Schulz 580HV20X, 580VL20X, 580VV20X, 7.580HV30X, 7.580VV30X User Manual

...

025.0513-0/Rev. 04

JUNE/06

HEAVY DUTY

Sc hu lz of Ame ri ca , Inc.

34 20 No vi s Pointe

Ac wo rt h, GA 30101

Ph on e # (77 0) 529-4731 / 32

Fax # (7 70 ) 529-4733

sa le s@ sc hu lz am er ic a. co m

ww w.schulzamerica.com

AIR COMPRESSOR

OWNER'S MANUAL

AIR COMPRESSOR

OWNER'S MANUAL

TABLE OF CONTENTS

SAFETY GUIDELINES 1

HAZARD SYMBOLS 1

PRECAUTIONS & WARNINGS 1

DESCRIPTION OF OPERATION 2

PRINCIPLES OF COMPRESSION CYCLES 2

APPLICATIONS 2

SYSTEM COMPONENTS 3

INSTALLATION 3

ELECTRICAL DIAGRAM 5

AIR DISTRIBUTION NETWORK TYPICAL INSTALLATION DIAGRAM 11

START-UP CHECKLIST 12

BREAK-IN PROCEDURES 12

MAINTENANCE SCHEDULE 13

SERVICE PROCEDURES 14

TROUBLESHOOTING 17

LIMITED WARRANTY 18

TECHNICAL DATA 360VL15X 19

AIR COMPRESSOR PARTS 19

BARE PUMP PARTS 20

TECHNICAL DATA 580VL20X 21

AIR COMPRESSOR PARTS 21

BARE PUMP PARTS 22

TECHNICAL DATA 580VL20X- NS 23

AIR COMPRESSOR PARTS 23

BARE PUMP PARTS 24

TECHNICAL DATA 580VV20X 25

AIR COMPRESSOR PARTS 25

BARE PUMP PARTS 26

TECHNICAL DATA 580HV20X 27

AIR COMPRESSOR PARTS 27

BARE PUMP PARTS 28

TECHNICAL DATA 7.580VL30X 29

AIR COMPRESSOR PARTS 29

BARE PUMP PARTS 30

TECHNICAL DATA 7.580VV30X 31

AIR COMPRESSOR PARTS 31

BARE PUMP PARTS 32

TECHNICAL DATA 7.580HV30X 33

AIR COMPRESSOR PARTS 33

BARE PUMP PARTS 34

TECHNICAL DATA 10120HL40X 35

AIR COMPRESSOR PARTS 36

BARE PUMP PARTS 37

TECHNICAL DATA 10120HW40X 38

AIR COMPRESSOR PARTS 39

BARE PUMP PARTS 40

TECHNICAL DATA15120HW60X 41

AIR COMPRESSOR PARTS 42

BARE PUMP PARTS 43

TECHNICAL DATA 20120HWV80X 44

AIR COMPRESSOR PARTS 45

BARE PUMP PARTS 46

ENVIRONMENTAL GUIDANCEAND RECOMMENDATIONS 47

AIR COMPRESSOR - OWNER'S MANUAL

SAFETY GUIDELINES

HAZARD SYMBOLS

Throughout this manual we have identified key safety hazards. The following symbols identify the level of hazard

seriousness.

DANGER

!

WARNING

!

CAUTION

!

Immediate hazard which will result in severe personal injury or death.

Hazards or unsafe practices that could result in severe personal injury or death.

Hazards or unsafe practices that could result in minor personal injury or product or property

damage.

PRECAUTIONS & WARNINGS

Air compressors are high-speed mechanical equipment requiring caution in operation to minimize harm to property and

personnel. There are many obvious safety rules that must be observed in the operation of this type of equipment.

Therefore notall safety precautions that mustbe observed with compressors and compressed air systemsare listed here.

Failure to follow any of these warnings may result in severe personal injury, death, property damage and/or compressor

damage.

- Air from this compressor will cause severe injury or death if used for breathing or food processing. Air used for

these processes mustmeet O.S.H.A. 29 C.F.R.1910.134 or F.D.A 178.3570 regulations.

- This compressoris designed foruse in thecompression of normalatmospheric air only. No othergases, vapors or

fumes should beexposed to the compressor intake,nor processed through the compressor.

- Turn off and lockout/tagout (per O.S.H.A. regulation 1910.147) the main power switch, then release all pressure

from the system,before attempting to service orperform maintenance procedures.

- Relieve allpressure internal to thecompressor prior to servicingper O.S.H.A. regulation 1910.147.Do not depend

on check valvesto hold system pressure.

- A properly sized safety relief valve must be installed in the discharge piping before (downstream) any shut-off

valve, heat exchanger, orifice or any potential blockage point. Failure to install a safety relief valve could result in

rupturing or explosionof some compressor or safetycomponent.

- Do notoperate the compressor overtheA.S.M.E. pressure vessel rating forthe receiver or theservice rating of the

compressor,whichever is lower.

- Do notchange the pressure settingof the safety relief valve,restrict function of the safetyrelief valve or replacethe

safety reliefvalve with aplug. Over pressurization of some systemor compressor componentcan occur, resulting

in severe personalinjury, death andproperty damage.

- Do notoperate the unit with anyof its safety guards, shields,or screens removed.

- Do notattempt to service any partof the unit while thecompressor is operating.

- Never useplastic pipe or rubberhose not specifically ratedfor the necessary pressureand temperature, or lead-in

soldered joints inany part of the compressedair system.

- Do not remove or paint over any DANGER!, WARNING!, CAUTION! or instructional materials attached to the

compressor. Lack of information regarding hazardous conditions can cause property damage or personal injury,

or death.

1

AIR COMPRESSOR - OWNER'S MANUAL

AIR COMPRESSOR - OWNER'S MANUAL

SAFETY GUIDELINES

- Provisions should be made to have the owners manual readily available to the operator and maintenance

personnel. If for any reason any part of the manual becomes illegible or the manual is lost, have it replaced

immediately. The owners manual should be read periodically to refresh one’s memory. It may prevent a serious or

fatal accident.

- Never usea flammable or toxic solventfor cleaning the air filteror any parts.

