Schneider Electric Systems Canada ER450-XXF01, EB450-XXF01 Users Manual

E Series Data Radio User Manual

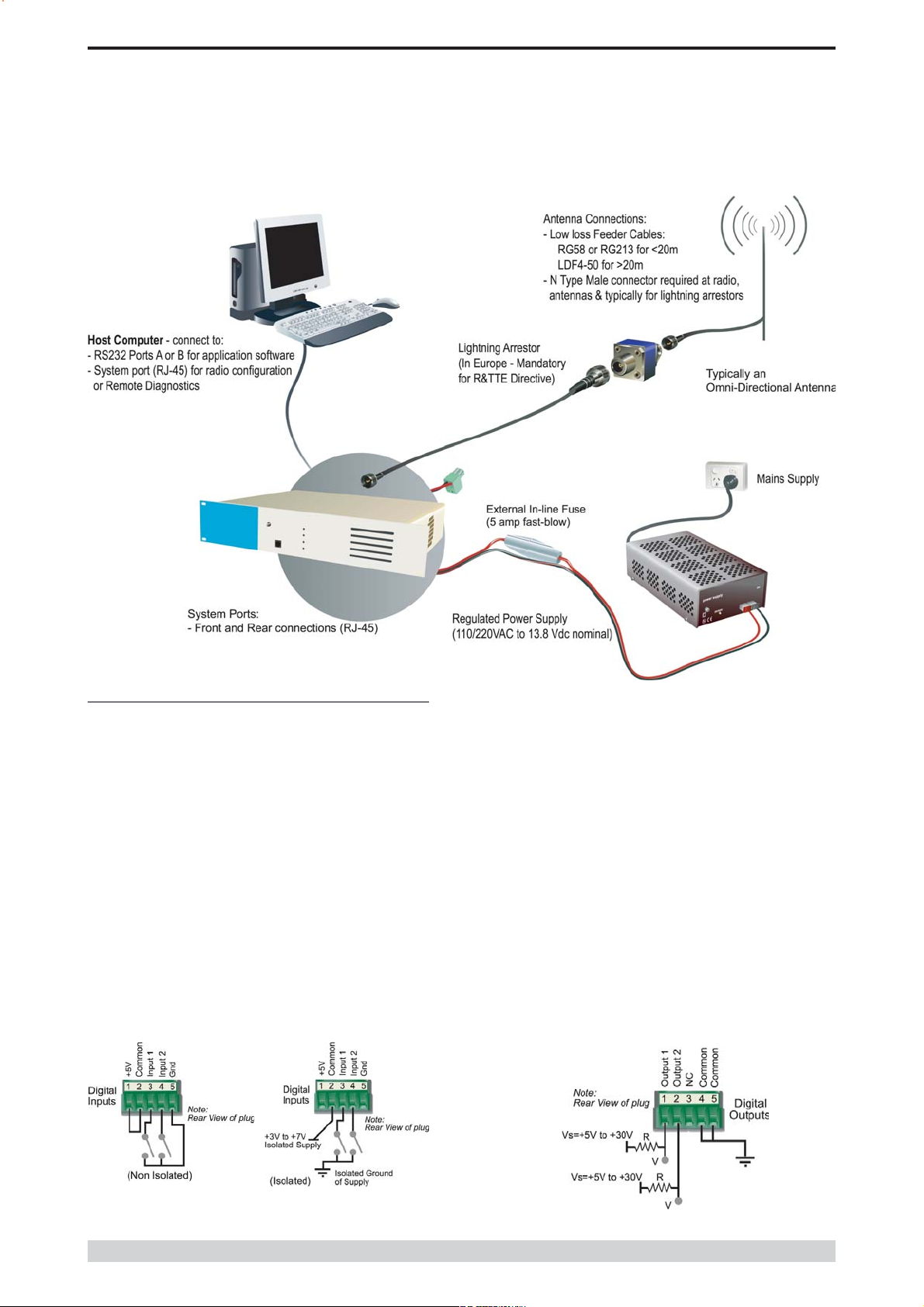

Typical Radio Setup

Part E Getting Started - EB450

Digital Inputs and Outputs

The EB450 provides a facility for two channels of digital user inputs

and outputs (Digital User I/O). Information on how to control and

monitor this I/O using TVIEW+ Diagnostics can be found in Part J TVIEW+ Management Suite - Remote Diagnostics & Network

Controller.

All user I/O is optocoupled for isolation between the EB450 and uses

equipment. When using the I/O facility the I/O electrical characteristics

and ratings must be observed. Failure to observe these ratings may

result in equipment damage.

Inputs

Two User Inputs are available. They have identical interface

characteristics. Each input has an internal resistance of 470 Ohms.

Some form of switching contact (ie: switch, relay) is normally used to

change the state of the input. Both an isolated and non-isolated input

configuration is possible.

