Saitel DP

Backplane & Chassis RTU

User Manual

This manual provides general information about Saitel DP Platform, including

installation, wiring and other useful data for installers and designers.

SE-F700-USR

Publication Date (06/2020)

Read carefully the information contained in this manual before assembly, installation and use of the

equipment.

www.schneider-electric.com

30/06/2020

User Manual – Saitel DP Platform

01

30-06-2020

Initial edition.

Easergy Builder user manual

FTE-S856-MSS

webApp user manual

FTE-S856-WAT

IEC101 user manual

FTE-S854-I1D

IEC104 user manual

FTE-S854-I4D

IEC103 Master user manual

FTE-S854-I3D

Modbus user manual

FTE-S854-MBD

ISaGRAF user manual

FTE-ISD-S854

DNP user manual

FTE-S854-DNP

SOE user manual

FTE-S854-SOE

IEC61850 Ed1 user manual

FTE-S854-IEC61-1

IEC61850 Ed2 user manual

FTE-S854-IEC61-2

SM_CPU866e user manual

SE-M578-USR

SM_DI32 user manual

SE-M583-USR

SM_AI16 user manual

SE-M523-USR

SM_DO32T user manual

SE-M580-USR

SM_DO16R user manual

SE-M586-USR

SM_AI8AO4 user manual

SE-M525-USR

SM_SER user manual

SE-M581-USR

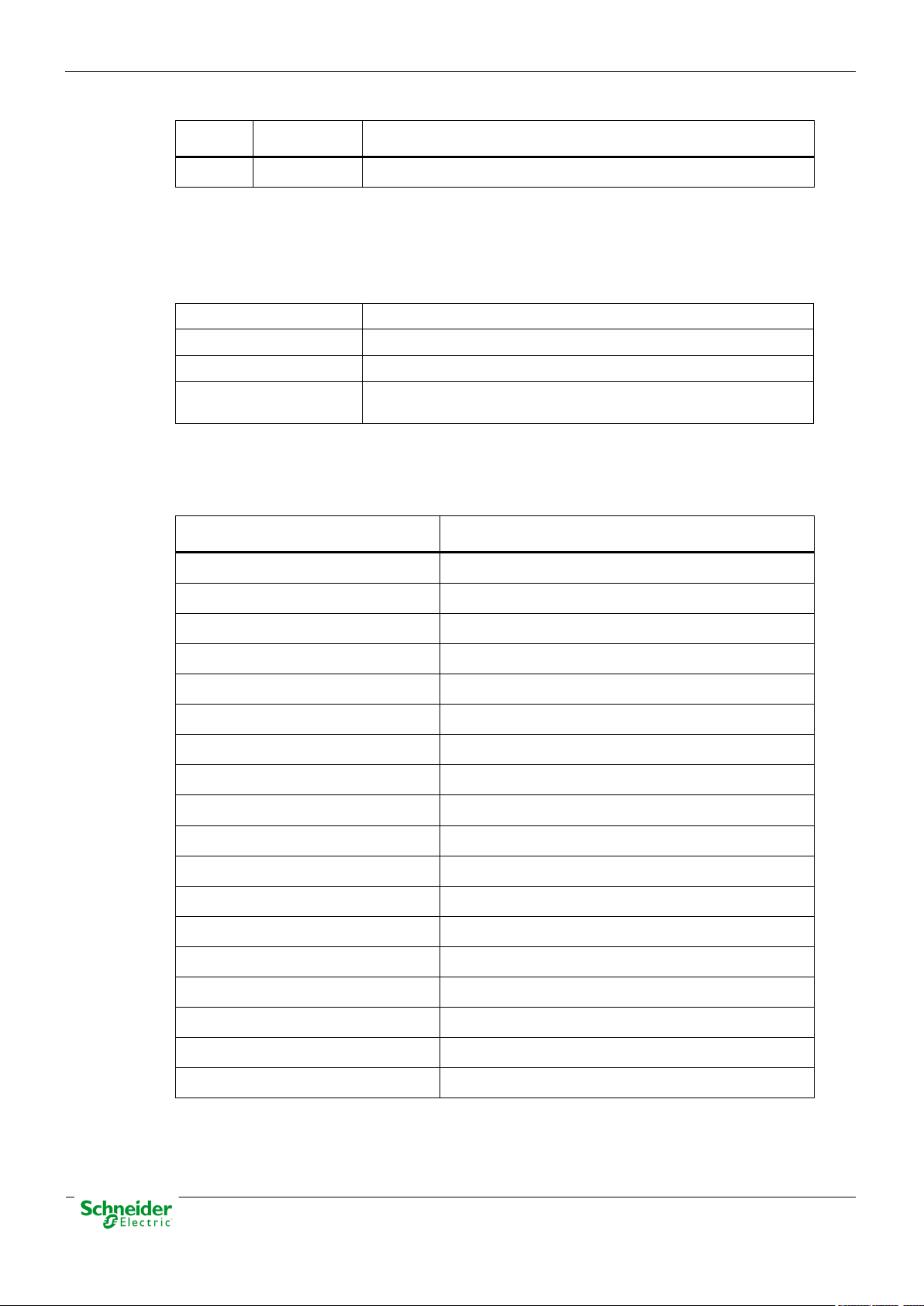

Change Control

Rev Date Description

General Information

The Saitel platform and all its components have been developed in accordance to the requirements

for a quality management system, complying with the ISO 9001:2015 Norm.

Document nº: SE-F700-USR

Revision/Date: 01 / 30-06-2020

File: Saitel DP Platform – User Manual_EN_01.pdf

Retention period:

Reference Documents

Permanent throughout its validation period + 3 years after its

cancellation.

User Manual Document Code

Pag 2

User Manual – Saitel DP Platform

30/06/2020

Software Version in this Manual

The information in this manual is valid for the software versions listed below. This information is

also valid for later versions, although some parameters may change slightly:

Module Description Version

Baseline Software Platform Baseline packaging 11.06.14

Operating System Linux 20.01.24.12.26.34

laqBinC Local Acquisition 10.00.02

thm Synchronization 06.00.02

coreDb coreDb 10.01.11

chan Channels 03.00.20

formBinC Formula 10.00.13

webServer Web server 03.03.02

webApp Web interface 01.00.27

supBinC Supervision 10.01.21

soeBinC Sequence of Events 10.00.07

ST_SER_C0.bin SM_SER firmware 01.00.08

ST_DO32T_C0.bin SM_DO32T firmware 01.00.04

ST_DI32_C0.bin SM_DI32 firmware 01.00.06

ST_AI16_C0.bin SM_AI16 firmware 01.00.03

ST_AI8AO4_C0.bin SM_AI8AO4 firmware 01.00.03

ST_DO16R_C0.bin SM_DO16R firmware 01.00.02

Pag 3

30/06/2020

User Manual – Saitel DP Platform

Content

1 SAFETY & HEALTH .................................................................................................. 5

2 SAITEL DP FAMILY ................................................................................................ 16

3 BASELINE SOFTWARE IN SAITEL DP ................................................................. 45

4 PHYSICAL MOUNTING & INSTALLING ................................................................ 58

5 CONFIGURATION & MAINTENANCE .................................................................... 99

Pag 4

User Manual – Saitel DP Platform

30/06/2020

1 Safety & Health

Pag 5

30/06/2020

User Manual – Saitel DP Platform

Content

1 SAFETY & HEALTH .................................................................................................. 5

1.1 INTRODUCTION ........................................................................................................ 7

1.1.1 I

1.1.2 P

1.2 I

1.3 S

1.4 I

1.5 E

1.5.1 E

1.5.2 F

1.6 H

1.7 T

1.7.1 P

1.7.2 E

1.7.3 S

1.8 T

1.9 P

1.10 D

NFORMATION OF SECURITY .............................................................................. 7

RESENTATION ................................................................................................ 8

NTRODUCTION TO SAFETY ....................................................................................... 8

YMBOLS AND LABELS ON THE EQUIPMENT ............................................................. 9

NSTALLATION, SETUP AND OPERATION ................................................................. 10

ARTHING ............................................................................................................. 11

LECTRICAL SAFETY ...................................................................................... 12

UNCTIONAL EARTH (EMC) ............................................................................ 12

ANDLING ELECTRONIC COMPONENTS .................................................................. 13

ECHNICAL SPECIFICATIONS FOR SAFETY .............................................................. 13

ROTECTIVE ELEMENTS ................................................................................. 13

NVIRONMENTAL CONDITIONS ........................................................................ 14

TORAGE CONDITIONS ................................................................................... 14

ECHNICAL LABEL ................................................................................................. 14

ACKING AND UNPACKING ..................................................................................... 15

ECOMMISSIONING AND DISPOSAL ......................................................................... 15

Pag 6

User Manual – Saitel DP Platform

30/06/2020

DANGER indicates a hazardous situation which, if not avoided, will result in death or serious

WARNING

WARNING indicates a hazardous situation which, if not avoided, could result in death or

NOTICE

NOTICE is used to address practices not related to physical injury. The safety alert symbol shall

WARNING

If this equipment is used in a different form from the recommended one by Schneider Electric,

the protection assured for the equipment could be compromised .

1.1 Introduction

1.1.1 Information of Security

Important information

The illustrations shown in this manual are intended for exemplary purposes. As there are variables

and requirements which depend on each particular installation, Schneider Electric will not be held

responsible for the misuse of the equipment based on the examples herein published

Read these instructions carefully and look at the equipment to become familiar with the device

before trying to install, operate, service or maintain it. In this manual you can find different types of

messages associated with situations that have different level of risk for people and / or for the

equipment.

injury.

This symbol indicates "DANGER" or "WARNING". This symbol informs of an

electrical risk that will cause personal injuries if the instructions are not followed.

This symbol is associated to a safety alert. It is used to warn of possible personal

injury hazards. The user must follow all instructions or messages associated to this

symbol to avoid possible injuries.

DANGER

serious injury.

not be used with this signal word.

Restricted Liability

Electrical equipment should be serviced and maintained only by qualified personnel. All person

who can contact the equipment must be informed and must read the chapter “Safety & Health” of

this manual.

No responsibility is assumed by Schneider Electric for any consequences arising out of the use of

this manual. This document is not intended as an instruction manual for untrained persons.

Pag 7

30/06/2020

User Manual – Saitel DP Platform

Before carrying out any work on the equipment the user should be familiar with the

WARNING

Before working with the terminal of connection, the device must be turned off and disconnected

To Keep in Mind

Electrical equipment should be installed, operated, serviced, and maintained only by qualified

personnel. No responsibility is assumed by Schneider Electric for any consequences arising out of

the use of this material.

A qualified person is who fulfill with requirements in 1.2 .

1.1.2 Presentation

This manual provides information for a safe handling, commissioning and testing. This Safety

chapter also includes descriptions of the labels on the equipment.

Documentation for equipment ordered from Schneider Electric is dispatched separately from

manufactured goods and may not be received at the same time. Therefore, this guide is provided

to ensure that printed information which may be present on the equipment is fully understood by

the recipient.

The technical data in this safety guide is typical only, see the technical data section of the user

manual for specific details of a particular equipment.

contents of this Safety chapter and the ratings on the equipment’s rating label.

THE SAFETY SECTION MUST BE READ BEFORE STARTING ANY WORK ON

THE EQUIPMENT.

1.2 Introduction to Safety

The information in this section is intended to get that equipment is properly installed and handled in

order to maintain it in safety conditions. It is assumed that everyone who will be associated with the

equipment will be familiar with the contents of that Safety section.

When electrical equipment is in operation, dangerous voltages will be present in certain parts of the

equipment. Failure to observe warning notices, an incorrect or improper use may endanger

personnel and equipment and also cause personal injury or physical damage.

of the feeding.

Proper and safe operation of the equipment depends on appropriate shipping and handling, proper

storage, installation and commissioning, and on careful operation, maintenance and servicing. For

this reason, only qualified operator may work on or operate the equipment.

Qualified operator are individuals who:

• Have read and understood the information on the device and its user manual.

• Are familiar with the installation, commissioning, and operation of the equipment and of the

system to which it is being connected.

• Are able to safely perform switching operations in accordance with accepted safety engineering

practices and are authorized to energize and de-energize equipment and to isolate, ground,

and label it.

