Page 1

English

8 P02 501 EN.01/01

www.schneider-electric.com

Page 2

General remarks

The following symbols should assist you in handling the instructions:

Advice, tip !

General information, note exactly !

The requirements for successful commissioning are correct selection of the device, proper planning and installation. If you have

any further questions, please contact the supplier of the device.

Capacitor discharge !

Before performing any work on or in the device, disconnect it from the mains and wait at least 15 minutes until the capacitors have

been fully discharged to ensure that there is no voltage on the device.

Automatic restart !

With certain parameter settings it may happen that the frequency inverter restarts automatically when the mains supply returns

after a power failure. Make sure that in this case neither persons nor equipment is in danger.

Commissioning and service !

Work on or in the device must be done only by duly qualified staff and in full compliance with the appropriate instructions and

pertinent regulations. In case of a fault contacts which are normally potential-free and/or PCBs may carry dangerous voltages. To

avoid any risk to humans, obey the regulations concerning "Work on Live Equipment" explicitly.

Terms of delivery

The latest edition "General Terms of Delivery of the Austrian Electrical and Electronics Industry Association" form the basis of our

deliveries and services.

Specifications in this document

We are always anxious to improve our products and adapt them to the latest state of the art. Therefore, we reserve the right to

modify the specifications given in this document at any time, particular those referring to weights and dimensions. All planning

recommendations and connection examples are non-binding suggestions for which we cannot assume liability, particularly

because the regulations to be complied depend on the type and place of installation and on the use of the devices.

All foreign-language translations result from the German or English version. Please consider those in case of unclarity.

Basis of contract

The specifications in text and drawings of this document are no subject of contract in the legal sense without explicit confirmation.

Regulations

The user is responsible to ensure that the device and its components are used in compliance with the applicable regulations. It is

not permitted to use these devices in residential environments without special measures to suppress radio frequency

interferences.

Trademark rights

Please note that we do not guarantee that the connections, devices and processes described herein are free from patent or

trademark rights of third parties.

Copyright

Layout, equipment, logos, texts, diagrams and pictures of this document are copyrighted. All rights are reserved.

Page 3

Altivar Frequency inverters for medium voltage motors

ATV61HC••N4D387 or ATV61HC••Y387

110...630, 3AC 380 to 480 V or

110...800, 3AC 500, 600 or 690 V

Theme Page

The inverter solution for medium voltage motors .....................3

Application...........................................................................4

Advantages of the speed control ........................................5

Speed control of medium voltage motors...........................7

Specification ..............................................................................8

Technical data .....................................................................8

Mains voltage 400 … 440 V, 50 Hz ...................................10

Mains voltage 480 V, 60 Hz...............................................12

Mains voltage 690 V, 50 Hz...............................................14

Step-down transformer (440 V, 50 Hz)..............................16

Step-down transformer (725 V, 50 Hz)..............................18

Technical data of the power transformer (step-down)......20

12-pulse supply .................................................................21

Technical data of the output transformer (step-up) ..........22

Wiring and connection.............................................................23

Wiring diagram for low voltage supply ..............................23

Wiring diagram for medium voltage supply ......................25

Allocation table for options depending on the power .......27

Parameterization......................................................................28

Frequency inverter settings ...............................................28

Motor data .........................................................................29

8 P02 501 EN.01/01 07/2010 8 P02 501 EN.01/01 07/2010

The instructions in hand cover the topics rating and dimensioning as well as parameterization of a

ATV61HC••N4D387 or ATV61HC••Y387 frequency inverter for the operation of medium voltage

motors.

Use this instructions additionally to the device documentation "Description of functions" and

"Mounting instructions".

1

Page 4

8 P02 501 EN.01/01 07/2010

2

Page 5

The inverter solution for medium voltage motors

(only with squared load torque)

The ATV61 adds even more numerous functions to the well-known

and extremely well-proven features of the Altivar inverter range. It

presents itself to the user as being even more robust with improved

operation and having a clearly wider range of user possibilities.

The choice comprises the ATV61 frequency inverter in

various cubicle designs in addition to the built-in and wallmounting designs.

The basic design of the Altivar customized enclosure

complies with protection degree IP23 and IP54 and

includes a main switch, mains fuses, AC choke, sinus filter

and motor terminals. Further installed components, such

as circuit breaker, line contactor, various control options,

alternatively with a field bus, safety relay, cubicle heating,

and much more, see ATV61 catalogue.

8 P02 501 EN.01/01 07/2010 8 P02 501 EN.01/01 07/2010

In addition, special designs are available such as changed

cubicle colour, cubicle cooling via an air conditioner or an

air/water heat exchanger, and customer-specific control

equipment.

3

Page 6

Application

There is a wide application area for medium voltage motors. Many existing systems from approx. 200 kW use

medium voltage motors for pumps or fans. The flow control often takes place by simple mechanical

components like valves and flaps and so it represents a very inefficient operation.

Also for new systems medium voltage motors with a power range below 1 MW are used. That applies mainly to

pump technology for petrochemical and geothermal applications. The length of the motor cables often

exceeds more than 1000 m but when using medium voltage motors undesired voltage drops at the lines can

be avoided.

