and close

rectly at the gripper.

Loading too large.

Check permissible weight and length of the

gripper fingers.

6.5

ly.

the module to the maximum that the move-

sufficient size in relation to compressed air

uct and directional control valve as short as

removed, even if the product has not

times mentioned in the latest catalog, we recommend the use of quick-air-vent-valves di-

34 02.00|PZH-plus 020-075|en

Maintenance

075|en

NOTICE

Damage caused by insufficient lubricant!

• Reduce the lubricant intervals accordingly.

Size

20 / 30

50 / 75

Interval [Mio. cycles]

5

2

Lubricant point

Lubricant

Metallic sliding surfaces

microGLEIT GP 360

All seals

Renolit HLT 2

Bores on the piston

Renolit HLT 2

7

7.1

7.2

7.3

Maintenance

Notes

Original spare parts

Use only original spare parts of SCHUNK when replacing spare and

wear parts.

Exchange of housing and base jaws

The base jaws and the guidance in the housing are matched. To exchange these parts, send the product with a repair order to SCHUNK

or order the housing with the base jaws as a set.

Maintenance and lubrication intervals

Lubricants harden more quickly at temperatures above 60°C, leading to possible product damage.

Maintenance- and lubrication interval

Lubricants/Lubrication points

SCHUNK recommends the lubricants listed.

During maintenance, treat all greased areas with lubricant. Thinly apply lubricant with a lint-free cloth.

02.00|PZH-plus 020-

35

Maintenance

Disassembly of the module

WARNING

Risk of injury from uncontrolled movements!

• Make sure there is no residual energy in the system

7.4

Position of the position numbers ( 8, Page 40)

Assembly tools are needed for disassembly ( 7.4.1,

Page 37)/( 7.4.2, Page 38).

system, parts may move unexpectedly and cause serious injuries.

• Switch off energy supply.

If the energy supply is switched on or residual energy remains in the

1 Close the gripper and remove the compressed air lines.

2 Remove the cover (15) and unclamp the eccentric (9). To do this,

rotate the eccentric (9) by 90° to the left. Marking has to show in

the direction of the outside wall.

3 Remove the nuts (61).

4 Remove the set-screw (45) and undo the screws (46) though the

base plate (13).

5 Remove the base plate (13).

6 Remove the toothed belt (11).

7 Remove the toothed belt (20).

8 Remove the bearings (20 / 21), fitting disks (39) and the

eccentric (9).

