Page 1

XPSMF2DO801 Remote

Output Module

Hardware Manual

07/2007

33003405.01

Page 2

2

Page 3

Table of Contents

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

About the Book. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Chapter 1 Overview: XPSMF2DO801 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

At a Glance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Representation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Chapter 2 Application and Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

At a Glance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Initial Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Application. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Offline Proof-Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Chapter 3 Equipment Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

At a Glance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Housing Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Reset Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

IP Addressing and System ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

SafeEthernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Operating Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Technical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Additional Items. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

3

Page 4

Appendices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

At a Glance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Appendix A Connection Diagrams, Examples of Application, and

Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

At a Glance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Wiring Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Configuration of Ethernet Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

4

Page 5

Safety Information

§

Important Information

NOTICE Read these instructions carefully, and look at the equipment to become familiar with

the device before trying to install, operate, or maintain it. The following special

messages may appear throughout this documentation or on the equipment to warn

of potential hazards or to call attention to information that clarifies or simplifies a

procedure.

The addition of this symbol to a Danger or Warning safety label indicates

that an electrical hazard exists, which will result in personal injury if the

instructions are not followed.

This is the safety alert symbol. It is used to alert you to potential personal

injury hazards. Obey all safety messages that follow this symbol to avoid

possible injury or death.

DANGER

DANGER indicates an imminently hazardous situation, which, if not avoided, will

result in death or serious injury.

WARNING

WARNING indicates a potentially hazardous situation, which, if not avoided, can result

in death, serious injury, or equipment damage.

CAUTION

CAUTION indicates a potentially hazardous situation, which, if not avoided, can result

in injury or equipment damage.

33003405 07/2007 5

Page 6

Safety Information

PLEASE NOTE Electrical equipment should be installed, operated, serviced, and maintained only by

qualified personnel. No responsibility is assumed by Schneider Electric for any

consequences arising out of the use of this material.

© 2007 Schneider Electric. All Rights Reserved.

6

33003405 07/2007

Page 7

About the Book

At a Glance

Document Scope This manual describes the XPSMF2DO801 remote output module.

The following descriptions of the XPSMF2DO801 are included in this manual:

l dimensions and installation

l application and function

l equipment description

l application examples

Validity Note The XPSMF2DO801 remote output module has been tested and certified by TÜV

for functional safety in accordance with CE and the standards listed below:

l TÜV Anlagentechnik GmbH Automation, software, and information technology

Am Grauen Stein 51105 Köln

l Certificate and test report No. 968/EZ 128.04/03 Safety-related automation

devices

HIMatrix F2DO801

l International standards:

l IEC 61508, parts 1-7: 2000, up to SIL 3

l EN 954-1: 1996, up to Category 4

l EN 298: 1994

l NFPA 8501:1997

l NFPA 8502: 1999

l EN 61131-2: 1994 and A11: 1996, A12: 2000

l EN 61000-6-2: 2000, EN 50082-2: 1996, EN 50081-2: 1993

l National standards:

l DIN V VDE 0801: 1990 and A1: 1994

l DIN V 19250: 1994, up to RC6

l DIN VDE 0116: 1989, prEN 50156-1: CDV 2000

33003405 07/2007 7

Page 8

About the Book

The corresponding programming software is XPSMFWIN. The software is

executable in the Microsoft Windows 2000/XP. The software helps the user to create

safety-related programs and operate the Programmable Electronic System (PES).

Note: The declaration of conformity is provided within the hardware product’s

packaging. All devices are labelled with the CE sign.

Product Related

Warnings

Schneider Electric assumes no responsibility for any errors that may appear in this

document. If you have suggestions for improvements or amendments or have found

errors in this publication, please notify us.

No part of this document may be reproduced in any form or by any means, electronic

or mechanical, including photocopying, without express written permission of

Schneider Electric.

All pertinent state, regional, and local safety regulations must be observed when

installing and using this product. For reasons of safety and to ensure compliance

with documented system data, only the manufacturer should perform repairs to

components.

Failure to use Schneider Electric software or approved software with our hardware

products may result in injury, harm, or improper operating results.

Failure to observe this product’s safety-related warning can result in injury or

equipment damage.

User Comments We welcome your comments about this document. You can reach us by e-mail at

techpub@schneider-electric.com

8

33003405 07/2007

Page 9

Overview: XPSMF2DO801

1

At a Glance

Overview This chapter contains an overview of the XPSMF2DO801 remote output module.

What's in this

Chapter?

This chapter contains the following topics:

Topic Page

Introduction 10

Representation 10

Dimensions 11

Installation 13

33003405 07/2007 9

Page 10

Overview

Introduction

XPSMF2DO801

Safety Remote

Output Module

XPSMF2DO801 is a safety remote output module which works with the XPSMF

Safety PLC range and does not contain a user program. It is designed to monitor

safety functions up to safety Category 4 according to EN 954-1 and SIL 3 according

to IEC 61508 and is used to expand a Safety PLC. XPSMF2DO801 is a compact

safety remote output module in a metal housing with 8 programmable relay contact

outputs.

The safety remote output module is a highly visible product thanks to its red color

housing. The product’s overall ingress protection rating is IP 20. The

XPSMF2DO801 is an extremely versatile product and can be used in all areas of a

factory floor. In areas where conditions are harsh, explosive or generally dangerous,

extra protection in the form of enclosures is available to optimize the product’s

performance, prolong its life, and improved safety within each factory environment.

The XPSMF2DO801 is a very powerful safety remote output module and is very

easy to program and install.

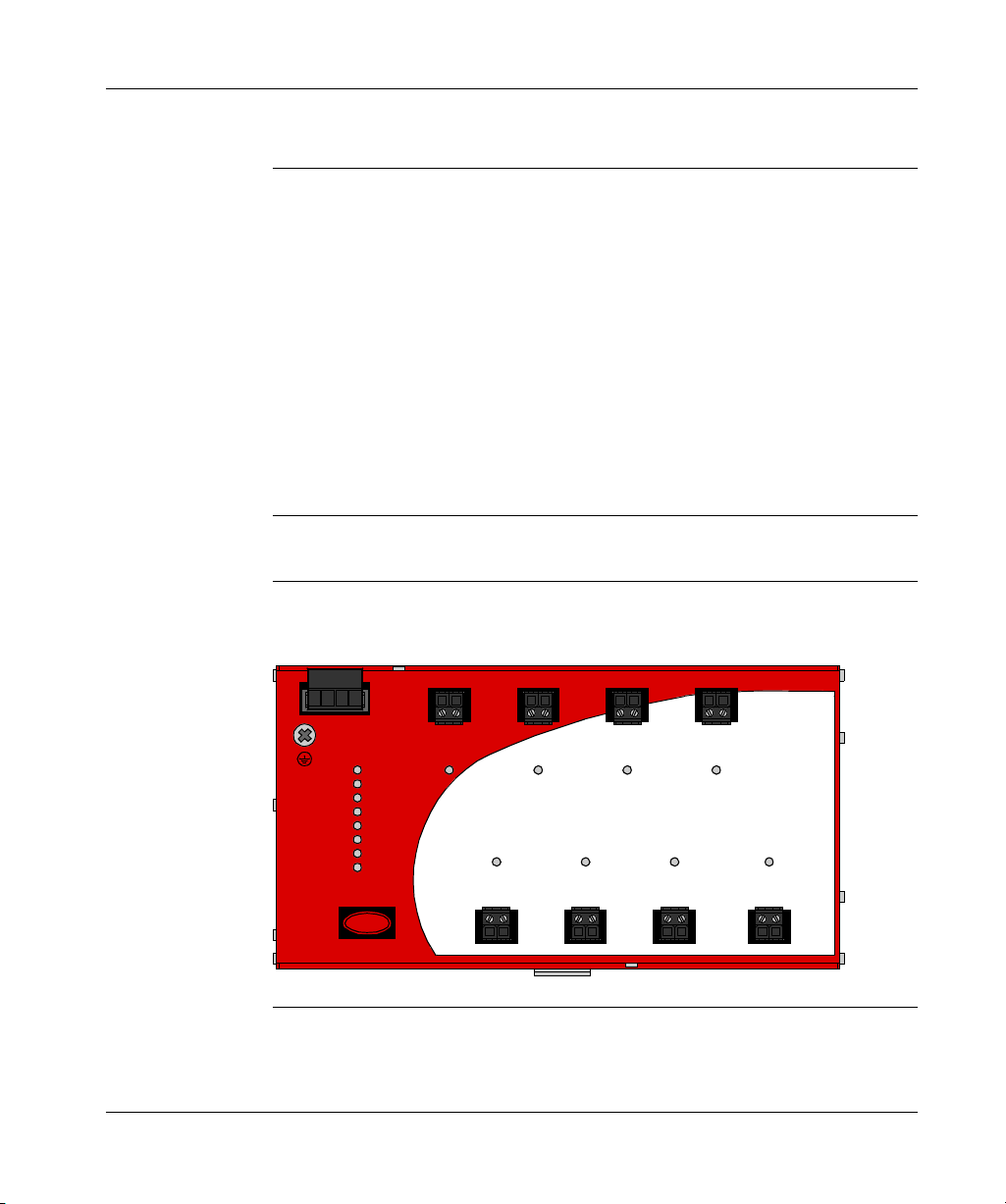

Representation

Front View The following image shows the front view of the XPSMF2DO801 remote output

module:

L- L- L+ L+

L- L+L+L-

1 10/100BaseT

24V DC

RUN

ERROR

PROG

FORCE

FAULT

OSL

BL

HIMA

10/100BaseT

12

DO1

2

34

DO2

56

DO3

HIMatrix

DO5

910

DO6

11 1 2

DO7

13 14

78

DO4

by HIMA

F2DO

8 01

DO8

15 16

10

33003405 07/2007

Page 11

Dimensions

Overview

Overview of

XPSMF2DO801

Front View

Dimensions

The following section contains information about the dimensions of the

XPSMF2DO801 safety remote output module showing the front and side views.

The following image shows the front view dimensions of the XPSMF2DO801 safety

remote output module:

mm

inch

L- L- L+ L+

L- L+L+L-

1 10/100B aseT

24V DC

RUN

ERROR

PROG

FORCE

FAU LT

OSL

BL

HIMA

10/100 BaseT

12

DO1

2

34

DO2

56

DO3

HIMatrix

DO5

910

DO6

11 12

202

7.95

206

8.11

DO7

13 14

78

DO4

by HIMA

F2DO

8 01

DO8

15 16

33003405 07/2007 11

Page 12

Overview

Side View

Dimensions

The following image shows the side view dimensions of the XPSMF2DO801 safety

remote output module:

mm

inch

3

0.12

111

4.37

114

4.49

37

1.46

3

83

3.27

112

4.41

28,5

0.12

1.12

12

33003405 07/2007

Page 13

Overview

Installation

Introduction The XPSMF2DO801 safety remote output module can be installed on mounting

bases and within closed cases, such as control stations, all terminal boxes, and

control racks. The XPSMF2DO801 has been developed in compliance with all

applicable standards for EMC, climate, and environmental requirements.

Procedure Mounting the remote output device requires the following steps:

Step Action

1 Pull down the quick release clip.

2 Position the remote output device on the DIN rail.

3 Release the clip.

33003405 07/2007 13

Page 14

Overview

Mounting the

Remote Output

Module

Mount the remote output module horizontally (so the F2DO logo on the front panel

is facing the user) to allow sufficient ventilation. We advise not to mount the remote

output module in a vertical position, because in this case additional measures are

required to ensure the device does not move.

The minimum distance to any neighboring device from another manufacturer is as

follows:

l vertical space of at least 100 mm (3.93 in.),

l horizontal space of at least 20 mm (0.78 in.).

Minimum clearances for the XPSMF2DO801 safety remote output module

(Compact Devices):

mm

inch

HIMatrix

HIMA

100

3.94

by HIMA

F3

HIMA

20

0.79

HIMatrix

by HIMA

F31

14

HIMatrix

HIMA

by HIMA

F30

HIMatrix

HIMA

by HIMA

F3

Note: The installation must be performed so that

l the device is not subject to heat emission from neighboring devices and

l devices with high EMC interference do not affect the XPSMF2DO801.

Heat emission and electromagnetic compatibility (EMC) must be checked for

devices from other manufacturers to ensure that operation of the remote output

device is not affected by any external device.

The overall installation space for all cables must also be taken into account to

ensure sufficient ventilation. Additional measures, such as installing heat

extraction fans, can be taken if the product’s housing becomes warm.

33003405 07/2007

Page 15

Overview

100

Air Circulation The ventilation slots in the housing must not be covered. When installing the

XPSMF2DO801 ensure that the height of the cable ducts does not exceed 40 mm

(1.57 in.). If the cable duct has the height greater than 40 mm(1.57 in.), spacers

must be placed behind the din rail. The illustration below shows an example of using

spacers.

Use of cable ducts with horizontal mounting of compact devices on rails:

mm

inch

1

Compact device

2

40

1.57

Cable duct

100

3.94

Compact device

33003405 07/2007 15

3.94

Spacer

H

40

1.57

L

Page 16

Overview

Installation with spacers:

No. Description

1 The cable ducts’ height is less than 40 mm / 1.57 in.

2 The cable ducts’ height is greater than 40 mm / 1.57 in.

The length of the required spacer is calculated as follows:

L = H - 40 mm / 1.57 in.

L = length of the spacer

H = height of the cable duct

If more than two devices (even when the minimum vertical clearance of 100 mm is

observed) are installed one above the other, additional ventilation measures are

required to ensure even temperature distribution. The illustration below shows the

minimum clearance in the event that the DIN rails are not installed on spacers.

16

33003405 07/2007

Page 17

Overview

The following images show the minimum clearance between the XPSMF2DO801

safety remote output devices:

mm

inch

1

2

by HIMA

F3

HIMatrix

40

80

3.15

80

3.15

1.57

by HIMA

HIMA

F31

HIMatrix

HIMA

33003405 07/2007 17

Page 18

Overview

Minimum clearance between the remote output devices and Safety PLCs:

No. Description

1 Installation with spacers: the cable ducts’ height is greater than 40 mm / 1,57 in.;

the vertical separation increases.

2 The XPSMF2DO801 safety remote output device is mounted vertically.

Note: Additional means are required to ensure that the remote output device does

not slide downwards while operating; any movement may cause strain on the

wiring.

On open mounting surfaces, observing the minimum clearance and ensuring

unobstructed air circulation will help maintain the optimum operating temperature.

Heat The increasing integration of electronic components into smaller parts results in

large amounts of heat dissipation on a small surface area. The amount of heat

produced depends on the device's external load. Depending on the design of the

device, installation, design location, air circulation, and environmental conditions

make a very significant impact on the product’s operating temperature.

It is important to comply with the approved environmental conditions when installing

the device. Reduced operating temperature extends the life of the device and

reliability of the installed components.

If the XPSMF2DO801 requires an additional enclosure to increase the ingress

protection, the enclosure case must be designed in such a way that the heat

generated inside it can dissipate from the surface of the enclosure. The type of

enclosure and location of installation selected must easily allow heat dissipation. If

possible, a fan should be used to ensure air circulation.

18

Note: An additional enclosure can be used to increase the ingress protection of the

XPSMF2DO801 safety remote output device.

33003405 07/2007

Page 19

Overview

The enclosure’s surface area, A is calculated depending on the mounting or

installation type as follows:

The following table is used to calculate the recommended enclosure size for

mounting the XPSMF2DO801:

Case installation

Single case free on all sides A = 1.8 x H x (W + D) + 1.4 x W x D

Single case for wall mounting A = 1.4 x W x (H + D) + 1.8 x H x D

End case free-standing A = 1.4 x D x (W + H) + 1.8 x W x H

End case for wall mounting A = 1.4 x H x (W + D) + 1.4 x W x D

Center case free-standing A = 1.8 x W x H + 1.4 x W x D + H x D

Calculation of A [m

2

] (1m2=10.76ft2)

Center case for wall mounting A = 1.4 x W x (H + D) + H x D

Center case for wall mounting, top

surface covered

A the enclosure’s surface area

W width

H height

D depth

33003405 07/2007 19

A = 1.4 x W x H + 0.7 x W x D + H x D

Page 20

Overview

Internal

Convection

With internal heat convection, the heat is dissipated outside through the walls of the

housing. This is possible when the ambient temperature is lower than that inside the

housing.

