Schumacher Mi7 Instruction Manual

Instruction Manual

S1497 ISS1

71-73 Tenter Road

Moulton Park

Northampton

NN3 6AX

U.K.

ADDITIONAL ITEMS REQUIRED

E.S.C

Servo

Motor

Pinion

Soldering Iron

CR266 40w

CR275 80w

U3107 - Solder

AM701011 - Low Profile 4mm Connector 24K - pk2

AM701012 - Low Profile 5mm Connector 24K - pk2

CR115

CORE RC Silicone Wire 12AWG Red/Black/Blue 50cm

CR233

Piston Drilling Kit

1.1-1.8mm (8 bits)

AM190003 Reamer With End Cap For Lexan Body

Schumacher Racing stocks and

distributes the following

manufacturers products and full

product listings are

available on our website at

www.racing-cars.com

PLEASE NOTE THAT SOME OF THE

PRODUCT RANGES BELOW ARE ONLY

AVAILABLE IN THE UNITED KINGDOM.

Li-Po Battery

Bodyshell

CORE RC Paint

CR600 to CR631

CR666 to CR672

PAGE 1

SK-100130

E660 Charger AC/DC 60W 6A

Wheels, tyres and glue

CR522 CORE RC

Pro Tyre Glue + 2 Nozzles

U4229 Steel Spanner - 5.5mm/3.9mm

CR044 Curved Body Scissors

AM150155 Nut Driver 5.5 (M3)

AM150170 Nut Driver 7.0 (M4)

AM110115 Allen Wrench 1.5

AM110120 Allen Wrench 2.0

AM110125 Allen Wrench 2.5

AM110130 Allen Wrench 3.0

IMPORTANT SAFETY NOTES

We strongly recommend that anyone driving RC cars, or organising events, should obtain third

party liability insurance. In the UK this can be done by joining the BRCA. www.brca.org

This product is not suitable for children under the age of 14, without the direct

supervision of a responsible adult.

Select an area for assembly that is away from the reach of small children.

The parts in this kit are small and can be swallowed by children causing choking

and possible internal injuries.

Exercise care when using hand tools and sharp instruments during assembly.

Carefully read all manufacturers warnings and cautions for any additional items

used in the construction.

In line with our policy of continuous development the exact details of the kit may vary.

DO NOT use this car on public roads or in places where it can interfere with

traffic, people or animals.

Always check the operation of the radio with the wheels off the ground, before

using the car.

Make sure the radio and car batteries are fully charged before use.

Disconnect and remove the battery from the car when not in use.

Always store and charge LiPo batteries in a fireproof container.

DO NOT put fingers or any objects inside rotating or moving parts as this may

cause injury.

Make sure the charger is correctly set for the type of battery you are using.

Incorrect charging may cause a fire.

Insulate all exposed electrical wiring. Exposed or damaged wires can cause

short circuits and fire.

The motor and speed controller can become hot during use.

DO NOT touch them immediately after using your car as this may cause injury.