- Make ageneral overall inspection of theunit daily and correctany unsafe conditions.

- Never play with compressed air. Reckless behavior of any kind involving compressed air can cause serious

personal injury.

- Periodically checkall pressure relief valves forproper operation.

-Any alterations to thecompressor must have prior factoryapproval.

DESCRIPTION OF OPERATION

PRINCIPLES OF COMPRESSION CYCLES

A reciprocating compressor is a piston type pump that develops pressure from the action of a piston moving through a

cylinder.The cylinder,or cylinders, may bevertical, horizontal, or angular.

SINGLE STAGE

compressor is referred to as a “single stage” pump. During the downstroke of a single stage compressor, air is drawn

through an intake valve in the head of the compressor and into the cylinder. At the bottom of the stroke, the intake valve

closes and airis trapped in the cylinder. The air isthen compressed in the cylinderduring the upstroke ofthe piston.

TWO STAGE

the pistonof a pump, airis drawn through an intake valve inthe head of the compressor, intothe low-pressure

cylinder and compressed duringthe upstroke of the piston. The compressedair is then released through a discharge valve

in the head of the compressor to an intercooler where the heat resulting from compression is allowed to dissipate. The

cooler compressed air is then drawn into a second compression cylinder, the high pressure cylinder, for compression to

final pressure. Fromthere the compressed air isreleased through a discharge valveto an air receivertank.

In one revolutionof the crankshaft a compressioncycle is completed.

- When air is drawn in from the atmosphere and compressed to its final pressure in a single stroke, the

- Compressing air to higher pressure it is accomplished by using multiple stages. During the downstroke of

“two stage”

ENVIRONMENTAL GUIDANCE AND RECOMMENDATIONS

1. Disposal of Liquid Effluents

The presence of liquid effluents or non-treated condensation from tank and separator in rivers, lakes or in other water

receiving bodies mayadversely affect the aquatic lifeand the water quality aswell.

The condensation withdrawn from the tank and separator, daily, according to the Preventive Maintenance Chapter, must

be kept ina container and/or in anappropriate collecting network forfurther treatment.

Schulz, the manufacturer of the product, recommends that the liquid effluent produced inside the receiver of the

compressor or condensed separator should be adequately treated through processes that aim at protecting the

environment and thehealthy quality of life ofthe population, complying withthe country's current regulation requirements.

Among the treatmentmethods available, one may choosethe physical-chemical, chemical, andbiological ones.

The treatment maybe carried out by thecompany itself or by outsourcing.

2. Draining theLubricant Oil from the CompressorUnit

The disposal of the lubricant oil coming from the lubricant oil change located in the crankcase of the piston compressor

must meet technical requirements, as well as the regulation requirements of the current legislation of the country the

product has beenexported to.

3. Disposal of Solid Waste (parts in general and product packages)

The generation of solid waste is an important aspect that must be considered by the users when using and maintaining

their piece of equipment. The impacts to the environment may cause meaningful changes in the quality of the soil, in

surface and underground water, and in the population's health, due to the inadequate disposal of the discarded residues

(on streets, watersprings, landfills, etc).

Schulz, the manufacturer of the product, recommends that the waste arising from the product, from its generation,

handling, transportation, and treatment to its final disposal should the handled carefully. Appropriate handling should

consider the following steps: quantification, qualification, classification, reduction at source, pick-ups and selective pickups, recycling, storage,transport, treatment and final destination.

The disposal of solid waste must be carried out according to the regulation requirements of the current legislation of the

country the producthas been exported to.

APPLICATIONS

Single estage compressors normally runs in the 95 up to 125 psi range. These pressure settings are designed to provide

working air in the 90 up to 100 psi range that most air tools operate. These compressors are generally used in lighter duty

applications such asin your garage at home.

A two-stage compressor normally run in the 145 up to 175 psi range. The higher-pressure setting of the two-stage unit is

required in commercial and industrial applications that have tools and equipment such as in-ground lifts and tire changers

that need air at higher pressure than a single stage compressor can provide. Two stage compressors are generally better

suited for commercial use for several other important reasons. First, this high-pressure air is store in the tank as “available

energy” so the compressor runs less. Secondly, two stage compressors run at much lower discharge temperatures so that

you have cooler, dryer air in the shop air system. The two-stage compressor is more versatile because it gives the shop

owner the ability to use the higher pressures when necessary but also use air regulated down of the 90 up to 100 psi range

for normal airtools.