TVIEW+ Diagnostics will recognise an input as being ON when the

switch is closed. If the switch is open (or not connected) TVIEW+

diagnostics will recognise the inputs as being OFF.

Outputs

Two User Outputs (Open Collector) are available. They have identical

interface characteristics. The maximum current allowed through each

output is 20ma. External resistors must be used keep the current

below this value.

Each output has an internal resistance of 100 Ohms.Ohms law can be

used to calculate the resistance required for a specific voltage (keeping

the current below 20mA). Nominally 1k Ohm is used for a +13v8

supply and 330 Ohms for a +5v supply.

When the OUTPUT is OFF, V = Vs. No current will flow when output

is off.

When the OUTPUT is ON, V = nominally 2.3 volts . Current is set

by resistor.

© Copyright 2004 Trio DataCom Pty. Ltd.

Is

Page 31

E Series Data Radio User Manual

Part E Getting Started - EB450

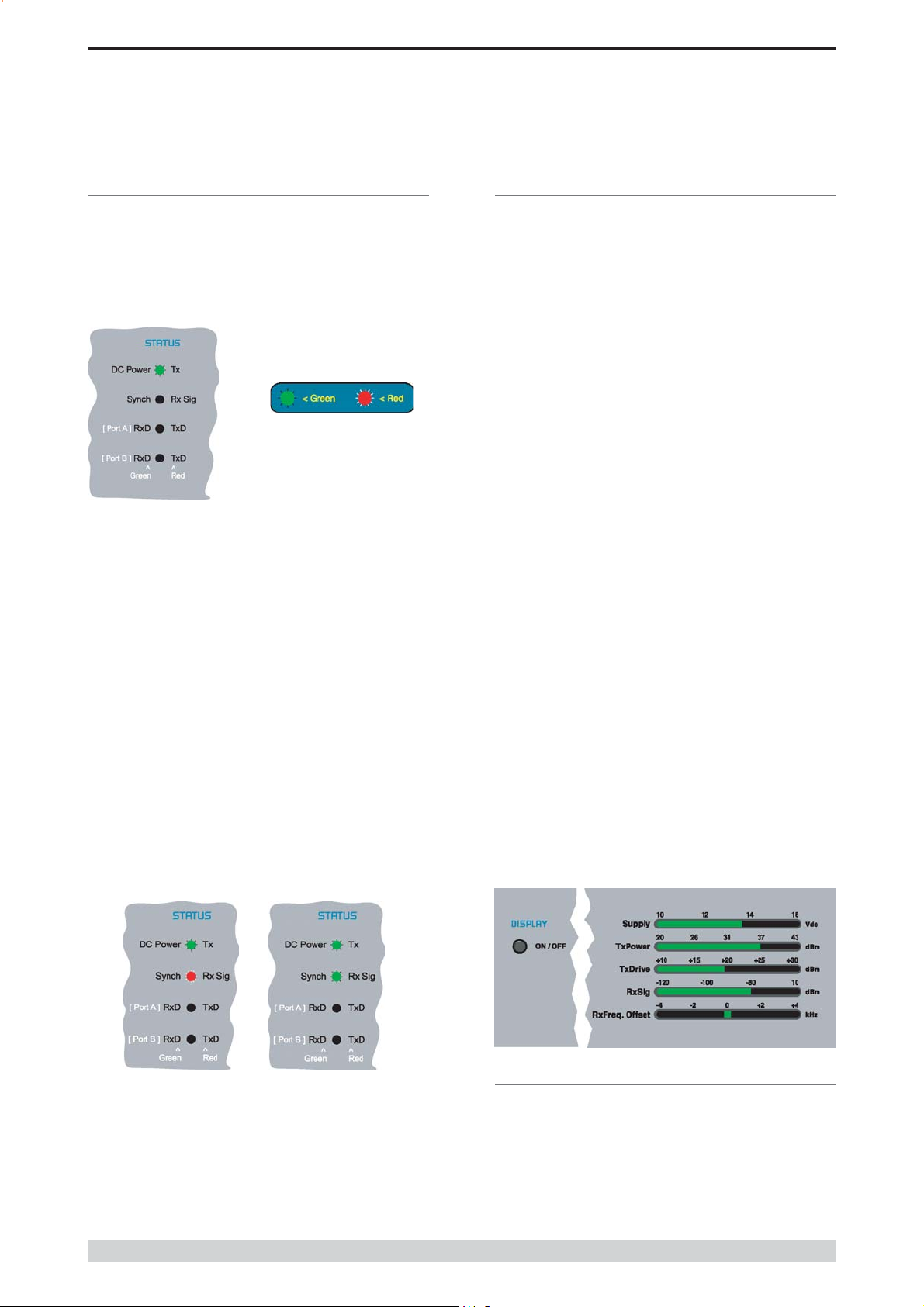

LED Indicators & Test outputs

Radio is Powered

If all the LEDs are off, no power is reaching the radio modem.