Pag 8

User Manual – Saitel DP Platform

30/06/2020

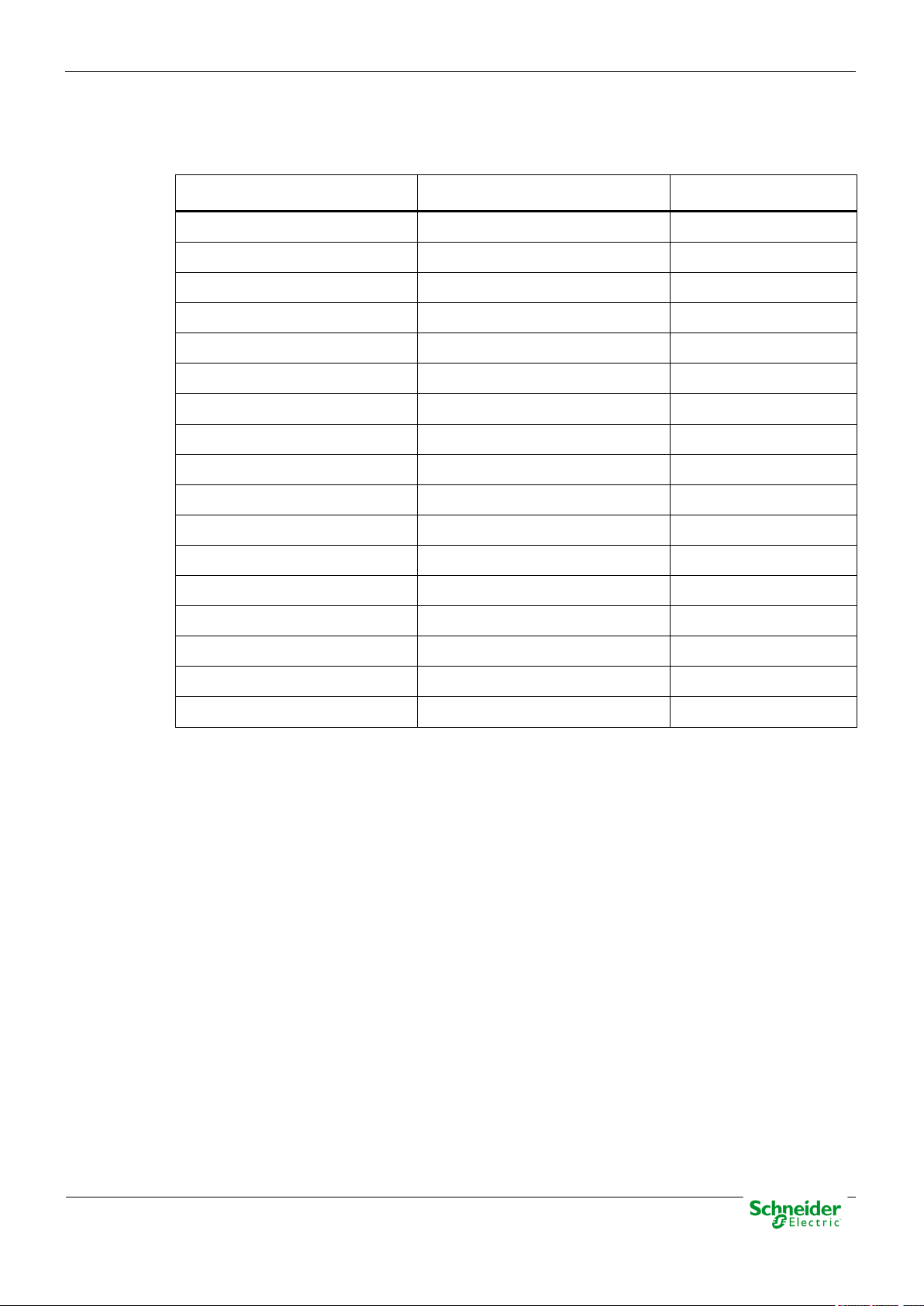

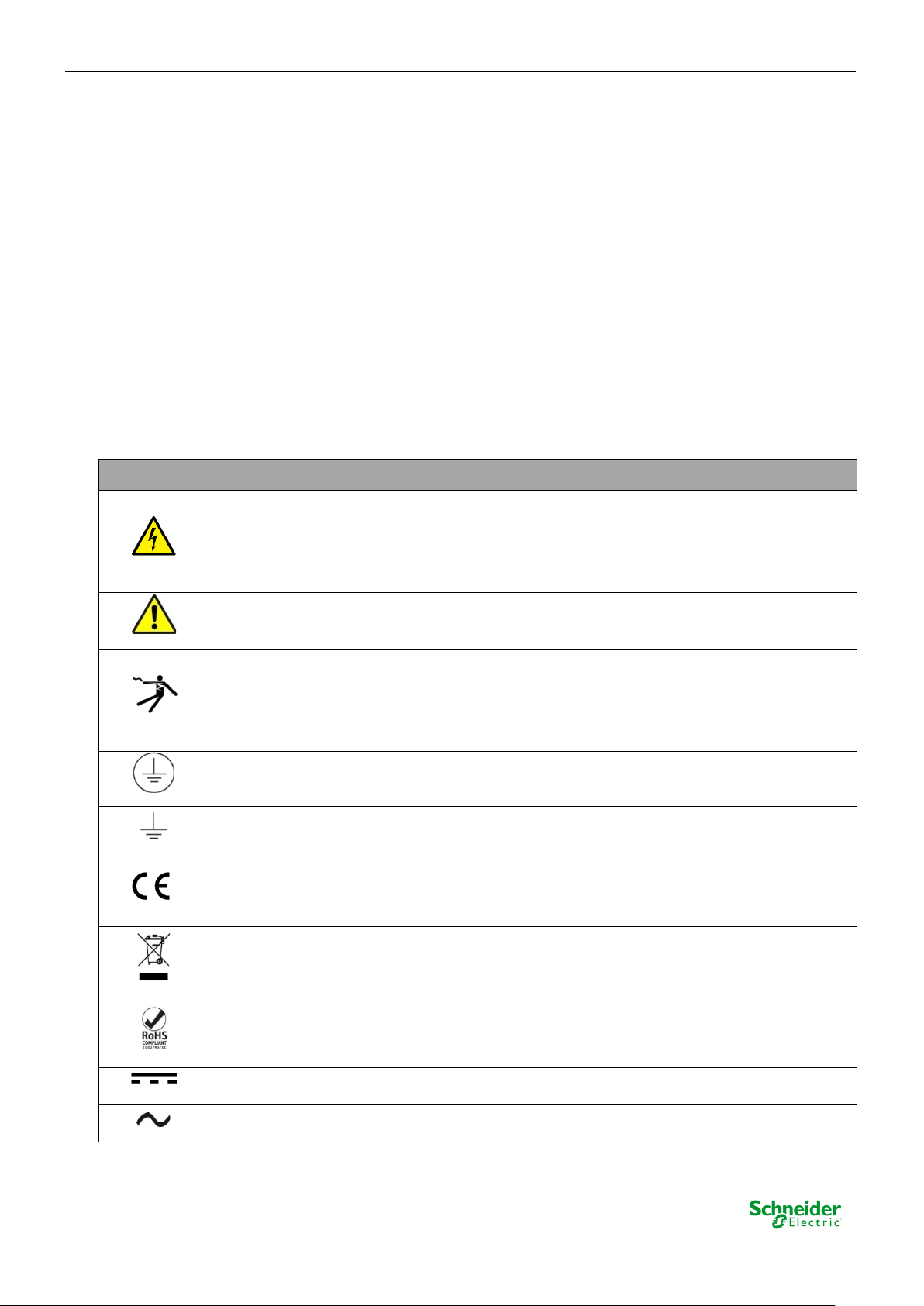

Symbol

Associated Text

Description

International Electrotechnical Commission (IEC) symbol

Symbol associated with a risk alert. The user must read

American National Standards Institute (ANSI) symbol

Associated symbol to the protective ground connection.

Associated symbol to the functional ground connection.

This symbol indicates that the equipment has been

This symbol indicates that, at the end of its life, this

The equipment has been designed and manufactured

Direct Voltage

Symbol of direct voltage (VDC).

Alternate Voltage

Symbol of alternate voltage (VAC).

• Are trained in the care and use of safety apparatus in accordance with safety engineering

practices.

• Are trained in emergency procedures (first aid).

It is necessary to consider that the documentation of the device collects the instructions for its

installation, set up and operation. However, the manuals could not cover all the possible

circumstances neither include specific information on all the details.

In case of questions or specific problems, contact with his office of sales Schneider Electric or with

the center of attention to the customer and request the necessary information.

1.3 Symbols and Labels on the Equipment

Before the equipment is installed or commissioned, the user must understand the following

symbols, which may be used on the equipment or referred to in the user documentation.

Table 1 – Symbols

associated to a DANGER or WARNING message

Possibility of electric chock

indicating that there is an electrical risk. Failure to follow

these instructions could cause damage to people or

death.

Caution, read the manual.

Possibility of electric chock

Protective earth connection

Functional earth connection

CE Mark

Electronic device. Special

instructions must be follow

for discard it.

Compliant with RoHS.

the manual before handling the equipment.

associated to a DANGER or WARNING message

indicating that there is an electrical risk. Failure to follow

these instructions could cause damage to people or

death.

See paragraph 1.5.1 in this manual.

See paragraph 1.5.2 in this manual.

developed in compliance with all applicable European

Directives.

module must be discarded according to the WEEE

Directive (Waste Electrical and Electronic Equipment).

according to RoHS Directive (Restriction of Hazardous

Substances).

Pag 9

30/06/2020

User Manual – Saitel DP Platform

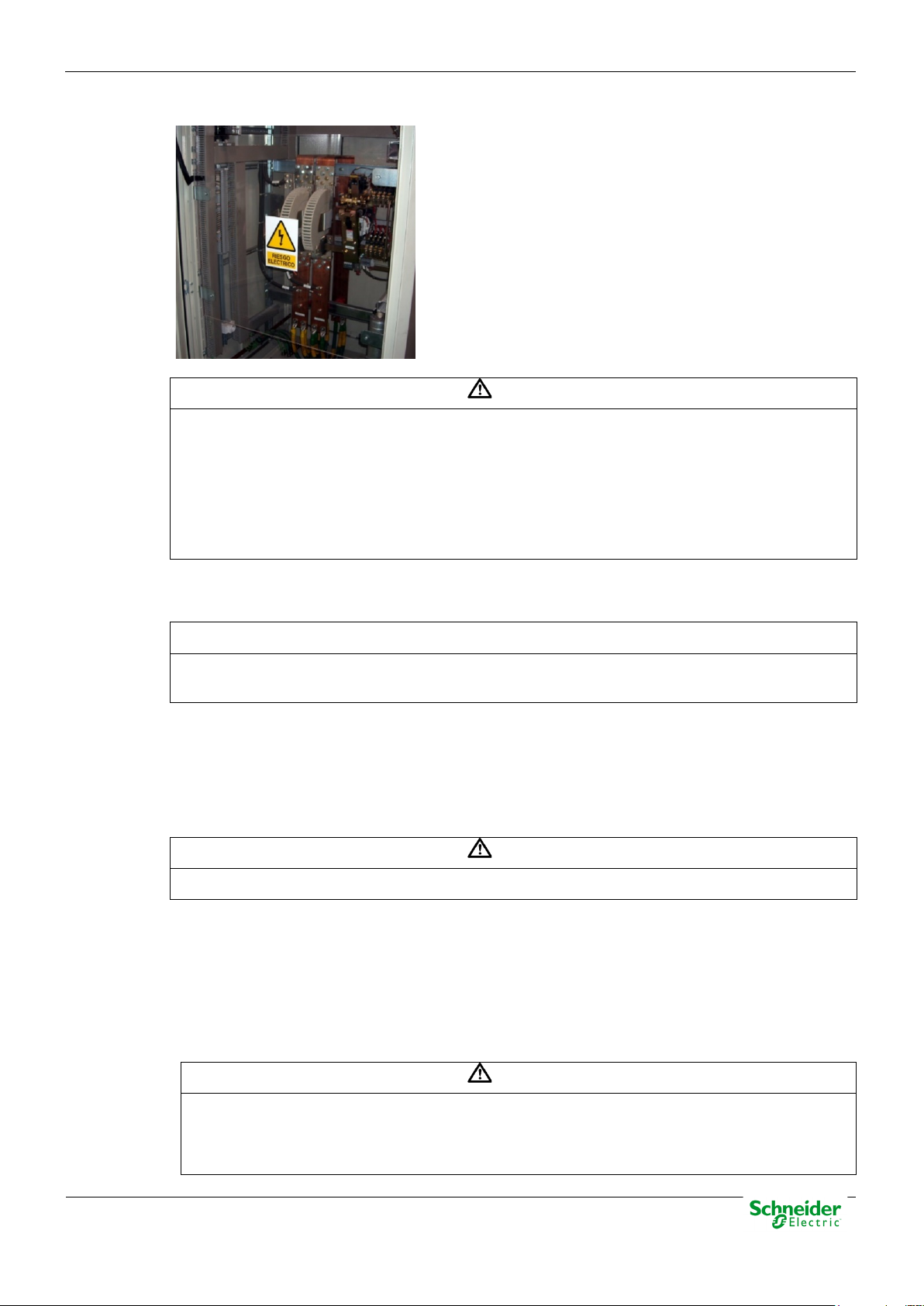

DANGER

Devices that handle dangerous tensions are marked with a sticker on the front label (size: 12,5

WARNING

If this type of cabinet isn't available, a barrier must be installed in order to avoid an accidental

1.4 Installation, Setup and Operation

The user is responsible for reading and following the device’s operating and installation instructions

before attempting to commission or maintain it. Failure to follow these instructions can affect device

operation and constitute a hazard for people and property.

