Page 1

Saitel DP

M562x0000y / AB_AC

User Manual

This manual provides information for the assembly, wiring, configuration and

maintenance of the AB_AC module.

SE-M562-USR

Publication Date (05/2020)

Read carefully the information contained in this manual before assembly, installation and use of the

equipment.

www.schneider-electric.com

Page 2

07/05/2020

User Manual – AB_AC

Page 2

R&D Digital Seville

HUe

11.06.06

HU_A

11.06.17

Linux

HUe

18.07.17.10.42.53

VxWork

HU_A

VxW_19_06_27_15_35_02

Easergy Builder Tool

Core

1.5.9.1

DSP

1.0.4

AT90CAN

02.00.13

Change control

01 04/09/2019 Initial edition.

Rev Date Description

02 07/05/2020

General Information

The Saitel platform and all its components have been developed in accordance to the requirements

for a quality management system, complying with the ISO 9001:2015 Norm.

Document nº:

Revision/Date:

File:

Retention period:

Reference Documents

Easergy Builder user manual FTE-S856-MSS

webAPP user manual FTE -S856-WPP

• Fixed some errors detected in previous version.

• Changed class and accuracy of the module.

SE-M562-USR

02 / 07-05-2020

AB_AC - User Manual _EN_02.pdf

Permanent throughout its validation period + 3 years after its

cancellation.

User Manual Document Code

webTool user manual FTE-S856-MSW

Saitel DR Platform user manual FTE-F800-USR

EOL Instructions FTE-EOLI-M562

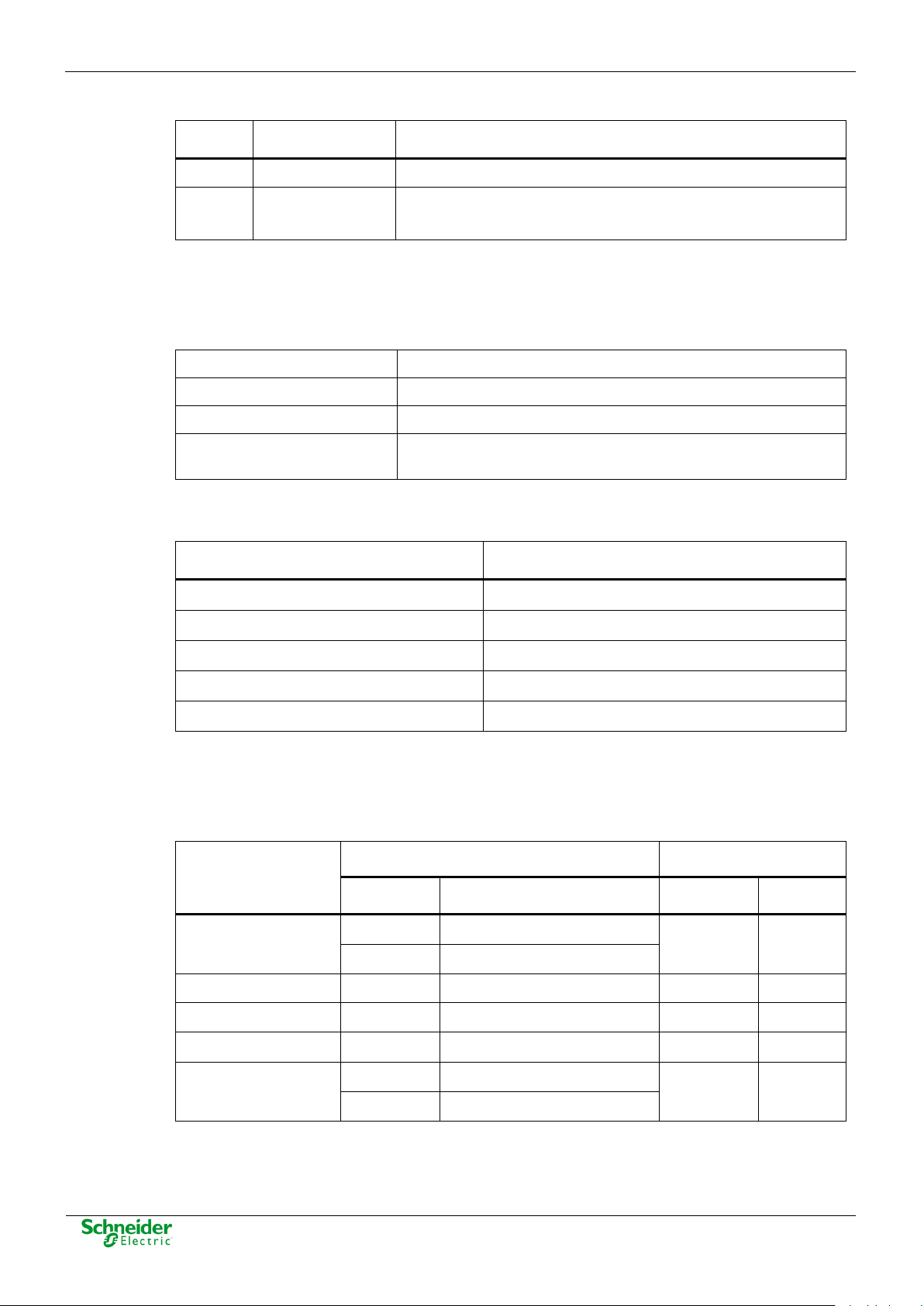

Software Versions

The information in this manual is valid for the software versions listed below. This information is

also valid for later versions, although some parameters may change slightly:

Module

Baseline

Software AB_AC

RTU Software Easergy Builder (Plugin)

Module Version Plugin Version

Page 3

User Manual – AB_AC

07/05/2020

R&D Digital Seville

Page 3

Page 4

07/05/2020

User Manual – AB_AC

Page 4

R&D Digital Seville

Content

1 SAFETY & HEALTH .................................................................................................. 5

2 GENERAL DESCRIPTION OF AB_AC ................................................................... 16

3 PHYSICAL MOUNTING & INSTALLING ................................................................ 22

4 CONFIGURATION & MAINTENANCE .................................................................... 31

5 TECHNICAL SPECIFICATION TABLE ................................................................... 60

Page 5

User Manual – AB_AC

07/05/2020

R&D Digital Seville

Page 5

1 Safety & Health

Page 6

07/05/2020

User Manual – AB_AC

Page 6

R&D Digital Seville

Content

1 SAFETY & HEALTH .................................................................................................. 5

1.1 INTRODUCTION ........................................................................................................ 7

1.1.1 I

1.1.2 P

1.2 I

1.3 S

1.4 I

1.5 E

1.5.1 E

1.5.2 F

1.6 H

1.7 T

1.7.1 P

1.7.2 E

1.7.3 S

1.8 T

1.9 P

1.10 D

NFORMATION OF SECURITY .............................................................................. 7

RESENTATION ................................................................................................ 7

NTRODUCTION TO SAFETY ....................................................................................... 8

YMBOLS AND LABELS ON THE EQUIPMENT ............................................................. 9

NSTALLATION, SETUP AND OPERATION ................................................................... 9

ARTHING ............................................................................................................. 11

LECTRICAL SAFETY ...................................................................................... 11

UNCTIONAL EARTH (EMC) ............................................................................ 12

ANDLING ELECTRONIC COMPONENTS .................................................................. 13

ECHNICAL SPECIFICATIONS FOR SAFETY .............................................................. 13

ROTECTIVE ELEMENTS ................................................................................. 13

NVIRONMENTAL CONDITIONS ........................................................................ 13

TORAGE CONDITIONS ................................................................................... 13

ECHNICAL LABEL ................................................................................................. 14

ACKING AND UNPACKING ..................................................................................... 14

ECOMMISSIONING AND DISPOSAL ....................................................................... 15

Page 7

User Manual – AB_AC

07/05/2020

R&D Digital Seville

Page 7

symbol to avoid possible injuries.

DANGER indicates a hazardous situation which, if not avoided, will result in death or serious

WARNING

WARNING indicates a hazardous situation which, if not avoided, could result in death or

NOTICE

NOTICE is used to address practices not related to physical injury. The safety alert symbol shall

1.1 Introduction

1.1.1 Information of Security

Important information

Read these instructions carefully and look at the equipment to become familiar with the device

before trying to install, operate, service or maintain it. In this manual you can find different types of

messages associated with situations that have different level of risk for people and / or for the

equipment.

This symbol indicates "DANGER" or "WARNING". This symbol informs of an

electrical risk that will cause personal injuries if the instructions are not followed.

This symbol is associated to a safety alert. It is used to warn of possible personal

injury hazards. The user must follow all instructions or messages associated to this

DANGER

injury.

serious injury.

not be used with this signal word.

To Keep in Mind

Electrical equipment should be installed, operated, serviced, and maintained only by qualified

personnel. No responsibility is assumed by Schneider Electric for any consequences arising out of

the use of this material.

A qualified person is who fulfill with requirements in paragraph 1.2 .

1.1.2 Presentation

This manual provides information for a safe handling, commissioning and testing. This Safety

chapter also includes descriptions of the labels on the equipment.

Documentation for equipment ordered from Schneider Electric is dispatched separately from

manufactured goods and may not be received at the same time. Therefore, this guide is provided

to ensure that printed information which may be present on the equipment is fully understood by

the recipient.

The technical data in this safety guide is typical only, see the technical data section of the user

manual for specific details of a particular equipment.

Page 8

07/05/2020

User Manual – AB_AC

Page 8

R&D Digital Seville

Before carrying out any work on the equipment the user should be familiar with the

THE EQUIPMENT.

WARNING

Before working with the terminal of connection, the device must be turned off and disconnected

contents of this Safety chapter and the ratings on the equipment’s rating label.

THE SAFETY SECTION MUST BE READ BEFORE STARTING ANY WORK ON

1.2 Introduction to Safety

The information in the Safety Section of the equipment documentation is intended to ensure that

equipment is properly installed and handled in order to maintain it in a safe condition. It is assumed

that everyone who will be associated with the equipment will be familiar with the contents of that

Safety Section, or this manual.

When electrical equipment is in operation, dangerous voltages will be present in certain parts of the

equipment. Failure to observe warning notices, incorrect use, or improper use may endanger

personnel and equipment and also cause personal injury or physical damage.

of the feeding.

Proper and safe operation of the equipment depends on appropriate shipping and handling, proper

storage, installation and commissioning, and on careful operation, maintenance and servicing. For

this reason only qualified personnel may work on or operate the equipment.

Qualified personnel are individuals who:

• Have read and understood the information on the device and its user manual.

• Are familiar with the installation, commissioning, and operation of the equipment and of the

system to which it is being connected.

• Are able to safely perform switching operations in accordance with accepted safety engineering

practices and are authorized to energize and de-energize equipment and to isolate, ground,

and label it.

• Are trained in the care and use of safety apparatus in accordance with safety engineering

practices.

• Are trained in emergency procedures (first aid).

It is necessary to consider that the documentation of the device collects the instructions for its

installation, set up and operation. However, the manuals could not cover all the possible

circumstances neither include specific information on all the details.

In case of questions or specific problems, contact with his office of sales Schneider Electric or with

the center of attention to the customer and request the necessary information.

