Schumacher CAT XLS Masami Instruction Manual

S1422-ISS1

71-73 Tenter Road

Moulton Park

Northampton

NN3 6AX

U.K.

Instruction Manual

Schumacher Racing stocks and

distributes the following

manufacturers products and full

product listings are

available on our website at

www.racing-cars.com

PLEASE NOTE THAT SOME OF THE

PRODUCT RANGES BELOW ARE ONLY

AVAILABLE IN THE UNITED KINGDOM.

IMPORTANT SAFETY NOTES

This product is not suitable for children under the age of 14, without the direct

supervision of a responsible adult.

Select an area for assembly that is away from the reach of small children.

The parts in this kit are small and can be swallowed by children causing choking

and possible internal injuries.

Exercise care when using hand tools and sharp instruments during assembly.

Carefully read all manufacturers warnings and cautions for any additional items

used in the construction.

In line with our policy of continuous development the exact details of the kit may vary.

DO NOT use this car on public roads or in places where it can interfere with

traffic, people or animals.

Always check the operation of the radio with the wheels off the ground, before

using the car.

Make sure the radio and car batteries are fully charged before use.

Disconnect and remove the battery from the car when not in use.

Always store and charge LiPo batteries in a fireproof container.

DO NOT put fingers or any objects inside rotating or moving parts as this may

cause injury.

Make sure the charger is correctly set for the type of battery you are using.

Incorrect charging may cause a fire.

Insulate all exposed electrical wiring. Exposed or damaged wires can cause

short circuits and fire.

The motor and speed controller can become hot during use.

DO NOT touch them immediately after using your car as this may cause injury.

Serrated Pliers

Pinion

Curved Body Scissors

Solder

Soldering Iron

Steel Spanner - 5.50mm

Steel Spanner - 4.00mm

Steel Spanner - 1/4”

Body Reamer

M3 Nut Driver

Hex Driver - 1.5mm

Hex Driver - 2.0mm

Hex Driver - 2.5mm

Phillips Screwdriver 4.0x120mm

Turnbuckle Wrench 4mm

Radio Transmitter and Receiver

(Batteries not included)

Battery Charger

Electronic Speed Controller

2S Shorty LiPo Battery

or

Traditional Stick Pack Battery NiMh or LiPo

IMPORTANT MOTOR LIMITATIONS

17.5 BRUSHLESS FOR STANDARD CAR

6.5 BRUSHLESS FOR PRO TRANSMISSION UPGRADE

Servo

Super Glue and Threadlock

Polycarbonate

Paint

Circlip Pliers

SEE PAGES 29 & 30 FOR COMPLETE TOOLS LISTINGS

LC RACING

ADDITIONAL ITEMS REQUIRED (See Spares Listings in the Manual)

PAGE 1

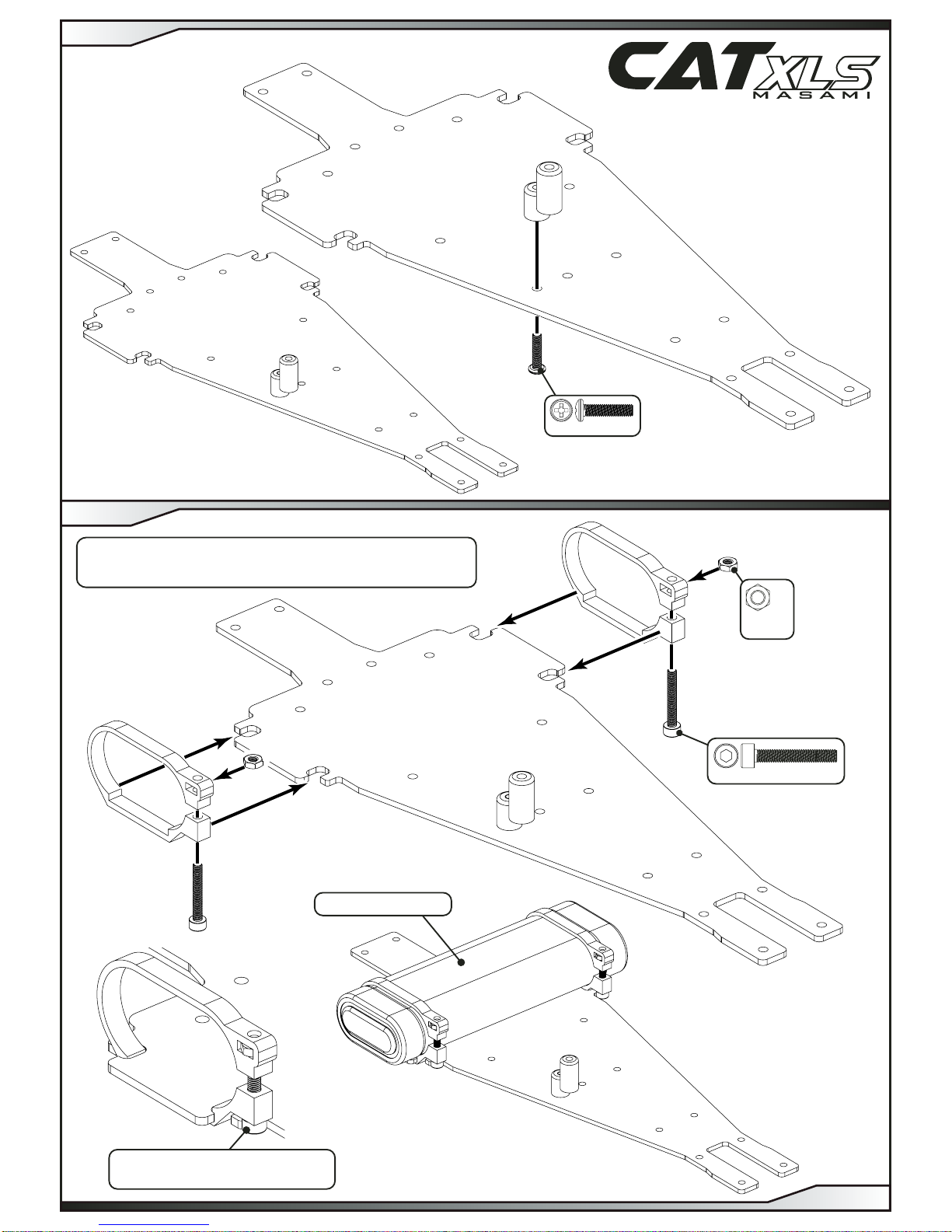

Tighten and loosen these screws

to open and close the battery clamps.

Battery not included.

