Page 1

®

Altivar

APOGEE® FLN P1 card

User manual

VW3A3314

10/2010

61

BBV10543

www.schneider-electric.com

Page 2

Page 3

Contents

While every precaution has been taken in the preparation of this document, Schneider

Electric SA assumes no liability for any omissions or errors it may contai n, nor for any

damages resulting from the application or use of the information herein.

The products described in this document may be changed or modified at any time,

either from a technical point of view or in the way they are operated. Their de scription

can in no way be considered contractual.

1. Important Information _______________________________________________________________________________________ 4

2. Before you begin_______________________________________________________________________________________ ____ 5

3. Introduction_______________________________________________________________________________________________ 7

4. Documentation structure_____________________________________________________________________________________ 8

5. Notation _________________________________________________________________________________________________ 9

6. Quick start_______________________________________________________________________________________________ 10

7. Hardware setup _____________________________________________________ _____________________________________ 11

7. 1. Receipt ____________________________________________________________________________________________ 11

7. 2. Hardware description _________________________________________________________________________________ 11

7. 3. Bus voltage measurement procedure_____________________________________________________________________ 12

7. 4. Installing the card in the drive___________________________________________________________________________ 12

8. Connecting to the bus__________________________________________________________________ ____________________ 13

8. 1. Cable routing practices________________________________________________________________________________ 13

8. 2. Network configuration_________________________________________________________________________________ 14

8. 3. Card connector pinout ________________________________________________________________________________ 14

9. Configuration ____________________________________________________________________________________________ 15

9. 1. Communication parameters ____________________________________________________________________________ 15

9. 2. Control _____________ _______________________________________________________________________________ 16

9. 3. Communication configuration___________________________________________________________________________ 23

9. 4. Monitored parameters________________________________ _________________________________________________ 24

10. Diagnostics_____________________________________________________________________________________________ 25

10. 1. Checking the address________________________________________________________________________________ 25

10. 2. Checking the communication __________________________________________________________________________ 25

10. 3. LEDs_____________________________________________________________________________________________ 25

10. 4. Control - Command _________________________________________________________________________________ 26

10. 5. Communication interruptions __________________________________________________________________________ 27

10. 6. Option card hardware conditions _______________________________________________________________________ 27

11. Network objects _________________________________________________________________________________________ 28

11. 1. Logical Analog Input (LAI) Summary ____________________________________________________________________ 28

11. 2. Logical Analog Output (LAO) Summary__________________________________________________________________ 30

11. 3. Logical Digital Input (LDI) Summary_____________________________________________________________________ 31

11. 4. Logical Digital Output (LDO) Summary __________________________________________________________________ 33

12. Message box function points _______________________________________________________________________________ 35

12. 1. ATV61 Parameter access point table____________________________________________________________________ 35

12. 2. FLN P1 Status Code_________________________________________________________________________________ 35

13. Reports________________________________________________________________________________________________ 36

BBV10543 10/2010 3

Page 4

1. Important Information

The addition of this symbol to a Danger or Warning safety label indicates that an electrical hazard exists, which will result in

personnal if the instruction are not followed.

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety messages that follow

this symbol to avoid possible injury or death.

NOTICE

Read these instructions carefully, and look at th e equip ment to bec ome fami liar with t he devi ce before t rying to insta ll, operat e, or maintain

it. The following special messages may appear throughout this documentation or on the equipment to warn of potential hazards or to call

attention to information that clarifies or simplifie s a procedure.

DANGER

DANGER indicates an imminently hazardous situation, which, if not avoided, will result in death or serious injury.

WARNING

Warning indicates a potentially hazardous situation, which, if not avoided, can result in death, serious injury, or

equipment damage.

CAUTION

CAUTION indicates a potentially hazardous situation, which, if not avoided, can result in injury or equipment

damage.

PLEASE NOTE

The word "drive" as it is used in this manual refers to the controller portion of the adjustable speed drive as defined by NEC.

Electrical equipment should be installed, operated, serviced, and maintained only by qualified personnel. No responsibility is assumed by

Schneider Electric for any consequences arising out of the use of this material.

© 2008 Schneider Electric All Rights Reserved Reserved.

4 BBV10543 10/2010

Page 5

2. Before you begin

Read and understand these instructions before performing any procedure with thi s drive.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Read and understand this manual before installing or operating the Al tivar 61 drive. Installation, adj ustment, repair, and

maintenance must be performed by qualified personnel.

• The user is responsible for compliance with all international and national electrical code requirements with respect to

grounding of all equipment.

• Many parts of this drive, including the printed circuit boards, operate at the line voltage. DO NOT TOUCH. Use only

electrically insulated tools.

• DO NOT touch unshielded components or terminal strip screw connections with voltage prese nt.

• DO NOT short across terminals PA/+ and PC/– or across the DC bus capacitors.

• Before servicing the drive:

- Disconnect all power, including external control power that may be present.

- Place a “DO NOT TURN ON” label on all power disconnects.

- Lock all power disconnects in the open position.

- WAIT 15 MINUTES to allow the DC bus capacitors to discharge. Then follow the “Bus Voltage Measurement

Procedure” page12

to verify that the DC voltage is less than 42 V. The drive LEDs are no t indicators of the ab sence

of DC bus voltage.

• Install and close all covers before applying power or starting and stopping the drive.

Failure to follow these instructions will result in death or serious injury .

DANGER

UNINTENDED EQUIPMENT OPERATION

• Test and ensure that any changes made to the parameter settings do not present any danger to personnel and

equipment during drive operation.

• Do not use this APOGEE® FLN P1 option card with

ATV61 drive firmware earlier than V ersion V1.6IE18. These versions

will not detect an inoperative card.

Failure to follow these instructions will result in death or serious injury .

WARNING

DAMAGED DRIVE EQUIPMENT

Do not operate or install any drive or drive accessory that appears damaged.

Failure to follow these instructions can result in death, serious injury or additional equipment damage.

BBV10543 10/2010 5

Page 6

2. Before you begin

WARNING

LOSS OF CONTROL

• The designer of any control scheme must consider the potential failure modes of control paths and, for certain critical

control functions, provide a means to achieve a safe state during and after a path failure. Examples of critical control

functions are emergency stop and overtravel stop.

• Separate or redundant control paths must be provided for critical control functions.

• System control paths may include communication links. Conside ration must be given to the implications of

unanticipated transmission delays or failures of the link.

a

• Each implementation of an ATV61 APOGEE® FLN P1 option card must be individually and thoroughl y tested for proper

operation before being placed into service.

Failure to follow these instructions can result in death, serious injury, or additional equipment damage.

a. For additional information, refer to NEMA ICS 1.1 (latest edition), “Safety Guidelines for the Application, Installation, and Maintenance of Solid State Control” and

to NEMA ICS 7.1 (latest edition), “Safety Standards for Construction and Guide for Selection, Installation and Operation of Adjustable-Speed Drive Systems.”

6 BBV10543 10/2010

Page 7

3. Introduction

Thank you for purchasing the APOGEE® FLN P1 option card (VW3A3314) for Altivar 61 drive.

IMPORTANT: this communication option card is fully supported with the version V1.6 IE 18 of the Altivar 61 firmware.

By Installing this board into the Altivar 61, data communication can be made with a host computer or other device via APOGEE® FLN P1

network.

The communication card has a 4 pole open style connector for connection to the network: A, B, GND, SCR.

Data exchanges give access to these Altivar 61 functions:

• Control (start, stop, reset, setpoint),

• Monitoring (status, current, voltage, thermal state...),

• Diagnostics (alarms).

The graphic display terminal or the integrated display terminal can be used to acce ss numerous functi ons for commun ication con figuration

and diagnostics.

BBV10543 10/2010 7

Page 8

4. Documentation structure

b APOGEE® FLN P1 manual

The present APOGEE® FLN P1 user manual describes:

• connection to APOGEE® FLN P1,

• configuration of the communication-specific parameters via the integrated HMI or the graphic HMI,

• diagnostics,

• networks variables.