Page 9

User Manual – AB_AC

07/05/2020

R&D Digital Seville

Page 9

IEC symbol associated to a DANGER or WARNING

Symbol associated with a risk alert. The user must

ANSY symbol associated to a DANGER or

Protective earth

Associated symbol to the protective ground

Functional earth

Associated symbol to the functional ground

This symbol indicates that the equipment has been

This symbol indicates that, at the end of its life, this

The equipment has been designed and

Direct Voltage

Symbol of direct voltage (VDC).

Alternate Voltage

Symbol of alternate voltage (VAC).

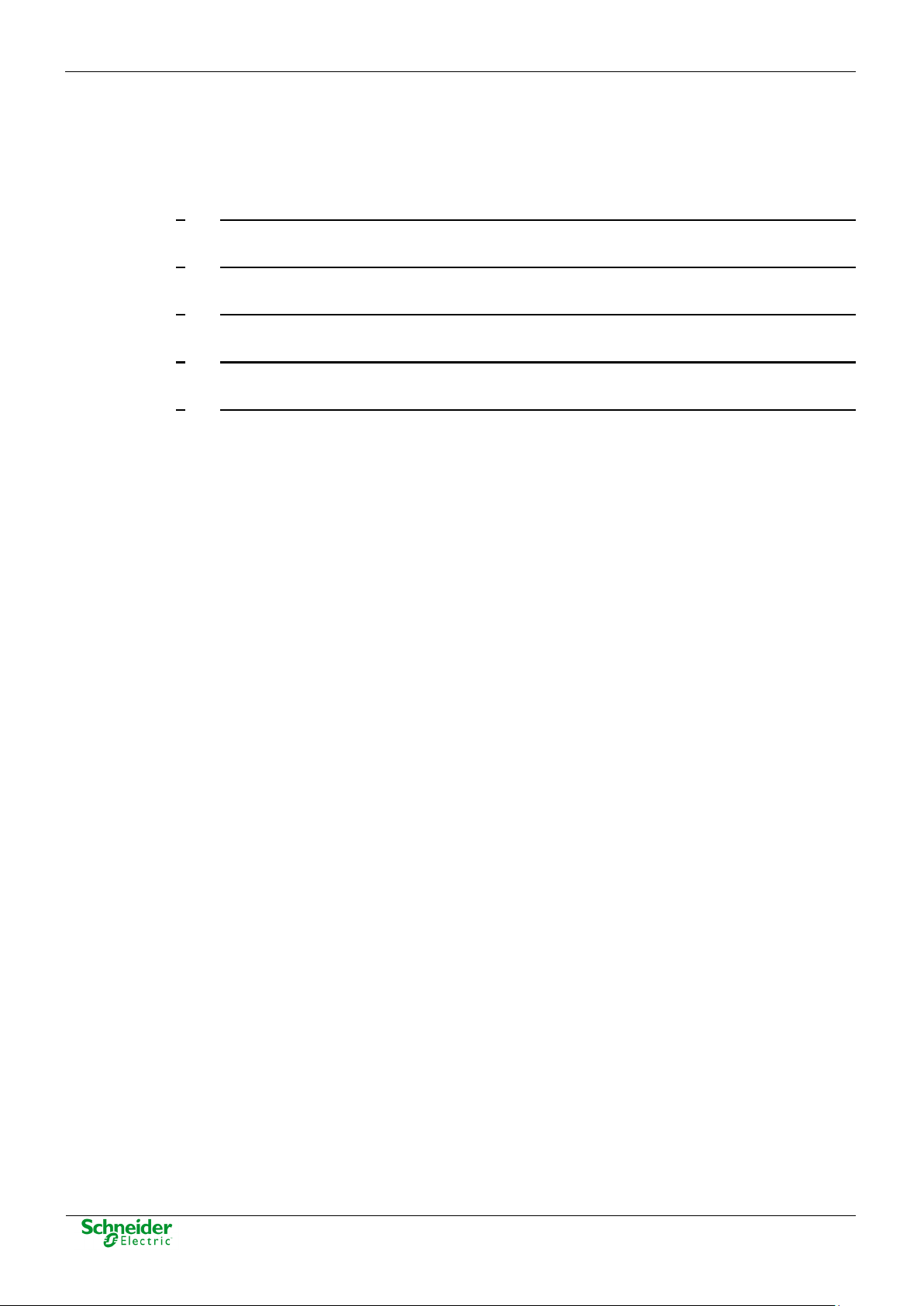

1.3 Symbols and Labels on the Equipment

For safety reasons the following symbols and external labels, which may be used on the equipment

or referred to in the equipment documentation, should be understood before the equipment is

installed or commissioned.

Table 1 – Symbols.

Symbol Associated Text Description

Possibility of electric

chock

Caution, read the manual.

Possibility of electric

chock

connection

connection

CE Mark

Electronic device. Special

instructions must be

follow for discard it.

message indicating that there is an electrical risk.

Failure to follow these instructions could cause

damage to people or death.

read the manual before handling the equipment.

WARNING message indicating that there is an

electrical risk. Failure to follow these instructions

could cause damage to people or death.

connection. See paragraph 1.5.1 in this manual.

connection. See paragraph 1.5.2 in this manual.

developed in compliance with all applicable

European Directives.

module must be discarded according to the WEEE

Directive (Waste Electrical and Electronic

Equipment).

Compliant with RoHS.

1.4 Installation, Setup and Operation

There are several acquisition blocks in Saitel DR that use dangerous tensions (> 50 V). The user is

responsible to check that the characteristics of each device are adapted and convenient for his

installation. The user should read the instructions of installation before proceeding to the use or

maintenance of the devices. Not following these instructions can be dangerous for the people and

the devices.

Not following these instructions can be dangerous for the people and the devices.

manufactured according to RoHS Directive

(Restriction of Hazardous Substances).

Page 10

07/05/2020

User Manual – AB_AC

Page 10

R&D Digital Seville

Devices that handle dangerous tensions are marked with a sticker on the front label (size: 12,5

WARNING

If this type of cabinet isn't available, a barrier must be installed in order to avoid an accidental

DANGER

mm). This label must be visible all the time while the module is installed on the DIN rail.

The following products handle dangerous tensions:

• HU120: High-performance CPU with acquisition (P/N M590xx000x).

• HU_AF: Advanced head unit with acquisition (P/N M503xx3x0x and P/N M503xx4x0x). For

other part numbers, depending on the voltage handled by the equipment connected to the

digital outputs (voltage > 50 V), this module must be marked with an electric risk label. It will

not be marked on factory.

• AB_DI: Digital inputs module (P/N: M55520000x, M55530000x and M55540000x).

• AB_DIDO: Input and output digital module (P/N M5722x000x, M5723x000x and M5724x000x).

For other part numbers, depending on the voltage handled by the equipment connected to the

digital outputs (voltage > 50 V), this module must be marked with a electric risk label. It will not

be marked on factory.

• AB_AC: Direct measurements module (P/N M562x0000x).

• AB_DO: This module does not handle high voltages, it will not be marked at the factory. This

module must be marked to inform about the risk when some equipment that manage voltage

higher than 50 V are connected to digital outputs.

It is recommended to install the RTU inside a cabinet with a key. This cabinet only should be

opened by a qualified person.

contact with these dangerous elements. This barrier only should can be removed using a

special tool.

If the barrier has to be removed in order to access to equipment, personnel responsible for the

task must be sure that the barrier is installed again when the task is finished.

While the RTU is accessible for a user, all people must follow all instructions to prevent

electrical risk or discharges.

Not following these instructions can give like result that the device do not work properly

or even can damage to the people or devices.

An electrical risk symbol with enough size must be included on the cabinet’s door or

on the barrier.

The following image shows an example:

Figure 1 - Barrier of protection for elements with dangerous voltages.

Page 11

User Manual – AB_AC

07/05/2020

R&D Digital Seville

Page 11

NOTICE

Terminals will not be accessible to the user directly once it has made the installation of the

WARNING

Don’t use liquid products of cleanliness due to the presence of active parts.

WARNING

connected to this screw.

WARNING

All devices with high voltage must be disconnected before dismount a module from the DIN rail.

device. The cabinet will have to remain closed with key or the screen of installed protection.

The cabinet or installation must have a general switch placed just in the cable entry of the

installation (see paragraph 1.7.1 )

For the cleaning of the equipment, it is recommended to remove the power and to use only a dry

cloth by the surface when it detects excessive presence of dust or any element deposited on the

surface.

Because of the variety of uses of the product, the managers of the application and use of this

device of control will have to take the measures to ensure the fulfillment of all the requests of

security and provision of each application. The requests do reference to the applicable laws,

regulations, codes and standard.

1.5 Earthing

Before energizer the device, it has to be placed to earth properly such as it indicates in section

1.5 . When installing the device, ground is the first thing that should be connected and the last

one that should be disconnected.

Saitel can need put to earth for two distinct needs:

• For purposes of electrical safety (Protective Earth, PE).

• Improve the behavior in EMC and derive perturbations to earth (functional Earth).

1.5.1 Electrical Safety

Only qualified personnel, with knowledge about hazards associate with electrical equipment is

allowed to install Saitel DR. In general, the installation will be following IEC 61010-1

recommendations in order to be compliant with this norm.

The modules must be installed on a metallic DIN Rail which is fixed on a metallic

surface. This metallic surface must have an M4 screw marked with this symbol.

According to the norm IEC 61010-1, the ground of the cabinet or installation must be

Saitel DR modules have a metallic enclosure offering protection for isolation faults. Earthing is

done by the metal rail fixing clip.

A dedicated connection with green/yellow wire should be used to have electric continuity to the

installation protective earth. Use a wire with adequate section according to IEC 61010.

Figure 2 - Yellow and Green cable for earthing.

Page 12

07/05/2020

User Manual – AB_AC

Page 12

R&D Digital Seville

WARNING

According to Electrical Safety:

NOTICE

The DIN rail must have terminals of earthing (of yellow and green color) necessary to connect

The design and installation of the cabinet is responsible for compliance with all the existing

international and national electrical codes concerning protective grounding of any device.

• The screw for ground must be exclusive for this use.

• The power voltage must be supplied by a power supply that offers double or reinforced

insulation against high voltages (higher than 50 V).

1.5.2 Functional Earth (EMC)

In this case the main rule is that the connection has to do with wires of the lower possible length to

the screen or connection of put to earth nearer. In this case the section of the driver is not notable,

is more, it advises that the use of flat wires or flexible conductive bands for a good behavior EMC.

the terminals of PE (if it is present).

Figure 3 - Terminal for functional earth (EMC).