The following table describes the variables used to calculate the internal convection:

Variable Description

[W] heat output (heat dissipation) of the electronic components

P

v

A [m

k [W/m

* (1m

2

]*

2

K]*

2

= 10.76ft2)

effective surface area of the housing

the housing heat transfer coefficient

(e.g., Steel sheet: approximately 5.5 W/m

2

K)*

The maximum temperature increase of all electronic devices inside the housing is

calculated as follows:

∆T()max

The power dissipation P

------------ -=

kA•

Pv

can be calculated based on the values of the electrical

v

power of the controller, its inputs, and outputs.

20

33003405 07/2007

Page 21

Overview

Temperature

State/Operating

Temperature

The remote output modules are designed to operate with the maximum temperature

o

of 60

C. The temperature states in single modules and PLCs are evaluated by the

CPU module or the remote output device’s CPU for compact systems. The

temperature state of a particular module or PLC is measured by a sensor. The

sensor monitors the temperature state of the remote output device automatically

and continuously.

The following table shows the ranges in which the temperature state signals the

measured temperature:

Temperature range Temperature state

< 60°C / 140°F Normal

60°C to 70°C / 140°F to 158°F High temperature

> 70°C / 158°F Very high temperature

Return to 64°C / 147.2°F High temperature

Return to < 54°C / 129.2°F Normal

Note: The difference in temperature increase and decrease ranges is the result of

the sensor’s hysteresis that equals 6°C / 10.8°F.

Temperature state High temperature indicates the following:

operating temperature = max temperature (delta T)max + ambient temperature

≥ 60°C / 140°F.

In this case, support the internal convection by adding air grilles or increasing the

free space between the remote output devices.

Temperature state Very high temperature indicates the following:

operating temperature = max temperature (delta T)max + ambient temperature

≥ 70°C / 158°F.

In this case, support the internal convection by integrating additional active cooling

elements (fan, coolant devices, etc.) or increasing the free space around the remote

output devices.

If the sensor indicates a temperature increase above the critical threshold, the

temperature state changes. The temperature states can be evaluated using the

Temperature State system signal of the XPSMFWIN.

33003405 07/2007 21

Page 22

Overview

22

33003405 07/2007

Page 23

Application and Function

2

At a Glance

Overview This chapter describes the application and function of XPSMF2DO801 safety

remote output module.

What's in this

Chapter?

This chapter contains the following topics:

Topic Page

Initial Operation 24

Application 25

Function 26

Offline Proof-Test 34

33003405 07/2007 23

Page 24

Application and Function

Initial Operation

Overview The following section contains information about the initial operation of the

XPSMF2DO801 safety remote output module.

First Power-Up The following table describes the first power-up behavior of the XPSMF2DO801

safety remote output module:

Stage Description

1 Power Supply LED (green) is illuminated for 0.5 sec.

2 All LEDs are illuminated for 5 sec.

3 24V DC LED is illuminated.

Prog LED (orange) is flashing.

DANGER

HAZARD OF ELECTRICAL SHOCK, EXPLOSION OR ARC FLASH

Disconnect all power before servicing equipment.

Failure to follow these instructions will result in death or serious injury.

24

33003405 07/2007

Page 25

Application and Function

Application

Overview The XPSMF2DO801 safety remote output module is certified to the following

standards:

l SIL 3, according to IEC 61508

l Category 4, according to EN 954-1

l IEC 61131-2

l prEN 501156

l DIN V 19250 up to RC 6

l NFPA 8501, NFPA 8502

The extensive hardware range and safe data transmission allow the system to be

optimized to suit anticipated or existing plant structures.

The safety-related networking of the remote output device takes place using

SafeEthernet protocol, which is based on standard Ethernet technology and is

certified to TÜV/BG. The Ethernet medium allows safety data to be transmitted up

to 100 Mbit/s half duplex and 10 Mbit/s full duplex and supports the use of the entire

range of Ethernet functions for networked applications.

A combination of a high-speed Safety PLC and a high-speed safety bus protocol

(SafeEthernet) offers new levels of flexibility for automation process solutions.

Today’s system limits of safety-related automation concepts are disappearing.

Scope is being created for truly application-based solutions.

Key features of the XPSMF2DO801 safety remote output module:

l Certification up to SIL 3, according to IEC 61508.

Category 4, EN 954-1.

l Communication via SafeEthernet

l Versatility. You can use the remote output device in all environmental conditions

with additional equipment.

l Quick and easy network configuration.

l User-friendly interfaces.

33003405 07/2007 25

Page 26

Application and Function

Function

Overview This section describes functions of the XPSMF2DO801 safety remote output

module.

Block Diagram The following is a block diagram of the XPSMF2DO801 safety remote output

module:

Double

processor

system

26

DO 1

.

.

DO 8

8

relay

outputs

Watchdog

Switch

RJ

45

RJ

45

The following is a short description of the diagram’s components:

l Outputs 8 relay outputs

l Double processor system

l Watchdog Control unit

l 2-port switch with a built-in auto cross-over function, which allows the use of

both the 1:1 and cross-over cables

l 2 RJ 45 connectors for 1:1 or cross-over cable

33003405 07/2007

Page 27

Application and Function

Safety-Related

Relay Outputs

The XPSMF2DO801 safety remote output module has eight relay outputs. Each

relay output has its own LED to indicate the status of the output.

Each output of the module is fitted with two safety relays in diversity with positively

guided contacts and one standard type relay. Internal fuses are used to limit the

switching current of the output contacts to 60% (3.15 A) of the maximum admissible

value (according to VDE 0116, En 298). The contact outputs can be used for safety

shutdowns. For DC switching the contact circuit must be additionally equipped with

an external fuse adapted to the maximum admissible current.

An output is in a safe state when it is de-energized. If a fault occurs, all outputs are

switched off.

If the module has a fault all outputs are switched off. In the event of a fault at

Ethernet communication the concerning output is set to the initial value. How the

actuators respond in such a case should be taken into account.

Faults in one or more channels as well as a fault on the module are indicated by the

FAULT LED on the front plate of the remote output module.

The relay outputs are connected to the following terminals:

Terminal No. Designation Function (relay output)

1 DO1 contact 1, terminal A

2 contact 1, terminal B

3 DO2 contact 2, terminal A

4 contact 2, terminal B

5 DO3 contact 3, terminal A

6 contact 3, terminal B

7 DO4 contact 4, terminal A

8 contact 4, terminal B

9 DO5 contact 5, terminal A

10 contact 5, terminal B

11 DO6 contact 6, terminal A

12 contact 6, terminal B

13 DO7 contact 7, terminal A

14 contact 7, terminal B

15 DO8 contact 8, terminal A

16 contact 8, terminal B

33003405 07/2007 27

Page 28

Application and Function

The output contacts are connected in pairs via terminal connectors, the terminals

are numbered. The terminal pins on the front plate of the module have the same

numbering sequence in order to prevent confusing connections.The terminal

connections meet the protection requirements according to IP 20. For higher

requirements the module must be enclosed in a housing with a suitable degree of

protection. The clearance and creepage distances are designed for overvoltage

category II up to 300 V according to IEC 61131-2.For the connection of voltages

besides SELV and PELV suitable cables must be used with double or reinforced

insulation (e.g. mains cable).

28

33003405 07/2007

Page 29

Application and Function

Cable

Disconnection

In a Safety PLC network, areas are covered using the Safety network. Therefore,

damage or disconnection of the communications cable may occur. In the system

below, the "X" represents a cable break between Safety PLC 2 and Safety PLC 3.

The communications between each of the systems will cease. As a result, the

following will occur:

l if the Safety PLC 2 system was dependent on the inputs of the Safety PLC 3

system, the corresponding outputs will automatically be set to "zero",

l if the Safety PLC 3 system was dependent on the inputs of the Safety PLC 2

system, the corresponding outputs will automatically be set to "zero", and

l if the systems are still provided with the 24 VDC power supply, the two systems

will continue to operate the remaining inputs and outputs of each separate

system.