8 P02 501 EN.01/01 07/2010

4

Page 7

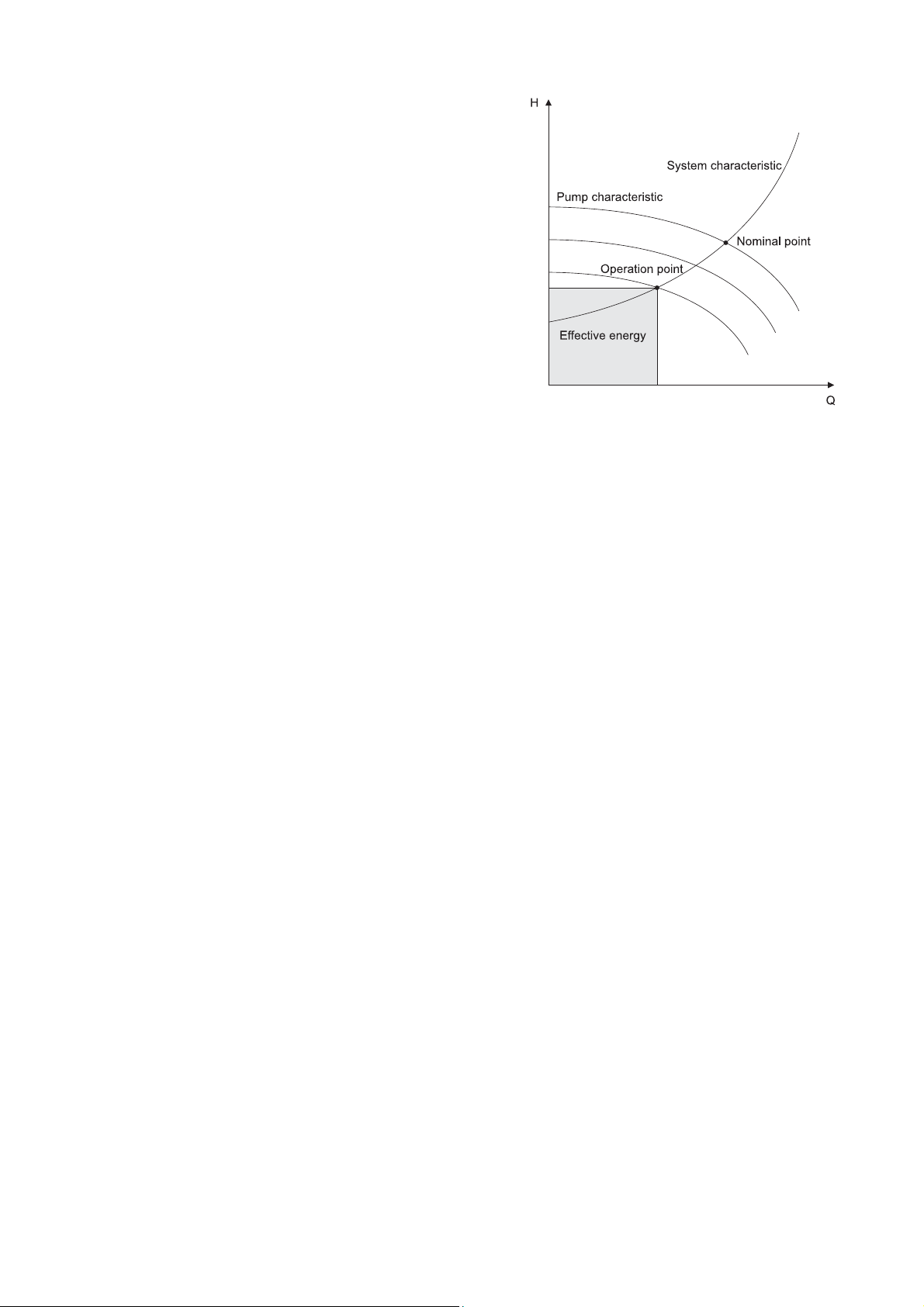

Advantages of the speed control

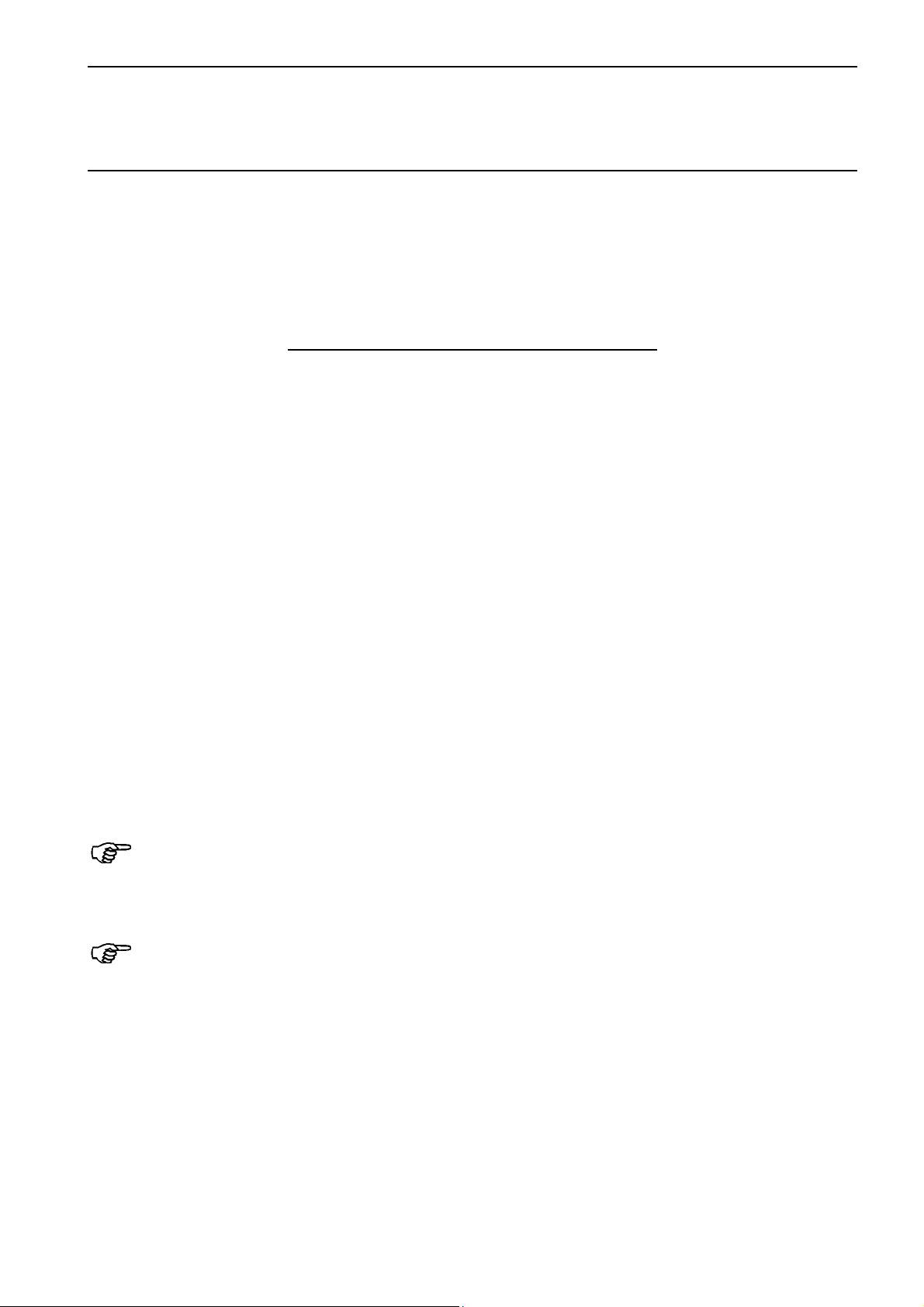

Restriction

The restriction of the flow rate is common practice. Thereby the

system characteristic is changed by increasing the friction due

to reduction of the cross section. The losses arising due to the

restriction are proportional to the area Q x H.