M3 x 12 x 1

M3 x 20 x 2

M3 Nut

Steel

x 2

Traditional stick pack option. (INCLUDED IN KIT)

(See also STEP 3)

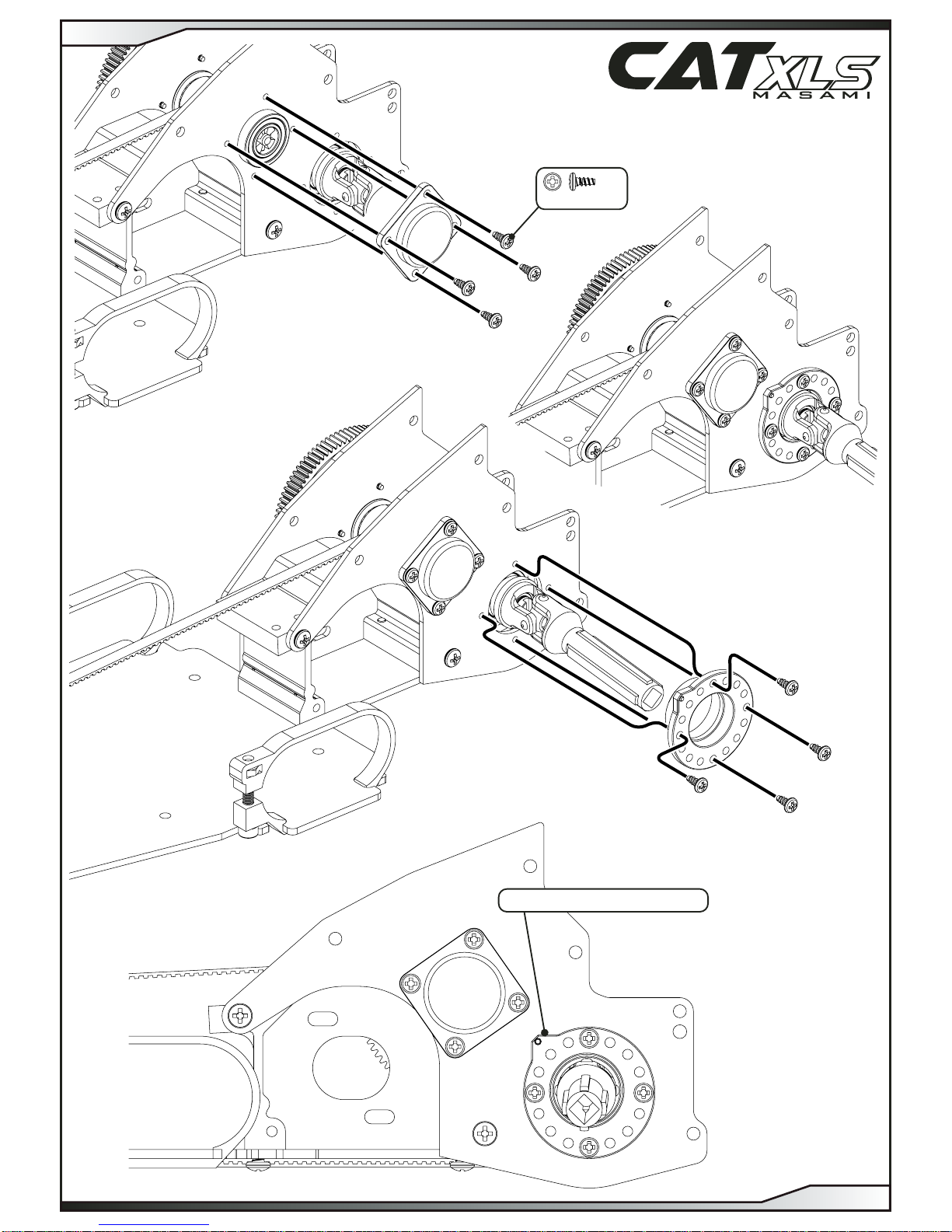

STEP 1

PAGE 2

STEP 2

8.00mm

Battery not included.

Shorty LiPo option.

(INCLUDED IN KIT)

(See also STEP 2)

