Schneider Electric France L Isle d Espagnac XCSR User Manual

XCSR

QGH1315301 03/2017

XCSR

Contactless RFID Safety Switches

User Manual

(Original Document)

03/2017

QGH1315301.00

www.schneider-electric.com

The information provided in this documentation contains general descriptions and/or technical characteristics of the performance of the products contained herein. This documentation is not intended as a

substitute for and is not to be used for determining suitability or reliability of these products for specific user

applications. It is the duty of any such user or integrator to perform the appropriate and complete risk

analysis, evaluation and testing of the products with respect to the relevant specific application or use

thereof. Neither Schneider Electric nor any of its affiliates or subsidiaries shall be responsible or liable for

misuse of the information contained herein. If you have any suggestions for improvements or amendments

or have found errors in this publication, please notify us.

No part of this document may be reproduced in any form or by any means, electronic or mechanical,

including photocopying, without express written permission of Schneider Electric.

All pertinent state, regional, and local safety regulations must be observed when installing and using this

product. For reasons of safety and to help ensure compliance with documented system data, only the

manufacturer should perform repairs to components.

When devices are used for applications with technical safety requirements, the relevant instructions must

be followed.

Failure to use Schneider Electric software or approved software with our hardware products may result in

injury, harm, or improper operating results.

Failure to observe this information can result in injury or equipment damage.

© 2017 Schneider Electric. All Rights Reserved.

2 QGH1315301 03/2017

Table of Contents

Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

About the Book . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Part I General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 1 Safety Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Safety Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2 Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.1 General Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

XCSR RFID Safety Switch General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How a XCSR RFID Safety Switch Works? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Zones (Sao – Sar) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Definition of Characteristic Times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Response Time (Process Safety Time) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Risk Assessment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 XCSR RFID Safety Switch Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

External Device Monitoring (EDM) or Machine Primary Control Element (MPCE) Monitoring

Operating and Output States, LED Meaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

XCSR Standalone Models. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

XCSR Series Connection (Daisy-Chain) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

XCSR Single Models. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pairing Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Components Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

XCSR Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part II Installation, Wiring, and Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 3 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mounting the XCSR RFID Safety Switch. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 4 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Electrical Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connection Schematics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part III Technical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 5 Technical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

XCSR RFID Safety Switch Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety Related Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part IV XCSRD210MDB Diagnostic Module. . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 6 XCSRD210MDB Diagnostic Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connections Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Modbus Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11

14

15

16

17

18

19

20

22

23

25

26

28

30

33

35

37

38

39

41

44

45

52

56

63

66

69

70

73

77

80

81

82

84

85

86

90

92

93

9

QGH1315301 03/2017 3

4 QGH1315301 03/2017

Safety Information

Important Information

NOTICE

Read these instructions carefully, and look at the equipment to become familiar with the device before

trying to install, operate, or maintain it. The following special messages may appear throughout this

documentation or on the equipment to warn of potential hazards or to call attention to information that

clarifies or simplifies a procedure.

PLEASE NOTE

Electrical equipment should be installed, operated, serviced, and maintained only by qualified personnel.

No responsibility is assumed by Schneider Electric for any consequences arising out of the use of this

material.

A qualified person is one who has skills and knowledge related to the construction and operation of

electrical equipment and its installation, and has received safety training to recognize and avoid the

hazards involved.

QGH1315301 03/2017 5

6 QGH1315301 03/2017

At a Glance

Document Scope

Validity Note

About the Book

This manual describes the features, installation, wiring, usage, and troubleshooting of the XCSR RFID

Safety Switches.

The technical characteristics of the devices described in this manual also appear online.

To access this information online:

Step Action

1Go to

2 In the Search box, type the model number of a product or the name of a product range.

3 If more than one model number appears in the Products search results, click on the

4 To save or print a data sheet as a .pdf file, click Download product datasheet.

The characteristics that are presented in this manual should be the same as those characteristics that

appear online. In line with our policy of constant improvement, we may revise content over time to improve

clarity and accuracy. If you see a difference between the manual and online information, use the online

information as your reference.

www.tesensors.com

Do not include blank spaces in the model number/product range.

model number that interests you.

.

QR Code

Related Documents

User Comments

A QR code including the Telemecanique Sensors web address is present on the XCSR RFID Safety Switch

marking. Technical documents are available in various languages in this website.

Title of documentation Reference number

XCSR RFID Safety Switches - Quick Start Guide NHA77770

XCSRD210MDB Diagnostic module - Quick Start Guide NHA77776

You can download these technical publications and other technical information from our website at

www.tesensors.com

We welcome your comments about this document. You can reach us by e-mail at

support@tesensors.com

.

customer-

QGH1315301 03/2017 7

8 QGH1315301 03/2017

Overview

What Is in This Part?

XCSR

General

QGH1315301 03/2017

General

Part I

General

This part provides detailed information about the safety requirements and product description.

This part contains the following chapters:

Chapter Chapter Name Page

1 Safety Requirements 11

2 Product Description 13

QGH1315301 03/2017 9

General

10

QGH1315301 03/2017

XCSR

Safety R equi remen ts

QGH1315301 03/2017

Safety Requirements

Chapter 1

Safety Requirements

Safety Requirements

Precautions

IMPROPER SETUP OR INSTALLATION

This equipment must only be installed and serviced by qualified personnel.

Read, understand, and follow the compliance below before installing the XCSR RFID Safety Switches.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

Meeting Full Compliance

The compliance of a machine and the XCSR RFID Safety Switches with safety regulations, depends on

the proper application, installation, maintenance, and operation of the XCSR RFID Safety Switches. These

are responsibilities of the purchaser, installer, and employer.

The employer is responsible for selecting and training the personnel necessary to properly install, operate,

and maintain the machine and its safeguarding systems. The XCSR RFID Safety Switches must only be

installed, checked, and maintained by a qualified person. A qualified person is defined as “a person or

persons who, by possession of a recognized degree or certificate of professional training, or who, by

extensive knowledge, training and experience, has successfully demonstrated the ability to solve problems

relating to the subject matter and work” (ANSI B30.2).

To use the XCSR RFID Safety Switches, the given requirements must be met:

The guarded machine must be able to stop anywhere in its cycle.

The guarded machine must not present metallic chips in the vicinity of the XCSR RFID Safety Switches.

The guarded machine must have a consistent stopping time and adequate control mechanisms.

All applicable governmental and local rules, codes, and regulations must be satisfied. This is the user

and employer responsibility.

All safety-related machine control elements must be designed so that an alarm in the control logic or the

control circuit breakdown does not lead to a XCSR RFID Safety Switches failure.

Perform a test of the XCSR RFID Safety Switches during installation and after maintenance or

adjustment. As well as in case of any modification of the machine controls, tooling, machine or of the

RFID guarding system.

The proper functioning of the XCSR RFID Safety Switches and its operating line must be checked on a

regular basis based on the level of security required by the application (for example, number of

operations, level of environmental pollution, …).

Perform only the test and diagnostic procedures outlined in this manual.

Follow all procedures in this manual for proper operation of the XCSR RFID Safety Switches.

All safety-related machine control circuit elements, including pneumatic, electric, or hydraulic controls

must be control-reliable.

The enforcement of these requirements is beyond the control of Schneider Electric. The employer has the

sole responsibility to follow the preceding requirements and any other procedures, conditions, and

requirements specific to the machinery.

WARNING

Product Support

For more information about products and services in your country, visit

QGH1315301 03/2017 11

www.tesensors.com

.

Safety Requirements

12

QGH1315301 03/2017

XCSR

Product Specification

QGH1315301 03/2017

Product Description

Chapter 2

Product Description

Overview

This chapter describes the general information, XCSR RFID Safety Switch functions, and system

components.