Successful power-up is indicated by the PWR LED indicating a

continuous (healthy) GREEN state. Note that this LED is turned RED

when the transmitter is active.

LED Legend

Hardware Error

A hardware error is indicated on the status LEDs by all LEDs flashing

RED at a rate of 1Hz. This indicates internal communications to the

exciter inside the basestation has been lost and the base station needs

to be returned to repair.

Received Signal Indicator

The RX/SYNC LED indicates the state of the receiver.

If the LED is off, no signal is being received.

A RED indication shows that an RF carrier is being received, but no

data stream can be decoded. This will briefly happen at the very start

of every valid received transmission or may indicate the presence of

interference, or another user on the channel.

A continuous GREEN indication shows that the modem is locked and

synchronised to the incoming signal, and has excellent Bit Error Rate

(BER). Any losses of synchronisation (BER errors) are shown as a

visible RED flicker of the LED.

Note: This might only be apparent on a PTMP slave when only

receiving.

Bar Graph Indicators

The bar graph indicators on the front panel provide variable information

regarding the performance of the Base Station. To enable / disable the

bar graph display depress the Display ON / OFF button. The display

will turn off automatically after 5 minutes.

DC Supply:

Indicates the supply input voltage at the exciter module. Typically

13.8Vdc.

Indication: <10Vdc no LEDs on, 10-10.9Vdc LEDs RED, 11-

15.6Vdc All LEDs GREEN, >=15.7Vdc last LED RED.

Tx Power:

Indicates forward RF power output as measured at the TX antenna

port. Typically +37dBm.

Indication: <20dBm no LEDs on, 20-40.6dBm (11.5W) LEDs

GREEN, >=40.7dBm last LED RED.

Tx Drive:

Indicates exciter drive level. Typically +20dBm.

Indication: <10dBm no LEDs on, 10.0-25.9dBm LEDs GREEN,

>=26.0dBm last LED RED.

Rx Sig:

Indicates receive signal strength. Typically -85 to -65dBm.

Indication: <-120dBm no LEDs on, -120 to -110.1dBm LEDs RED,

>=-110dBm LEDs GREEN.

RxFreq. Offset:

Indicates offset of receiver AFC - useful in determining frequency drift.

Typically 0kHz.

Indication: Single GREEN LED to indicate current value, <-3.6kHz or

>+3.6kHz LED is RED. No signal, all LEDs OFF.

Note: 5 second peak hold circuitry.

Data Flow breakout LEDs

There are also two LEDs to indicate data flow into and out of the two

user ports.

Input data to be transmitted is shown as a RED flash, and received

data to be output to the port is shown as a GREEN flash.

If data is alternately flowing in and out quickly, then the indicator

appears Orange.

Page 32

Test Mode

The Bar Graph indicators have a Test Mode, which cycles all LEDs

for correct operation (before returning to their normal operation). To

activate this mode, simply depress the ON / OFF button while

applying power to the unit.

© Copyright 2004 Trio DataCom Pty. Ltd.

E Series Data Radio User Manual

Part E Getting Started - EH450

EH450 Quick Start Guide

Introduction

Welcome to the Quick Start Guide for the EH450 Hot Standby Base /

Repeater Station. This section provides additional step-by-step

instructions to install, commission and operate the EH450 Hot

Standby Base Station. This document should be read in conjunction

with the EB450 Base Station Quick Start Guide.

The EH450 is a fully redundant, hot standby digital data radio base /

repeater station providing automatic changeover facilities.

The EH450 is designed as a modular solution, comprising 2 identical

EB450 base station units (standard) linked to a central, fail-safe

monitoring and changeover controller (Hot Standby Controller). Either

base station may be taken out for maintenance without the need for

any system down time. The automatic changeover is triggered by out

of tolerance (alarm) conditions based on either RF and/or user data

throughput parameters.