M4 x 20

x 2

M3 x 8

x 2

M3 x 8 x 4

STEP 3

PAGE 3

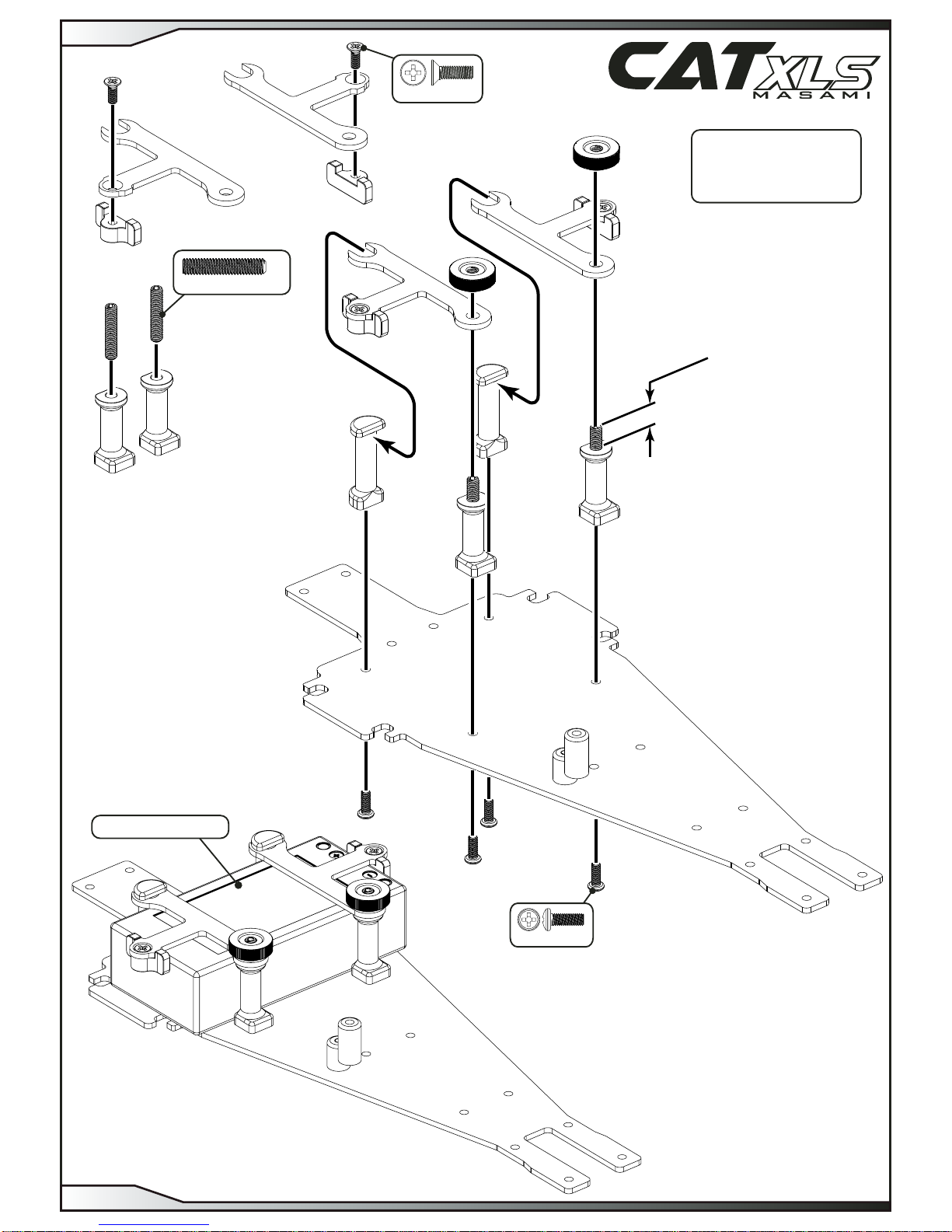

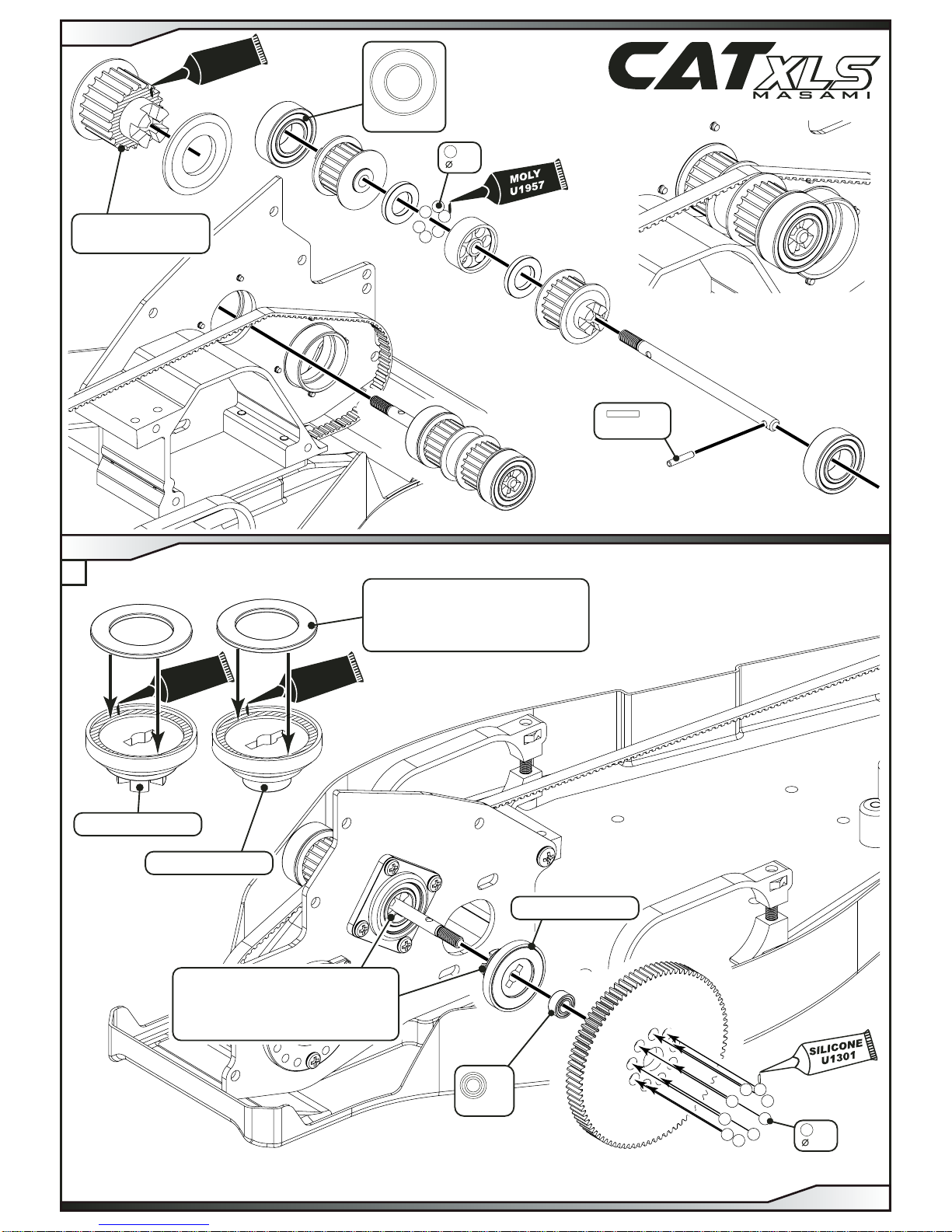

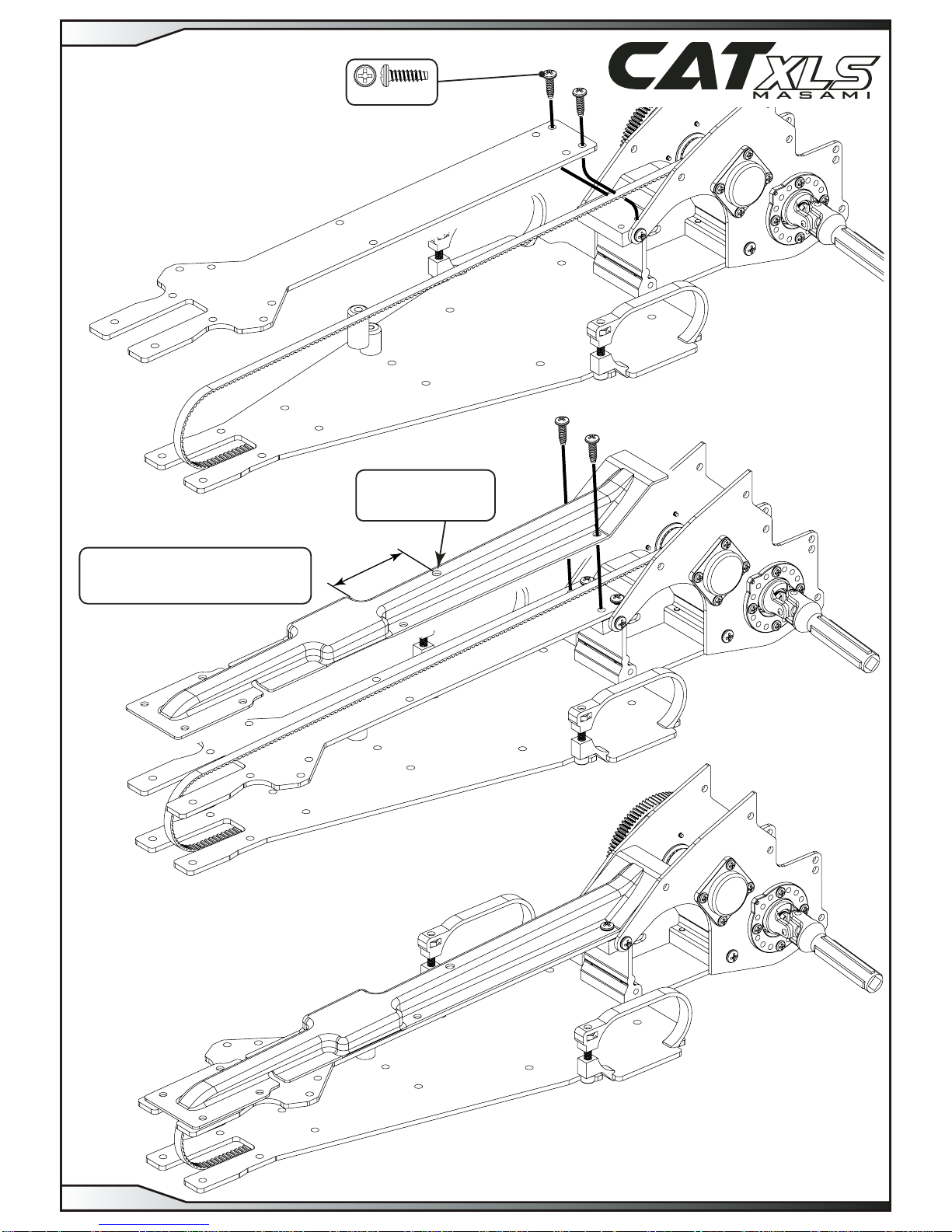

Cut out the undertray as

shown before assembly.

No4 x 3/8” x 7

Assemble belt as shown.

STEP 4

PAGE 4

Set the eccentric as shown for now.