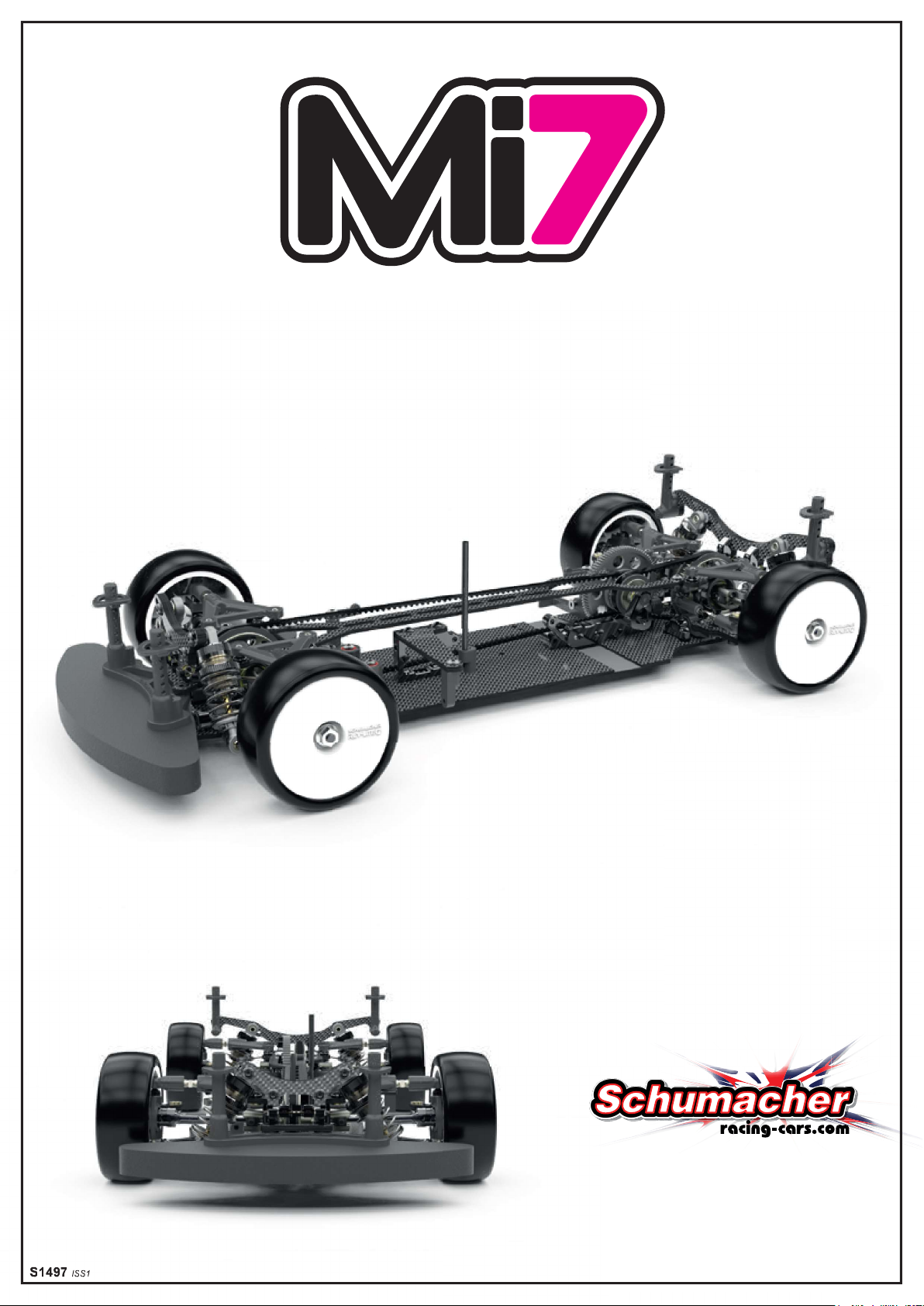

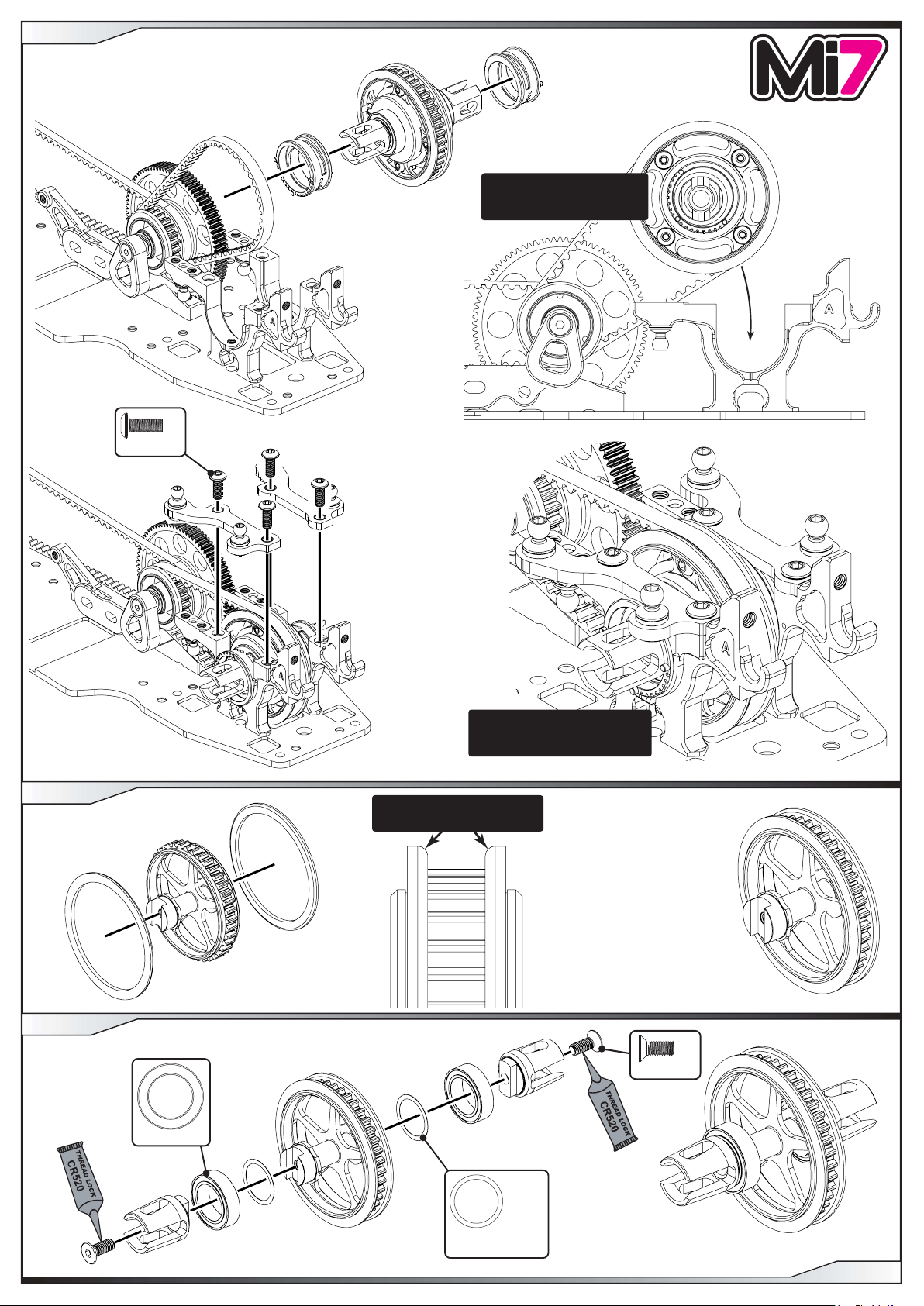

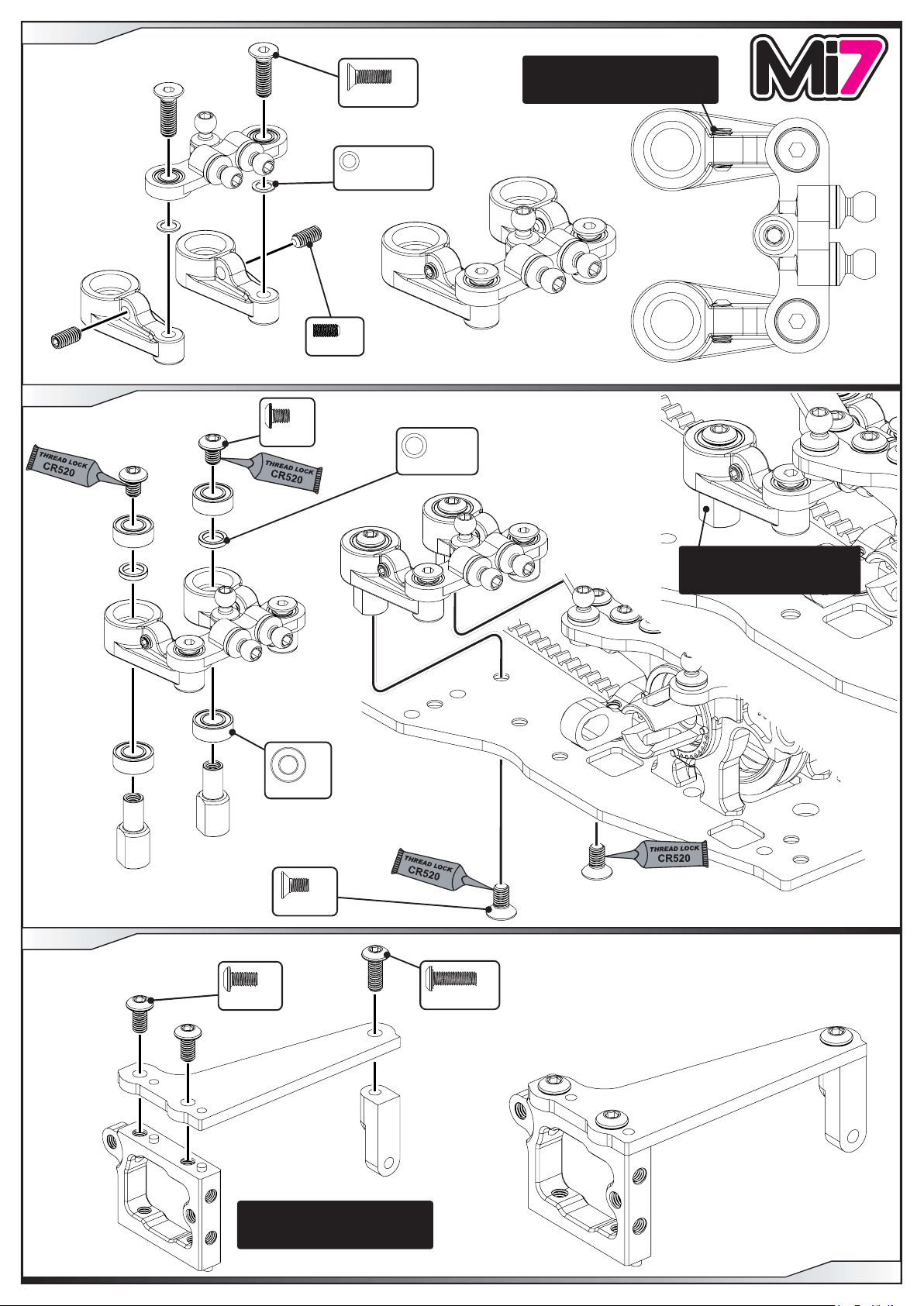

STEP 1

‘A’

The housings

are doweled

into the chassis.

STEP 2

x 2

Black 1.5 mm

The housings may be a tight fit

in the chassis, this is to ensure

accurate alignment.

‘B’

x 2

Black

Ball Stud Short

x 4

M3 x 6

STEP 3

‘B’

The housings may be a tight fit

in the chassis, this is to ensure

accurate alignment.

‘A’

The housings

are doweled

into the chassis.

x 4

M3 x 6

The motor mount may be a tight fit

in the chassis, this is to ensure

accurate alignment.