What Is in This Chapter?

This chapter contains the following sections:

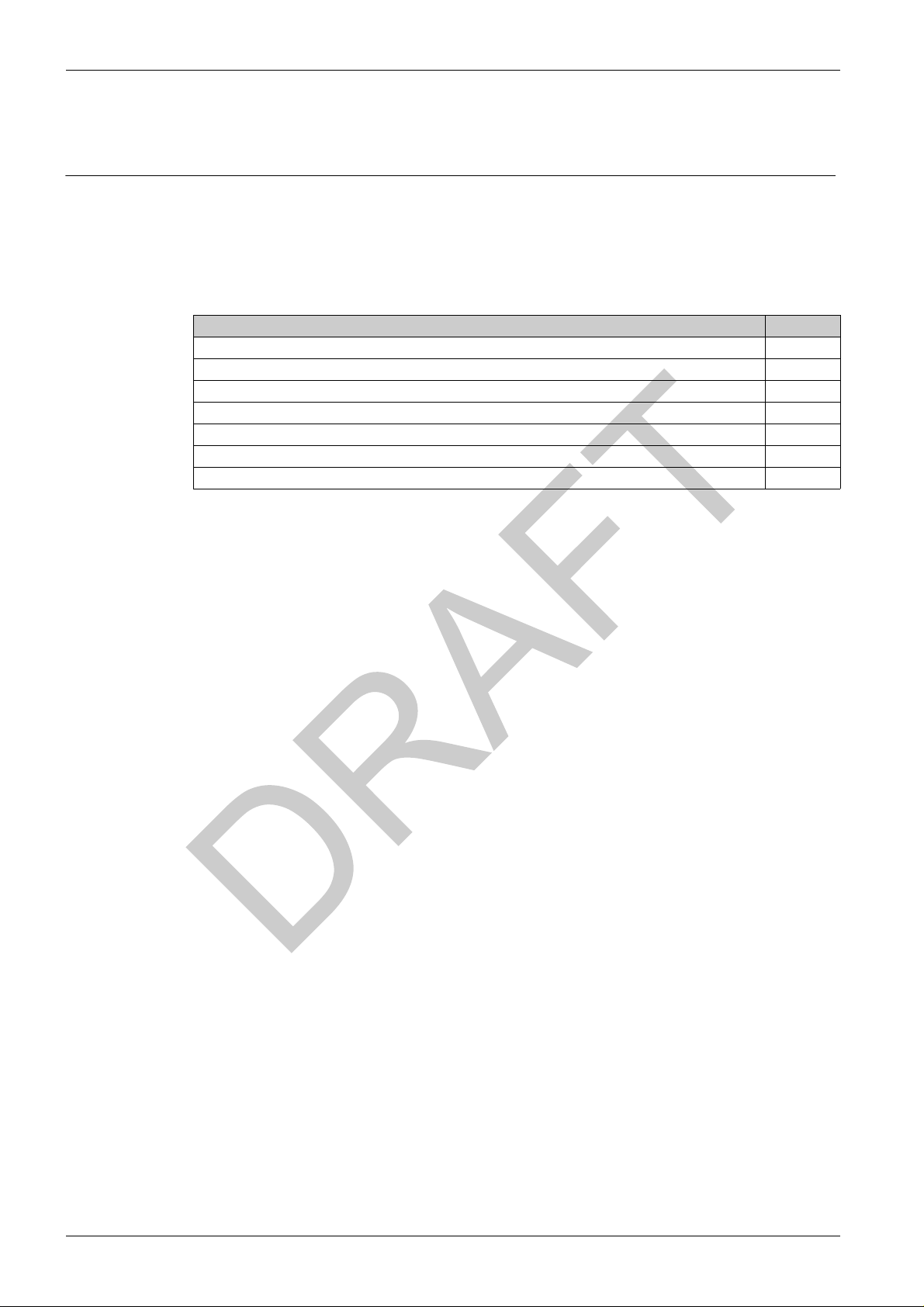

Section Topic Page

2.1 General Information 14

2.2 XCSR RFID Safety Switch Functions 22

2.3 System Components 37

QGH1315301 03/2017 13

Product Specification

General Information

Section 2.1

General Information

Overview

This section describes general information of the XCSR RFID Safety Switches.

What Is in This Section?

This section contains the following topics:

XCSR RFID Safety Switch General Description 15

How a XCSR RFID Safety Switch Works? 16

Operating Zones (S

Definition of Characteristic Times 18

System Response Time (Process Safety Time) 19

Risk Assessment 20

Topic Page

– Sar) 17

ao

14

QGH1315301 03/2017

XCSR RFID Safety Switch General Description

Overview

The XCSR RFID Safety Switches are used where personnel protection is required. The basic applications

are for monitoring the position of movable safety guards to prevent hazardous situations from occurring

when the safety guard is opened. Such as, for example:

Robotic work cells

Mobile equipments

Transfer lines

Assembly lines

Roll handling equipments

Automated equipments

Machine tools

Food and beverage equipments

Packaging machines

Product Specification

QGH1315301 03/2017 15

Product Specification

How a XCSR RFID Safety Switch Works?

General Description

A XCSR RFID Safety Switch is a contactless system that consists of a microprocessor-controlled switch

(also called "sensor" or "reader") and a transponder (also called "tag" or "coded actuator").

The reader is to be mounted on the fixed part of the safety guard, and the transponder on the mobile part.

There is no contact between the transponder and the switch, a radio-frequency technology is used for the

communication.

The reader and the transponder are paired in factory. During the manufacturing, the reader loads into the

transponder with which it is sold, a unique code. This saved digital code is the unique "key" accepted by

the paired reader.

When the transponder enters the radio frequency field generated by the reader (by closing a guard door

for example), the reader detects the transponder and reads the data in the transponder memory.

If the transponder code demanded by the reader is correct, the reader switches its two redundant safety

outputs (OSSDs) to the ON state, indicating that the safety guard is closed and thus allowing the machine

operation. For more details, refer to XCSR RFID Safety Switch Functions

When the transponder goes outside the field generated by the reader (by opening a guard door for

example) the reader switches its two redundant safety outputs (OSSDs) to the OFF state in order to stop

the machine, indicating that the safety guard is opened.

By the use of a unique coding, RFID technology is robust against tampering (Type 4 - High level of coding

- according to ISO 14119).

A transponder cannot be reprogrammed. If for any reason, like a tampering attempt, the reader does not

receive from a transponder the only expected code saved in factory, the communication with the

transponder is rejected by the reader. The reader then enters in Error mode and switches its safety outputs

to the OFF state. A new power-up is then required. XCSR RFID Safety Switch is designed to be compliant

with the safety requirements PLe - Cat 4 (EN ISO 13849-1), SIL3 (IEC 61508) and SILCL3 (IEC 62061).