No2 x 3/16” x 8

STEP 5

PAGE 5

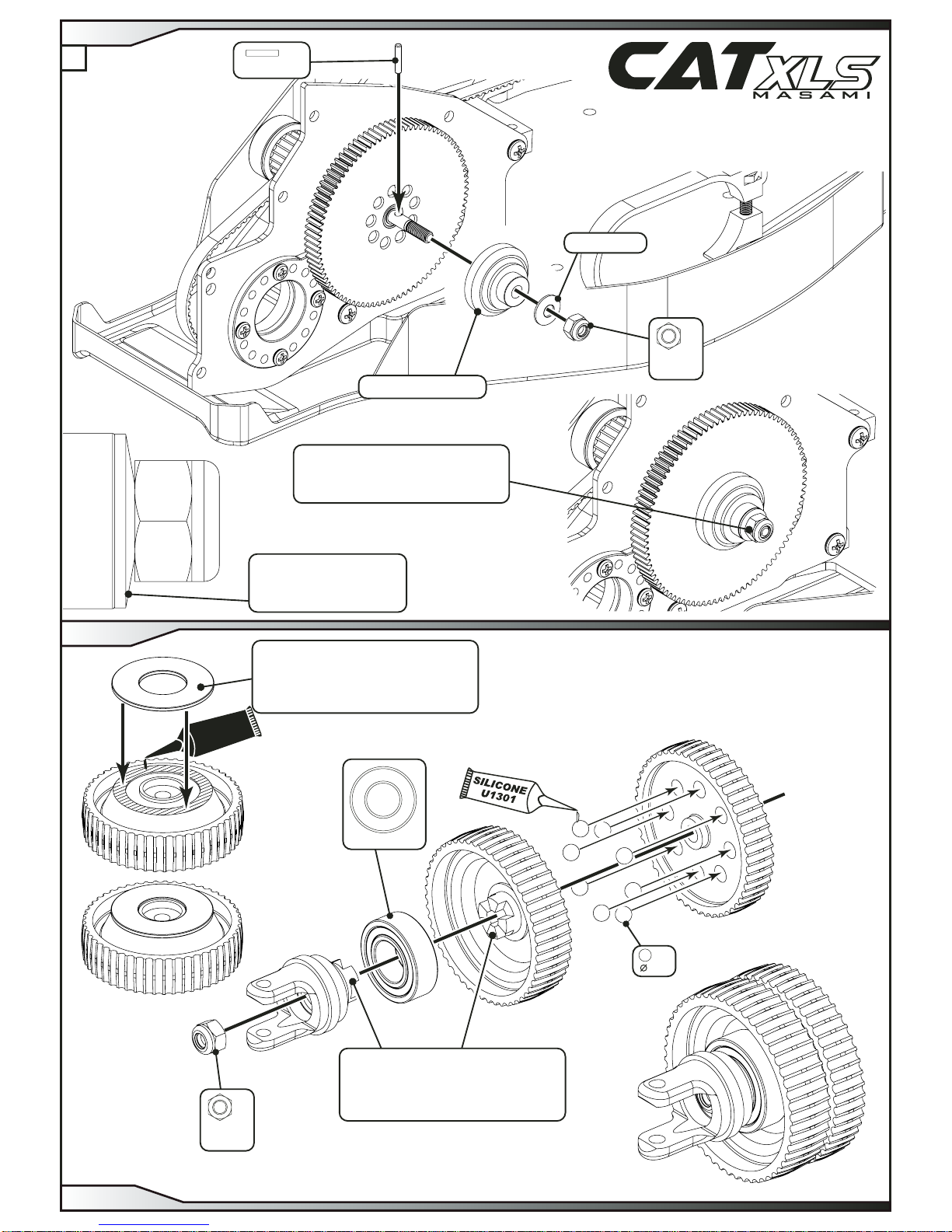

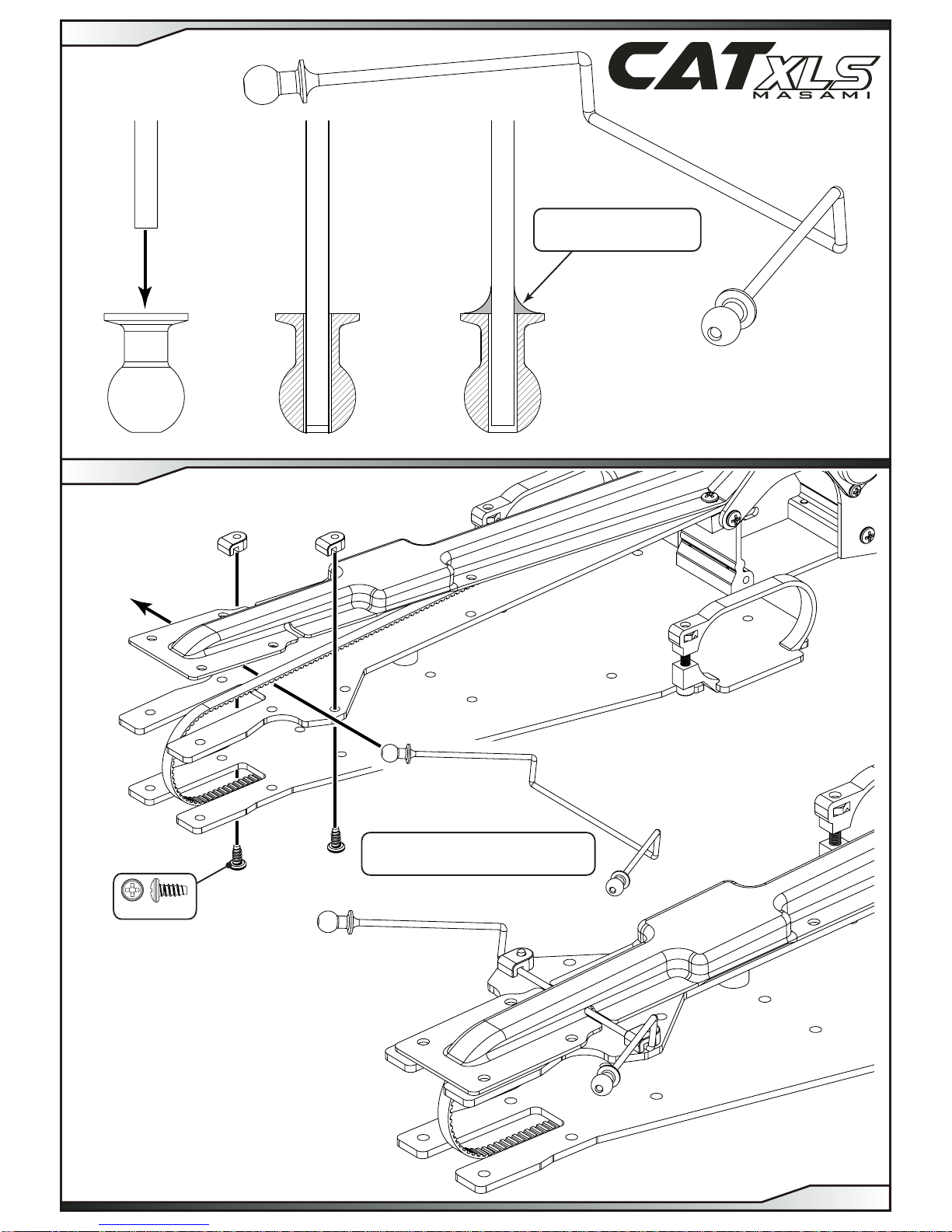

Super Glue

H1057

Super Glue

H1057

Super Glue

H1057

ø1.5 X 7.8

x 1

3.00

x 6

8 x 16 x 5

x 2

IMPORTANT

Ensure the washers are fully

degreased before applying super glue.

(Two part epoxy may also be used)

L/H washer carrier.

R/H washer carrier.

L/H washer carrier.

1/8”x1/4”

x 1

3.00

x 9

Super glue the fences

onto the pulleys.

IMPORTANT

Ensure the drive dogs engage

correctly and push the parts

together firmly.

STEP 6

PAGE 6

STEP 7

A

ø1.5 X 7.8

x 1

IMPORTANT

Ensure the disk spring

is assembled as shown.

R/H washer carrier.

Disc Spring

x 1

M3 Nyloc

Steel

x 1

IMPORTANT

Tighten nut to flatten the disk spring

then undo 1/4 turn.

IMPORTANT

Ensure the washer is fully

degreased before applying super glue.