2

47

AIR COMPRESSOR - OWNER'S MANUAL

AIR COMPRESSOR - OWNER'S MANUAL

TECHNICAL DATA 20120HWV80X

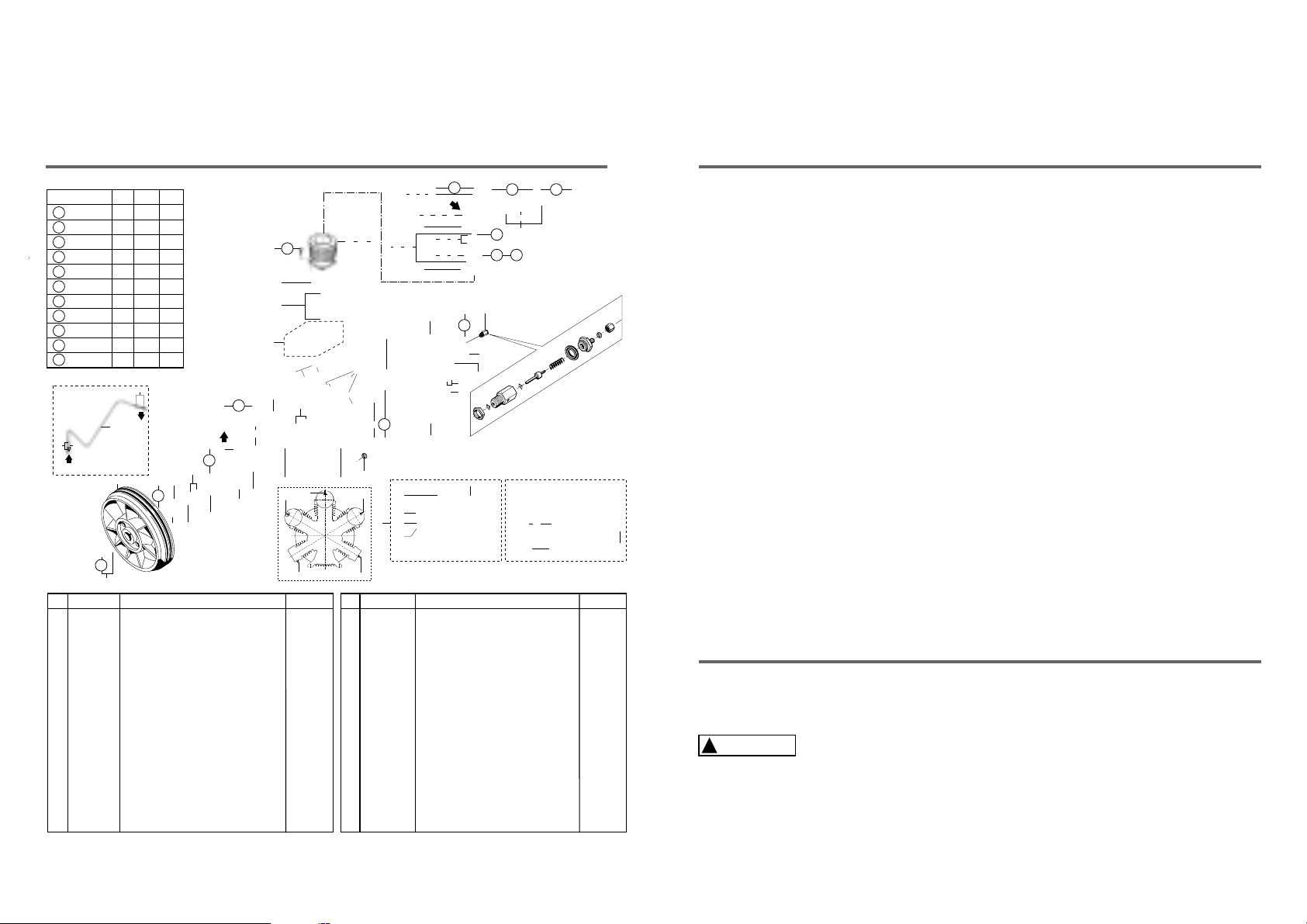

BARE PUMP PARTS

Position lbf.in

ft.lb

T1

T2

T3

5.8

T4

T5

T6

101

27.8

T7

T8

T9

HP-LP 40-41-59

LP 40-41-59

T10

T11

TABLE 1 - TORQUE

ESPECIFICATION FOR BOLTS

9

1.6

3.6

55

57

A

T5

12

No. No.

CODE CODEQTY QTYDENOMINATION DENOMINATION

709.1346-0

1

*

2

20505001

3

830.1033-0/NA

4

60082501

5

830.0932-0

6

60154502

7

*

8

60259501

9

20504001

10

60154501

11

830.0933-0

12

60267503

13

*

14

20508005

15

830.0934-0

16

30008502

17

830.0938-0

18

60152502

19

60152501

20

30007007

21

830.0937-0

22

*

23

20501001

24

003.0029-2

25

830.0775-0

26

709.1316-0

27

*

28

003.0031-4

29

60273501

30

830.1000-0

31

830.0939-0

32

000.0077-0

33

000.0080-0

34

000.0075-0

35

* Part available in the market - not sold by Schulz

Note: HP = high pressure LP = low pressure

N.m

25

30449

7048

702

15828

1,21512

33414

18523

14161

19

44

26458 30

56

B

214

137

34

80

8

18

38

21

16

2.2

5

14

A

8

T2

6

58

13

15

12

22

T3

7

53

Flywheel

UNC 1/4" x 3/4" head bolt

Flange cover

Crankcase gasket kit

Oil seal

Lock washer and nut kit

33109 bearing

NC 1/2" x 1" head bolt

Straight fitting

Flange

32211 bearing

Crankshaft kit

Key

UNF 3/8" x 3" head bolt

Crankshaft counter weight

Connecting rod pin kit

Connecting rod

Master connecting rod

Connecting rod inner bushing

Connecting rod bushing

Counter weight with centrifugal mechanism

Counter weight kit with centrifugal mechanism

UNF 5/16" x 1.1/4" Allen head bolt

Crankcase

3/8" plug

3/4" oil level sight kit

Crankcase cover

UNC 5/16" x 3/4" head bolt

3/4" plug

LP 4.3/4" piston

HP 90mm piston kit

HP 2.1/2" piston kit

LP 4.3/4" ring kit

HP 90mm ring kit

HP 2.1/2" ring kit

T6

9

10

35 - 34 - 33

32 - 31 - 30

12

13

11

8

T2

4

17

15

16

12 62

64

64

01

04

01

01

01

01

01

26

01

01

01

01

01

02

01

04

03

01

02

07

01

01

02

01

01

01

01

06

01

03

01

01

03

01

01

37 38 39

20

18

20

19

21

T7

23

22

63

64

65

6868

830.1031-0/NA

36

709.1306-0

37

709.1308-0

38

709.1347-0

39

830.0955-0

40

830.1002-0

41

809.1028-0

42

809.1027-0

43

809.1029-0

44

709.1272-0

45

709.1423-0

46

709.1424-0

47

709.1389-0

48

49

709.1457-0

50

709.1459-0

51

709.1458-0

52

21011004

53

21029003

54

830.0340-5

55

003.0054-3

56

830.0599-8

57

383.0111-0

58

830.0957-0

59

830.1032-0

60

013.0752-0

61

830.1202-0

62

019.0079-0

63

022.0177-0

64

809.1043-0

65

709.1369-0

66

709.1456-0

67

022.0215-0

68

21011002

69

61

60 59 41 40

48 47 46 45

36

40 41 59

44 43 42

40 41 59

36

29

4

24

51

69

50

54

** See code page 44

Upper gasket kit

LP 4.3/4" cylinder

HP 90mm cylinder

HP 2.1/2" cylinder

LP 4.3/4" valve plate kit

HP 90 mm valve plate kit

LP 4.3/4" valve plate

HP 90mm valve plate

HP 2.1/2" valve plate

LP 4.3/4" cylinder cover (with breather)

