Page 1

S1000/2000/3000

For Commercial HVAC Applications

Product ov

erview

Viconics' latest generation S1000/2000/3000 series sensors have been especially developed for the VT7600

programmable and non-programmable thermostats as well as future Viconics thermostats. These robust

sensors have provide accurate and stable temperature reading using a 10 Kohm thermistor element.

The S3000 series include all wall/room sensors, the S2000 series include all the duct/outdoor air models, and

the S1000 include in duct change over sensing and submersible water sensing . Temperature averaging

applications using only two or three S3000 sensors can easily be done by setting the dip switches to the

appropriate position. It is to be noted that temperature averaging with the usual 4, 9, 16, 25, etc sensors can

also be done, both with the S2000 and S3000 series. See table below for specific model numbers:

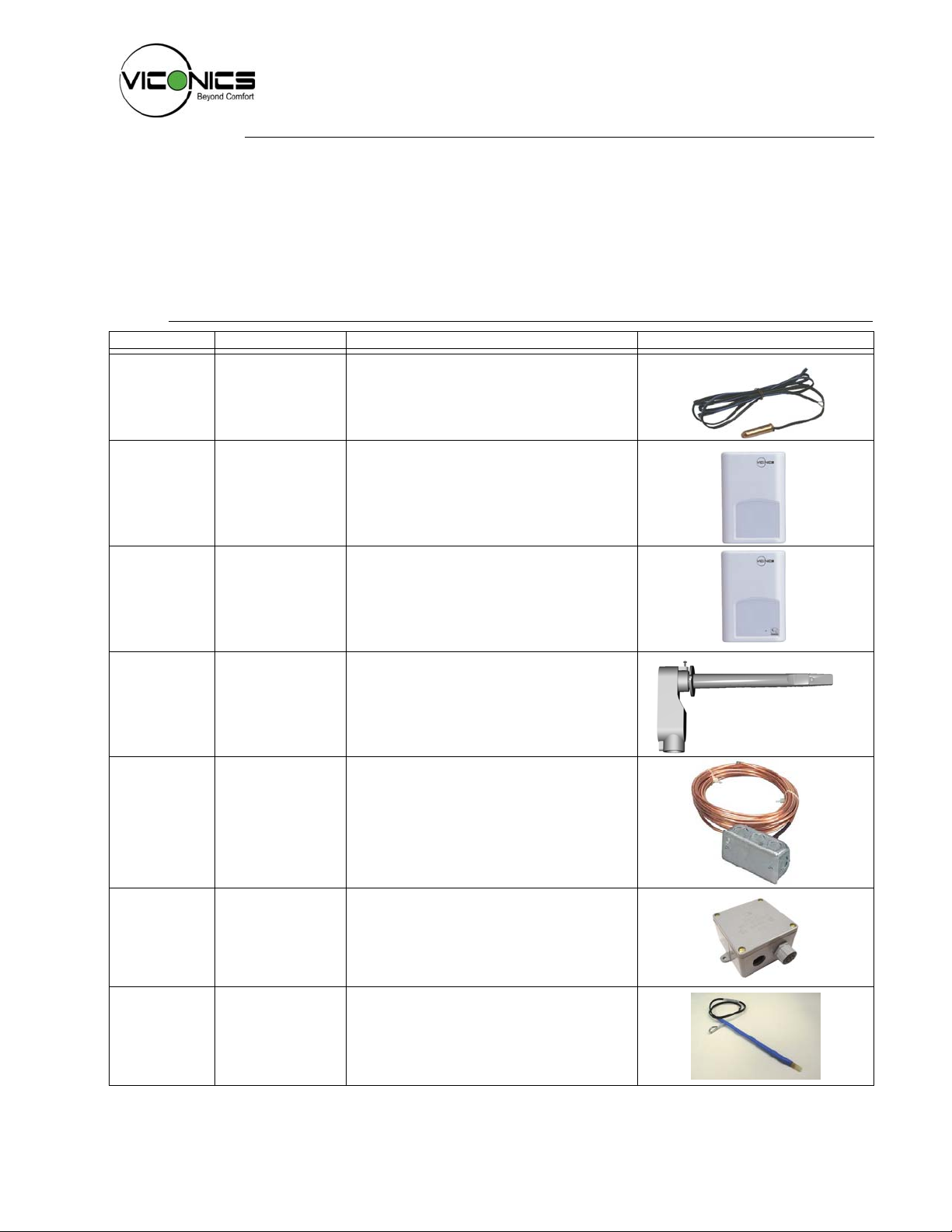

Models

Model: Description: Application: Picture:

S1010E1000 Capsule type

sensor for multipurpose use, ¼”

dia. capsule with

65 inch leads

S3010W1000 Room sensor

S3020W1000 Room sensor with

temporary

override key and

occupancy LED

• Remote sensing easy to dissimulate for

indoor and outdoor use

• Water temperature sensing strapped on

pipe or in an immersion well

• Remote room sensing

• 3 thermistors with 2 dip switches are

provided with each sensor for various

averaging combinations

• Remote room sensing with override key

and occupancy LED

• 3 thermistors with 2 dip switches are

provided with each sensor for various

averaging combinations

S2000D1000

S2060A1000

S2020E1000

S1010D1000

Duct sensor with

junction box

Duct averaging

sensor, with 6 ft

sensor

Outside air

sensor, NEMA 4

enclosure

Duct Mounted

Change Over

Sensor

• Remote return air temperature sensing

with the sensor mounted on the return air

duct.

• Outside air temperature sensing with the

sensor installed in the fresh air plenum.

• Supply air temperature sensor

• Remote averaging discharge air

temperature sensing with the sensor

mounted on the supply air duct.

• Outside air temperature averaging

sensing with the sensor installed in the

fresh air plenum.

• Mixed air temperature averaging sensor

for economizer models with the sensor in

• Outside air temperature sensing with the

sensor installed directly exposed to the

elements.