You will also find important information in other Altivar 61 technical documents. They are available on the Web site www.schneider-

electric.com.

b Installation manual

The installation manual describes:

• how to assemble the drive (particularly how to mount the APOGEE® FLN P1 card),

• how to connect the drive.

b Programming manual

The programming manual describes:

• the functions and parameters of the drive,

• how to use the drive HMI (integrated HMI and graphic HMI).

b Communication parameters manual

The Communication parameters manual describes:

• the operating modes specific to communication (CiA 402 state chart),

• the interaction between communication and local control (HMI and termi nals),

• the drive parameters with specific information for use via a communication network (addresses, formats, etc).

When using the APOGEE® FLN P1 card, some sections of the Communication parameters manual are not relevant :

-profiles,

- I/O profile

- CiA 402 profile.

The description of drive parameters is useful only if you use the parameters access function of the APOGEE® FLN P1 (MBOX READ,

MBOX WRITE, MBOX PARAM, MBOX DATA).

8 BBV10543 10/2010

Page 9

5. Notation

b Drive terminal displays

The graphic display terminal menus are shown in square brackets.

Example: [1.9 COMMUNICATION].

The integrated 7-segment display terminal menus are shown in round brackets with a "-" at the end.

Example: (COM-).

Parameter names displayed on the graphic display terminal are written in square brackets.

Example: [Fallback speed]

Parameter codes displayed on the integrated 7-segment display terminal are written in round brackets.

Example: (LFF).

b Formats

Hexadecimal values are written as follows: 16# or 0x

Binary values are written as follows: 2#

b Abbreviations

O = Optional

M = Mandatory

BBV10543 10/2010 9

Page 10

6. Quick start

The integrated 7-segment display terminal menus are not shown in this table.

Operation Refer to

A How to reset the drive to the factory settings:

[1 DRIVE MENU]

[1.12 FACTORY SETTINGS]

• Select [Config. Source]: Macro-conf,

• Select [PARAMETER GROUP LIST]: All

• Select

B How to configure the main APOGEE® FLN P1 communication parameters:

In the menu:

[1 DRIVE MENU]

[1.9 COMMUNICATION]

[P1]

• Check [Address] to the desired APOGEE® FLN P1 address

C How to configure the drive so that control comes from the APOGEE® FLN P1 network

In the menu:

[1 DRIVE MENU]

[1.6 COMMAND]

• Change [Ref.1 channel] from "AI1" to "Com. card"

D Monitor and Control the drive throug h the APOGEE FLN P1 network

• Control start / stop by the binary value CMD STP.STRT,

• Control the velocity setpoint by the analog value INPUTREF 1,

• Control direction of rotation by the binary value CMD FWD.REV,

• Monitor if the drive is controlled via local or remote (APOGEE® FLN P1) by the binary value FLN

• Monitor the running / stopped state by the binary value STOP.RUN,

• Monitor the actual direction of rotation by the binary value FWD.REV,

• Monitor the actual speed or frequency by the analog value SPEED or PCT OUTPUT.

[Goto FACTORY SETTINGS]

LOC CTL ACT,

Programming manual

[1.12 FACTORY SETTINGS]

(FCS-)

Communication parameters”,

“

page 15

Control”, page 16

“

Network objects page 28

11.

Detected fault management:

• Monitor the operating state by the binary value OK.FAULT,

• Monitor the detail by th e analog value ERROR STATUS,

• Remote reset the communication card by the binary value RESET FAULT.

E Switch local / remote by the drive HMI

Press F4 key (marked TK) to switch alternately from between APOGEE® FLN P1 and HMI.

The right of the upper display line:

- REM: control by APOGEE® FLN P1,

- LOC: control by HMI.

F Monitor and diagnose the status of the APOGEE FLN P1 network communication by the

drive HMII

In the menu:

[1 DRIVE MENU]

[1.2 - MONITORING]

[COMMUNICATION MAP]

[DIAG NETWORK]

G Diagnose APOGEE® FLN P1 communication by the drive HMI

In the menu:

[1 DRIVE MENU]

[1.2 - MONITORING]

[COMMUNICATION MAP]

• Check that the Command Channel is Com. card,

• Check that Active ref. channel is Com. card.

H Disable network fault detection for testing

In the menu:

[1 DRIVE MENU]

[1.8 FAULT MANAGEMENT] (FLt-)

Configure [COM. FAULT MANAGEMENT] to [Ignore].

Programming manual

Graphic display terminal

Description of the graphic screen

Checking the communication”,

“

page 25

Checking the communication”,

“

page 25

Programming manual

[1.8 FAULT MANAGEMENT]

(FLt-)

10 BBV10543 10/2010

Page 11

7. Hardware setup

CAUTION

STATIC SENSITIVE COMPONENTS

The APOGEE® FLN P1 option card can be damaged by static electricity. Observe the electrostatic precautions below

when handling circuit boards or testing components.

Failure to follow these instructions can result in injury or equipment damage.

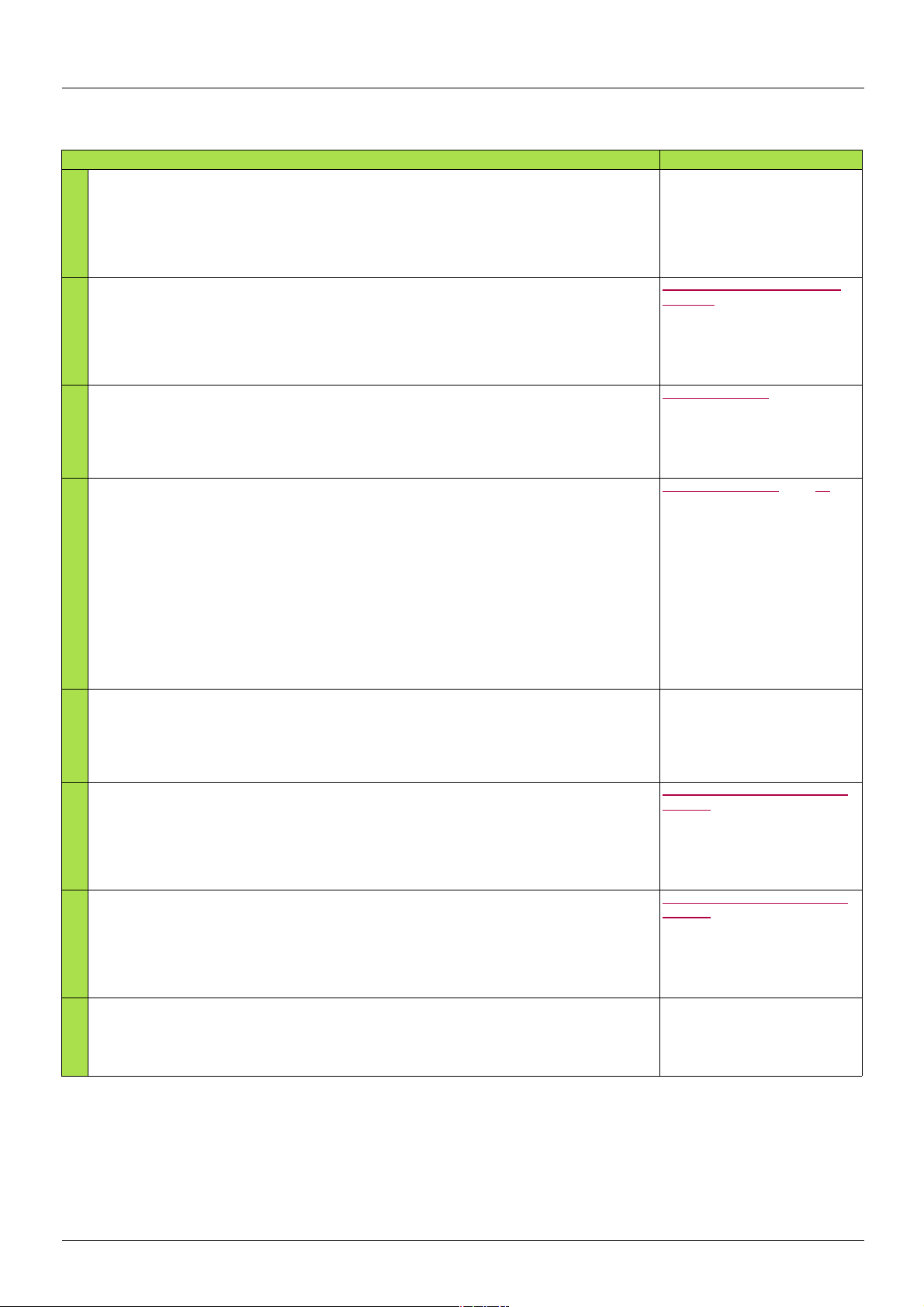

Ground Plate

Reserved for

Schneider internal use

Termination

resistor

SW(SW102)