There are several acquisition blocks in Saitel DP that use high voltages (> 50 V). The user is

responsible to check that the characteristics of each equipment are adapted and convenient for his

installation.

Not following these instructions can be dangerous for the people and the equipment.

mm). This label must be visible when the module’s door is open, and the field connectors are

accessible.

The following products handle dangerous tensions:

• SM_PS40: Power supply module (P/N: M5084x000x and M5085x000x).

• SM_DI32: Digital inputs module (P/N: M583x0000x).

• SM_DO32T and SM_DO16R: These modules do not handle high voltages, they will not be

marked at the factory. These modules must be marked with an electric risk label when some

equipment that manage voltage higher than 50 V are connected to digital outputs.

It is recommended to install the RTU inside a cabinet with a key. This cabinet only should be

opened by a qualified person.

contact with these dangerous elements. This barrier only should can be removed using a

special tool.

If the barrier has to be removed in order to access to equipment, personnel responsible for the

task must be sure that the barrier is installed again when the task is finished.

While the RTU is accessible for a user, all people must follow all instructions to prevent

electrical risk or discharges.

Not following these instructions can give like result that the device do not work properly

or even can damage to the people or devices.

An electrical risk symbol with enough size must be included on the cabinet’s door or

on the barrier.

The following image shows an example:

Pag 10

User Manual – Saitel DP Platform

30/06/2020

WARNING

If the barrier has to be removed in order to access to equipment, personnel responsible for the

NOTICE

The cabinet must remain closed with key or the protection barrier installed after the installation is

WARNING

Don’t use liquid products of cleanliness due to the presence of active parts.

WARNING

Figure 1 – Barrier of protection for elements with dangerous voltages.

task must be sure that the barrier is installed again when the task is finished.

While the RTU is accessible for a user, all people must follow all instructions to prevent electrical

risk or discharges.

Not following these instructions can give like result that the device do not work properly or

even can damage to the people or devices.

Terminals will not be accessible to the user directly once it has made the installation of the

equipment.

finished.

The cabinet or installation must have a general switch placed just in the cable entry of the

installation (see paragraph 1.7.1 )

For the cleaning of the equipment, it is recommended to remove the power and to use only a dry

cloth by the surface when it detects excessive presence of dust or any element deposited on the

surface.

Because of the variety of uses of the product, the managers of the application and use of this

controller device will have to take the measures to ensure the fulfillment of all the requests of

security and provision of each application. The requests do reference to the applicable laws,

regulations, codes and standard.

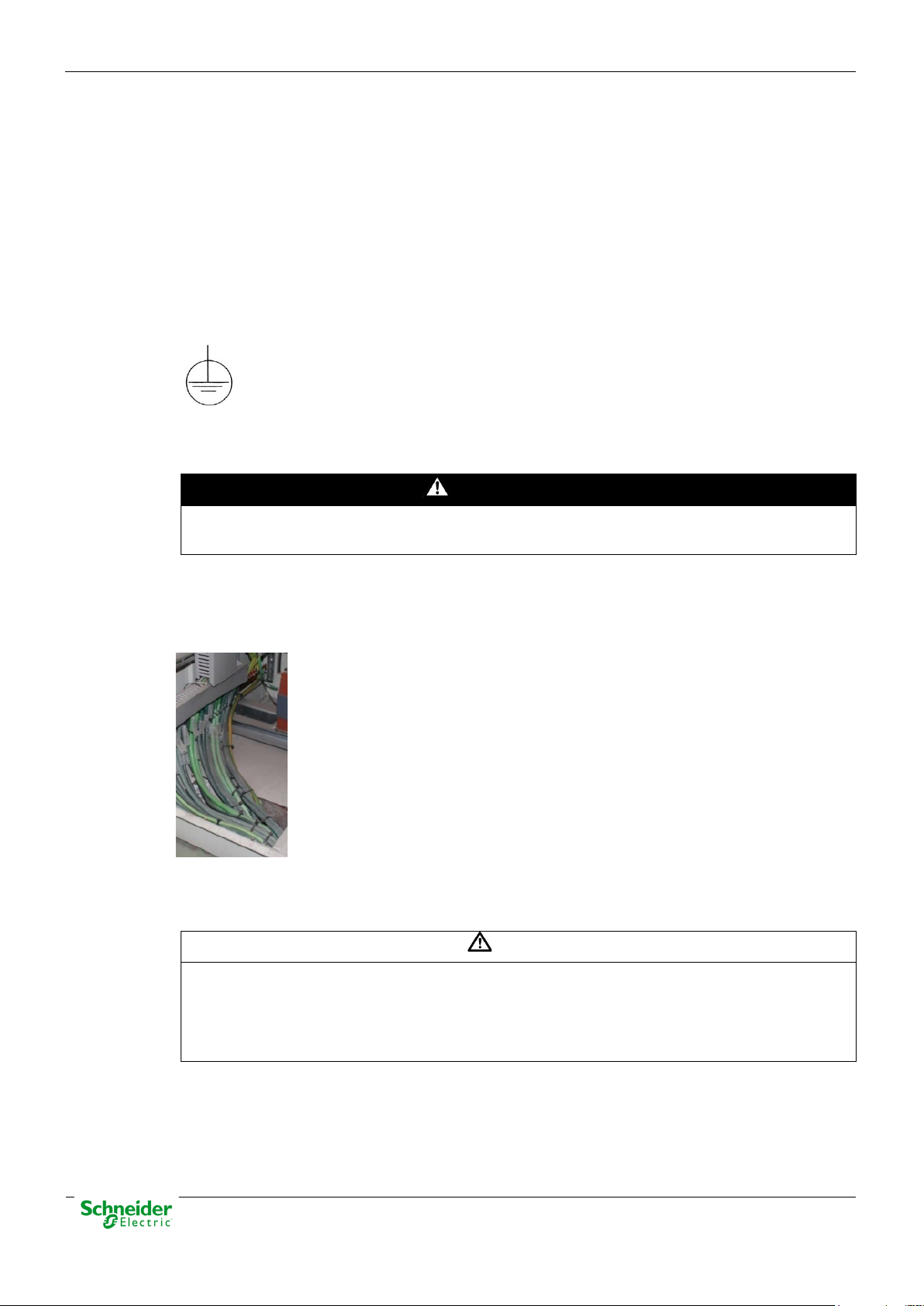

1.5 Earthing

Before energizer the device, it has to be placed to earth properly such as it indicates in this

section. When installing the device, ground is the first thing that should be connected and the

last one that should be disconnected.

Pag 11

30/06/2020

User Manual – Saitel DP Platform

DANGER

Hazardous voltages can cause shock, burns or death. Disconnect and lockout all power

WARNING

According to the electrical safety standards:

Saitel can need put to earth for two distinct needs:

• For purposes of electrical safety (Protective Earth, PE).

• Improve the behavior in Electromagnetic Compatibility (EMC) and derive perturbations to earth

(functional Earth).

1.5.1 Electrical Safety

Only qualified personnel, with knowledge about hazards associate with electrical equipment is

allowed to install Saitel DP. In general, the installation will be following IEC 61010-1

recommendations in order to be compliant with this norm.

When Saitel DP is mounted on back-panel, the metallic enclosure of the backplane

must be connected to the ground of the cabinet or installation according to the norm

IEC 61010-1. When Saitel DP is mounted on a chassis, this chassis must be

connected to the ground of the installation.

Saitel DP modules have a plastic enclosure offering protection for isolation faults. Earthing

sources before servicing and to dismount modules.

A dedicated connection with green/yellow wire should be used to have electric continuity to the

installation protective earth. Use a wire with adequate section according to IEC 61010.

Figure 2 - Example of yellow/green cable for earthing.

The design and installation of the cabinet is responsible for compliance with all the existing

international and national electrical codes concerning protective grounding of any device.

• The screw for ground must be exclusive for this use.

• The power voltage must be supplied by a power supply that offers double or reinforced

insulation against dangerous voltages.

1.5.2 Functional Earth (EMC)

A rear connector available in each module allows the bus connection and it offers protection in

case of electric derive. The EMC grounding is implemented via three pins of this connector.

Pag 12

User Manual – Saitel DP Platform

30/06/2020

WARNING

Never connect modules on the backplanes if the power supply hasn’t been disconnected of all

WARNING

The enclosure ONLY should be removed when is strictly necessary, because this action has a

WARNING

The connection / disconnection switch must be installed in a fixed element (for example the wall

circuits with high voltages.

The only modules with a ground connection are the power supplies (SM_PS and SM_PS40). Both

must be connected to the ground of the cabinet.

1.6 Handling Electronic Components

Saitel is susceptible to receive electrostatic discharges during the handling. It is necessary to take

the usual measures to minimize this risk, since serious damage to the equipment can be caused,

which may not be detected immediately but which may affect the reliability of the product.

risk for the equipment:

• Before removing the enclosure, the operator must be equipotential with the equipment.

• Avoid touching the electronic. The board must be always manipulated for the edges.

• If the equipment has to be passed between two persons, both must be equipotential.

• Put the module always on an antistatic surface or on a surface equipotential with you.

• During the storage and transport, the module will remain in the packaging.

Not following these instructions can give like result that the equipment do not work

properly or even can damage the people or equipment.

1.7 Technical Specifications for Safety

1.7.1 Protective Elements

The cabinet's engineering and installation must include a general automatic switch next to the

cables' input in the cabinet; once the door is opened, high voltages must be interrupted inside. This

switch must be located at a place which is not accessible by a third person while the operator is

using the boards in the cabinet.

Moreover, the installation will incorporate a circuit breaker of 5A next to the cabinet protecting it

from possible overcurrent in the power supply.

Both switches will be labeled with the symbol O as "Off" and I as “On”.

of the cabinet) and it mustn’t break any earthing wire.

Pag 13

30/06/2020

User Manual – Saitel DP Platform

WARNING

This equipment has been designed ONLY for indoor use.

1.7.2 Environmental Conditions

The protection degree of the device is IP20.

It is designed only for indoor use. If necessary for use in an outdoor environment, it must be

mounted in a specific cabinet providing an IP54 degree of protection (typical and minimum for

ATEX conditions), that is, protected against dust and water splashes.

The electronic cards of the modules will be able to be tropicalized or no according to the option of

setting chosen. The tropicalized used is the AVR80, of the company ABchimie. It can consult all the

technical information of this type of finishing in http://www.abchimie.com/

Other data to take into account about the environmental are:

• Altitude until 2000 m.

• Operation temperature range: Between -40 ºC and 70 ºC. (IEC 60068-2-1 and IEC 60068-2-2).

• Maximum relative humidity of 95%. (IEC 60068-2-30)

• Degree of pollution II. (IEC 60255-5)

.

• Overvoltage transitory until levels of Category III. (IEC 60255-5)

1.7.3 Storage Conditions

The continuous exhibition to some high levels of humidity during the storage can cause damages

to the electronic components and reduce the useful life of the device.

It is recommended that, in the enclosure of storage, the relative humidity do not exceed 50%.

Before the installation of an electrical equipment, it is recommended to leave the necessary time for

the acclimatization of the environmental temperature.

1.8 Technical Label

Each Saitel product includes a technical label with the following information:

Figure 3 - Technical label.

Pag 14

User Manual – Saitel DP Platform

30/06/2020

NOTICE

On the “Technical data” zone, you can see relevant information about the input and output

NOTICE

Our products leave our factory in closed, sealed original packaging. If at receipt of the delivery

WARNING

Only a qualified person should change the battery when is necessary, and the same model of

voltage in the module. Any voltage greater than 50 V must be consider as a high voltage.

1.9 Packing and Unpacking

All Saitel modules are packaged separately in their own carton box and shipped inside outer

packaging. Use special care when unpacking the device. Don’t use force.

the transport packaging is open or the seal is broken, the confidentiality and authenticity of the

information contained in the products cannot be ensured.

The design revision and manufacturing options can be determined using the P/N included in the

packaging label on packaging.