9 Base jaw clamping piece (10) and centering sleeves (62).

10 Remove the base jaw (4).

36 02.00|PZH-plus 020-075|en

Maintenance

075|en

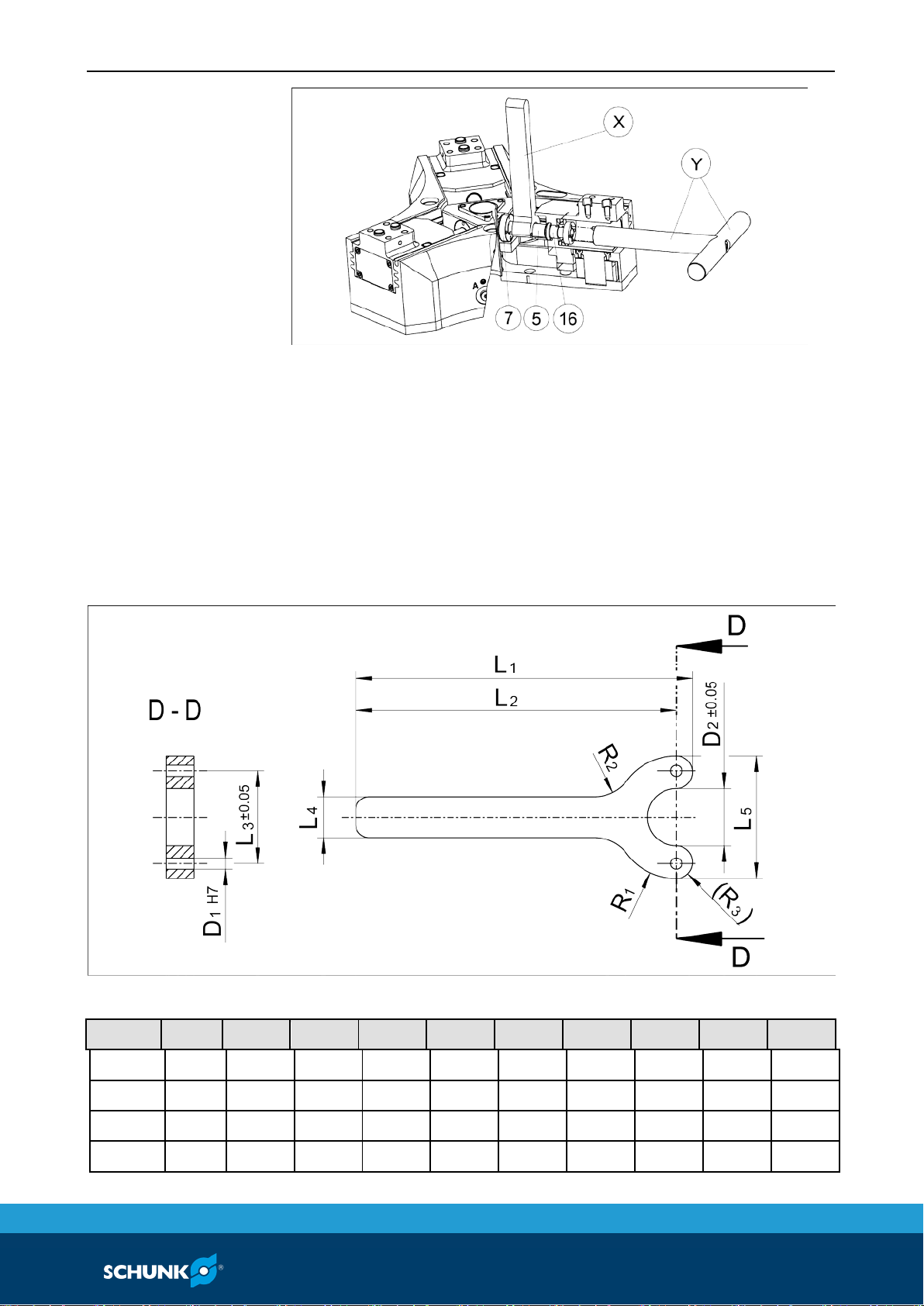

11 Remove the lock nut (16) with the assembly tool (Y).

PZH-plus

L1

L2

L3

L4

L5

D1

D2

R1

R2

R3

20

113.95

112.0

10.5

10.0

16.0

1.6

8.2

8.0

5.0

1.95

30

111.5

109.0

17.0

10.0

22.0

2.6

12.0

11.0

5.0

2.5

50

107.75

104.0

25.5

13.0

32.0

3.1

17.0

16.0

8.0

3.75

75

123.5

117.5

34.0

15.0

45.0

4.1

21.0

22.5

15.0

6.0

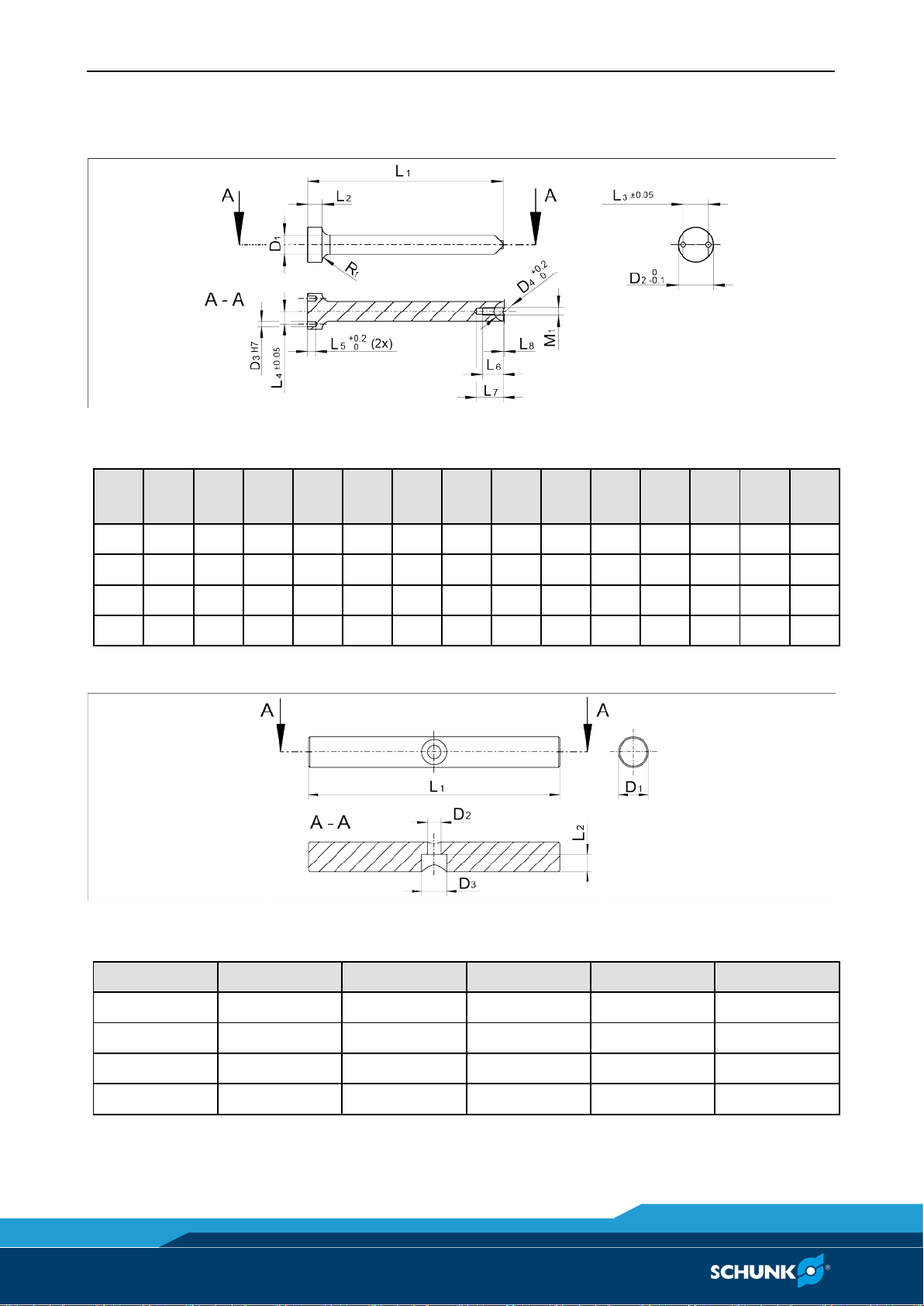

7.4.1

12 Pull the base jaw (2) with the piston (3) out of the housing (1)

and remove the piston (3) from the base jaw (2).

13 Remove the piston rod clamping nut (7) with the assembly

tool (X) and take out the piston rod (5).

14 Remove the sleeve (12).

15 Remove the air diffuser piece (6) from the housing (1).

Assembly tool X

(Dimensions in mm)

02.00|PZH-plus 020-

37

Maintenance

Assembly tool Y

PZHplus

L1

L2

L3

L4

L5

L6

L7

L8

D1

D2

D3

D4

M1

R1

20

100

-

9.0

4.5

3.0

13.0

17.0

1.0

12.0

12.0

1.6

12.0

M5

-

30

100

-

11.5

5.75

5.0

13.0

17.0

1.0

15.0

15.0

2.6

15.0

M5

-

50

130

15.0

17.0

8.5

8.0

13.0

17.0

1.0

15.0

25.0

2.6

15.0

M5

R8

75

200

15.0

26.0

13.0

8.0

21.0

27.0

1.0

20.0

36.0

5.1

20.0

M8

R8

PZH-plus

L1

L2

D1

D2

D3

20

100 7 12

5.5

10

30

100 7 15

5.5

10

50

100 7 15

5.5

10

75

150

11

20 9 15

7.4.2

Assembly tool Y, part 1

(Dimensions in mm)