M3 x 6

The motor mount

is doweled

into the chassis.

x 3

PAGE 2

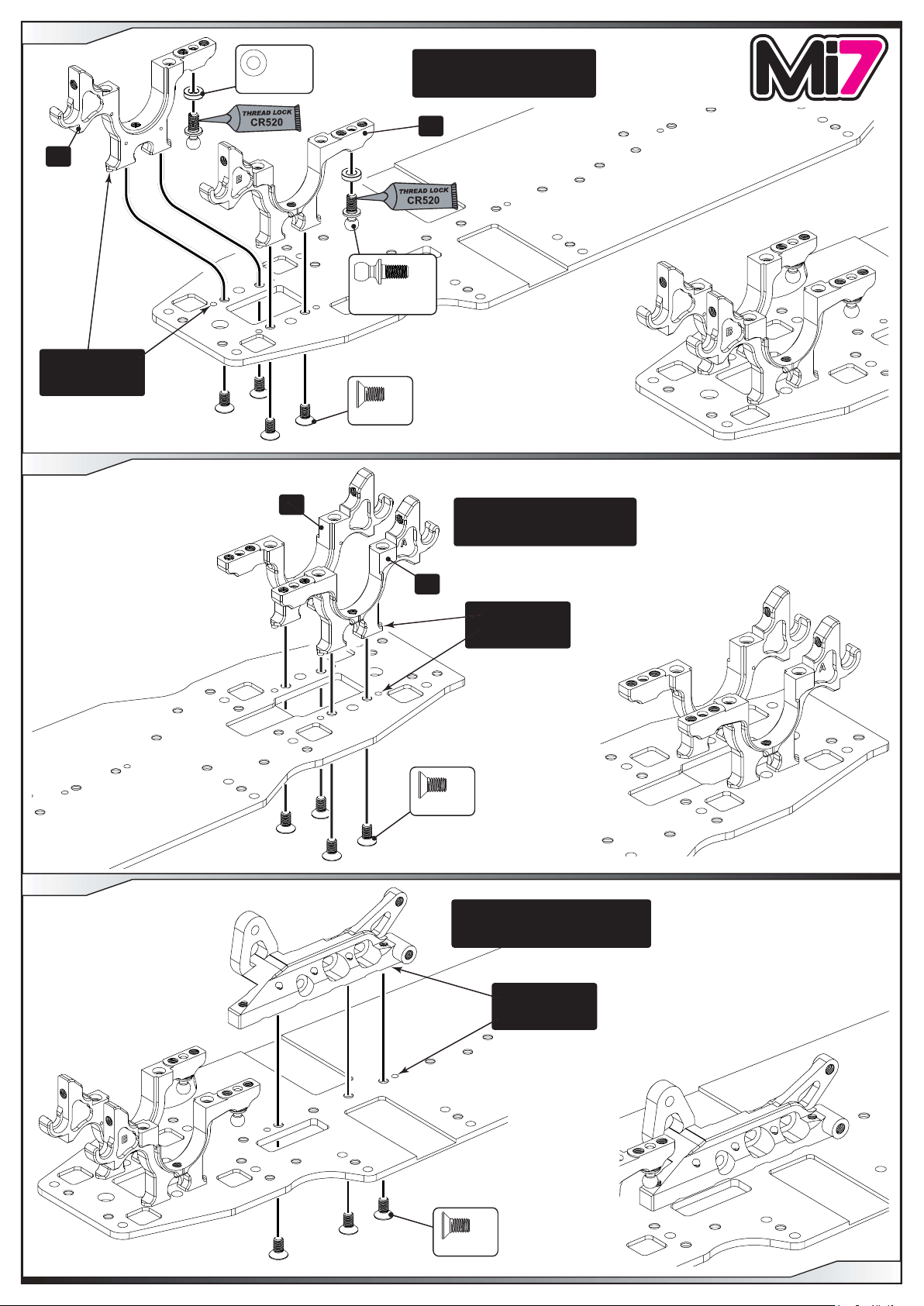

STEP 4

x 1

M3 x 4

The pulley should spin

freely on the shaft.

x 2

Flanged

ø3/16” x ø5/16”

STEP 5

Ensure fence is assembled

as shown.

STEP 6

Use the 5.5mm spanner to

ensure the screw is tight.

The bearings may be a

tight fit on the layshaft.

x 3

Spur Gear Screw

PAGE 3

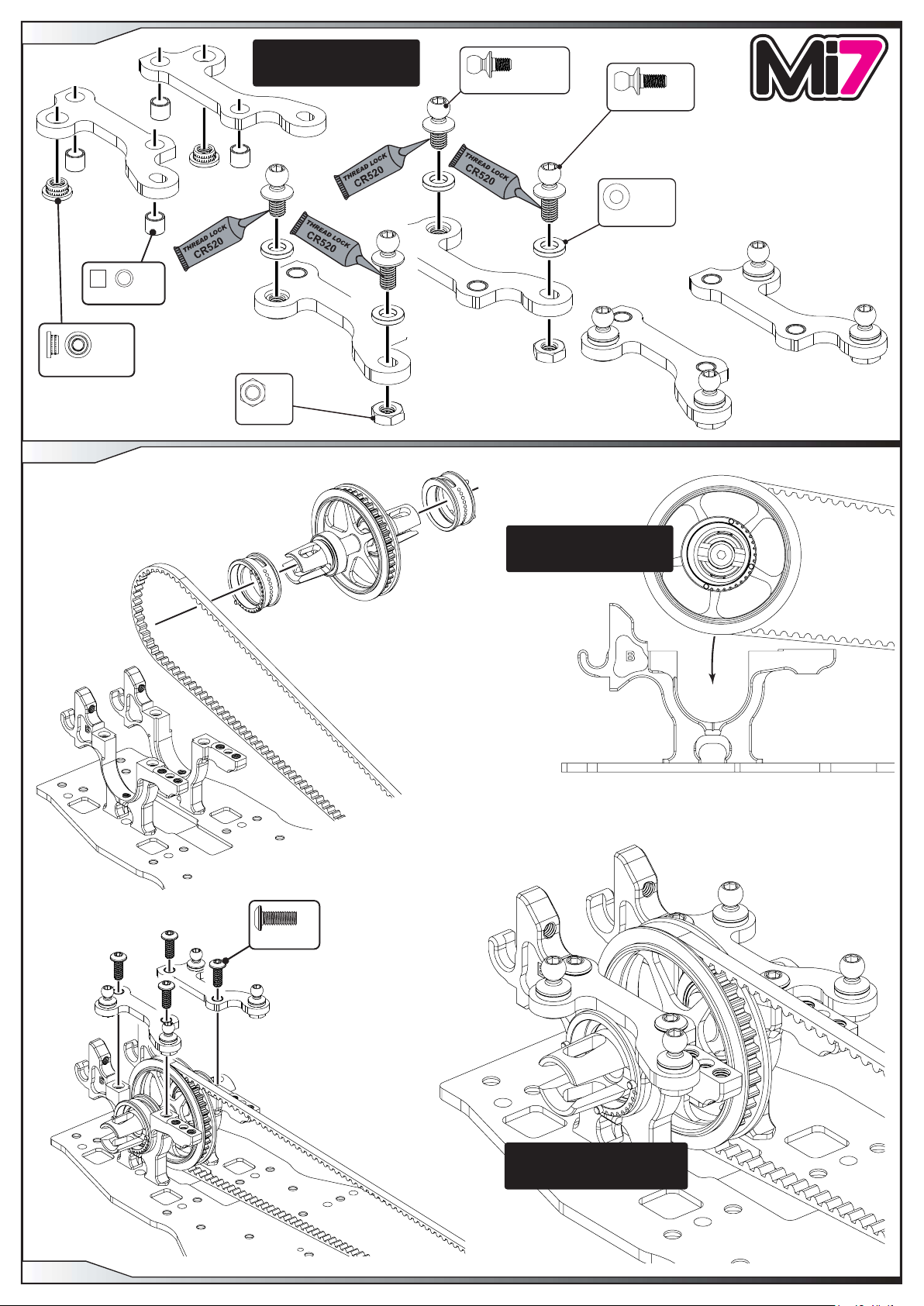

Use the 5.5mm spanner to

ensure the screw is tight.

x 1

M3 x 12

STEP 7

x 1

x 2

ø6.4 x ø8.0 x 0.1

PIN ASSEMBLY PROCEDURE

Use if needed

Use a small amount of oil

to hold all of the parts in

place during assembly.