After unpacking the device, inspect it visually to be sure it is in proper mechanical condition.

If the product needs to be shipped, the original packaging must be used, including foams and the

carton box. If the original packaging is no longer available, make sure that the packaging used is

according to ISO 2248 specifications for a drop height 1 m.

1.10 Decommissioning and Disposal

Saitel products are marked with this symbol, it means that, at the end of its life cycle,

you mustn't dispose the product together with habitual residues. To avoid the

possible damage to the environment or to the human health that represents the

uncontrolled elimination of residues, please, separate the battery (if there is one) of

the other elements, and each one must be recycled according to the local regulation.

SM_CPU866e module includes a Lithium battery NOT rechargeable. More information about the

model in the technical data table included in the SM_CPU866e user manual.

battery must be used. More information in the technical specifications table at the end of each

user manual.

Pag 15

30/06/2020

User Manual – Saitel DP Platform

2 Saitel DP Family

Pag 16

User Manual – Saitel DP Platform

30/06/2020

Content

2 SAITEL DP FAMILY ................................................................................................ 16

2.1 FIRST APPROACH .................................................................................................. 18

2.2 S

2.3 T

2.4 P

2.5 R

2.6 RTU

AITEL DP MODULES ............................................................................................ 19

2.2.1 G

2.2.2 C

2.2.3 LED

2.3.1 CPU

2.3.2 C

2.3.3 I/O

2.3.4 O

2.4.1 S

2.4.2 RTU

2.5.1 P

2.5.2 CPU

2.5.3 A

2.5.4 S

2.5.5 R

ENERAL FEATURES ...................................................................................... 19

ONFIGURATION SWITCHES ............................................................................ 19

INDICATORS ........................................................................................... 20

YPES OF MODULES .............................................................................................. 21

MODULES .............................................................................................. 21

OMMUNICATION MODULES ............................................................................ 21

MODULES ................................................................................................. 22

THER MODULES ........................................................................................... 24

ROFIBUS & SAITEL DP ......................................................................................... 26

YSTEM BUSES .............................................................................................. 26

BASIC FUNCTIONS .................................................................................. 28

EDUNDANT CONFIGURATIONS IN SAITEL DP ......................................................... 30

OWER SUPPLY REDUNDANCY ....................................................................... 30

REDUNDANCY ........................................................................................ 34

CQUISITION BUS REDUNDANCY ..................................................................... 39

YSTEM’S DUALITY ......................................................................................... 40

ECOMMENDATIONS ....................................................................................... 41

EXPANSION ................................................................................................... 42

Pag 17

30/06/2020

User Manual – Saitel DP Platform

2.1 First Approach

The Saitel DP platform is a complete set of devices provided by Schneider Electric for real-time

control applications and power line automation. It is a high-technology platform which gives a

solution to the business areas of Schneider Electric.

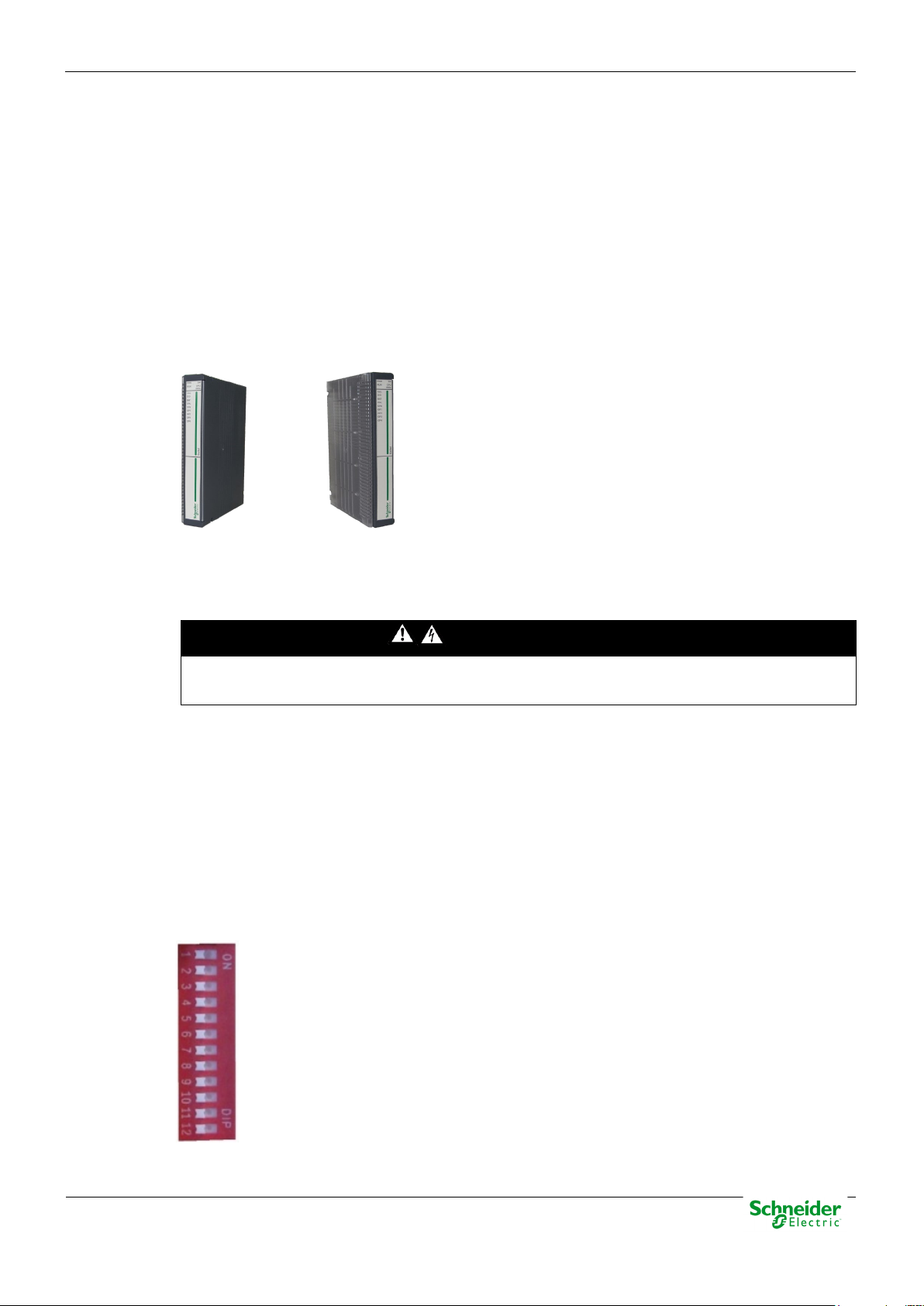

Figure 4 – Saitel DP in chassis and backplane.

Saitel DP’s design has been optimized to meet the most demanding requirements of multiple

sectors:

• Cost-efficiency, minimum downtime, and compliance with electrical safety, electromagnetic

compatibility and environmental standards.

• Safety and reliability requirements for power, gas, water, residual water supply, etc.

• Centralized monitoring and control of geographically-distributed systems which support

hierarchical data acquisition and redundant networks.

• Local monitoring and control with data sharing capabilities of plant-distributed devices.

• Quick troubleshooting by means of programmable automation execution.

• One of the most remarkable features of Saitel DP is its modular design. All I/O, CPU, power

supply and communication modules have an identical format, sharing the same enclosure.

Figure 5 – Saitel DP architecture.

Pag 18

User Manual – Saitel DP Platform

30/06/2020

Never open the module’s enclosure. Never install an electronic board without the plastic

2.2 Saitel DP Modules

The Saitel DP electronic modules have been designed to operate in aggressive industrial

environments, complying with the highest standards, such as Electromagnetic compatibility (EMC).

The low-consumption design allows modules to operate without a forced ventilation system, which

creates a wide range of possible applications.

2.2.1 General Features

The next figure shows an example of a Saitel DP module:

Figure 6 – Saitel DP module

The modules have a plastic enclosure that especially it is designed to facilitate the insertion and the

wiring of the modules. The level of protection provided by the enclosure is IP20connections and

disconnections.

enclosure.

Internally, all modules are electrically connected to the backplane using a 48-pin connector on the

rear side. In relation to the connection with external devices, all the elements required for the

module’s operation and maintenance tasks are located on the front side.

2.2.2 Configuration Switches

The modules integrate a 12-position switch on the rear side. The function of these switches

depends on the module type, but in general, it is used to set the addresses and communication

rate.

Figure 7 – Module’s configuration switches

DANGER

Pag 19

30/06/2020

User Manual – Saitel DP Platform

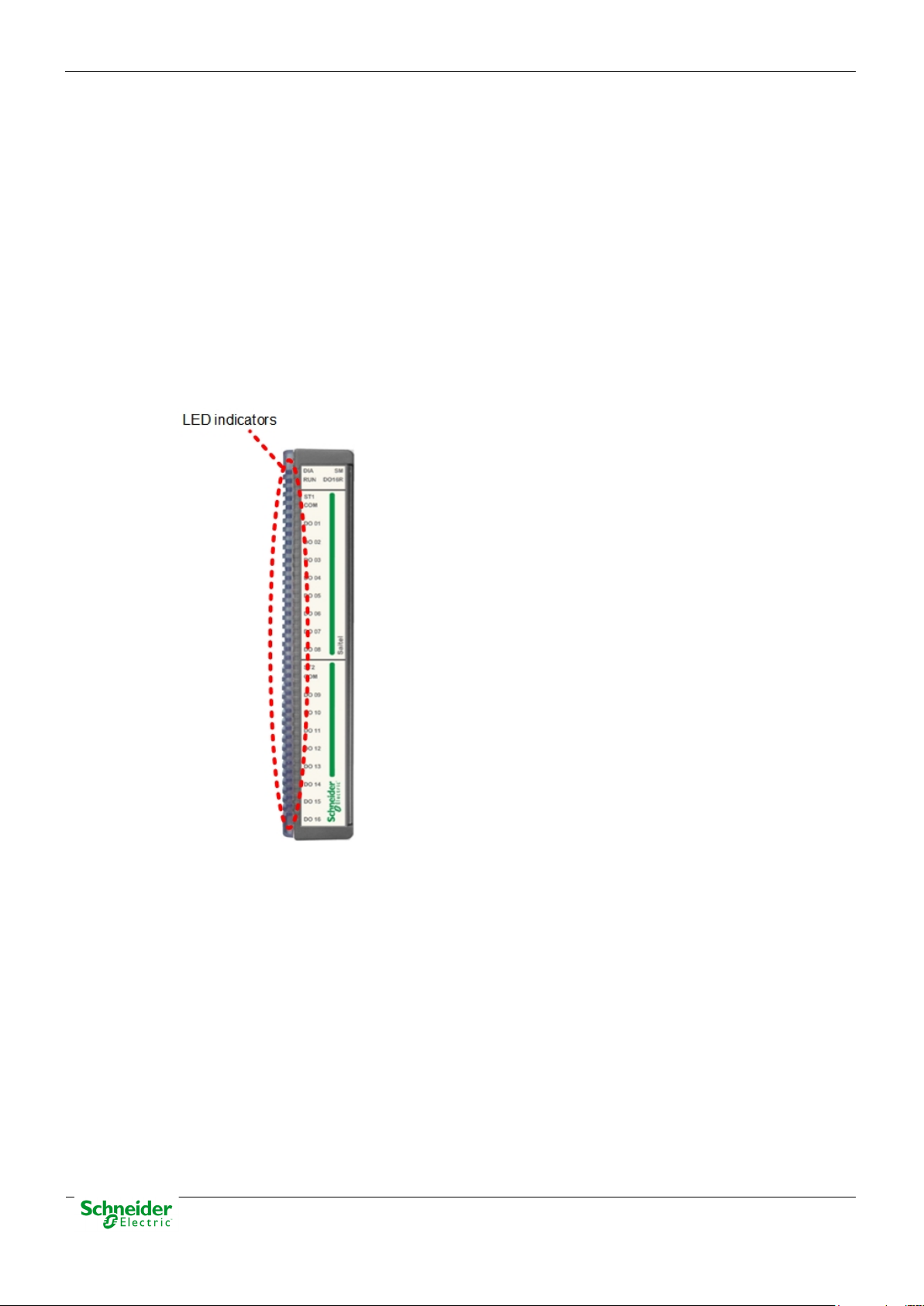

2.2.3 LED Indicators

The Saitel DP modules include some visible LEDs (light emitting diodes) on the front side. All

acquisition modules have common LEDs, and the rest are specific for each module, which are

detailed in the corresponding user manual.

The front panel of each acquisition module has a red indicator DIA and a green indicator RUN. The

module performs a self-check during the start-up process. When successful, the red indicator is

switched off and the green indicator displays the module’s configuration status.

