Schneider Electric Systems Canada EB450-XXF01 Users Manual

E Series Data Radio – User Manual

Front Panel Operation

Part E Getting Started - EH450

Switches

Select Switch

The 3 position switch (1 / Auto / 2) on the front panel provides the

following functionality:

• Position 1: base station 1 is forced into operation

• Position Auto: changeover hardware will select the online base

station

• Position 2: base station 2 is forced into operation

The select switch is also used to identify the target base station for

configuration programming.

Adjacent to the select switch are two LEDs: These LEDs indicate the

current active base station.

Select LED’s

• Green - Auto Mode

• Red - Remote Force

• Amber - Local Force

2 Green Firmware Download

2 Amber Test Mode

2 Red Fatal Error - refer user manual

Reset Switch

This is a momentary close switch which when depressed will reset all

LED alarm indications.

System Port

There are two system port connection points, one on the rear panel

and one on the front panel. Both have the same functionality and can

be used for local diagnostics, firmware front panel downloads and hot

standby controller testing. T o access the system port use the

diagnostic/programming cable supplied.

Note: Wnen connection is made to front panel system rear system

port is disabled.

Alarm Status LEDs

There are 10 alarm LEDs on the fron panel, five for base 1 and five for

base 2. These LEDs provide a general indication of base station

status. More detailed base station status information is available by

using the diagnostic utility software.

The indicated alarms for each base station are:

Freq. => Frequency Error

RxSig => Receive Signal (RF) Error

Data => Receive Data Error

TxPower => Transm it Power (RF) Er ror

Supply => DC Voltage Error

The status of each alarm is represented as follows:

Green => No Error

Red => Current (active) Error condition

Amber => Recovered Error condition

Any active or recovered error LEDs will turn to green after the reset

alarms switch has been pushed or remotely reset.

© Copyright 2002 Trio DataCom Pty. Ltd.

Page 35

E Series Data Radio – User Manual

Part F - Operational Features

Part F Operational Features

Multistream functionality (SID

codes)

The E Series sends data messages in packets. A feature of the E

Series is that an address can be embedded in each packet. This

address is called the stream identifier code (SID).

By configuring a user serial port for a specific SID code, it is

possible to steer messages to similarly configured ports between

radio modems. In effect, it is possible to use the multiple serial

ports available on the E Series, to enable multiple protocols to

share the same RF channel. The SID codes also facilitate the use

of other features such as TView diagnostics. Unique selective

routing, repeating, and data splitting functions available in the radio

modems configuration allow data steering and bandwidth

management in complex systems.

See Part I - TView+ Management Suite - Programmer and Part J TView Remote Diagnostics and Network Controller for details.

Collision Avoidance (digital and

RFCD based)

Where multiple “un synchronised” protocols co-exist on a common

“multiple access” radio channel, there is always a possibility that

both “hosts” may poll different “remote” devices at the same time. If

both devices attempt to answer back to the single master radio at

the same time, it follows that a collision could occur on the radio

channel.

RF Carrier Detect RSSI based Collision

Avoidance

In half duplex systems, the receiver’s RF carrier detect is used to

inhibit the transmitter whilst a signal is being received.

Digipeater Operation

A feature of the E Series radio modems is the ability to internally

repeat data packets to provide stand alone repeater facilities

without the need for external intelligence.

This is done by programming “SID Codes” to “Repeat” a stream or

range of streams. Wizard templates can be used to simplify setup

of this and other features.

See Part I - TVIEW+ Management Suite for details.

TVIEW+ Diagnostics

The E Series has an inbuilt remote configuration and diagnostics

utility.

This facility allows transparent remote access to the key

configuration and operating parameters of the radio.

See Part J - TView Remote Diagnostics and Network Controller for

details.

To facilitate the operation of multiple protocol operation on the

radio channel, a transparent collision management system has been

implemented : See Part I - TView+ Management Suite - Programmer

for details.

Digital Collision Avoidance System

If the “multiple access master” has been configured for full duplex

operation, it is possible to use the inbuilt collision avoidance signaling

system.

Once the master radio receives a valid incoming data stream from a

remote, a flag within the “outbound” data stream is used to alert all

other remote devices that the channel has become busy. Remote

devices wishing to send data will buffer the message until the channel

status flag indicates that the channel is clear. A pseudo-random timing

value is added to the retry facility to ensure that waiting remotes do not

retry at the same time.

Page 36

© Copyright 2002 Trio DataCom Pty . Ltd.