ø10 x ø15 x 4

STEP 8

x 1

ø5 x ø8 x 2.5

SHIM

ø10 x ø12.5 x 0.10

Ensure fences are assembled

as shown.

x 1

x 1

O’ring ø5 x 1.5

x 1

SHIM

ø5 x ø15 x 0.2

x 1

ø2.0 x 9.8

STEP 9

x 1

ø5 x ø8 x 2.5

x 1

ø10 x ø15 x 4

ø6.4 x ø8.0 x 0.1

SHIM

ø10 x ø12.5 x 0.10

x 2

x 1

Use if needed

x 1

O’ring ø5 x 1.5

ø2.0 x 9.8

x 1

SHIM

ø5 x ø15 x 0.2

x 1

SEE STEP 7 FOR

PIN ASSEMBLY PROCEDURE

PAGE 4

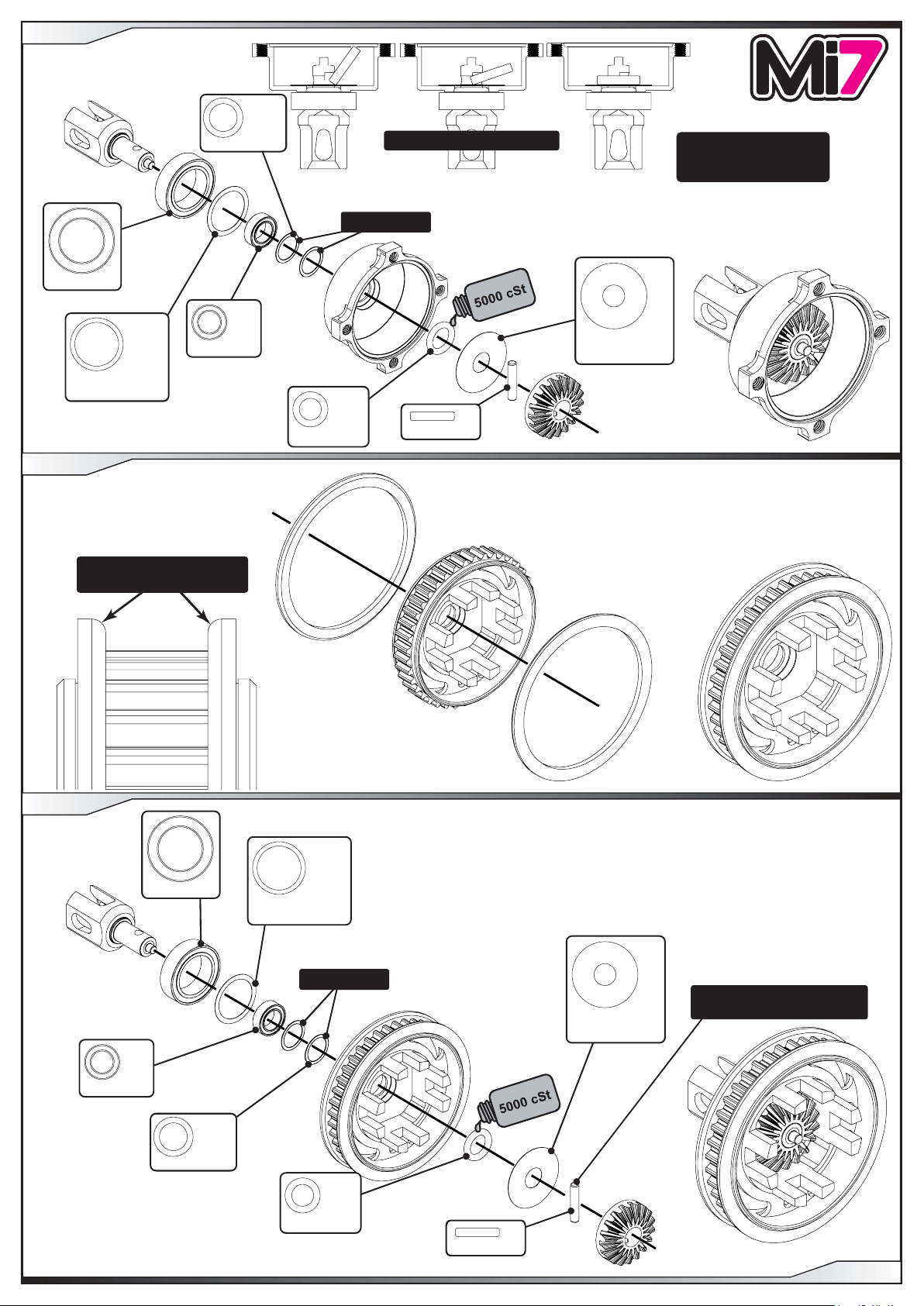

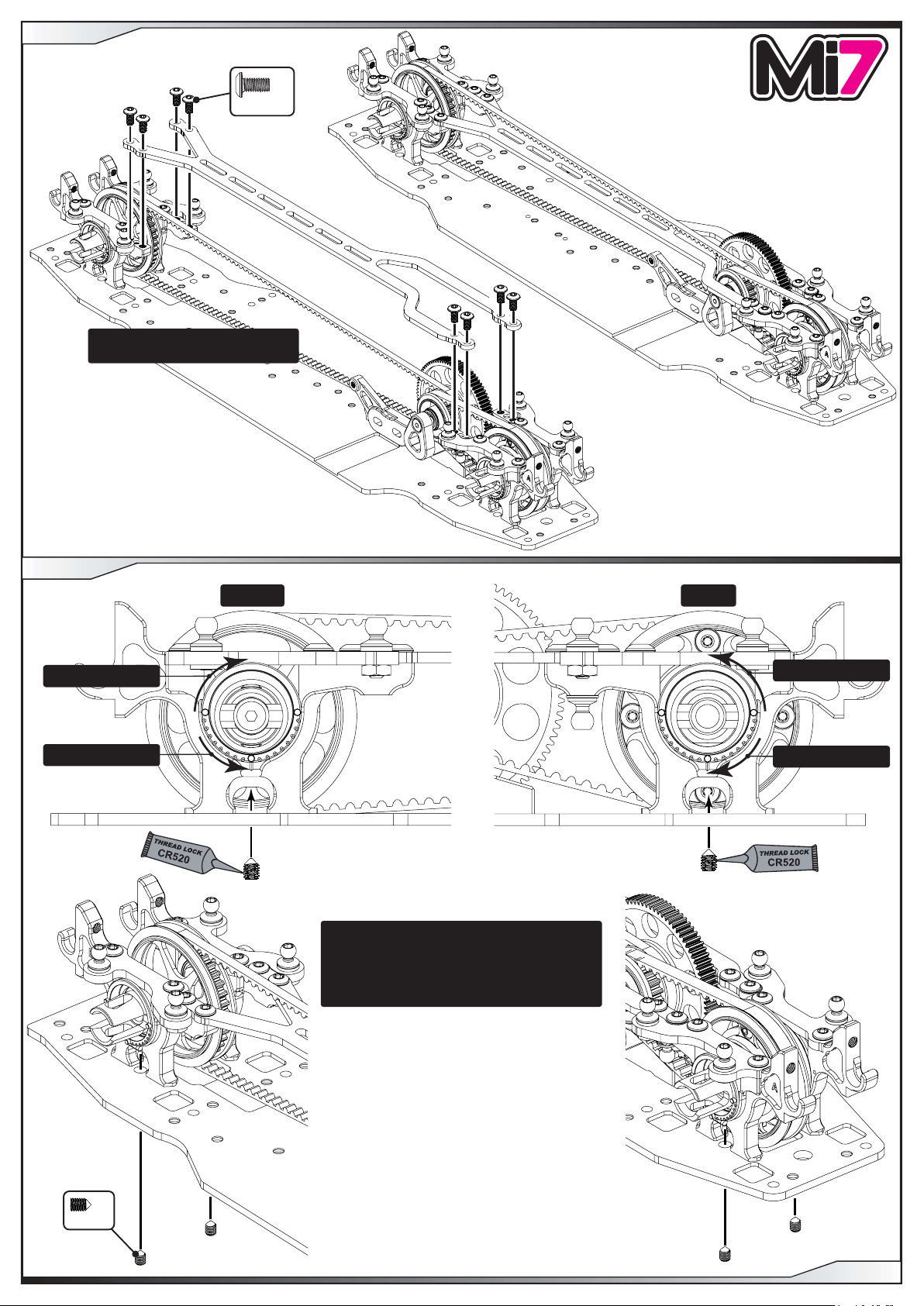

STEP 10

x 2

ø2 x ø5 x 1.5

x 4

SHIM

ø3.5 x ø9.5 x 0.1

Use a small amount of oil

to hold all of the parts in

place during assembly.

x 4

M2.5 x 4

Use 1.6 grams of oil (just

covering the bevel gear).