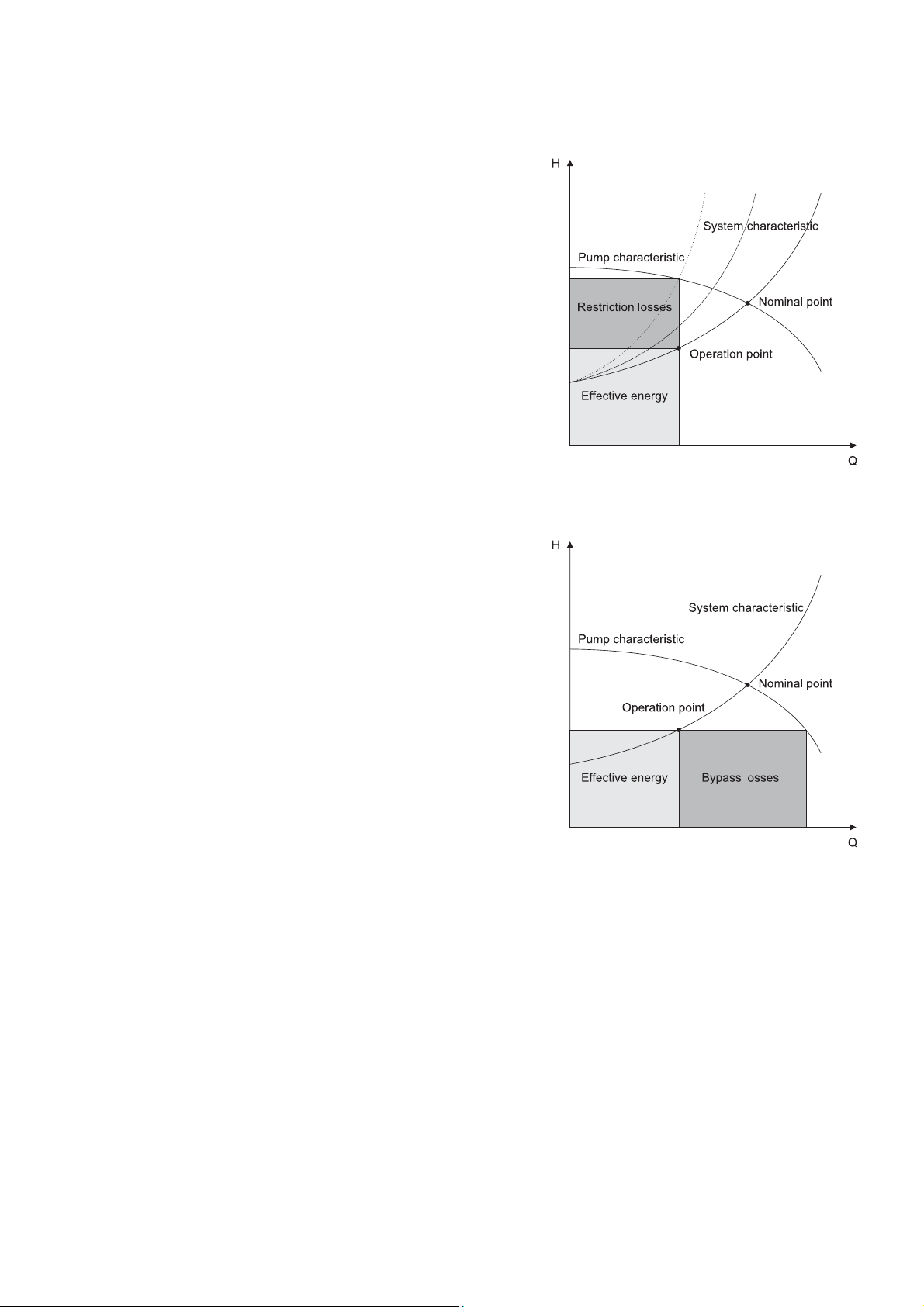

Bypass

In case of a pump operated with constant speed the flow rate

can be controlled in such a way that only those part is

separated which is required for the system and the residual

rate is returned to the intake area. The arising losses due to the

returning flow medium is proportional to the area Q x H.

8 P02 501 EN.01/01 07/2010 8 P02 501 EN.01/01 07/2010

5

Page 8

Speed control

Regarding technic and energy the most advantageous

possiblity for changing the flow rate is the operation of the

centrifugal pump with variable speed. This operating mode

leads to a parallel displacement of the pump characteristic. In

case of this method additional, continuous actuators in the

system are not necessary because the pump also assumes the

part of the actuator with integral function.

At the operation of a centrifugal pump the effect occurs that

the efficiency remains within its optimum range for speed

control ranges from 1:3 to 1:5. This property of the centrifugal

pump is the basis for the fact that speed control is a very low

price variant in comparison with other methods. Because of the

achieved energy saving the costs for purchasing the frequency

inverter amortize within short time.

Further advantages of the speed control are avoiding current peaks in the supplying mains due to direct-online starting as well as preserving the mechanics of the pump and avoiding shock pressures in the hydraulic

system by controlled acceleration and deceleration along the set ramps.

8 P02 501 EN.01/01 07/2010

6

Page 9

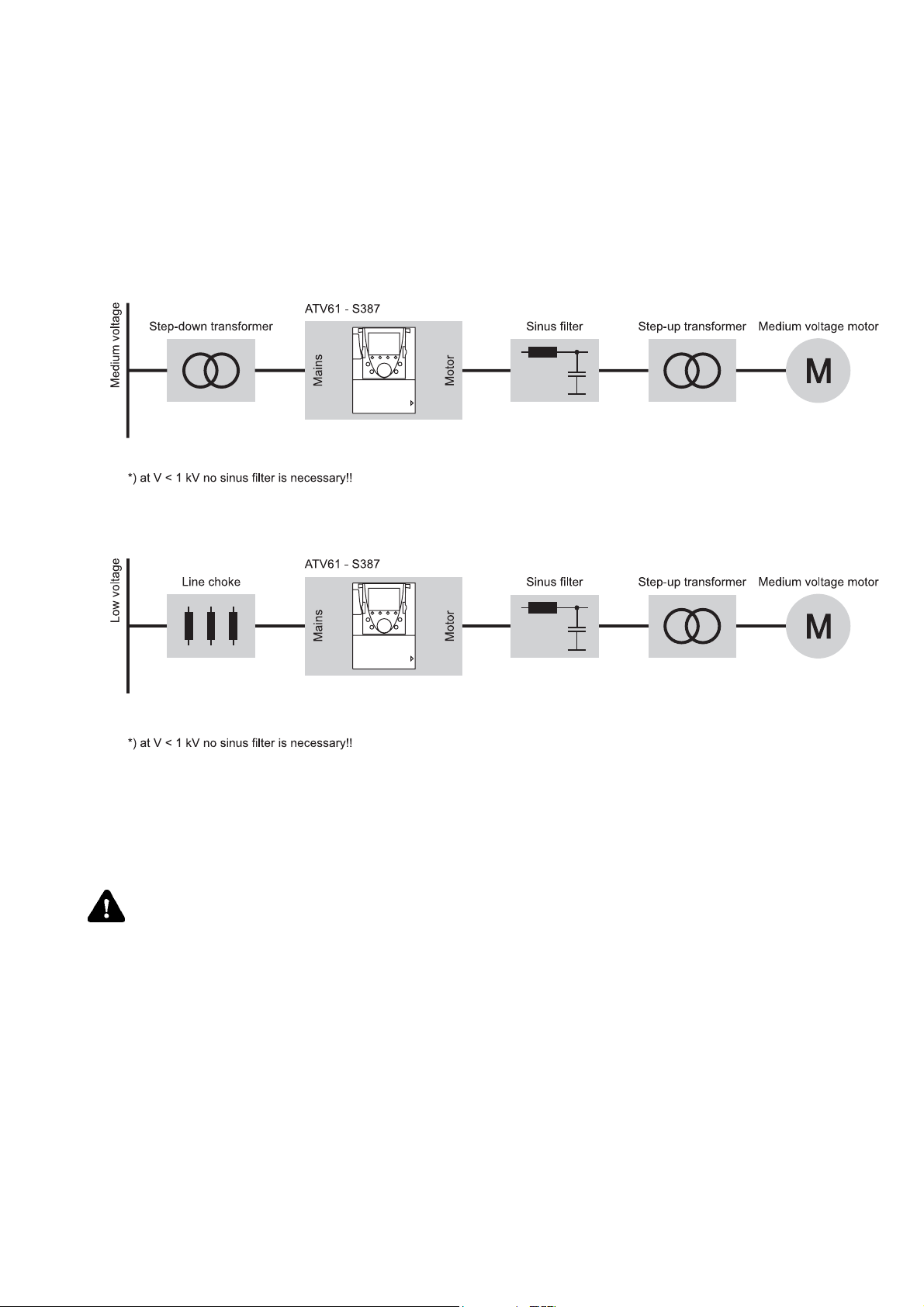

Speed control of medium voltage motors

A medium voltage frequency inverter is not the only solution for the speed control of medium voltage motors.

Based on standard well proven low voltage components the Altivar transformer solution is a very economical

alternative.

There are two configurations in principle:

1. The drive is connected in the medium voltage line of the motor

2. The drive is supplied by low voltage and operates a medium voltage motor

8 P02 501 EN.01/01 07/2010 8 P02 501 EN.01/01 07/2010

Thereby the medium voltage value of the motor is not defined because accurate adaptation takes place by the

transformers.

These ATV61 are available from 110 kW and above!