E Series Data Radio – User Manual

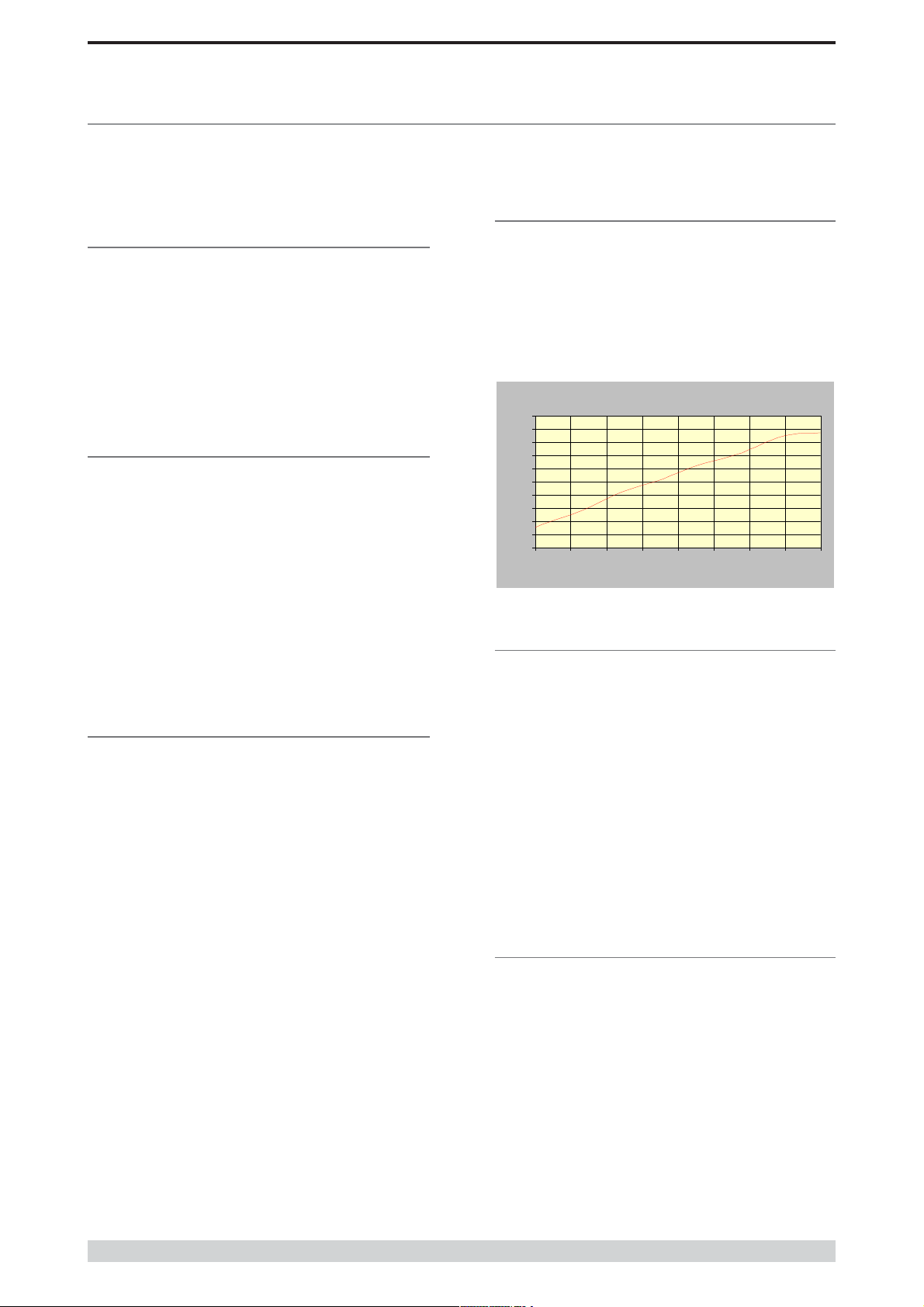

Analog RSSI Output Ch aracteristics - E Seri es Data Radi o

0

0.511.522.533.544.55-120

-110

-100

-90

-80

-70

-60

-50

-40

RF Level (dBm)

)

Part G Commissioning

Part G Commissioning

Check DC power connector for correct voltage (10-16VDC) and

polarity, BEFORE plugging in the power connector.

Power-up

Upon power up, the radio will self test and shortly after the green

power LED will be displayed.

Failure of the power LED to light indicates no power, or failure of

the fuse due to incorrect polarity or over-voltage.

Other failure such as fatal internal errors will initiate error modes

indicated by a flashing sequence of all LEDS red, followed by one

or more green LED’s to indicate the nature of the failure (see Part E

– Getting Started: LED Indicators and Test Outputs).

LED Indicators

Will depend on the system architecture. If the device is a remote site

receiving a base station with a constant carrier, then the RXSIG/

SYNC LED should be green to indicate healthy reception of the

wanted signal.

If the site has been configured as a constantly transmitting base station,

then the PWR/TX LED should show red.

In other types of systems, TX and RX bursts would be indicated by

the RX or TX LED’s as above.

Data flow to and from the user ports is indicated by the TXD/RXD

LEDs for each port.

(See Part E – Getting Started: LED Indicators and Test Outputs.)

Data Transfer Indications

Bi-colour LEDs are provided to indicate RS232 data being

transmitted and received on each data port. A RED flash indicates

a byte (or bytes) of incoming data from the serial line which will be

transmitted to air, and a green flash indicates a byte of data

received “off air” being released onto the serial line.

If data is being sent to the radio modem and the Data LED does

not flash RED, this may indicate a wiring or configuration problem.

Check that the TX and RX data lines are correctly wired (see Part E

– Getting Started: LED Indicators and Test Outputs).

Also check that character set and parity settings (i.e. N,8,1 etc) are

set identically at the terminal and the radio modem. Note that some

incorrect settings of the character set parameter can still produce

transmittable data, even though the data will not be understood by

the application.

Antenna Alignment and RSSI

Testing

Once the RXSIG LED is lit, it is possible to confirm RX signal strength

and align a directional antenna by monitoring the RSSI output.

This DC voltage appears at Pin 9 of Port B.

A ground reference can be obtained from chassis ground or Pin 5 of

Port A or B.

The chart below shows Pin 9 voltage as it relates to signal strength.

RSSI (DC Volts

Link Establishment and BER

Testing

Once communications has been established, it is possible to confirm

the packet error rate performance of the radio path, and thus estimate

the BER figure.

There are a number of tools provided to do this. The easiest is to use

the “indicative packet error test” provided within the TVIEW+

Diagnostics under “statistical performance tools”. Alternatively, it is

possible to use hyper terminal, or other packet test instruments or

PC programs to run end to end or perform “loopback” testing.

Please note that when using a “loopback plug” some understanding of

the packetising process is necessary, since each “test message’ must

be carried in a single packet for meaningful results to be obtained.

Note also that in PTMP systems, allowance must be made for

collision potential if other data is being exchanged on the system.

VSWR Testing

VSWR testing is achieved using specialized VSWR testing

equipment, or a “Thruline” power meter that measures forward and

reverse power.

© Copyright 2002 Trio DataCom Pty. Ltd.

VSWR is the ratio between forward and reflected transmitter

power, and indicates the health and tuning of the antenna and

feeder system.

VSWR should be better than 3 to 1, or expressed as a power ratio,

<6dB or no more than 25%. To activate the radios transmiter for

VSWR testing, use:

a) An RTS loop

b) A system port PTT plug

Page 37

E Series Data Radio – User Manual

Part H Maintenance

Routine Maintenance

Considerations

The E Series hardware itself does not require routine maintenance.

However all radio products contain crystal frequency references,

and the stability of these crystals changes with time. The effect of

this is that the product will slowly drift off frequency, and eventually

it will require re-calibration. E Series radios are designed with high

quality, low drift specification references, to ensure a long

maintenance free lifespan. The length of this lifespan will depend

on the severity of temperature extremes in the operating

environment, but is normally 3–5 years. Extended frequency drift

can be detected using TVIEW+ Diagnostics “Freq error” parameter.

Generally, recalibration is achieved by replacing the radio in the

field with a spare, and returning the radio to a service centre for recalibration and specification testing at moderate cost.

Part H Maintenance

Routine maintenance should be performed on external equipment

subject to greater environmental stresses including antennas, RF

feeder cables, backup batteries and cooling fans (if required). This

maintenance should include testing of site commissioning figures

such as received signal strength, VSWR, P/S voltage etc.

Page 38

© Copyright 2002 Trio DataCom Pty . Ltd.