Features and Benefits

Individual and identical base stations with separate control logic

changeover panel

Modules are hot swapable without user downtime

Flexible antenna options single, separate Tx & Rx, two Tx

and two Rx

Both on-line and off-line units monitored regardless of active

status

Also refer to the common Features and Benefits list of the E

Series Data Radio

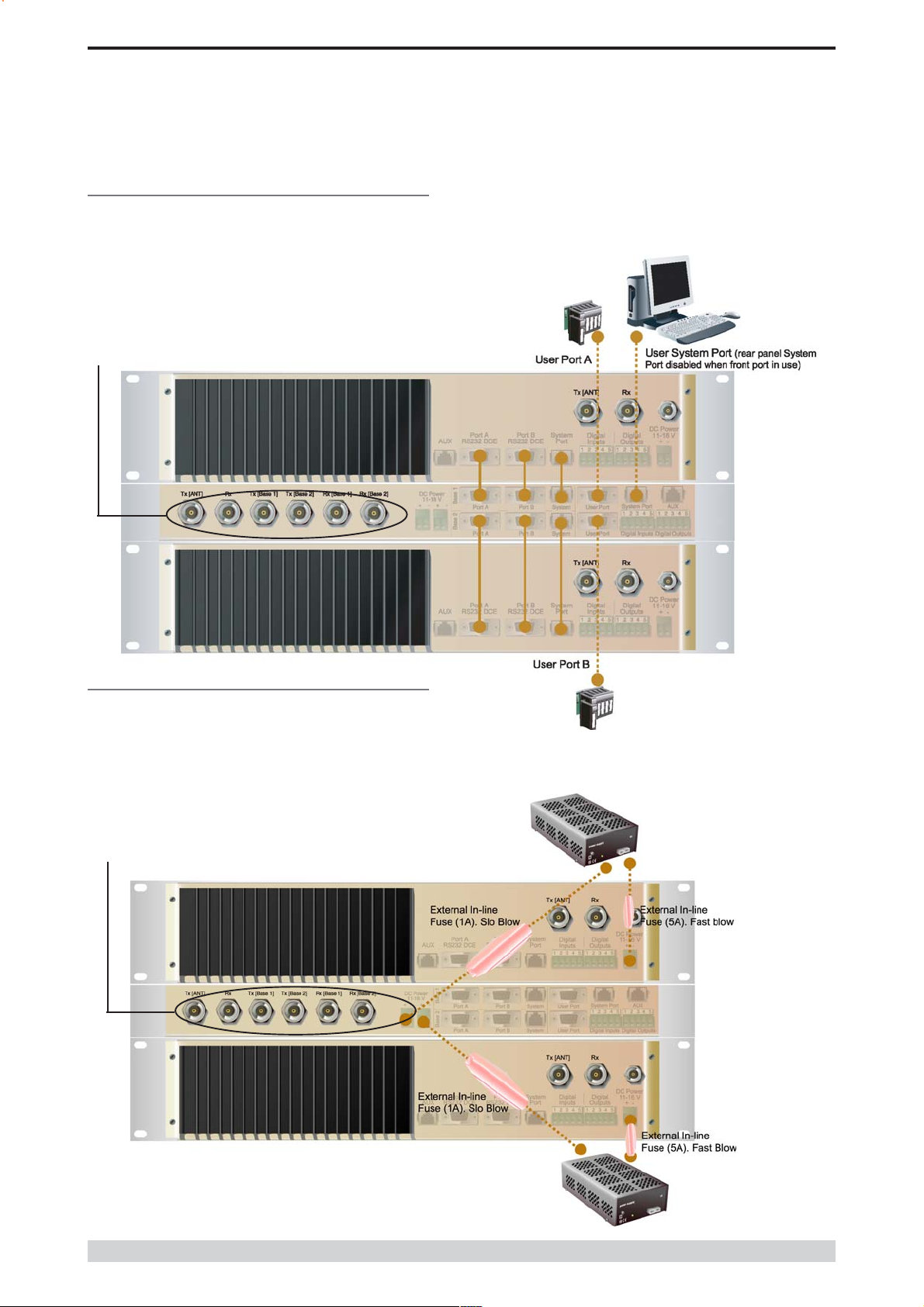

Base / Repeater Unit

Note: RF connectors not used on ETSI version

Base / Repeater Unit

Hot Standby Controller Unit

Rear View

© Copyright 2004 Trio DataCom Pty. Ltd.

Page 33

E Series Data Radio User Manual

Part E Getting Started - EH450

Operational Description

The Hot Standby Controller (HSC) unit is a 1RU rack mounted

module that interfaces to two physically separate base stations (each

2RU rack mounted modules) via a number of RF and data cables.

Both base stations are operating simultaneously and both units are

constantly receiving signals, however only data from one base

station, the online base station is directed to the user equipment. The

online base station is the only base station transmitting at any time.

The Hot Standby Controller has the following functions:

Diplex the transmit and receive paths (Assuming internal

duplexer fitted), TX Only.

Amplify and split the incoming signal two ways so both base

stations receive at once.

Monitor status reports from both base stations to identify faults

and swap over the online base station if required.

Switch the antenna via internal coaxial relay duplexer to the

online base station transmitter and inhibit the offline base station

from transmitting.

Switch the User A and B data ports through to the online base

station.

An optocoupler based switch in the base station controller directs data

to and from ports A and B on the rear panel directly to ports A and B

on the on-line base station without any involvement from the Hot

Standby controller microcontrollers (apart from selecting the on-line

base). This provides protection of the system from failure of the

microcontroller.