7

Page 10

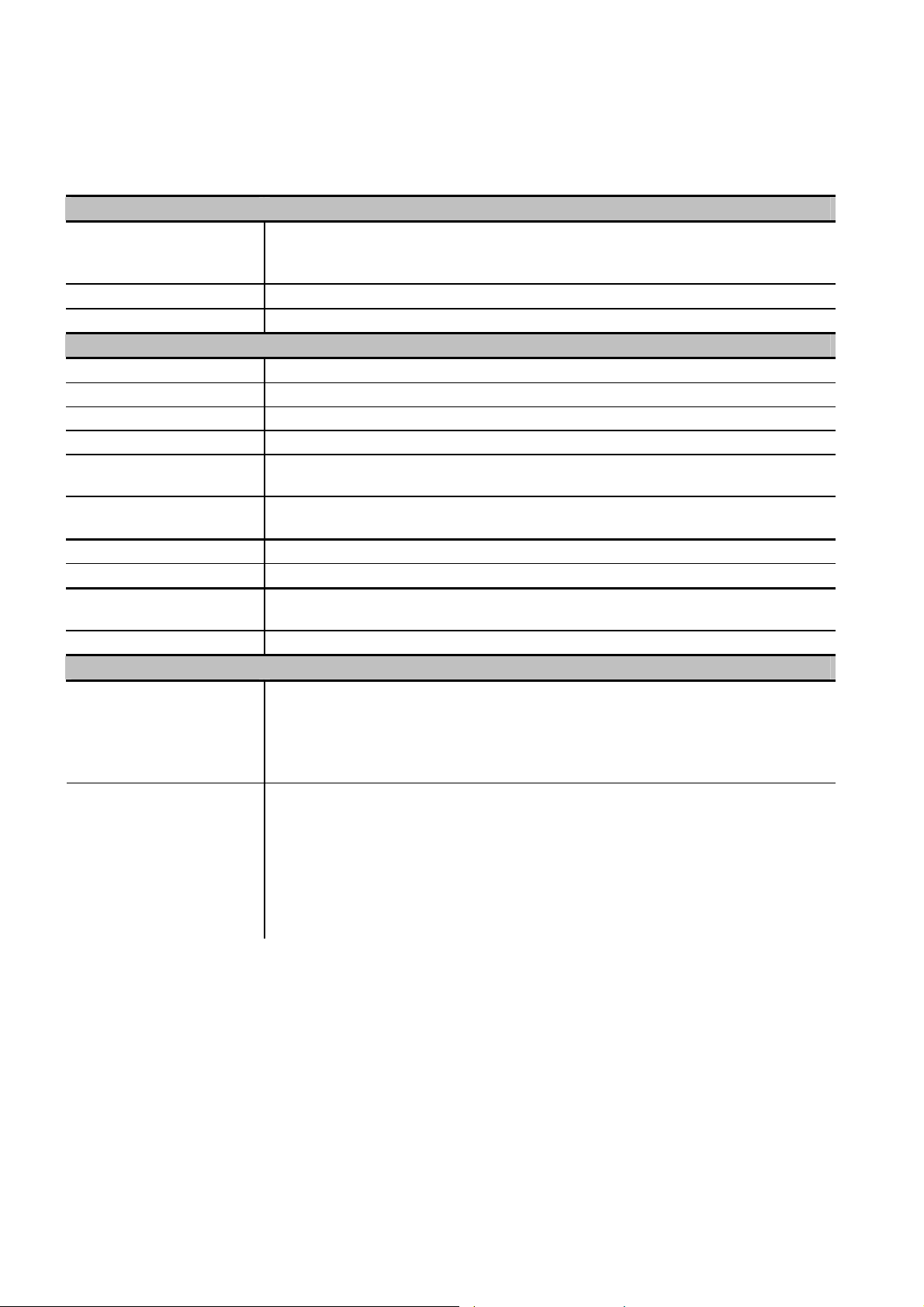

Specification

Technical data

Input

ATV61HC••N4D387: 380 V -15% to 480 V +10% for TT, TN or IT-mains *)

Voltage

Frequency

Overvoltage class Class III according to EN 50178

Output

Control method V/f-characteristic

Voltage 3 AC 0...100% mains voltage, dynamic voltage stabilization

Overload 20 % for 60 s or 35 % for 2 s

Pulse frequency 2.5 kHz, not adjustable

Frequency / Base

frequency

Short circuit protection

Design Built-in unit for vertical mounting

Cooling forced

Frequency resolution,

digital

Speed accuracy Slip frequency

Mechanical strength

Mechanical vibration

Shock

*) See ATV61 catalogue for technical data and remarks for mains voltages.

ATV61HC••Y387: 500 V -15% to 690 V +10% for TT, TN or IT-mains *)

not for corner grounded

50 / 60 Hz ±5 % *)

0...100 Hz / 25...100 Hz, adjustable

All-pole protected against short circuit and earth fault by means of overcurrent

switch-off

0.01 Hz / 50 Hz, frequency stability: ±0.01 % / 50 Hz

according to IEC/EN 60068-2-6

ATV61HC11N4D387…63N4D387

ATV61HC11Y387…80Y387:

1.5 mm in the range of 3...10 Hz,

0.6 g at 10...200 Hz

(3M3 according to IEC/EN 60721-3-3)

according to IEC/EN 60068-2-27

ATV61HC11N4D387…16N4D387

ATV61HC11Y387…20Y387:

ATV61HC22N4D387…63N4D387

ATV61HC25Y387…80Y387:

7 g for 11 ms

(3M3 according to IEC/EN 60721-3-3)

4 g for 11 ms

(3M3 according to IEC/EN 60721-3-3)

8 P02 501 EN.01/01 07/2010

8

Page 11

Ambient conditions

Operating temperature

Storage / Transport

temperature

Protection degree

Environmental class / Humidity

Altitude

Allowed pollution

-10...+45°C

(3K3 according to IEC/EN 60721-3-3)

up to +60°C with derating

-25...+70°C

sideways, front IP31

top IP20 (IP31 with DC box)

bottom IP00 (IP31 with terminal box)

Class 3K3 in accordance with IEC/EN 60721-3-3 / no condensation, max.

95 % relative humidity

ATV61HC••N4D387: up to 1000 m, beyond power decrease up to 3000 m

ATV61HC••Y387: up to 1000 m, beyond power decrease up to 2400 m

Pollution degree 2 according to EN 61800-5-1

3C2 and 3S2 according to

EN 60721-3-3

Protection class Class 1 according EN 50178

Standards

Basic standard The devices are designed, built and tested on the basis of EN 50178.

EMC immunity

EMC emission

8 P02 501 EN.01/01 07/2010 8 P02 501 EN.01/01 07/2010

Insulation

According to EN 61800-3, 1st and 2nd environment

(IEC 1000-4-2; IEC 1000-4-3; IEC 1000-4-4; IEC 1000-4-5; IEC 1000-4-6)

in accordance with product standard EN 61800-3,

2nd environment, category C3

Galvanic insulation in accordance with EN 50178 PELV (Protective Extra

Low Voltage)

Approvals CE, UL, CSA

9

Page 12

Mains voltage 400 … 440 V, 50 Hz

The ATV61HC••N4D387 frequency inverter is supplied with low

voltage. The voltage on the motor side will be transformed to

medium voltage via a step-up transformer in order to supply

the medium voltage motor.