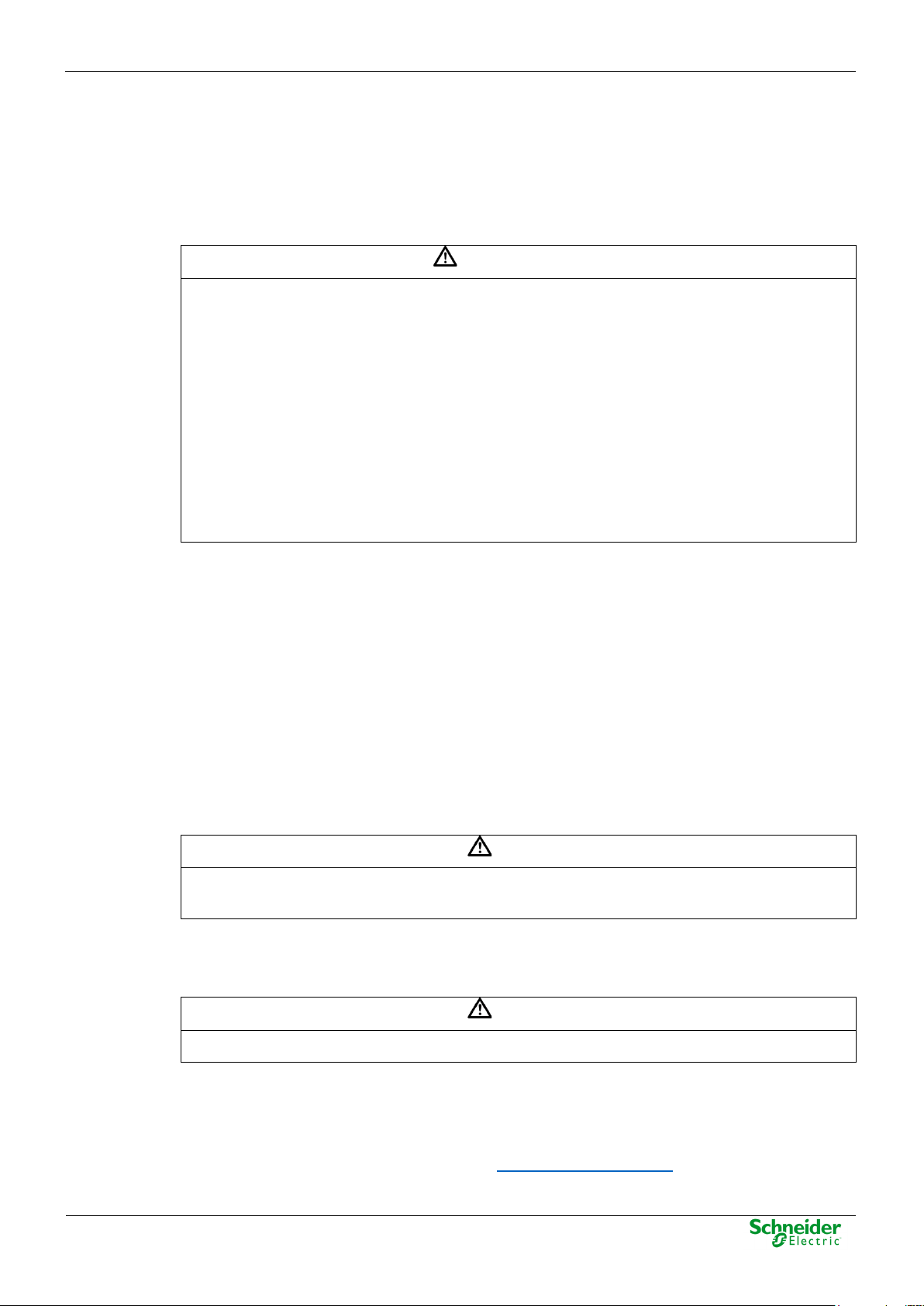

All Saitel DR modules with power or polarization connector have an exclusive terminal for earthing

EMC. These modules are HU120, HUe, HU_A, HU_AF, XU, AB_DO, AB_DIDO and AB_SER with

external polarization.

Figure 4 - Example of earthing for EMC.

Page 13

User Manual – AB_AC

07/05/2020

R&D Digital Seville

Page 13

WARNING

The enclosure ONLY should be removed when is strictly necessary, because this action has a

WARNING

The connection / disconnection switch must be installed in a fixed element (for example the wall

WARNING

This equipment has been designed ONLY for indoor use.

1.6 Handling Electronic Components

Like any electronic device, Saitel is susceptible to receive electrostatic discharges during the

handling. It is necessary to take the usual measures to minimize this risk, since serious damage to

the equipment can be caused, which may not be detected immediately but which may affect the

reliability of the product.

risk for the equipment:

• Before removing the enclosure, the operator must be equipotential with the equipment.

• Avoid touching the electronic. The board must be always manipulated for the edges.

• If the equipment has to be passed between two persons, both must be equipotential.

• Put the module always on an antistatic surface or on a surface equipotential with you.

• During the storage and transport, the module will remain in the packaging.

Not following these instructions can give like result that the device do not work properly

or even can damage to the people or devices.

1.7 Technical Specifications for Safety

1.7.1 Protective Elements

The cabinet's engineering and installation must include a general automatic switch next to the

cables' input in the cabinet; once the door is opened, high voltages must be interrupted inside. This

switch must be located at a place which is not accessible by a third person while the operator is

using the boards in the cabinet.

Moreover, the installation will incorporate a circuit breaker of 5A next to the cabinet protecting it

from possible overcurrent in the power supply.

Both switches will be labeled with the symbol O as "Off" and I as “On”.

of the cabinet) and it mustn’t break any earthing wire.

1.7.2 Environmental Conditions

The protection degree of the device is IP20.

If it is necessary for his use in some external surroundings, it has to mount in a cabinet or specific

accommodation that contributes a degree of protection IP54, protected against the dust and water.

The electronic cards of the modules will be able to be tropicalized or no according to the option of

setting chosen. The tropicalized used is the AVR80, of the company ABchimie. It can consult all the

technical information of this type of finishing in http://www.abchimie.com/

Other data to take into account about the environmental are:

.

Page 14

07/05/2020

User Manual – AB_AC

Page 14

R&D Digital Seville

WARNING

According to the standard 60950-1, all electrical safety tests have been done in an

NOTICE

On the “Technical data” zone, you can see relevant information about the input and output

• Altitude until 2000 m.

• Operation temperature range: Between -40 ºC and 70 ºC. (IEC 60068-2-1 and IEC 60068-2-2).

environmental temperature range of -40 ºC to 60 ºC. For higher temperature (> 60 ºC), the

module must be handled with care, since the metal surface could reach a dangerous

temperature for the user.

• Maximum relative humidity of 95%. (IEC 60068-2-30)

• Degree of pollution II. (IEC 60255-5)

• Overvoltage transitory until levels of Category III. (IEC 60255-5)

1.7.3 Storage Conditions

The continuous exhibition to some high levels of humidity during the storage can cause damages

to the electronic components and reduce the useful life of the device.

We recommend that, in the enclosure of storage, the relative humidity do not exceed 50%.

Before the installation of an electrical equipment, it is recommended to leave the necessary time for

the acclimatization of the environmental temperature.

1.8 Technical Label

Each Saitel product includes a technical label with the following information:

Figure 5 - Technical label.

voltage in the module. Any voltage greater than 50 V must be consider as a high voltage.

1.9 Packing and Unpacking

All Saitel modules are packaged separately in their own carton box and shipped inside outer

packaging. Use special care when unpacking the device. Don’t use force.

Page 15

User Manual – AB_AC

07/05/2020

R&D Digital Seville

Page 15

NOTICE

Our products leave our factory in closed, sealed original packaging. If at receipt of the delivery

the other elements, and each one must be recycled according to the local regulation.

the transport packaging is open or the seal is broken, the confidentiality and authenticity of the

information contained in the products cannot be ensured.

The design revision and manufacturing options can be determined using the P/N included in the

packaging label on packaging.

After unpacking the device, inspect it visually to be sure it is in proper mechanical condition.

If the product needs to be shipped, the original packaging must be used, including foams and the

carton box. If the original packaging is no longer available, make sure that the packaging used is

according to ISO 2248 specifications for a drop height 1 m.

1.10 Decommissioning and Disposal

When the product is marked with this symbol, it means that, at the end of its life

cycle, you mustn't dispose the product together with habitual residues. To avoid the

possible damage to the environment or to the human health that represents the

uncontrolled elimination of residues, please, separate the battery (if there is one) of

Page 16

07/05/2020

User Manual – AB_AC

Page 16

R&D Digital Seville

2 General Description of AB_AC

Page 17

User Manual – AB_AC

07/05/2020

R&D Digital Seville

Page 17

Content

2 GENERAL DESCRIPTION OF AB_AC ................................................................... 16

2.1 SAITEL DR PLATFORM ........................................................................................... 18

2.2 AB_AC

2.3 I

NTERFACES .......................................................................................................... 20

2.4 H

ARDWARE ARCHITECTURE ................................................................................... 20

FUNCTIONS .............................................................................................. 18

Page 18

07/05/2020

User Manual – AB_AC

Page 18

R&D Digital Seville

WARNING

Please note Saitel DR does not support hot-swapping, that is, module replacements during

2.1 Saitel DR Platform

Saitel DR is a hardware platform by Schneider Electric. It consists of a set of equipment which

have been specifically designed for real-time control and automation applications. Saitel DR is a

high-technology platform which serves Schneider Electric’s business areas.

On this hardware platform, the Baseline Software Platform is installed. This software is used in

Saitel families (Saitel DP and Saitel DR) and other Schneider Electric products.

Other features identifying Saitel DR are:

• A DIN rail is used for the mechanical installation.

• The communication between the controls units integrated in a distributed system is mainly

established by Ethernet.

• The terminal blocks for field-connection are completely built into acquisition blocks.

Figure 6 - Saitel DR.

Saitel DR’s design has been optimized to meet the most demanding requirements of multiple

sectors:

• Safety and reliability requirements for power, gas and water supply, as well as sewage

treatment plants, etc.

• Compliance with electric safety, electromagnetic compatibility, and environmental standards.

• Centralized monitoring and control of geographically-distributed systems which support

hierarchical data acquisition and sharing networks.

• Local monitoring and control with data sharing capabilities of plant-distributed equipments.

• Quick troubleshooting, including the possibility of using programmable automation execution.

operation.

2.2 AB_AC Functions

The AB_AC module is used for magnitudes measurements in alternating current networks and for

energy measurements. This module performs, as well, other typical functions in transmission and

distribution networks, for instance, synchronism checking between two power lines

(Synchrocheck).

