Twido and Altivar

Magelis & OTB FTB

System User Guide

[source code]

33003614.01

Sep 2006

Contents

Application Source Code................................................................................... 4

Typical Applications.......................................................................................... 5

System................................................................ ................................................ 6

Architecture .....................................................................................................................6

Installation.......................................................................................................................9

Hardware ..............................................................................................................................................16

Software ...............................................................................................................................................24

Communication ....................................................................................................................................25

Implementation..............................................................................................................29

Communication ....................................................................................................................................32

HMI .......................................................................................................................................................38

PLC.......................................................................................................................................................55

Devices.................................................................................................................................................88

Performance....................................................................................................................................... 101

Appendix ........................................................................................................ 102

Detailed Component List............................................................................................. 102

Component Protection Classes................................................................................... 106

Component Features...................................................................................................107

Contact........................................................................................................... 115

Introduction

This document is intended to provide a quick introduction to the described System.

It is not intended to replace any specific product documentation. On the contrary, it offers

additional information to the product documentation, for installing, configuring and starting up

the system.

A detailed functional description or the specification for a specific user application is not part of

this document. Nevertheless, the document outlines some typical applications where the

system might be implemented.

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

2

Abbreviations

Word / Expression Signification

AC

Advantys

Altivar (ATV)

CANopen

CB

CoDeSys

ConneXium

DC

EDS

E-OFF, E-STOP

Harmony

HMI

I/O

IclA (ICLA)

Lexium/Lexium05/LXM

Magelis

MB - SL

Micro

NIM

PC

Phaseo

PLC

Powersuite

Premium

Preventa

PS1131 (CoDeSys)

PS

SE

Sycon

Telefast

TesysU

Twido

TwidoSoft

TwidoSuite

Unity (Pro)

Vijeo Designer

VSD

WxHxD

XBT-L1000

Alternating Current

SE product name for a family of I/O modules

SE product name for a family of VSDs

Name for a communications maschine bus system

Circuit Breaker

Hardware-independant IEC 61131-3 programming software

SE product name for a Family of Transparent Factory devices

Direct Current

Electronic Data Sheet

Emergency Off switch

SE product name for a family of switches and indicators

Human Machine Interface

Input/Output

SE product name for a compact drive

SE product name for a family of servo-drives

SE product name for a family of HMI-Devices

SE name for a serial Modbus communications protocol

SE product name for a middle range family of PLCs

SE product name for a Network Interface Module

Personal Computer

SE product name for a family of power supplies

Programmable Logic Computer

An SE software product for configuring ALTIVAR drives

SE product name for a middle range family of PLCs

SE product name for a family of safety devices

SE Product name for PLC programming software with CoDeSys

Power Supply

Schneider Electric

SE product name of a Field bus programming software

SE product name for a series of distributed I/O devices

SE product name for a decentralised I/O System

SE product name of a middle range family of PLCs

SE product name for a PLC programming software

SE product name for a PLC programming software

SE product name for a PLC programming software

An SE software product for programming Magelis HMI devices

Variable Speed Drive

Dimensions : Width, Height and Depth

An SE software product for programming Magelis HMI devices

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

3

Introduction

Application Source Code

Examples of the source code and wiring diagrams used to attain the system function as

described in this document can be downloaded from our website under this link.

The example source code is in the form of configuration, application and import files. Use the

appropriate software tool to either open or import the files.

Extension File Type Software Tool Required

AIW

CNF Configuration File

CO CANopen definitions file

CSV Comma Seperated Values, Spreadsheet

CTX

DCF Device Configuration File

DIB Device Independent Bitmap

DOC Document file

DOP

EDS Electronic Data Sheet – Device Definition

FEF

GSD EDS file (Geraete Stamm Datei)

ISL Island file, project file

PB Profibus definitions file

PDF Portable Document Format - document

PS2

RTF Rich Text File - docume nt

SPA

STU

STX

TLX

TWD

VDZ

XEF

XPR

ZM2

Configuration File Advantys

Sycon

Sycon

Twidosoft

Unity

Advantys

Sycon

Microsoft Word

Project File Magelis XBTL

Industrial standard

Export file PL7

Profibus

Advantys

Sycon

Adobe Acrobat

Export file Powersuite export file

Microsoft Word

Schneider Product Archive TwidoSuite

Project file Unity Pro

Project file PL7

Project file Twinline control tool

Project file TwidoSoft

Project file Vijeo Designer

Export file Unity Pro

Project File TwidoSuite

Project File Zeliosoft

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

4

Introduction

Typi cal Applications

Here you will find a list of the typical applications, and their market segments, where this

system or subsystem can be applied:

Industrial

Small automated machine or plant components

Remote automation systems used to supplement large and medium-sized machines

Buildings/Services

Conveyor belt with turntable

Irrigation systems for greenhouses

Infrastructure

Air-conditioning/ventilation for tunnel systems

Food & Beverage/Pharmaceuticals

Control and monitoring of pumps and valves

Application Description Image

Conveyor belt with

turntable

Irrigation systems for

greenhouses

These plant components are

often connected upstream of a

larger packaging or filling plant

as feeder system components.

Sorting is possible using photo

barriers or weight sensors.

This application controls

irrigation in greenhouses.

Temperature, light and humidity

sensors permit the correct

irrigation of all types of plants.

Air-conditioning/

ventilation for tunnel

systems

Control and monitoring

of pumps and valves

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

Tunnel systems must be

ventilated according to weather

and traffic conditions. Smallscale systems can control

turbines and valves in

ventilation shafts and monitor

carbon monoxide levels and air

quality.

As part of an overall plant or

external station in a water

supply/drainage system.

Pressure sensors, flow meters

and level measuring (e.g.,

inductive measurements) can

be used to adjust delivery

according to demand.

5

Introduction

General

System

The system chapter describes the architecture, the dimensions, the quantities and different

types of compone nts used within this system.