E Series Data Radio – User Manual

SECTION 2 TVIEW+ Management Suite

SECTION 2

Part I TVIEW+ Management Suite Programmer

Part J TVIEW Remote Diagnostics and

Network Controller

Part K Appendices

Part L - Support Options

© Copyright 2002 Trio DataCom Pty. Ltd.

Page 39

E Series Data Radio – User Manual

Part I TVIEW+ Management Suite - Programmer

Part I TVIEW+ Management Suite Programmer

Introduction

This manual covers the installation and operation of the E Series

TVIEW+ Management Suite which incorporates 3 utilities:

• Programmer for configuration of the radio RF parameters,

system parameters and data ports

• Diagnostics* for real-time monitoring and logging of radio

performance parameters

• Firmware Update for loading new firmware releases into the

radio data modem

All utilities can be run on any IBM compatible computer running

Windows 95® and above. This section describes use of the

programmer and firmware Update utilities in detail. Users should refer

to the separate Diagnostics section for information about this utility.

The programmer is used to set configuration parameters within the

ER450 data radio modem and EB450 base station. The utility permits

configuration of modems connected directly to the PC as well as over

the air to a remote unit. Configuration parameters can be saved to a

disk file for later retrieval, or used for clone programming of other

modems.

All configuration parameters are held in non-volatile memory

(NVRAM) on the Data Radio Modem. Configuration is fully

programmable via the Systems Port using the programming adaptor

and cable supplied. Disassembly of the unit is not required for any

reason other than for servicing.

The diagnostics utility permits monitoring and logging of radio

performance parameters for both E Series* as well as D Series* data

radio modems and base stations. It supports homogeneous systems

of radios as well as mixed systems of both E and D series radios.

The firmware update utility permits field upgrade of the firmware in an

ER450 data radio modem, EB450 base station and EH450 hot

standby unit connected directly to the PC. A special serial adaptor

cable is required to be connected to Port B to load firmware into the

unit.

Installation

Unit Connection

Programmer and Diagnostics Utilities

The unit is connected to the PC using the supplied DB9-RJ45 adaptor

cable (part no. TVIEW+ Cable) for local configuration changes or

diagnostic monitoring. The cable should be connected to the RJ45

System Port of the unit and a valid PC serial port (eg; COM 1) DB9

connector.

(See Part E - Getting Started: Communications Ports)

Firmware Update Utility

The unit to be updated with firmware connects to the PC using the

DB9-DB9 adaptor (part no. DRPROG). The cable should be

connected to the DB9 Port B connector on the unit and a valid PC

serial port (See Appendix C for details) DB9 connector.

Software

Please take a moment to read this important information before you

install the software.

The installation of this Software Suite is a 2 step process.

Step 1 completes the typical installation of the TVIEW+ Management

Suite and will install the Programming Software together with the E

Series Documentation.

Step 2 installs the Diagnostic Software and is optional. This step is

only required if your radios have Remote Diagnostics enabled.

STEP 1: Installation - TVIEW+ Management

Suite

Note: If a previous version of the TVIEW+ Management Suite has

been installed on your PC, you must uninstall it via Control Panel

“Add/Remove Programs”.

• Close down all other programs currently running.

* Requires the optional DIAGS Network Management and Remote

Diagnostic Facility to be installed - per radio.

Page 40

• Place the CD-ROM in the drive on the PC.

• Using Windows Explorer locate the files on the CD-ROM.

• In Windows Explorer double click on the file called

TVIEW+_(Version#)_install.exe

• After the installer starts follow directions.

© Copyright 2002 Trio DataCom Pty . Ltd.

E Series Data Radio – User Manual

Part I TVIEW+ Management Suite - Programmer

STEP 2: Installation - TView Diagnostic

Software (Optional)

Note: If a previous version of the “TView WinDiags” software has

been installed on your PC, you must uninstall it via Control Panel

“Add/Remove Programs”.

• Close down all other programs currently running.

• Place the CD-ROM in the drive on the PC.

• Using Windows Explorer open the “Diagnostics” directory on

the CR-ROM.

• Double click on the file called setup.exe

• After the installer starts follow directions.

Other:

The current E Series Manuals are supplied and installed as part of the

TVIEW+ Management Suite installation in Adobe Acrobat format.

Adobe Acrobat Reader is provided on the CD-ROM for installation if

required.