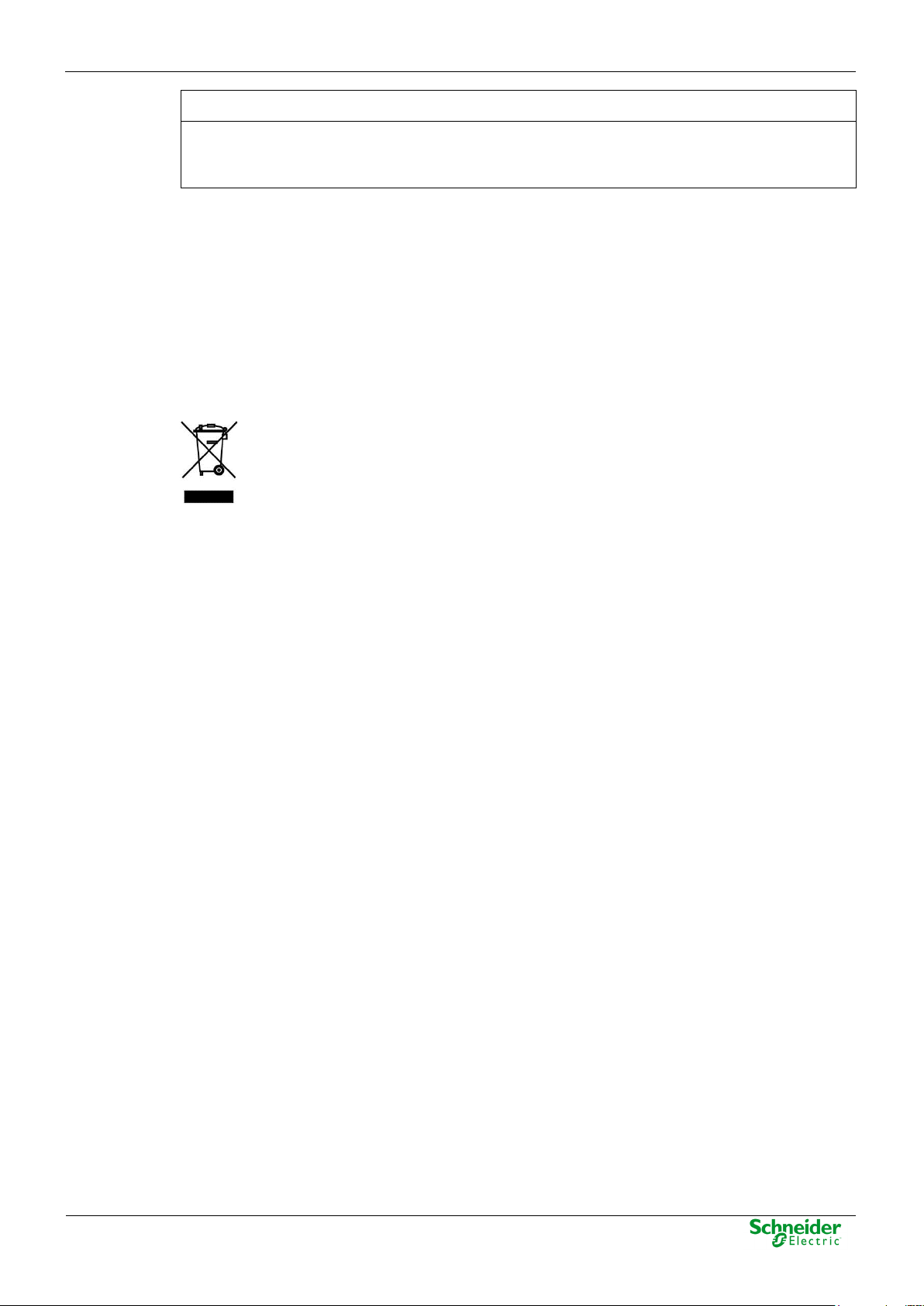

The diagram below illustrates the functional block diagram:

Figure 7 - Functional block diagram.

Page 19

User Manual – AB_AC

07/05/2020

R&D Digital Seville

Page 19

WARNING

If a calibration is performed on the channels, the factory calibration will be deleted.

Power Supply

The AB_AC module receives its power supply through the CAN communications bus.

Through this general power supply, the polarization is supplied internally to the digital inputs and

outputs.

The AB_AC module has a consumption of 2 W at 25 ºC.

Digital Input and Output

The direct measurement module integrates a digital input and a digital output with the adequate

protection elements.

Currently, these two signals are reserved for Synchrocheck aplication, so if this functionality is not

selected, neither the input or the output should be wired.

Analog Inputs

The AB_AC module allows connecting:

• 3 independent voltage inputs.

• 3 independent current inputs.

• An additional input for the neutral current line.

All signals are connected usin 2-wire connectors.

The system allows processing signals for a nominal frequency of 50 or 60Hz. The user can select

the frequency using Easergy Builder.

Each channel is protected separately against electromagnetic disturbances.

The user can calibrate these channels using the console connection available in all HU types and

Saitel Webtool (only advanced HUs).

Field Signals Adaptation Block

This block contains all the required elements to adapt the field signals to the value ranges used by

this processing unit. It also provides the required protection elements for the galvanic isolation of

each channel.

Technical data for A1 ordering options are specified in chapter “5 Technical Specification Table”.

Other values are available, upon request.

Page 20

07/05/2020

User Manual – AB_AC

Page 20

R&D Digital Seville

Processing Block

The processing block filters the analog signals coming from the adaptation block and, then, it

digitalizes them at a 6.4 kHz frequency (for a 50Hz electric line frequency) and at a 7.68 kHz

frequency (for a 60 Hz electric line frequency).

Control Block

This block manages the communications through the internal bus, as well as the storage of the

module´s calibration parameters.

2.3 Interfaces

Following interfaces are available in this module:

• 1 removable terminal block to connect three voltage inputs.

• 1 removable terminal block to connect one digital output.

• 1 removable terminal block to connect one digital input.

• 1 screw terminal block to connect three current inputs and one neutral (homopolar) current.

• 8 LED indicators.

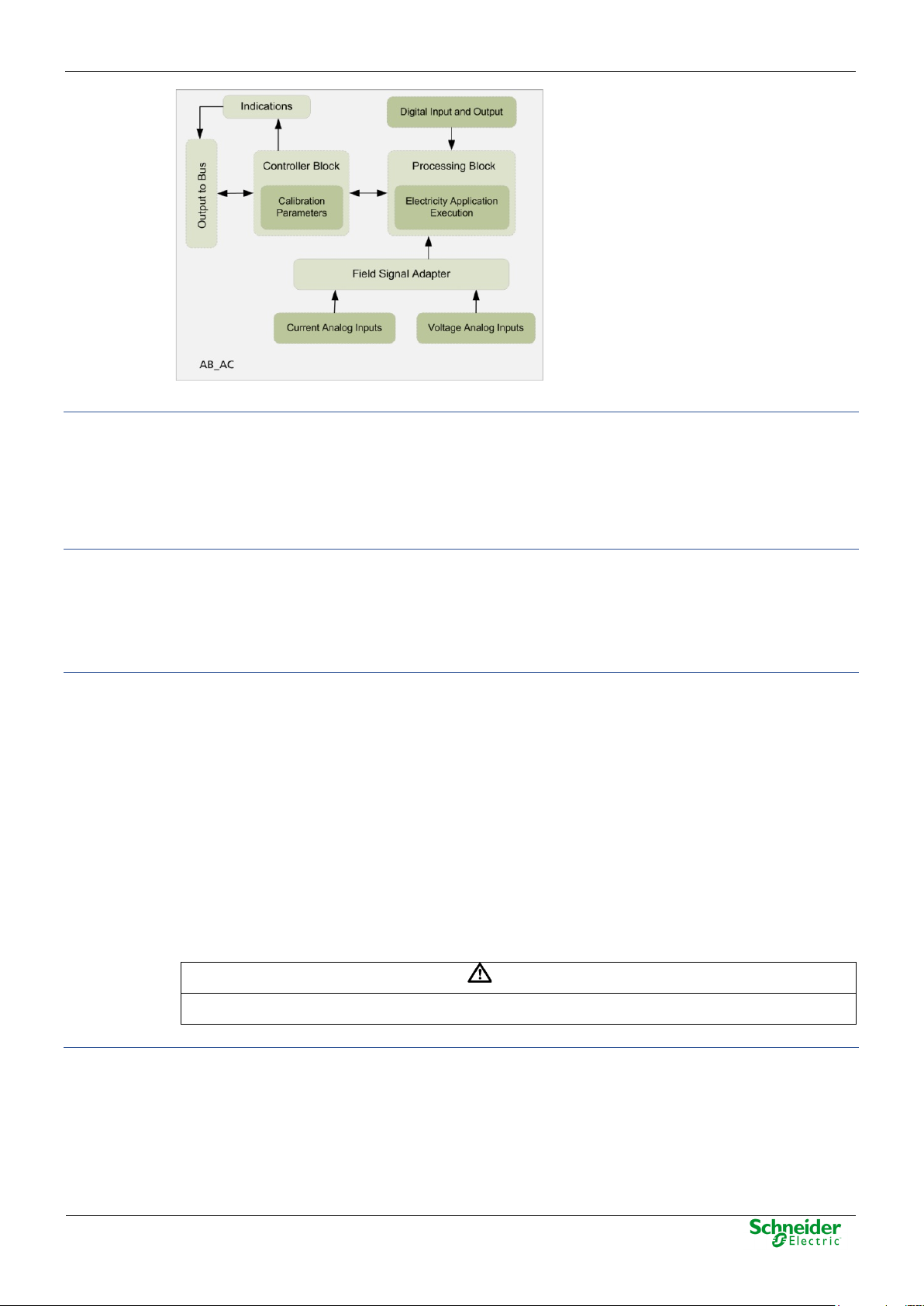

Figure 8 - AB_AC - Front panel.

2.4 Hardware Architecture

The P/N for this module is the following one:

Figure 9 - AB_AC P/N.

Ordering options:

• (A1) Voltage Inputs: 110 V

• (A2) Voltage Inputs: 400 V

(Phase – Phase).

AC

(Phase – Phase).