Architecture

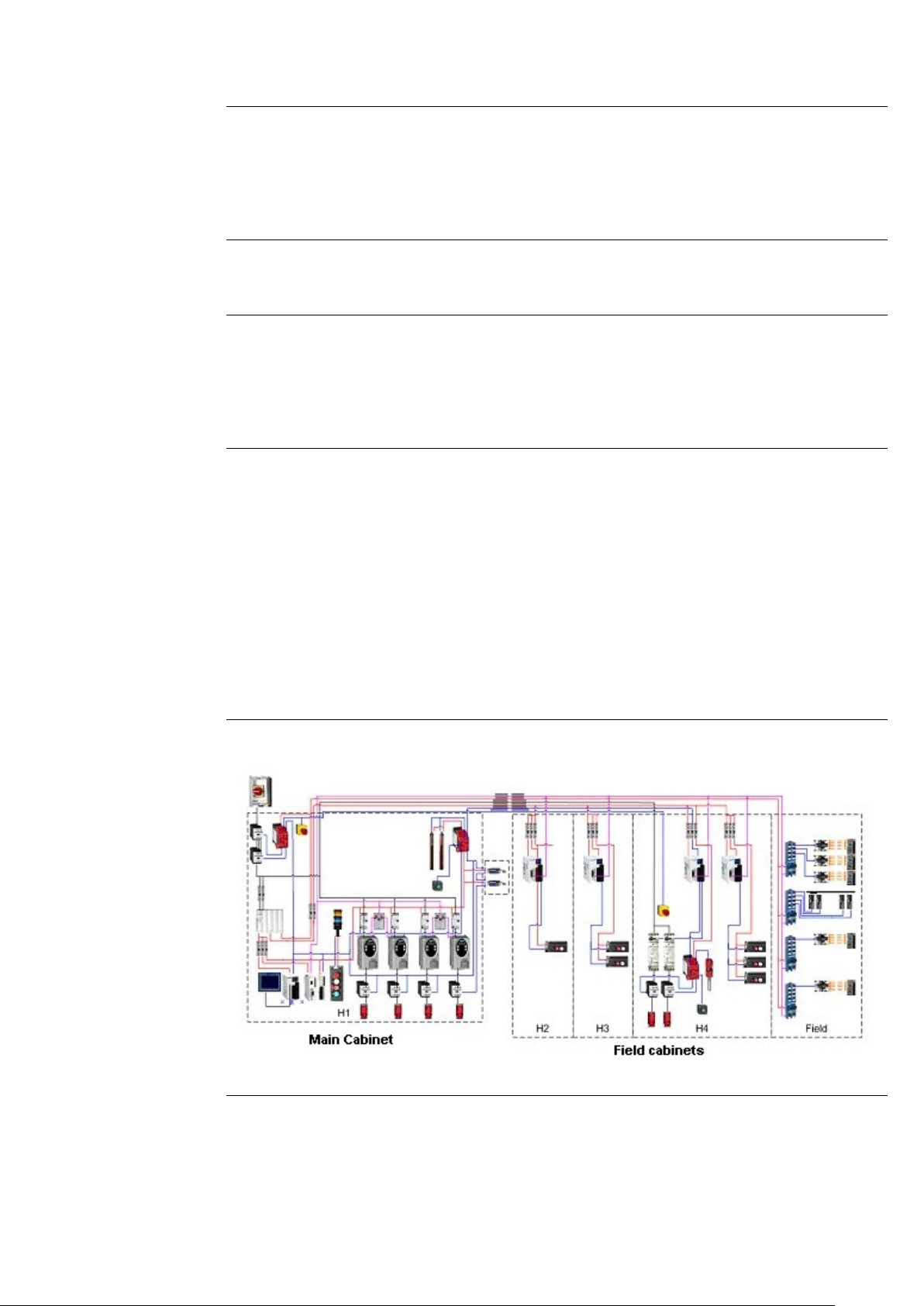

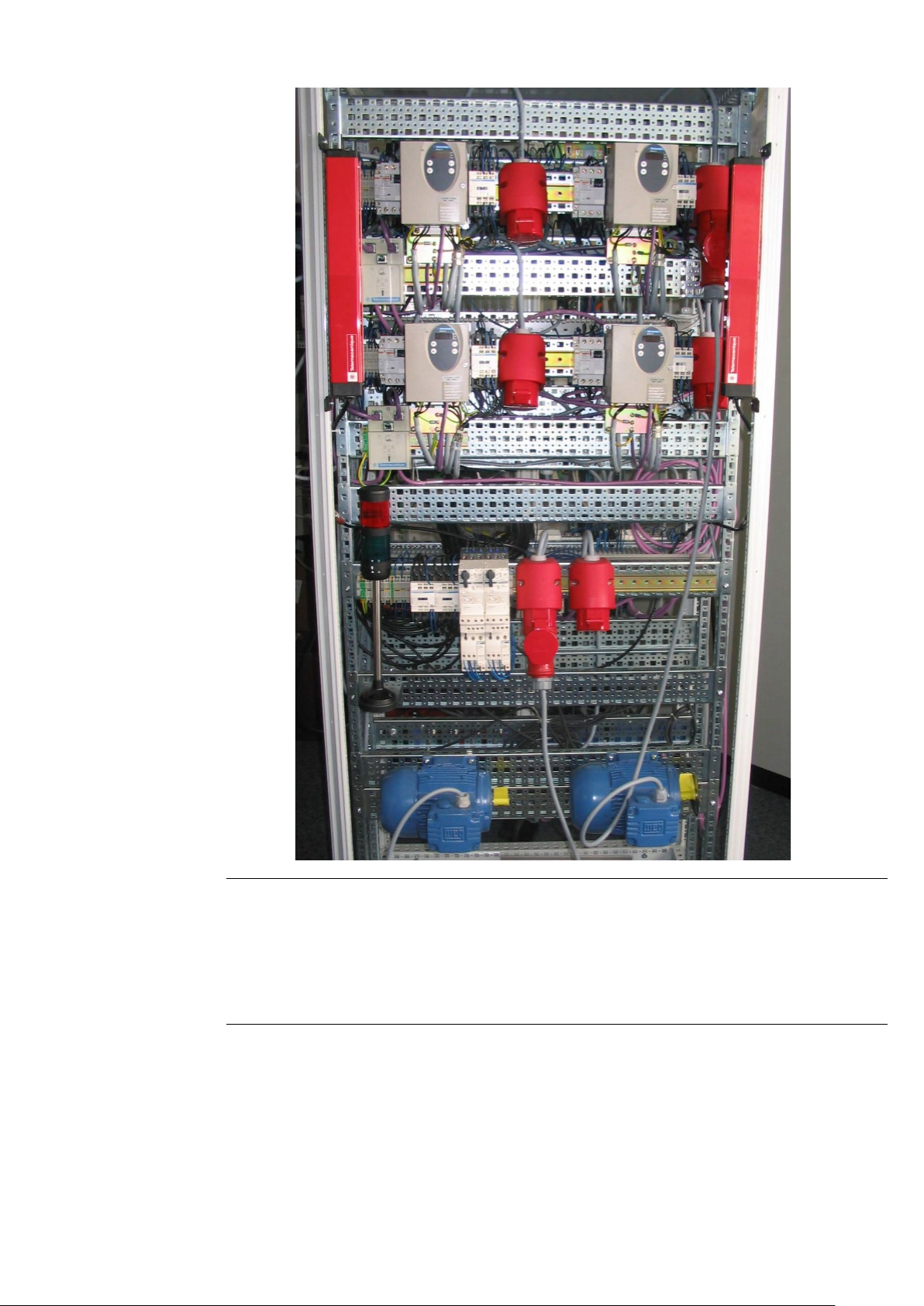

The control section of this application consists of a Twido PLC, which can be controlled via

a connected Magelis HMI panel. The load section is implemented using Altivar 31 VSDs,

which are connected to the control system via the CANopen bus system and two

TeSys U-line starter-controllers with reversing contactors.

The solution illustrated below offers three optional safety packages: a Preventa evaluation

unit featuring an emergency-off function that can be accessed via 2 tamper-proof

emergency-off buttons, and an evaluation unit of the same type that ensures door safety

within the context of this application by using safety limit switches. A Preventa evaluation

unit is also used to monitor a ligh t curtain.

Four other OTBs are used as digital I/O for the remote locations H2-H3. Four FTBs are

used for sensor acquisition in the field.

Layout

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

6

Components

Hardware:

Emergency Off Master switch, 3-pole, 20A, 7.5KW (VCF 02GE)

Motor fuse protector Multi 9 21107

Altivar ATV31 variable speed drive with CANopen interface

Motor starter, TeSysU-line type

XALK locking-type emergency-off button with rotary unlocking (tamper-proof)

Emergency-off switchin g devices, Preventa type

Phaseo ABL7 RE power supply unit

Modular/compact Twido PLC with CANopen module

Magelis XBT-G compact color display terminal

Advantys OTB and FTB modules for CANopen

ZB5 pushbuttons and indicator lamps

OSI family sensors (Osiprox, Osiswitch, Osiris)

Standard AC motors

Software:

TwidoSuite Version 1.0

Advantys Lite Version 1.4

PowerSuite 2.3

Vijeo Designer V4.4

Quantities of

Components

Degree of Protection

Technical Data

For a complete and detailed list of components, the quantities required and the order

numbers, please refer to the components list at the rear of this document.

Not all the components in this configuration are designed to withstand the same

environmental conditions. Some components may need additional protection, in the form of

housings, depending on the environment in which you intend to use them. For

environmental details of the individual components please refer to the list in the appendix of

this document and the appropriate user manual.

Supply voltage 400 V AC

Total supply output ~ 11 kW

Drive rated powers 4 x 0.37 kW

Motor brake None

Connector cross-section 5 x 2.5mm² (L1, L2, L3, N, PE)