LP 4.3/4" cylinder cover (without breather)

HP 90mm cylinder cover

HP 2.1/2" cylinder cover

*

UNC 3/8" x 1.1/2" head bolt

Short intercooler No. 2

Medium intercooler No. 3

Long intercooler No. 4

3/4" nut for intercooler

Intercooler holder

1/4" crankcase breather tube

1/8" x 1/4" straight connection

1/4" ring kit

HP 5/16" x 1.1/2" Allen hex bolt

HP 2.1/2" valve plate kit

Washer kit

M6 x 1 x 55 Allen hex bolt

Connecting rod with needle bearing

Needle bearing

LP 1/8" ASME safety valve

Intercooler kit without tube No. 1 (item 66)

Discharge tube No. 1

Discharge tube No. 5

HP 1/8" ASME safety valve

3/4" x 3/4” straight connection

46

T8

B

T9T9T10

28

28**

T4

27

4

26

25

ASSEMBLY OF INTERCOOLERS

52

T1

49 58

44**

43**

67 65

66

DESCRIPTION OF OPERATION

T11

53

01

03

01

01

03

01

03

01

01

01

02

01

01

23

01

01

01

10

03

01

01

01

06

01

01

08

01

02

03

01

01

01

02

06

SYSTEM COMPONENTS

Pressure Switch

pressure drops belowthe cut in setting.

Once the pump builds the pressure up to the maximum or cut out pressure, the pressure switch shuts off the motor and

bleeds down theair pressure between the pumpand check valve. This allowsthe motor to restart inan unloaded mode.

Check Valve

the checkvalve is “open”, allowing theair to flow from thepump to the tank. Whenthe compressor stops, the checkvalve is

“closed” and keepsthe air in the tankfrom trying to back upto the pump.

Pressure ReliefValve

pressure in theevent the pump did notshut off at the maximumsetting.

Tank Drain Valve

will form insidethe tank every time thecompressor runs, it is importantto drain the tankdaily.

Intake Air Filter

filter element becomes clogged with dirt it creates a high vacuum condition in the cylinder which can cause the oil from the

crankcase to besucked up past the ringsand into the tank.

ON / OFFSwitch

can startautomatically. Thecompressor should not be turnedoff in mid-cycle using the switch (except in an emergency) so

that the pressureswitch is allowed to relievethe head pressure when ittums off the compressor.

Pressure Gauge

SHUT OFF Valve

valve is used during scheduled maintenance to separate the compressor from the rest of the air system. It could also be

important to quicklyshut off the air fromthe tank in case ofa problem like an airlinebreaking.

Cooling System

generated, the cooling system of thecompressor is critical to the life of the pump. Compressor pumps are heavily finned to

dissipate heat. Cooling air is blown over the fins by the fan blades designed into the flywheel of the pump. The inter cooler

and after coolerlower the air temperature significantly, thereby making iteasier to compress the air.

- Thepressure switch senses the air pressure in the system and automatically starts the motor whenthe

- The check valve is a device that allowsthe air to flow in only onedirection. While the compressor is running,

- This valve is often called a “pop-off” ora “safety relief valve”. Its job is toopen up andrelieve the air

- This valve, also knownas a petcock, isto drain out any condensationin the tank. Since some moisture

- As air is drawn into the compressor pump it must pass through a filter to remove dirt and dust. When the

- Starts andstops the air compressor. It is importantto remember that inthe “On” position, the compressor

- The pressure gaugereads the air pressurein the tank or airsystem.

- A ball or gate valve that is installed on the tank where the air is going out to the shop air system. This

- Air compressor pumps create remarkable amount of heat as they operate. Because so much heat is

INSTALLATION

Location - The air compressor shouldbe installedin a clean, dry, well lighted, and well ventilated area on a level floor. The

flywheel side of the compressor should be towards the wall and the distance between the compressor and the wall should

be a minimumof 30” to allow forproper cooling air circulation, inspections,and maintenance.

WARNING

!

Mounting - Yourcompressor mustbe installedaccording toall applicable State and Local Laws. Shims may be needed to

level the legs. Care must be taken when tightening anchor bolts. Uneven torque can lead to excessive vibration that can

weaken welds andcause explosions. Tighten three leveled legsequally and leave the fourthnut loose.

Under no circumstances a compressor be placedin anarea that may be exposed to a

toxic, volatile or corrosive atmosphere nor should toxic, volatile or corrosive agents be

stored near thecompressor.

should

3

AIR COMPRESSOR - OWNER'S MANUAL

AIR COMPRESSOR - OWNER'S MANUAL

INSTALLATION

Air Intake - Do not locate the compressor where it could ingest toxic, volatile or corrosive vapors or extremely dirty air. If a

remote inlet filter is going to be installed you must increase one pipe size for every ten feet in length and use a flex hose

between the pumpand any solid pipe tominimize the potential of damagefrom vibration.

Piping - The main distribution line should not be any smaller than the pipe size of the shut off valve of the compressor. It is

recommended that the shop air system be connected to the air compressor shut off valve with a flexible coupler to reduce

the risk of damage from vibration. All airlines should slope to an accessible drain or moisture trap for removal of

condensation. Make sure that there are no leaks in the airlines as even small leaks can cause your compressor to run

outside ofthe rated duty cycle. A typical installationis shown on page 11, note thatthe feeder lines come off of the topof the

main distribution lineso that moisture can't enterthe feeder line.

WARNING

!

DANGER

!

Wiring -

Before starting the installation procedure, check that the building's electrical service has an adequate

capacity to handle the motor and the same electrical characteristcs (voltage, cycle, and phase). Install the compressor

as close to the main power supply as possible and follow all National Electric Safety Codes as well as those dictated

by State and Local authorities. A qualified electrician must do the electrical installation. Every compressor model has a

specific power requirement and the wire size used is critical to a proper installation. The two tables (shown below) are

for reference only and should not supersede specific National, State or Local code requirements. The compressor can

be mannufactured without a , according to the product version.power switch The must not be

directly connected to the motor but to a control circuit. See "Electrical Diagram" page 5 and 6 to correct

installation, according to the product version.