(Two part epoxy may also be used)

8 x 16 x 5

x 1

3.00

x 8

IMPORTANT

Ensure the drive dogs engage

correctly and push the parts

together firmly.

Super Glue

H1057

M3 Nyloc

Steel

x 1

STEP 7

PAGE 7

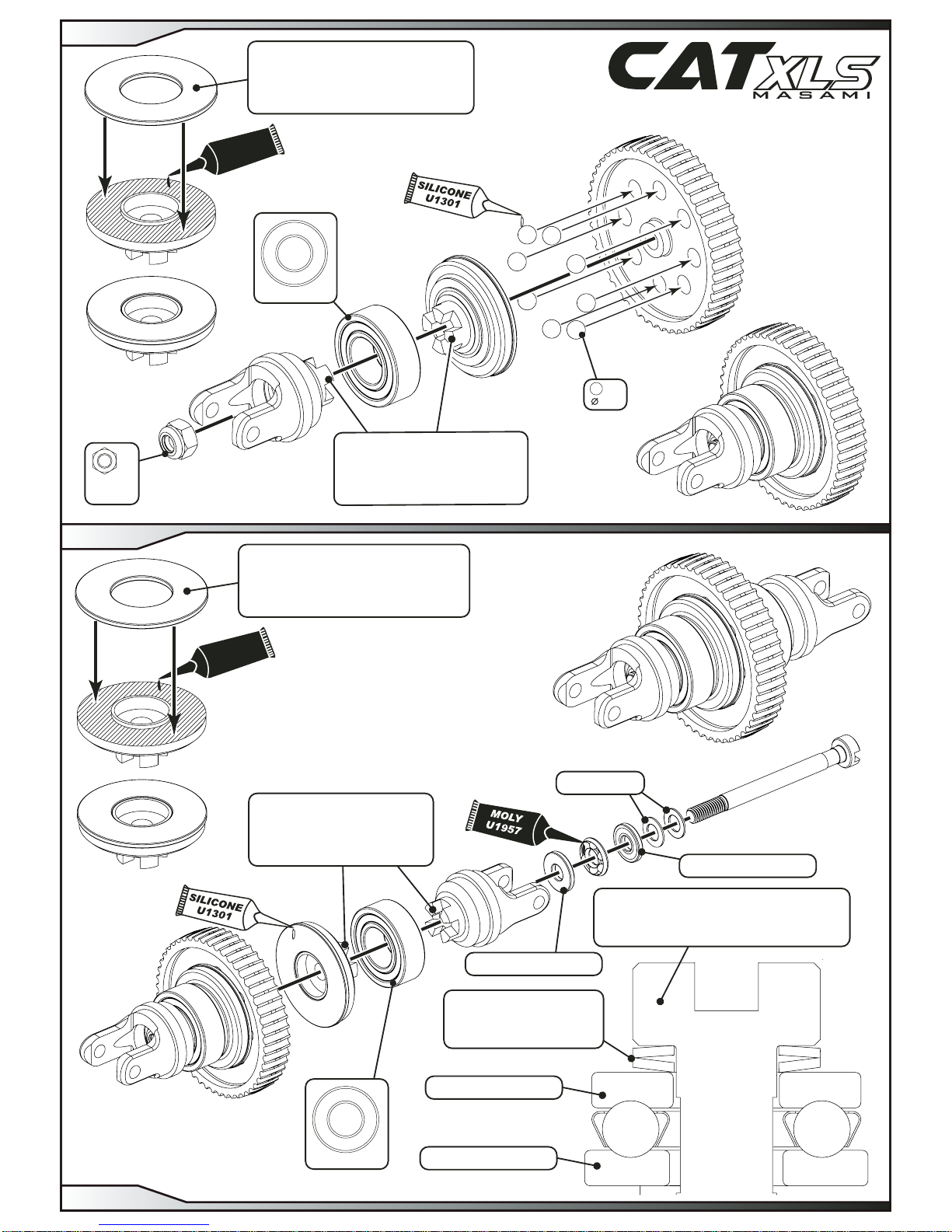

STEP 8

B

IMPORTANT

Ensure the washer is fully

degreased before applying super glue.

(Two part epoxy may also be used)

Super Glue

H1057

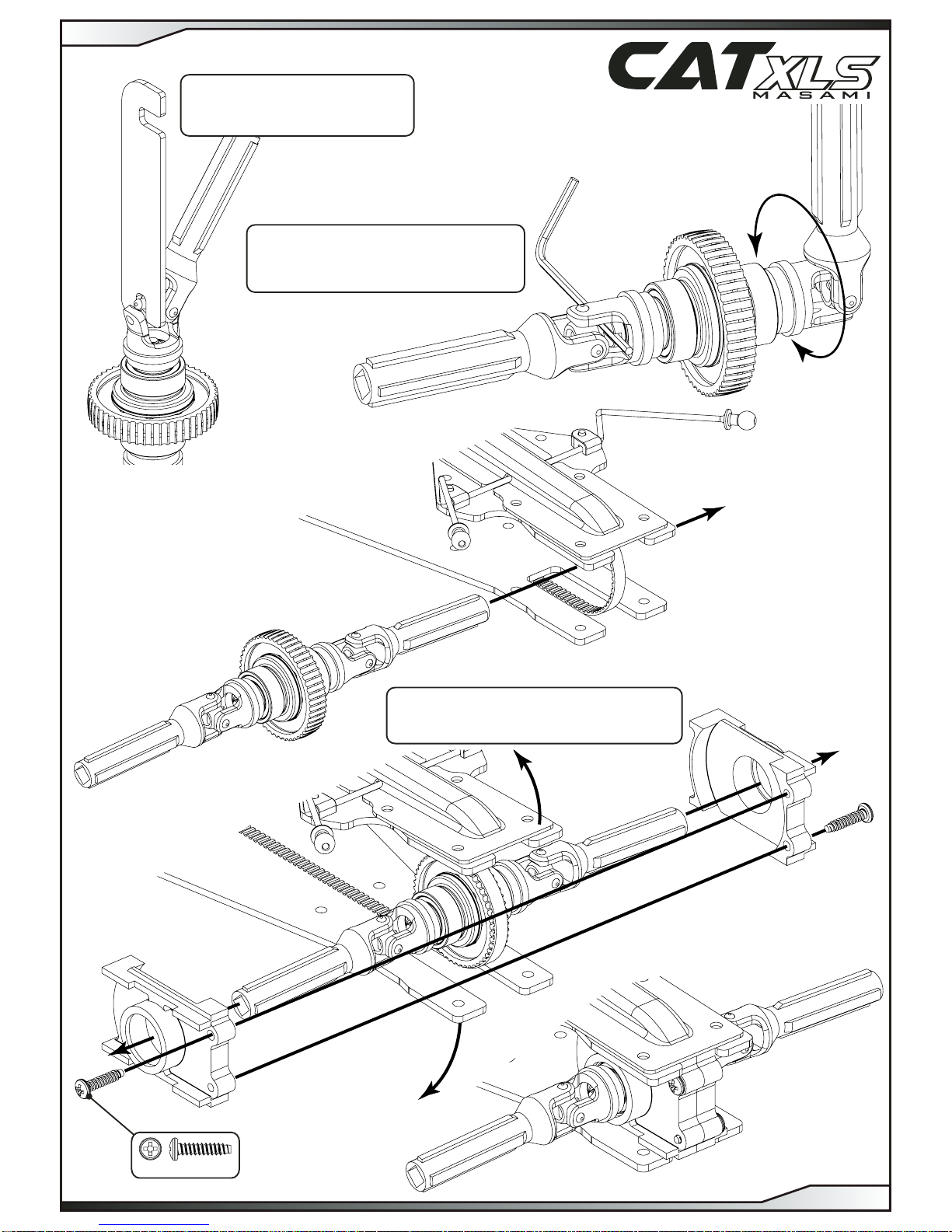

INTEGRATOR DEFINITION.