Safety category Cat. 3 (optional)

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

7

Safety notice

Dimensions

The standard and level of safety you apply to your application is determined by your

system design and the overall extent to which your system may be a hazard to people

and machinery.

As there are no moving mechanical parts in this application example, category 3

(according to EN954-1) has been selected as an optional safety level.

Whether or not the above safety category should be applied to your system should be

ascertained with a proper risk analysis.

This document is not comprehensive for any systems using the given architecture and

does not absolve users of their duty to uphold the safety requirements with respect to the

equipment used in their systems or of complian ce with either national or international

safety laws and regulations

The dimensions of the devices used for H1 (e.g., the PLC, variable speed drive and the

power supply) are suitable for installation inside a small control cabinet measuring

800x600x300 mm (WxHxD).

In addition, the display and control elements (e.g., start/emergency-off acknowledgment)

can be integrated into the control cabinet door along with the Magelis HMI.

The Advantys OTB devices for H2 and H3 with their connection components should be

installed directly on site in two small cabinet measuring 300x300x250mm (WxHxD). The

buttons can be fed through or, with greater depths (300mm), installed inside the cabinet.

The Advantys OTB devices combined with the TeSys U units in H4 should be installed in

a cabinet measuring 600x600x300mm (WxHxD). In addition, the display and control

elements (e.g., start/emergency-off acknowledgment) can be integrated into the control

cabinet door.

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

8

Introduction

Assembly

Installation

This chapter describes the steps required to assemble the hardware and install the

software in order to solve the application task concerned.

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

9

Assembly

Contd.

Note

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

The configuration used for this application is based on the example of a pallet conveyor

system with a turntable.

The components and I/O points listed below represent a cross-section of the components

and signals that are essential for control and display purposes, and a number of optional

inputs and outputs that can be used in this application with the architecture described.