If any problem is detected, the red indicator DIA is switched off. The meaning of these LEDs

depends on the module type and it is explained in the user manual for each module.

This information will only be valid if the module is completely configured and operational.

Figure 8 – LED indicators

Consult the module’s user manual for more information regarding interfaces, configuration switches

and led indicators.

Pag 20

User Manual – Saitel DP Platform

30/06/2020

2.3 Types of Modules

2.3.1 CPU Modules

SM_CPU866e – High-Performance CPU

• OS: Linux.

• Web tool: webApp.

• Ethernet ports: 4 (copper or fiber optic).

• USB port and SD card.

• Synchronization: GPS / SNTP / IRIG-B / Protocol.

• Serial communications: 4 ports (RS-232 / RS-485).

• Watchdog output.

• Command console tool: RJ-45 port.

• Cybersecurity

2.3.2 Communication Modules

SM_SER – Communication module

• 8 serial ports.

• RJ-45

• Synchronous and asynchronous communications

• Synchronization from SM_CPU866e.

• RS-232 / RS-485 / RS-422

Pag 21

30/06/2020

User Manual – Saitel DP Platform

2.3.3 I/O Modules

The following I/O modules are available:

SM_DI32 – Digital Inputs

• 32 digital inputs (single/double/slow

counter)

• Two removable connectors.

• Field connection: Terminal blocks or

Flat Ribbon

• Auto-range for DI polarization. Available

ranges:

o 12 - 24 VDC

48 - 60 V

o

o 110 - 125 V

o

220 V

DC

DC

DC

SM_DO32T – Digital Outputs to Transistor

• 32 digital outputs to transistor.

• Two removable connectors for signals.

• One removable connector for polarization (only for field

connection using flat ribbon).

• Field connection: Terminal blocks or Flat Ribbon

• Outputs type: Normally Open or Normally Closed contacts

(configurable in the external terminal lock).

• DO polarization (auto-detected). Available levels:

o 12 V

o 24 V

o 48 V

DC

DC

DC

Pag 22

User Manual – Saitel DP Platform

30/06/2020

SM_DO16R – Digital Outputs to Relay

• 16 digital outputs to relay.

• Two removable connectors for signals.

• Only terminal block is available for field connection.

• Outputs type: SPST or Normally Open contacts.

• Two polarization levels are available for DO. Depending on

the ordering options, polarization input will be:

o B2: 24 VDC

o B3: 48 V

DC

SM_AI16 – Analog Inputs

• 16 analog inputs

o Voltage

o Current (external resistor is

required).

• Two removable connectors for signals.

• Field connection: Terminal blocks or

Flat Ribbon

Pag 23

30/06/2020

User Manual – Saitel DP Platform

SM_AI8AO4 – Analog Inputs

• 8 analog inputs

o Voltage

o Current (external resistor is

required).

• 4 analog outputs

o Voltage (external resistor is

required)

o Current multirange.

• Two removable connectors for signals.

• Field connection: Terminal blocks or

Flat Ribbon

2.3.4 Other Modules

Other modules are available in Saitel DP: power supply, backplanes, chassis and BP2F.

SM_PS40 – Power Supply

Saitel DP includes a power supply module which has been specifically designed to power the

electronic components on the backplanes and provide the required polarization voltage to the

acquisition modules. Saitel DP backplanes also support external power supplies.

• Power input depending on the P/N:

o A2: 24 V

o A3: 48 V

o A4: 110 / 125 V

o A5: 110 / 230 V

• Power output: 5.4 V

• Auxiliary power output: 24 V

.

DC

.

DC

.

DC

.

DC/AC

to the backplane.

DC

DC

, available or not depending

on the P/N.

Pag 24

User Manual – Saitel DP Platform

30/06/2020

SM_BPX – 9-slot or 4-slot Backplane

Saitel DP modules must be mounted on an electronic board named “backplane”. SM_BPX mounts

this electronic board in a metallic enclosure which can be installed in a panel or flat wall.

• Power input: 5.4 V

DC

(if a

SM_PS40 module is not used)

• Two connectors for expansion

and one connector for external

power supply.

• Configuration switches for

Profibus and synchronization

expansion.

• Led indicators for bus

communications and power.

• The number of slots depends of

the P/N:

o A4: 4-slot

o A9: 9-slot

SM_CHX – 19-inch Chassis

The electronic board backplane can be mounted in a 19-inch chassis:

• Power input: 5.4 V

(if a SM_PS40

DC

module is not used)

• Two connectors for expansion and one

connector for external power supply.

• Configuration switches for Profibus and

synchronization expansion.

• Led indicators for bus communications

and power.

• The number of slots depends of the P/N:

o A4: 8-slot (2 x 4-slot)

o A9: 9-slot

Pag 25

30/06/2020

User Manual – Saitel DP Platform

NOTICE

It is important to note that, both the first chassis and the last chassis or backplane, must be

BP2F – Auxiliary Module for Expansion

BP2F (Backplane to Fiber) is a RS-485 to fiber optics converter, specifically designed by Schneider

Electric for the communication between Saitel DP backplanes. This device allows the creation of a

fiber optics bus for communications between backplanes physically far away avoiding distance and

electromagnetic problems.

• Type of fiber optic depending on the P/N:

o A1: 820 nm.

o A2: 650 nm.

• Power input: 5.4 V

DC

.

2.4 Profibus & Saitel DP

2.4.1 System Buses

Each backplane includes a multifunctional bus (Profibus TTL) that covers the power and

intercommunication requirements. This bus is designed to be tolerant to power and communication

failures. Additionally, a Profibus RS-485 is included to support backplane expansion.

The figure below shows schematically the situation of both buses in the system:

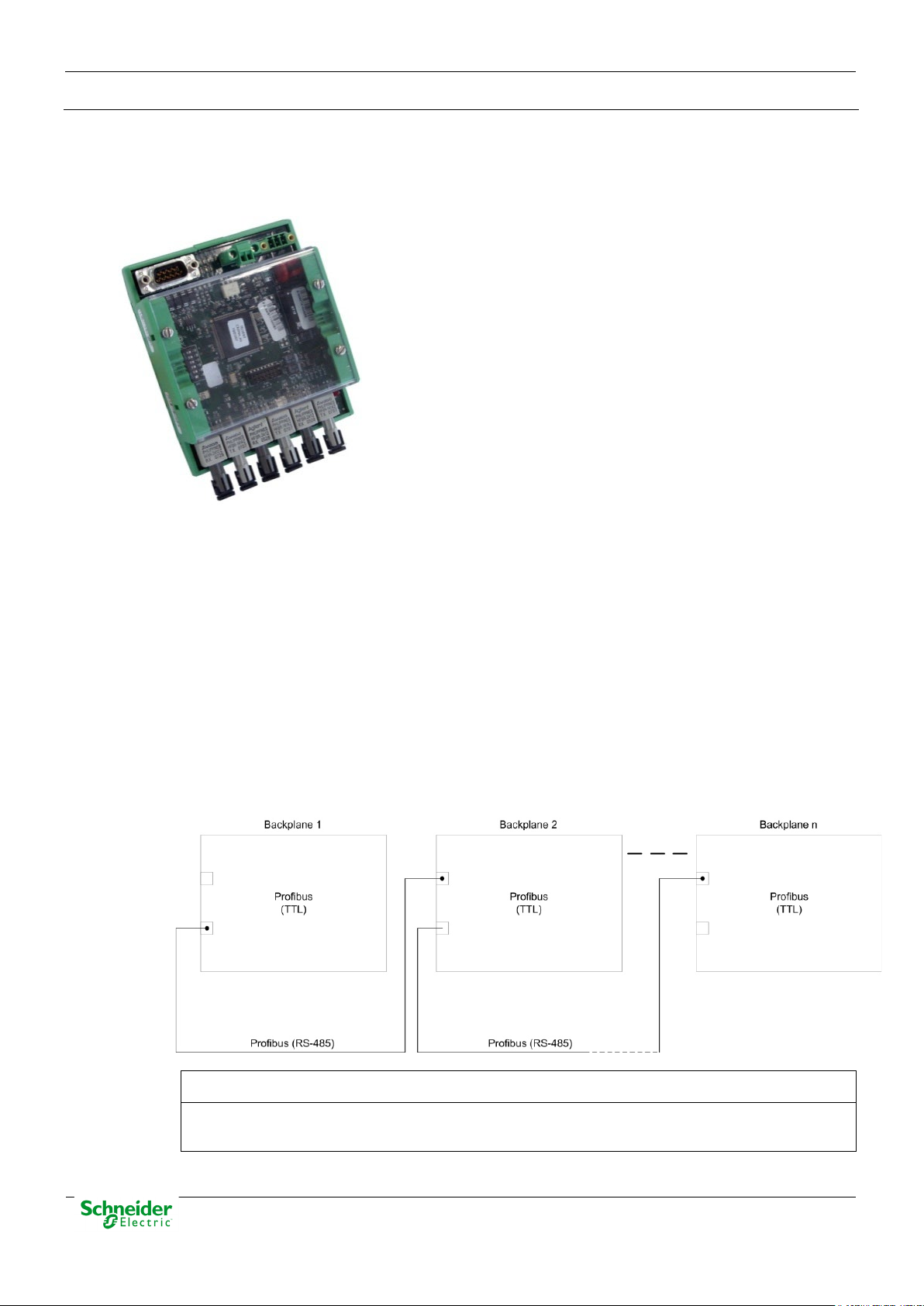

Figure 9 – Profibus TTL and Profibus RS-485

configured as bus terminations. See section 4.2 Backplane Modules in this manual.

Pag 26

User Manual – Saitel DP Platform

30/06/2020

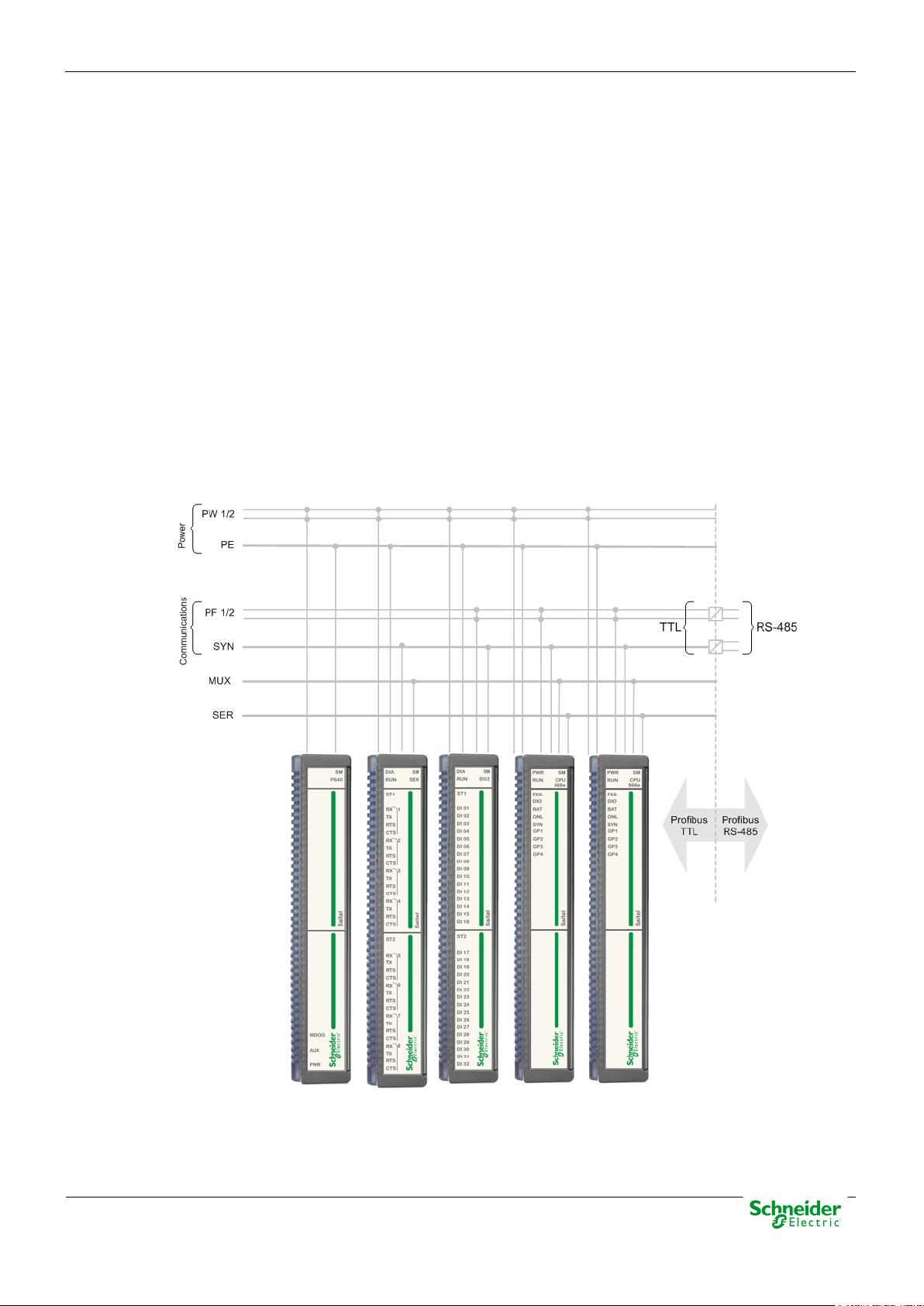

These buses integrate the following bus lines:

• Profibus TTL:

o PE - Protection ground.

o PW1/2 – Power bus (primary and redundant).

o PF1/2 (TTL) - Primary and redundant Profibus TTL buses.

o MUX - Serial data bus for communications with the SM_SER module.

o SYN (TTL) - Bus for synchronization for the modules. (Pulse Per Second or PPS).

o SER - Serial bus for synchronization between redundant CPU modules.