AC

Page 21

User Manual – AB_AC

07/05/2020

R&D Digital Seville

Page 21

Indicators

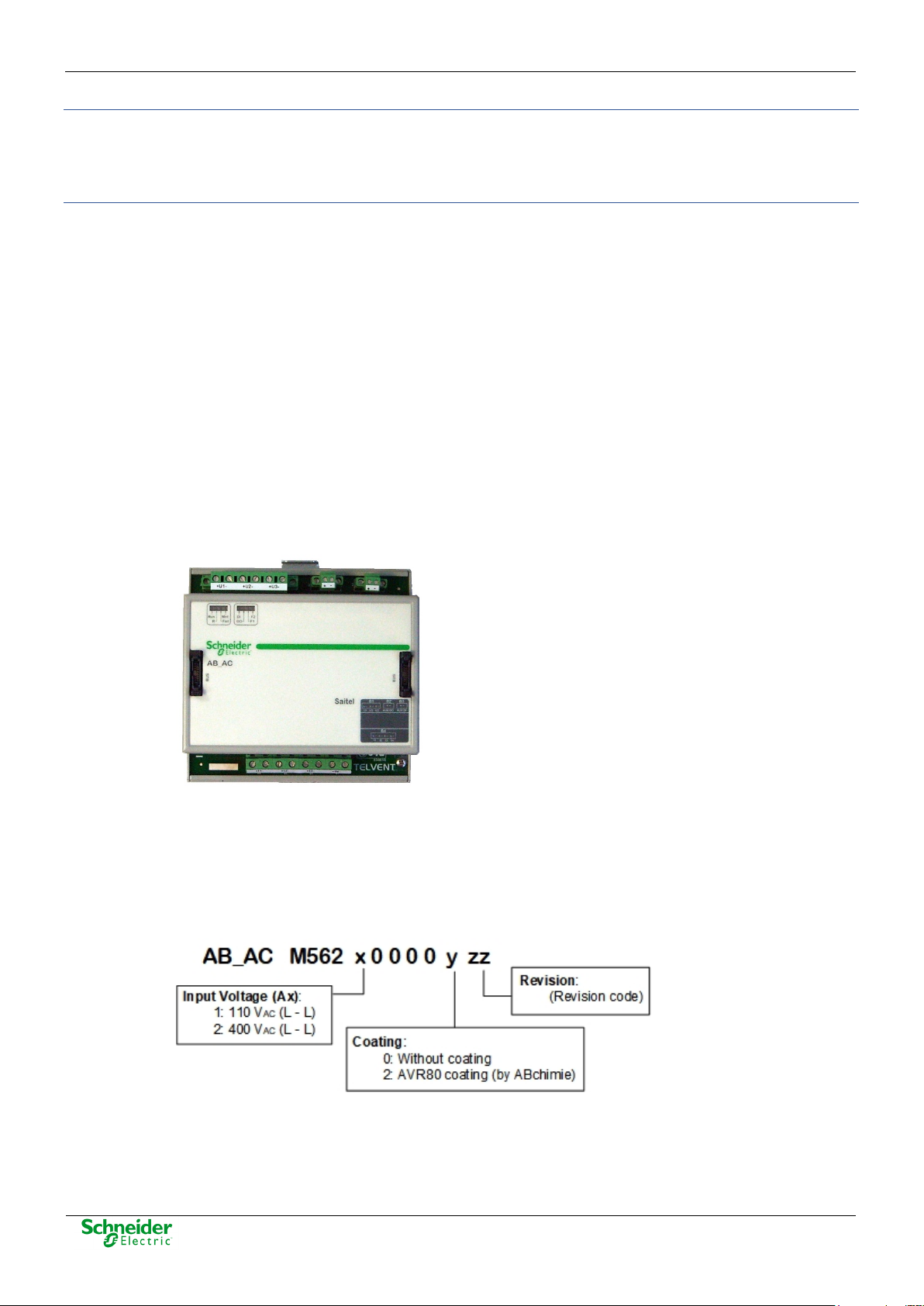

The following figure illustrates the AB_AC hardware blocks diagram:

Figure 10 - AB_AC - Hardware blocks diagram

There are 8 LED indicators on the module’s front panel which provide information about the module

and the features.

Section 3.3 provides detailed information about the operation of each LED.

Voltage Inputs (B1) and Current (B4) Inputs

Both voltage and current inputs are connected to the module by means of screw terminals. The B1

terminal block includes six terminals: two for each voltage input whereas the B4 terminal block

includes eight terminals: two for each phase current and the remaining two for the neutral current

Digital Input and Output (B2 and B3)

• The digital output is a voltage free contact.

• The digital input is only for syncrocheck applications and must be polarized with 24 V.

These terminal blocks are only used with Synchrocheck. There are several options to wire them to

signals. Project’s engineers should analyze each option to apply the best solution, according the

advantages and disadvantages of each option.

Page 22

07/05/2020

User Manual – AB_AC

Page 22

R&D Digital Seville

3 Physical Mounting & Installing

Page 23

User Manual – AB_AC

07/05/2020

R&D Digital Seville

Page 23

Content

3 PHYSICAL MOUNTING & INSTALLING ................................................................ 22

3.1 INSTALLATION ....................................................................................................... 24

3.1.1 H

3.1.2 M

3.1.3 P

3.1.4 M

3.2 W

3.2.1 W

3.2.2 B

3.2.3 S

3.3 LED

ANDLING ...................................................................................................... 24

ODULE LOCATION IN THE ITB ....................................................................... 24

OWER SUPPLY REQUIREMENTS .................................................................... 24

OUNT AND DISMOUNT PROCEDURES ............................................................ 24

IRING AB_AC .................................................................................................... 26

IRING RECOMMENDATIONS .......................................................................... 26

ASIC APPLICATION WIRING ........................................................................... 26

YNCHROCHECK WIRING ................................................................................ 26

INDICATORS ................................................................................................... 29

Page 24

07/05/2020

User Manual – AB_AC

Page 24

R&D Digital Seville

The module AB_AC has hazard of electric shock, electric arc or burns. For any of these

WARNING

An electrostatic discharge might degrade electronic components or cause permanent damages.

WARNING

It is important to assure that handling is always done while the ITB elements are unpowered.

3.1 Installation

3.1.1 Handling

cases, follow these instructions:

• Only qualified operator should install this equipment. Such work should be performed only

after reading this entire set of instructions and checking the technical characteristics of the

device.

• NEVER work alone.

• Turn off all power supplying this equipment before working on or inside it. Consider all

sources of power, including the possibility of back feeding.

• Always use a properly rated voltage sensing device to confirm that all power is off.

• Start by connecting the device to the protective ground and to the functional ground.

• Screw tight all terminals, even those not in use.

Failure to follow these instructions will result in death or serious injury.

DANGER

To avoid electrostatic damage, the following precautions must be strictly followed:

• Do not touch the bus connector pins.

• If unused, keep the modules in the antistatic bag.

3.1.2 Module Location in the ITB

There is not special considerations for locating this module in the ITB.

3.1.3 Power Supply Requirements

To calculate the cabinet’s power supply requirements, you will need to consider the power

consumption of each module. The modules’ power consumptions must be added plus a safety

margin (min. 20%).

In order to avoid ITB overload, the power supply performance should also be considered (typically,

70-90%).

The power consumption data is detailed in the technical specifications table of each module.

3.1.4 Mount and Dismount Procedures

Don’t remove the flat ribbon while the ITB is powered.

All Saitel DR modules have a DIN-rail bracket at the rear side that allows mounting on a DIN rail:

Page 25

User Manual – AB_AC

07/05/2020

R&D Digital Seville

Page 25

Figure 11 - DIN rail

The mounting procedure is described below:

• Switch off the power supply.

• Attach the module’s rear bracket on the upper DIN rail.

• Press the lower front panel gently until a click confirms that the bracket is fit on the rail.

• Verifying the module is anchored firmly to the rail, although lateral movement is possible.

Figure 12 - Mounted

The module is dismounted from the DIN rail as follows:

• Switch off the power supply.

• If necessary, disconnect the bridge(s) connecting the module to the system bus.

• Holding the module by the front panel, push the upper metal tab downward. The user can

also pull the tab down using for example a screwdriver as shown in

Figure 13 - Dismount

• Pressing the tab, remove the module from the lower DIN rail.

• Once detached, the module can be removed easily.

Page 26

07/05/2020

User Manual – AB_AC

Page 26

R&D Digital Seville

NOTICE

As shown in the figure previous, the neutral wire is not wired. These pines are reserved for use

NOTICE

When Synchrocheck functionality is selected in the module, the current inputs (B4) will not be

3.2 Wiring AB_AC

3.2.1 Wiring Recommendations

The following table shows several wiring recommendations for signals, communications and power:

Table 2 - Wiring recommendation

Voltage Inputs 7 mm

Current Inputs 7 mm

Digital input 7 mm

Digital output 7 mm

3.2.2 Basic Application Wiring

If the direct measurements module is installed to acquire voltage and current measurements, the

only required wiring includes the terminal blocks for voltage and current inputs.

Voltage inputs are labeled as Vx whereas current inputs are labeled as Cx. The figure below

illustrates the wiring for B1 and B4 terminal blocks:

Figure 14 - Basic Application – B1 and B4 terminal blocks wiring.

2.5 mm²

13 AWG

2.5 mm²

13 AWG

1.5 mm²

15 AWG

1.5 mm²

15 AWG

0.5 Nm Copper

0.5 Nm Copper

0.5 Nm

Copper,

shielded

0.5 Nm Copper

Type of wire

in other applications.

3.2.3 Synchrocheck Wiring

used and, only the first two voltage inputs should be connected. You will need to wire both the

digital input (B3) and the digital output (B2).

The figure below illustrates the B1 wiring:

Page 27

User Manual – AB_AC

07/05/2020

R&D Digital Seville

Page 27

NOTICE

Figure 15 - Synchrocheck application – B1 terminal block wiring.

There are several options to implement the Synchrocheck functionality. The project’s engineers

should analyze them to apply the best solution.

Command from an AB_DO

The close command is transmitted from the relay contacts of an AB_DO.

Figure 16 - Synchrocheck application – Close command by the AB_DO.

In this case, Synchrocheck operates as follows:

The AB_DO module will execute the close command only when the signal CLOSURE_ENA

defined in coreDb is 1, indicating that both lines are in optimal conditions of synchronism.

The direct measurements module triggers the digital output at the same time that activates

CLOSURE_ENA in coreDb. The output signal will remain active, while synchronism conditions are

satisfied or the switch closure has not been detected.

When any synchronism condition fails, the direct measurements module will deactivate the digital

output , so the signal CLOSURE_ENA will be set to 0 in coreDb; therefore, the digital output will not

be activated by the AB_DO.

• Advantages:

o The close command is completely safe, since the commands transmitted from an

AB_DO are supervised. Thus, the generation of unwanted commands due to a

simple failure is not possible.

• Disadvantages:

o The command is conditioned by the bus management delay, database management,

logic programs, etc, so a slight and random delay might occur, even though this delay

is admissible in most cases. There are also configurable time parameters that can be

adjusted to the output activation relay.

o The presence of an AB_DO module is required.

Page 28

07/05/2020

User Manual – AB_AC

Page 28

R&D Digital Seville

It is important to note that we have to define in coreDb the CLOSURE_ENA signal. We must

always configure the required times for the correct function of this mechanism).

Command from the AB_AC module DO

The close command is transmitted directly from the relay contacts connected to the existing

AB_AC digital output.

Figure 17 - Sychrocheck application – Close command by the AB_AC.

When relay closure conditions are satisfied, the direct measurements module will activate the

digital output which is directly wired to the relay. At the time that any of the conditions of

synchronism fails or the relay is closed, the module will disable this signal.

• Advantages:

o The delays since the synchronism condition is satisfied until the relay is enabled are

minimal. This delay corresponds basically with the relay delay itself, so it is a

determinist delay. This time can be included in the configuration parameters, in order

to advance the output activation to correct for the relay delay.

o An additional AB_DO module is not required.

• Disadvantages:

o The AB_AC digital output does not integrate the sophisticated security method

available in the AB_DO outputs. Although very unlikely, a fail in the transistor when

short-circuited may generate a close command in unwanted situations. When the

output is connected to the digital input, if a fault occurs on the output, an alarm will be

activated, although it is the user who should take appropriate actions.

Combined Command (AB_DO + DO of AB_AC Module)

In this case, the two outputs, AB_DO and AB_AC modules, will be wired serially.

Figure 18 - Synchrocheck application – Close command by the AB_AC and AB_DO.

When optimal synchronism conditions are satisfied, the direct measurements module’s contact will

close and this will activate the signal CLOSURE_ENA in coreDb. Only if a close command is

Page 29

User Manual – AB_AC

07/05/2020

R&D Digital Seville

Page 29

NOTICE

This is the most recommendable option, especially if there is in the system any AB_DO with a

R

received from the AB_DO during the time when CLOSURE_ENA remains active, the command will

be completed and the switch will close.