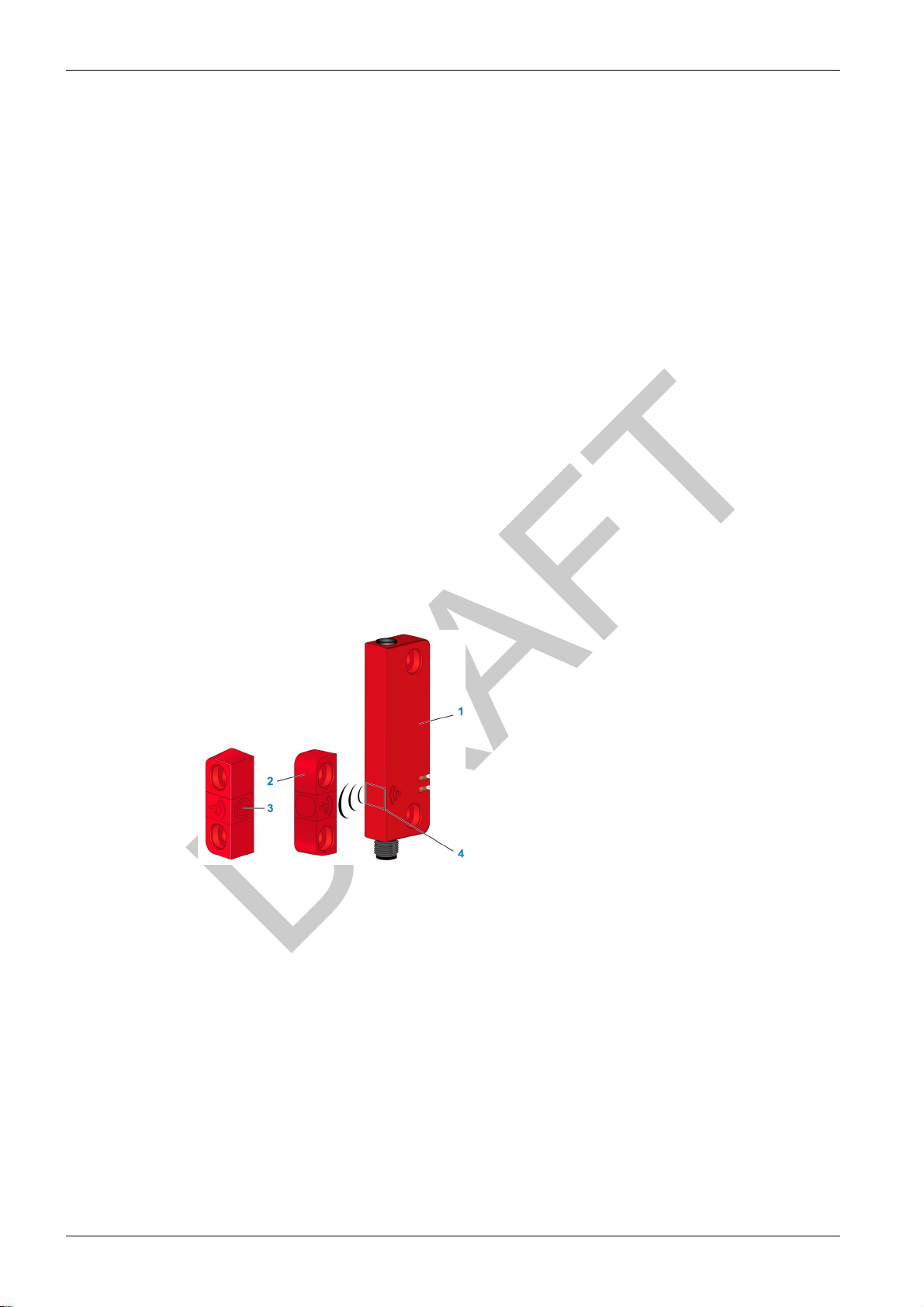

This illustration presents the XCSR RFID Safety Switch:

(see page 22)

.

16

1 Reader

2 Transponder

3 Transponder sensitive area

4 Reader sensitive area

QGH1315301 03/2017

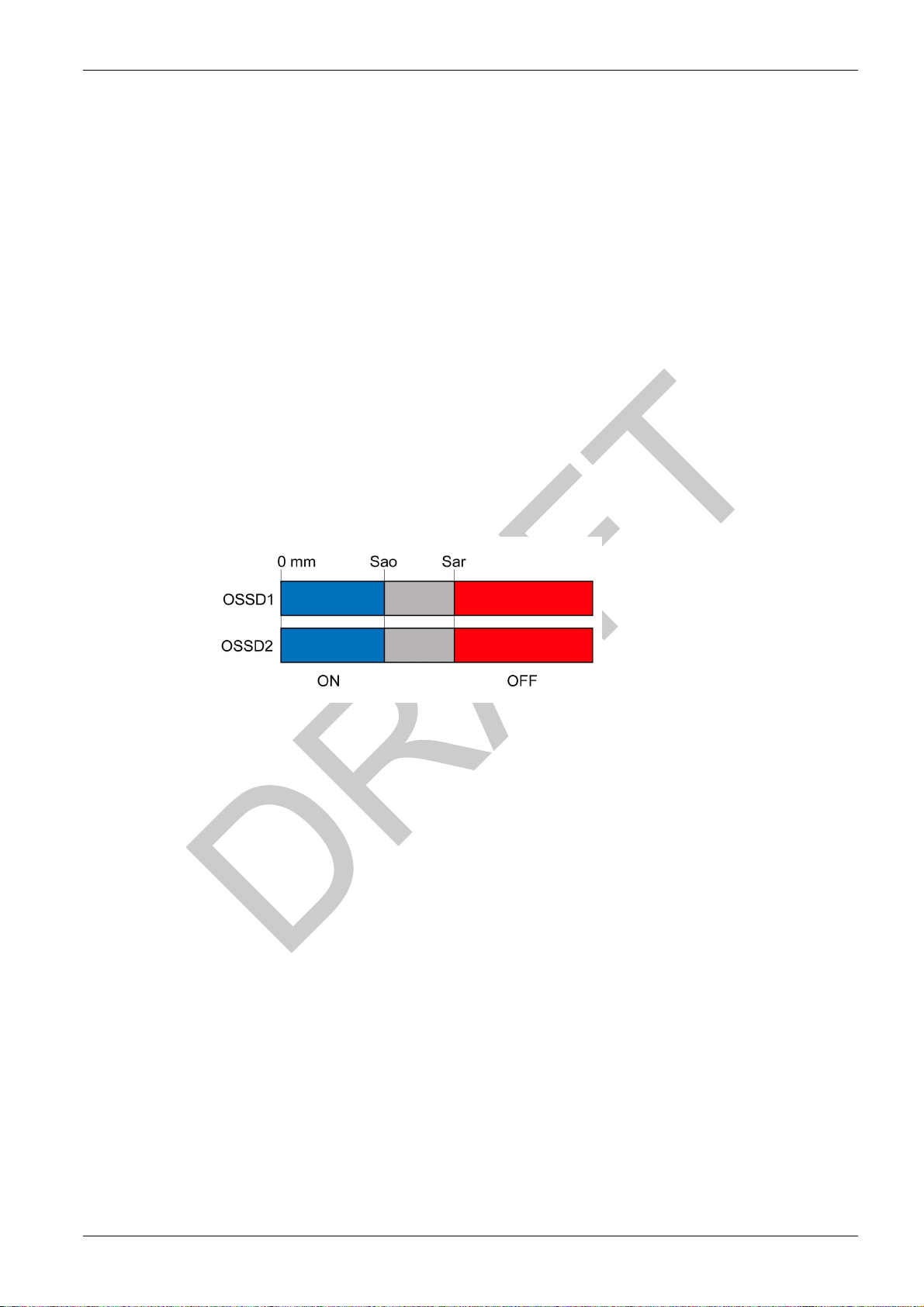

Operating Zones (Sao – Sar)

General Description

When paired transponder and reader are both operating:

S

(Assured operating sensing distance) is the distance from the sensing face within which the

ao

presence of the specified target is correctly detected under all specified environmental conditions (for

example: operating temperature, material of the mounting support) and manufacturing tolerances.

S

(Assured release sensing distance) is the distance from the sensing face beyond which the absence

ar

of the specified target is correctly detected under all specified environmental conditions (e.g operating

temperature, material of the mounting support) and manufacturing tolerances.