ATV61HC 11N4D387 13N4D387 16N4D387 22N4D387 25N4D387

Motor rating

PN [kW] 110 132 160 200 250

Reachable motor power

P [kW] VN = 400 V 104 126 155 189 238

P [kW] VN = 440 V 110 132 160 200 250

Nominal data

Continuous output power

S

[kVA] VN = 400 V 132 160 196 238 299

N 400

S

[kVA] VN = 440 V 149 181 221 270 338

N 440

Continuous output current

IN [A] 215 259 314 387 481

Maximum current for 60 s per 10 minutes

I

[A] 258 311 377 464 577

MAX

Input current

IIN [A] 188 226 271 338 418

Characteristics of the inverter

Efficiency [%] 97.5 97.5 97.6 97.7 97.7

Losses [W] at IN 2810 3330 3710 4450 5890

Weight approx. [kg] 60 74 80 110 140

Characteristics of sinus filter

Losses [W] at IN 945 1360 1600 1900 2100

Weight approx. [kg] 130 165 190 190 235

Ambient conditions

Volume of cooling air

3

/h]

[m

Sound pressure level

[dB(A)]

Mains short circuit

current [kA]

400 600 600 800 1200

61 69 71 72 73

35 35 50 50 50

8 P02 501 EN.01/01 07/2010

10

Page 13

ATV61HC 31N4D387 40N4D387 50N4D387 63N4D387

Motor rating

PN [kW] 315 400 500 630

Reachable motor power

P [kW] VN = 400 V 302 384 474 588

P [kW] VN = 440 V 315 400 500 630

Nominal data

Continuous output power

S

[kVA] VN = 400 V 378 477 586 730

N 400

S

[kVA] VN = 440 V 427 539 661 826

N 440

Continuous output current

IN [A] 616 759 941 1188

Maximum current for 60 s per 10 minutes

I

[A] 739 911 1129 1426

MAX

Input current

IIN [A] 527 660 834 1037

Characteristics of the inverter

Efficiency [%] 97.7 97.8 97.8 97.8

Losses [W] at IN 7250 8810 11150 13830

Weight approx. [kg] 140 215 225 300

Characteristics of sinus filter

Losses [W] at IN 2370 3300 4100 5150

Weight approx. [kg] 235 600 600 600

Ambient conditions

Volume of cooling air

3

/h]

[m

8 P02 501 EN.01/01 07/2010 8 P02 501 EN.01/01 07/2010

Sound pressure level

[dB(A)]

Mains short circuit

current [kA]

1200 1800 1800 2400

73 75 75 75

50 50 50 50

11

Page 14

Mains voltage 480 V, 60 Hz

The ATV61HC••N4D387 frequency inverter is supplied with low

voltage. The voltage on the motor side will be transformed to

medium voltage via a step-up transformer in order to supply

the medium voltage motor.

ATV61HC 11N4D387 13N4D387 16N4D387 22N4D387 25N4D387

Motor rating

PN [HP] 150 200 250 300 400

Reachable motor power

P [HP] UN = 480 V 150 200 245 298 376

Nominal data

Continuous output power

S

[kVA] VN = 480 V 156 190 233 283 355

N 480

Continuous output current

IN [A] 215 259 314 387 481

Maximum current for 60 s per 10 minutes

I

[A] 258 311 377 464 577

MAX

Input current

IIN [A] 168 224 275 331 435

Characteristics of the inverter

Efficiency [%] 97.5 97.5 97.6 97.7 97.7

Losses [W] at IN 2810 3330 3710 4450 5890

Weight approx. [kg] 60 74 80 110 140

Characteristics of sinus filter

Losses [W] at IN 945 1360 1600 1900 2100

Weight approx. [kg] 130 165 190 190 235

Ambient conditions

Volume of cooling air

3

/h]

[m

Sound pressure level

[dB(A)]

Mains short circuit

current [kA]

400 600 600 800 1200

61 69 71 72 73

35 35 50 50 50

8 P02 501 EN.01/01 07/2010

12

Page 15

ATV61HC 31N4D387 40N4D387 50N4D387 63N4D387

Motor rating

PN [HP] 500 600 700 900

Reachable motor power

P [HP] UN = 480 V 475 600 700 900

Nominal data

Continuous output power

S

[kVA] VN = 480 V 448 568 695 865

N 480

Continuous output current

IN [A] 616 759 941 1188

Maximum current for 60 s per 10 minutes

I

[A] 739 911 1129 1426

MAX

Input current

IIN [A] 544 644 760 964

Characteristics of the inverter

Efficiency [%] 97.7 97.8 97.8 97.8

Losses [W] at IN 7250 8810 11150 13830

Weight approx. [kg] 140 215 225 300

Characteristics of sinus filter

Losses [W] at IN 2370 3300 4100 5150

Weight approx. [kg] 235 600 600 600

Ambient conditions

Volume of cooling air

3

/h]

[m

Sound pressure level

[dB(A)]

8 P02 501 EN.01/01 07/2010 8 P02 501 EN.01/01 07/2010

Mains short circuit

current [kA]

1200 1800 1800 2400

73 75 75 75

50 50 50 50

13

Page 16

Mains voltage 690 V, 50 Hz

The ATV61HC••Y387 frequency inverter is supplied with low

voltage. The voltage on the motor side will be transformed to

medium voltage via a step-up transformer in order to supply

the medium voltage motor.

ATV61HC 11Y387 13Y387 16Y387 20Y387 25Y387

Motor rating

PN [kW] 110 132 160 200 250

Reachable motor power

P [kW] VN = 690 V 108 130 158 192 250

Nominal data

Continuous output power

SN [kVA] 139 167 201 242 326

Continuous output current

IN [A] 125 150 180 220 290

Maximum current for 60 s per 10 minutes

I

[A] 150 180 216 264 348

MAX

Input current

IIN [A] 117 137 163 199 257

Characteristics of the inverter

Efficiency [%] 97.9 97.9 97.9 97.9 98.0

Losses [W] at IN 2320 2750 3290 4030 5160

Weight approx. [kg] 80 80 80 80 140

Characteristics of sinus filter

Losses [W] at IN 800 1000 1200 1500 1900

Weight approx. [kg] 210 210 210 210 300

Ambient conditions

Volume of cooling air

3

/h]

[m

Sound pressure level

[dB(A)]

Mains short circuit

current [kA]

600 600 600 600 1200

71 71 71 71 73

28 28 35 35 35

8 P02 501 EN.01/01 07/2010

14

Page 17

ATV61HC 31Y387 40Y387 50Y387 63Y387 80Y387

Motor rating

PN [kW] 315 400 500 630 800

Reachable motor power

P [kW] VN = 690 V 315 371 495 605 749

Nominal data

Continuous output power

SN [kVA] 395 463 612 752 924

Continuous output current

IN [A] 355 420 543 675 840

Maximum current for 60 s per 10 minutes

I

[A] 426 504 652 810 1008

MAX

Input current

IIN [A] 317 394 505 616 775

Characteristics of the inverter

Efficiency [%] 98.0 98.0 98.0 98.0 98.0

Losses [W] at IN 6310 7550 9660 11950 14980

Weight approx. [kg] 140 140 300 300 300

Characteristics of sinus filter

Losses [W] at IN 2300 2800 3200 3800 4810

Weight approx. [kg] 300 300 400 400 400

Ambient conditions

Volume of cooling air

3

/h]

[m

Sound pressure level

[dB(A)]

8 P02 501 EN.01/01 07/2010 8 P02 501 EN.01/01 07/2010

Mains short circuit

current [kA]

1200 1200 2400 2400 2400

73 73 75 75 75

35 42 42 42 42

15

Page 18

Step-down transformer (up to 6 kV mains voltage)

The ATV61HC••N4D387 frequency inverter is supplied via a

step-down transformer with low voltage from a medium

voltage mains. The voltage on the motor side will be

transformed to medium voltage via a step-up transformer

again in order to supply the medium voltage motor.