30 amp circuit

0-30 ft.

31-50 ft.

51-70 ft.

71 ft and up:

call factory

Orientative table for wiring

Grounding instructions: This product must be

grounded to reducethe risk of an electricshock. Connect

the Grounding cable to the motor's terminal, or if there is

no terminal tothe motor's frame.

WARNING

The incorrect installation of the grounding wire connector may result in an electric shock. If it is

necessary to replaceor repair both thecable and the connector, do not connector join the groundingwire

to the neutral wire or other. The green wire, with or without yellow stripes, is only to the grounding

function. In case of doubts regarding the grounding information or whether the product is properly

grounded, make sureyou contact a qualified electricianto verify the connections.

ASME coded pressure vessels must not be modified, welded, repaired, reworked or

subjected to operating conditions outside the nameplate ratings. Such actions will negate

code status, affect insurance status and may cause severe personal injury, death and

property damage.

High voltage may cause personal injury or death. Disconnect and lockout/tagout per

O.S.H.A. Regulation 1910.147 all electrical power supplies before opening the electrical

enclosure or servicing.

pressure switch

10 ga

8 ga

6 ga

40 amp circuit

0-25 ft.

26-50 ft.

51-75 ft.

76 ft and up:

call factory

8 ga

6 ga

4 ga

60 amp circuit

0-10 ft.

11-30 ft.

31-50 ft.

51 ft and up:

call factory

8 ga

6 ga

4 ga

Motor power [ hp ]

single-phase

Orientative table for fuses

* type 2 coordination

three-phase

3

5

-

7.5

-

-

-

-

-

-

-

-

-

-

5

-

7.5

7.5

10

10

15

15

20

20

Input supply

voltage [V]

230

230

460

230

230

460

230

460

230

460

230

460

Max.fuse

(gL/gG)* [A]

50

35

20

80

50

25

63

35

100

50

100

63

4

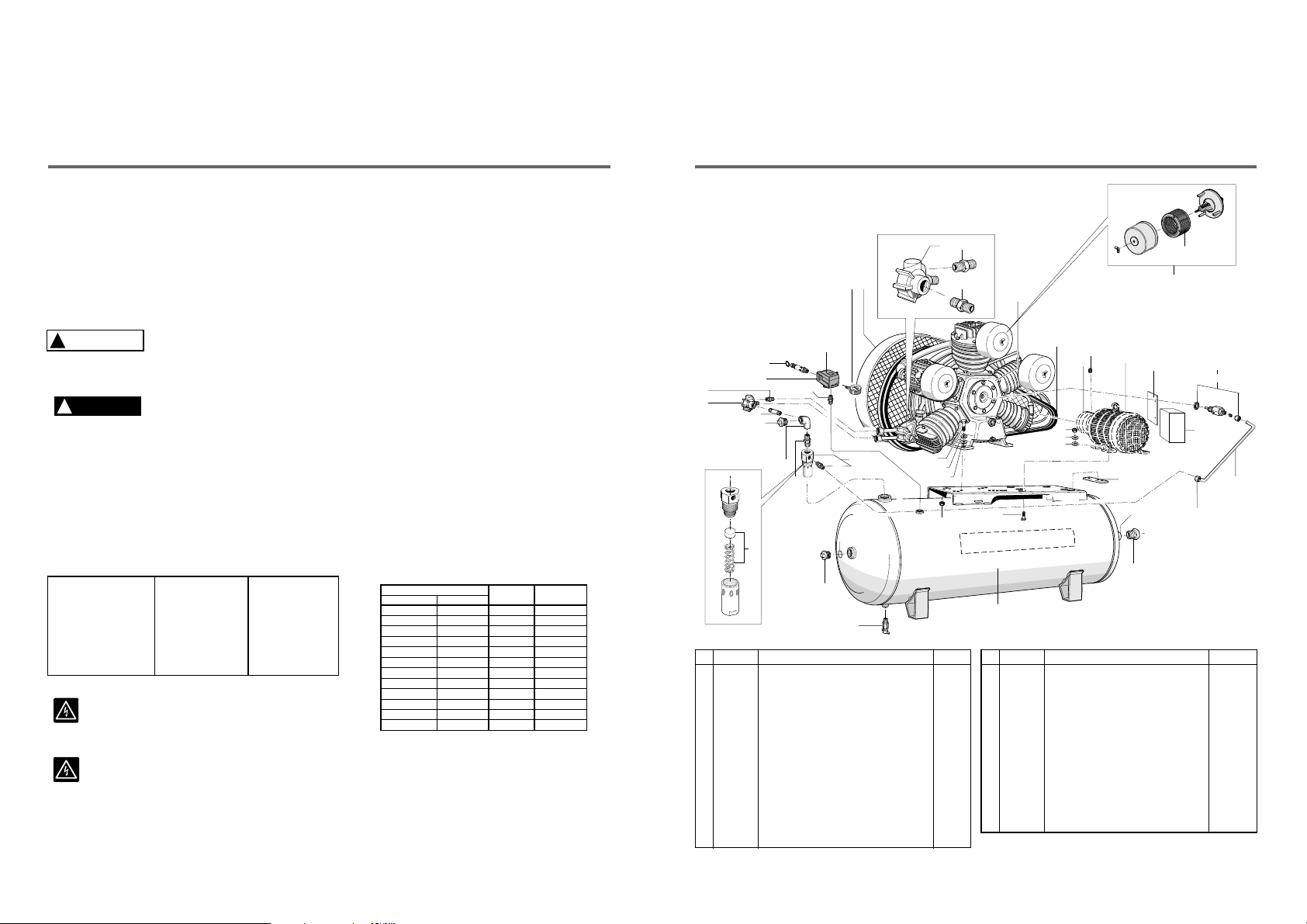

TECHNICAL DATA 20120HWV80X

AIR COMPRESSOR PARTS

67

8

9

14

2

19

DENOMINATION

18

20

21 - 45

16

No.