The value of S

(the black area in the drawing hereunder = OSSDs ON)

The value of S

certainty (the white area in the drawing hereunder = OSSDs OFF)

S

is the real switch-on sensing distance.

r

The gray zone represents the “transient state”. Inside the gray area, the commutation points are thus not

guaranteed (dispersions zone).

and Sar values depend on the approach directions and the misalignment between the transponder and

S

ao

the reader (refer to Mounting and Operating Distances

The reader and the transponder parts must be mounted in accordance with the given S

to ensure a switch ON and a switch OFF respectively in the black (<S

This diagram describes the operating zones:

Product Specification

is the switching distance below which the ON state is defined with an absolute certainty

ao

is the switching distance beyond which the OFF state is defined with an absolute

ar

(see page 45)

).

ao

) and white (>Sar) areas.

ao

and Sar values

Guaranteed sensing distances for XCSR RFID Safety Switch are given in face to face configuration and

without misalignment between the transponder and the reader:

S

= 10 mm (0.39 in)

ao

S

= 35 mm (1.38 in)

ar

Hysteresis: 3% x Sr ≤ Hr ≤ 20% x Sr

Refer to face to face mounting configuration

(see page 47)

.

A slight delay between the switching of the two OSSDs exists and is defined as the “OSSDs Delay Time

)”

(see page 18)

(T

DT

.

QGH1315301 03/2017 17

Product Specification

Definition of Characteristic Times

Response Time (Tt)

Time between the transponder is entering the operating zone, and the switching of the OSSDs to the ON

state. Typical T

additional switch increases this time by 50 ms.

For Standalone models, the typical response time is T

= 120 ms. This time applies for only one reader. In daisy-chain configuration, each

t

=250ms.

t

Risk Time (T

)

r

Time between the transponder is leaving the operating zone, and the switching of the OSSDs to the OFF

state. T

< 120 ms. This time applies for only one reader. In daisy-chain configuration, each additional

r

switch increases this time by 18 ms.

First-up Time (TON)

After a power-up, the system is performing self-tests for checking its integrity. The first-up time is the delay,

from power-up, after which the system is ready for operation. T

Pairing Mode Time (T

PM

)

Time during which a new transponder pairing is possible (for “re-pairing enabled models” only).

= 10 s from First-up Time (TON) (10 s after the initialization phase).

T

PM

Safety Inputs Inconsistency Time (T

For daisy-chain configuration, maximum time-out allowed for an inconsistency between the states of the

two safety-related inputs. If the time-out is over with a persistent discrepancy, the OSSDs switch to the OFF

state. TIT < 18 ms.

OSSDs Delay Time (T

DT

)

Defines the time difference between the OSSDs for switching to the OFF state. TDT < 18 ms.

OSSDs Pulse Time (T

PT

)

This time is the width of the periodic pulses generated on each OSSD to perform the monitoring of the

safety outputs (short-circuit detection for example). This pulse duration must be compatible with the

downstream equipment connected to the OSSDs (safety interface for example). TPTmax = 1.4 ms, duty

cycle maximum 300 ms.

< 5 s.

ON

)

IT

18

QGH1315301 03/2017

System Response Time (Process Safety Time)

General Description

According to EN ISO 13855, the total response time (T) corresponding to the overall system stopping

performance is calculated by the given formula:

+ t

T = t

1

2

Where:

= Response time of the protection system (in second). It is the total time between the actuation of the

t

1

safeguard and the switching to the OFF state of its output components. This time corresponds to the “Risk

Time” (T

= Stopping time of the machine (in seconds): maximum time required to terminate the hazardous

t

2

machine function after the output signal from the safeguard achieves the OFF-state. This information is

supplied by the machine manufacturer. The response time of the control and the output systems of the

machine is included in t2.

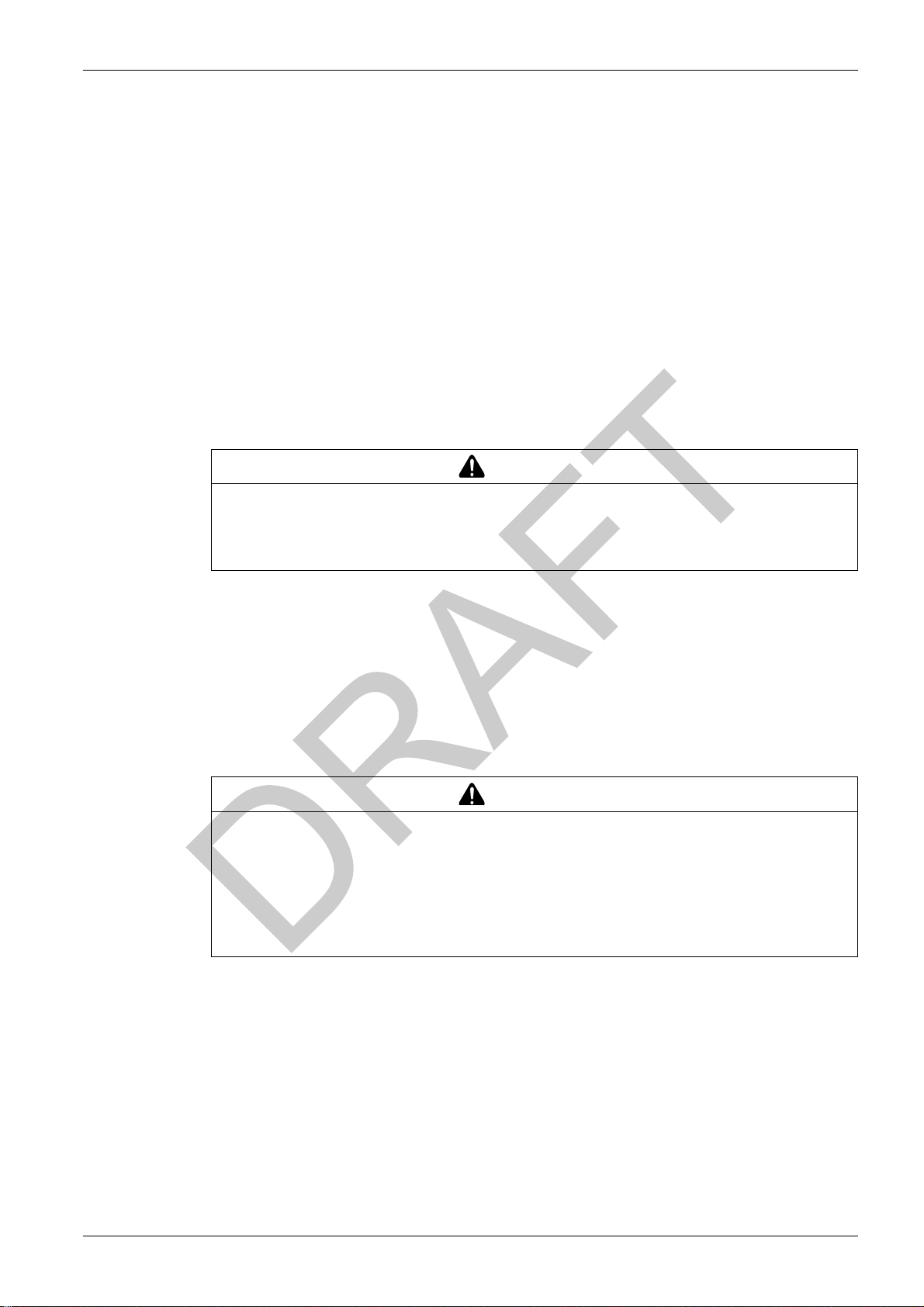

IMPROPER SETUP

Ensure that the XCSR RFID Safety Switch is mounted far enough away from the operations hazard to

When using a safety interface like safety relays or controllers, the response time of the safety interface

Failure to follow these instructions can result in death, serious injury, or equipment damage.

)

r

fully accommodate the stopping time.

must be added to the overall system stopping time.