10

Wiring of the

Control

Inputs and

Outputs

Twido PLC

inputs

Twido PLC

outputs

Twido

power supply

%I 0.0

%I 0.1

%I 0.2

%I 0.3

%I 0.4

%I 0.5

%I 0.6

%I 0.7

%I 0.8

%I 0.9

%I 0.10

%I 0.11

%I 2.0

%I 2.1

%I 2.2

%I 2.3

%I 2.4

%I 2.5

%I 2.6

%I 2.7

%Q 1.0 (Trans)

%Q 1.1 (Trans)

%Q 1.2

%Q 1.3

%Q 1.4

%Q 1.5

%Q 1.6

%Q 1.7

Com (inputs)

-V

Com (+)

Com 1

Com 2

Com 3

Emergency-off Preventa activated

Emergency-off switch 1 pressed

Emergency-off contactor activ ated

Light curtain activated

Light curtain Preventa activated

Motor contactors 1-4 controlled

Acknowledge button error

Start button

Stop button

Manua l mode button

Free

Free

Limit switch 1 activated

Limit switch 2 activated

Emergency-off switch 2 pressed

Free

Belt 1 fuse OK

Belt 2 fuse OK

Belt 3 fuse OK

Turntable fuse OK

Free

Free

Signal lamps – green - Running

Signal lamps – yellow - Manual mode

Signal lamps – red - Fault

Button – blue - Running

Button – white - Manual mode

Button – blue – Acknow. light curtain

0 V DC reference voltage

0 V DC reference voltage

+24 V DC

+24 V DC

+24 V DC

+24 V DC

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

11

Wiring of OTB1

Advantys

OTB inputs

Advantys

OTB outputs

Advantys

OTB power

supply

%IWC1.8.0:X0

%IWC1.8.0:X1

%IWC1.8.0:X2

%IWC1.8.0:X3

%IWC1.8.0:X4

%IWC1.8.0:X5

%IWC1.8.0:X6

%IWC1.8.0:X7

%IWC1.8.1:X0

%IWC1.8.1:X1

%IWC1.8.1:X2

%IWC1.8.1:X3

%QWC1.8.0:X0 Trans

%QWC1.8.0:X1 Trans

%QWC1.8.0:X2

%QWC1.8.0:X3

%QWC1.8.0:X4

%QWC1.8.0:X5

%QWC1.8.0:X6

%QWC1.8.0:X7

Com (inputs)

-V

Com (+)

Com 1

Com 2

Com 3

CANopen

Reverse belt 1

Stop belt 1

Forward belt 1

Free

Free

Free

Free

Free

Free

Free

Free

Free

Free

Free

Free

Free

Free

Free

Free

Free

0 V DC reference voltage

0 V DC reference voltage

+24 V DC

+24 V DC

+24 V DC

+24 V DC

Wiring of OTB2

Advantys

OTB inputs

Advantys

OTB outputs

Advantys

OTB power

supply

%IWC1.9.0:X0

%IWC1.9.0:X1

%IWC1.9.0:X2

%IWC1.9.0:X3

%IWC1.9.0:X4

%IWC1.9.0:X5

%IWC1.9.0:X6

%IWC1.9.0:X7

%IWC1.9.1:X0

%IWC1.9.1:X1

%IWC1.9.1:X2

%IWC1.9.1:X3

%QWC1.9.0:X0 Trans

%QWC1.9.0:X1 Trans

%QWC1.9.0:X2

%QWC1.9.0:X3

%QWC1.9.0:X4

%QWC1.9.0:X5

%QWC1.9.0:X6

%QWC1.9.0:X7

Com (inputs)

-V

Com (+)

Com 1

Com 2

Com 3

CANopen

Reverse belt 2

Stop belt 2

Forward belt 2

Reverse belt 3

Stop belt 3

Forward belt 3

free

free

free

free

free

free

free

free

free

free

free

free

free

free

0 V DC reference voltage

0 V DC reference voltage

+24 V DC

+24 V DC

+24 V DC

+24 V DC

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

12

Wiring of OTB3

Advantys

OTB inputs

Advantys OTB outputs

Advantys OTB power supply

%IWC1.10.0:X0

%IWC1.10.0:X1

%IWC1.10.0:X2

%IWC1.10.0:X3

%IWC1.10.0:X4

%IWC1.10.0:X5

%IWC1.10.0:X6

%IWC1.10.0:X7

%IWC1.10.1:X0

%IWC1.10.1:X1

%IWC1.10.1:X2

%IWC1.10.1:X3

%QWC1.10.0:X0 Trans

%QWC1.10.0:X1Trans

%QWC1.10.0:X2

%QWC1.10.0:X3

%QWC1.10.0:X4

%QWC1.10.0:X5

%QWC1.10.0:X6

%QWC1.10.0:X7

Com (inputs)

-V

Com (+)

Com 1

Com 2

Com 3

CANopen

free

Reverse belt turntable

Stop belt turntable

Forwards belt turntable

Reverse belt process

Stop belt process

Forwards belt process

Reverse turntable

Stop turntable

Forwards turntable

free

free

free

free

free

free

free

free

free

free

0 V DC reference voltage

0 V DC reference vo ltage

+24 V DC

+24 V DC

+24 V DC

+24 V DC

Wiring of OTB4

Advantys

OTB inputs

Advantys OTB outputs

Advantys OTB power supply

%IWC1.11.0:X0

%IWC1.11.0:X1

%IWC1.11.0:X2

%IWC1.11.0:X3

%IWC1.11.0:X4

%IWC1.11.0:X5

%IWC1.11.0:X6

%IWC1.11.0:X7

%IWC1.11.1:X0

%IWC1.11.1:X1

%IWC1.11.1:X2

%IWC1.11.1:X3

%QWC1.11.0 :X0 Trans

%QWC1.11.0 :X1Trans

%QWC1.11.0:X2

%QWC1.11.0:X3

%QWC1.11.0:X4

%QWC1.11.0:X5

%QWC1.11.0:X6

%QWC1.11.0:X7

Com (inputs)

-V

Com (+)