ATV61HC 11N4D387 13N4D387 16N4D387 22N4D387 25N4D387

Motor rating

PN [kW] 110 132 160 200 250

Reachable motor power

P [kW] VN = 440 V 110 132 160 200 250

Nominal data

Continuous output power

SN [kVA] 151 184 224 273 342

Continuous output current

IN [A] 215 259 314 387 481

Maximum current for 60 s per 10 minutes

I

[A] 258 311 377 464 577

MAX

Input current

IIN [A] 188 226 271 338 418

Characteristics of the inverter

Efficiency [%] 97.5 97.5 97.6 97.7 97.7

Losses [W] at IN 2810 3330 3710 4450 5890

Weight approx. [kg] 60 74 80 110 140

Characteristics of sinus filter

Losses [W] at IN 945 1360 1600 1900 2100

Weight approx. [kg] 130 165 190 190 235

Ambient conditions

Volume of cooling air

3

/h]

[m

Sound pressure level

[dB(A)]

400 600 600 800 1200

61 69 71 72 73

8 P02 501 EN.01/01 07/2010

16

Page 19

ATV61HC 31N4D387 40N4D387 50N4D387 63N4D387

Motor rating

PN [kW] 315 400 500 630

Reachable motor power

P [kW] VN = 440 V 315 400 500 630

Nominal data

Continuous output power

SN [kVA] 433 546 670 836

Continuous output current

IN [A] 616 759 941 1188

Maximum current for 60 s per 10 minutes

I

[A] 739 911 1129 1426

MAX

Input current

IIN [A] 527 660 834 1037

Characteristics of the inverter

Efficiency [%] 97.7 97.8 97.8 97.8

Losses [W] at IN 7250 8810 11150 13830

Weight approx. [kg] 140 215 225 300

Characteristics of sinus filter

Losses [W] at IN 2370 3300 4100 5150

Weight approx. [kg] 235 600 600 600

Ambient conditions

Volume of cooling air

3

/h]

[m

Sound pressure level

[dB(A)]

8 P02 501 EN.01/01 07/2010 8 P02 501 EN.01/01 07/2010

1200 1800 1800 2400

73 75 75 75

17

Page 20

Step-down transformer (up to 6 kV mains voltage)

The ATV61HC••Y387 frequency inverter is supplied via a

step-down transformer with low voltage from a medium

voltage mains. The voltage on the motor side will be

transformed to medium voltage via a step-up transformer

again in order to supply the medium voltage motor.

ATV61HC 11Y387 *) 13Y387 *) 16Y387 *) 20Y387 *) 25Y387 *)

Motor rating

PN [kW] 110 132 160 200 250

Reachable motor power

P [kW] VN = 725 V 110 132 160 200 250

Nominal data

Continuous output power

SN [kVA] 144 173 209 252 339

Continuous output current

IN [A] 125 150 180 220 290

Maximum current for 60 s per 10 minutes

I

[A] 150 180 216 264 348

MAX

Input current

IIN [A] 117 137 163 199 257

Characteristics of the inverter

Efficiency [%] 97.9 97.9 97.9 97.9 98.0

Losses [W] at IN 2320 2750 3290 4030 5160

Weight approx. [kg] 80 80 80 80 140

Characteristics of sinus filter

Losses [W] at IN 800 1000 1200 1500 1900

Weight approx. [kg] 210 210 210 210 300

Ambient conditions

Volume of cooling air

3

/h]

[m

Sound pressure level

[dB(A)]

*) ... Can be used as alternative to the 400V drives.

600 600 600 600 1200

71 71 71 71 73

8 P02 501 EN.01/01 07/2010

18

Page 21

ATV61HC 31Y387 *) 40Y387 *) 50Y387 *) 63Y387 *) 80Y387

Motor rating

PN [kW] 315 400 500 630 800

Reachable motor power

P [kW] VN = 725 V 315 387 500 630 780

Nominal data

Continuous output power

SN [kVA] 411 481 637 783 962

Continuous output current

IN [A] 355 420 543 675 840

Maximum current for 60 s per 10 minutes

I

[A] 426 504 652 810 1008

MAX

Input current

IIN [A] 317 394 505 616 775

Characteristics of the inverter

Efficiency [%] 98.0 98.0 98.0 98.0 98.0

Losses [W] at IN 6310 7550 9660 11950 14980

Weight approx. [kg] 140 140 300 300 300

Characteristics of sinus filter

Losses [W] at IN 2300 2800 3200 3800 4810

Weight approx. [kg] 300 300 400 400 400

Ambient conditions

Volume of cooling air

3

/h]

[m

Sound pressure level

[dB(A)]

8 P02 501 EN.01/01 07/2010 8 P02 501 EN.01/01 07/2010

1200 1200 2400 2400 2400

73 73 75 75 75

*) ... Can be used as alternative to the 400V drives.

19

Page 22

Technical data of the power transformer (step-down)

A three-phase resin-encapsulated transformer has to be used which is suitable to supply a frequency inverter

with a diode rectifier.

Select the primary voltage in accordance to the mains voltage. The transformer must contain taps to adapt the

voltage between ±5 % (or 2 x ±2.5 %).

The secondary voltage (no-load voltage of the transformer) is 440 V at ATV61HC••N4D387 and 725 V at

ATV61HC••Y387.

Choose the nominal transformer power from the table below.

Altivar Transformer output current Recommended vSC Harmonic content

ATV61HC11N4D387 188 A 4 % 42 %

ATV61HC13N4D387 226 A 4 % 42 %

ATV61HC16N4D387 271 A 4 % 42 %

ATV61HC22N4D387 338 A 4 % 42 %

ATV61HC25N4D387

ATV61HC31N4D387 527 A 4 % 42 %

ATV61HC40N4D387 660 A 6 % 35 %

ATV61HC50N4D387

ATV61HC63N4D387

ATV61HC11Y387

ATV61HC13Y387

ATV61HC16Y387

ATV61HC20Y387

ATV61HC25Y387

ATV61HC31Y387 317 A 4 % 42 %

ATV61HC40Y387 394 A 6 % 35 %

ATV61HC50Y387

ATV61HC63Y387

ATV61HC80Y387

418 A

6-pulse: 834 A

12-pulse: 2 x 417 A

6-pulse: 1037 A

12-pulse: 2 x 519 A

4 % 42 %

6 % 35 %

6 % 35 %

117 A 4 % 42 %

137 A 4 % 42 %

163 A 4 % 42 %

199 A 4 % 42 %

257 A 4 % 42 %

6-pulse: 505 A

12-pulse: 2 x 253 A

6-pulse: 616 A

12-pulse: 2 x 308 A

6-pulse: 775 A

12-pulse: 2 x 388 A

6 % 35 %

6 % 35 %

6 % 35 %

8 P02 501 EN.01/01 07/2010

20

Page 23

12-pulse supply

The following inverters are standard equipped with two parallel input rectifiers and therefore are suitable for a

12-pulse rectification

ATV61HC50N4D387…HC63N4D387

ATV61HC50Y387…HC80Y387

The supply results from a separate transformer with two out-of-phase secondary windings (e.g. Yy6d5).

On the main side of the transformer the 5th and 7th current harmonics are practically non-existent as they have

been cancelled by the shifted transformer windings.

The transformer must keep to the following tolerances in order to guarantee a constant current sharing:

Tolerance of the transmission rates ± 0.3 % of r

Tolerance of the relative short circuit voltage ± 5.0 % of v

The nominal output voltage of a transformer is specified at no load operation. Therefore this value has

to be appr. 5 % higher than the rated voltage of the drive.

NOM

SC_NOM

*) Line chokes are only necessary if a trans-

former is used for several inverters or if the

transformer power is notedly larger than the

inverter power.

In case of 12-pulse supply the radio frequency interference filters, which are built into the ATV61 as

standard, must be reconnected onto setting "IT mains".

8 P02 501 EN.01/01 07/2010 8 P02 501 EN.01/01 07/2010

21

Page 24

Technical data of the output transformer (step-up)

A three-phase resin-encapsulated transformer has to be used.

Select the primary voltage as well as the secondary voltage (no-load voltage) of the transformer in the table

below for motors with a nominal voltage of 6kV:

Primary voltage

Input voltage of the frequency inverter

of the

transformer

ATV61HC••N4D387 at 400V mains 365 V 6450 V 6550 V

ATV61HC••N4D387 at 440V mains 410 V 6400 V 6500 V

ATV61HC••N4D387 at 480V mains 430 V 6450 V 6500 V

ATV61HC••N4D387 with step-down transformer 410 V 6400 V 6500 V

ATV61HC••Y387 at 690V mains 645 V 6500 V 6500 V

ATV61HC••Y387 with step-down transformer 670 V 6500 V 6500 V

The no-load voltage of the transformer can be calculated for motors with different nominal voltage as follows:

Transformer no-load voltage = Secondary transformer voltage (acc. table) * nominal motor voltage / 6000 V

Example: ATV61HC••N4D387 at 400 V mains, with step-up transformer with 4 % v

nominal voltage

Transformer no-load voltage = 6450 V * 4160 V / 6000 V = 4472 V

The transformer must be designed for a DC-voltage share of 100 mV.