3

4

1

2

3

4

6

7

8

9

10

11

13

14

15

16

17

18

19

20

21

23

24

25

CODE

933.9385-0

003.0036-5

21011001

20517005

830.1023-0

011.0118-0

012.0845-0

003.0174-4

012.0723-0

022.0057-0

21011006

003.0343-0

003.0031-4

60281501

34004508

003.0054-3

003.0514-0

023.0339-0

022.0185-0

*

*

25003832A

11

10

13

15

17

Bare pump

3/4 nipple

NPT 3/4 x 1/2 straight connection

Upper tubing adaptor

Belt guard

Pressure gauge

Pressure switch

1/4 nipple

Strain relief

1/4 ASME safety valve

3/4 x 126mm nipple

3/4 side elbow

3/4 plug

Check valve

Check valve kit

NPT 1/8 x 1/4 straight connection

2 Plug

O - ring

1/4 tank drain valve

W 1/2 x 1.1/2 hex head bolt

BSW 1/2 hex nut

120 gal horiz. Tank

4 3

2

23

35

36

24

QTY

01

02

04

02

01

01

01

01

01

01

01

01

01

01

01

01

01

02

01

04

04

01

1

31

38

30

37

34

35

36

32

33

25

No.

CODE

26

003.0512-0

27

709.1671-0

28

022.0174-0

29

830.1043-0

30

015.0604-0

31

004.0022-0

32

21028539

33

*

34

*

35

*

36

*

37

709.1349-0

38

*

39

012.0941-0

40

701.0381-0

41

012.0907-0

42

012.0910-0

43

809.1085-0

44

007.0118-0

45

709.1246-0

* Part available in the market - not sold by Schulz.

** Optional start switch

DENOMINATION

2 x 1 reduction bushing

1/4 tube

Centrifugal unloading valve

Centrifugal unloading valve kit

Motor 208/230/460V (three-phase)

Belt

Motor fastening plate

7/16 x 1.3/4 hex head bolt

7/16 hex nut

1/2 lock washer

1/2 washer

Pulley

3/8 x 1/2 Allen hex without head

Start switch**

Support start switch**

Start switch pressure switch cord (not shown)**

Motor start switch cord (not shown)**

3/4 NPT air filter

Filter element

Hose for tank drain (not shown)

20

26

44

43

40

29

28

39

27

18

QTY

01

01

01

01

01

02

02

04

04

08

08

01

01

01

01

01

01

03

03

01

45

AIR COMPRESSOR - OWNER'S MANUAL

AIR COMPRESSOR - OWNER'S MANUAL

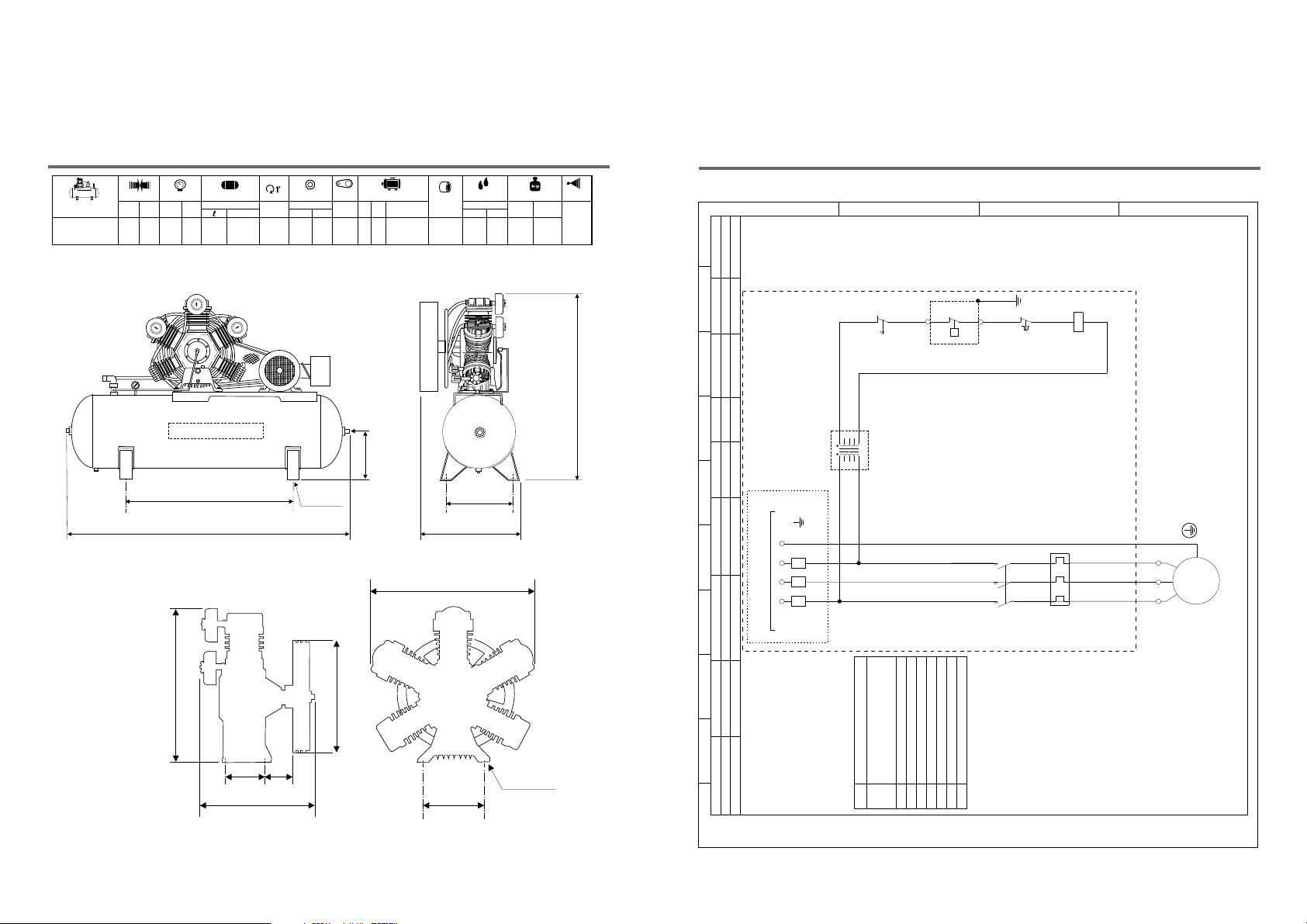

TECHNICAL DATA 20120HWV80X

427 113

47.3/1,200

78.3/1,990

TANK

Geom. Volume

MODEL

20120HWV80X

DISPLACEMENT

MAX. PRESSURE

cfm psig bar

l/min

80 2,264 175 12

INSTALLATION

BELT

Ø PULLEY

2P

rpm

gal

910 5.7

inches

mm

145

ELECTRIC MOTOR OIL CAP.