APOGEE® FLN P1

Connector

Reserved for Schneider

internal use

APOGEE® FLN P1 LED

indicator

Connector to the drive

Panel mounting tabs

7. 1. Receipt

• Check that the card reference printed on the label is the same as that on the delivery note corresponding to the purchase order.

• Remove the option card from its packaging and check that it has not been damaged in transit.

Electrostatic Precautions

Observe the following precautions for handling static-sensitive components:

• Keep static-producing material such as plastic, upholstery, and carpeting out of the immediate work area.

• Store the APOGEE® FLN P1 card in its protective packaging when it is not installed in the drive.

• When handling the APOGEE® FLN P1 card, wear a conductive wrist strap connected to the card through a minimum of 1 megohm

resistance.

• Avoid touching exposed conductors and component leads with skin or clothing.

7. 2. Hardware description

BBV10543 10/2010 11

Page 12

7. Hardware setup

7. 3. Bus voltage measurement procedure

Before working on the drive, remove all power and wait 15 minutes to allow the DC bus to discharge. Then measure the DC bus voltage

between the PA/+ and PC/– terminals.

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

Read and understand the precautions in “Before you begin” on page5 before performing this procedure.

Failure to follow these instructions will result in death or serious injury.

The DC bus voltage can exceed 1,000 Vdc. Use a properly rate d volt ag e-sensing dev ice when pe rformi ng th is procedure. To measure the

DC bus voltage:

1 Disconnect all power.

2 Wait 15 m in u te s to al lo w th e DC bu s t o disc h ar ge .

3 Measure the voltage of the DC bus between the PA/+ and PC/– terminals to ensure that the voltage is less than 42 Vdc.

4 If the DC bus capacitors do not discharge completely, contact your local Schneider Electric representative. Do not repair or operate the

drive.

7. 4. Installing the card in the drive

Refer to the Installation manual.

12 BBV10543 10/2010

Page 13

8. Connecting to the bus

WARNING

IMPROPER WIRING PRACTICES

• Follow the wiring practices described in this document in addition to those already required by the National Electrical

Code and local electrical codes.

• Check the power connections before energizing the drive.

• If replacing another drive, verify that all wiri ng conne ctions to the ATV61 dri ve comply with al l wi ring i nstructio ns in thi s

manual.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

8. 1. Cable routing practices

When wiring Altivar 61 drives to a APOGEE® FLN P1 network, follow all wiring practices required by national and local electrical codes.

Also observe the following guidelines:

• Avoid areas of high temperature, moisture, vibration, or other mechanical stress.

• Secure the cable where necessary to prevent its weight and the weight of other cables from pulling or twisting the cable.

• Use cable ducts, raceways, or other structures to protect th e cable. Use these structures for signal wiring paths. They must not contain

power wiring.

• Avoid sources of electrical interference th at can induce noise into the cabl e. Use the maximum practicable separat ion from such sources.

When planning cable routing within a building, follow these guidelines:

• Maintain a minimum separation of 1 m (3.3 ft) from the followin g equipment:

- air conditioners and large blowers,

- elevators and escalators,

- radios and televisions,

- intercom and security systems,

- fluorescent, incandescent, and neon lighting fixtures.

• Maintain a minimum separation of 3 m (9.8 ft) from the followin g equipment:

- line and motor power wiring,

- transformers,

- generators,

- alternators.

When wiring in electrical equipment rooms or large electrical equipment line-ups, observe the following guidelines for cable segregation

and separation of circuits:

• Use metallic conduit for drive wiring. Do not run control network and power wiring in the same conduit.

• Separate non-metallic conduits or cable trays used to carry power wiring from metallic conduit carrying low-level control network wiring

by at least 300 mm (12 in).

• Separate metallic conduits carrying power wiring or low-level control network wiring by at least 80 mm (3 in).

• Cross the metallic conduits and non-metallic conduits at right angles whenever power and control network wiring cross.

• Attenuate conducted emissions f rom the drive to t he line in some installations to help prevent inte rference with tel ecommunication, radio,

and sensitive electronic equipment. Such instances may require attenuating filters. Consult the Altivar catalog for selection and

application of these filters.

Maximum length of bus 1000 m (3280 ft) at 19,200 bps (9600 bps max. with APOGEE® FLN P1)

Maximum number of stations 32 stations, i.e, 31 slaves (without repeater)

BBV10543 10/2010 13

Page 14

8. Connecting to the bus

8. 2. Network configuration

Make up the network as follows:

- Transmit/receive signals (A, B)

Connect all transmit / receive data lines to ensure proper data transmission.

- Signal common (GND)

GND is the signal common.

- Grounding the shield of the network cable (SCR)

Connect the shield lines of network cable. Only ground the shield at one point to help prevent noise currents from being created and

interfering with network communications.

- Termination resistor

A termination resistance of 120 ohms

option card has a built in terminating resistor. To use this resistor, refer to section 7. 2.

At least one set, and no more than two sets, of net work bias resistors shall exis t for each segment. Th is option has local bia s resistors.

+/- 5% should be connected at each of the two ends of the network segment. The ATV61 P1

Hardware description.

* It is recommended that the Siemens Building Automat ion FL N Trunk Termi nator (PN: 538-66 4) be used and tha t the n et work termi n ation

switch on the APOGEE® FLN P1 card, SW102, be set to OFF.

N.B.: Do not connect the SCR terminal to the power ground of drives or other unit s.

Keep the network cables 20 cm or more separate from the power cables to h elp prevent fr om malfunctioni ng due to elect romagnetic noise.

8. 3. Card connector pinout

Contact Signal

B+

AGND GND

SCR Shield

• The cable sheath should be stripped off by about 10 mm (0.4 in).

• For wiring the terminals, use a slotted screwdriver with a 0.6 mm (0.02 in) thick and 3.5 mm (0.14 in) width blade.

• Tightening torque for the terminal block is 0.5 to 0.6 N·m (0.37-0.44 ft·lb).

14 BBV10543 10/2010

Page 15

9. Configuration

9. 1. Communication parameters

Configure the following parameters in the [1.9 - COMMUNICATION] (COM-) menu, [P1] (P1-) submenu.

These parameters can only be modified when the motor is stopped.

Parameter Possible values Terminal Display Default value

[Address] (1)

(AdrC)

0 to 99

0,99: disabled.

[99] (99) 99

[Baud rate] (2)

(Bdr)

[Network time out]

(tLP)

(1)Modifications will be taken into account immediatly.

(2)Modifications will only be taken into account by the drive after power cycled.