The following diagram shows an example of the Safety PLC network interruption:

Safety PLC Safety PLC Safety PLC

Remote I/O module

Remote I/O module

Remote I/O module

Remote I/O module

Remote I/O module

If the local network is reacting only on the inputs of the same system, the PLC

system continues to run without failure.

33003405 07/2007 29

Page 30

Application and Function

Power Supply

Interruption

Small System

Reconfiguration

Large System

Reconfiguration

The following table shows reactions to the changes in operating voltage:

Voltage level Reaction of the controller

19.3 to 28.8 VDC Normal operation

< 18.0 VDC Alarm state (internal variables are written and put to the inputs/

outputs).

< 12.0 VDC Inputs and outputs are switched off.

If power supply is interrupted, all inputs and outputs discontinue and return to the off

"safe" state.

A Safety PLC can be reconfigured while the network is executing an existing

configuration. Resources which require configuration must be stopped. The

following table describes the reconfiguration procedure:

Step Action

1 Using the XPSMFWIN programming environment, stop the Safety PLC’s

system which requires the new configuration.

2 Download the new configuration fully checked by a qualified safety engineer to

the Safety PLC via Ethernet cable Cat 5, grade D or better.

3 Once the module is re-programmed, start the device.

4 Execute the new configuration immediately.

The following table describes the reconfiguration procedure for large systems:

Step Action

1 Stop the relevant resources within the network using the XPSMFWIN

programming environment. Small segments of a network can be reconfigured in

stages.

2 Connect your PC to any Ethernet communications point.

3 Download the new configuration(s) fully checked by a qualified safety engineer

to the Safety PLC network via Ethernet cable Cat 5, grade D or better.

4 Restart all devices, preferably in stages - system by system.

30

33003405 07/2007

Page 31

Application and Function

Short-Circuit

Characteristics

of the Output

Channels

If a short-circuit occurs in an output channel, the safety remote device switches off

the affected channel. If multiple short-circuits occur, the channels are switched off

individually in accordance with their power consumption.

If the maximally permitted current for all outputs is exceeded, all outputs are shut

down and cyclically reconnected.

WARNING

SHORT-CIRCUIT CONDITION

The output circuit terminals must not be connected with the connected load. In case

of a short-circuit, the resulting high current may damage the terminals.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

Diagnostics Using the XPSMFWIN programming environment, all the safety remote output

device’s diagnostics can be viewed. Each safety remote device provides diagnostic

signals with reference to their status, error codes, and channel status.

In XPSMFWIN all diagnostic information can be viewed in two ways:

l Using the On-line test function - it can monitor the values of the signals and

variables within the logic plan, while the systems are executing the program.

l Using the Diagnostics window that displays all states of the CPU, COM, and

I/O modules.

33003405 07/2007 31

Page 32

Application and Function

Replacing Faulty

Modules

Testing the

Inputs and

Outputs for

Interference

Voltage and

Earth Faults

If a safety remote output device fails, the following replacement procedure is used:

Step Action

1 Disconnect power supply to the specific module.

2 Disconnect all terminals (removing input or output wires is not required).

3 Disconnect communication - Ethernet from the remote output module.

4 Loosen the DIN rail clip and dismount the module.

5 Mount the new module and release the DIN rail clip.

6 Re-connect power supply.

7 Connect to the PC that is executing XPSMFWIN via Ethernet cable.

8 Enter new communication settings for MAC address and IP address.

9 Download the configuration used by the previous module.

10 Connect all output terminals to the new module. Rewiring is not necessary, but

the terminals must be inspected to ensure they are in good operating condition.

11 Re-establish network connection.

12 Run the module.

Inadmissible interference voltage can be measured with a universal tester. We

recommend testing every single terminal for unapproved interference voltage.

When testing the external cables for insulation resistance, short-circuit, and line

break, the cables must not be connected at both ends to prevent defects or

destruction of the XPSMF2DO801 caused by excessive voltages.

Earth faults are to be tested before connecting the field cable to the devices. The

feed voltage must be disconnected from the sensors, as well as between the

negative pole and the actuators. If the negative pole is earthed during operation, the

earth connection must be disconnected while testing for earth faults. This also

applies to the earth connection of an existing earth fault tester. Every terminal can

only be tested against earth with a resistance tester or a similar test instrument.

Testing the insulation of one or more wires against earth is admissible, but not two

muted wires. High voltage testing is also not admissible.

Guidelines to measure circuit voltage and insulation resistance can be found in

EN 50178.

32

33003405 07/2007

Page 33

Application and Function

Maintenance The XPSMF2DO801 safety remote output module is designed for industrial

applications. All the components have a very high availability and are compliant with

the requirements of IEC 61508 for PFD and PFH in accordance with SIL 3.

Note: For safety-related use, the modules have to be subjected to an offline proof

test in intervals of 3 years. For Offline Proof Test, see Offline Proof-Test, p. 34.

WARNING

OFFLINE PROOF TEST

Offline Proof Test according to IEC 61508-4 must be conducted to verify proper

operation.

Failure to follow these instructions can result in death, serious injury, or

equipment damage.

Repair of Remote

Output Modules

You may not repair the XPSMF2DO801 safety remote output device. Defective

devices must be returned to Schneider Electric for repair.

The validity of the safety certificate will expire if unauthorized repairs have been

made on the device. The manufacturer will bear no responsibility for unauthorized

repairs. Unauthorized repairs will also cancel all warranties for the device.

33003405 07/2007 33

Page 34

Application and Function

Offline Proof-Test

Overview The offline proof-test recognizes dangerous concealed faults that would affect the

safe function of the plant.

Safety systems have to be subjected to an offline proof test in intervals of 10 years.

By an analysis using the calculation tool SILence, the interval often may be

extended. (SILence is a separate program. Contact the service for more information

or take a look at the HIMA homepage for a test version of the software SILence.)

For relay modules, the proof test for the relays has to be carried out in intervals

defined for the respective plant.

Execution of the

Offline Proof

Test

Periodic Proof

Testing

The execution of the offline proof test depends on the configuration of the plant

(EUC = equipment under control), which risk potential it has, and which standards

for operation are applied and form the bases for the approval by the test authority in

charge.

According to the standards IEC 61508 1-7, IEC 61511 1-3, IEC 62061, and

VDI/VDE 2180 sheet 1 to 4, in case of safety-related systems the operating

company has to arrange for proof tests.

The modules can be proof tested by executing the full safety loop.

In practice the input and output field devices have a more frequent proof test interval

(e.g., every 6 or 12 months) than the modules. If the end-user tests the complete

safety loop because of the field devices then the modules are automatically included

in these tests. No additional periodic tests are required for the modules.

If the proof test of the field devices does not include the modules then the PES needs

to be tested as a minimum once in 10 year. This can be done by executing a reset

of the modules.

In case there are periodic proof test requirements for specific modules then the enduser should refer to the data sheets of these modules.

34

33003405 07/2007

Page 35

Equipment Description

3

At a Glance

Overview This chapter contains the equipment description of XPSMF2DO801 safety remote

output module.

What's in this

Chapter?

This chapter contains the following topics:

Topic Page

Housing Elements 36

Reset Button 39

Communication 40

LEDs 44

Wiring 47

IP Addressing and System ID 49

SafeEthernet 50

Operating Conditions 56

Technical Characteristics 59

Additional Items 62

33003405 07/2007 35

Page 36

Equipment Description

Housing Elements

Front View The following image shows the various elements of the front panel of

XPSMF2DO801 safety remote output module:

1

L- L- L+ L+

L- L+L+L-

24V DC

RUN

ERROR

PROG

FORCE

FAU LT

OSL

BL

2 2

12

DO1

2 2

34

DO2

56

DO3

HIMatrix

DO5

DO6

78

DO4

DO7

HIMA

1 10/100BaseT

10/100 BaseT

2

910

3

2 2

11 12

13 14

2

Elements of the front panel:

No. Description

1 Power supply input

2 Relay outputs

3 Indicators

by HIMA

F2DO

8 01

DO8

15 16

36

33003405 07/2007

Page 37

Top View The following image shows the elements of the top panel:

13 1411 12910 15 16

Reset button

Bottom View The following image shows the elements of the bottom panel:

78563412

Equipment Description

SafeEthernet

33003405 07/2007 37

Page 38

Equipment Description

Back Panel The following image shows elements of the back panel:

DIN rail recess

Quick release clip

38

33003405 07/2007

Page 39

Equipment Description

Reset Button

Overview The device is equipped with a reset button. The reset button is used if the PC

connection password is lost.