STEP 11

M3 Washer

x 4

M3 x 12

Tighten the screw until

the M3 thread insert is

pulled into the carbon fibre

part as shown.

x 1

Use the M3x12 cap head

screw and washers to fit the

inserts and dowels.

x 2

M3 Thread Insert

x 1

M3 Nyloc

x 4

Dowel

ø3 x ø4 x 3.5

Tighten the nut until the

dowel is pulled into

the carbon fibre part

as shown.

PAGE 5

M3 Nut

M3 Thread Insert

x 2

Low Ball Short

x 2

x 4

Black 0.5 mm

Dowel

ø3 x ø4 x 3.5

x 2

Low Ball Ultra Short

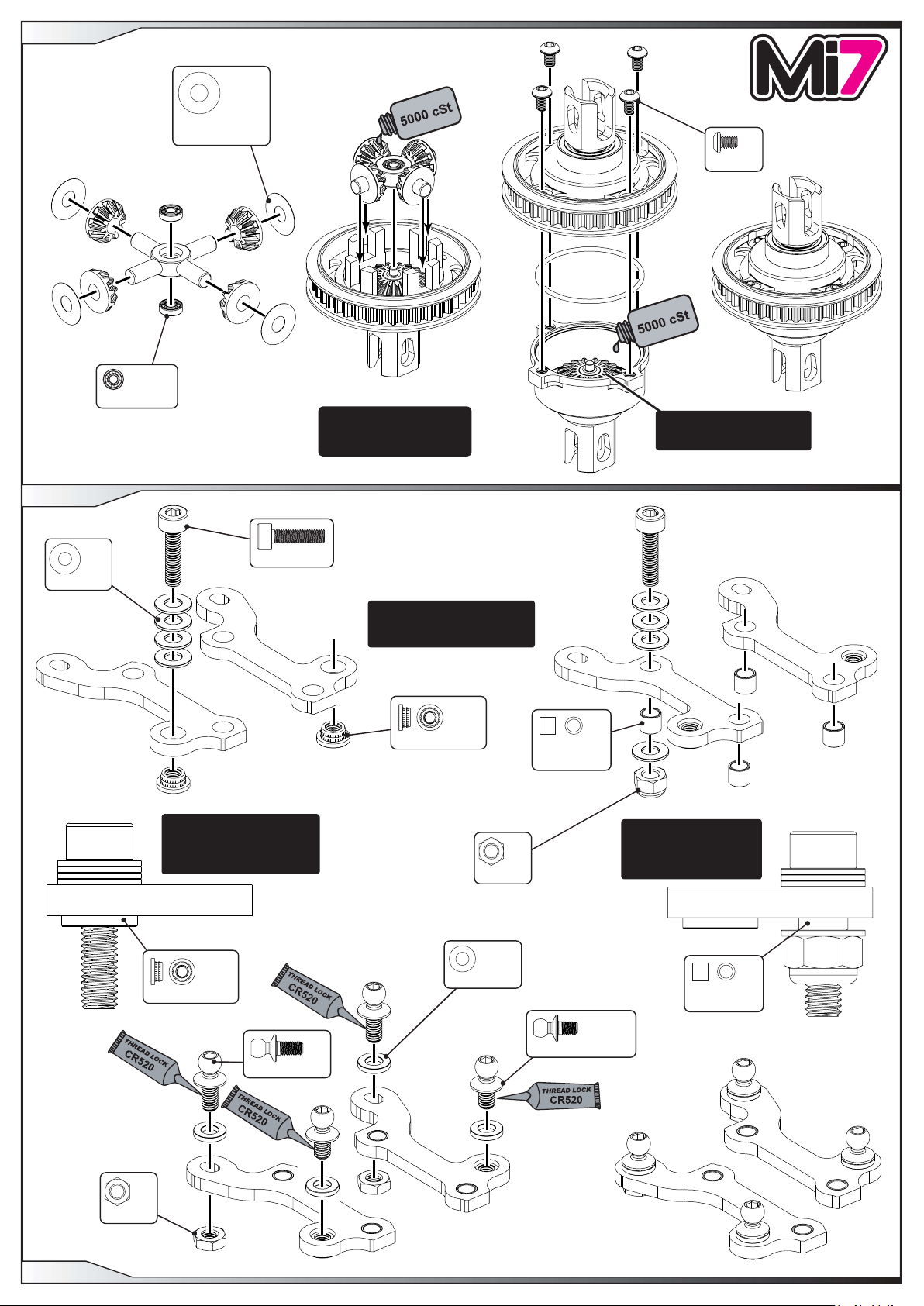

STEP 12

Make sure the pips on the

eccentric match the image

as shown.

x 4

M3 x 8

STEP 13

STEP 14

The eccentrics are free to rotate.

The belt tension will be set later

when the top deck is fitted.

Ensure fences are assembled

as shown.