• Profibus RS-485:

o PF1/2 (485) - Primary and redundant Profibus RS-485 buses.

o SYN (485) - Bus RS-485 for synchronization for the modules. (PPS).

The figure below shows the buses available in the backplane:

Figure 10 – Buses in a backplane.

Pag 27

30/06/2020

User Manual – Saitel DP Platform

NOTICE

The primary source is used to synchronize the RTU, if available. Otherwise, the secondary

2.4.2 RTU Basic Functions

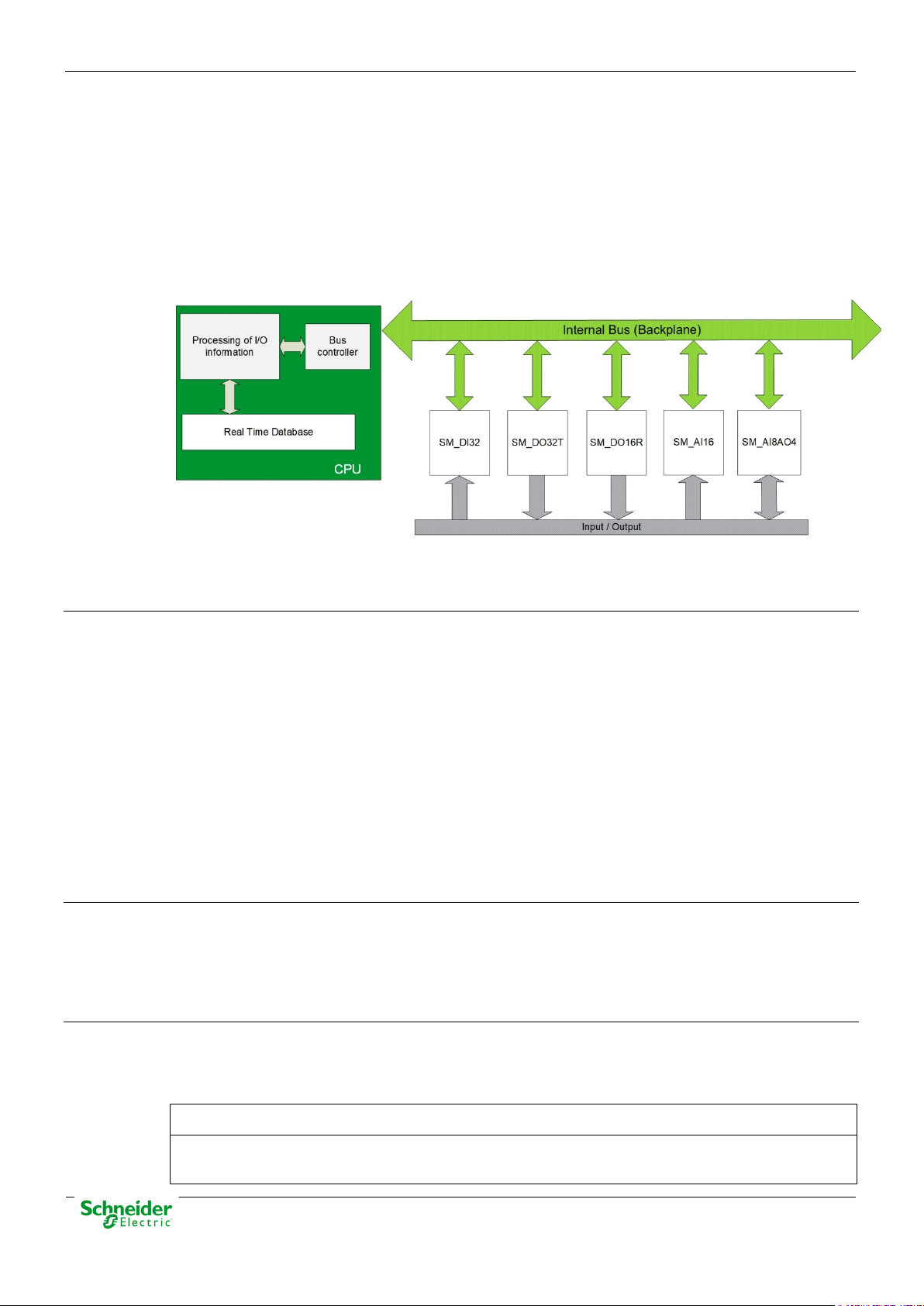

The control unit (CPU) performs the control functions for the complete system, centralizes the

information acquired by other modules, and executes the programmable logic control,

communication protocols and user-specific applications.

The communication with I/O modules is established by an internal high-speed bus that makes the

system highly reliable even in noisy environments. This bus is implemented in the backplane

Figure 11 – Communication between the CPU and I/O modules.

The CPU module controls and manages the following functions:

Bus Controller

The Baseline software installed in the CPU controls the operation of both, CPU and I/O modules

connected to the backplane.

This control includes:

• Operation mode monitoring. It performs functions as hardware and software Watchdog control,

• Interface with the operator through the console, webApp (for supervision and maintenance)

• Firmware upgrade by SFTP or webApp (using an Ethernet port) or USB 2.0 port.

RTU Configuration

The CPU maintains and manages the information that supports the real-time database, coreDb. In

this database, the I/O signals are related to the communication protocols signals. The configuration

is based on XML files that are generated with the Easergy Builder tool. These files are generated

on a PC and sent to the CPU via an SFTP connection through Ethernet ports.

the states control of the I/O modules and the CPU and the provision of diagnostic information

about the RTU status through LED indicators and several log files. These files can be

consulted by a user with sufficient privileges through SFTP or webApp.

and Easergy Builder (for configuration).

RTU Synchronization

Up to two different synchronization sources can be configured. In this configuration is included the

priority level for each source, so there will be a primary and a secondary source. If both sources

are active, only the primary source will synchronize the system.

source is used.

Pag 28

User Manual – Saitel DP Platform

30/06/2020

The available synchronization sources are:

• GPS: A GPS connected to a serial port. The time received from the GPS is used to set the

system’s clock and the RTC.

• SNTP: A SNTP source through Ethernet. CPU modules can operate as an SNTP client or as

an SNTP server.

• Protocol: Most control protocols allow synchronizing slave devices.

• Console: The user can set the system's time manually from the console terminal.

• IRIG-B: It’s possible to configure the CPU as a server and/or client. The communication always

will be made with IRIG-B compliant devices.

If the synchronization source is not configured, the console device will always be created by

default. The console operates as the lowest priority when another source is configured.

CPU Communications

Saitel DP supports the following communication protocols with field devices:

• IEC101 master and slave.

• IEC103 master.

• IEC104 master and slave.

• DNP 3.0 master and slave.

• Modbus master and slave.

• IEC61850 client, Edition 1 and 2.

• IEC61850 server, Edition 1 and 2.

I/O Acquisition

The CPU manages the information exchange with the I/O modules. This information is sent from

the acquisition module to the CPU through the bus.

The software in the CPU adds the following features:

• Processing I/O information, which offers an added value to the information from field.

• Accessing the internal bus to exchange information with the I/O modules.

Real-time Database (coreDb)

The core of the Baseline Software Platform is the real-time database or coreDb. It is a real-time

database which stores not only the information acquired from field devices, but also the information

about the status of the CPU modules and I/O modules included in the RTU.

coreDb also relates the acquisition signals to the communication protocol signals. This database is

generated in the CPU by using the configuration information.

The information which is received from field in real time is processed, stored in the coreDb and

then related to the communication protocols signals of the RTU, which function is to transfer that

information to the master device.

Pag 29

30/06/2020

User Manual – Saitel DP Platform

coreDb can also have as a source of information the result of a logic, which can be implemented by

a third-party software such as ISaGRAF® or within the database itself witch an internal device of

the type “Formula”.

Consult more information about this functionality in the Easergy Builder user manual.

Cybersecurity

SM_CPU866e is supplied with a standard security policy, complemented with the definition of an

RBAC model (Role-Based Access Control). This model is defined and managed through a special

tool, CAE (EcoStruxure™ Cybersecurity Admin Expert.

2.5 Redundant Configurations in Saitel DP

Due to the wide range of redundant configurations supported by Baseline Software Platform and

Saitel DP, it is necessary to make a detailed analysis in order to determine the concepts applicable

to functionalities and to set a common terminology.

It should be highlighted that redundancy always intends to increase the level of reliability and

availability of the critical elements within a control system.

Redundant configurations are defined to strengthen the following parts of the control system:

• Power supply: This is the first doubled element in the system, since a power supply fails

would mean a total power-off of the system. Power supply units are also devices which transfer

powers, sometimes extremely high and could cause a significant wear of the components. All

Saitel P modules and most auxiliary elements support a redundant power supply.

• CPU: The SM_CPU866 and SM_CPU866e modules allow defining configurations with CPU

redundancy with a high level of flexibility meeting the specific requirements of any system.

• Acquisition bus: The acquisition bus allows the CPU to acquire data from acquisition

modules. Saitel DP backplanes include a double acquisition bus. The CPU module together

with the acquisition modules implement the functions to make an efficient use of these

redundant communications.

• Communication channels: Several master and slave communication protocols support a

double communication channel, which are switched with certain rules according to the protocol.

• System’s duality: All the system’s components are doubled under this configuration. This is

the typical configuration of data hubs and communication front-ends.

Different types of redundancy can be combined in order to make the system as much robust as

possible with doubled elements..

2.5.1 Power Supply Redundancy

Power supply redundancy consist of the use of multiple power supply units for the same backplane.

Thus, the power supply reliability is much improved.

The SM_BPX and SM_CHX backplane have two different power supply options available:

• Power supply using SM_PS40 units

• Power supply using external power supply units.

In both cases, it is possible to have a simple or redundant configuration.

Pag 30

User Manual – Saitel DP Platform

30/06/2020

WARNING

If two power supplies are connected as primary or secondary power supplies, the electronic

Power Supply Redundancy in SM_BPX

In the redundant configuration, the first SM_PS40 module is connected to the slot 1 in the

backplane and the second SM_PS40 module is connected to the slot 2 in the backplane.

Figure 12 – SM_BPX backplane with two SM_PS40 modules.

If an external power supply module is used to power the backplane, it is connected to the lateral

connector (see connector 5 in Figure 47). The connector pinout is shown in paragraph 0.

The combination of an external power supply unit and a SM_PS40 module is possible providing

they both are not the primary or secondary power supplies.

components may be damaged.

Each power supply must be available to provide the 100% of the required power, regardless if

SM_PS40, an external power supply or a combination of the two options is used. Therefore, there

are four possible redundant configurations

Figure 13 – Two SM_PS40 modules.

Figure 14 – Two external power supplies.

Pag 31

30/06/2020

User Manual – Saitel DP Platform

Figure 15 – One SM_PS40 (primary) and one external PS (secondary).

Figure 16 – One external PS (primary) and one SM_PS40 (secondary).

For any of the configurations described above, the power redundancy is achieves using the

adequate wiring.

Power Supply Redundancy in SM_CHX

The SM_CHX backplane has the same power supply options as the SM_BPX backplane, so the

redundancy configuration is similar.

The difference is that the connectors for external power sources are located at the back of the

circuit board rather than on the side (see connector 3 in Figure 49). The pinout of this connector is

detailed in section 0 of this manual.

There are four possible redundant configurations.

Figure 17 – Two SM_PS40 modules.

Pag 32

User Manual – Saitel DP Platform

30/06/2020

Figure 18 – Two external power supplies.