Product Specification

WARNING

QGH1315301 03/2017 19

Product Specification

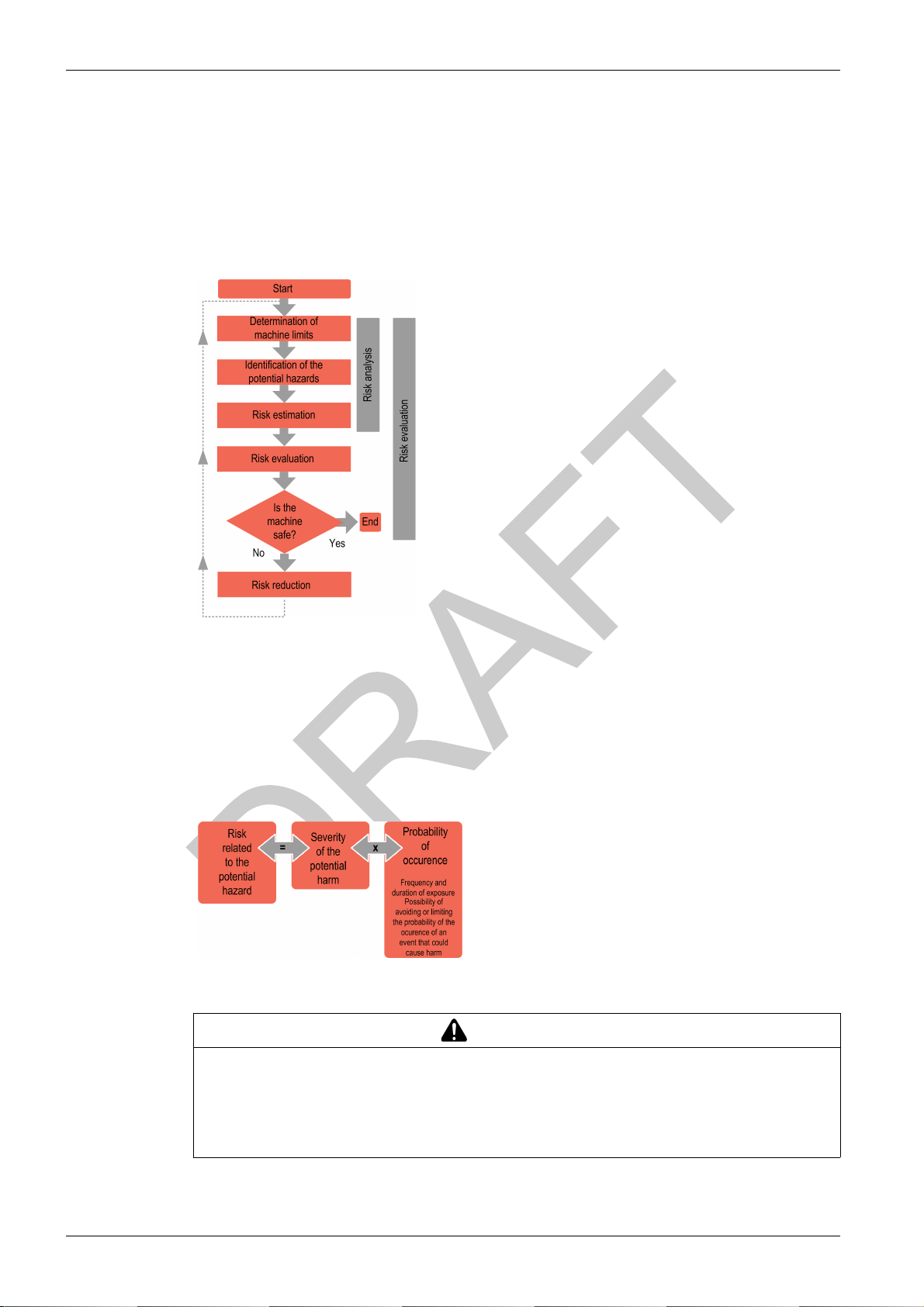

Risk Assessment

General Description

Risk assessment and risk reduction are iterative processes described in EN ISO 12100, IEC 61508 &

IEC 62061 (SIL and SILCL), and EN ISO 13849-1 (PL).There are various techniques for risk assessment,

and not one of it can be considered as the right way to perform risk assessment. The standard specifies

some general principles but does not specify exactly what has to be done in each case.

For safety-related data, refer to Safety Related Data section

(see page 69)

.

This flowchart describes the risk assessment process:

Essential steps for risk assessment are the following:

Define tolerable risk level.

Identify hazards.

Analyze hazards.

Determine whether the risks are below an acceptable level.

Define protection measures if risks are above a tolerable level.

Check whether protection measures taken lead to an effective risk reduction (Iterative process).

This figure describes the elements of risk to take into account for the risk estimation:

WARNING

IMPROPER TYPE UTILIZATION

It is the responsibility of the user or integrator to check whether the use of the XCSR RFID Safety Switch

is consistent with the application risk assessment.

To choose the right product for your application, perform a risk assessment.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