x 2

M3 x 8

x 2

ø10 x ø15 x 4

x 2

SHIM

ø10 x ø12.5 x 0.10

PAGE 6

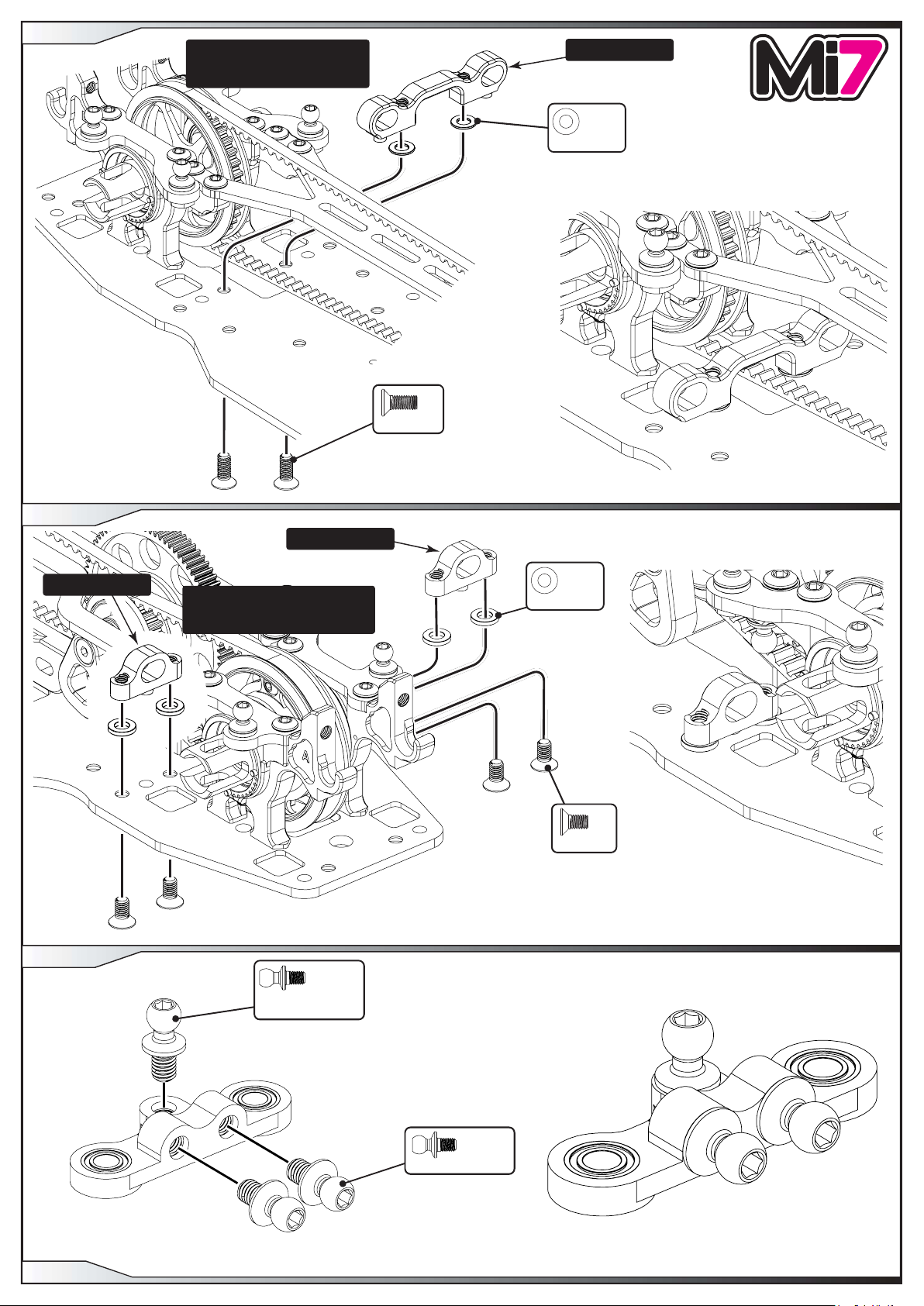

STEP 15

M3 Thread Insert

STEP 16

x 4

ø3 x ø4 x 3.5

x 2

See Page 5 Step 11 for how

to assemble the inserts and

dowels.

x 2

M3 Nut

x 2

Low Ball Ultra Short

x 2

Low Ball Short

x 4

Black 0.5 mm

M3 x 8

Make sure the pips on the

eccentric match the image

as shown.

x 4

PAGE 7

The eccentrics are free to rotate.

The belt tension will be set later

when the top deck is fitted.

STEP 17

x 8

M3 x 6

Make sure you assemble the top deck

under the front belt. (see final image).

STEP 18

Tighter belt tension.

Looser belt tension.

FRONT REAR

Tighter belt tension.

Looser belt tension.

Set the eccentric position with the grub screw.

IMPORTANT

Make sure both sides are set the same and

only tighten this grub screw when indents

on the eccentrics and housings line up.

DO NOT OVER TIGHTEN

M3 x 4

x 4

PAGE 8

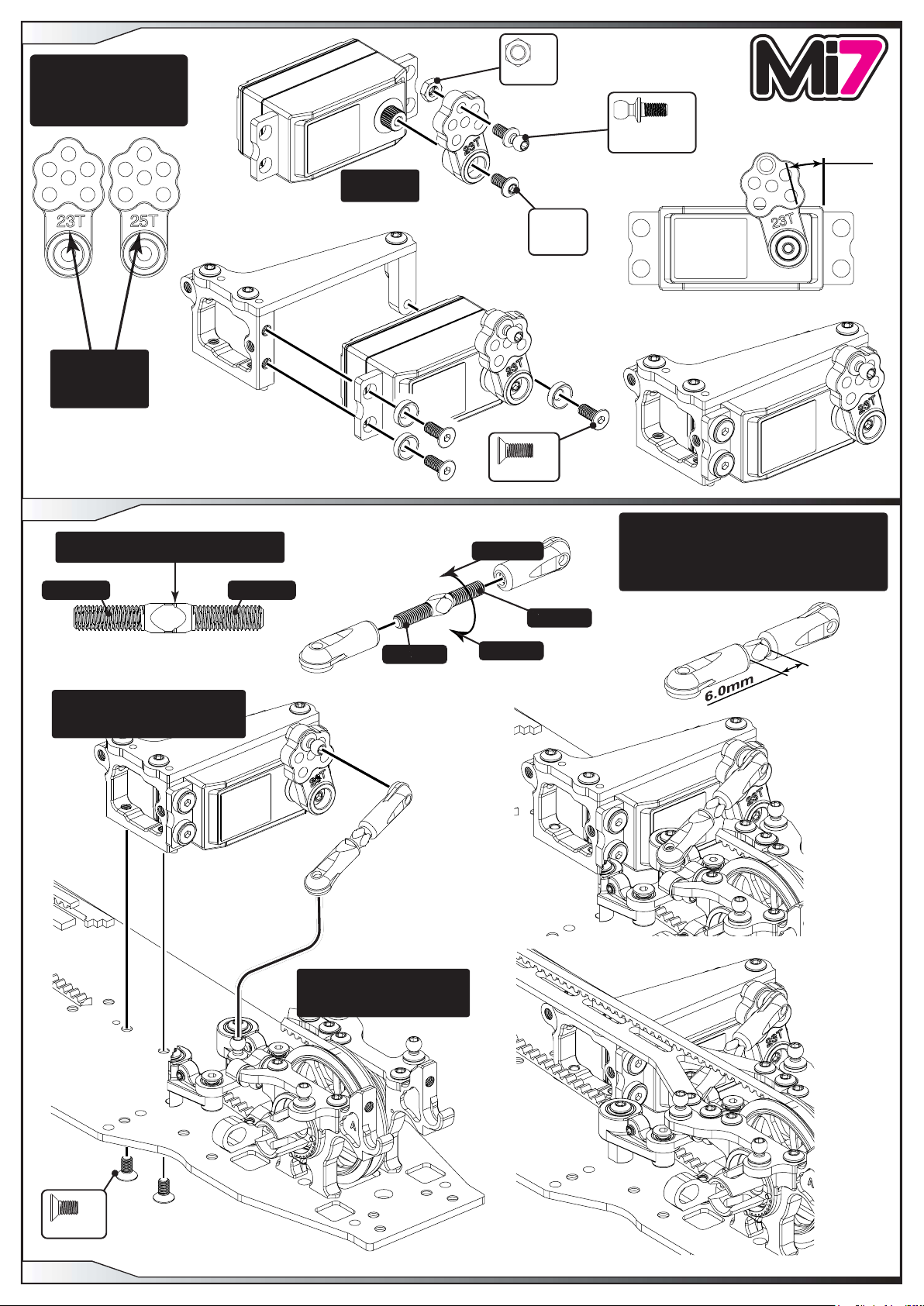

STEP 19

The strap may be a tight fit

in the chassis, this is to ensure

accurate alignment.

Chamfer this side.

x 2

Black 0.5 mm

x 2

M3 x 8

STEP 20

Chamfer this side.

STEP 21

Chamfer this side.

The split blocks may be a tight fit

in the chassis, this is to ensure

accurate alignment.

x 1

Black

Ball Stud Ultra Short

x 4

Black 1.0 mm

x 4

M3 x 6

PAGE 9

x 2

Low Ball Ultra Short

STEP 22

STEP 23

M3 x 4

M3 x 6

x 2

x 2

M3 x 10

x 2

ø3.0 x ø4.5 x 0.25

x 2

ø4 x ø5.65 x 1

Assemble the grub screw central

to the steering lever. See track

settings on how to set this.

x 2

STEP 24

M3 x 6

ø4 x ø8 x 3

M3 x 6

x 2

Ensure the flats on the steering

posts are parallel to the sides

of the chassis.

x 4

x 2

x 1

M3 x 10

The servo mount may be a tight fit

in the servo plate, this is to ensure

accurate alignment.

PAGE 10

STEP 25

Before you assemble

the servo horn, connect up

your radio gear and set the

steering servo to

neutral.

IMPORTANT

Select the

correct horn for

your servo.

x 1

M3 Nut

x 1

Black

Ball Stud Short

15°

SERVO NOT

INCLUDED

Screw

supplied

with servo

x 3

M3 x 8

STEP 26

Note the shape of the turnbuckle.