Using Reset

Button

You can access the pushbutton through a small round opening on the upper side of

the housing, about 40...50 mm (1.57...1.97 in.) from the left rim.

Use the button only while you reboot the device and keep the button pressed for at

least 20 s. Pushing the reset button while the device is running produces no result.

Effect When you push the Reset button,

l all accounts are deactivated (except the default Administrator account

without password) and

l IP addresses and system ID (SRS) are set to default values.

Note: After activation of the reset button, values are modified and remain valid until

the next reboot. After the next reboot the previous values are restored. You can

enter new information, if necessary.

33003405 07/2007 39

Page 40

Equipment Description

Communication

Overview The Safety PLCs and remote output devices communicate with each other and the

PC over Ethernet using SafeEthernet protocol.

The Safety PLCs communicate with each other and with a PC through a star or

linear Ethernet layout. A PC can be connected at any place in the network.

The communication section is connected to the safe microprocessor system. It

controls communication between PES and other systems via powerful interfaces,

such as 100 BaseT: SafeEthernet, Modbus TCP/IP

Safety-Related

Communication

Communication via switches

The switch integrated into each system for SafeEthernet communication is shown

on the block diagram (see Block Diagram, p. 26).

In contrast to a hub, a switch can store data packets for a short period of time in

order to establish a temporary connection between two communication partners

(transmitter/receiver) for transferring data. This way, collisions (typically occurring in

hubs) can be avoided, and the load on the network can be reduced. For controlled

data transfer, every switch needs an address/port relation table. This table will be

automatically generated in a self-learning process. Each port in the switch is

corellated to the defined MAC addresses. According to this table, incoming data

packets are switched directly to the corresponding port.

The switch automatically switches between the transfer rates of 10 and 100 MBit/s

full and half duplex transmissions.

The switch controls communication between different devices. The switch can

address up to 1000 absolute MAC addresses.

Autocrossing recognises if cables with crossed wires have been connected, and the

switch adjusts accordingly.

For networking via Ethernet, the XPSMF2DO801 safety remote output device is

equipped with two connections arranged on the lower side panel of the case.

Various systems can be networked as required via Ethernet star or line

configuration. A PC can also be connected wherever required.

Note: When building the network, ensure that no network loops are formed. The

system must receive data along only one path.

40

33003405 07/2007

Page 41

Equipment Description

The following scheme shows a SafeEthernet networking example:

Telemecan ique

XPS-MF

XPSMFPS01

from other F60 or other XPSMF device

PC w ith XPSMFWIN

SafeEthernet protocol

24V DC

RUN

ERROR

PROG

FORCE

FAU LT

OSL

BL

HIMA

24V DC

RUN

ERROR

PROG

FORCE

FAU LT

OSL

BL

HIMA

24V DC

RUN

ERRO R

PROG

FORCE

FAUL T

OSL

BL

HIMA

HIMatrix

24V DC

RUN

ERROR

PROG

FORCE

FAULT

OSL

BL

HIMA

HIMatrix

HIMa-

by HIMA

F3DI

by HIMA

F1

by HIMA

F30

DI

24V DC

RUN

ERROR

PROG

FORCE

FAU LT

OSL

BL

HIMA

24V DC

RUN

ERROR

PROG

FORCE

FAU LT

OSL

BL

HIMA

24V DC

RUN

ERROR

PROG

FORCE

FAU LT

OSL

BL

HIMA

HIMatrix

HIMatrix

HIMatrix

HIMatrix

by HIMA

F35

by HIMA

F31

by HIMA

F2DO

by HIMA

F3AIO

33003405 07/2007 41

Page 42

Equipment Description

The following is a Ethernet cable connection diagram:

HIMA

HIMA

HIMA

HIMA

HIMA

HIMA

Legend:

HIMatrix F3 1

HIMatrix F3 1

HIMatrix F3 1

HIMatrix F3 1

HIMatrix F3 1

HIMatrix F3 1

by HIMA

HIMA

by HIMA

HIMA

by HIMA

HIMA

by HIMA

HIMA

by HIMA

HIMA

by HIMA

HIMA

HIMatrix F3 1

HIMatrix F3 1

HIMatrix F3 1

HIMatrix F3 1

HIMatrix F3 1

HIMatrix F3 1

by HIMA

by HIMA

by HIMA

by HIMA

by HIMA

by HIMA

1

2

3

4

5

6

42

by HIMA

HIMatrix F3 1

HIMA

Device in case Connector Coupling (plug and socket

Connector pairs and cable distances:

Number Number of plug connector pairs Maximum cable distance

1 2 100 m / 328.1 ft

2 2 100 m / 328.1 ft

3 3 100 m / 328.1 ft

4 3 100 m / 328.1 ft

5 4 100 m / 328.1 ft

6 4 100 m / 328.1 ft

33003405 07/2007

Page 43

Equipment Description

When using specified cables and plug connectors approved to 100 MHz, the

maximum cable distance is 100 m (328.1 ft) with a maximum of six connector pairs.

A combination of a plug and a socket is considered one pair.

Use optic fiber cables with converters for greater distances.

Using SafeEthernet protocol has the following advantages:

l Very fast packet transfer between the collision areas

l Significant increase of data throughput with full-duplex mode

l Prevention of collisions allows deterministic operation.

33003405 07/2007 43

Page 44

Equipment Description

LEDs

Overview The XPSMF2DO801 safety remote output module LEDs:

L- L- L+ L+

L- L+L+L-

1 10/100BaseT

24V DC

RUN

ERROR

PROG

FORCE

FAULT

OSL

BL

HIMA

10/100BaseT

12

DO1

34

DO2

56

DO3

78

DO4

by HIMA

HIMatrix

DO5

2

910

DO6

11 1 2

DO7

13 14

F2DO

8 01

DO8

15 16

44

33003405 07/2007

Page 45

Equipment Description

LED Description The following table describes behaviors of the LEDs:

LED Color Status Meaning

Relay Contact

Outputs 1-8

24 VDC Green On 24 V DC operating voltage present

RUN Green On Normal state of PES (RUN) A loader user program is executed (not in

ERROR Red On The CPU has discovered a hardware fault in the CPU and is switching

PROG Orange On The CPU is being loaded with a new configuration.

FORCE Not illuminated Off FORCE is not signalled.

FAULT Orange On Error display for Line Control. The user program has caused an error.

OSL Orange Flash Emergency loader of the operating system is active.

BL Orange Flash COM in

Orange On An Output signal is being sent.

Not illuminated Off No operating voltage

remote I/O modules). The CPU reads inputs, processes the logic, and

writes outputs; communication and hardware/software tests are

carried out.

Green Flash The CPU is in STOP and is not executing any user program. All outputs

are reset to a safe de-energized state. STOP can be triggered by

setting the Emergency stop system variable to TRUE in the user

program or by a direct command from the PC. Seen when PLC is

switched on for approximately 10s during the system check.

Not illuminated Off The CPU in ERROR STOP (see ERROR below).

to ERROR STOP. The CPU has discovered a software error in the

operating system. The watchdog has triggered ERROR STOP,

because the cycle time has been exceeded. The CPU has stopped the

execution of the user program, ended all hardware and software tests,

and all outputs have been reset. The CPU can only be started again

through a command from the PC.

Not illuminated Off No error has been detected.

Orange Flash The Flash ROM is being loaded with a new operating system.

Not illuminated Off No loading of configuration or operating system.

Orange On Forcing active.

The PES configuration is faulty. The loading of a new operating system

was faulty, and the operating system is corrupt.

Orange Flash An error has occured during the write cycle for a Flash ROM (during

the oprating system update). One or more I/O errors have occured.

Not illuminated Off None of the above errors has occured.

INIT_FAIL state.

33003405 07/2007 45

Page 46

Equipment Description

LED Color Status Meaning

RJ45 Green On Full duplex operation.