SIZE

2P

2-B

hp kW

20

15

208/230/460

VOLTAGE (V)

Three-phase

DISCHARGE

SIZE

1’’

ml

4,500

Volume

in qt.

4,620

WEIGHT WITH MOTOR

lbs

1,370

620

COLOR

REF.

Kg

Black

(pump)

Gray

(tank)

57.5/1,460

1'' BSP

13.3/340

4 x Ø 5/8/16

18.9/480

25.6/650

37.8/960

ELECTRICAL DIAGRAM

A

9

8

7

STARTLINE

PROTECTION

AND CONTROL

6

5

GROUND

LINE CIRCUIT

4

COMPRESSOR MOTOR

SUPPLY 230/460* VCA-60Hz

3

T

S

230/460* V 60HZ

R

Customer's responsibility

B

C

DD

**

***

21

11

12

B1

T

*

230V

460V

22

P

P1

X1.1

F1 F2 F3

95

96

A1

A2

FT1

X1.2

5

6

3

4

1

2

K1

K1

* According to the product version

** Customer’s responsability according to the

product version.

*** For the model 580VL20X - NS, the electric leads

are carried through directly to the electric

components without the terminal blocks (X1).

5

6

3

4

1

2

FT1

3

2

M

3~

1

30.7/780

9.6/244 4.7/120

Ø 21.2/540

Note: dimensions in inch/mm.