Choose the primary current from the table below:

Altivar

ATV61HC11N4D387

ATV61HC13N4D387

ATV61HC16N4D387

ATV61HC22N4D387

ATV61HC25N4D387

ATV61HC31N4D387

ATV61HC40N4D387

ATV61HC50N4D387

ATV61HC63N4D387

ATV61HC11Y387

ATV61HC13Y387

Transformer input

current

215 A 4 %

259 A 4 %

314 A 4 %

387 A 4 %

481 A 4 %

616 A 4 %

759 A 4 %

941 A 6 %

1188 A 6 %

125 A 4 %

150 A 4 %

Recommended

vSC

ATV61HC16Y387 180 A 4 %

ATV61HC20Y387 220 A 4 %

ATV61HC25Y387 290 A 4 %

ATV61HC31Y387 355 A 4 %

ATV61HC40Y387 420 A 4 %

ATV61HC50Y387 543 A 6 %

ATV61HC63Y387 675 A 6 %

ATV61HC80Y387 840 A 6 %

Secondary voltage of the

transformer

at vSC = 4 % at vSC = 6 %

and motor with 4160 V

SC

8 P02 501 EN.01/01 07/2010

22

Page 25

Wiring and connection

Wiring diagram for low voltage supply

The following diagrams show the typical wiring of the ATV61 frequency inverters including the options which

may be required for protection of the plant or the device, depending on the application.

ATV61HC11N4D387…HC40N4D387 or ATV61HC11Y387… HC40Y387

supplied by a low voltage mains

ATV61 ...................Frequency inverter

Q1 ......................... Main switch (to be used if required according to the local regulations)

F1.......................... Mains fuses considering the table in the product catalogue (absolutely necessary)

8 P02 501 EN.01/01 07/2010 8 P02 501 EN.01/01 07/2010

KM1 ......................Mains contactor (to be used if required according to the local regulations)

line choke..............Line reactor

Option to reduce the current harmonics on the mains caused by the DC link.

internal filter ..........Radio frequency interference filter built-in as standard

considering category C3 according to EN 61800-3 "Use in industrial environments"

sinus filter.............. Output sinus filter

To uncouple the step-up transformer from the PWM output voltage of the frequency

inverter.

Step-up trafo ........Output transformer to adapt the inverter output voltage to the medium voltage motor.

23

Page 26

ATV61HC50N4D387…HC63N4D387 or ATV61HC50Y387… HC80Y387

supplied by a low voltage mains

ATV61 ...................Frequency inverter

Q1 .........................Main switch (to be used if required according to the local regulations)

F1 ..........................Mains fuses considering the table in the product catalogue (absolutely necessary)

KM1.......................Mains contactor (to be used if required according to the local regulations)

line choke..............Line reactor

Option to reduce the current harmonics on the mains caused by the DC link.

internal filter ..........Radio frequency interference filter built-in as standard

considering category C3 according to EN 61800-3 "Use in industrial environments"

sinus filter.............. Output sinus filter

To uncouple the step-up transformer from the PWM output voltage of the frequency

inverter.

Step-up trafo ........Output transformer to adapt the inverter output voltage to the medium voltage motor.

1. The inverter supply must be split up in front of the line reactors, if they are used.

2. The monitoring of the fuses is used to protect the inverter against unbalanced load. It must act on mains

contactor or pulse inhibit (e.g. assign a digital input to EtF "External fault"). This is not obligatory, because

the inverter monitors the mains voltage. Therefor set the parameter IPL "Input phase loss" to "YES".

8 P02 501 EN.01/01 07/2010

24

Page 27

Wiring diagram for medium voltage supply

ATV61HC11N4D387…HC40N4D387 or ATV61HC11Y387… HC40Y387

with supply by means of a step-down transformer

ATV61 ...................Frequency inverter

Step-down trafo....Mains transformer for the adaptation of the mains voltage from medium- to low voltage.

Q0 ......................... Disconnecting switch (to be used according to the local regulations)

F0.......................... Mains fuses to protect the transformer (alternatively a circuit breaker can be used)

Q1 ......................... Main switch (to be used if required according to the local regulations)

F1.......................... Mains fuses considering the table in the product catalogue (absolutely necessary)

KM1 ......................Mains contactor (to be used if required according to the local regulations)

internal filter ..........Radio frequency interference filter built-in as standard

considering category C3 according to EN 61800-3 "Use in industrial environments"

sinus filter.............. Output sinus filter

8 P02 501 EN.01/01 07/2010 8 P02 501 EN.01/01 07/2010

Step-up trafo ........Output transformer to adapt the inverter output voltage to the medium voltage motor.

1. The neutral point of the step-down transformer can be grounded or alternatively an insulation monitoring

relay can be used.

To uncouple the step-up transformer from the PWM output voltage of the frequency

inverter.

25

Page 28

ATV61HC50N4D387…HC63N4D387 or ATV61HC50Y387… HC80Y387

with 12-pulse supply by means of a step-down transformer

ATV61 ...................Frequency inverter

Step-down trafo.... Mains transformer with two out-of-phase secondary windings (e.g. Yy6 d5) for adaptation of

the mains voltage from medium- to low voltage.

Q0 .........................Disconnecting switch (to be used according to the local regulations)

F0 ..........................Mains fuses to protect the transformer (alternatively a circuit breaker can be used)

Q1 .........................Main switch (to be used if required according to the local regulations)

F1 ..........................Mains fuses considering the table in the product catalogue (absolutely necessary)

KM1.......................Mains contactor (to be used if required according to the local regulations)

TS..........................Disconnecting switch (to be used according to the local regulations)

internal filter ..........Radio frequency interference filter built-in as standard

considering category C3 according to EN 61800-3 "Use in industrial environments"

sinus filter.............. Output sinus filter

To uncouple the step-up transformer from the PWM output voltage of the frequency

inverter.

Step-up trafo ........Output transformer to adapt the inverter output voltage to the medium voltage motor.

1. The neutral point of the step-down transformer can be grounded or alternatively an insulation monitoring

relay can be used.

2. The monitoring of the fuses is used to protect the inverter against unbalanced load. It must act on mains

contactor or pulse inhibit (e.g. assign a digital input to EtF "External fault"). This is not obligatory, because

the inverter monitors the mains voltage. Therefor set the parameter IPL "Input phase loss" to "YES".

ATV61 frequency inverters are a product of the restricted sales according to IEC 61800-3. In a

residential environment this product can cause radio frequency interferences whereupon the user can

be called on to take suitable measures.