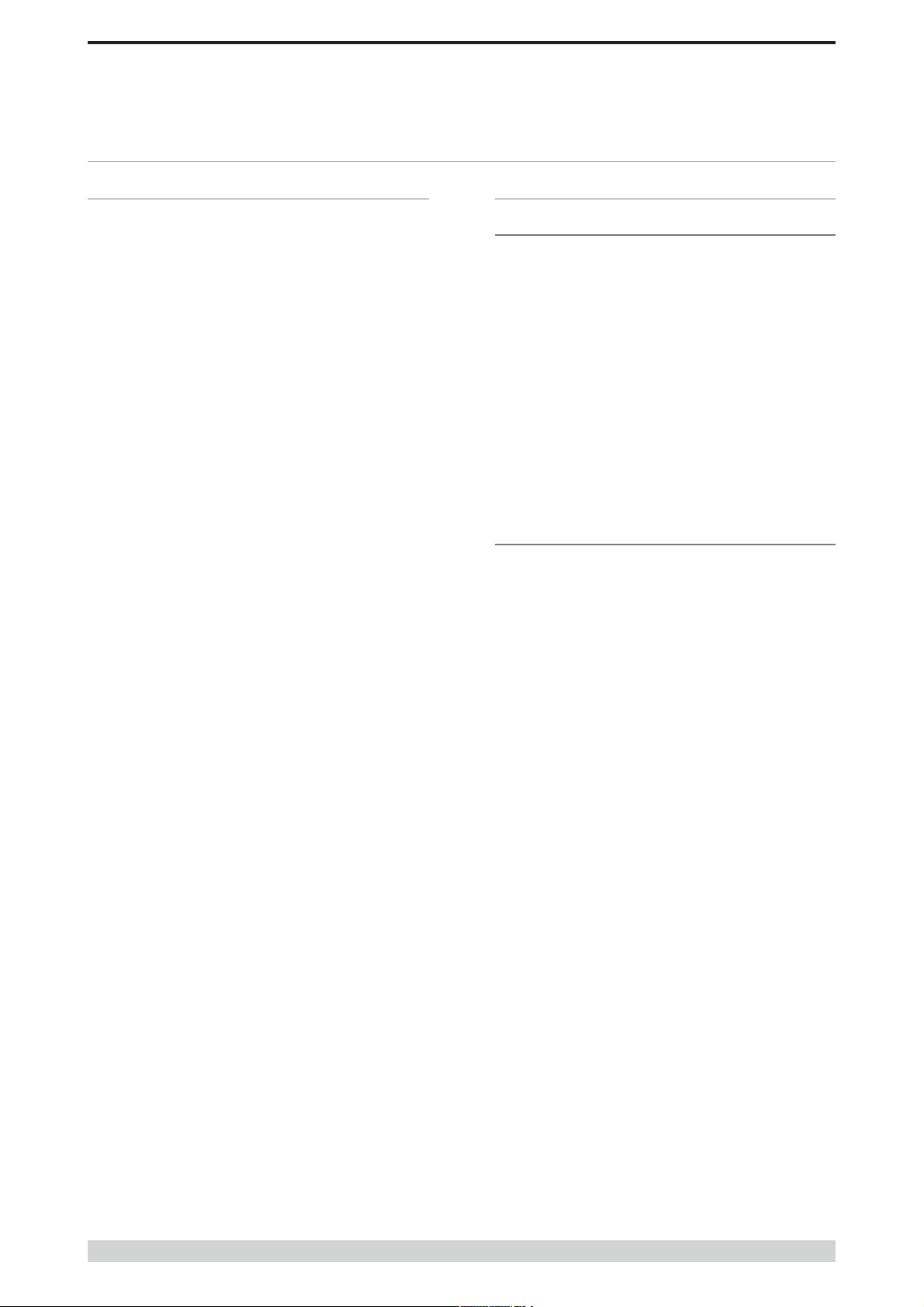

TVIEW+ Front Panel

When started the TVIEW+ front panel appears. The larger buttons

permit each of the three utilities to be started. The diagnostics button

may be greyed out if this utility has not been installed or found in the

correct file directory. Access to local help and an exit facility are

provided by the remaining 2 buttons.

Programmer

Main Window

When first started the programmer is in file mode as indicated by the

mode field at the bottom right of the panel shown below. In this mode it

is possible to open a previously saved configuration file, or configure

various programming options and save the configuration to a file.

Note: Modulation type is not available in this mode.

T o commence programming a unit (radio remote or base station) a

session must first be established by using the “READ” function. This

function reads the current configuration from the unit and displays it in

the main window. The “mode” displays changes to local or remote

depending on the type of session selected at the read function. Several

options in the main window may be blanked out until a session has

been established with a unit.

Note: Changing any item on the menu will in general not take effect

until data is written back to the unit using the “WRITE” function.

The procedure to follow for normal programming of unit is:

• Read unit

• Configure parameters (or Open a previously saved

configuration file)

• Write unit

Several modems of the same radio type can be programmed with the

same configuration using the clone facility described in Clone Mode. It

is important to note that when using this facility the cloned radio should

be of the same type to ensure it does not operate outside its capability.

© Copyright 2002 Trio DataCom Pty. Ltd.

Page 41

E Series Data Radio – User Manual

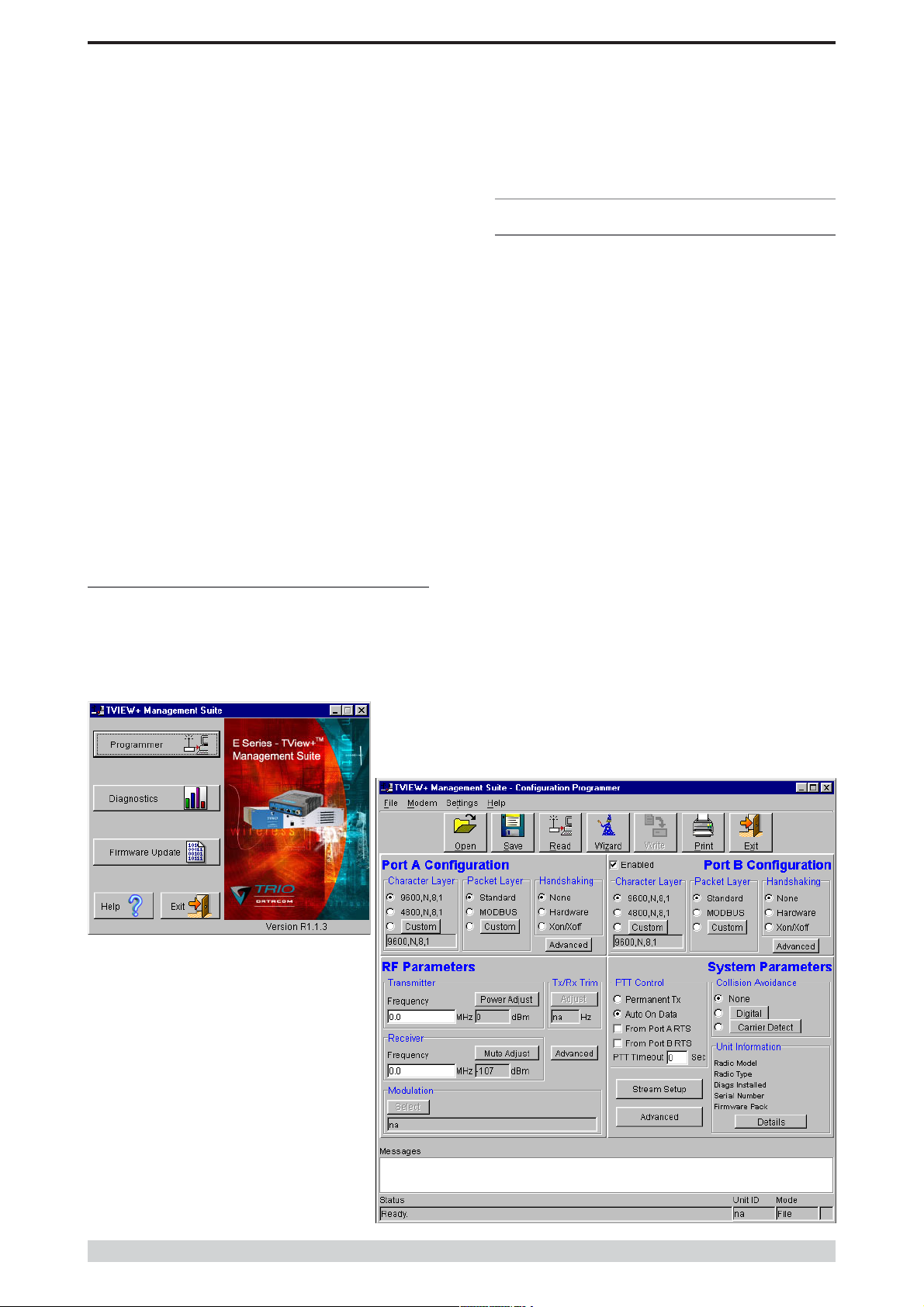

Pull Down Menus and Toolbar Buttons

The items on the pull-down menus can be selected either directly with

a mouse or using the ALT key in combination with a HOT KEY (eg

ALT-F to select the file menu). Several of the functions within each

menu are also available on the toolbar (click once to select).