Flash Collision

Off Half-duplex operation, no collision

Yellow On Connection established

Flash Interface activity

46

33003405 07/2007

Page 47

Equipment Description

Wiring

Ethernet Wiring Industrial standard cables can be subjected to extreme mechanical stresses. The

minimum for SafeEthernet protocol communication requires Category 5 twisted pair

cable with a class D rating, for greater distances and less possibility for errors

occurring, fiber optic cable should be used.

The controllers communicate at 100 Mbit/s (Fast Ethernet) and 10 Mbit/s during full

duplex mode. The XPSMF2DO801 safety remote output device has an auto "crossover" function built into the switch, which allows the use of both a 1:1 cable and a

cross-over cable.

The outer shielding of the twisted pair cable must be earthed at both ends. If an

RJ 45 connector is used, it automatically connects the cable's shield to the

controller’s housing.

Interface

Elements

When connecting a module or a PLC over Ethernet communication, the following

interface elements are recommended: FL CAT5 TERMINAL BOX of Phoenix

Contact

(R)

. The controllers are mounted on an earthed EN mounting rail. The

conductors of the field cable are attached to the interface terminals. It is important

to make sure that the cable shield is also connected via the strain relief.

Prefabricated patch cables are used to connect the interface element and the

XPSMF2DO801 safety remote output device. If the rail is earthed in accordance with

the standards, it is enough to mount an interface element on a rail.

33003405 07/2007 47

Page 48

Equipment Description

Specified Cables The cables are specified by category depending on their transmission and high-

frequency properties as follows:

Category Specification Approved

1- No

2 up to 1 MHz No

3 up to 16 MHz No

4 up to 20 MHz No

5 up to 100 MHz Yes

6 up to 250 MHz Yes

7 up to 600 MHz Yes

The channel as a point-to-point transmission path is defined as follows:

Class Specification Approved

A up to 0.1 MHz No

Bup to 1 MHz No

C up to 16 MHz No

D up to 100 MHz Yes

E up to 250 MHz Yes

F up to 600 MHz Yes

The higher the letter, the greater the demand on the transmission channel. For

Ethernet communication at 100 MHz, Category 5 (or higher) cables and at least

Class D capacity are required.

RJ45 Connector For direct Ethernet plug connections without interface elements, you can use

connectors such as IP 20 Data Plug (Harting

(R)

). You can assemble the cable

quickly by crimping the conductors; special tools are not required.

Switches To span distances of more than 100 m (328.1 ft) using SafeEthernet protocol, rail

switches of the RS2 series (Hirschmann

(R)

) with optical fibre ports are

recommended.

48

33003405 07/2007

Page 49

Equipment Description

IP Addressing and System ID

Overview A transparent label provided with the controller can be used to note the IP address

and system ID (SRS, System-Rack-Slot) following a modification:

IP_._._._SRS_._._

Default value for IP address: 192.168.0.99

Default value for SRS: 60000.1.0

The ventilation slots in the housing of the Safety PLC must not be covered with the

label.

For more information about changing the IP address and system ID, see the

XPSMFWIN Software manual.

Note: Each Ethernet board has a unique Ethernet address. It is a 48 bit number:

the first 24 bits indicate the manufacturer, while the last 24 bits are a unique

number for each Ethernet board/controller-chip assigned by the manufacturer. The

number is also called MAC ID.

TCP/IP

Description

The IP address is an identifier for a device in a network. IP addresses are 32-bit

numbers. To make it easier to memorize them, they are usually expressed in four

8-bit numbers (e.g., 192.168.10.1)

IP addresses are unique, no other device within the network can share the same

address:

l the IP address assigned to the PC

l the part of the IP address (the subnet mask) that distinguishes other networks

Note: The operator must ensure that the Ethernet used for Peer-to-Peer

communication is adequately protected from unauthorized access (i.e. by

hackers). The nature and extent of the measures to be taken must be determined

in conjunction with the approval authorities.

33003405 07/2007 49

Page 50

Equipment Description

SafeEthernet

Overview This section provides information about SafeEthernet protocol and OSI model.

Description In the field of automation, requirements, such as determinism, reliability,

interchangeability, extensibility, interoperability and the overall safety are central

themes. Based on the Ethernet technology, SafeEthernet provides a transfer

protocol for transmitting safety-related data up to RC 6 or SIL 3. SafeEthernet

implements a mechanism that can detect and react to the following:

l Corruption of transmitted data

l Incorrect address allocation for the messages (transmitter, receiver)

l Incorrect data sequence (repetition, loss, change)

l Incorrect timing (delay, echo)

SafeEthernet is based on the standard Ethernet or FastEthernet according to

IEEE 802.3.

The transmission of the safety-related data does not change the protocol frame of

the standard Ethernet.

According to the Black Channel Approach in SafeEthernet, "insecure transmission

channels" (Ethernet) are used and controlled by safety-related protocol mechanism

at transmitter and receiver. This way, regular Ethernet network components, such

as hubs, switches, routers, and PCs supplied with network interfaces can be used

within a safety-related network. The significant difference to standard Ethernet is

determinism, the real-time ability of SafeEthernet.

A special protocol mechanism ensures deterministic behavior even in case faults

occur or new communication participants emerge. New components are

automatically integrated into the running system. All components of the network

could be changed while the system is running. With the use of switches,

transmission times can be clearly defined. This way, Ethernet works in real time.

Possible transfer speed up to 100Mbit/s for safety-related data is higher than the

speed normally used. Copper lines as well as fiber optic cables can be used as

transmission media. The integration of firm intranets as well as connections to the

Internet, can be realized with SafeEthernet technology. The terms for safety-related

communication have to be considered.

50

33003405 07/2007

Page 51

Equipment Description

Therefore, only one network for safety and non-safety data transfer is necessary.

SafeEthernet can be fitted to existing Ethernet networks with adjustable network

profiles. With SafeEthernet, you can set up flexible built-up system structures for

decentral automation with defined reaction times. According to the requirements,

the intelligence can be centralized or distributed to the participants in a decentral

way within the network. There is no limit to the number of safe participants of the

network and the amount of transferred safe data to get the needed reaction times.

A central controller and the built-up of parallel structures is therefore superfluous.

The transmission of standard and safe data can be integrated into one network. A

separate safety bus can be saved. The switches of the safety remote I/O device

perform the tasks normally carried out by network switches.

33003405 07/2007 51

Page 52

Equipment Description

Operation

Parameters of

the Ethernet

Interfaces

Up to COM OS version 8.32 all Ethernet ports of the integrated Ethernet switches

have the same settings:

l Autoneg/Autoneg for Speed Mode

l Flow-control Mode

Other settings are not possible and will be rejected by the PLC when loading a

configuration.

The Ethernet interfaces 10/100 BaseT of the device have the following parameters:

Firm operating parameters

Speed Mode Autoneg

Flow-Control Mode Autoneg

Other devices combined with the Safety PLC or remote I/O device must have the

following network settings:

Admissible settings of other devices

Speed Mode Autoneg

Flow-Control Mode Autoneg

or

Speed Mode Autoneg

Flow-Control Mode Half Duplex

or

Speed Mode 10 or 100 Mbit/s

Flow-Control Mode Half Duplex

52

Non-admissible settings of other devices

Speed Mode Autoneg or 10 or 100 Mbit/s

Flow-Control Mode Full Duplex

For COM OS version > 8.32 and XPSMFWIN Hardware Management version

> 7.56.10 each Ethernet port of the integrated switch can be individually configured.

See also in the appendix Connection Diagrams, Examples of Application, and Error

Codes, p. 67.

33003405 07/2007

Page 53

Equipment Description

Connections for

SafeEthernet/

Networking

Examples

For the networking via SafeEthernet protocol, the devices are equipped - depending

on the design - with two connections arranged on the lower side panel of the case.

See example of a Safety-Related Communication, p. 40.

The various systems can be networked together as required via Ethernet (star or line

configuration). A programming unit (PC) can also be connected wherever required.

Note: Ensure that no network loops are formed when connecting systems

together. The system must receive data packets along one path only.

Modbus TCP/IP The Modbus serial slave field bus protocol can communicate with the Modbus

TCP/IP protocol via the Ethernet interfaces on the Safety PLC.

Standard Modbus communication transfers the slave address and a CRC checksum

in addition to the instruction code and the data. In Modbus TCP/IP the subordinate

TCP/IP protocol handles this function.