Com 1

Com 2

Com 3

CANopen

Free

Free

Free

Door safety contactor

Door safety Preventa Module

Belt Turntable in reverse

Belt Turntable running forwards

Belt Process in reverse

Belt Process running forwards

free

free

free

free

free

Belt Turntable command reverse

Belt Turntable command forwards

Belt Process command reverse

Belt Process command reverse

free

free

0 V DC reference voltage

0 V DC reference voltage

+24 V DC

+24 V DC

+24 V DC

+24 V DC

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

13

Wiring of FTB1

Advantys

FTB

Advantys FTB power supply

%IWC1.4.0:X0

%IWC1.4.0:X1

%IWC1.4.0:X2

%IWC1.4.0:X3

%IWC1.4.0:X4

%IWC1.4.0:X5

%IWC1.4.0:X6

%IWC1.4.0:X7

%QWC1.4.0

%QWC1.4.1

CANopen

light curtain belt 1

light curtain belt 2

light curtain belt 3

free

free

free

free

free

free

free

Wiring of FTB2

Advantys

FTB

Advantys FTB power supply

%IWC1.5.0:X0

%IWC1.5.0:X1

%IWC1.5.0:X2

%IWC1.5.0:X3

%IWC1.5.0:X4

%IWC1.5.0:X5

%IWC1.5.0:X6

%IWC1.5.0:X7

%QWC1.5.0

%QWC1.5.1

CANopen

Proximity sensor Pos1

Proximity sensor Pos1.2

Proximity sensor Pos2

Proximity sensor Pos2.2

free

free

free

free

frei

frei

See FTB1

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

14

Wiring of FTB3

Wiring of FTB4

Advantys

FTB

Advantys FTB power supply

Advantys

FTB

Advantys FTB power supply

%IWC1.6.0:X0

%IWC1.6.0:X1

%IWC1.6.0:X2

%IWC1.6.0:X3

%IWC1.6.0:X4

%IWC1.6.0:X5

%IWC1.6.0:X6

%IWC1.6.0:X7

%QWC1.6.0

%QWC1.6.1

CANopen

%IWC1.7.0:X0

%IWC1.7.0:X1

%IWC1.7.0:X2

%IWC1.7.0:X3

%IWC1.7.0:X4

%IWC1.7.0:X5

%IWC1.7.0:X6

%IWC1.7.0:X7

%QWC1.7.0

%QWC1.7.1

CANopen

Photo barrier belt turntable

free

free

free

free

free

free

free

frei

frei

See FTB1

Photo barrier belt sequence

free

free

free

free

free

free

free

free

free

See FTB1

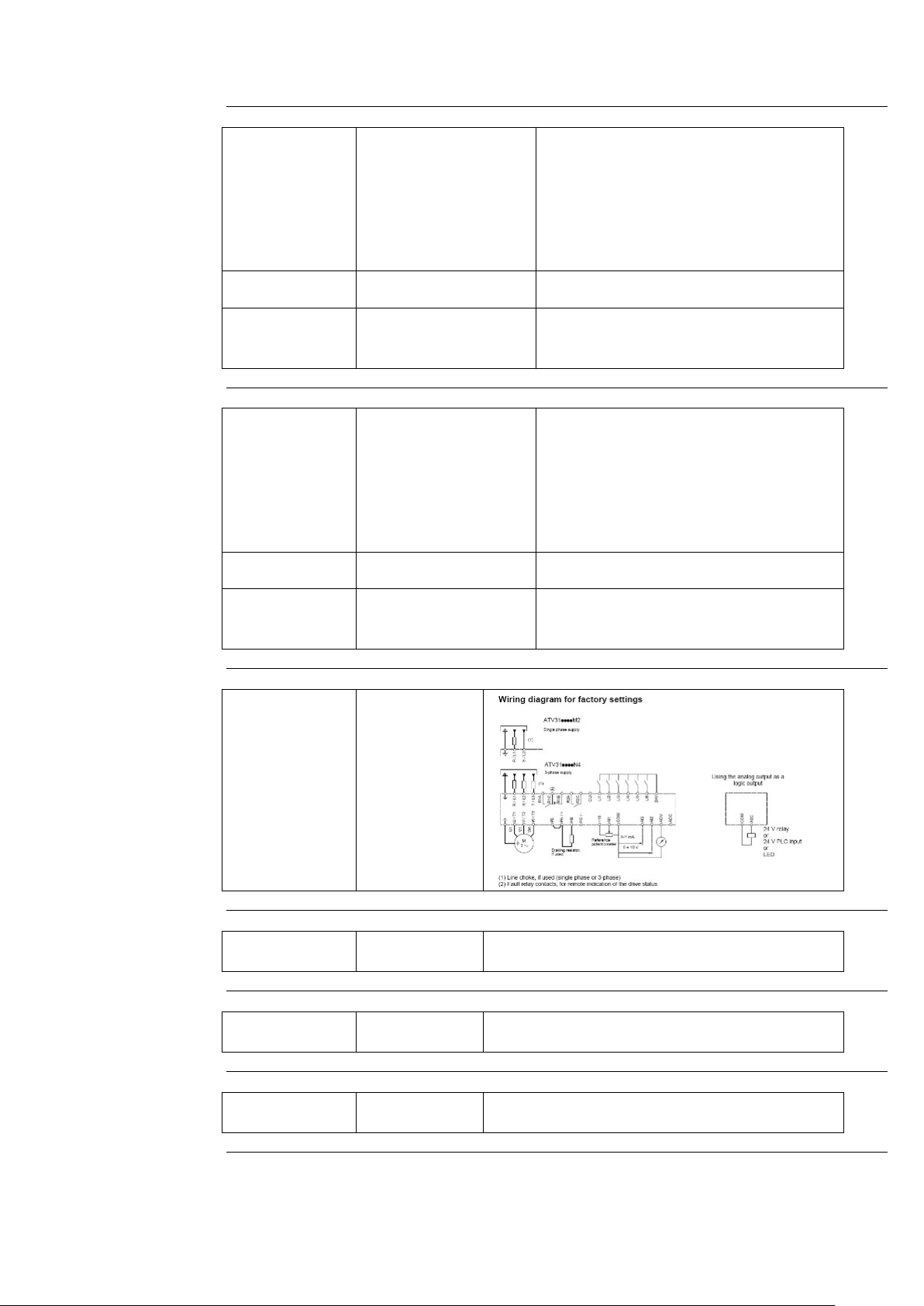

Wiring of VSD1

Wiring of VSD2

Wiring of VSD3

Wiring of VSD4

ATV31

ATV31

ATV31

ATV31

CANopen

CANopen

CANopen

CANopen

See VSD1

See VSD1

See VSD1

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

15

Hardware

General The components designed for installation in a control cabinet, i.e., master switch, Twido

PLC, Phaseo power supply unit, emergency-off switching device, line circuit breaker,

contactors and motor circuit breaker, can be snapped onto a 35 mm DIN rail.