File Menu

The file menu allows the user to load (open) or save configuration data

as well as to quit the program. The files are saved with an “.cfg” file

extension

Open (also available on the toolbar)

This function is used to load an existing configuration file that can be

used to directly program the radio or to use as a starting point to edit

configuration parameters. Note that a session must be established

with the unit by initially reading the configuration parameters from the

unit prior to being written to a unit.

If in file mode the modulation type will not be displayed. If in local/

remote mode and a file that was saved from local/remote mode is

opened, then modulation type will be imported and used, but only if it

is valid for the connected hardware. If not then the units read

modulation type will be used.

Save (also available on the toolbar)

Part I TVIEW+ Management Suite - Programmer

xit (also available on the toolbar)

E

This function terminates the program. The user is requested to confirm

this selection before exiting the application.

Modem Menu

This radio menu allows configuration data to be read

from and written to the unit (remote radio or base

station) using the selected PC serial port connection

(see Settings menu). The action of reading the

configuration establishes a session with the unit.

Communications is maintained with the unit to ensure

that the session remains open. If the session has been lost due to data

transmission errors or disconnection of the programming cable it will

need to be re-established to ensure any updated configuration is written

successfully to the unit.

Read (also available on the toolbar)

This function establishes a session with the unit, reads configuration

data from the unit and displays it in the programmer main window.

When selected a dialogue window appears prompting the user to

choose whether the unit to read is local (connected directly to the serial

port or remote (connected over the air to the unit connected to serial

port). Unit no. (serial no.) musty be entered and the stream SID code

is “on” (default =0)). After configuration data is read from the unit it is

available for editing and writing back to the unit or saving to a file. The

progress of data transfer to or from the unit is indicated by a message

window as well as a rotating indicator in the bottom right hand corner

of the main window.

This function is used to save the current configuration parameters to a

file for future recall.

If in “file mode” only basic RF , Port and System parameters are

saved and re called. If in local/remote mode then modulation type is

saved and re called.

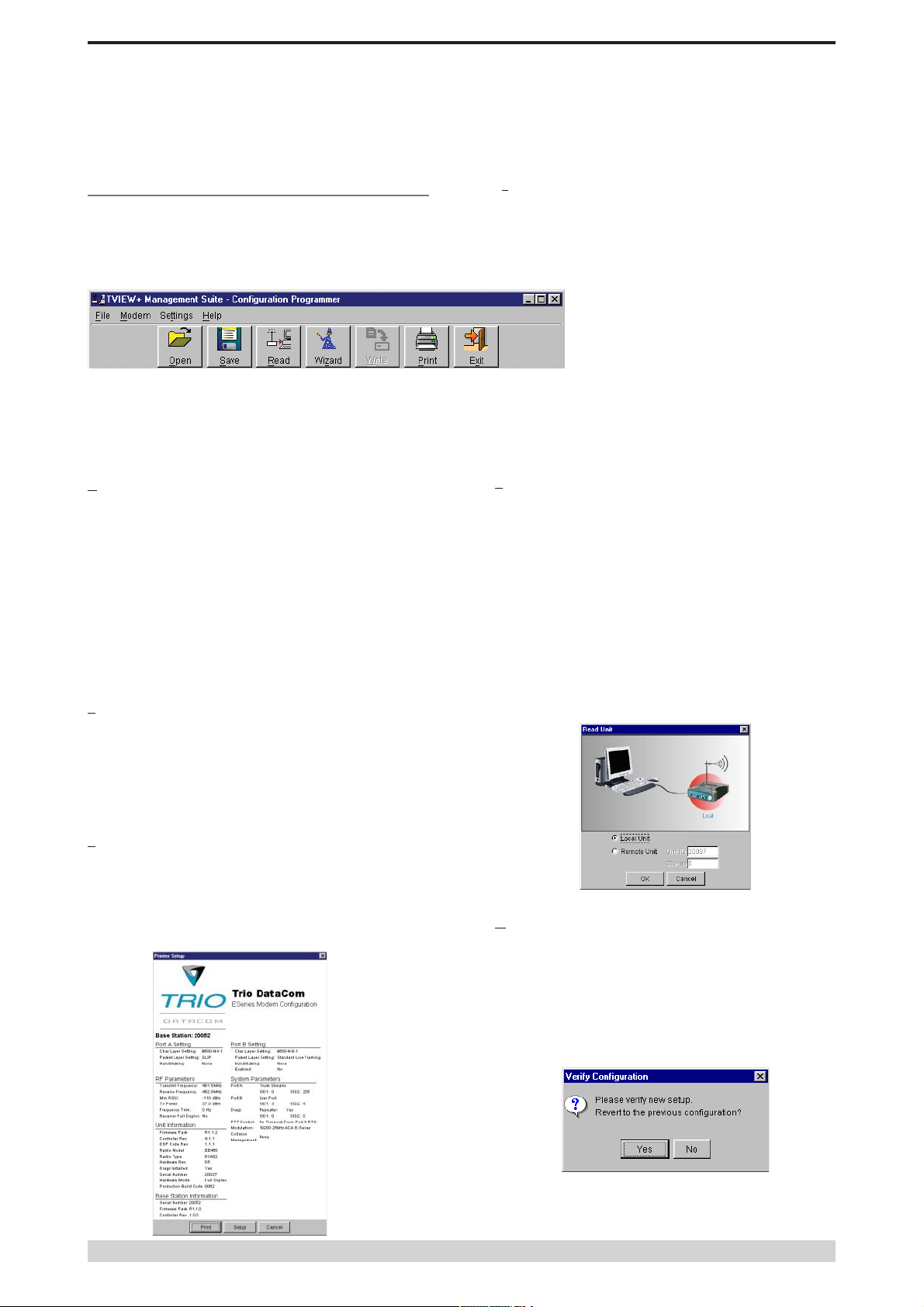

Print (also available on the toolbar)

This function prints out the configuration data to the default printer in a

standard format. There are no options for this item.

This should be used if a complete record is required for site/unit

configuration. Firmware/Modulation/Diags/Hardware type are all

printed.

Write (also available on the toolbar)

This function writes configuration data displayed in the main window to

the unit and reboots the unit. When selected a dialogue window

appears prompting the user to confirm whether to proceed. A progress

indicator in the bottom right hand corner of the main window is

displayed while data is being read. This selection is only available if a

session has been previously established and maintained with the unit.