[4800 Bd] (4-8)

[9600 Bd] (9_6)

[19200 Bd] (19_2)

[38400 Bd] (38_4)

[57600 Bd] (57_6)

[76800 Bd] (76_8)

2.0 to 60.0 seconds [2] (2) 10.0

[4800 Bd] (4-8)

[9600 Bd] (9_6)

[19200 Bd] (19_2)

[38400 Bd] (38_4)

[57600 Bd] (57_6)

[76800 Bd] (76_8)

9600

BBV10543 10/2010 15

Page 16

9. Configuration

APOGEE® FLN P1

APOGEE® FLN P1

9. 2. Control

Numerous configurations are possible. For more information, refer to the Programming manual and the Communication parameters

manual.

The following configurations are just some of the possibili ties available.

b Allowed configurations

If the drive is only monitored by APOGEE® FLN P1:

There is no configuration constraint.

If the drive is controlled by APOGEE® FLN P1:

The parameter [Profile] (CHCF) must be configured to [Not separ.] (SIM) or [Separate] (SEP). [Not separ.] (SIM) is the default value.

It is not allowed to configure the parameter [Profile] (CHCF) to the value [8 serie] (SE8) or [I/O profile] (IO).

If an unallowed configuration is set, the drive will trip on [External fault com.] (EPF2).

However, if the I/O profile is configured and no command channels are assigned to the communication card, the drive will not trip.

b Control via APOGEE® FLN P1

The command and the setpoint come from APOGEE® FLN P1.

Configure the following parameters:

Parameter Value Comment

Profile Not separate Both the start/stop command and speed reference come

Setpoint 1 and command configuration Network card The setpoint and command come from APOGEE® FLN P1.

Configuration via the graphic display terminal or the integrated display terminal:

Menu Parameter Value

[1.6 - COMMAND] (CtL-) [Profile] (CHCF) [Not separ.] (SIM): default value

16 BBV10543 10/2010

from the same channel set in [Ref.1 chan]. The run start/stop

command follows the CiA402 profile.

[Ref.1 chan] (Fr1) [Com. card] (nEt)

Page 17

9. Configuration

APOGEE® FLN P1

APOGEE® FLN P1

APOGEE® FLN P1

APOGEE® FLN P1

LDO#68 (bit C312)

FLN.LOC.CTL

LDO#69 (C313)

FLN.LOC.REF

b Control via APOGEE® FLN P1 or via the terminals

The command and the setpoint both come from APOGEE® FLN P1 or the terminals.

Depending on the configuration, the application functions are or are not used.

Two different cases are described below showing how the setpoint is switched from APOGEE® FLN P1 to the terminals. In the first case,

the application functions apply but not in the second on e.

An alternate solution can also be used: the setpoint and the command can be switched separately from the network. Two Logical Digital

Out (LDO) are dedicated to this function: LDO#68 and LDO#69. These 2 points command C312 and C313 respectively.

Note:

When using the previous operating mode, it is important that the P1 mast er controller monitors t he drive state (by pol ling signif icant points).

Therefore when the control and/or the setpoint are switched back to APOGEE® FLN P1, the controller will react properly (when the Drive

is switched to local mode, all overridden commands are released).

Important: In this case, a communication interruption message can appear if the connection is interrupted.

BBV10543 10/2010 17

Page 18

9. Configuration

APOGEE® FLN P1

Switching of control and setpoint from APOGEE® FLN P1 to the terminals with application function

In this example, logic input LI5 i s used to switch t he control and the setpoint between APOGEE® FLN P1 an d the terminals. When switched

to the terminals, the application functions (summing…) remain active.

Configure the following parameters:

Parameter Value Comment

Profile Separate profile The command and the setpoint can come from different channels.

Setpoint 1 configuration Network card Setpoint 1 comes from APOGEE® FLN P1.

Setpoint 1B configuration Analog input 1 on the terminal s Setpoint 1B comes from input AI1 on the terminals.

Setpoint switching Input LI5 Input LI 5 swi tche s th e set poi nt (1

Command 1 configuration Network card Command 1 comes from APOGEE® FLN P1.

Command 2 configuration Terminals Command 2 comes from the terminals.

Command switching Input LI5 Input LI5 switches the command. C313 (LDO#69) can also be configured f or the

Setpoint 1B is directly connected to the functions of the drive. If the reference is switched to the terminals using Setpoint 1B, the functions

that affect the reference (summing, PID, etc) are active.

Configuration via the graphic display terminal or the integrated display terminal:

Menu Parameter Value

[1.6 - COMMAND] (CtL-) [Profile] (CHCF) [Separate] (SEP)

[1.7 - APPLICATION FUNCT.] (FUn-)

[REFERENCE SWITCH]

for the command switching

↔ 1B). C312 (LDO#68) can also be configured

setpoint

[Ref.1 channel] (Fr1) [Com. card] (nEt)

[Cmd channel 1] (cd1) [Com. card] (nEt)

[Cmd channel 2] (cd2) [Terminals] (tEr)

[Cmd switching] (CCS) [LI5] (LI5)

[Ref.1B channel] (Fr1b) [Ref. AI1] (AI1) or C312

[Ref.1B switching] (rCb) [LI5] (LI5) or C313

18 BBV10543 10/2010

Page 19

9. Configuration

APOGEE® FLN P1

Switching of control and setpoint from APOGEE® FLN P1 to the terminals without application function

In this example, logic input LI5 is used to switch the control and the setpoint between APOGEE® FLN P1 and the terminals. When

Reference Channel 2 is used for reference switching, the application functions (summing…) are not active.

Configure the following parameters:

Parameter Value Comment

Profile Not separate profile The command and the setpoint come from the same channel.

Setpoint 1 configuration Network card Setpoint 1 and command 1 comes from APOGEE® FLN P1.

Setpoint 2 configuration Analog input 1 on the terminals Setpoint 2 and command 2 comes from input AI1 on the terminals.

Setpoint switching Input LI5 Input LI5 switches the setpoint (1

Configuration via the graphic display terminal or the integrated display terminal:

Menu Parameter Value

[1.6 - COMMAND] (CtL-) [Profile] (CHCF) [Not separ.] (SIM): default value

can also be configured for the set point switching

↔ 2) and the command. C313 (LDO#69)

[Ref.1 chan] (Fr1) [Com. card] (nEt)

[Ref.2 chan] (Fr2) [AI1 ref.] (AI1)

[Ref.2 switching] (rFC) [LI5] (LI5) or [C313] C313

BBV10543 10/2010 19

Page 20

9. Configuration

APOGEE® FLN P1

APOGEE® FLN P1

b Control via APOGEE® FLN P1 and setpoint switching

The command comes from APOGEE® FLN P1.

The setpoint comes either from APOGEE® FLN P1 or from the terminals.

Depending on the configuration, the application functions are enabled or disabled.

Note:

When using the previous operating mode, it is important that the P1 mast er controller monitors t he drive state (by pol ling signif icant points).

Therefore when the control and/or the setpoint are switched back to APOGEE® FLN P1, the controller will react properly (when the drive

is switched to local mode, overridden commands are released).

20 BBV10543 10/2010

Page 21

9. Configuration

APOGEE® FLN

P1

Control via APOGEE® FLN P1 and switching of the setpoint at the terminals with application function

In this example, the command comes from APOGEE® FLN P1. logic input LI5 is used to switch the setpoint between APOGEE® FLN P1

and the terminals. When switched to the terminals, the application functions (summing…) remain active.

Configure the following parameters:

Parameter Value Comment

Profile Separate profile The command

Setpoint 1 configuration Network card Setpoint 1 comes from APOGEE® FLN P1.

Setpoint 1B configuration Analog input 1 on the terminals Setpoint 1B comes from input AI1 on the terminals.

Setpoint switching Input LI5 Input LI5 switches the reference (1

Command 1 configuration Network card Command 1 comes from APOGEE® FLN P1.

Command switching Channel 1 Channel 1 is the command channel.

Reference 1B is directly connected to t he functions of t he drive. If the reference is switched to the terminal s using Setpoint 1B, the functions

that affect the reference (summing, PID, etc) are active.