20

QGH1315301 03/2017

Product Specification

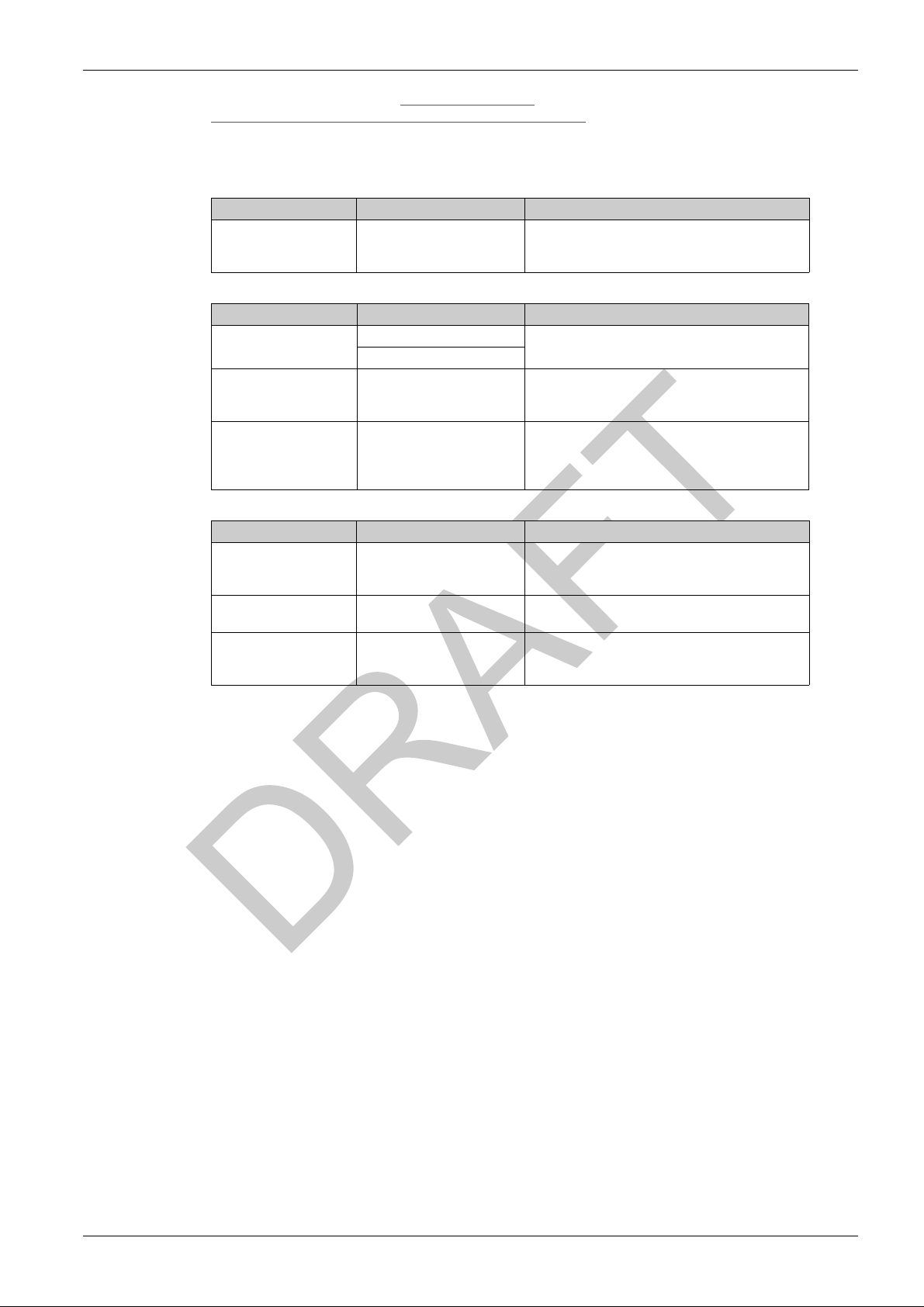

Reference Standards

For more information, refer to:

electric.com/ww/en/download/document/DIA4ED1100102EN

http://www.schneider-

.

The following table describes the main reference standards:

Standard Risk assessment Description

EN ISO 12100 Risk assessment and risk

reduction

Standard Safety level Description

EN ISO 13849-1 Performance level (PL) Safety-related part of control system.

Category (Cat)

IEC 61508 Safety integrity level (SIL) Functional safety of

IEC 62061 Safety integrity level claim

limit (SILCL)

Standard Type-B standards Description

ISO 14119 Safeguards

(interlocking devices)

EN/IEC 60947-5-2 Low-voltage switchgear and

controlgear

EN/IEC 60947-5-3 Low-voltage switchgear and

controlgear

Safety of machinery.

General principles for design.

Risk assessment and risk reduction.

General principles for design.

electrical/electronic/programmable electronic

safety-related systems.

Safety of machinery.

Functional safety of safety-related electrical,

electronic, and programmable electronic control

systems.

Safety of machinery.

Interlocking devices associated with guards.

Principles for design and selection.

Control circuit devices and switching elements.

Proximity switches.

Control circuit devices and switching elements.

Requirements for proximity devices with defined

behavior under fault found conditions (PDDB).

QGH1315301 03/2017 21

Product Specification

XCSR RFID Safety Switch Functions

Section 2.2

XCSR RFID Safety Switch Functions

Overview

This section describes the various functions of XCSR RFID Safety Switch.

What Is in This Section?

This section contains the following topics:

Operating Modes 23

External Device Monitoring (EDM) or Machine Primary Control Element (MPCE) Monitoring 25

Operating and Output States, LED Meaning 26

XCSR Standalone Models 28

XCSR Series Connection (Daisy-Chain) 30

XCSR Single Models 33

Pairing Modes 35

Topic Page

22

QGH1315301 03/2017

Operating Modes

Introduction

Automatic Start

Product Specification

The operating mode determines the start-up and operating behavior of the XCSR RFID Safety Switch. The

operating mode descriptions in this section are derived from the operating state definitions

In this mode, the system enters the Run state after startup without operator intervention, as long as the

paired transponder is in the reader detection zone. When the XCSR RFID Safety Switch is powered up, it

enters the initialization phase during which its safety outputs are OFF. If no faults are detected and the

safety guard is closed, it enters the Run state

up Time

leaves the operating zone (safety guard opening), the XCSR RFID Safety Switch changes from Run state

to Stop state

the paired transponder enters again the detection zone (without any fault detected): the XCSR RFID Safety

Switch then automatically changes from Stop state to Run state and the two safety outputs switch to ON

state.

Automatic Start is available on XCSRC•1AM12 standalone models

(see page 18)

(see page 26)

) and the two safety outputs switch to ON state. In this state, when the transponder

(the two safety outputs switch to OFF state), and remains in the Stop state until

(see page 26)

after 5 seconds maximum (refer to TON First-

(see page 26)

WARNING

IMPROPER AUTOMATIC START UTILIZATION

The manual Start/Restart is required in most safety applications. If you use the automatic start function,

check that this automatic start mode is compatible with risk assessment performed for the application.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

.

Manual Start/Restart

When the XCSR RFID Safety Switch is powered up, it enters the initialization phase during which its safety

outputs are OFF. If no faults are detected after the first-up time, it enters the Start/Restart state. To enter

the Run state and switch the OSSDs to ON, the paired transponder must be in the reader detection zone,

no faults detected, and the operator must press and release ("monitored start") the Start button. Then, if

the XCSR RFID Safety Switch leaves the detection zone when it is in Run state, the XCSR RFID Safety

Switch changes to Stop state and the safety outputs change from ON to OFF state.

If the paired transponder enters the detection zone again (and no faults are detected), the safety outputs

stay at the OFF state until the push button is actuated.

WARNING

UNINTENDED EQUIPMENT OPERATION

Follow the requirements concerning start/restart operating modes defined in ISO 12100:

“Requirements for interlocking guards with a start function (control guards)” section.

The Restart command must be installed outside the dangerous area in such way that the whole working

and hazardous areas are observable. You must not access the Start/Restart command inside the hazard