Assembly tool Y, part 2

(Dimensions in mm)

38 02.00|PZH-plus 020-075|en

Maintenance

075|en

Item

42

46

47

48

54

56

20

0.8

1.3

0.8

0.8

1.3

1.3

30

1.3

6.0

1.3

1.3

6.0

6.0

50

10.0

6.0

6.0

1.3

10.0

6.0

75

25.0

48.0

25.0

1.3

48.0

10.0

7.5

Maintenance

Assembly

7.5.1

Servicing and assembling the module

Position of the position numbers ( 8, Page 40)

• Clean all parts thoroughly and check for damage and wear.

• Treat all greased areas with lubricant.

( 7.3, Page 35)

• Oil or grease bare external steel parts.

• Replace all wear parts / seals.

– Position of the wearing parts ( 8, Page 40)

– Seal kit ( 1.4.1, Page 7)

Assembly takes place in the opposite order to disassembly. Observe

the following:

• Unless otherwise specified, secure all screws and nuts with Loctite

no. 243 and tighten with the appropriate tightening

torque.( 7.5.1, Page 39)

Screw tightening torques

Values in Nm

Position of the position numbers ( 8, Page 40)

02.00|PZH-plus 020-

39

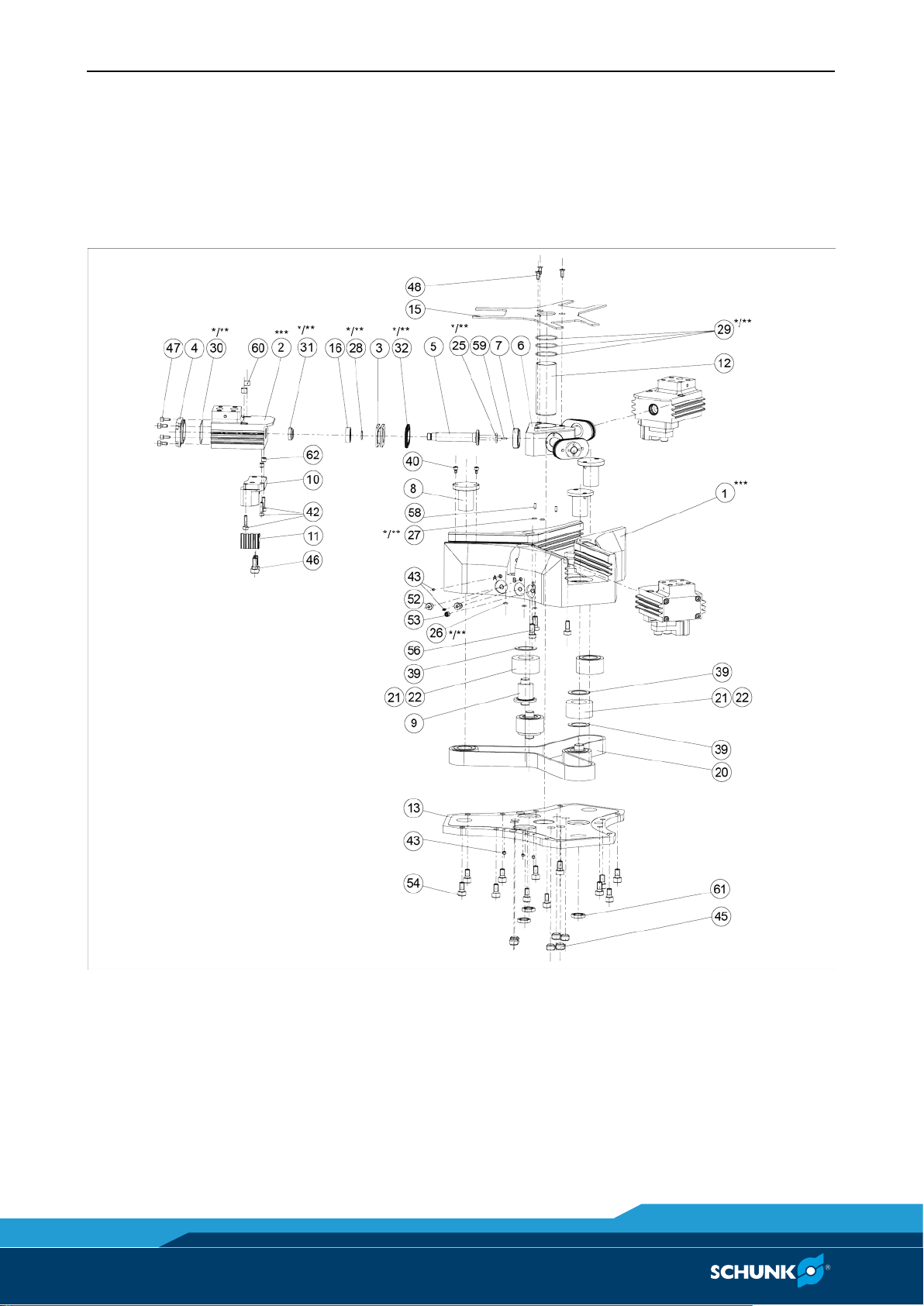

Assembly drawing

*

Wearing part, replace during maintenance.

**

Included in the seal kit. Seal kit can only be ordered completely.

***

Positions are adapted to each other and can not be replaced by the customer.

8

Assembly drawing

The following figure is an example image.

It serves for illustration and assignment of the spare parts.

Variations are possible depending on size and variant.

Assembly

40 02.00|PZH-plus 020-075|en

Translation of original declaration of incorporation

075|en

in terms of the Directive 2006/42/EG, Annex II, Part 1.B of the European Parliament and of

the Council on machinery.

Manufacturer/