This groove indicates the left hand thread.

RH Thread

The servo mount may be a tight

fit in the chassis, this is to ensure

accurate alignment.

LH Thread

RH Thread

Shorter link

Longer link

Carefully screw the sockets onto the turnbuckle

until no threads are visible.

Then undo them to the desired length.

This allows for easier adjustment on the car.

(Greasing the threads will also help)

LH Thread

M3 x 6

PAGE 11

NOTE.

The car has been cut away for

assembly clarification.

x 2

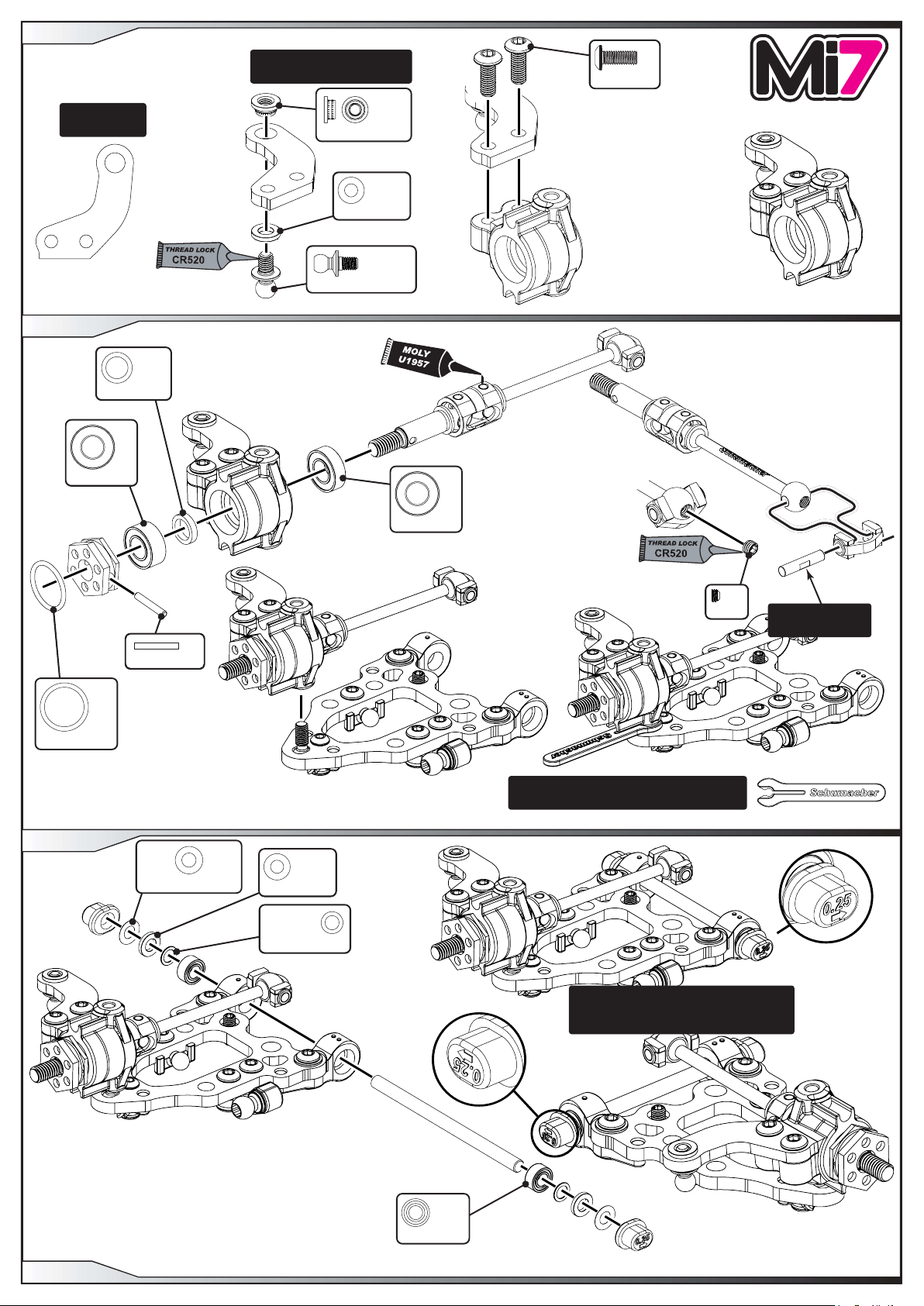

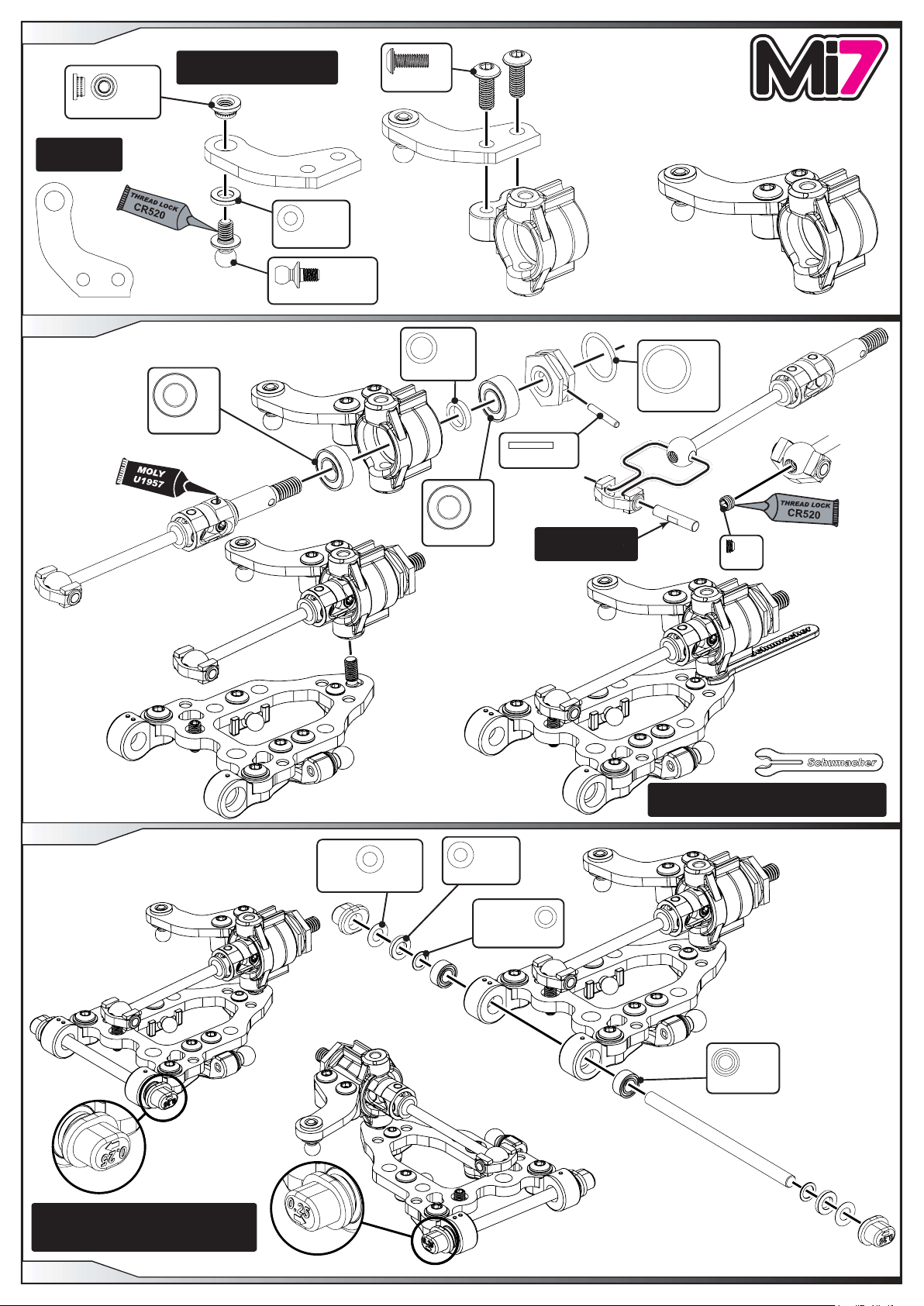

STEP 27 - Right Hand Side Front Suspension

x 2

M3 x 6

M3 Washer

The sphere is

on the bottom

of the wishbone.