While the AB_AC digital output is open, a close command cannot be executed from the AB_DO.

• Advantages:

o The command is very safe, as the condition is transmitted by an AB_DO command.

o The delay between the optimal condition of synchronism and the relay (AB_DO)

triggering is practically zero if the delay introduced by this relay was indicated in its

corresponding configuration parameter.

• Disadvantages:

o The presence of an AB_DO module is required.

free output.

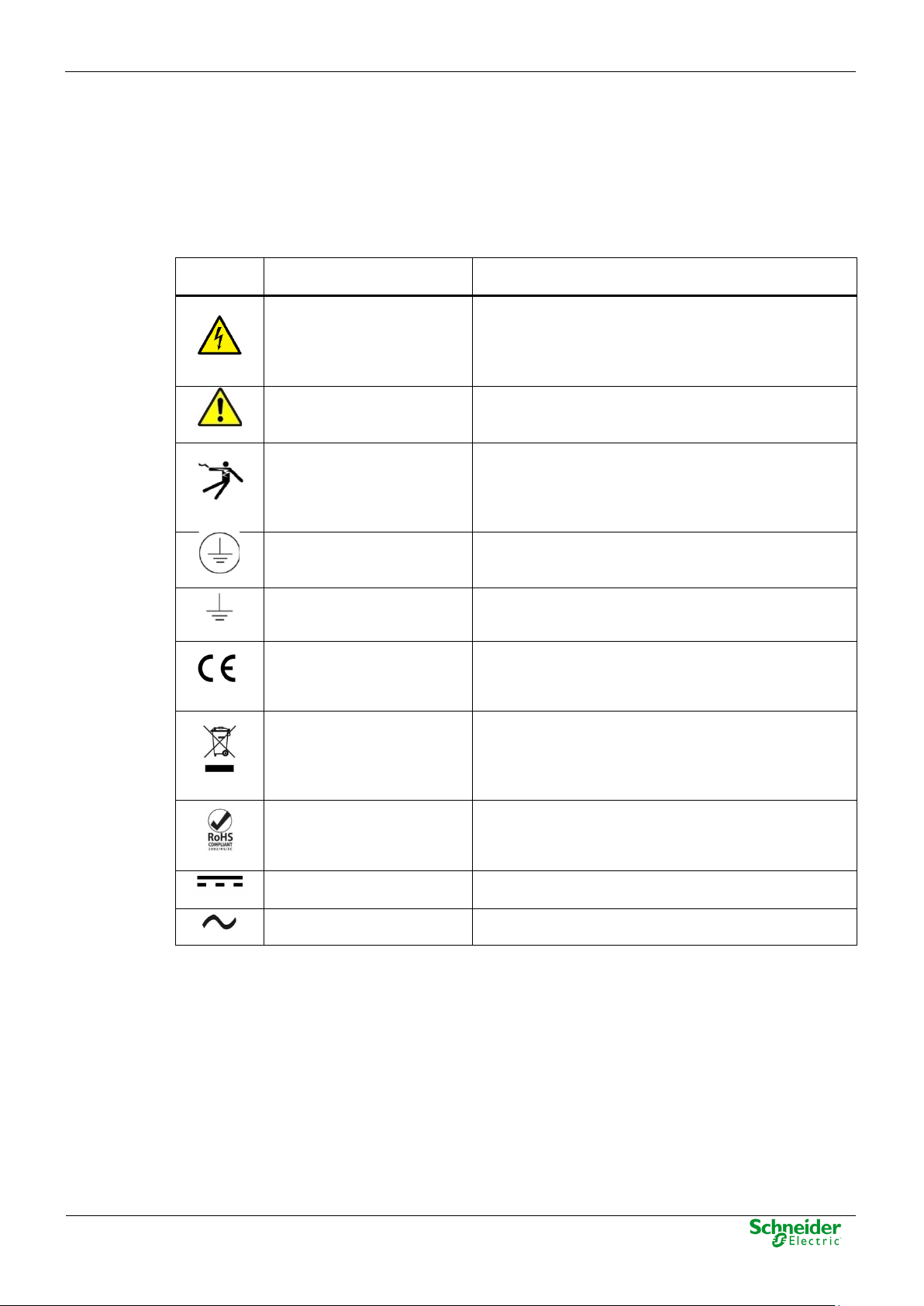

3.3 LED Indicators

The AB_AC module integrates the following indicators on the front panel:

Blinking

On

Off

Table 3 - LED indicators

LED State Description Recommended action

Run

Module working properly

Module without enough power Connect the CPU to a

correct power supply.

Not used

Fail

AB not configured or in abnormal state Configure AB_AC properly

with Easergy Builder

Failure in EEPROM

Not fail has been detected in the module

Mnt

The module is in maintenance (Flashing, addressing)

It may also indicate that the module has lost calibration

values or has not been calibrated.

For software versions 02.00.15 (AT90CAN) / 02.00.06

(DSP) and later homopolar current in not calibrated.

Homopolar current must be

calibrated.

The module is in operation

DI

Active digital input (DSP)

Inactive digital input (DSP)

DO

Synchrocheck

Closure enabled

(CLOSURE_ENA=1)

Basic application Active digital output (DSP)

Page 30

07/05/2020

User Manual – AB_AC

Page 30

R&D Digital Seville

LED State Description Recommended action

F1

F2

Synchrocheck

Closure disabled

(CLOSURE_ENA<>1)

Basic application Inactive digital output (DSP)

On firmware upgrade Upgrade completed

Undervoltage detected.

Synchrocheck

(DEATH_R DEATH_S=1 or

UNDERV=1)

On firmware upgrade Upgrading in progress

Undervoltage not detected

Synchrocheck

DEATH_R DEATH_S and

UNDERV <> 1

On firmware upgrade Upgrade completed

Synchrocheck Synchronism condition detected

On calibration Calibration in progress

On firmware upgrade Upgrading in progress

On calibration Calibration completed

Don’t disconnect the

module

Don’t finish the injection

with the signal generator

Don’t disconnect the

module

Synchrocheck

Synchronism condition not

detected

Page 31

4 Configuration & Maintenance

Page 32

07/05/2020

User Manual – AB_AC

Page 32

R&D Digital Seville

Content

4 CONFIGURATION & MAINTENANCE .................................................................... 31

4.1 ITB CONFIGURATION ............................................................................................. 33

4.2 M

4.3 M

4.4 F

4.5 C

ODULE CONFIGURATION ...................................................................................... 35

4.2.1 B

4.2.2 S

4.3.1

4.3.2 U

4.3.3 U

4.5.1 W

4.5.2 C

4.5.3

4.5.4

ASIC APPLICATION ........................................................................................ 36

YCHROCHECK .............................................................................................. 40

AINTENANCE OF MODULE VIA WEB ..................................................................... 44

WEBAPP VS WEBTOOL .................................................................................... 44

SING WEBAPP .............................................................................................. 45

SING WEBTOOL ............................................................................................ 48

IRMWARE UPDATE ............................................................................................... 52

ALIBRATION ........................................................................................................ 54

IRING FOR CALIBRATION .............................................................................. 55

ONSOLE TERMINAL ....................................................................................... 56

WEBTOOL ...................................................................................................... 57

WEBAPP ........................................................................................................ 58

Page 33

User Manual – AB_AC

07/05/2020

R&D Digital Seville

Page 33

NOTICE

To perform the operations described in this chapter, the user must be familiar with the Easergy

4.1 ITB Configuration

Builder tool. Otherwise, please refer to the tool's manual.

In the Workspace of Easergy Builder, create a new RTU using button or pressing right button

of the mouse in an empty area of the RTUs tree:

Figure 19 - Adding new RTU.

Pressing button next to the graphical ITB, you can add, remove or change the I/O modules

included on the default configuration.

The user needs understand some basic concepts about Saitel DR before configuring the

acquisition:

• An ITB is a set of acquisition blocks connected to a CPU (HU).

• An Acquisition Block or AB is a Saitel DR input/output module.

• Each acquisition block is allocated to a unique address in the ITB, the Node Number; this

number identifies both the module and its I/O points. In the case of HU_AF and HU_BI, the HU

has also a node number assigned (In this case, the HU node will take address number 1 and

cannot be changed).

• The procedure AAP (Automatic Addressing Procedure) is performed by the operator every

time an AB module is added, deleted, replaced or moved inside the ITB. It can be launched

manually or automatically by setting switch #3 in the HU module to auto (please, refer to “Saitel

DR Modules Manual”).

Figure 20 - Acquisition modules in a default configuration.

The number between parentheses next to each module's name is the node number. You can

select an AB and use buttons to change its physical position.

When “Auto Address” box is checked (by default), if you reorder, add or delete an AB, all

addresses are automatically recalculated matching their physical position in the rail. Address

number 1 is assigned to the AB closest to the HU module (for HU_AF or HU_BI, address number 1

will be attached to the HU itself).

If “Auto Address” box is unchecked, modules will retain the allocated address, ignoring any

changes made. If rechecked, the following message will appear:

Page 34

07/05/2020

User Manual – AB_AC

Page 34

R&D Digital Seville

Figure 21 - Confirmation for automatic addressing.

Select an AB (click on the AB image) and use button to remove it.

Use button to add a new AB. Select the type of AB in the following window:

Figure 22 - Adding one (or several) AB.

If “Auto Address” is checked, you can add several AB at one time. This window allows selecting

the quantity of modules to be added. If “Auto Address” in unchecked, you only can add one AB

each time and you have to select the address to be assigned.

To create a new configuration, select RTU in the tree and pulse right button of the mouse or use

button.

Figure 23 - Adding new configuration.

If the field "Create acquisition points defined in the RTU" is marked, all points of the local

acquisition of the acquisition blocks included in the default acquisition configuration associated with

the RTU will be included in coreDb.

For example, if a HUe has an ITB with a AB_AO module, if "Create acquisition points defined in

the RTU", following points are generated:

• 4 digital inputs in Status table.

• 4 analog outputs in Setpoint table.

• The supervision points of each AB module.

At the end of the operation, the new configuration will appear in the RTUs tree. We double-click on

it, and the Easergy Builder tool goes into Configuration mode.

Figure 24 - Configuration screen.

Page 35

User Manual – AB_AC

07/05/2020

R&D Digital Seville

Page 35

NOTICE

The graphical interface does not take into account if the ITB is assembled in one or multiple

Within the configuration, pressing double in claq we can change the address of the modules again.

4.2 Module Configuration

The local acquisition Device for Saitel DR is named “claq”. The main functionality of the Local

Acquisition Device Controller is supporting the communication between the inputs and the outputs

managed by the acquisition blocks and coreDb points.

The first step to configure the acquisition settings is assembling the ITB in the graphical interface,

including both the HU and the acquisition blocks in the same order as they are physically installed

in the DIN rail.

rows. The modules should always be added in the adequate order, regardless the number of

TU-XU modules that we have installed.

Currently, the following applications for AB_AC module are available:

• Basic application: The calculation of electrical measurements (voltage, current, power and

energy measurements).