Mounting and Environmental

Considerations

The EH450 Hot Standby Base Station is housed as a 5RU 19 rack

mounted set, encompassing 2 x 2RU Base Station units and 1 x 1RU

Hot Standby Controller unit. The mounting holes on the front panels

should be used to secure the units to the rack.

The unit should be mounted in a clean and dry location, protected from

water, excessive dust, corrosive fumes, extremes of temperature and

direct sunlight. Please allow sufficient passive or active ventilation to

allow the radio modems heatsink to operate efficiently.

All permanent connections are made at the rear of the unit. This

includes: Power, Antenna, Communications Ports, Digital I/O and

System Port. The front panel has an additional System Port

connection point for easy access.

The Base Station front panel system ports must not be used while in

this configuration.

As well as ports A and B, each base has a system port. The system

port of each base station is interfaced to the microcontroller on the Hot

Standby controller. This allows the microcontroller in charge of

selecting the base station to receive diagnostic messages from each

base station to decide their health.

The base station has its own system port on the rear panel and this is

interfaced to the Hot Standby Controller Module. The HSC will route

diagnostics at the rear panel system port to and from the system ports

of the base stations.

Warning

The base station front panel system port has priority over the rear

panel port, which is used for communication between the base station

and the Hot Standby Controller. This is to permit service personnel to

reconfigure the base station module without disconnection from the Hot

Standby Controller. It should be noted however, that when the front

panel port is accessed, a changeover event will occur due to lost

communications with the Hot Standby Controller.

Page 34

© Copyright 2004 Trio DataCom Pty. Ltd.

E Series Data Radio User Manual

Part E Getting Started - EH450

Communications Ports

The A & B Data Ports and System Ports of each Base Station

connect directly to the Hot Standby Controller units corresponding

ports with the cables provided. Ensure all clamping screws on the

Data Port cables are firmly secured and the System Port cables are

clipped in correctly. See figure below for further details.

Note: Only the front or rear User System Port can be used at any

one time on the Hot Standby Controller.

Note: RF Connectors not used on ETSI version

The Hot Standby Controller units A & B Data Ports connect directly to

you application device and the System Port connects directly to your

local PC. See ER450 Quick Start Guide Section for further details.

Power Supply and Protection

The EH450 has facilities for dual power supplies to provide for a

redundant system. A separate power supply should be used for each

of the Base Station units. The Hot Standby Controller unit has

connections for dual power supplies and it is recommended that the

power supplies from each of the Base Stations also be used to power

the Hot Standby Controller unit. See Figure below for further details.

See ER450 Quick Start Guide Section for detailed wiring information.

Note: RF Connectors not used on ETSI version

© Copyright 2004 Trio DataCom Pty. Ltd.