Configuration via the graphic display terminal or the integrated display terminal:

Menu Parameter Value

[1.6 - COMMAND] (CtL-) [Profile] (CHCF) [Separate] (SEP)

[1.7 - APPLICATION FUNCT.] (FUn-)

[REFERENCE SWITCH]

and the setpoint can come from different channels.

↔ 1B). C313 (LDO#69) can also

be configured for the set point switching.

[Ref.1 channel] (Fr1) [Com. card] (nEt)

[Cmd channel 1] (cd1) [Com. card] (nEt)

[Cmd switching] (CCS) [ch1 active] (Cd1)

[Ref.1B channel] (Fr1b) [Ref. AI1] (AI1)

[Ref.1B switching] (rCb) [LI5] (LI5) or [C313] C313

BBV10543 10/2010 21

Page 22

9. Configuration

APOGEE® FLN P1

Control via APOGEE® FLN P1 and switching of the setpoint at the terminals with application function

In this example, the command comes from APOGEE® FLN P1. logic input LI5 is used to switch the setpoint between APOGEE® FLN P1

and the terminals. When switched to the terminals, the application functions (summing…) are not active.

Configure the following parameters:

Parameter Value Comment

Profile Separate profile The command and the setpoint can come from different channels.

Setpoint 1 configuration Network card Setpoint 1 comes from APOGEE® FLN P1.

Setpoint 2 configuration Analog input 1 on the terminals Setpoint 2 comes from input AI1 on the terminals.

Setpoint switching Input LI5 Input LI5 switches the setpoint (1

Command 1 configuration Network card Command 1 comes from APOGEE® FLN P1.

Command switching Channel 1 Channel 1 is the command channel.

Setpoint 1B is connected to the functions (Summing, etc) that remain active even after switching.

Configuration via the graphic display terminal or the integrated display terminal:

Menu Parameter Value

[1.6 – COMMAND] (CtL-) [Profile] (CHCF) [Separate] (SEP)

configured for the set point switching.

↔ 2). C313 (LDO#69) can also be

[Ref.1 chan] (Fr1) [Com. card] (nEt)

[Ref.2 chan] (Fr2) [AI1 ref.] (AI1)

[Ref 2 switching] (rFc) [LI5] (LI5) or [C313] C313

[Cmd channel 1] (Cd1) [Com. card] (nEt)

[Cmd switching] (CCS) [ch1 active] (Cd1)

22 BBV10543 10/2010

Page 23

9. Configuration

9. 3. Communication configuration

An APOGEE® FLN P1 trip is triggered if the APOGEE® FLN P1 card does not receive any APOGEE® FLN P1 messages (regardless of

address) at its address within a predefined time period (timeout defined by tLP). APOGEE® FLN P1 request types are taken into account

(read, write, etc.).

The response of the drive in the event of a APOGEE® FLN P1 communication interruption can be configured.

RDY NET +0.00Hz 0A

COM. FAULT MANAGEMENT

Configuration can be performed using the graphic display terminal or

integrated display terminal using the [Network fault mgt] (CLL)

parameter in the [1.8 FAULT MANAGEMENT] (FLt-) menu, [COM.

FAULT MANAGEMENT] (CLL-) submenu.

The values of the [Network fault mgt] (CLL) parameter, which trigger a [Com. network] (CnF) condition, are:

Value Meaning

[Freewheel] (YES) Freewheel stop (factory setting)

[Ramp stop] (rMP) Stop on ramp

[Fast stop] (FSt) Fast stop

[DC injection]

(dCI) DC injection stop

Network fault mgt : Freewheel

CANopen fault mgt : Freewheel

Modbus fault mgt : Freewheel

Code Quick

The values of the [Network fault mgt] (CLL) parameter, which do not trigger a [Com. network] (CnF) condition, are:

Value Meaning

[Ignore] (nO) Condition ignored

[Per STT] (Stt) Stop according to configuration of [Type of stop]

[fallback spd] (LFF)

[Spd maint.]

The fallback speed can be configured via the [Fallback speed]

(rLS)

Switch to fallback speed, maintained as long as the condition is present and the run command is not

disabled.

The drive maintains the speed at the time the fault was detected, as long as the condition persists and

the run command has not been removed.

(LFF) parameter in the [1.8 – FAULT MANAGEMENT] (FLt-) menu.

(Stt).

BBV10543 10/2010 23

Page 24

9. Configuration

9. 4. Monitored parameters

It is possible to select up to 4 parameters to display their values in the [1.2 - MONITORING] menu ([COMMUNICATION MAP] submenu)

on the graphic display terminal.

The selection is made via the [6 – MONITOR CONFIG.] menu ([6.3 - CONFIG. COMM. MAP] submenu).

Each parameter [Address 1 select] ... [Address 4 selec t] can be used to

choose the logic address of the parameter. Select an address of zero

to disable the function.

In the example given here, the monitored words are:

• Parameter 1 = Motor current (LCr): logic address 3204;

signed decimal format

• Parameter 2 = Motor torque (Otr): logic address 3205; signed

decimal format

• Parameter 3 = Last detected fault occurred (LFt): l ogic address 7121;

hexadecimal format

• Disabled parameter: address 0; default format: hexadecimal format

RDY NET +0.00Hz 0A

6.3 CONFIG. COMM. MAP.

Address 1 select : 3204

FORMAT 1 : Signed

Address 2 select : 3205

FORMAT 2 : Signed

Address 3 select : 7121

Code Quick

FORMAT 3 : Hex

Address 4 select : 0

FORMAT 4 : Hex

One of the three display formats below can be assigned to each monitored word:

Format Range Terminal display

Hexadecimal 0000 ... FFFF [Hex]

Signed decimal -32,767 ... 32,767 [Signed]

Unsigned decimal 0 ... 65,535 [Unsigned]

24 BBV10543 10/2010

Page 25

10. Diagnostics

1.1

1.2

1.3

1.4

1.5

2.1

2.2

2.3

2.4

2.5

RUN (green)

ERR (red)

10. 1. Checking the address

On the graphic display terminal or integrated d isplay t ermi nal , check t he addres s th at has been se t co rre ctl y us ing the [Address] (AdrC)

parameter in the [1.9 COMMUNICATION] (COM-) menu, [P1] (MEt) submenu.

10. 2. Checking the communication

On the graphic display terminal, in the [1.2 - MONITORING] (SUP) menu [COMMUNICATION MAP] (CMM-) menu [DIAG NETWORK]

(nEt):

Contents of the DIAG NETWORK sub menu with a APOGEE® FLN P1 communication board:

Parameter Comment

[Address] (AdrC) Displays the device's address

[Frame counter] (tFC) Displays the total number of frames received by the communication card since the last power ON.

[Invalid Frame counter] EFC) Displays the total number of bad frames received by the communication card since the last power ON.

10. 3. LEDs

The APOGEE® FLN P1 card has 2 LEDs, RUN and ERR, which are visible through the drive cover.

b LEDs Indication Table

LED Comment

RUN LED: OFF

ERR LED: Flashing 5 times in 1 second

RUN LED: OFF

ERR LED: Flashes 3 times in 2 seconds, Off for

1 second

RUN LED: ON

ERR LED: On for 0.5 seconds, Off for 0.5

seconds

RUN LED: Flashing

ERR LED: -

RUN LED: ERR LED: Flashing

RUN LED: OFF

ERR LED: OFF

APOGEE® FLN P1 card inoperable.

Communication loss detected. Confirm the network condition and

connection of the network cable.

Invalid configuration detected.

Valid message received for this node.

Invalid message received (any node)

No communication with the drive (e.g. : drive power is off) or the baud

rate is set incorrectly.