The Integrator combines the two outputs from the spur gear differential into a single drive to the front belt

and drive to the rear wheels.

IMPORTANT

Ensure the disc springs

are assembled as shown.

IMPORTANT INTEGRATOR SETTING

Tighten screw to flatten the disk

springs then undo 1/4 turn.

IMPORTANT

The sequence of drawings below shows

the assembly procedure of all universal joints,

driveshafts, axles and diff outputs.

NOTE

Warming the plastic parts

will help make the assembly easier.

U.J Spanner

8 x 16 x 5

x 1

IMPORTANT

Ensure the drive dogs engage

correctly and push the parts

together firmly.

Small grooved washer

Big grooved washer

Small grooved washer

Big grooved washer

Disc springs

1

2

3

STEP 9

PAGE 8

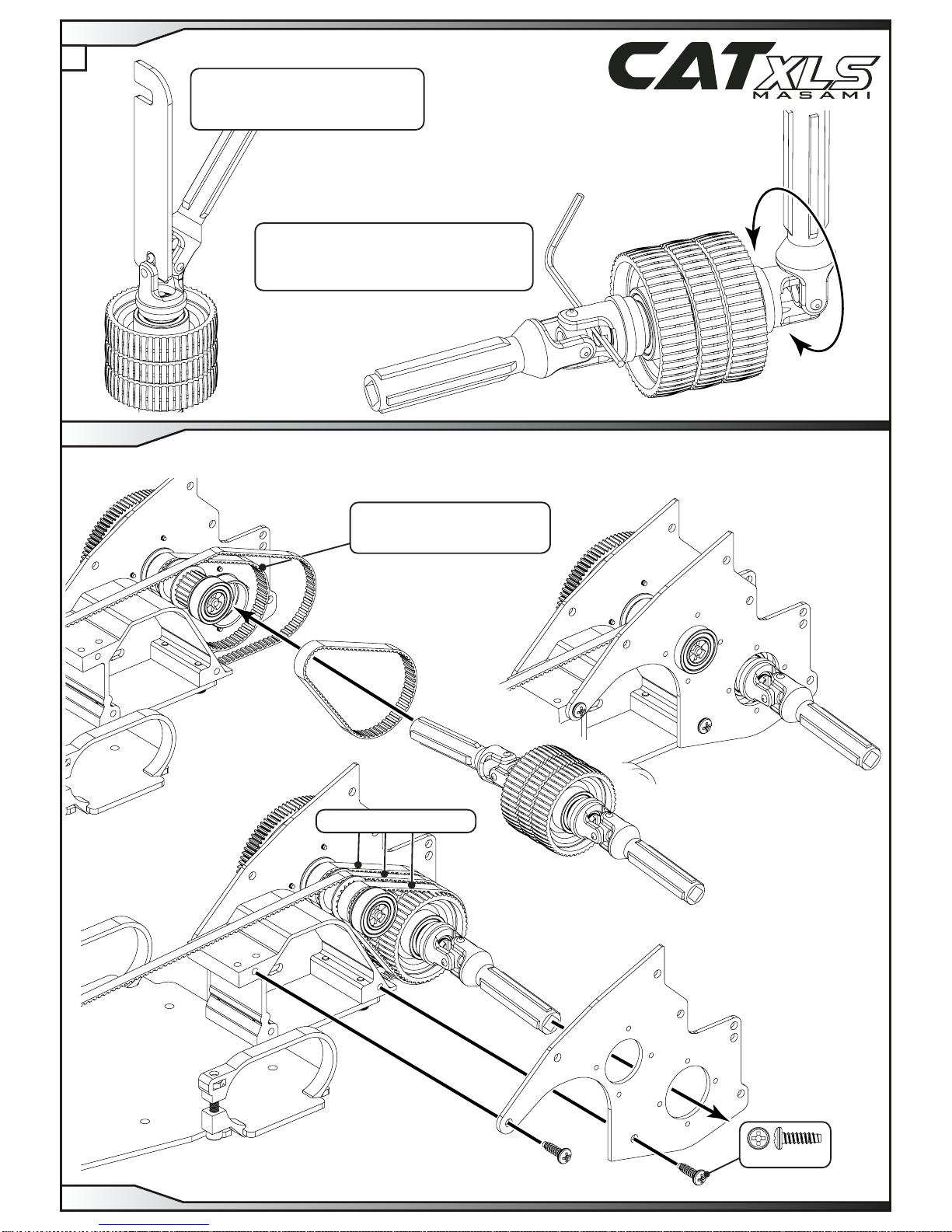

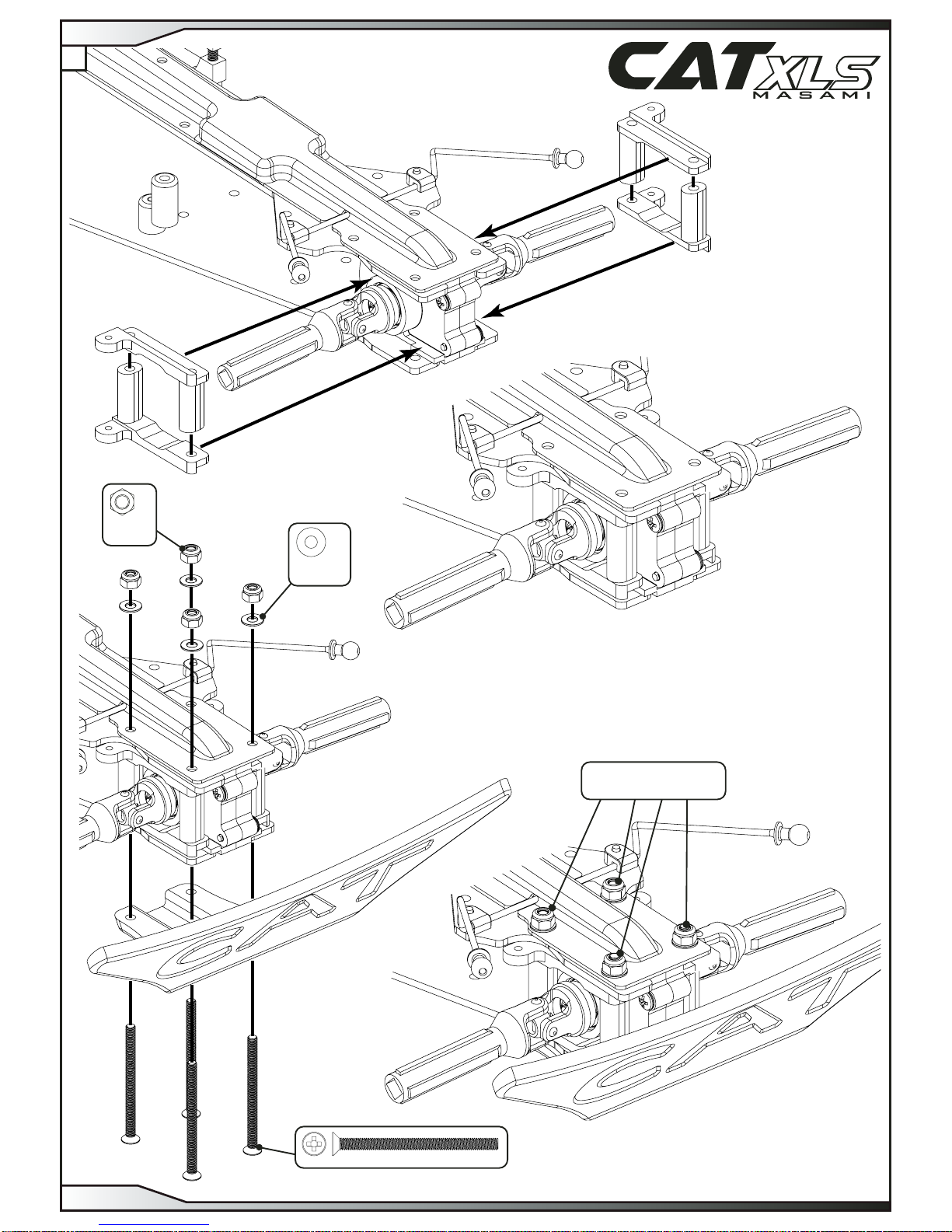

STEP 10

A

IMPORTANT

Use the same assembly procedure

as shown on page 8 STEP 10 A.