Figure 19 – One SM_PS40 (primary) and one external PS (secondary).

Figure 20 – One external PS (primary) and one SM_PS40 (secondary).

Pag 33

30/06/2020

User Manual – Saitel DP Platform

NOTICE

Both CPU modules must be installed in consecutive slots in the backplane.

2.5.2 CPU Redundancy

The SM_CPU866e module, together with the backplanes (SM_BPX and SM_CHX), supports the

definition of different redundancy configurations of the CPU.

The redundancy types are defined by:

• Physical site: The two CPU are installed consecutively in the same backplane or in different

backplanes.

• Switching mechanism: The switching can be arbitrated by the MSAC module or managed by

the CPU modules themselves.

• Switching type: Both "cold" and "hot" switching are possible. In the first case, the database of

the STANDBY device is not updated with the ONLINE device’s database, but it only updates

when switching is triggered. In the second case, the STANDBY device is constantly updating

the database with the ONLINE device.

• IP address allocation: Baseline Software Platform allows configuring a number of IP

addresses associated to the ONLINE CPU. These addresses are assigned dynamically to

allow CPU modules in redundant systems to inter-communicate and use the same IP address

after switching.

2.5.2.1 CPU Physical Site

Two CPU Modules in the Same Backplane

This is the simplest redundant configuration as it makes the best use as possible of the features of

the backplanes (SM_BPX and SM_CHX). It is the only configuration which allows the two CPU

modules to share the SM_SER communication modules. It also allows (alike in other

configurations) acquisition modules to be shared.

If there are two CPU modules in the same backplane, the switching mechanism can be controlled

by the MSAC module or be managed by the two CPU. In this case, Both CPU can

intercommunicate through a dedicated high-speed channel included in the backplanes or through a

serial or Ethernet link.

Its main disadvantage is that a malfunction in the CPUs’ backplane, caused by any of the modules,

affects the two CPU similarly. Therefore, there are simple faults which might make the two CPU

fail.

Figure 21 – Two CPU modules in the same backplane.

Pag 34

User Manual – Saitel DP Platform

30/06/2020

NOTICE

No other acquisition module can be installed in the backplanes in which the CPU modules are

Two CPU Modules in Different Backplanes

This configuration requires an additional backplane; moreover, the number of SM_SER

communication modules, which are doubled, cannot communicate with the CPU if they are nor in

the same backplane.

The switching mechanism is controlled by the MSAC module or managed directly by the two CPU

modules. In this case, both CPU can intercommunicate through a serial or Ethernet link.

This configuration prevents a simple failure in the backplane from affecting the system completely.

located, since the CPU will not be able to access the acquisition data of the modules located in

the backplane of the other CPU.

Figure 22 – Two CPUs in different backplanes.

2.5.2.2 Switching Mechanisms

MSAC Module

MSAC (Signaling, Arbitration and Switching Module) can, in redundant CPU configurations,

perform the following functions:

• Using a powerful "hardware" protocol, it detects if a CPU is operational or not. It arbitrates

which of the two CPU is ONLINE or STANDBY.

• If a GPS is used for synchronization, the synchronization signal is broadcasted to the two CPU.

• It links each CPU to a relay output, which is activated if the device is operational (ONLINE or

STANDBY) and deactivated if a FAIL status is detected. This relay output can interrupt the

output polarization, signaling, etc.

The MSAC module includes a set of LEDs to indicate the state of each CPU.

Pag 35

30/06/2020

User Manual – Saitel DP Platform

Figure 23 – Switching using the MSAC module.

The CPU (A or B) reports its status to the MSAC. If it is ONLINE, it generates a pulse train, which is

not generated if it is FAIL. The MSAC reports the other CPU whether it should switch to ONLINE or

not, and if the other CPU is in a FAIL status.

RCAP Protocol

If there is no MSAC module installed, the switching van be performed through the RCAP

(Redundancy Control Asymmetric Protocol) protocol.

In this case, there is a communication channel, which can also be redundant, between the CPU

modules. Using this channel, the CPU modules manage the switching through a Schneider Electric

proprietary protocol (RCAP). The communication channels include:

• Ethernet. Communications are established using an IP address through an Ethernet port.

• Serial. The CPU modules communicate using a serial port in the SM_CPU866e module.

• Communication through the backplane (only available when the two CPU are installed in the

same backplane). The backplane incorporates a dedicated serial channel so that the CPU

modules can communicate.

This switching mechanism is specially recommended when the two control modules are installed in

the same backplane or when they are installed at a short distance.

2.5.2.3 Switching Mode

There are two types of switching: “Cold Data” and “Hot Data”.

Cold Data

Under this mode, there is no communication between the two CPU, and when the switching is

performed, the new ONLINE CPU initializes with a database with default values.

Pag 36

User Manual – Saitel DP Platform

30/06/2020

Figure 24 – Switching status under Cold Data mode.

Hot Data

There are three status defined for each CPU:

• STANDBY: Under this status, the CPU is operational, the defined software modules (coreDb,

synchronization, web server,...) in AutoLoad.cfg, the supervision module and ISaGRAF are

loaded. The other BinControllers are not executed. The CPU does not access to the acquisition

bus, the SM_SER communication bus or generate the PPS. The database is not updated.

• ONLINE: Under this mode, the CPU is operational and all applications are executing. The

protocol BinControllers are executed. The communication is activated through the acquisition

bus and SM_SER communication bus; the PPS is generated.

After the switching, communications and acquisition are resumed, and all parameters use

default values.

• FAIL: Under this status, the CPU is not operational.

By adding a second CPU to a control system, this configuration has the advantage of improving

availability considerably so that maintenance, database modifications and testing tasks can be

carried out over the STANDBY CPU, not comprising the system’s performance.

Under Hot Data mode, there is a high-speed communication channel (Ethernet or backplane)

between the two CPU, which is used to update the STANDBY CPU’s database with the ONLINE

CPU’s database. When a switching is performed, the new ONLINE CPU starts with updated

values. In this operation mode, database IDs must be the identical.

The update is performed by exception; it only sends the values of the points which have changed,

except for the first time when the entire database is updated.

The information which is shared by the two CPU is exclusively related to coreDb points; internal

information about the BinControllers is not shared. This is the reason why, some information may

be lost after a switching. Examples of this type of information are events and commands.

The use of a BinController of the laq type which uses a Profibus protocol sending the status of the

outputs constantly achieves that the values sent as outputs will match the values corresponding to

the actuations performed on the points associated in coreDb.

Pag 37

30/06/2020

User Manual – Saitel DP Platform

NOTICE

Hot Data switching has several peculiarities. We recommend you to contact Saitel Support

For BinControllers using other protocols (101,104, DNP) which send commands by exception, no

command is sent after a switching.

ISaGRAF and supervision BinControllers are executed in the STANDBY CPU. The points with

sources in the supervision BinController are not shared by the two CPU.

Both CPU can initialize in different moments, so there is no guarantee that ISaGRAF sequential

program is under the same status in both CPU. If status synchronization between both programs is

required, it must be implemented in the program itself using ISaGRAF variables mapped to coreDb

signals.

Figure 25 – Switching status under Hot Data mode.

There are three status defined for each CPU:

• STANDBY: Under this status, the CPU is operational, the defined software modules in

AutoLoad.cfg (coreDb, synchronization, web server,...), the supervision module and ISaGRAF

are executed. The other BinControllers are not executed. The CPU does not access to the

acquisition bus, the SM_SER communication bus; the PPS is not generated and dbNET is

disabled. Data related to the point status are received from the other CPU and updated in

coreDb.

• ONLINE: Under this mode, the CPU is operational and all applications and protocol

BinControllers are executing. The communication is activated through the acquisition bus and

communication bus; the PPS is generated.

• FAIL: Under this status, the CPU is not operational.

Service to analyses each particular case.

Pag 38

User Manual – Saitel DP Platform

30/06/2020

NOTICE

The backplanes in Saitel DP family have a jumper (J2) which is required to configure the system

2.5.3 Acquisition Bus Redundancy

The backplanes in Saitel DP include four communication buses for module interconnection.

Figure 26 – Communication buses in the backplane

These four buses are:

• Double Profibus-DP communication bus for the communication between I/O modules and

control module (PF1 and PF2).

• Communication bus for synchronizing acquisition modules (SYN).

• High-speed communication bus for the communication between the control module and

communication modules, SM_SER.

• High-speed communication bus for the communication between the two control modules

installed at the same backplane (CPU).

The acquisition bus redundancy in Saitel DP is achieved by the Profibus DP (RS-485) double bus.

This bus enable distributed acquisition architectures to be defined; it is highly flexible and robust

and can cover distances of up to 1500 meters. The communication rate for these channels is

selectable from 9.6 kbps and 1.5 Mbps.

Profibus redundancy is expandable to other backplanes since the channels: PF1, PF2 and SYN

are outputs in the backplane through the expansion connectors.

with Profibus-DP redundant communications. If the jumper is installed, the Profibus-DP

redundancy is enabled.

Figure 27 – Jumper for Redundancy

Pag 39

30/06/2020

User Manual – Saitel DP Platform

Profibus implementation for Saitel DP has the following features:

• There is only one serial controller for the two Profibus buses.

• Messages both from the master and the slaves are broadcasted through the two buses.

• Both the master and the slaves select the reception bus.

• The redundant bridge must be installed in the backplane in order to be able to select the

listening bus. If uninstalled, the listening bus will always be the bus 1.

• When there is no response in the master (including the attempts), the system switches to the

active listening bus.

• If communication is lost between a slave and the master through the two channels during more

than 8 seconds, this event is detected and the adequate diagnostic led is lit.

• The buses are alternatively monitored every minute. Therefore, both fault detection and

recovery may be delayed one minute.

2.5.4 System’s Duality

The system’s duality is the last option in order to maximize the system’s availability. Duplicity

means that all system's elements are doubled. This is the typical configuration of data hubs and

communication front-ends.

In terms of redundancy, there are two CPU in different backplanes with a specific number of

communication modules associated. Both hot and cold switching, which is arbitrated by the MSAC

module, are possible. Even though generally there is no acquisition, it is possible to have

acquisition modules installed in the CPU's backplanes in this case.

Communication channels are multiplexed by using a logic device.

Figure 28 – Dual system

Pag 40

User Manual – Saitel DP Platform

30/06/2020

+

-

+

-

2.5.5 Recommendations

Following paragraphs provide information about the different types of existing redundancies and

which is the most adequate redundancy for each case. Due to the wide range of redundancy

possibilities available for Saitel 2000DP, these proposals are general and open, so it is possible

that the least recommended options here are the most appropriate for a specific project

2.5.5.1 Power Supply

In non-redundant configurations, the use of an external power supply module is recommended as

the most appropriate option for the backplanes. For the same reasons, it is the recommended

option here.

In this case, two slots are not occupied; they can be used for communication or acquisition

modules. Moreover, since the power supply source is different to the polarization source (if

acquisition is available), one can be down without affecting the other.