area.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

QGH1315301 03/2017 23

Product Specification

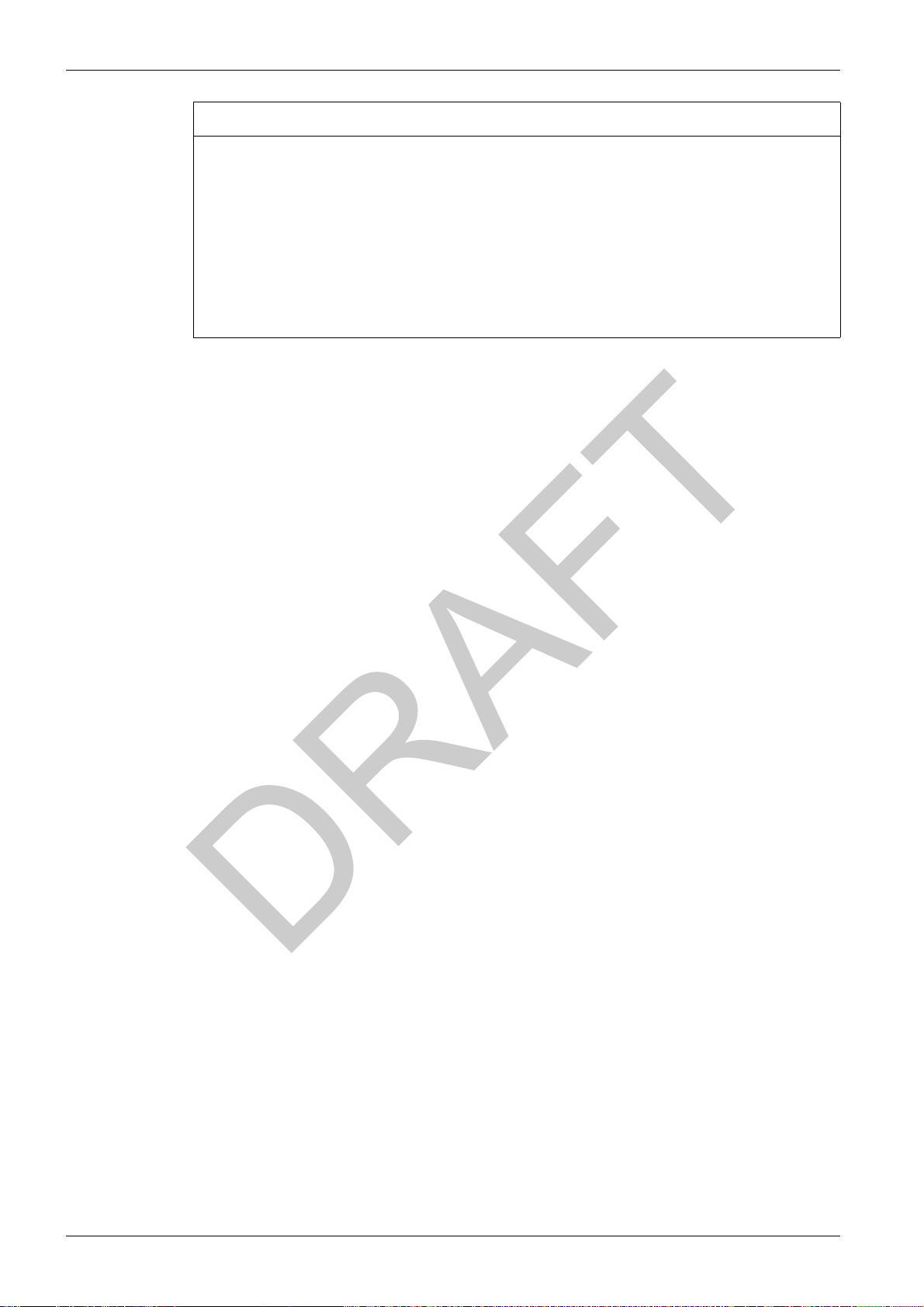

NOTICE

UNINTENDED EQUIPMENT OPERATION

For "monitored manual Start/Restart", the command is effective after the operator has pressed and

released the Start button, which means a transition sequence 0 Vdc –> 24 Vdc –> 0 Vdc on the start

command. The minimum duration of this sequence must be between 200 ms and 5 s. Beyond the 5 s,

the release action on the command will not activate the XCSR RFID Safety Switch. The operator will have

to repeat the start/restart sequence and release the command before 5 s.

The "monitored manual Start/Restart" is available exclusively on XCSRC•1MM12 standalone models.

For Single and Daisy-Chain XCSR RFID Safety Switch models, refer to the safety interface operating

instructions.

Failure to follow these instructions can result in equipment damage.

24

QGH1315301 03/2017

Product Specification

External Device Monitoring (EDM) or Machine Primary Control Element (MPCE) Monitoring

General Description

EDM monitoring is an important safety function.

The EDM monitors the interface between XCSR RFID Safety Switch and the guarded machine to:

Confirm that the external devices such as switching devices like contactors are responding correctly to

the XCSR safety outputs.

Detect any inconsistency between the two external devices (that is, control relays or contactors) which

could prevent a stop signal from reaching the machine primary control elements (for example, power

contactors or electrovalve relays).

The EDM controls the external contactors KM1/KM2 connected to the two OSSDs. To achieve this,

normally closed contacts of the external contactors are monitored.

To perform this function, the contactors KM1/KM2 must have:

Normally closed mirror contact, according to IEC 60947-4-1 (Annex F) for power contactors.

Linked contacts (or force-guided contacts), according to IEC 60947-5-1 (Annex L) or EN 50205 for

auxiliary contactors or control relays.

XCSR RFID Safety Switch standalone models have built-in EDM function. For Daisy-Chain and Single

models, refer to the safety interface operating instructions (e.g safety relay or safety controller).

To manage the EDM function, refer to wiring instructions

(seepage54)

.

QGH1315301 03/2017 25

Product Specification

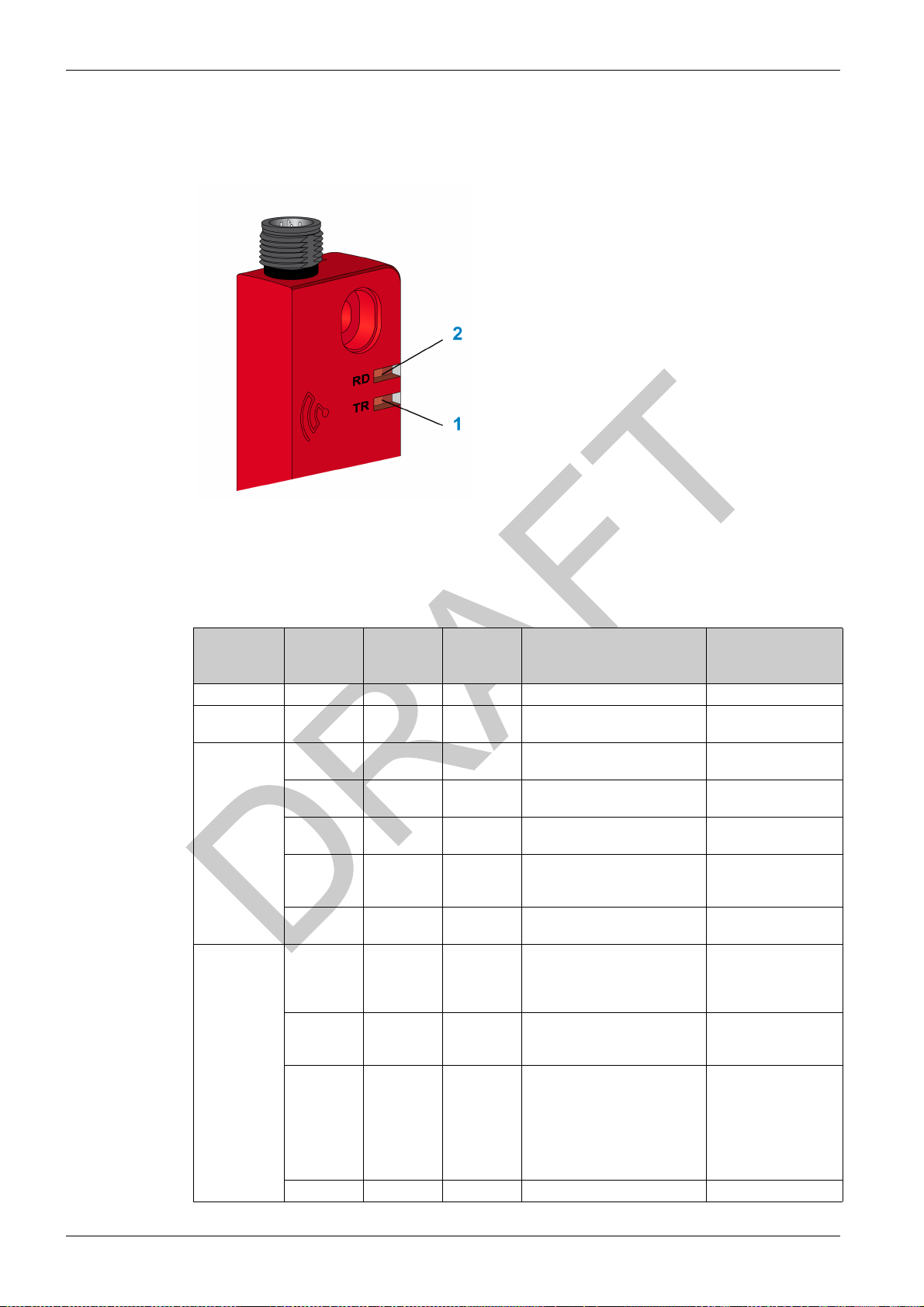

Operating and Output States, LED Meaning

Introduction

This figure describes the Diagnostic LED of the XCSR reader:

LED 1 (TR) Transponder state

LED 2 (RD) Reader/Output state

Diagnostic LED Meanings

This table describes the operating and output states with LED meanings and output states of the XCSR

RFID Safety Switch:

Operating

Initialization Orange Orange OFF XCSR reader initialization in

Configuration Orange

LED 1

state

OFF OFF OFF OFF XCSR reader is unpowered -

Run Green Orange

Transponde

r

Fast blinking

Green Orange

Orange

Blinking

Red

Blinking

Orange

Fast blinking

Green Green ON Paired transponder detected

Green Red OFF Paired transponder detected but

OFF Red OFF No transponder in the field Door opened

LED 2

Reader

Orange

Fast blinking

Fast blinking

Red OFF Maximum of pairing reached -

Red OFF Invalid transponder detected Transponder not blank

Red OFF Pairing process unsuccessful Only for “re-pairing

Blinking

OSSDs LEDs meaning Comment

progress

OFF XCSR reader is in configuration

mode

OFF Pairing with new transponder

done: new power-up required

OFF Paired transponder detected:

waiting for the start condition

and/or KM1_KM2 feedback

(EDM)

and all other operating

conditions are correct

the safety inputs are at the OFF

state.