IMPORTANT

To adjust the integrator setting when assembled

place an allen key into the screw head slot

and turn the output on the opposite side.

No4 x 3/8”

x 2

Assemble belts as shown.

Assemble the right hand rear belt

first, then the Integrator

and then the left hand rear belt.

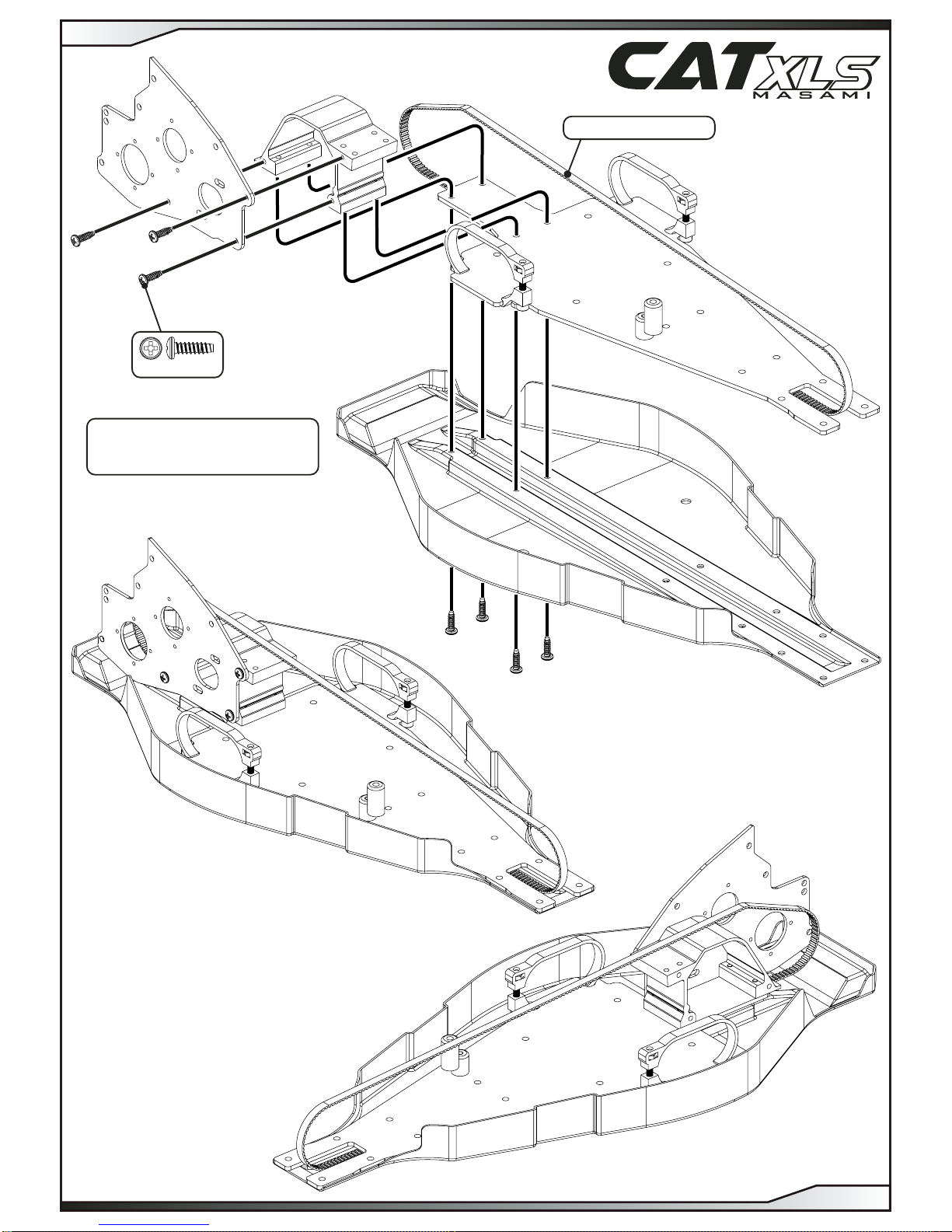

THE UNDERTRAY HAS BEEN HIDDEN FOR ILLUSTRATION PURPOSES ONLY.

(DO NOT REMOVE THE UNDERTRAY)

STEP 10

PAGE 9

STEP 11

B

Set the eccentric as shown for now.

No2 x 3/16” x 8

STEP 12

PAGE 10

34.00 mm

No4 x 3/8” x 4

Optional ø3.00 hole

for checking the front

belt tension.

Cut out the belt cover as

shown before assembly.

STEP 13

PAGE 11

Solder the anti-roll bar to

the roll bar balls as shown.

IMPORTANT

The roll bar must go under the belt.

x 2

No4 x 1/4”

STEP 14

PAGE 12

STEP 15

IMPORTANT

Ensure the washer is fully

degreased before applying super glue.

(Two part epoxy may also be used)

8 x 16 x 5

x 1

3.00

x 8

IMPORTANT

Ensure the drive dogs engage

correctly and push the parts

together firmly.

Super Glue

H1057

M3 Nyloc

Steel

x 1

IMPORTANT

Ensure the washer is fully

degreased before applying super glue.

(Two part epoxy may also be used)

Super Glue

H1057

IMPORTANT

Ensure the disc springs

are assembled as shown.

IMPORTANT FRONT DIFF SETTING

Tighten screw to flatten the disk

springs then undo 1/4 turn.

8 x 16 x 5

x 1

IMPORTANT

Ensure the drive dogs engage

correctly and push the parts

together firmly.

Small grooved washer

Big grooved washer

Small grooved washer

Big grooved washer

Disc springs

STEP 16

PAGE 13

STEP 17

IMPORTANT

Use the same assembly procedure

as shown on page 8 STEP 10 A.

IMPORTANT

To adjust the front differential when assembled,

place an allen key into the screw head slot

and turn the output on the opposite side.