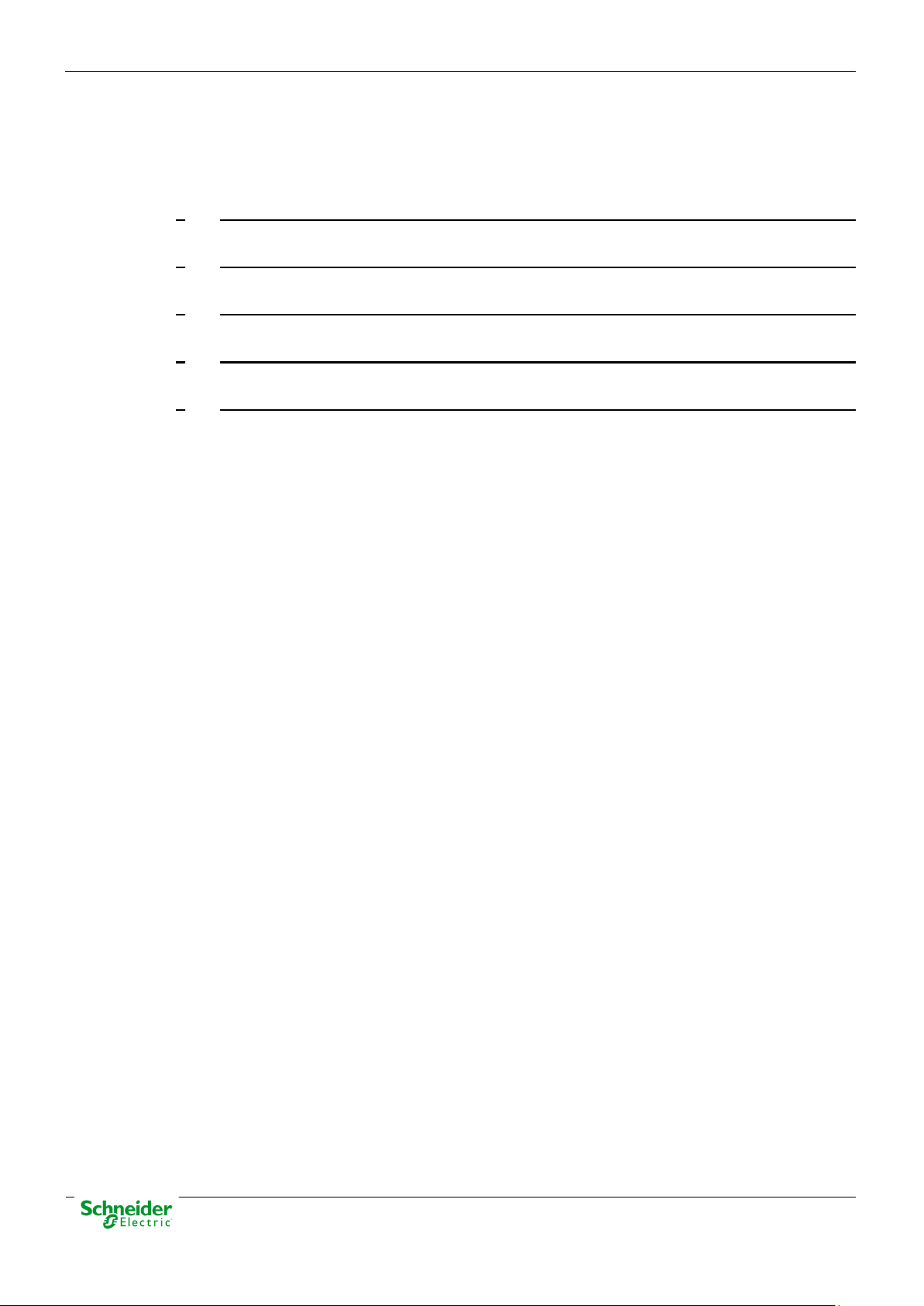

The table below summarizes the options in order of preference:

Table 2 – Recommendation for redundant power supplies

Configuration

Two external PS

One SM_PS40 (primary) and one external PS (secondary)

One external PS (primary) y one SM_PS40 (secondary)

Two SM_PS40

2.5.5.2 Control Unit

It should be noted that all options are not possible sometimes, especially due to location

restrictions in the CPU modules, database specifications or other requirements.

This section does not cover the switching modes, since it is case-specific.

Regardless these aspects, the preferences both in terms of the control mechanism of the CPU

modules and the exchange methods for the database are explained in detailed in further sections.

The recommendations below take into consideration not only the reliability but also the

communication rate provided by each option.

Table 3 – Recommendation for redundant CPU modules

Configuration Features

Backplane

The dedicated communication channel integrated in the backplane

for switching is very robust and accessible for the CPU modules

only.

Channel through a

serial port.

Channel through a

Ethernet port.

MSAC

A direct wiring between the configured serial ports should be used,

preferably ports in the CPU module although the SM_SER module

is also possible.

A crossed Ethernet cable must be used, since it allows longer

distances than serial communication to be covered. In this case, a

dedicated channel is not required but very recommended.

This option allows for a single synchronization source for the

entire system.

Pag 41

30/06/2020

User Manual – Saitel DP Platform

NOTICE

Cooper wired are generally recommended for the connection within a cabinet and optic fiber

+

-

Table 4 – Communication options for “Hot Data” CPU modules

Configuration Features

The dedicated communication channel integrated in the backplane

Backplane

Channel through a

Ethernet port.

to transmit the database values is the same as the channel for

switching control.

It is less robust than the existing channel in the backplane, but it is

the only method available to update the database of the stand-by

CPU if it is installed in a different backplane. Whenever possible, it

is recommended to have this channel in a dedicated network.

2.5.5.3 Acquisition Bus (Profibus)

If the specific subsystem consists only on a backplane, a Profibus redundancy (that is, setting the

enabling jumper or not) has no effect. Nevertheless, when communications with the acquisition

must be established outside the backplane, then they must be more secured.

To do so, it is possible to take two channels from the same expansion connector or obtain each

channel for a connector.

When distances are relatively long, copper wires should not be used, but optic fiber instead. In this

case, the recommended converter is BP2F.

wires between different cabinets.

For the particular case of a system with redundant CPU modules in different backplanes, the status

of Profibus communications in the STANDBY (inoperational) CPU can be monitored by the

ONLINE CPU.

To do so, at least one acquisition module is required in the CPU backplanes. The ONLINE CPU will

be able to access to those modules, and the status of the module’s diagnostic signals of the

STANDBY CPU will be the status of the Profibus channel (or channels) of the STANDBY CPU.

Therefore, the status of the Profibus channel in the backplane of the STANDBY CPU will be

provided by the acquisition module.

Following paragraph includes some example of Probifus expansion.

If the bottom CPU is the ONLINE CPU will be able to know that the upper CPU in STANDBY status

has lost the Profibus channel when the I/O module does not respond.

2.6 RTU Expansion

The RTU can be expanded to other backplanes (including only I/O modules) according to the

system requirements. All technical information about RTU expansion is included in chapter

Physical Mounting & Installing.in this manual.

Each backplane must be connected to the following using only one or two DB9 connectors,

depending on the system architecture.

Pag 42

User Manual – Saitel DP Platform

30/06/2020

NOTICE

It is important to consider that the synchronization bus (SYN) only can be expanded using one

cable. You could expand it using the PF1 or PF2 cable, but only one of them. Otherwise the

system could have problems with the synchronization in the acquisition backplanes.

Following figures show some example for single and redundant systems, using copper or fiber

optic:

Figure 29 – Backplane expansion – A main backplane / A single expansion cable

Figure 30 – Backplane expansion – A main backplane / A cable for each profibus

Pag 43

30/06/2020

User Manual – Saitel DP Platform

Figure 31 – Backplane expansion (using copper) – Redundant backplanes / Two expansion cables

Figure 32 – Backplane expansion (using FO) – Redundant backplanes / Two expansion cables

Pag 44

User Manual – Saitel DP Platform

30/06/2020

3 Baseline Software in Saitel DP

Pag 45

30/06/2020

User Manual – Saitel DP Platform

Contents

3 BASELINE SOFTWARE IN SAITEL DP ................................................................. 45

3.1 GENERAL DESCRIPTION ......................................................................................... 47

3.2 M

3.3 S

3.4 S

3.5 L

3.6 T

AIN ELEMENTS .................................................................................................... 49

3.2.1

3.2.2 D

3.2.3 U

3.2.4 C

3.6.1 I

3.6.2 D

3.6.3 D

3.6.4 A

3.6.5 A

COREDB – REAL TIME DATABASE (RTDB) ...................................................... 49

EVICES ........................................................................................................ 50

SER INTERFACES ......................................................................................... 50

YBERSECURITY ............................................................................................ 50

OFTWARE TOOLS ................................................................................................. 50

OFTWARE COMPATIBILITY .................................................................................... 51

OCAL ACQUISITION .............................................................................................. 52

REATMENT OF LOCAL ACQUISITION SIGNALS ........................................................ 52

NTRODUCTION ............................................................................................... 52

IGITAL INPUTS .............................................................................................. 53

IGITAL OUTPUTS .......................................................................................... 54

NALOG INPUTS ............................................................................................. 55

NALOG OUTPUTS.......................................................................................... 56

Pag 46

User Manual – Saitel DP Platform

30/06/2020

3.1 General Description

The Baseline Software Platform is used with Saitel products and other Schneider Electric products.

It consists of:

• Real-time operating system (RTOS): Linux.

• Real-time applications and configuration files (XML format).

• Software tools: Configuration, local and remote maintenance, supervision and monitorization.

The following figure shows the different applications included in the software platform, as well as

additional applications (Devices) implementing new Devices or protocols to upgrade Easergy

Builder.

Figure 33 – Baseline Software Platform.

The operating system abstracts the hardware from the software applications and manages the

applications in real time. It integrates the basic protocols to access the remote unit (SFTP, SSH,

etc.) and manage multiple users.

The real-time database, named coreDb, is probably the most important element. All the other

elements are developed around coreDb.

Pag 47

30/06/2020

User Manual – Saitel DP Platform

NOTICE

It should be noted that any coreDb signal can be associated to more than one source; this is

Figure 34 – Relation between coreDb and other applications.

The following concepts are related to coreDb:

• Device Controller (also referred to as Controller): Real-time application that accesses coreDb.

Each Controller acts as a producer and/or consumer of information managed by coreDb.

• Point: Each register of coreDb is a point. A point can be included in the table Status, Analog,

Command or Setpoint.

• Device: A set of I/O points that share a common source/destination. A typical example of a

Device is an IED that communicates with the RTU, or the representation of a SCADA

exchanging information acquired or generated by the RTU. A Device is always associated to a

type of Controller.

• Source: Origin of the value of a coreDb data point. Any coreDb data point can have several

different sources (in one or several Devices). This means that a value of a database point can

be configured to be updated by several different entities.

• Destination: Target of the value of a coreDb data point. coreDb data points can be configured

to have several different destinations (in one or several Devices).

only applicable to Command and SetPoint tables. Allocating more than source to one point is

not recommended in Status and Analog tables.

• Coordinate: Point identification within a Device. It is unique for each point and has a different

structure for each Controller.

• Configuration Plugin: Specific Configuration plugins extend the Easergy Builder application to

configure Device Controllers.

The user can modify the configuration of each Controller and Device using the appropriate Plugin.

Once the database is completely configured, the files with the new information can be generated

and transferred to the RTU, where they will be processed by the software on startup.

Pag 48

User Manual – Saitel DP Platform

30/06/2020

NOTICE

The information exchange, that is, the exchange of configuration data between the RTU and

Easergy Builder is not continuous, but performed through XML files under user’s request. When

the configuration is modified in Easergy Builder and the XML files are sent to the RTU, it

is necessary to reboot the RTU.

3.2 Main Elements

For the user, the Baseline Software Platform has the following main elements:

3.2.1 coreDb – Real Time DataBase (RTDB)

coreDb is the real-time database which stores not only the information acquired from field devices,

but also the information about the CPU and I/O modules status that are part of the RTU. coreDb

also relates the acquisition signals to the communication protocol signals. This database is

generated in the CPU by using the configuration information.

The information which is received from field in real time is processed, stored in the RTDB and then

related to the communication protocols signals of the RTU, which function is to transfer that

information to the master device.

Figure 35 – Interfaces with coreDb.

CoreDb points are organized in four tables: Status, Analog, SetPoint and Command to group the

different types of points. These internal tables present the following differences:

• Depending on the point type: status, and command tables support integer values, whereas

setpoint and analog tables manage floating values.

• Depending on the treatment of the point: Status and Analog points can be locked or reset to

initial values, whereas the other two signal types cannot. All types can retain the value in a

non-volatile memory.

Pag 49

30/06/2020

User Manual – Saitel DP Platform

3.2.2 Devices

Each type of device keeps a list of its associated points, identified by unique labels. These labels

allow the identification of each device point unequivocally as source or destination of a coreDb data

point.

Each point is a piece of information produced (or consumed) by a Device. Within a single Device,

point identifiers (coordinates) are unique and cannot be used by two different points.

3.2.3 User Interfaces

The user can use the following tools in order to access to the RTU information:

• Easergy Builder: configuration tool for Schneider Electric RTUs that uses the Baseline

Software Platform. It has to be installed in a PC, and among other features, it can be used to

perform: offline configuration of the general settings of an RTU (IP address, user

administration, communication channels and so on), design and maintenance of coreDb,

administration of the synchronization mechanisms, configuration of the supervision and

monitoring features.

• Console: advanced diagnostic (for expert users only, local or remote connection). It is possible

to connect the PC through the serial cable to the CON port or using an Ethernet cable to an

ETH port and SSH.

• webApp: is the local and remote user interface for online monitoring, operating and

maintaining the CPU.

3.2.4 Cybersecurity

The module SM_CPU866e is provided with a standard security policy and a default RBAC (RoleBased Access Control) model), allowing different levels of user access adapted to this CPU usage

compliant with standard IEC 62351-8. This model is defined and managed by a special tool - CAE.

Based in this model, authorized users can create and manage other users in the system. Also, the

CPU includes a firewall.

3.3 Software Tools

A basic configuration is included with CPU, which should be adapted to the requirement of the

system. Depending on the CPU and the baseline installed on it, following software tools will be

available for configuration or maintenance:

• Easergy Builder: Engineering tool for the RTU OFFLINE configuration. It allows to include and