• Sensor uses a water resistant NEMA 4

PVC enclosure for outdoor applications

• Change Over Duct Sensing

• Mounting: Through hole in duct, with

eyelet

028-0106

028-0106 INS-S2030-B02

Page 2

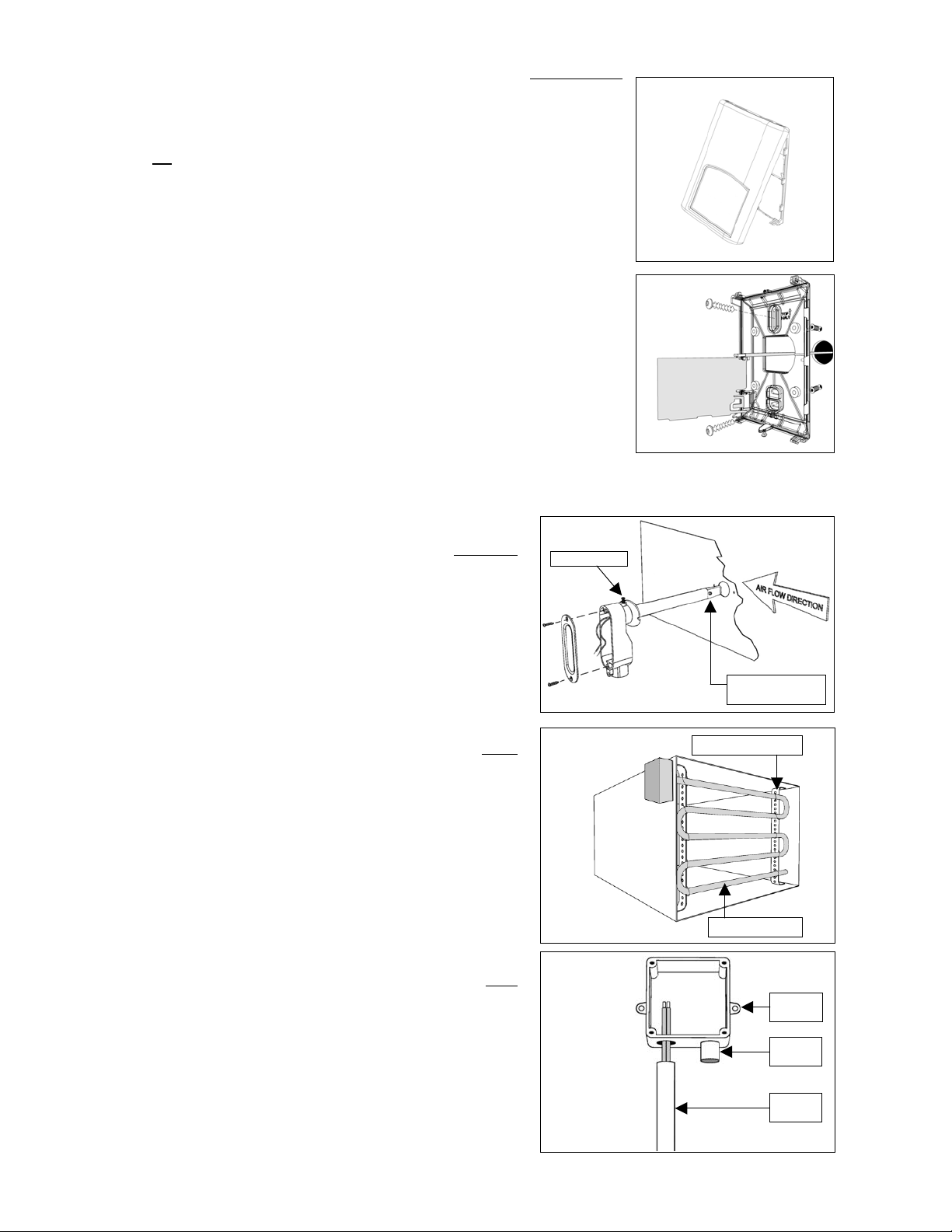

Installation of room sensors (S3010W1000 and S3020W1000)

p

• Remove security screw on the bottom of sensor cover.

• Open up by pulling on the bottom side of sensor. (Fig.1)

Location:

1- Should

2- Must be installed away from any heat source.

3- Should not be installed near an air discharge grill.

4- Should not be affected by direct sun radiation.

5- Nothing must restrain vertical air circulation to the sensor.

Installation:

1.

Remove security screw on the bottom of thermostat cover.

2. Open up by pulling on the bottom side of thermostat.

3. Pull out cables 6” out of the wall.

4. Wall surface must be flat and clean.

5. Insert cable in the central hole of the base.

6. Flip printed circuit board to access mounting hole

7. Align the base and mark the location of the two mounting holes on the wall. Install

proper side of base up.

8. Install anchors in the wall.

9. Insert screws in mounting holes on each side of the base. DO NOT

OVERTIGHTEN

10. Strip each wire 1/4 inch.

11. Insert each wire according to wiring diagram.

12. Gently push back into hole excess wring back into the wall.

13. Press back printed circuit board into place

14. Install the cover, top side

15. Install security screw.

not be installed on an outside wall.

Fig. 1

Fig. 2

2

Installation of duct sensors (S2000D1000) – (Fig.3)

1. Drill 1” [25mm] hole mid height on the side of the duct to insert the

probe.

2.

Loosen swivel screw and direct the probe so that the flat side of

probe tip is facing the airflow.

3. Mark the position of the two holes to be drilled for mounting the

sensor on the duct. Fasten the sensor to the duct with the two

screws provided. Do not overtighten!

4. Junction box must be directed downwards or sideways.

5. For best results, locate sensor as far as you can from

heating/cooling source.

Installation of averaging sensor (S2060A1000) - (Fig.4)

1. Drill 5/8” [16 mm] hole for the element to pass into the duct.

2. Run the sensing element into the duct.

3. Remove the cover from the unit.

4.

Mark the position of the holes to be drilled for mounting the case

on the duct.

5. Fasten the sensor element in an “S” shaped pattern in order to

cover the entire duct section area. Ensure that the probe does not

touch the duct.

6. Firmly support the element in the duct using perforated steel strap

and wire fastenings.

7. For best results, locate sensor as far as you can from

heating/cooling source.

Installation of outside air sensor (S2020E1000) – (Fig.5)

1. Install sensor using mounting holes on each side.

2. Install on a vertical surface, respect mounting orientation

3. Remove the four screws and remove the cover.

4. Strip each wire 1/4 inch.

5. Insert each wire according to wiring diagram.

6. Install the cover with supplied screws.

7. In snowy area allow sufficient height for snow accumulation.

Swivel screw

Fig.3

Fig.4

Fig.5

Probe tip, flat side

facing airflow

Perforated steel

Sensing element

Mounting

hole

Sensing

robe

EMT

conduit

Page 3

Wiring example of single remote room sensor:

r

p

VT7600 Series

Thermostat

Scom

RS

AU

C

D1

D2

1x 3020W1000

Wiring 1 sensor

S2-1 = ON / S2-2 = ON

ScomRSScom

RS

Aux

C

DI

OR

S3010W1000

Wiring 1 sensor

S2-1 = ON / S2-2 = ON

ScomRSScom

RS

Wiring examples of 2 remote room sensors for averaging applications:

VT7600

Series

Scom

RS

AU

C

D1

D2

2x S3020W1000

Wiring 2 sensors

S2-1 = OFF / S2-2 = ON

ScomRSScom

RS

Aux

C

DI

ScomRSScom

RS

Aux

C

DI

D2

VT7600

Series

Scom

RS

AU

C

D1

Dip switch

setting for:

1 senso

2x S3010W1000

Wiring 2 sensors

S2-1 = OFF / S2-2 = ON

ScomRSScom

RS

ScomRSScom

RS

ON

1

S2-1 = ON

S2-2 = ON

2

3

VT7600

Series

Scom

RS

AU

D1

D2

C

1x S3010W1000 and 1x S3020W1000

Wiring 2 sensors

ScomRSScom

RS

Notes for averaging applications:

• S3010W1000 and S3020W1000 can be mixed matched.

• S3010W

S2-1 = OFF / S2-2 = ON

ScomRSScom

RS

Aux

C

DI

• Res

1000 and S3020W1000 are to be wired in parallel.

ect the dip switch setting in each remote sensor.

Wiring examples of 3 remote room sensors for averaging applications:

VT7600

Series

Scom

RS

AU

D1

D2

C

2x S3010W1000 and 1x S3020W1000

Wiring 3 sensors

ScomRSScom

RS

ScomRSScom

RS

S2-1 = OFF / S2-2 = OFF

ScomRSScom

RS

Aux

C

DI

VT7600 Series

Thermostat

Scom

RS

AU

C

D1

D2

1x S3010W1000 and 2x S3020W1000

Wiring 3 sensors

S2-1 = OFF / S2-2 = OFF

ScomRSScom

Temperature vs resistance chart for 10 kOhm NTC thermistor

(R

= 10KΩ±3% - B

25°C

ºC ºF kohms ºC ºF kohms ºC ºF kohms ºC ºF kohms ºC ºF kohms

-20 -4 94.5149 -10 14 54.1988 0 32 32.1910 10 50 19.7390 20 68 12.4601

-19 -2 89.2521 -9 16 51.3692 1 34 30.6120 11 52 18.8277 21 70 11.9177

-18 0 84.3147 -8 18 48.7042 2 36 29.1167 12 54 17.9636 22 72 11.4018

-17 1 79.6808 -7 19 46.1933 3 37 27.7088 13 55 17.1440 23 73 10.9112

-16 3 75.3299 -6 21 43.8268 4 39 26.3744 14 57 16.3665 24 75 10.4443

-15 5 71.2430 -5 23 41.5956 5 41 25.1119 15 59 15.6286 25 77 10.0000

-14 7 67.4028 -4 25 39.4912 6 43 23.9172 16 61 14.9280 26 79 9.5754

-13 9 63.7928 -3 27 37.5056 7 45 22.7861 17 63 14.2629 27 81 9.1711

-12 10 60.3980 -2 28 35.6316 8 46 21.7151 18 64 13.6310 28 82 8.7860

-11 12 57.2044 -1 30 33.8622 9 48 20.7004 19 66 13.0307 29 84 8.4190

= 3975K±1.5%)

25/85°C

RS

Aux

C

DI

ScomRSScom

RS

Aux

C

DI

Dip switch

setting for:

2 sensors

ScomRSScom

Dip switch

setting for:

3 sensors

Fig.6

ON

S2-1 = OFF

S2-2 = ON

2

1

RS

ON

S2-1 = OFF

-

=

2

1

ON

12

Wall mounted sensor

Dip switch location

WIRING S2000D1000, S2060A1000 and S2020E1000

Remote wiring 1 sensor Remote wiring 4 sensors

10 K

10 K

10 K

10 K

10 K

VT7600 Series thermostat VT7600 Series thermostat

RS

ScomMSScom

or

or

OS

Scom

RS

Scom

or

MS

Scom

or

OS

Scom

Page 4

Specifications:

F

0

General for all sensors

4

Fig.7

Sensor ty

pe: 10 K ohm NTC thermistor

Maximum wire length: 5,000 feet [1,525 m]

for 24 GA wire and up

Room sensors (S3010W1000 and S3020W1000)

Operating conditions:

0 °C to 50 °C ( 32 °F to 122 °F )

0% to 95% R.H. non-condensing

Storage conditions:

-30 °C to 50 °C ( -22 °F to 122 °

0% to 95% R.H. non-condensing

Dimensions:

4.94” [125 mm] high

3.38” [86 mm] wide

1.13” [29 mm] thick

Approximate shipping

weight: 0.34 LBS (155 grams )

Enclosure plastic type ABS - FRI [WT1337V] UV stabilized

Duct sensor (S2000D1000)

Operating conditions:

-40 °C to 50 °C ( -40 °F to 122 °

0% to 95% R.H. non-condensing

Storage conditions:

-40 °C to 70 °C ( -40 °F to 122 °

0% to 95% R.H. non-condensing

Dimensions:

(refer to draw

ing Fig.8)

Approximate shipping

w

eight: 0.7 LBS [0.3 Kg]

Probe tip plastic type: Fire retarding grade "HB" ABS

Averaging sensor (S2060A1000)

F )

F )

F )

ig.8

Fig.9

1.75" [44 mm]

4.40" [112 mm]

1.30" [33 mm]

4.25" [108 mm]

3.38" [86 mm]

2.25" [57 mm]

4.94" [125 mm]

1.13" [29 mm]

7.00" [178 mm]

1/2" [13 mm] FPT

c/c 1.75" [44mm]

Ø 5/32" [4 mm]

2.10" [53 mm]

Ø 0.75" [19 mm]

72" [1829 mm]

Ø 3/16" [5 mm]

Operating conditions:

-40 °C to 50 °C ( -40 °F to 122 °

0% to 95% R.H. non-condensing

Storage conditions:

-40 °C to 70 °C ( -40 °F to 158 °

0% to 95% R.H. non-condensing

Sensing element length

72 in [1,83 m]

Sensing element diameter /

material:

Dimensions:

3/16” [5 mm] / copper tube

(refer to drawing Fig.9)

Approximate shipping

weight: 1.6 LBS [0.7 Kg]

Outside air sensor (S2020E1000)

Operating and storage

conditions:

Dimensions:

-40 °C to 50 °C ( -40 °F to 122 °

0% to 100% R.H.

(refer to draw

ing Fig.10)

Approximate shipping

w

eight: 1.1 LBS [0.5 Kg]

Enclosure plastic type: NEMA 4 PVC

Duct Mounted Temperature Sensor (S1010D1000)

Operating conditions:

Sensing Bulb Type:

Up

to 85ºC [185ºF]

Plastic Heatshrink

Dimensions: (refer to drawing Fig.11)

Probe length / Diameter:

Wire Length:

12” [305 mm]

4-1/2” [114 mm]/

1/4” [6 mm]

F )

F )

F )

Fig. 1

c/c

Fig. 11

UNIT: INCH [mm] / NTS

4.00" [102 mm]

3.45" [88 mm]

3.45"

[88 m m ]

4.88" [124 mm]

1.19" [30 mm] 1.19" [30 mm]

1

[6]

4

FRONT VIEW

13

[20]

16

EYELET FOR MAX.Ø

3.67" [93 mm]

Ø 0.25"

[6 mm ]

Ø 8-32*

* Threa d e d

bras s i n s ert

c/c 4.68" [119 mm]

5.25" [133 mm]

3

4

[111 ]

8

DATE: 2002/04/19 - REV.0

[42 mm]

1.75"

[45 mm]

1.63"

Ø 7/8"

[22 m m ]

WIRE 12 [30 4 ]

3

[Ø5 ] S E LF-DRIL L ING SC R EW

16

DRAWN BY: P. DUMAS

0.25" [6 m m ]

2.125"

[54 m m ]

2.00"

[51 m m ]

7

[22]

8

4.00"

[102 m m ]

DWG N o.: 022-0114.dwg

1

[6]

4

Important notice

All

S1000, S2000 and S3000 series sensors are for use as operating controls only and are not safety devices. These instruments

have undergone rigorous tests and verifications prior to shipment to ensure proper and reliable operation in the field. Whenever a

control failure could lead to personal injury and/or loss of property, it becomes the responsibility of the user / installer / electrical

system designer to incorporate safety devices ( such as relays, flow switch, thermal protections, etc…) and/or alarm system to

protect the entire system against such catastrophic failures. Tampering of the devices or miss application of the device will void

warranty.

Loading...

Loading...