Page 42

© Copyright 2002 Trio DataCom Pty . Ltd.

E Series Data Radio – User Manual

Part I TVIEW+ Management Suite - Programmer

This dialog provides a facility for reversing any remote configuration

changes and reverting to the previous configuration.

Select “No” to send a command to the unit to accept the new

configuration changes and to close the session. Select “Yes” to send a

command to the unit to cancel the new configuration changes and to

close the session.

The configuration settings will revert to their previous values if the data

communications circuit with the unit has been interrupted after the new

changes have been made, but before they have been verified, as just

described, then the unit will automatically discard the new changes. A

“Timeout Error” message will appearin the event of such an

interruption and the programmer will revert back to file mode.

After configuration data has been written the session with the unit is

closed and the programmer goes back to file mode

NOTE: In general any change made on the programmer screen must

be written to the unit using this function before it becomes permanently

stored. Changes to Power Adjust, Mute Adjust and Tx/Rx Trim

however do take immediate effect to permit a tuning capability prior to

being permanent stored.

Cancel Session (also available on the toolbar)

This function closes the session with unit and puts the programmer

back into file mode. All configuration changes are discarded including

changes to Power Adjust, Mute Adjust and Tx/Rx Trim.

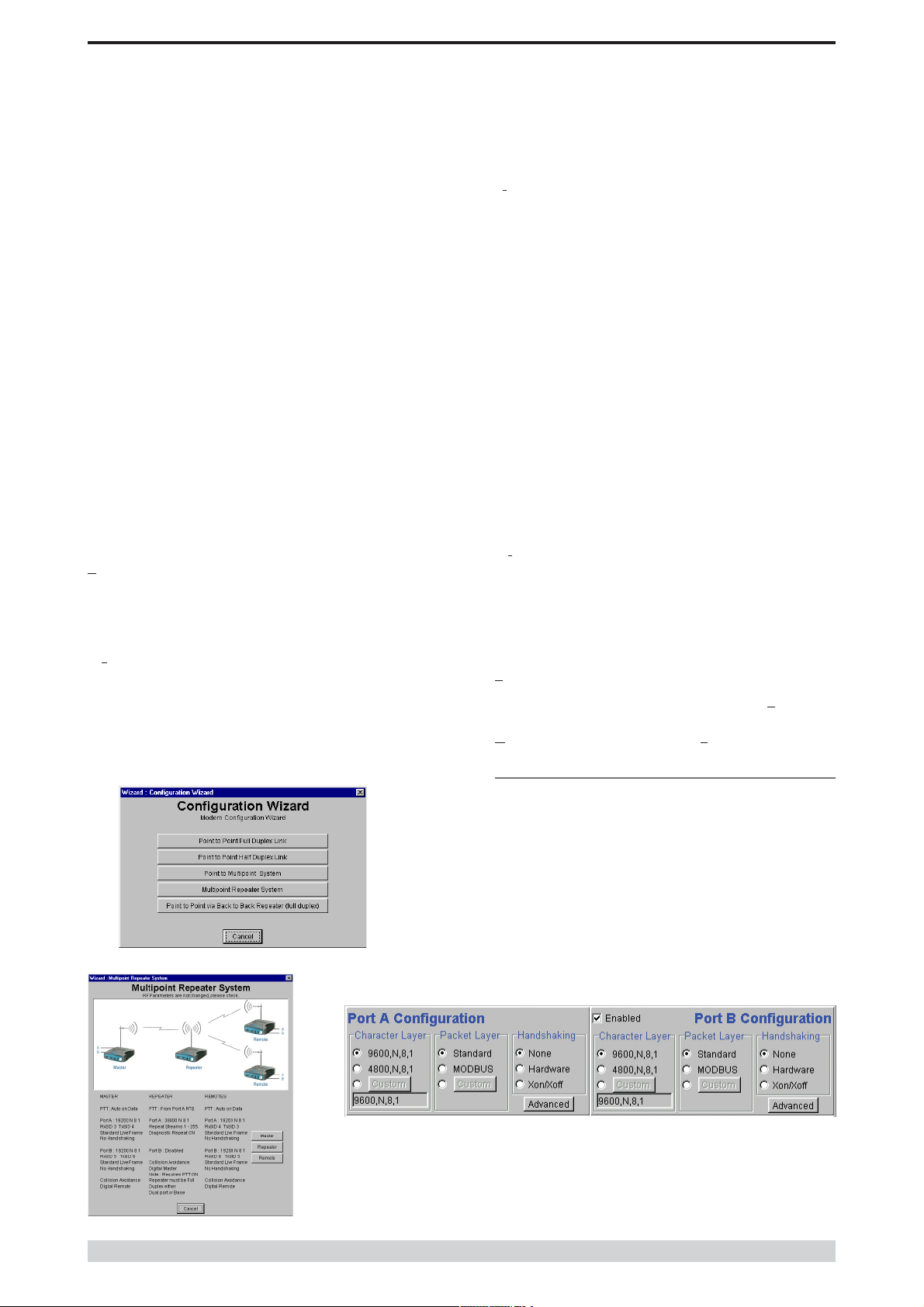

zard (also available on toolbar)

Wi

This function permits the user to select standard configurations after the

configuration from a unit has been read or a file opened. The user is

prompted via a series of dialogue windows to select the desired

configuration that can then be written to the unit (remote radio or base

station).

C

lone Mode

This function permits writing of the same configuration data to several

units. This feature is normally used for configuring data radio modems

connected locally. The procedure is:

• Read the configuration from the first unit

• Configure the parameters (or Open a previously saved

configuration file)

• Select Clone Mode (Modem menu)

• Write the configuration to the first unit

• The changes will take effect when repowered

• Connect the next unit

• Write the next unit which establishes a session and recognises

the unit serial number and type, and then configures the unit

• Repower the unit for changes to take effect

• Repeat the last 3 steps for the remaining units.

ttings

Se

This menu permits selection of the PC serial port (COM1 to COM4)

to be used for communications with the unit. COM1 is the default

selection and if a different port is to be used it must be set before

establishing a session by reading the configuration from a unit. Whilst

a session is established with a unit this menu can not be accessed.

Help

This menu permits selection of help information using the

key. W arnings regarding use of the programmer software using the

Warnings key and version detail using the About key .