Page 35

E Series Data Radio User Manual

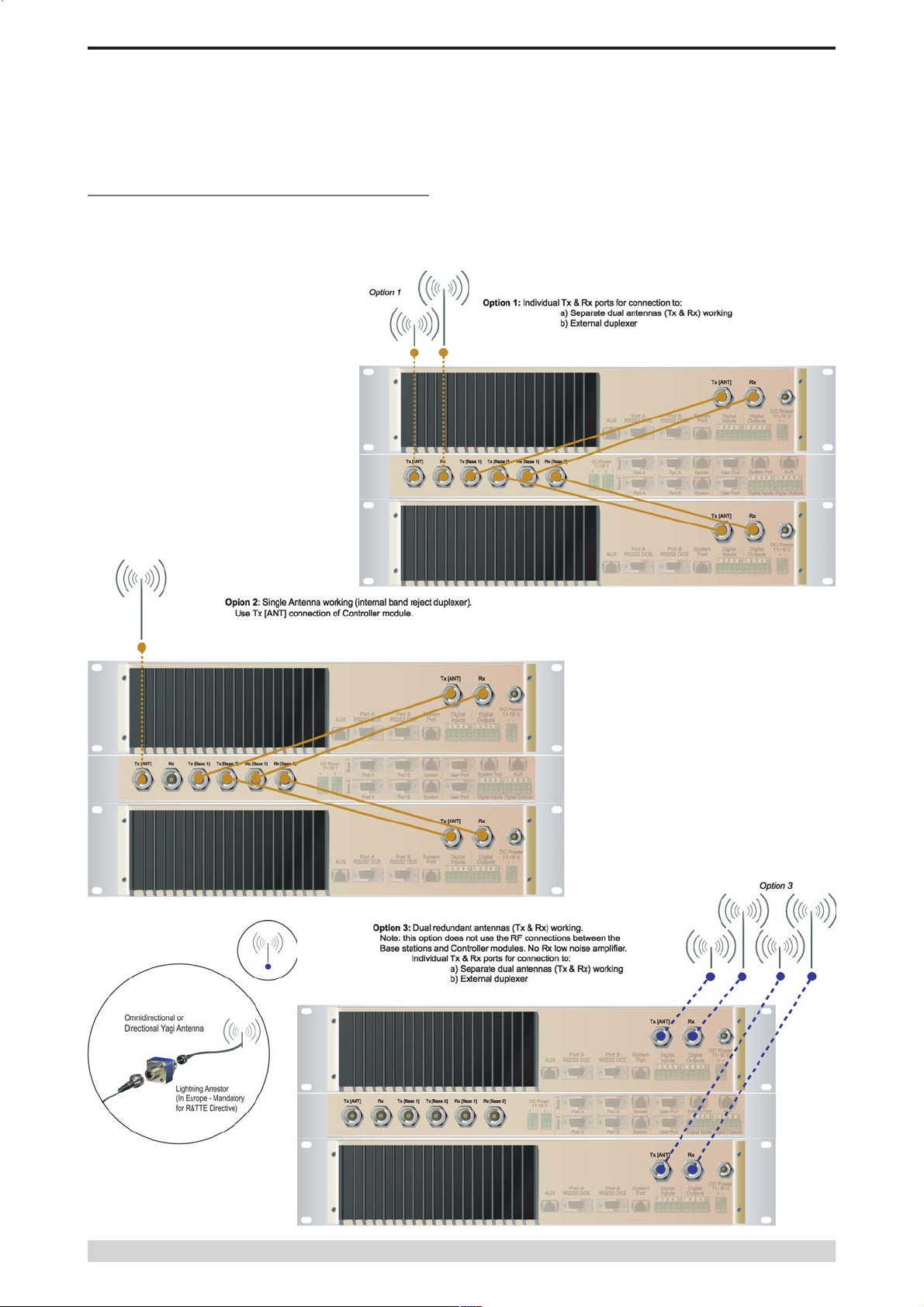

Connecting Antennas and RF Feeders

There are 3 primary antenna connection options. All connectors used

are standard N Type sockets. See figures below for further details.

See ER450 Quick Start Guide for detailed wiring information.

Part E Getting Started - EH450

Page 36

© Copyright 2004 Trio DataCom Pty. Ltd.

E Series Data Radio User Manual

Front Panel Operation

Part E Getting Started - EH450

Switches

Select Switch

The 3 position switch (1 / Auto / 2) on the front panel provides the

following functionality:

Position 1: base station 1 is forced into operation

Position Auto: changeover hardware will select the online base

station

Position 2: base station 2 is forced into operation

The select switch is also used to identify the target base station for

configuration programming.

Adjacent to the select switch are two LEDs: These LEDs indicate the

current active base station.

Select LEDs

Green - Auto Mode

Red - Remote Force

Amber - Local Force

2 Green Firmware Download

2 Amber Test Mode

2 Red Fatal Error - refer User Manual

Reset Switch

This is a momentary close switch which when depressed will reset all

LED alarm indications.

System Port

There are two system port connection points, one on the rear panel

and one on the front panel. Both have the same functionality and can

be used for local diagnostics, firmware front panel downloads and hot

standby controller testing. To access the system port use the

diagnostic/programming cable supplied.

Note: When connection is made to front panel system rear system

port is disabled.

Alarm Status LEDs

There are 10 alarm LEDs on the front panel, five for base 1 and five for

base 2. These LEDs provide a general indication of base station

status. More detailed base station status information is available by

using the diagnostic utility software.

The indicated alarms for each base station are:

Freq. => Frequency Error

RxSig => Receive Signal (RF) Error

Data => Receive Data Error

TxPower => Transmit Power (RF) Error

Supply => DC Voltage Error

The status of each alarm is represented as follows:

OFF => Unknown

Green => No Error

Red => Current (active) Error condition

Amber => Recovered Error condition

© Copyright 2004 Trio DataCom Pty. Ltd.

Any active or recovered error LEDs will turn to green after the reset

alarms switch has been pushed or remotely reset.

Page 37

E Series Data Radio User Manual

Part F - Operational Features

Part F Operational Features

Multistream functionality (SID

codes)

The E Series sends data messages in packets. A feature of the E

Series is that an address can be embedded in each packet. This

address is called the stream identifier code (SID).

By configuring a user serial port for a specific SID code, it is

possible to steer messages to similarly configured ports between

radio modems. In effect, it is possible to use the multiple serial

ports available on the E Series, to enable multiple protocols to

share the same RF channel. The SID codes also facilitate the use

of other features such as TView diagnostics. Unique selective

routing, repeating, and data splitting functions available in the radio

modems configuration allow data steering and bandwidth

management in complex systems.