BBV10543 10/2010 25

Page 26

10. Diagnostics

RUN NET +50.00Hz 80A

COMMUNICATION MAP

Command Channel : Com. card

Cmd value : 000F

Hex

Active ref. channel : Com. card

Frequency ref. : 500.0

Hz

Status word : 8627

Hex

Code Quick

W3204 : 53

W3205 : 725

W7132 : 0000

Hex

W0 : -----

Hex

COM. SCANNER INPUT MAP

COM SCAN OUTPUT MAP

CMD. WORD IMAGE

FREQ. REF. WORD MAP

MODBUS NETWORK DIAG

MODBUS HMI DIAG

CANopen MAP

PROG. CARD SCANNER

DIAG NETWORK

Address

Frame counter

Error Frame counter

Active command channel

Value of control word used

to control the drive

(hexadecimal format)

Active reference channel

Value of frequency reference

(unit 0.1 Hz) used to control the drive

Value of status word

(hexadecimal format)

Values of the four monitored words selected by the user.

The address and display format of these parameters

can be configured in the

[6 - MONITORING CONFIG.] menu,

[6.3 - COM. MAP CONFIG.]

submenu (see “

Monitored parameters”, page 24).

The value of a monitored word is equal to "-----" if:

-Monitoring is not activated

(address equal to 0)

-The parameter is protected

-The parameter is not known (e.g., 3200)

Value of input variables

Value of output variables

Control word from APOGEE® FLN P1

[COM. card cmd.] (CMd3)

Frequency reference from APOGEE® FLN P1

[Com. card ref.] (LFr3)

Communication

scanner

10. 4. Control - Command

On the graphic display terminal only, the [1.2 - MONITORING] menu ([COMMUNICATION MAP] submenu) can be used to display cont rolsignal diagnostic information between the drive and the master:

26 BBV10543 10/2010

Page 27

10. Diagnostics

10. 5. Communication interruptions

APOGEE® FLN P1 communication interruptions are indicated by the red ERR LED on the APOGEE® FLN P1 card.

In the factory default configuration, a communication timeout will trigger a resettable [Com. network] (CnF) condition and initiate a

freewheel stop.

It is possible to change the response of the drive in the event of a APOGEE® FLN P1 communication interruption (see the Configuration

section).

- [Com. network] (CnF) condition (freewheel stop, stop on ramp, fast stop or DC injection braking stop)

- No [Com. network] (CnF) condition ignore, (stop, maintain, fallback)

The Parameters Manual contains a detailed description of how to manage communication interruptions (see the "Communication

monitoring" section).

• Following initialization (power-up), the drive checks that at least one command or referenc e parameter has been wri tten for the first time

by APOGEE® FLN P1.

• Then, if a communication interruption occurs on APOGEE® FLN P1, the drive will react according to the configuration con dition (maintain,

fallback, etc.).

10. 6. Option card hardware conditions

The [Internal com. link] (ILF) appears when the following occur:

- Hardware related issue on the APOGEE® FLN P1 card

- Communication interruption between the APOGEE® FLN P1 card and the drive

The drive responds to an [Internal com. link] (ILF) message by going into a freewheel stop mode. This event cannot be reset without

cycling power to the equipment.

Two diagnostic parameters can be used to obtain more detailed information about the origin of the [internal com. link] (ILF) event:

- [Internal link fault 1] (ILF1) if the event has occurred on option card no. 1 (installed directly on the dri ve)

- [Internal link fault 2] (ILF2) if the event has occurred on option card no. 2 (installed on top of option card no. 1)

The APOGEE® FLN P1 card can be in position 1 or 2.

The [Internal link fault 1] (ILF1) and [Internal link fault 2] (ILF2) parameters can only be accessed on the graphic display terminal in

the [1.10 DIAGNOSTICS] (DGt-) menu, [MORE FAULT INFO] (AFI-) submenu.

Value Description of the values of the [Internal link fault 1] (ILF1) and [Internal link fault 2] (ILF2) parameters

0Okay

1 Loss of internal communication with the drive

2 Potential hardware problem detected

3 Potential problem in the EEPROM checksum

4 EEPROM analysis needed

5 Flash memory analysis needed

6 RAM memory analysis needed

7 NVRAM memory analysis needed

8 Analog input analysis needed

9 Analog output analysis needed

10 Logic input analysis needed

11 Logic output analysis needed

101 Unknown card

102 Exchange problem on the drive internal bus

103 Time out on the drive internal bus (500 ms)

BBV10543 10/2010 27

Page 28

11. Network objects

11. 1. Logical Analog Input (LAI) Summary

Logical Analog Input (LAI) points are used for monitoring drive status items such as output frequency, current and voltage.

The APOGEE® FLN P1 card supports 24 different logical analog input points. Change of value (COV) of LAI points can be enabled (LAI

points are capable of being characterized). LAI points will respond to write point and memorize point commands, but will not change their

actual values or indicate override active.

Logical Analog Input (LAI) Summary

Poin Number Point Name Factory Default Eng. Units Slope Intercept Min Max

03 FREQ OUTPUT 0 HZ 0.1 0 0 32767

04 PCT OUTPUT 0 PCT 0.1 0 0 32767

05 SPEED 0 RPM 1 0 0 32767

06 CURRENT 0 A 0.1 0 0 32767

07 TORQUE 2000 PCT 0.1 -200 0 32767

08 POWER 0 KW 0.1 0 0 32767

09 DRIVE TEMP 0 PCT 0.1 0 0 32767

10 DRIVE KWH 0 kWH 1 0 0 32767

11 DRIVE MWH 0 MWH 1 0 0 32767

12 RUN TIME 0 H 1 0 0 32767

13 DC BUS VOLT 0 V 1 0 0 32767

14 OUTPUT VOLT 0 V 1 0 0 32767

15 PRC PID FBCK 0 PCT 0.1 0 0 32767

16 PRC PID DEV 0 PCT 0.1 N/A 0 32767

17 MOTOR TEMP 0 PCT 0.1 N/A 0 32767

82 AI 1 ACTUA L 0 PCT 0.1 0 0 32767

83 AI 2 ACTUA L 0 PCT 0.1 0 0 32767

84 AO 1 ACTUAL 0 PCT 0.1 0 0 32767

85 AO 2 ACTUAL 0 PCT 0.1 0 0 32767

88 ALARM WO RD 1* 0 - 1 0 0 32767

89 ALARM WO RD 2* 0 - 1 0 0 32767

90 LAST FAULT* 0 - 1 0 0 32767

91 PREV FAULT 1* 0 - 1 0 0 32767

92 PREV FAULT 2* 0 - 1 0 0 32767

* Refer to the ATV61 programming manual.

28 BBV10543 10/2010

Page 29

11. Network objects

b LAI Point Descriptions

Logical Analog Input (LAI) Point Descriptions.

Point

Number

03 Adrc FREQ OUTPUT The output frequency applied to the motor, in Hertz.

04 - PCT OUTPUT The ratio of the output frequency or speed to the corresponding base frequency.

05 rFr SPEED The calculated speed of the motor, in RPM.

06 LCr CURRENT The measured output current.

07 Otr TORQUE The calculated output torque of the motor as a percentage of nominal torque.

08 Oprp POWER T he measured output power in kW.

09 hd DRIVE TEMP The calculated thermal state of the drive.

10 Iphr DRIVE KWH The drive's cumulative power consumption in kilowatt-hours.This value may be reset by

11 Iph DRIVE MWH The drive's cumulative power consumption in megawatt-hours. This value may be reset by

12 rth RUN TIME The drive's cumulative run time in hours.

13 ULn DC BUS VOLT The DC bus voltage level of the drive.

14 Uop OUTPUT VOLT The AC output voltage applied to the motor.

15 rpF PRC PID FBCK The ratio of PID feedback signal to the corresponding vl(base frequency).

16 - (PRC PID DEV) Reserved

17 - (MOTOR TEMP) Reserved

82 Ai1L AI 1 ACTUAL Indicates the input level of analog input 1.

83 Ai2L AI 2 ACTUAL Indicates the input level of analog input 2.

84 Ao1L AO 1 ACTUAL Indicates the output level of analog output1terminal.

85 Ao2L AO 2 ACTUAL Indicates the output level of analog output 2 terminal.

88 ur1 ALARM WORD 1 This point is a bit-field indicating active alarms in the drive.