The Altivar variable speed drive can also be snapped onto a DIN rail using an adapter,

but can also be screwed directly onto the mounting plate without the need for an

adapter plate.

The emergency-off and door-safety switches, indicator bank as well as the housing for

display and acknowledge indicators, are designed for backplane assembly in the field;

with the exception of the door-safety switch, all switches can also be installed directly in

a control cubicle (e.g., in cubicle door) without their enclosing housings.

There are two options for installing XB5 pus hbuttons or indicator lamps: These

pushbuttons or switches can be installed either in a 22 mm hole, e.g., drilled into the

front door of the control cabinet, or in an XALD-type housing suitable for up to 5

pushbuttons or indicator lamps. The XALD pushbutton housing is designed for

backplane assembly or direct wall mounting.

The individual components must be interconnected in accordance with the detailed circuit

diagram in order to ensure they function correctly.

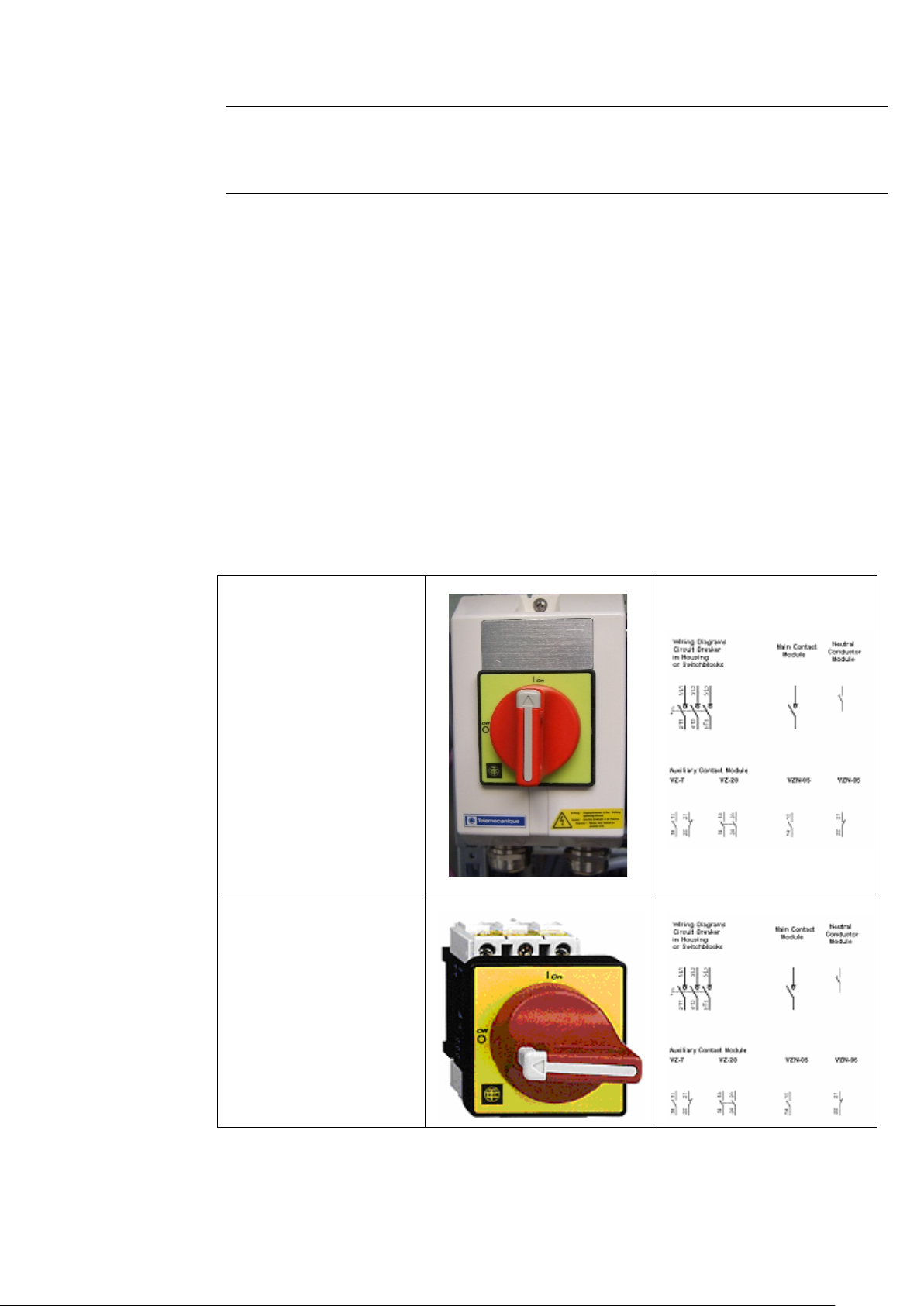

Master switch complete

VCF02GE

Option

for Cabinet door

Emergency OFF

Master Switch

VCD0

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

16

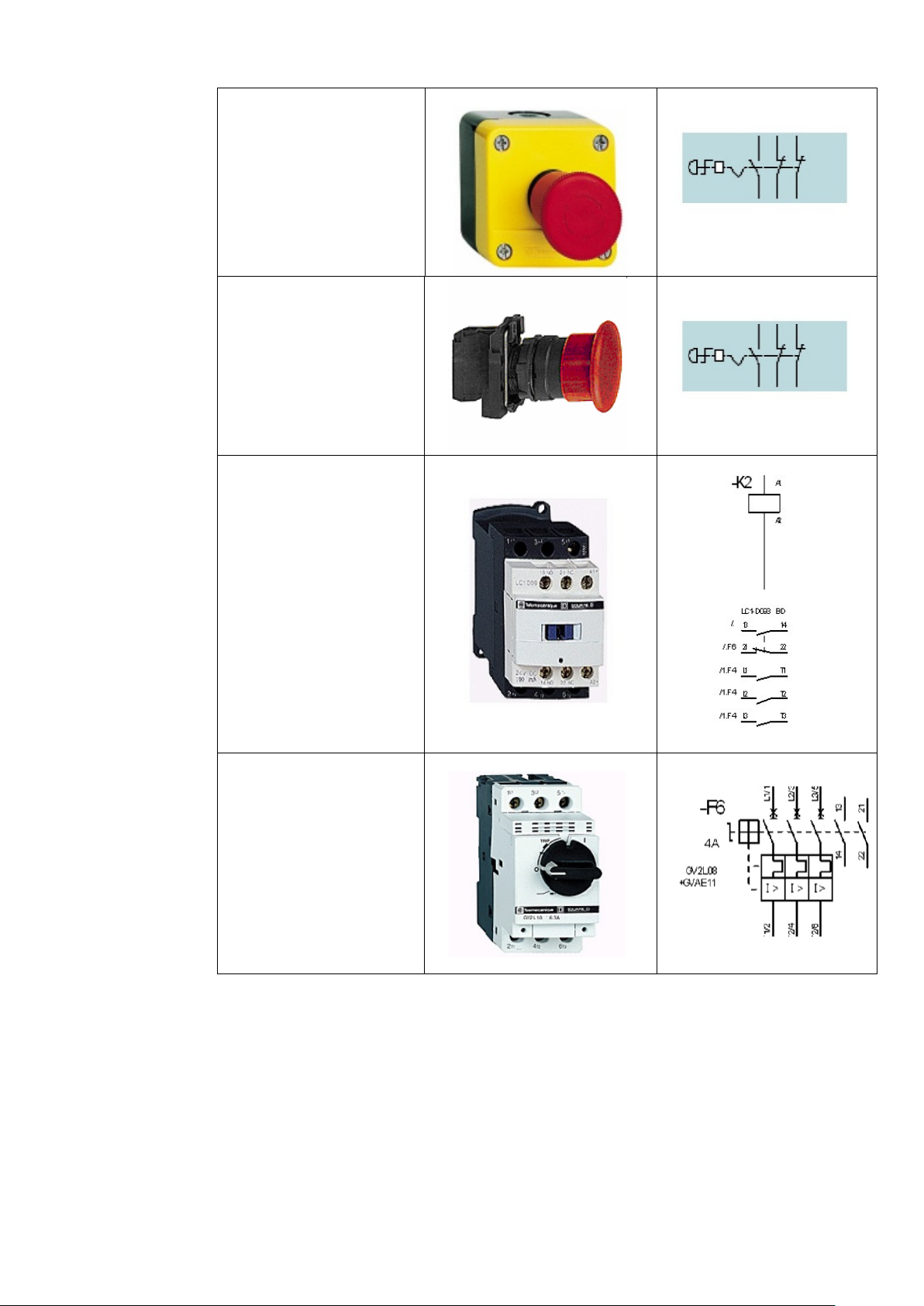

EMERGENCY-OFF

switch

(tamper-proof)

XALK174G

Option

for Cabinet door

Emergency OFF

Switch

(Tamper Proof)