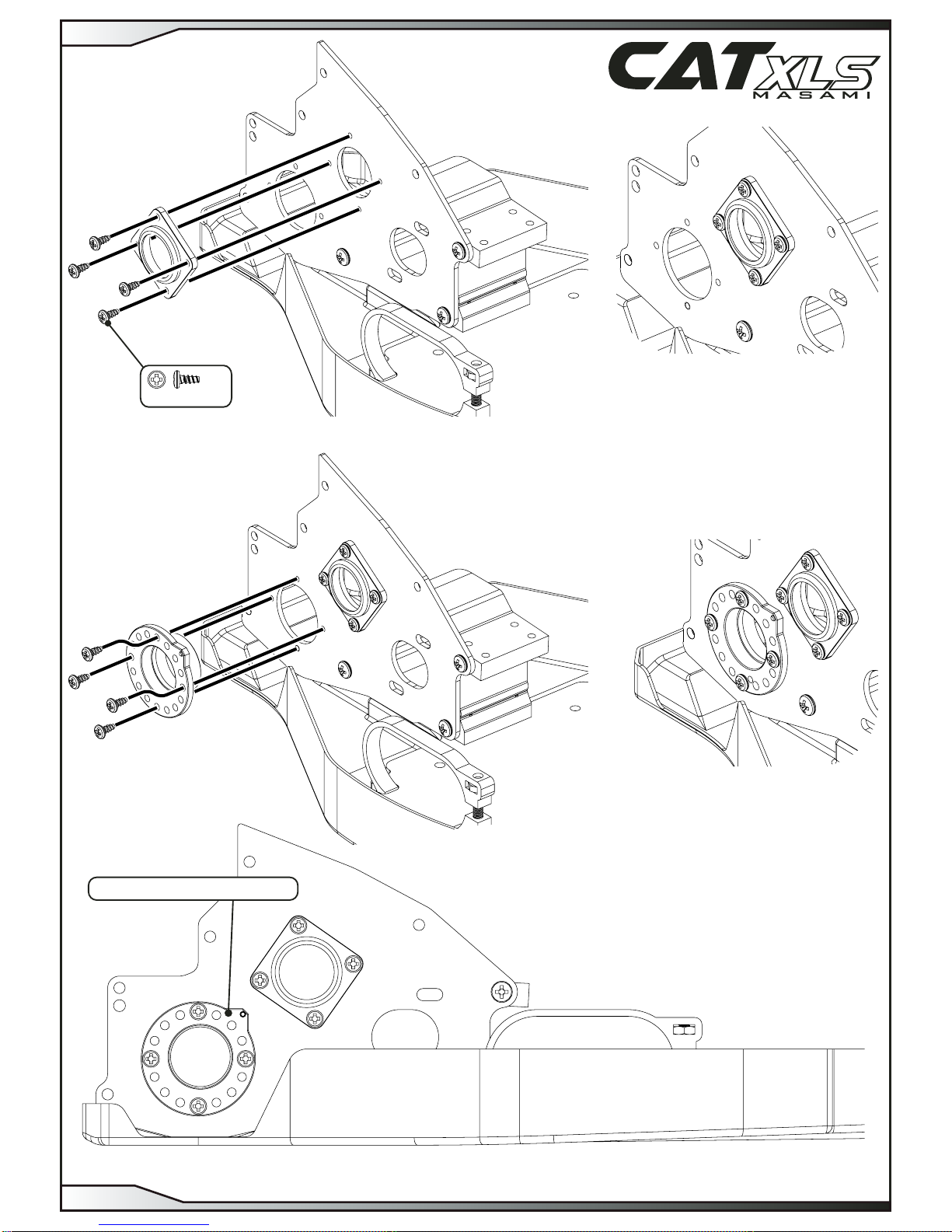

IMPORTANT

Bend the chassis and topdeck

to allow the transmission housings to slot into place.

No4 x 1/2” x 2

STEP 18

PAGE 14

M3 x 40

x 4

M3

Washer

x 4

M3 Nyloc

Steel

x 4

IMPORTANT

Leave loose for now.

STEP 19

PAGE 15

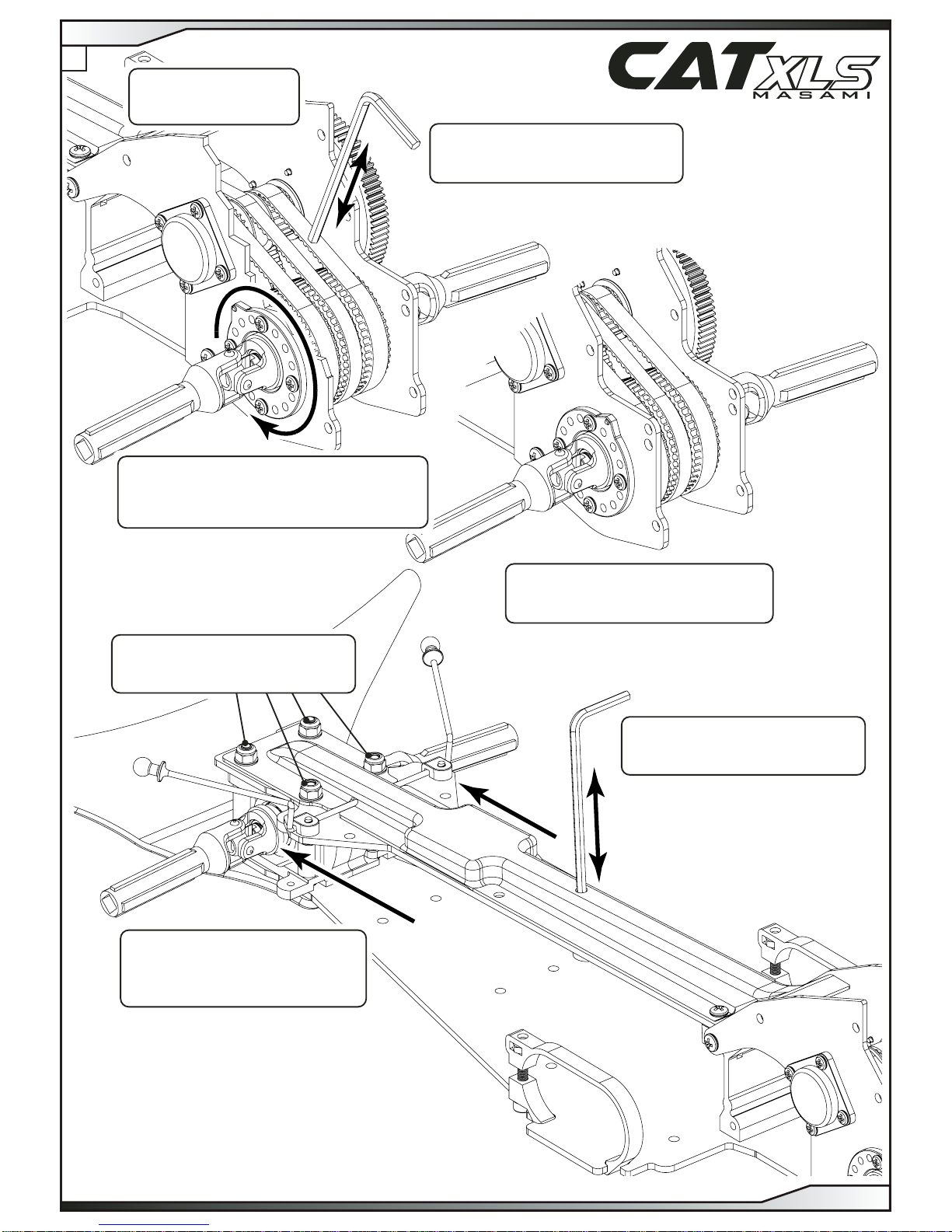

A

Rear Belt Adjustment

Check the rear belt tensions

by pushing on the belts with an allen key.

Rear Belt Adjustment

The eccentrics are already assembled in their loosest

position, rotate as shown to tighten the belt.

ensure both sides are set the same.

Front Belt

Check the front belt tension

by pushing on the belt with an allen key.

Front Belt Adjustment

Pull the front transmission housing

forwards to tighten the front belt tension.

Push it backwards to loosen the belt.

Front Belt

Tighten the nuts fully after the

required front belt tension is acheived.

NOTE

Side frame cut away

for illustration purposes only.

IMPORTANT

Always set the rear belt

tension before the front belt tension

STEP 19

PAGE 16

B