89 ur2 ALARM WORD 2 This point is a bit-field indicating active alarms in the drive.

90 LFt LAST FAULT This point is first in the drive's detected fault log and indicates the most recent interruption.

91 dp1 PREV FAULT 1 This point is second in the drive's detected faul t log and indicates the previous interruption

92 dp2 PREV FAULT 2 This point is last in the drive's detected fault log and indicates the olde st interruption in the log.

Drive relative

parameter

Point

Name

Description

commanding FLN point 49, RESET KWH.

commanding FLN point 49, RESET KWH.

declared.

BBV10543 10/2010 29

Page 30

11. Network objects

11. 2. Logical Analog Output (LAO) Summary

Logical Analog Output (LAO) points are used for setting and monitoring control points such as the drive's frequency command and

configuration parameters.

The APOGEE® FLN p1 card supports 11 different logical analog output points (7 of them are for the ATV61 parameters and commands,

while other 4 special points are reserved for maintaining compliance). The values of logical analog output points can be modified by write

point or memorize point commands. Release commands will not cause the logi cal analog out pu t poi nts to auto mati cal ly return t o th eir preoverride values. LAO points do not support COV.

Logical Analog Output (LAO) Summary

Point

Number

01 CTLR ADDRESS 99 - 1 0 0 99

02 APPLICATION 2748 - 1 0 0 32767

20 OVRD TIME 1 H 1 0 0 255

30 CURRENT LIM 0 A 0.1 0 0 32767

31 ACCEL TIME 1 Reserved

32 DECEL TIME 1 Reserved

46 AO 1 COMMAND 0 PCT 0.1 0 0 32767

47 AO 2 COMMAND 0 PCT 0.1 0 0 32767

50 PRC PID GAIN Reserved

51 PRC PID ITIM *** Reserved

52 PRC PID DTIM Reserved

53 (PRC PID DFIL) Reserved

60 INPUT REF1 * 0 PCT 0.1 0 0 32767

61 INPUT REF2 Reserved

66 SPD OUT MIN 0 PCT 0.1 0 0 32767

67 SPD OUT MAX 1000 PCT 0.1 0 0 32767

95 MBOX PARAM ** - - 1 0 0 32767

96 MBOX DATA ** - - 1 0 0 32767

99 ERROR STATUS - - 1 0 0 255

** About MBOX function, refer to chapter 12 : "Message function box"

Point

Name

Factory

Default

Eng.

Units

Slope Intercept Min Max

b LAO Point Descriptions

Logical Analog Output (LAO) Point Descriptions

Point

Number

01 AdrC CTLR ADDRESS The FLN address of the drive. It can be set from the FLN network and with the local

02 - APPLICATION The Applica ti on ID fo r APOGEE® FLN P1 card

20 - OVRD TIME 1 of the 5 mandatory FLN points required for compatibility with Siemens control

30 cli CURRENT LIM Sets the output current limit of the drive. The value is memorized if it is written by P1

46 Ao1r AO 1 COMMAND Controls analog output 1(AO1).

47 Ao2r AO 2 COMMAND Controls analog output 2(AO2).

60 Based on :

66 Based on :

67 Based on :

95 - MBOX PARAM Sets the parameter to be used by the mailbox function. (Refer to chapter 12)

96 - MBOX DATA Sets or indicates the data value of the mailbox function. (Refer to chapter 12)

99 - STATUS 1 of the 5 mandatory FLN points required for compatibility with Siemens control

Drive relative

parameter

LFr/tFr

LSp/tFr

HSp/tFr

Point

Name

INPUT REF1 Drive speed setpoint from the network

SPD OUT MIN Sets the minimum output speed of the drive as a percentage of the motor nominal rating.

SPD OUT MAX Sets the maximum out put speed of the drive as a percentage of the motor nominal

Description

HMI, graphic keypad or the comissioning software.

systems. It has no functionality in the drive application.

network.

If this output is not assigned to a drive function.

If this output is not assigned to a drive function.

The value is memorized if it is written by P1 network.

rating. The value is memorized if it is written by P1 network.

systems. It has no functionality in the drive application.

30 BBV10543 10/2010

Page 31

11. Network objects

11. 3. Logical Digital Input (LDI) Summary

Logical Digital Input (LDI) points are used for drive status monitoring such as terminal ON/OFF conditions and fault status.

The APOGEE® FLN P1 card supports 24 different logical digital input points. LDI points support COV (LDI points are capable of being

characterized). LDI points will respond to write point and memorize point commands, but will not change their actual values or indicate

override active.

Logical Digital Input (LDI) Summary

Point

Number

21 FWD.REV FWD 1 0 REV FWD

23 STOP.RUN STOP 1 0 RUN STOP

25 EXT1.2 ACT Reserved

27 DRIVE READY NOTRDY 1 0 R EA DY NOTRDY

28 AT SETPOINT NO 1 0 YES NO

33 HANDAUTO ACT AUTO 1 0 HAND AUTO

36 FLN LOC ACT AUTO 1 0 FLN AUTO

37 CTL SRC Reserved

38 FLN REF1 SRC Reserved

39 FLN REF2 SRC Reserved

70 DI 1 ACTUAL OFF 1 0 ON OFF

71 DI 2 ACTUAL OFF 1 0 ON OFF

72 DI 3 ACTUAL OFF 1 0 ON OFF

73 DI 4 ACTUAL OFF 1 0 ON OFF

74 DI 5 ACTUAL OFF 1 0 ON OFF

75 DI 6 ACTUAL OFF 1 0 ON OFF

76 DO 1 ACTUAL OFF (1) 1 0 ON OFF

77 DO 2 ACTUAL OFF (1) 1 0 ON OFF

78 DO 3 ACTUAL OFF (2) 1 0 ON OFF

79 DO 4 ACTUAL OFF (2) 1 0 ON OFF

80 DO 5 ACTUAL Reserved 1 0 ON OFF

81 DO 6 ACTUAL Reserved 1 0 ON OFF

86 OK.ALARM OK 1 0 ALARM OK

93 OK.FAULT OK 1 0 FAULT OK

Point

Name

Factory

Default

Slope Intercept ON (1)

Text

OFF (0)

Test

(1) If IO basic card (VW3A3201) has been inserted.

(2) If IO extended card (VW3A3202) has been inserted.

BBV10543 10/2010 31

Page 32

11. Network objects

b LDI Point Descriptions

Logical Digital Input (LDI) Point Descriptions

Point

Number

21 EtA bit 15 FWD.REV Indicates the rotational direction of the motor, regardless of control source.

23 EtA bit 1 STOP.RUN Indicates the run status of the drive, regardless of control source.

27 EtA bit 0 & 4=1 DRIVE READY Indicates the drive is ready to accept a run command.

28 EtA bit 10 AT SETPOINT Indicates the drive has reached its commanded setpoint

33 EtA bit 9 HANDAUTO ACT Indicates whether the drive is in local (HAND) or remote (AUTO) control.

36 ccS = C312

70 iL1L bit 0 DI 1 ACTUAL Indicates the status of logical Input 1.

71 iL1L bit 1 DI 2 ACTUAL Indicates the status of logical Input 2.

72 iL1L bit 2 DI 3 ACTUAL Indicates the status of logical Input 3.

73 iL1L bit 3 DI 4 ACTUAL Indicates the status of logical Input 4.

74 iL1L bit 4 DI 5 ACTUAL Indicates the status of logical Input 5.

75 iL1L bit 5 DI 6 ACTUAL Indicates the status of logical Input 6.

76 oL1L bit 0 DO 1 ACTUAL Indicates the status of logical output 1 (1).

77 oL1L bit 1 DO 2 ACTUAL Indicates the status of logical output 2 (1).