IMPORTANT

This is the 3 dot wishbone.

Make sure to use the same

wishbone on both sides of the car.

M3 Thread Insert

See Page 5 Step 11 for how

to assemble the inserts.

STEP 28

x 1

M3 x 8 Dome Ended

x 2

Set the grub screw

central for now.

x 1

Adjust this screw to fine

tune the ball fit.

Do NOT overtighten.

STEP 29

x 1

M3 x 6

M2.5 x 8

Wishbone Ball

x 1

x 1

M3 x 8

x 2

Fit the grub screw into

the moulding first. Then

screw on the shock ball.

Set the grub

screw flush.

Pivot Ball x 1

x 1

Black 0.5 mm

x 1

M3 x 10

PAGE 12

STEP 30

See Page 5 Step 11 for how

to assemble the inserts.

x 2

M3 x 8

Full size front

steering arm.

STEP 31

ø5 x ø10 x 4

x 1

M3 Thread Insert

x 1

Black 1.0 mm

x 1

Low Ball Ultra Short

x 1

ø5 x ø7 x 1.5

x 1

x 1

ø5 x ø10 x 3

O’ring ø9 x 1.0

STEP 32

x 1

ø1.5 x 9.8

x 1

SHIM

ø3.25 x ø6.25 x 0.1

x 2

x 2

Black 1.0 mm

THRUST

x 2

SHIM

ø5 x ø3.25 x 0.3

x 1

M3 x 2

Use the hub height setting tool to

set the gap between the hub and wishbone.

IMPORTANT

Ensure correct orientation of the inserts.

Use 0.25 as the BASE setting.

The flat must face

the grub screw.

PAGE 13

x 2

ø1/8” x ø1/4”

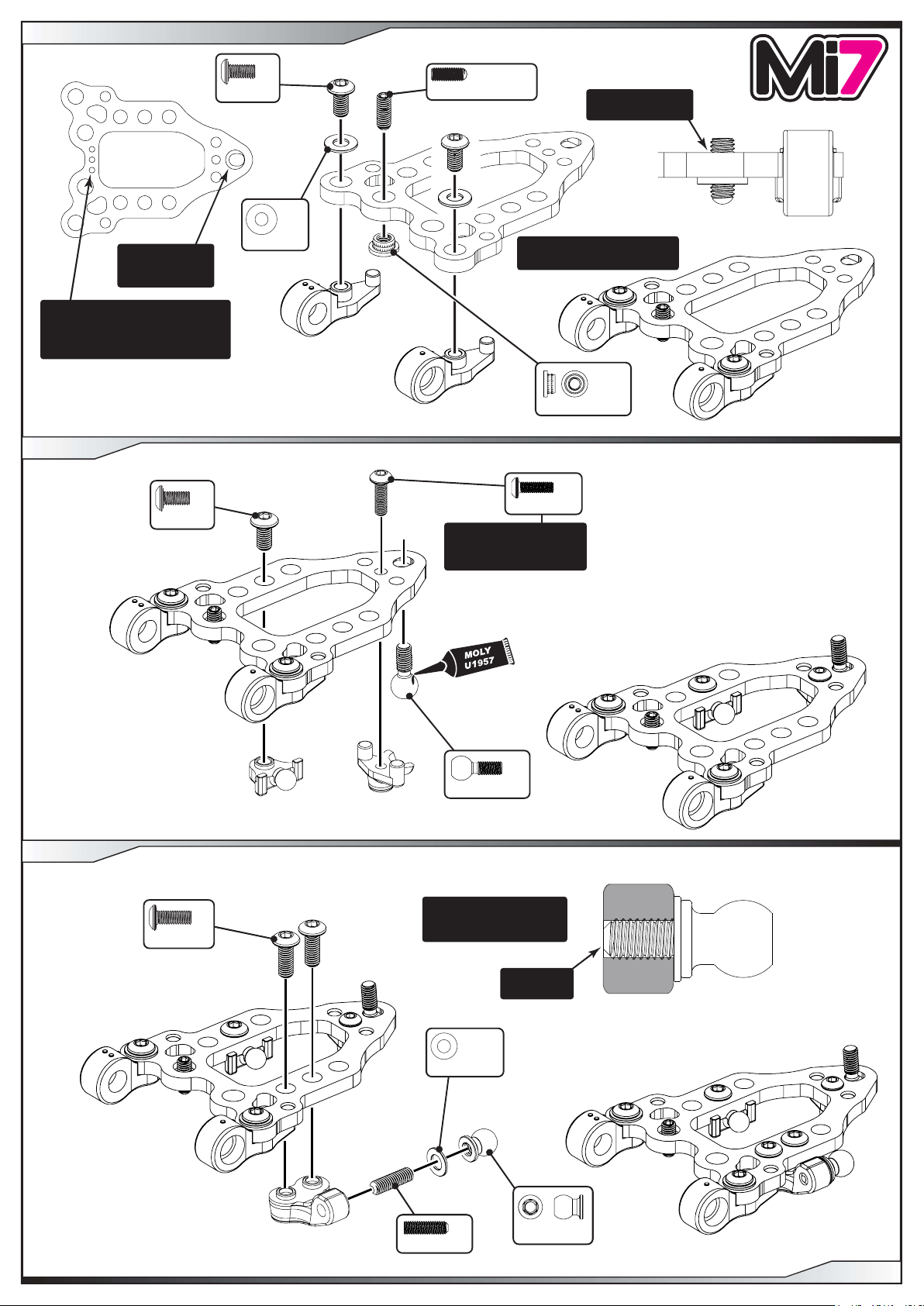

STEP 33 - Left Hand Side Front Suspension

The sphere is

on the bottom

of the wishbone.

IMPORTANT

This is the 3 dot wishbone.

Make sure to use the same

wishbone on both sides of the car.

STEP 34

M3 x 6

x 1

M3 x 6

x 2

x 2

M3 Washer

x 1

M3 x 8 Dome Ended

M2.5 x 8

Adjust this screw to fine

tune the ball fit.

Do NOT overtighten.

Set the grub screw

central for now.

See Page 5 Step 11 for how

to assemble the insert.

x 1

M3 Thread Insert

x 1

STEP 35

M3 x 8

x 2

x 1

Wishbone Ball

Fit the grub screw into

the moulding first. Then

screw on the shock ball.

Set the grub

screw flush.

x 1

Black 0.5 mm

M3 x 10

x 1

Pivot Ball x 1

PAGE 14

STEP 36

M3 Thread Insert

Full size front

steering arm.

STEP 37

x 1

ø5 x ø10 x 3

See Page 5 Step 11 for how

to assemble the inserts.

Black 1.0 mm

Low Ball Ultra Short

x 1

x 1

x 1

M3 x 8

ø5 x ø7 x 1.5

x 2

x 1

x 1

O’ring ø9 x 1.0

x 1

ø1.5 x 9.8

STEP 38

SHIM

ø3.25 x ø6.25 x 0.1

x 2

x 1

ø5 x ø10 x 4

Black 1.0 mm

The flat must face

the grub screw.

x 2

THRUST

x 2

SHIM

ø5 x ø3.25 x 0.3

x 1

M3 x 2

Use the hub height setting tool to

set the gap between the hub and wishbone.

Ensure correct orientation of the inserts.

IMPORTANT

Use 0.25 as the BASE setting.

PAGE 15

x 2

ø1/8” x ø1/4”

Loading...

Loading...