Contents

Port A and Port B Configuration

Data from these two user ports is multiplexed for transmission over the

air. Each port can be configured separately for the Character layer

(Data speed, number of data bits, number of stop bits, parity), Packet

layer and Handshaking (flow control). Port B must be enabled if

required by setting the check box at the top of its configuration section.

if Port B is off, the 16K memory is split equally between Port A Rx/Tx

buffers (ie: 8K & 8 K). If Port B is on, then the 16K is split equally

across Port A & B Rx/Tx buffers (ie: 4K, 4K, 4K & 4K).

The following description is common to both ports.

© Copyright 2002 Trio DataCom Pty. Ltd.

Page 43

E Series Data Radio – User Manual

Part I TVIEW+ Management Suite - Programmer

Character Layer

There are two standard formats and a custom format that can be

selected by checking the appropriate control button to the left of the

description. The standard formats are:

• 9600,N,8,1 (data speed = 9600 bps, no parity , 8 data bits, 1

stop bit)

• 4800,N,8,1 (data speed = 4800 bps, no parity , 8 data bits, 1

stop bit)

A non-standard format can be selected via the Custom button that

displays a dialogue box to permit selection of data speed, parity,

number of data bits and stop bits. Once selected the OK button should

be used to complete the selection. The custom selection is also

displayed in the main window below the Custom button.

For example a constant stream of 300 baud user data placed onto a

9600 baud channel will result in 1 character per frame being

transmitted. If the user baud rate was lifted to 9600,N,8,1 with a

continuous data stream, then the frame size would settle to about 16

characters plus 32 overhead bits. If collision avoidance is enabled as

master the average frame size will increase to 32 characters plus

overhead bits.

The number of data bits associated with the user data stream will also

have an effect on the average size of a frame. For instance the

number of stop bits, and number of data bits per character.

The system designer must choose the best compromise of all the

above items to ensure the most efficient method of data transmission.

Note: The first character is always packetized and sent by itself

regardless of all the above variables.

Modbus

This selection configures the PAD driver with options automatically set

to implement the MODBUS protocol. eg: 5 mSec timer.

Custom

Other configurations of the PAD driver can be selected via the Custom

button which displays a dialogue box to permit selection of several

configuration options as follows:

SLIP / DIAGNOSTICS

Packet Layer

There are two standard configurations and a custom configuration

which can be selected by checking the appropriate control button to the

left of the description. There are essentially two basic modes of

operation for the packet assembler and disassembler (PAD). The first

is where the PAD operates in a standard mode with data received at

the port being immediately sent over the radio channel. The second is

a store and forward or delayed mode where whole data packets are

received from the port before being sent over the radio channel. In both

cases data is sent over the radio channel in variable length frames and

delineation of these frames is dependent on the configuration selected

as well as the characteristics of the data stream received at the data

port.

The packet layer configuration options which can be selected are:

Standard (live framing)

With standard live framing data received from the host by the modem

is immediately placed into a frame and transferred onto the radio

channel. This avoids placing “store and forward” delays in the data

transmission.

If a stream of characters is received by the modem, then several

characters at a time may be placed into the same frame. The number

of characters in the frame depends mainly on the respective baud

rates of the user port and the primary channel baud rate of the modem,

as well as the level of overheads experienced on the radio channel

and the user data stream.

SLIP is a well known protocol for transferring binary data

packets over a data link. Each data packet is delineated by

<FEND> characters, and a substitution mechanism exists that

allows these characters to be included in the data packet.

Appendix B describes the SLIP protocol which is used

extensively in UNIX(tm) based systems, and is closely

associated with TCP/IP networks.

The diagnostics controller package uses the SLIP protocol to

communicate between base station and remote modems.

DNP-3 / IEC870

This selection configures the PAD driver to implement the DNP-3

Protocol and IEC870 Protocol.

Pull Down Menu Selection

The PAD driver can be configured for a number of vendor

specific protocols by selecting the desired option.

Page 44

© Copyright 2002 Trio DataCom Pty . Ltd.

E Series Data Radio – User Manual

Part I TVIEW+ Management Suite - Programmer

Custom Format

This selection permits PAD driver to be configured in a variety of

ways and requires a greater understanding of the system design.

For the modem to successfully transmit its packets (or frames) of

data over the radio channel, it must be told on what basis to

delineate data packets received at the data port. Once the end of

a data packet has been received at the port the data frame is

closed and transmission over the radio channel commences.

Delineation of data packets can be configured to occur via any

combination of:

• A predefined minimum time delay between packets received

at the port. Typically the time delay would reflect the absence

of a couple of characters in the data stream at the specified

user port baud rate.

• Limiting the maximum number of characters which can be put

in the data frame sent over the radio channel.

• Receipt of a selected end of message (EOM) character at the

port. An ASCII carriage return (character 13) is often used for

this purpose.

As each data frame to be transmitted over the radio channel has

overhead data consisting of checksums and SID codes. The

system designer must determine the best compromise between

the ratio of overhead versus user data which depends on packet

size and user data packet transmission latency.

The fields which can be configured are:

Character Input timer: Set the input timer value in ms or enter

•

zero to disable. Range 0 - 255.

Maximum Frame Size: Set the maximum number of

•

characters or enter zero to disable. Range 0 - 4095.

EOM Character: Select the check box to the left of the

•

description to enable and enter the EOM character as a

decimal value. Range 0 - 255.

Handshaking

If the standard PAD is selected (i.e. any settings apart from SLIP/

Diagnostics), then flow control can be either hardware handshaking,

XON/XOFF protocol or none.

The XON/XOFF flow control is not possible when using either the

SLIP/Diagnostics protocol.

The Handshaking section of the screen allows the selection of either of

the handshaking methods as well as allowing handshaking to be

disabled.

Details of the two handshaking methods are given below.

Hardware

The modem acts as Data Communications Equipment (DCE) and

supplies to the host controller the following interface signals:

Data Set Ready (DSR)

Data Carrier Detect (DCD)

Clear To Send (CTS)

Receive Data Output (RXD)

The host controller must act as Data T erminal Equipment (DTE) and

supplies to the modem the following interface signals :

Data T erminal Ready (DTR)

Request To Send (RTS)

Transmit Data Input (TXD)

• DCD

DCD has several modes of operation. It is set to TRUE when

data is being transferred from the modem to the host - RXD line

active. The signal is asserted approximately 500ms before the

start bit of the first character in the data stream and remains for

approximately 1 character after the last bit in the data stream. The

other modes of operation are dependent on the advanced

settings.

• DSR

© Copyright 2002 Trio DataCom Pty. Ltd.

DSR is permanently set to TRUE.

• CTS

The CTS is a signal from the modem to the host informing the

host that the modem is able to accept incoming data on the TXD

line. It responds to the actions of the RTS line similar to the

operation of a “standard” line modem.