SCHUNK GmbH & Co. KG Spann- und Greiftechnik

D-74348 Lauffen/Neckar

We hereby declare that on the date of the declaration the following incomplete machine

modifications are made to the product.

Product designation:

3-finger centric gripper / PZH-plus 020-075 / pneumatic

ID number

0305360, 0305370, 0305380, 0305390

The incomplete machine may not be put into operation until conformity of the machine into

rective (2006/42/EC) is confirmed.

Applied harmonized standards, especially:

DIN EN ISO 12100:2011-03

Safety of machinery - General principles for design Risk assessment and risk reduction

The manufacturer agrees to forward on demand the relevant technical documentation for

completed machinery, has been created.

Person authorized to compile the technical documentation:

Robert Leuthner, Address: see manufacturer's address

Lauffen/Neckar, October 2016

p.p. Ralf Winkler,

Head of Gripping Systems Development

9

Distributor

Translation of original declaration of incorporation

Bahnhofstr. 106 – 134

complied with all basic safety and health regulations found in the directive 2006/42/EC of the

European Parliament and of the Council on machinery. The declaration is rendered invalid if

which the incomplete machine is to be installed with the provisions of the Machinery Di-

the partly completed machinery in electronic form to national authorities.

The relevant technical documentation according to Annex VII, Part B, belonging to the partly

02.00|PZH-plus 020-

41

Annex to Declaration of Incorporation

1.Description of the essential health and safety requirements pursuant to 2006/42/EC, Annex

I that are applicable and that have been fulfilled with:

Product designation

3-finger centric gripper

Type designation

PZH-plus

ID number

0305360, 0305370, 0305380, 0305390

To be provided by the System Integrator for the overall machine

⇓

Fulfilled for the scope of the incomplete machine

⇓

Not relevant

⇓

1.1

Essential Requirements

1.1.1

Definitions

X

1.1.2

Principles of safety integration

X

1.1.3

Materials and products

X 1.1.4

Lighting

X 1.1.5

Design of machinery to facilitate its handling

X 1.1.6

Ergonomics

X 1.1.7

Operating positions

X

1.1.8

Seating

X

1.2

Control Systems

1.2.1

Safety and reliability of control systems

X 1.2.2

Control devices

X 1.2.3

Starting

X 1.2.4

Stopping

X

1.2.4.1

Normal stop

X

1.2.4.2

Operational stop

X 1.2.4.3

Emergency stop

X 1.2.4.4

Assembly of machinery

X 1.2.5

Selection of control or operating modes

X

1.2.6

Failure of the power supply

X

0

Annex to Declaration of Incorporation

1

according 2006/42/EG, Annex II, No. 1 B

42 02.00|PZH-plus 020-075|en

075|en

1.3

Protection against mechanical hazards

1.3.1

Risk of loss of stability

X

1.3.2

Risk of break-up during operation

X

1.3.3

Risks due to falling or ejected objects

X

1.3.4

Risks due to surfaces, edges or angles

X

1.3.5

Risks related to combined machinery

X

1.3.6

Risks related to variations in operating conditions

X

1.3.7

Risks related to moving parts

X 1.3.8

Choice of protection against risks arising from moving parts

X

1.3.8.1

Moving transmission parts

X 1.3.8.2

Moving parts involved in the process

X

1.3.9

Risks of uncontrolled movements

X

1.4

Required characteristics of guards and protective devices

1.4.1

General requirements

X

1.4.2

Special requirements for guards

X

1.4.2.1

Fixed guards

X

1.4.2.2

Interlocking movable guards

X

1.4.2.3

Adjustable guards restricting access

X

1.4.3

Special requirements for protective devices

X

1.5

Risks due to other hazards

1.5.1

Electricity supply

X 1.5.2

Static electricity

X

1.5.3

Energy supply other than electricity

X 1.5.4

Errors of fitting

X 1.5.5

Extreme temperatures

X

1.45.6

Fire

X

1.5.7

Explosion

X

1.5.8

Noise

X

1.5.9

Vibrations

X

1.5.10

Radiation

X

1.5.11

External radiation

X

1.5.12

Laser radiation

X

1.5.13

Emissions of hazardous materials and substances

X

1.5.14

Risk of being trapped in a machine

X

1.5.15

Risk of slipping, tripping or falling

X

1.5.16

Lightning

X

02.00|PZH-plus 020-

43

Annex to Declaration of Incorporation

1.6

Maintenance

1.6.1

Machinery maintenance

X

1.6.2

Access to operating positions and servicing points

X 1.6.3

Isolation of energy sources

X

1.6.4

Operator intervention

X

1.6.5

Cleaning of internal parts

X

1.7

Information

1.7.1

Information and warnings on the machinery

X 1.7.1.1

Information and information devices

X 1.7.1.2

Warning devices

X

1.7.2

Warning of residual risks

X

1.7.3

Marking of machinery

X

1.7.4

Instructions

X

1.7.4.1

General principles for the drafting of instructions

X

1.7.4.2

Contents of the instructions

X

1.7.4.3

Sales literature

X

The classification from Annex 1 is to be supplemented from here forward.

2

Supplementary essential health and safety requirements for certain categories of machinery

X

2.1

Foodstuffs machinery and machinery for cosmetics or pharmaceutical

products

X

2.2

Portable hand-held and/or guided machinery

X

2.2.1

Portable fixing and other impact machinery

X

2.3

Machinery for working wood and material with similar physical characteristics

X 3 Supplementary essential health and safety requirements to offset hazards

due to the mobility of machinery

X 4

Supplementary essential health and safety requirements to offset hazards

due to lifting operations

X 5

Supplementary essential health and safety requirements for machinery

intended for underground work

X 6 Supplementary essential health and safety requirements for machinery

presenting particular hazards due to the lifting of persons

X

X

44 02.00|PZH-plus 020-075|en

Loading...

Loading...