See Part I - TView+ Management Suite - Programmer and Part J TView Remote Diagnostics and Network Controller for details.

Collision Avoidance (digital and

RFCD based)

Where multiple unsynchronised protocols coexist on a common

multiple access radio channel, there is always a possibility that

both hosts may poll different remote devices at the same time. If

both devices attempt to answer back to the single master radio at

the same time, it follows that a collision could occur on the radio

channel.

RF Carrier Detect RSSI based Collision

Avoidance

In half duplex systems, the receivers RF carrier detect is used to

inhibit the transmitter whilst a signal is being received.

Digipeater Operation

A feature of the E Series radio modems is the ability to internally

repeat data packets to provide stand alone repeater facilities

without the need for external intelligence.

This is done by programming SID Codes to Repeat a stream or

range of streams. Wizard templates can be used to simplify setup

of this and other features.

See Part I - TVIEW+ Management Suite for details.

TVIEW+ Diagnostics

The E Series has an inbuilt remote configuration and diagnostics

utility.

This facility allows transparent remote access to the key

configuration and operating parameters of the radio.

See Part J - TView Remote Diagnostics and Network Controller for

details.

Poor VSWR Sensing

To facilitate the operation of multiple protocol operation on the

radio channel, a transparent collision management system has been

implemented : See Part I - TView+ Management Suite - Programmer

for details.

Digital Collision Avoidance System

If the multiple access master has been configured for full duplex

operation, it is possible to use the inbuilt collision avoidance signalling

system.

Once the master radio receives a valid incoming data stream from a

remote, a flag within the outbound data stream is used to alert all

other remote devices that the channel has become busy. Remote

devices wishing to send data will buffer the message until the channel

status flag indicates that the channel is clear. A pseudo-random timing

value is added to the retry facility to ensure that waiting remotes do not

retry at the same time.

To protect the transmitter, forward and reverse power are measured on

each transmission.

If a VSWR of 3:1 or greater is measured, transmitter output power is

reduced to +31 dBm.

Page 38

© Copyright 2004 Trio DataCom Pty. Ltd.

E Series Data Radio User Manual

Part G Commissioning

Part G Commissioning

Check DC power connector for correct voltage (10-16VDC) and

polarity, BEFORE plugging in the power connector.

Power-up

Upon power up, the radio will self test and shortly after the green

power LED will be displayed.

Failure of the power LED to light indicates no power, or failure of the

fuse due to incorrect polarity or over-voltage.

Other failure such as fatal internal errors will initiate error modes as

detailed in Part E - Getting Started: LED Indicators and Test Outputs.

LED Indicators

Will depend on the system architecture. If the device is a remote site

receiving a base station with a constant carrier, then the RXSIG/

SYNC LED should be green to indicate healthy reception of the

wanted signal.

If the site has been configured as a constantly transmitting base station,

then the PWR/TX LED should show red.

In other types of systems, TX and RX bursts would be indicated by

the RX or TX LEDs as above.

Data flow to and from the user ports is indicated by the TXD/RXD

LEDs for each port.

(See Part E Getting Started: LED Indicators and Test Outputs.)

Data Transfer Indications

Bi-colour LEDs are provided to indicate RS232 data being transmitted

and received on each data port. A RED flash indicates a byte (or

bytes) of incoming data from the serial line which will be transmitted to

air, and a green flash indicates a byte of data received off air being

released onto the serial line.

If data is being sent to the radio modem and the Data LED does not

flash RED, this may indicate a wiring or configuration problem. Check

that the TX and RX data lines are correctly wired (see Part E Getting

Started: LED Indicators and Test Outputs).

Also check that character set and parity settings (i.e. N,8,1 etc) are set

identically at the terminal and the radio modem. Note that some

incorrect settings of the character set parameter can still produce

transmittable data, even though the data will not be understood by the

application.