The CTS is FALSE if the RTS line is F ALSE. Once the R TS line

is set to TRUE (signalling that the host wants to send some data

to the modem on the TXD line), then the CTS will be set TRUE

within 1ms, if the modem is capable of accepting more data.

The CTS line will be set to FALSE if the transmit buffer in the

modem exceeds 4075 bytes, or the number of queued frames

exceeds 29 to ensure that no overflow condition can occur.

Page 45

E Series Data Radio – User Manual

Part I TVIEW+ Management Suite - Programmer

• RTS

The RTS line is used for two reasons. The first is to assert the

CTS line in response to RTS. The RTS line can also be used to

key up the transmitter stage of the modem.

• DTR

The DTR line is used for flow control of data being sent from the

modem to the host controller. When the host is able to accept

data it sets this line to TRUE, and if data is available within the

modem, it will be sent to the host. If the host cannot accept any

more data, then it sets the DTR to FALSE, and the modem will

stop all transmissions to the host.

• Xon/Xoff

If the flow control mechanism is XON/XOFF then the modem

uses the standard ASCII control codes of DC1

{^Q=11(Hex)=17(Dec)} for XON and DC3

{^S=13(Hex)=19(Dec)} for XOFF . The DTR input line is totally

ignored.

NOTE: There is no substitution mechanism employed in the

XON/XOFF protocol, so care must be taken when transferring

binary data to ensure that invalid flow control characters are not

generated.

Advanced

This button provides access to the advanced features of the port

configuration. When selected a dialogue box appears which permits

selection of the source for the port DCD output signal.

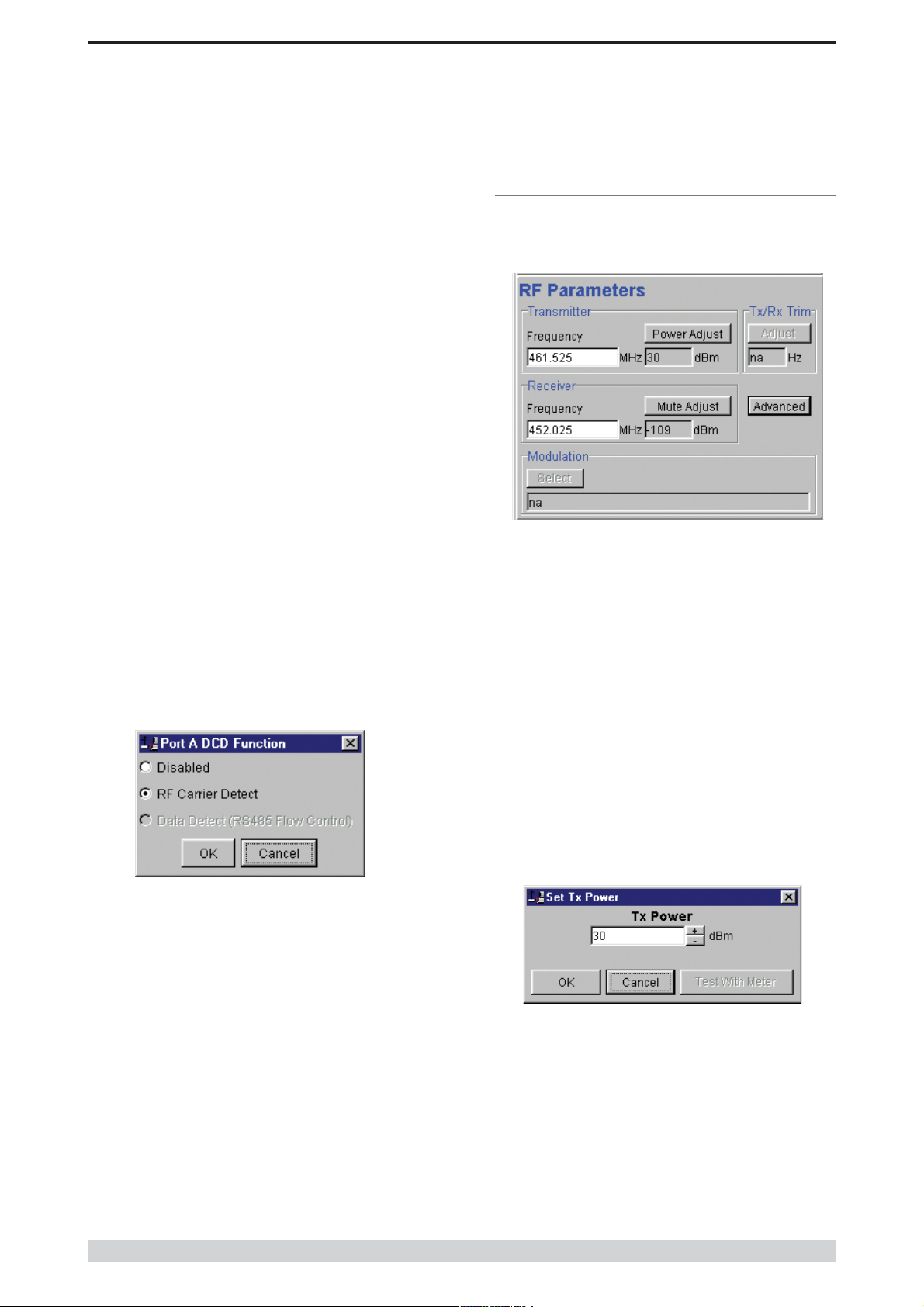

RF Parameters

This section of the main window permits adjustment of transmitter and

receiver, radio channel modulation scheme, frequency trim and

advanced features.

Transmitter

The transmitter can be configured for transmit frequency and power

level.

Frequency

The required transmit frequency in MHz can be entered in the display

field. The programmer checks that the selected frequency is in the

range for the particular model of radio and provides warnings if not.

Disabled

This selection disables the DCD output on the port. This selection is

not permissible if hardware based flow control has been selected.

RF Carrier Detect

This selection causes DCD to be asserted at the onset of a received

RF signal being detected. This will generally occur several

milliseconds before data is transmitted from the port.

Data Detect (RS485 Flow Control)

This selection causes DCD to be asserted when data is about to be

transmitted from the port. This option is not available if handshaking is

set to “None” or “Xon/Xoff”.

Power Adjust

The currently selected transmit power is displayed below the button in

dBm. The power level can be adjusted by selecting this button which

displays a dialogue box. The up/down keys, or a typed in value, can

be used to select the required power level in dBm steps. There are

two methods for setting the power.

Page 46

© Copyright 2002 Trio DataCom Pty . Ltd.

Loading...

Loading...