8 P02 501 EN.01/01 07/2010

26

Page 29

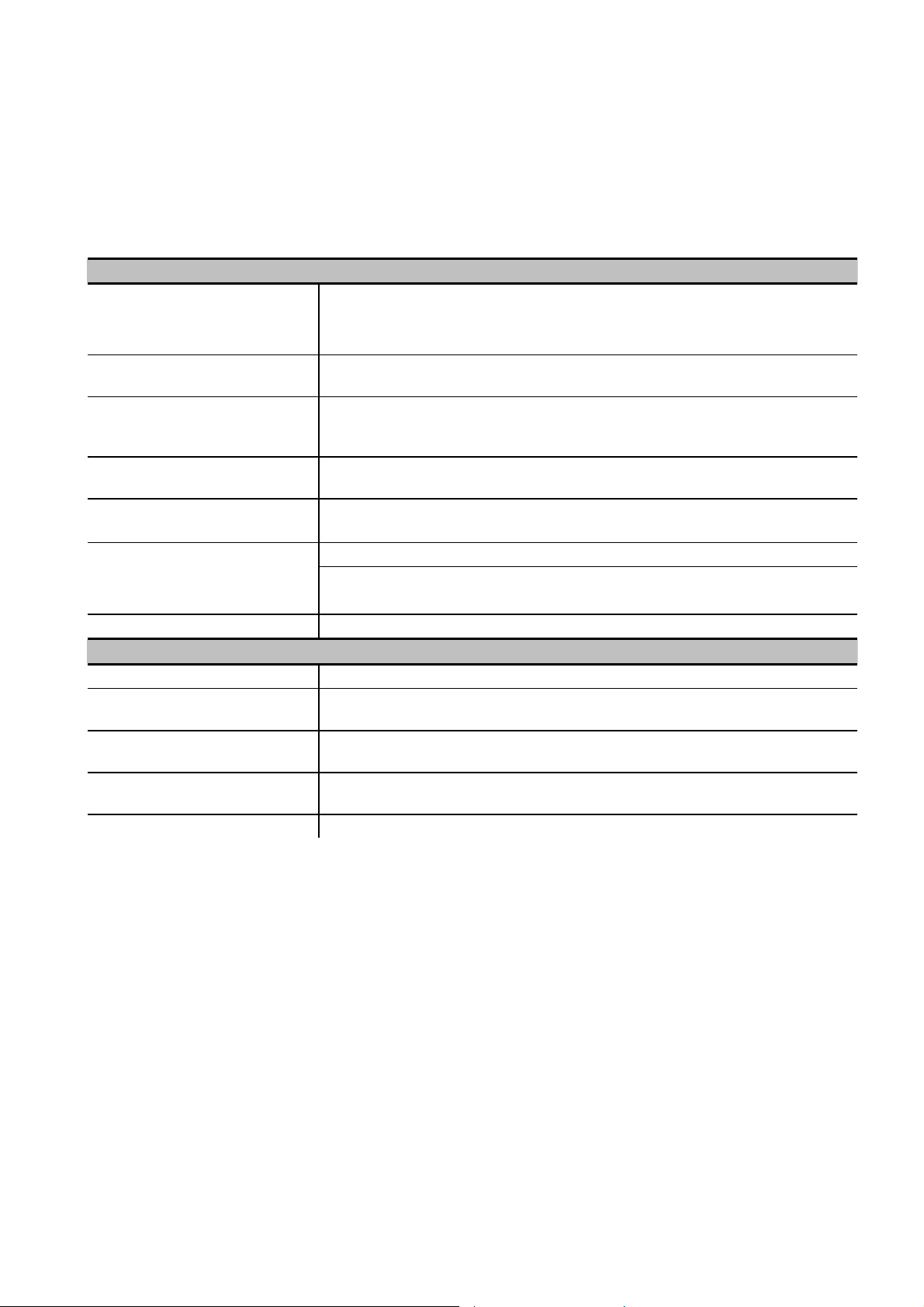

Allocation table for options depending on the power

Altivar Line choke Sinus filter

ATV61HC11N4D387 VW3 A4 559 VW3 A5 207 S387

ATV61HC13N4D387 VW3 A4 560 VW3 A5 208 S387

ATV61HC16N4D387 VW3 A4 568 VW3 A5 209 S387

ATV61HC22N4D387 VW3 A4 561 VW3 A5 209 S387

ATV61HC25N4D387 VW3 A4 569 VW3 A5 210 S387

ATV61HC31N4D387 VW3 A4 564 VW3 A5 210 S387

ATV61HC40N4D387 VW3 A4 565 VW3 A5 211 S387

ATV61HC50N4D387 2 x VW3 A4 569 VW3 A5 211 S387

ATV61HC63N4D387 2 x VW3 A4 564 VW3 A5 211 S387

ATV61HC11Y387 VW3 A4 570 VW3 A5 212 S387

ATV61HC13Y387 VW3 A4 570 VW3 A5 212 S387

ATV61HC16Y387 VW3 A4 571 VW3 A5 212 S387

ATV61HC20Y387 VW3 A4 571 VW3 A5 212 S387

ATV61HC25Y387 VW3 A4 560 VW3 A5 213 S387

ATV61HC31Y387 VW3 A4 572 VW3 A5 213 S387

ATV61HC40Y387 VW3 A4 572 VW3 A5 213 S387

ATV61HC50Y387 2 x VW3 A4 568 VW3 A5 214 S387

ATV61HC63Y387 2 x VW3 A4 572 VW3 A5 214 S387

ATV61HC80Y387 2 x VW3 A4 572 VW3 A5 214 S387

8 P02 501 EN.01/01 07/2010 8 P02 501 EN.01/01 07/2010

27

Page 30

Parameterization

Due to the use of a step-up transformer at the inverter output all parameter data referring to the motor have to

be calculated.

The autotuning function which allows high drive performance is not necessary in combination with a step-up

transformer at the inverter output. Because of this the factory default settings should not be changed in normal

case.

Frequency inverter settings

• UrES "Mains voltage"

Input voltage of the frequency inverter Mains voltage (UrES)

ATV61HC••N4D387 at 400V mains 400 V

ATV61HC••N4D387 at 440V mains

ATV61HC••N4D387 at 480V mains

ATV61HC••N4D387 with step-down

transformer

ATV61HC••Y387 at 690V mains 690 V

ATV61HC••Y387 with step-down transformer 690 V

• Ctt "Motor control type"

This parameter has always to be set to "UF9“.

• LSP "Low speed"

Remain this parameter at setting "5Hz".

• SFr "Switching freq."

Do not change the factory default setting "2.5 kHz" of this parameter.

• OFI "Sinus filter"

This parameter has always to be set to "YES“.

440 V

480 V

440 V

8 P02 501 EN.01/01 07/2010

28

Page 31

Motor data

• nPr "Rated motor power"

Set this parameter according to the nominal motor power of the name plate.

• nCr "Rated mot. current"

Calculate the nominal current in accordance with the ratio of the step-up transformer in order to set this

parameter.

V I

×

In

MOT_LV

==Cr

V

TRAFO_HVMOT_HV

TRAFO_LV

• UnS "Rated motor volt."

Setting of the nominal point of the motor voltage. This motor voltage depends on the mains voltage of the

inverter mains supply.

Input voltage of the frequency inverter Rated motor volt. (UnS)

ATV61HC••N4D387 at 400V mains 365 V

ATV61HC••N4D387 at 440V mains 410 V

ATV61HC••N4D387 at 480V mains 430 V

ATV61HC••N4D387 with step-down transformer 410 V

ATV61HC••Y387 at 690V mains 645 V

ATV61HC••Y387 with step-down transformer 670 V

• FrS "Rated motor freq."

Set this parameter according to the nominal motor frequency of the name plate.

• nSP "Rated motor speed"

• Set this parameter according to the nominal motor speed of the name plate.

8 P02 501 EN.01/01 07/2010 8 P02 501 EN.01/01 07/2010

29

Page 32

8 P02 501 EN.01/01 07/2010

30

Page 33

Page 34

Schneider Electric Power Drives GmbH

8 P02 501 EN.01/01

Ruthnergasse 1

A-1210 Vienna

+43 (0) 1 29191 0

Phone:

+43 (0) 1 29191 15

Fax:

Due to evolution of standards and equipment, the characteristics indicated in texts and images of

this document do not constitute a commitment on our part without confirmation.

Design: Schneider Electric Power Drives

Photos: Schneider Electric Power Drives

07 / 2010

Loading...

Loading...