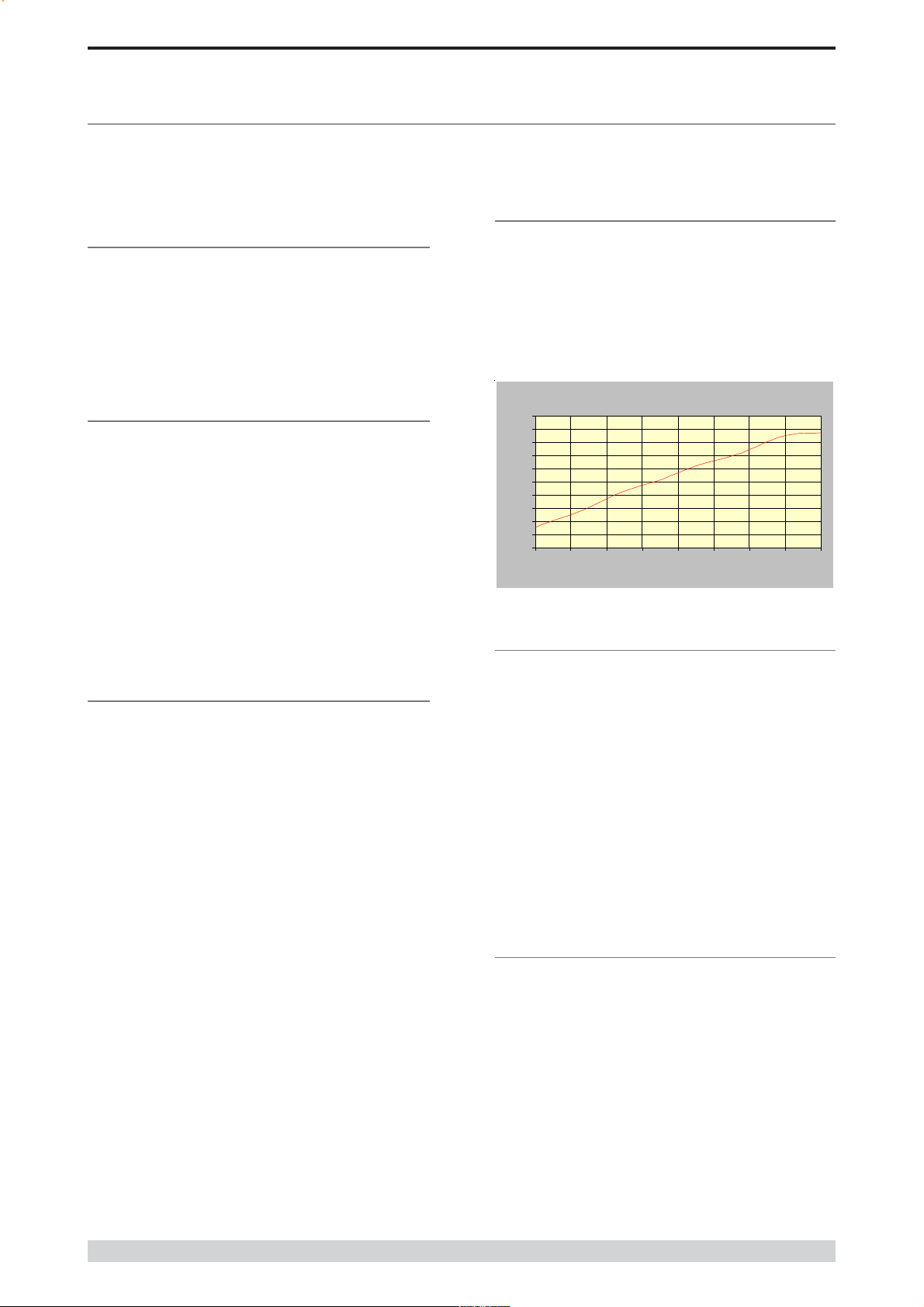

Antenna Alignment and RSSI

Testing

Once the RXSIG LED is lit, it is possible to confirm RX signal strength

and align a directional antenna by monitoring the RSSI output.

This DC voltage appears at Pin 9 of Port B.

A ground reference can be obtained from chassis ground or Pin 5 of

Port A or B.

The chart below shows Pin 9 voltage as it relates to signal strength.

Analog RSSI Output Char acteristi cs - E Series Da t a R adio

5

4.5

4

3.5

3

2.5

2

1.5

RSSI (DC Volts)

1

0.5

0

-120 -110 -100 -90 -80 -70 -60 -50 -40

RF Level (dBm)

Link Establishment and BER

Testing

Once communications has been established, it is possible to confirm

the packet error rate performance of the radio path, and thus estimate

the BER figure.

There are a number of tools provided to do this. The easiest is to use

the indicative packet error test provided within the TVIEW+

Diagnostics under statistical performance tools. Alternatively, it is

possible to use hyper terminal, or other packet test instruments or PC

programs to run end to end or perform loopback testing.

Please note that when using a loopback plug some understanding of

the packetising process is necessary, since each test message must

be carried in a single packet for meaningful results to be obtained.

Note also that in PTMP systems, allowance must be made for

collision potential if other data is being exchanged on the system.

VSWR Testing

VSWR testing is achieved using specialized VSWR testing

equipment, or a Thruline power meter that measures forward and

reverse power.

© Copyright 2004 Trio DataCom Pty. Ltd.

VSWR is the ratio between forward and reflected transmitter power,

and indicates the health and tuning of the antenna and feeder system.

VSWR should be better than 3 to 1, or expressed as a power ratio,

<6dB or no more than 25%. To activate the radios transmitter for

VSWR testing, use:

a) An RTS loop

b) A system port PTT plug

Page 39

Loading...

Loading...