• Synchrocheck. This application monitors and controls the status of a switch based on certain

conditions of synchronism.

These applications can be chosen in Easergy Builder when AB_AC is selected:

Figure 25 - New slave Saitel DR acquisition.

Applications cannot operate simultaneously in the same module.

Figure 26 - AB_AC module applications.

Page 36

07/05/2020

User Manual – AB_AC

Page 36

R&D Digital Seville

4.2.1 Basic Application

The basic application allows the calculation of electrical measurements (voltage, current, power

and energy measurements).

Figure 27 - AB_AC Basic Application.

Figure 28 - Basic application setting.

The configurable parameters for the basic application are:

Table 4 – Parameters for AB_AC (Power).

Page 37

User Manual – AB_AC

07/05/2020

R&D Digital Seville

Page 37

Identifier Name Description Default Value

ID:0 ID license ID configuration ID Configuration Menu

(button Configuration)

ID:21 Power. Reset Energy

Reset of the energy counters 0

Counters

ID:48

Voltage Transformer Ratio

(V:1)

ID:49 Phase Current Transformer

Ratio (A:1)

ID:50

Neutral Current

Transformer Ratio (A:1)

Ratio of external voltage transformer

(transducer) if applicable.

Ratio of an external phase current

transformer (transducer) if applicable

Ratio of an external homopolar

current transformer (transducer) if

100

100

100

applicable

ID configuration menu allows to configure the following features:

• Frequency: Define the power system frequency. (50Hz or 60Hz)

• INFIELD: Define the analog input filed connection topology.

o Element connection: 3 phase-neutral voltages Va, Vb, Vc and 3 phase currents Ia, Ib,

Ic.

o 3+1 elements connection: 3 phase-neutral voltages Va, Vb, Vc, 3 phase currents Ia,

Ib, Ic and the neutral current.

• PPS: Activate the acquisition of the internal PPS source provided by CAN bus for signal

acquistion

Sampling mode selection is not used in AB_AC current version.

Figure 29 - ID configuration.

Table 5 – Measurements in coreDb of AB_AC (Power).

Page 38

07/05/2020

User Manual – AB_AC

Page 38

R&D Digital Seville

Measure Description

VRrms Power. VRrms - Effective voltage R

VSrms Power. VSrms - Effective voltage S

VTrms Power. VTrms - Effective voltage T

IRrms Power. IRrms - Effective current R

ISrms Power. ISrms - Effective current S

ITrms Power. ITrms - Effective current T

AR Power. AR - Apparent power R

PR Power. PR - Active power R

QR Power. QR - Reactive power R

AS Power. AS - Apparent power S

PS Power. PS - Active power S

QS Power. QS - Reactive power S

AT Power. AT - Apparent power T

PT Power. PT - Active power T

QT Power. QT - Reactive power T

A3phase Power. A3Phase - Three-phase apparent power

P3phase Power. P3Phase - Three-phase active power

Q3phase Power. Q3Phase - Three-phase reactive power

VRS Power. VRS - Phase-Phase voltage R-S

VRT Power. VRT - Phase-Phase voltage R-T

VST Power. VST - Phase-Phase voltage S-T

Freq Power. Freq - Frequency

PFR Power. PFR - Power factor R

PFS Power. PFS - Power factor S

PFT Power. PFT - Power factor T

VNrms Power. VNrms - Effective voltage N

INrms Power. INrms - Effective current N (Direct input)

VRphase Power. VRPhase - Voltage displacement R

VSphase Power. VSPhase - Voltage displacement S

VTphase Power. VTPhase - Voltage displacement T

VNphase Power. VNPhase - Voltage displacement N

IRphase Power. IRPhase - Current displacement R

ISphase Power. ISPhase - Current displacement S

ITphase Power. ITPhase - Current displacement T

INphase Power. INPhase - Current displacement N (Direct input)

VRsec Power. VRsec - Secondary effective voltage R

VSsec Power. VSsec - Secondary effective voltage S

VTsec Power. VTsec - Secondary effective voltage T

Page 39

User Manual – AB_AC

07/05/2020

R&D Digital Seville

Page 39

Measure Description

VNsec Power. VNsec - Secondary effective voltage N

IRsec Power. IRsec: Secondary effective current R

ISsec Power. ISsec: Secondary effective current S

ITsec Power. ITsec: Secondary effective current T

INsec Power. INsec: Secondary effective current N

ERin Power. ERin - Active energy demand R

ERout Power. ERout - Active energy supply R

ERL Power. ERL - Inductive energy R

ERC Power. ERC - Capacitive energy R

ESin Power. ESin - Active energy demand S

ESout Power. ESout - Active energy supply S

ESL Power. ESL - Inductive energy S

ESC Power. ESC - Capacitive energy S

ETin Power. ETin - Active energy demand T

ETout Power. ETout - Active energy supply T

ETL Power. ETL - Inductive energy T

ETC Power. ETC - Capacitive energy T

Ein3Phase Power. Ein3Phase - Three-phase active energy demand

Eout3phase Power. Eout3Phase - Three-phase active energy supply

EL3phase Power. EL3Phase - Three-phase inductive energy

EC3phase Power. EC3Phase - Three-phase capacitive energy

The units provided are:

• Voltage: Volts (V).

• Current: Amperes (A).

• Active Power: Watt (W):

o ID:24 x ID:25 <1000 → Watt (W).

o ID:24 x ID:25 >= 1000 → Kilowatt (kW).

o ID:24 x ID:25 >= 1000000 → Megawatt (MW).

• Apparent Power: Volt-Ampere (VA).

o ID:24 x ID:25 <1000 → Volt-Ampere (VA).

o ID:24 x ID:25 >= 1000 → Kilovolt-ampere (kVA).

o ID:24 x ID:25 >= 1000000 → Megavolt-ampere (MVA).

• Reactive Power: Volt-Ampere Reactive (VAr).

o ID:24 x ID:25 <1000 → Volt-Ampere Reactive (VAr).

o ID:24 x ID:25 >= 1000 → Kilovolt-ampere Reactive (kVAr).

o ID:24 x ID:25 >= 1000000 → Megavolt-ampere Reactive (MVAr).

• Energy: Depends on the multiplication of ID:24 and ID:25:

Page 40

07/05/2020

User Manual – AB_AC

Page 40

R&D Digital Seville

NOTICE

The digital output is a dry contact solid state relay that supports up to 200 V.

o ID:24 x ID:25 <1000 → Watt/hour (Wh).

o ID:24 x ID:25 >= 1000 → Kilowatt/hour (kWh).

o ID:24 x ID:25 >= 1000000 → Megawatt/hour (MWh).

• Phase: Degrees (º).

• Frequency: Hertz (Hz).

Energy Counters Reseting

In Easergy Builder a parameter (ID: 21, "Reset energy counters") is available, which allows the

user to reset the energy counters. After activation of this parameter (either a command or using the

web tool), the module counters will be reset after a minute.

4.2.2 Sychrocheck

This application monitors and controls the status of a switch based on certain conditions of

synchronism.

Figure 30 - AB_AC Synchrocheck application.

When Synchrocheck is used, both analog and digital input/output signals have a special function.

With Synchrocheck, no current inputs are used. With respect to the three voltage inputs, only two

will be used. These two inputs must be connected to the same phase line but at both ends of the

switch. Its state will be controlled by the module, based on the user-defined synchronism

conditions.

The digital output is designed to manage the closure of the switch that interconnects the two

supervised lines, and the digital input to supervise the switch state.

The digital input is continuously checked to verify that the switch state matches the command sent.

If any discordance is detected, the module will activate an alarm to inform the user. The user will be

responsible of acting in accordance with the detected failure.

There will be discordance in case of wrong wiring or a failure in the switch.

Synchrocheck allows selecting between two working modes:

• Doubly Energized (DE mode) for energized lines in the two inputs.

Page 41

User Manual – AB_AC

07/05/2020

R&D Digital Seville

Page 41

NOTICE

In case both modes are selected, if at least one of the lines is under the voltage threshold

NOTICE

There are two different thresholds to be configured by the user, one to set the alive condition

DE Mode

SE Mode

• Single Energized (SE mode) for energized lines in only one input.

Both modes can be enabled at the same time in the same equipment.

(VMIN), the module will be working in SE mode.

In this mode, the device will continuously analyze the RMS voltages, frequencies and phase

differences between both lines. It will allow the switch closure when the phases match and the

voltage and frequency differences are within the configured limits.

It is possible to establish an additional restriction, setting up a low voltage limit, to prevent the

switch closure when one of the lines has a RMS voltage under the configured limit.

In this mode the closure permission command will be sent when the line conditions match the user

requirements. There are three possible situations:

• VRAVSD: VR input line alive and VS input line death.

• VRDVSA: VR input line death and VS input line alive.

• VRDVSD: VR and VS input lines death.

The equipment can be set to work under any combination of these three configurations. A line is

said to be alive when the RMS voltage level is above the configured threshold. Likewise, the line is

said to be death when the RMS voltage level is below the corresponding threshold.

and one to set the death condition. It should be considered that the alive condition threshold

must be always greater or equal to the death condition threshold.

Figure 31 - Synchrocheck setting.

The configurable parameters for the basic application are:

Table 6 – Parameters for AB_AC (Synchrocheck)

Page 42

07/05/2020

User Manual – AB_AC

Page 42

R&D Digital Seville

Θ

Identifier Acronym Name Default Value

ID:0 - ID configuration ID Configuration Menu

(button Configuration)

ID:4 - Synchrocheck application Sychrocheck application

Menu (button Configuration)

ID:5 (∆VTHRESHOLD) Voltage difference threshold (%). 15

ID:6 (∆fTHRESHOLD) Frequency difference threshold. 0.02

ID:7 (∆

THRESHOLD)

Instantaneous phase difference

0.17453

threshold.

ID:8 (VDEAT H) Undervoltage threshold for SE

30

mode.

ID:9 (VALIVE ) Alive threshold for SE mode. 50

ID:10 (VMIN)

Minimum voltage threshold for DE

40

mode.

ID:11 (TMAN_T IMEOUT) Timeout for manual

10000

synchronization in DE mode.

ID:12 (TSEMAN) Validation time for SE mode. 10

ID:13 (TDIG) System latency time. 3

ID:14 (TSWITCH) Relay latency time. 5

ID:15 - Proportional Constant PID 10

ID:16 - Integral Constant PID 0.5

ID:17 - Derivate Constant PID 10

ID:18 - Relay Status 1

ID:19 - Automatic or Manual Mode 1

ID:20 - Enable Operation in Manual Mode 0

ID configuration menu allows to configure the following features:

• Frequency: Define the power system frequency. (50Hz or 60Hz)

• INFIELD: Define the analog input filed connection topology.

o element connection: 3 phase-neutral voltages Va, Vb, Vc and 3 phase currents Ia, Ib,

Ic.

o 3+1 elements connection: 3 phase-neutral voltages Va, Vb, Vc, 3 phase currents Ia,

Ib, Ic and the neutral current.

• PPS: Activate the acquisition of the internal PPS source provided by CAN bus for signal

acquistion

Sampling mode selection is not used in AB_AC current version.

Figure 32 - ID configuration.