-

-

Only for “re-pairing

enabled models”

or not Telemecanique

transponder

enabled models”

Only for standalone

versions

Door closed

For Daisy-Chain

models: at least one of

the previous readers

has its OSSDs at the

OFF state (door

opened, error detected

or OFF state)

26

QGH1315301 03/2017

Product Specification

Operating

state

Transponde

Error detected Red

Blinking

Green or

OFF

LED 1

r

LED 2

Reader

Red

Blinking

1, 2, 3, or 4

red flashes

OSSDs LEDs meaning Comment

OFF Invalid transponder or non-

paired transponder detected:

new power-up required after

Possible attempted

fraud or transponder

damaged

fault clearance

OFF Internal error detected. Contact

the customer support of your

country.

The color of the LED 1

depends on the

presence of the

transponder:

Green: transponder

OFF: no

detected

transponder

detected

QGH1315301 03/2017 27

Product Specification

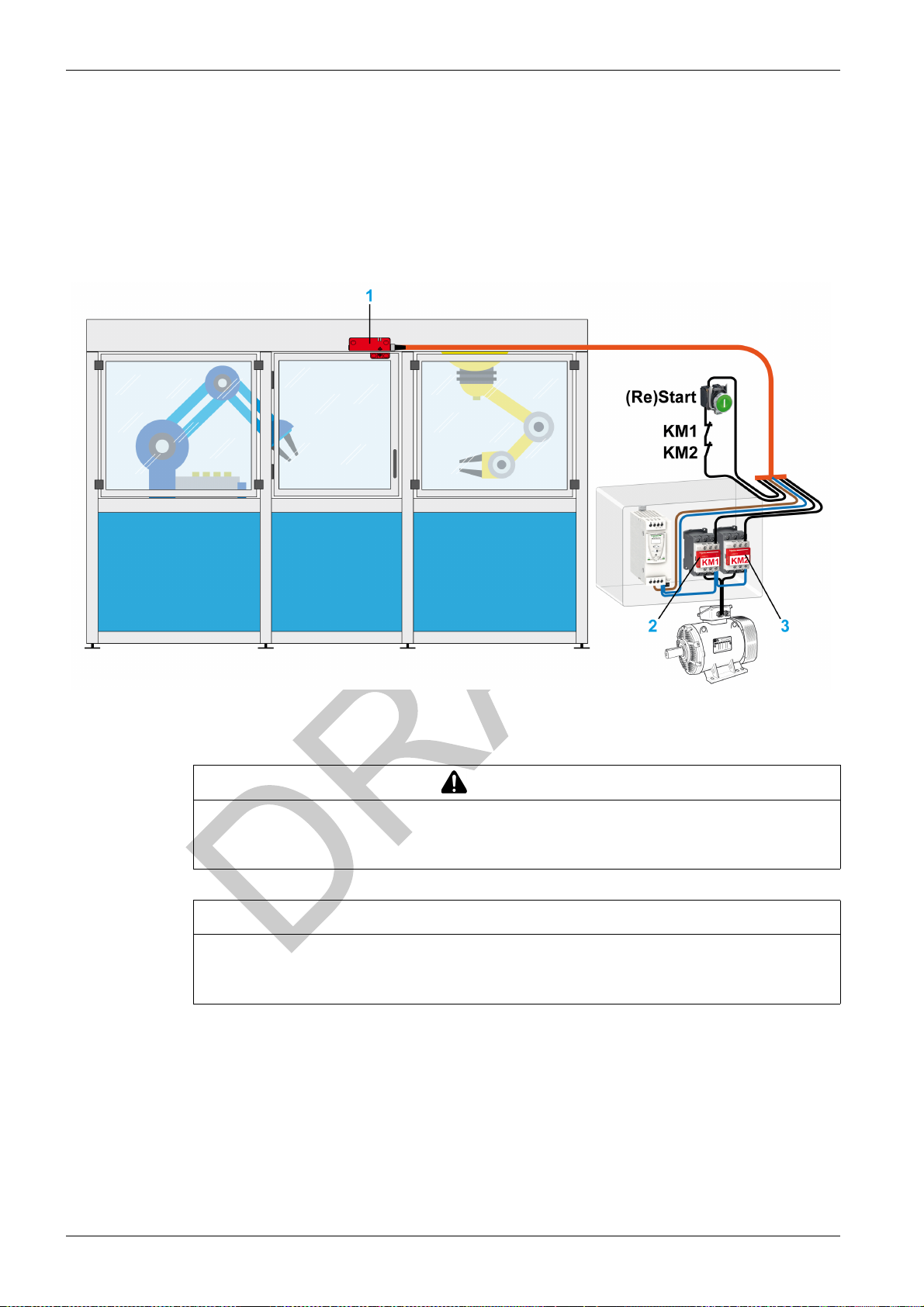

XCSR Standalone Models

General Description

Special models of the XCSR RFID Safety Switches (XCSRC•1•M12) are designed to be used as

standalone products, when associated with contactors having mechanically linked contacts (force-guided)

connected to the OSSDs that is, without any safety relay, controller, or PLC. In standalone operation, the

two OSSDs are connected directly to the contactors. This connection is made through a pre-wired 8 pins

M12 connector.

Refer to Connection Schematics

(see page 56)

.

1 XCSRC•1MM12: XCSR RFID Safety Switch standalone model

2 KM1: contactor 1 - OSSD1

3 KM2: contactor 2 - OSSD2

UNINTENTED EQUIPMENT OPERATION

The KM1 and KM2 contactors must have force-guided contacts.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

UNINTENTED EQUIPMENT OPERATION

Use of arc suppressors for KM1 & KM2 is recommended.

Failure to follow these instructions can result in equipment damage.

Features and Requirements

The XCSR RFID Safety Switch standalone models have the given features and requirements:

2 OSSDs

External Device Monitoring (EDM) (selected by wiring)

Start feature:

Monitored manual Start/Restart: XCSR•1MM12

Automatic Start: XCSR•1AM12

XCSRC•1•M12 standalone models are compliant with the following safety standards SIL3 (IEC 61508)

SILCL3 (IEC 62061), and PLe- Cat.4 (EN ISO 13849-1)

WARNING

NOTICE

28

QGH1315301 03/2017

Product Specification

It is the aim of the risk analysis to determine whether the use of XCSRC•1•M12 standalone models are

compatible with the expected safety integrity level of the entire system.

WARNING

IMPROPER UTILIZATION

It is the responsibility of the user or integrator to check whether the use of standalone XCS R RF ID Safe ty

Switch is consistent with the application risk assessment.

Perform a risk assessment to choose the right product for your application.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

QGH1315301 03/2017 29

Loading...

Loading...