44

2

1

DESCRIPTION

FUSES

PRESSURE SWITCH

COMMAND TRANSFORMER

MAIN CONTACTOR

OVERLOAD RELAY

ELECTRIC MOTOR

EMERGENCY BUTTON

13.5/34425.5/650

F1F2F3P1TK1FT1MB1

TAG

Ø 0.55/14

TERMINAL BLOCK

X1

0

MULTIWIRE DIAGRAM

5, 7.5, 10, 15 and 20 hp - THREE PHASE

5

AIR COMPRESSOR - OWNER'S MANUAL

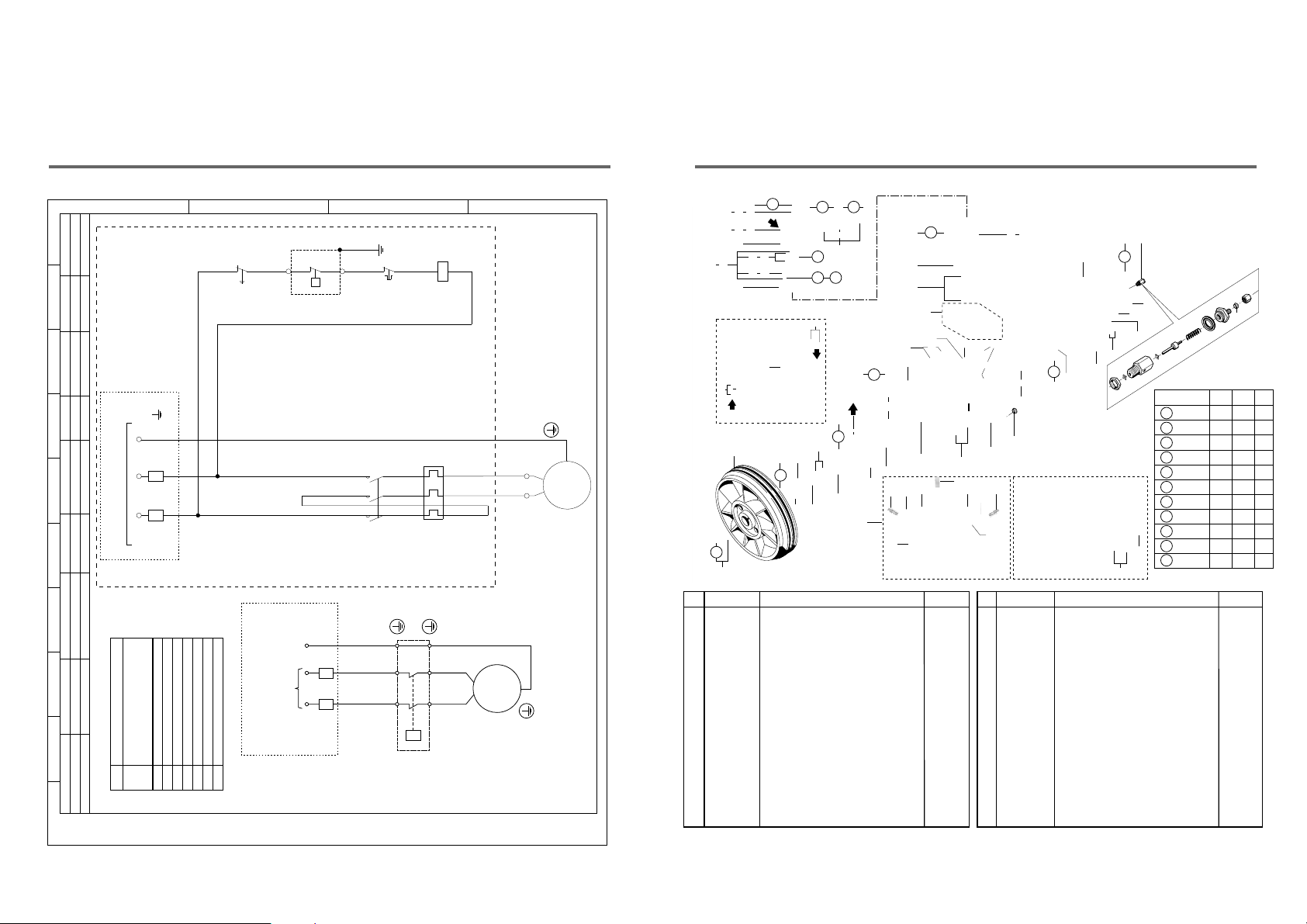

AIR COMPRESSOR - OWNER'S MANUAL

INSTALLATION

ELECTRICAL DIAGRAM

A

9

STARTLINE

PROTECTION

AND CONTROL

8

7

6

5

SUPPLY 230 VCA-60Hz

4

3

2

1

0

LINE CIRCUIT

COMPRESSOR MOTOR

GROUND

N

230V 60HZ

L

Customer's responsibility

DESCRIPTION

FUSES

F1F2F3P1TK1FT1MB1

TAG

B1 11

F1

PRESSURE SWITCH

COMMAND TRANSFORMER

MAIN CONTACTOR

OVERLOAD RELAY

ELECTRIC MOTOR

EMERGENCY BUTTON

TERMINAL BLOCK

X1

B

***

12

X1.1

GROUND

Supply

voltage

Customer's responsibility

TECHNICAL DATA 15120HW60X

BARE PUMP PARTS

T8

C

DD

**

95

21

22

P

P1

X1.2

F1

6

96

A1

A2

FT1

K1

MULTIWIRE DIAGRAM

5 and 7.5 hp - SINGLE PHASE

** Customer’s responsability according to the

product version.

*** For the model 580VL20X - NS, the electric leads

are carried through directly to the electric

components without the terminal blocks (X1).

5

5

6

3

4

1

2

K1

6

3

4

1

2

FT1

P

2

M

1~

1

No. No.

1

2

3

4

5

6

7

8

9

10

11

M

1~

3 hp - SINGLE PHASE

MULTIWIRE DIAGRAM

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

55

59 37 34

B

42

41 40

33

34 37

39

38

34 37

33

49

51

58

A

214

T3

T5

11

CODE CODE

709.1307-0

20505001

830.1033-0/NA

60082501

830.0932-0

60154502

20504001

60154501

830.0933-0

60267503

20508005

830.0934-0

30008502

830.0930-0

60152502

60152501

30007001

830.0937-0

20501002

830.0775-0

003.0029-2

709.1316-0

003.0031-4

60273501

830.1000-0

000.0080-0

Flywheel

*

UNC 1/4" x 3/4" head bolt

Flange cover

Crankcase gasket kit

Oil seal

Lock washer and nut kit

33109 bearing

*

NC 1/2" x 1" head bolt

Flange

32211 bearing

Crankshaft kit

Key

*

UNF 3/8" x 3" head bolt

Crankshaft counter weight

Auxiliary connecting rod pin kit

Connecting rod

Master connecting rod

Connecting rod inner bushing

Connecting rod bushing

Counter weight with centrifugal mechanism

Counter weight kit with centrifugal mechanism

*

UNF 5/16" x 1.1/4" Allen head bolt

Crankcase

3/4" oil level sight kit

3/8" plug

Crankcase cover

*

UNC 5/16" x 3/4" head bolt

3/4" plug

LP 4.3/4" piston

HP 90 mm piston

LP 90 mm ring kit

43 56

T11

T1

8

4

32 - 31

30 - 29

16

14

12

11

10

57

52

48

T2

17

19

11

45 44 60

17

19

18

53

15

52

47

QTY QTY

01

32

04

01

01

01

01

01

18

01

01

01

01

02

01

02

01

01

02

03

01

01

02

01

01

01

01

06

01

02

01

01

830.1001-0/NA

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

* Part available in the market - not sold by Schulz

Note: HP = high pressure LP = low pressure

47**

46**

T9

T9

T10

50

B

13

T6

A

8

T2

6

9

7

53

** See code page 41

DENOMINATION DENOMINATION

46

43

35 36

20

21

54

000.0077-0

830.1002-0

709.1306-0

709.1308-0

830.0955-0

809.1028-0

809.1027-0

709.1272-0

709.1423-0

709.1424-0

*

709.1322-0/C

709.1322-0/L

709.1322-0

21011004

21029003

830.0340-5

003.0054-3

830.0599-8

022.0177-0

830.1202-0

019.0079-0

013.0752-0

383.0111-0

003.0111-6

60259501

830.1032-0

022.0215-0

830.1099-0

27

32**

T4

28

4

25

24

23

T7

4

22

13**

61

HP 4.3/4" ring kit

Upper gasket kit

HP 90 mm valve plate kit

LP 4.3/4" cylinder

HP 90 mm cylinder

LP 4.3/4" valve plate kit

LP 4.3/4" valve plate

HP 90 mm valve plate

LP 4.3/4" cylinder cover with breather

LP 4.3/4" cylinder cover

HP 90 mm cylinder cover

LP UNC 3/8" x 1.1/2" head bolt

No. 1 shortintercooler

No. 2 long intercooler

Intercooler kit

3/4" nut for intercooler

Intercooler holder

1/4" crankcase breather tube

NPT 1/8" x 1/4" straight connection

1/4" ring kit

1/8" LP ASME safety valve

Connecting rod with needle bearing

Needle bearing

M6 x 1 x 55 Allen hex bolt

HP 5/16" x 1.1/2" Allen hex bolt

0

BSP 90 3/4" elbow

Straight fitting

Washer kit

HP 1/8" ASME safety valve

No. 3 aftercooler kit

26

Position lbf.in

T1

8

T2

2

T3

27

T4

11

T5

13

T6

22

T7

56

T8

T9

HP-LP 34/37

HP 37

T10

T11

59

TABLE 1 - TORQUE

ESPECIFICATION FOR BOLTS

ft.lb

1.6

51

30443

704

70

158

1,215

334

185

141

19

44

264

02

01

01

02

01

02

02

01

01

01

01

12

01

01

01

04

02

01

01

01

02

01

02

05

06

02

01

01

01

01

N.m

3425.3

8058.6

85.8

1813

137101

3827.8

2115.4

1611.7

2.2

53.6

3022

Loading...

Loading...