78 oL1L bit 2 DO 3 ACTUAL Indicates the status of logical output 3 (2).

79 oL1L bit 3 DO 4 ACTUAL Indicates the status of logical output 4 (2).

80 oL1L bit 4 DO 5 ACTU AL Reserved

81 oL1L bit 5 DO 6 ACTU AL Reserved

86 - OK.ALARM Indicates the current alarm state of the drive.

93 EtA bit 3 OK.FAULT Indicates the current state of the drive.

Drive relative

parameter

or

rCb = C313

Point

Name

FLN LOC ACT Indicates if the drive has been placed in "FLN LOCAL" mode by commanding either

Description

point 68 (FLN LOC CTL) or point 69 (FLN LOC REF). Commanding either of these

points to FLN overrides control from its normal source and places in under FLN

control.Note that the HAND mode of the panel has priority over FLN local control.

(1) If IO basic card (VW3A3201) has been inserted.

(2) If IO extended card (VW3A3202) has been inserted.

32 BBV10543 10/2010

Page 33

11. Network objects

11. 4. Logical Digital Output (LDO) Summary

Logical Digital Output (LDO) points are used for executing drive commands such as RUN/STOP and reset. The APOGEE® FLN P1 card

supports 16 different logical digital output points (15 among them are for drive control, one special point is reserved for maintaining

compliance). The values of logical digital output points can be modified by write point or memorize point commands. Release commands

will not cause the logical digital output points to aut omatically return to their pre-override values. LDO points do not support COV.

Logical Digital Output (LDO) Summary

Point

Number

22 CMD FWD.REV FWD 1 0 REV FWD

24 CMD STP.STRT STOP 1 0 RUN STOP

26 EXT1.2 CM D Reserved

29 DAY.NIGHT DAY 1 0 NIGHT DAY

40 DO 1 COMMAND OFF (1) 1 0 ON OFF

41 DO 2 COMMAND OFF (1) 1 0 ON OFF

42 DO 3 COMMAND OFF (2) 1 0 ON OFF

43 DO 4 COMMAND OFF (2) 1 0 ON OFF

44 DO 5 COMMAND Reserved 1 0 ON OFF

45 DO 6 COMMAND Reserved 1 0 ON OFF

48 RST RUN TIME NO 1 0 RESET NO

49 RESET KWH NO 1 0 RESET NO

59 LOCK PANEL Reserved

68 FLN LOC CTL AUTO 1 0 FLN AUTO

69 FLN LOC REF AUTO 1 0 FLN AUTO

94 RESET FAULT NO 1 0 RESET NO

97 MBOX READ DONE 1 0 READ DONE

98 MBOX WRITE DONE 1 0 WRITE DONE

(1) If IO basic card (VW3A3201) has been inserted.

(2) If IO extended card (VW3A3202) has been inserted.

Point

Name

Factory

Default

Slope Intercept ON (1)

Text

OFF (0)

Test

BBV10543 10/2010 33

Page 34

11. Network objects

b LDO Point Descriptions

Logical Digital Output (LDO) Point Descriptions

Point

Number

22 - CMD FWD.REV Acts on the CiA402 drive state machine.For more details, please refer to the programming

24 - CMD STP.STRT Acts on the CiA402 drive state machine.For more details, please refer to the programming

29 - DAY.NIGHT 1 of the 5 mandatory FLN points required for compatibility with Siemens control systems. It

40 OL1r bit 0 DO 1 COMMAND Logical output 1 (1)

41 OL1r bit 1 DO 2 COMMAND Logical output 2 (1)

42 OL1r bit 2 DO 3 COMMAND Logical output 3 (2)

43 OL1r bit 3 DO 4 COMMAND Logical output 4 (2)

44 OL1r bit 8 DO 5 COMMAND Reserved

45 OL1r bit 9 DO 6 COMMAND Reserved

48 rpr = 2 RST RUN TIME Reset run time counter

49 rpr = 5 RESET KWH Commanded by the FLN network to reset the cumulative kilowatt-hour and megawatt-hours

68 C312 FLN LOC CTL Commanded from the FLN network to temporarily "steal" start/stop control of the drive from

69 C313 FLN LOC REF Commanded from the FLN network to temporarily "steal" input setpoint control of the drive

94 CMd bit 7 RESET FAULT Command from the FLN network to reset a drive (1 = RESET, 0 = NO).The control input is

97 - MBOX READ Refer to chapter “

98 - MBOX WRITE Refer to chapter “

Drive relative

parameter

Point

Name

Parameter

manual

manual

has no functionality in the drive application.

counter (1 = RESET, 0 = NO).

its normal source and place it under FLN network control. Note : this function is active if the

control switching has been configured to C312 (see chap ter “

from its normal source and place it under the FLN network control. Note : this function is

active if the control switching has been configured to C313 (see ch apt er “

rising-edge sensitive, so, once the comman d is i ssu ed, t hi s po int aut omatica ll y returns t o i ts

inactive state. This "momentary" operation avoid s any need for an expl icit command to cl ear

the point before a subsequent reset can be issued.

Message box function points”, page 35 .

Message box function points”, page 35.

Control”, page 16)

Control”, page 16)

(1) If IO basic card (VW3A3201) has been inserted.

(2) If IO extended card (VW3A3202) has been inserted.

34 BBV10543 10/2010

Page 35

12. Message box function points

12. 1. ATV61 Parameter access point table

Using below APOGEE® FLN P1 points, drive parameters can be read and written.

Point

Number

95 LAO MBOX PARAM The communication number (hex.) of the access parameter is set.

96 LAO MBOX DATA The parameter's data. The data unit depends on the parameter specification. Refer to the drive

97 LDO MBOX READ The parameter value specified by MBOX PARAM is read to MBOX DATA by setting 1(READ). When

98 LDO MBOX WRITE Data of MBOX DATA is written in at a parameter of MBOX PARAM in 1(WRITE) by a set. When written

Example 1) Read the acceleration time (ACC, Modbus address: 9001 = 16#2329)

• Write 9001* as the communication number to MBOX PARAM (LAO #95).

* decimal number

• Write "1" to MBOX READ (LDO #97).

• Confirm whether it was read in MBOX READ (LDO #97).

• The read value can be read in MBOX DATA (LAO #96). Note: The unit is 0.1 Hz.

Example 2) Write "55.0Hz" to High speed (HSP Modbus address: 3104 = 16#C20)

• Write 3104 as the communication number to MBOX PARAM (LAO #95).

• Write "550" to MBOX WRITE (LDO #98).

* 550 = 55.00Hz, unit is 0.1Hz

• Write "1" to MBOX WRITE (LDO #98).

Point

Type

Point

Name

Note

instruction manual.

they were read normally, these points return to 0. When not read normally, these points remain 1.

normally, these points return to 0. When unable to be written normally, these points remain 1.

12. 2. FLN P1 Status Code

When an operation cannot be completed as a result of a P1 command, an error code is returned with the NAK.

Below is a list of possible error codes that can be returned by a FLN device.

FLN P1 Status Code

Status Code Description

0x00D7 Operator priority too low. A number of situations can return this status code.

0x00F9 Invalid point number.

0x00FB No COVs to report.

0x00FC Request Characterization.

0x00FD Invalid command.

0x00FE Invalid value. *

* Including the response for Dump Memory command (0x0018) and Modify Memory command (0x00 19). APOGEE® FLN P1 card does not

support these commands.

BBV10543 10/2010 35

Page 36

13. Reports

The APOGEE® FLN P1 card is able to generate 6 predefined reports :

•Device

•Startup

•Overview

•Drive I/O

• Drive Config

• Process PID

These reports are initiated from the P1 controller, please refer to the manufacturer instructions before pro c eeding.

Here are 2 examples of reports:

36 BBV10543 10/2010

Page 37

AT V61_Apogée_FLN_P1_EN_BBV10543_04

BBV10543 10/2010

Loading...

Loading...