Note: More information about Modbus TCP/IP protocol can you find in the online

help of XPSMFWIN.

Used Network

Ports for

Ethernet

Communication

UDP ports and usage

UDP Ports Usage

8000 programming and operation with XPSMFWIN

8001 configuration of the remote I/O via PLC

6010 SafeEthernet

6005/6012 if TCS_DIRECT was not activated within HH network

TCP ports and usage

UDP Ports Usage

502 Modbus (changeable by user)

33003405 07/2007 53

Page 54

Equipment Description

OSI model The model divides the functions of a protocol into a series of layers known as a

’protocol stack’ (e.g., TCP/IP stack). Lower layers are implemented in hardware,

while higher layers are used in software. Each of the layers is a transport platform

for the next higher level and relies on the next lower level .

The following image is a graphic representation of the OSI layers:

Data Layer

Media Layers Host Layers

Data

Data

Data

Segments

Packets

Frames

Bits

Application

Network Process to Application

Presentation

Data Representation and Encryption

Session

Interhost Communication

Transport

End-to-End Connections and Reliability

Network

Path Determination and IP

Data Link

MAC and LLC

Physical

Media, Signal, and Binary Transmission

54

33003405 07/2007

Page 55

The following table describes the seven OSI layers (bottom-top):

Number Layer Data Description

Media Layers

1 Physical layer

Media, Signal, and Binary

Transmission

2 Data link layer

MAC and LLC

3Network layer

Path Determination and IP

Host Layers

4 Transport layer

End-to-End Connections and

Reliability

5 Session layer

Interhost Communication

6 Presentation layer

Data Representation and

Encryption

7 Application layer

Network Process to

Application

Bits Defines all electrical and physical specifications for the

devices.

Frames Provides the functional and procedural means to transfer

data between network entities and detect and correct

errors that may occur in the Physical layer.

Packets Provides the functional and procedural means of

transferring variable length data sequences from a

source to a destination via one or more networks.

Segments Provides transparent transfer of data between end users.

Data Provides the mechanism for managing the dialog

between end-user application processes.

Data Relieves the Application layer of concern regarding

syntactical differences in data representation within the

end-user systems.

Data Interfaces directly to and performs common application

services for the application processes.

Equipment Description

33003405 07/2007 55

Page 56

Equipment Description

Operating Conditions

Overview The XPSMF2DO801 safety remote output module has been developed in

compliance with the requirements of the following standards for EMC, climate and

environment:

IEC 61131-2 Programmable Controllers, Part 2, Equipment Requirements and

Tests

IEC 61000-6-2 EMC Generic Standards, Part 6-2

IEC 61000-6-4 EMC General Emission Standard, Industrial Environment

To use the XPSMF2DO801 safety remote output module, the following conditions

must be fulfilled:

Protection Class Protection class II according to IEC/EN 61131-2

Pollution Pollution degree II

Altitude < 2000 m / 6561.7 ft

Enclosure Standard: IP 20 If requested by the relevant application standards

(e.g., EN 60204, EN 954-1), the device must be installed in a required

enclosure (e.g., IP 54).

Climatic

Conditions

56

The most important tests and limit values for climatic conditions are listed in the

following table:

EN 61131-2 Climatic Tests

Operating temperature: 0°C to 60°C / 32°F to 140°F

(Test limits -10°C to +70°C / 14°F to 158°F)

Storage temperature: -40°C to 85°C / -40°F to 185°F (with battery

only -30°C / -22°F)

6.3.4.2 Dry heat and cold withstand test: 70°C / -25°C (158°F / -13°F, 96 h,

EUT power supply disconnected

6.3.4.3 Change of temperature, withstand and immunity test: -25°C / 70°C

(-13°F / 158°F) and 0°C / 55°C (32°F / 131°F), EUT power supply

disconnected

6.3.4.4 Cyclic damp heat withstand test: 25°C / 55°C (77°F / 131°F), 95%

relative humidity, EUT power supply disconnected

33003405 07/2007

Page 57

Equipment Description

Mechanical

Conditions

The most important test and limit values for mechanical conditions are listed in the

following table:

EN 61131-2 Mechanical Tests

Vibration test, operating: 5 Hz to 9 Hz / 3.5 mm, 9 Hz to

150 Hz / 1g

6.3.5.1 Immunity vibration test: 10 Hz to 150 Hz, 1 g, EUT

operating, 10 cycles per axis

6.3.5.2 Immunity shock test: 15g, 11ms, EUT operating, 2 cycles

per axis

EMC Conditions The most important tests and limit values for EMC conditions are listed in the

following tables:

EN 61131-2 Noise Immunity Test

6.3.6.2.1 IEC/EN 61000-4-2 ESD test: 4 kV contact/ 8 kV air discharge

6.3.6.2.2 IEC/EN 61000-4-3 RFI test (10 V/m): 26 MHz to 1 GHz, 80% AM

6.3.6.2.3 IEC/EN 61000-4-4 Burst test: 2 kV power supply / 1 kV signal lines

6.3.6.2.4 IEC/EN 61000-4-12 Damped oscillatory wave immunity test: 1 kV

IEC/EN 61000-6-2 Noise Immunity Test

IEC/EN 61000-4-6 Radio frequency common mode: 10 V

150 kHz to 80 MHz, AM

IEC/EN 61000-4-3 900 MHz pulses

IEC/EN 61000-4-5 Surge: 1 kV, 0.5 kV

IEC/EN 61000-6-4 Noise Emission Test

EN50011 Class A Emission test: radiated, conducted

33003405 07/2007 57

Page 58

Equipment Description

Voltage Supply The most important tests and limit values for the voltage supply of the equipment are

listed in the following table:

IEC/EN 61131-2 Verification of DC Power Supply Characteristics

The power supply must meet alternatively the following

standards: IEC 61131-2 or SELV (Safety Extra Low

Voltage) or PELV (Protective Extra Low Voltage)

Fusing the XPSMF2DO801 safety remote output device

must be performed according to this manual only.

6.3.7.1.1 Voltage range test: 24 V DC, -20% to 25% (19.2 V DC to

30.0 V DC)

6.3.7.2.1 Momentary interruption immunity test: DC, PS 2: 10ms

6.3.7.4.1 Reversal of DC power supply polarity test

6.3.7.5.1 Backup duration withstand test: Test B, 1000 h, Lithium

battery is used for backup.

58

33003405 07/2007

Page 59

Technical Characteristics

Mechanical Data Power Supply Connectors 1

Connection diameters, single lead connection

Without lead end sleeves

Stranded with lead and sleeves (without

plastic sleeves)

Stranded with lead end sleeves (with plastic

sleeves)

Power Supply Connectors 2

Connection diameters, multiple lead connections (2 leads max, same diameters)

Without lead end sleeves

Stranded with lead and sleeves (without

plastic sleeves)

Stranded with lead end sleeves (with plastic

sleeves)

Equipment Description

2

Solid 0.2 to 2.5 mm

Stranded 0.2 to 2.5 mm

AWG 24-12

2

0.25 to 2.5 mm

AWG 22-14

2

0.25 to 2.5 mm

AWG 22-14

2

Solid 0.14 to 1.5 mm

Stranded 0.14 to 1.5 mm

AWG 28-16

2

0.25 to 1.5 mm

AWG 22-16

2

0.25 to 0.5 mm

AWG 22-20

2

2

Signal Line Connectors 1

Connection diameters, single lead connection

Without lead end sleeves

Solid 0.14 to 1.5 mm

Stranded 0.14 to 1.5 mm

AWG 28-16

Stranded with lead and sleeves (without

plastic sleeves)

Stranded with lead end sleeves (with plastic

sleeves)

33003405 07/2007 59

0.25 to 1.5 mm

AWG 22-16

0.25 to 0.5 mm

AWG 22-20

2

2

2

2

Page 60

Equipment Description

Signal Line Connectors 2

Connection diameters, multiple lead connections (2 leads max, same diameters)

Without lead end sleeves

Solid 0.14 to 0.5 mm

2

AWG 28-20

2

Stranded 0.14 to 0.75 mm

AWG 28-18

Stranded with lead and sleeves (without

plastic sleeves)

Stranded with lead end sleeves (with plastic

sleeves)