Page 43

User Manual – AB_AC

07/05/2020

R&D Digital Seville

Page 43

NOTICE

When setting these parameters it is very important to make sure that it always satisfies the

thres

thres

SWITCHDIG

fTT∆

∆Θ

<+

π

2

Configuration of the Synchrocheck application menu allows to configure the following features:

• DE: DE mode selection.

• SE: SE mode selection.

• VRAVSD: Closure condition with VR alive and VS death.

• VRDVSA: Closure condition with VR death and VS alive.

• VRDVSD: Closure condition with VR and VS death.

• VMIN_EN: Voltage supervision enabled for DE mode.

Figure 33 - Sychrocheck application configuration.

following condition:

TDIG+TSWITCH is the time it takes the digital output to be processed until the corresponding

relay is activated. If this time is too large it is possible that when the closure is enabled, signals

are no longer in sync. This condition is set to avoid such situations. If satisfied, it ensures that

the relay closure will occur under the synchronism condition and when the phase delay between

the two signals is minimal.

In case the configured parameters were too restrictive, and the closure condition could not be

met, the closure command will be sent when the phase difference is lower than the configured

limit.

In Synchrocheck following analog signals can be monitored:

Table 7 – Analog signals to be monitored for AB_AC (Synchrocheck)

Page 44

07/05/2020

User Manual – AB_AC

Page 44

R&D Digital Seville

NOTICE

Analog signal Description

VR RMS voltage input line VR

VS RMS voltage input line VS

FR Frequency input VR

FS Frequency input VS

AV Voltage difference VR-VS

A0 Phase delay difference VR-VS. (rad)

AF Frequency difference VR-VS. (Hz)

And indicators related to Synchrocheck application in coreDb are:

Table 8 – Indicators for AB_AC (Synchrocheck)

Indicators

CLOSURE_ENA Enables or disables the contact closing

DOFAIL Error in close command

SYNCHRO Sychronism condition between VR and VS lines

SPEED_FAST Reserved

SPEED_SLOW Reserved

DEADVR Voltage in VS below “Undervoltage threshold” (ID:8)

DEADVS Voltage in VR below “Undervoltage threshold” (ID:8)

FAILSYN No synchronism condition has been found in manual mode

UNDERV Voltage line below “Minimum voltage threshold” (ID:10)

Apart from these signals, the user should define a set of signals in Easergy Builder, which will have

the AB_AC as destination, in order to configure the operation mode as manual or automatic.

When the automatic mode is selected, the system continuously checks the conditions configured to

order the switch closure. In manual mode, this check is only performed when the ENA value is

active. This is used in maintenance mode, to monitor the system with the assurance that it will not

execute any commands.

The signals to be mapped are:

• SW_ST: Switch status. (0 open / 1 closed).

• AUX_MAN: Selection of manual (0) or automatic (1) operating mode.

• ENA: It enables the manual operating mode. (0 No operation/ 1 Operation enabled).

4.3 Maintenance of Module via WEB

4.3.1 webApp vs webTool

WebApp and Webtool are remote user interfaces for consulting, monitoring and maintenance

tasks. Once the username and password have been entered, you can access to the main window

and, depending on the web tool, several sections are available.

Page 45

User Manual – AB_AC

07/05/2020

R&D Digital Seville

Page 45

webApp has been designed to work only with the cyber security brick. This functionality is not

available in systems that don’t include the cyber security brick and doesn’t work in systems

without the external web server either. Pages are loaded dynamically according to the user’s

roles.

When use webApp, the following message is shown previously to access the tool:

Figure 34 - Disclaimer information.

Please, read this information and take it into account.

In this manual, only the information about AB_AC is shown. For more information about these

tools, please, consult the user manual for each one.

4.3.2 Using webApp

Figure 35 - Access screen.

This screen contains 5 menus:

• Home

• Monitoring & Control

• Diagnostic

• Maintenance

• Settings

The information on this page identifies the system to which the user is connected. Some of this

information can be filled in by the user:

• GPS coordinates corresponding to the substation or location where the RTU is installed.

• Image associated to the RTU. It could be useful to include a location map corresponding to the

GPS coordinates.

• Notes added by users.

• Device information: name, description, owner, …

Page 46

07/05/2020

User Manual – AB_AC

Page 46

R&D Digital Seville

• Factory information: manufacturer, model and current software version installed.

Monitoring and Control

Figure 36 - Monitoring and Control view - System information.

Please consider that the correspondent supervision points must be installed, otherwise, you will

see a warning like the one in the example above (PLC information not available).

In this section, all the mapped points in Easergy Builder can be seen. There are 4 pages for

viewing status and measurement data or for sending commands.

• Status page: For viewing the status of the indicators described in point 3.1.

• Command page: For sending change of state commands to reset fault indicators described in

point 3.1.

• Analog page: For viewing measurement values described in point 3.1.

• Setpoint page: For changing configuration parameters of the AB_AC.

From webApp go to ‘Monitoring and control’ ‘Data’ ‘Command’ and the user can see the point

mapped with Easergy Builder.

For all types of points, each page has the same format. If the user locks the signal and click in

in the “value” column, the value of the correspondent signal can be changed.

Figure 37 - Edit value (1).

If the user locks the signal and click in in the “quality” column, the value of the correspondent

signal can be changed.

Figure 38 - Edit value (2).

Page 47

User Manual – AB_AC

07/05/2020

R&D Digital Seville

Page 47

Regarding the quality information of the point:

Figure 39 - Signals Quality control

Each code of quality bit has a different meaning. See next tables to know the description of each

one.

Table 9 – Local quality bits

Values (Hexadecimal) Description

0x00000000 OK

0x00000001 There has been an overflow

0x00000002 There has been a carry on a counter or a roll-over.

0x00000004 There has been a counter adjustment.

0x00000008 Excessive changes in a digital input.

0x00000010 Locked Point (blocked)

0x00000020 Point manually replaced (manual)

0x00000040 The point has not yet been written into the database (No refresh)

0x00000080 Invalid value (Error)

0x00000100 The value of the item has exceeded Highest Limit Alarm.

0x00000200

The value of the item has exceeded High Limit Alarm.

0x00000400 The value of the point has fallen down of Low Limit Alarm.

0x00000800

The value of the point has fallen down of Lowest Limit Alarm.

0x00001000 Invalid time.

Table 10 – Quality bits from the Device

Page 48

07/05/2020

User Manual – AB_AC

Page 48

R&D Digital Seville

NOTICE

If more than one error is detected for a signal, the hexadecimal value monitored for quality bits

Values (Hexadecimal) Description

0x00000000 OK

0x00010000

0x00020000

0x00040000

0x00080000

0x00100000

0x00200000

0x00400000

0x00800000

0x10000000 Invalid time.

will result from the sum of all. For example:

0x00000001 indicates that an overflow has occurred and 0x00000002 indicates that there has

been a carry on a counter or a roll-over. The value 0x00000003 would appear monitored.

There has been an overflow.

There has been a carry on a counter or a roll-over.

There has been a counter adjustment.

Excessive changes in a digital input.

Locked Point.

Point manually replaced.

The point has not yet been written into the database.

Invalid value.

4.3.3 Using webTool

Saitel webTool is the tool used for maintenance and monitoring of Saitel RTUs which is supplied

with the baseline software platform. The values of all the coreDb signals in real-time can be

monitored through the Saitel webTool as well as the quality data related to these values.

Saitel webTool has an access control that allows differentiating the users who are able to connect.

To get the window access, please write https://< CPU IP address> in the navigation address bar.

If the browser has been correctly configured, and the remote equipment is connected to the PC,

the login window will prompt:

Figure 40 - Login window of Saitel webTool

Once the username and the password are introduced in the login window, the main workspace is

displayed:

Page 49

User Manual – AB_AC

07/05/2020

R&D Digital Seville

Page 49

Figure 41 - Initial screen of Saitel Webtool

This window shows:

• Information about the user who opened the session (Login: admin).

• Button “Exit” in order to close the current session.

• It is possible to select the language through the field “Language”.

• The main menu is located on the left side of the screen. Each button gives access to all the

information of the RTU:

Information

o Information: General information about the CPU configuration.

o Monitoring: Gives access to the coreDb tables and the values for each register and

field.

o Bins: Gives access to the devices that have been configured in the RTU.

o Network configuration: Gives information about the physical devices and rooters.

Clicking Information on the main menu, you can see general information about the system.

The following real-time information can be monitored on this menu:

• System’s Configuration

• Hardware Status

• Synchronization Status

• Software Versions

Figure 42 - Information section

Page 50

07/05/2020

User Manual – AB_AC

Page 50

R&D Digital Seville

NOTICE

If the value of the quality bit associated to the signal is “Unrefreshed” (0x00000040) or “Invalid”

Monitoring

The top area of the screen includes the following information for any signal type (go to “Monitoring

Status”, “Monitoring Command”, “Monitoring Analog” or “Monitoring Setpoint”):

Figure 43 - Status monitoring screen

The information available for all types of signals is the following:

• Point name: Signal's name in coreDb.

• Value: Current value of the signal. This value is retrieved from the signal’s source and it is

updated in Saitel Webtool according to the refresh period specified in the RT field.

• QF: Current quality flags of the value displayed for this signal

(0x00000080), the signal value will be “???”.

Clinking in “Set”, the value and the quality flag can be modified.

Figure 44 - Set Value screen

Page 51

User Manual – AB_AC

07/05/2020

R&D Digital Seville

Page 51

Each code of quality bit has a different meaning. See next tables to know the description of each

one.

Table 11 – Local quality bits

Values (Hexadecimal) Description

0x00000000 OK

0x00000001 There has been an overflow

0x00000002 There has been a carry on a counter or a roll-over.

0x00000004 There has been a counter adjustment.

0x00000008 Excessive changes in a digital input.

0x00000010 Locked Point (blocked)

0x00000020 Point manually replaced (manual)

0x00000040 The point has not yet been written into the database (No refresh)

0x00000080 Invalid value (Error)

0x00000100 The value of the item has exceeded Highest Limit Alarm.

0x00000200

The value of the item has exceeded High Limit Alarm.

0x00000400 The value of the point has fallen down of Low Limit Alarm.

0x00000800

The value of the point has fallen down of Lowest Limit Alarm.

0x00001000 Invalid time.

Table 12 – Quality bits from the Device

Page 52

07/05/2020

User Manual – AB_AC

Page 52

R&D Digital Seville

NOTICE

If more than one error is detected for a signal, the hexadecimal value monitored for quality bits

Values (Hexadecimal) Description

0x00000000 OK

0x00010000

0x00020000

0x00040000

0x00080000

0x00100000

0x00200000

0x00400000

0x00800000

0x10000000 Invalid time.

will result from the sum of all. For example:

0x00000001 indicates that an overflow has occurred and 0x00000002 indicates that there has

been a carry on a counter or a roll-over. The value 0x00000003 would appear monitored

• Blocked: This checkbox indicates whether the signal’s source is blocked or not, that is, if the

signal’s value is refreshed with the changes made to the source’s value. If blocked, the number

displayed in the VALUE field can be edited. This change can be sent to the CPU using the SET