0.25 to 0.34 mm

AWG 22

2

0.5 mm

AWG 20

2

Stripping Length and Torque

Stripping length 9 mm (0.35 in)

Torque 0.22 to 0.25 Nm (1.9 to 2.2 lb-in)

Technical Data The XPSMF2DO801 safety remote output device technical data are presented in

the following tables:

Interface Ethernet 2*RJ-45, 10/100 Base T with integrated switch

Operating Voltage 24 VDC -15%/+20%, Wss <=15%, from a power supply

with protective separation, conforming to IEC 61131-2

requirements

Current Consumption max. 0.6 A

Operation Temperature 0 to 60°C / 32°F to 140°F

Storage Temperature -40 to +85°C / -40°F to 185°F

Fuse (external) 10 A (Slow blow)

Battery backup none

Protection IP 20

Max dimensions width: 207 mm / 8.15 in. (with housing screws)

height: 114 mm / 4.49 in. (with latch)

depth: 86 mm / 3.39 in. (with grounding bolt)

Weight 1.3 kg / 2.87 lb

60

33003405 07/2007

Page 61

Equipment Description

Relay Outputs

Relay Types per Channel 2 Safety relays with positively guided contacts,

1 standard type relay

Number of Outputs 8 Potential-free NO contacts in diversity

Output Voltage 2 VDC

Switching Voltage

Switching Current internally fused with 3.15 A

Switching Capacity AC UL:

Switching Capacity DC (nonInductive)

Contact Material silver alloy

Switching Time approx. 30 mS

Reset Time approx. 10 mS

Bounce Time approx. 15 mS

Service Life Mechanical and

Electrical

≥ 5 V, ≤ 250 VAC / 250 VDC

breaking capacity 100 A

250 VAC @ 6 A GP

TÜV:

max. 250 VA, cos

max. 625 VA, cos

ϕ ≥ 0.5, at max. 250 VAC

ϕ = 1

UL: 24 VDC @ 1 A at resistive load

TÜV:

up to 30 VDC: Max. 90 W (3.15 A)

up to 70 VDC: Max. 22 W (0.315 A)

up to 127 VDC: Max. 25 W (0.25 A)

up to 250 VDC: Max. 40 W (0.16 A)

(external fusing adapted)

6

≥ 3 x 10

≥ 2.5 x 10

switching cycles

5

switching cycles with resistive full load and

≤ 0.1 switching cycles per second

Supply Voltage The XPSMF2DO801 safety remote output device is a single voltage system. The

required operating voltage is defined as follows in accordance with IEC/EN 61131-2.

Supply voltage

Nominal value 24 VDC, -15...+20%

Max. permissible function

limits in continuous operation

Max. peak value 35 VDC for 0.1 s

Permissible ripple w < 5% as r.m.s. value w

Reference potential L - (negative pole)

33003405 07/2007 61

18.5 to 30.2 VDC (including ripple)

< 15% as value peak-to-peak

ss

Earthing the reference potential is permitted.

Page 62

Equipment Description

Additional Items

Overview This section lists additional items that can be used with or alongside the

XPSMF2DO801 safety remote output device.

List of Additional

Items

l Power Supply Unit-24VDC with protective separation from power supply:

IEC 61131-2

Product ranges: ABL7RE or ABL8RP

Location: www.telemecanique.com

l Suitable DIN Rail for mounting the controller

AM1** range of DIN rail is acceptable and can be found under the Cable and

Wiring Accessories in Control and Connection Components Catalog.

l OtherSafe PLC controllers and IO

l XPSMF60** The XPSMF60 controller is a modular PES in a rack system

housing. The controller is able to house up to six of the folowing modules (see

the table below). The number of times a particular module is used in the

XPSMF60 is not restricted.

l XPSMF3DIO** Remote Input and Output modules. The number of inputs and

outputs may vary depending on the model.

l XPSMF2DO** Remote Output Module. The number of outputs varies.

l XPSMF1DI1601 Remote Input Module with 16 digital outputs.

l Safety Modules Various safety modules and safety controllers (see Machine

Safety in the Essential Guide). Module functions range from emergency stop to

light curtain monitoring.

l Standard Controllers: Non-Safety data transfer (see Automation, automation and

Control, Essential Guide, 2005). Standard controllers operate both large and

small machinery. Ranges: Twido, Micro, Premium, and Quantum.

l Safety Devices Switches and Actuators:

l Coded Magnetic Switches, Limit Switches, Rotary Lever or spindle,

Emergency Stops, Foot Switches, Switch Disconnectors

l Mat

l Light Curtains

l 2 Hand Control units

l Motor Starters

(See Safety section or the Essential Guide for more details.)

62

33003405 07/2007

Page 63

Equipment Description

l Human Machine Interface Devices (to increase safety awareness)

l Pushbuttons and Pilot Lamps

l Beacons

l Sirens

l Magelis Displays

(See Operator Dialog section of the Essential Guide for more information.)

Note: All the catalogs and guides are available at http://www.telemecanique.com.

33003405 07/2007 63

Page 64

Equipment Description

64

33003405 07/2007

Page 65

Appendices

At a Glance

Overview This chapter contains error codes and examples of wiring diagrams.

What's in this

Appendix?

The appendix contains the following chapters:

Chapter Chapter Name Page

A Connection Diagrams, Examples of Application, and Error

Codes

67

33003405 07/2007 65

Page 66

Appendices

66

33003405 07/2007

Page 67

Connection Diagrams, Examples of Application, and Error Codes

A

At a Glance

Overview This chapter contains connection diagrams, examples of application, and error

codes.

What's in this

Chapter?

This chapter contains the following topics:

Topic Page

Error Codes 68

Wiring Examples 70

Configuration of Ethernet Interfaces 73

33003405 07/2007 67

Page 68

Brief description of the functional devices

Error Codes

Description of

Error Codes

The error codes listed in this section appear in XPSMFWIN programming

environment.

The following table describes error codes of relay outputs:

System signal R/W Meaning

Module.SRS [

Module.Type [

Module.Error Code [

DO.Error Code [

UDINT] R slot number (System-Rack-Slot)

UINT] R type of module, setpoint: 0x003C [60

WORD] R error codes of the module

0x0000

0x0001

0x0002

0x0004

0x0010

0x0020

0x0040

0x0080

WORD] R error codes of all digital outputs

0x0001

0x0002

0x0004

0x0008

0x0010

0x0020

0x0040

0x0080

0x0100

0x0400

0x0800

0x1000

0x2000

0x4000

]

dez

I/O processing, may be faulty, see further error codes

no I/O processing (CPU not in RUN)

no I/O processing during start-up tests

manufacturer interface in operation

no I/O processing: incorrect configuration

no I/O processing: error rate exceeded

no I/O processing: configured module not inserted

module error

MEZ test, safety switch 1 failed

MEZ test, safety switch 2 failed

FTZ test of test pattern failed

MEZ test of readback channels failed

MEZ test, active disconnection failed

error with initialization: relays

FTZ test: error of relay voltage

FTZ test of CS (chip select) signals failed

FTZ test: 1. temperature threshold exceeded

FTZ test: 2. temperature threshold exceeded

MEZ test: status of safety switch 1

MEZ test: status of safety switches

MEZ test: active disconection by watchdog failed

68

33003405 07/2007

Page 69

Brief description of the functional devices

System signal R/W Meaning

DO[xx].Error Code [BYTE] W error codes of the digital output channels

0x01

0x04

0x10

error in digital output module

error reading back the digital outputs

error reading back relay [x].1

(the channel is permanently deactivated)

0x20

error reading back relay [x].2

(the channel is permanently deactivated)

DO[xx].Value [

0x080

BOOL] W output value of digital output channels

0

1

channel still can not be activated after deactivation by

l application

l forcing

l channel/module failure

output power-free

output activated

33003405 07/2007 69

Page 70

Brief description of the functional devices

Wiring Examples

SafeEthernetProtocol and

Ethernet Wiring

Example

The following scheme shows an example of Ethernet and SafeEthernet protocol

networking:

6

Ethernet (SafeEthernet)

Medium (protocol)

1

7

Ethernet (Mo dbus TCP/IP)

Ethernet (Modbus T CP/IP)