XB5AS8445

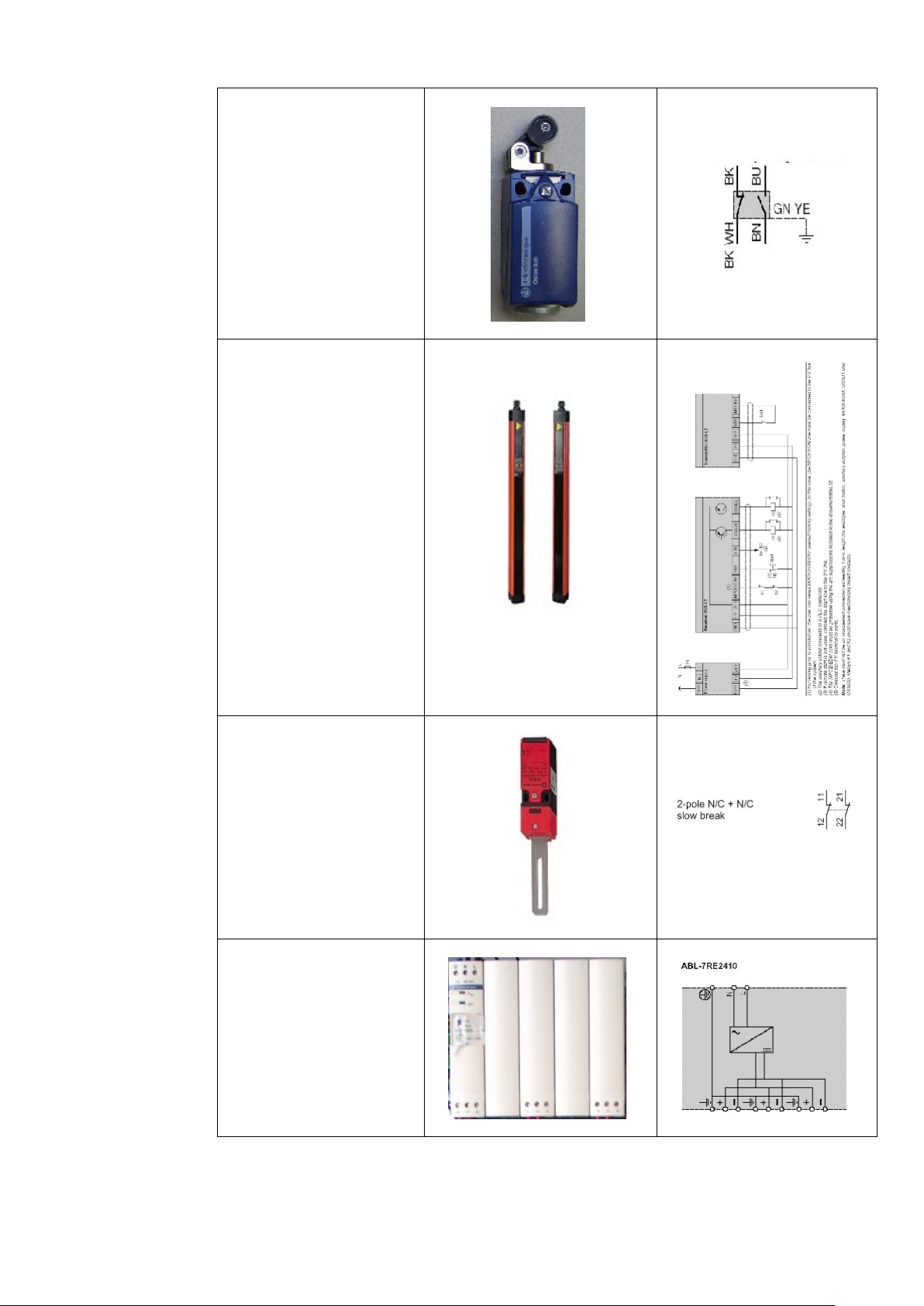

Contactor

TesysD

LC1D093BD

Contactor

TeSys

GV2L08

+GV2AE11

(Maintenance Switch)

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

17

TeSys U-line module

contactor

LUB12

+

LU2B12BL

+

LUA1C11

+

LUFN11

+

LUCA05BL

Preventa

safety relay

XPS AK331144P

Indicator Beacon

XVB-C

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

18

Position switch

OsiSwitch

XCKD2121P16

Light curtain

XUSLTR5A0350

+ cable extensions

XSZTCR10

XSZTCT10

Safety limit sw itch

with door safety operating

lever

XCSPL751

Phaseo power supply

unit

ABL7RE2410

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

19

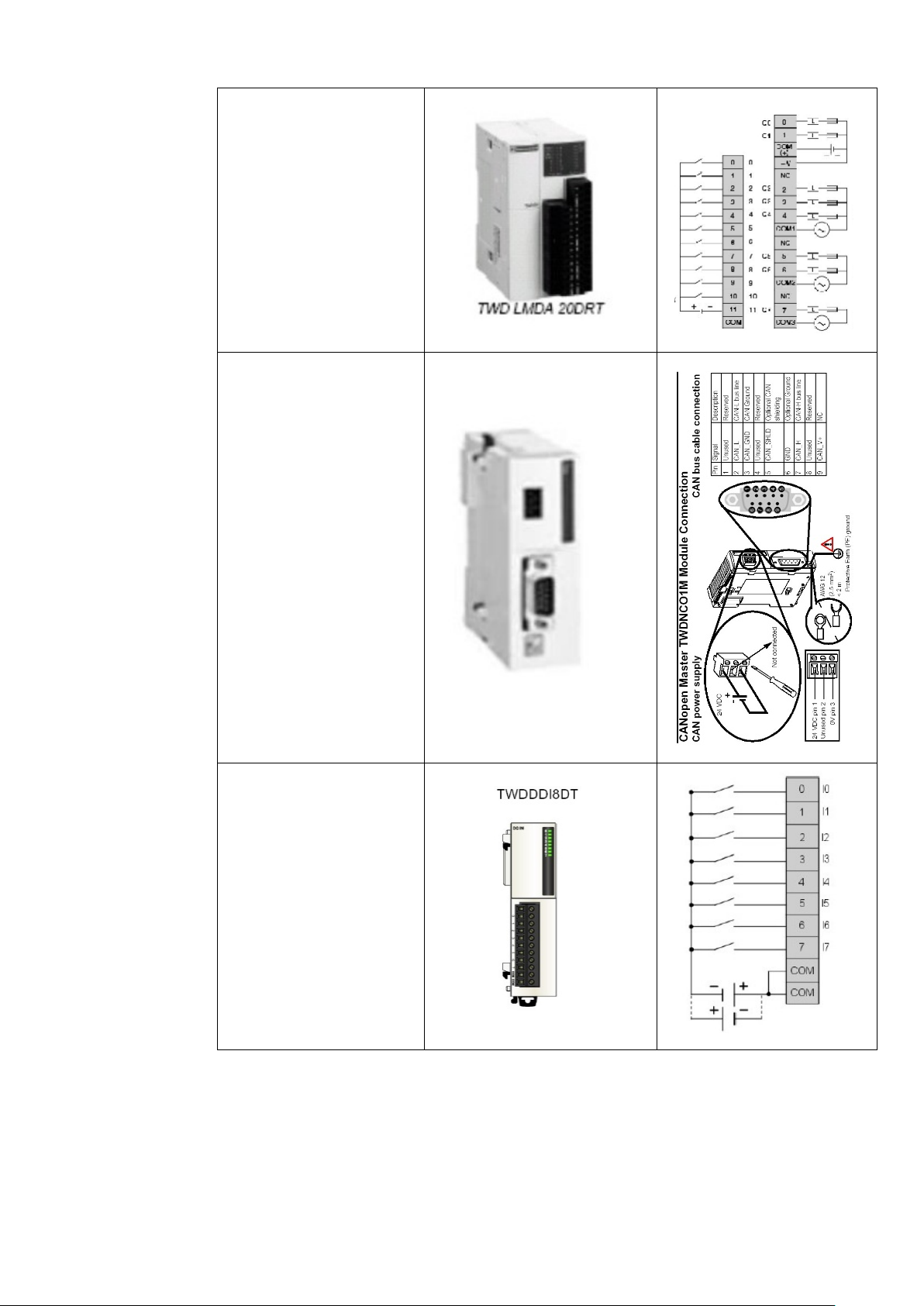

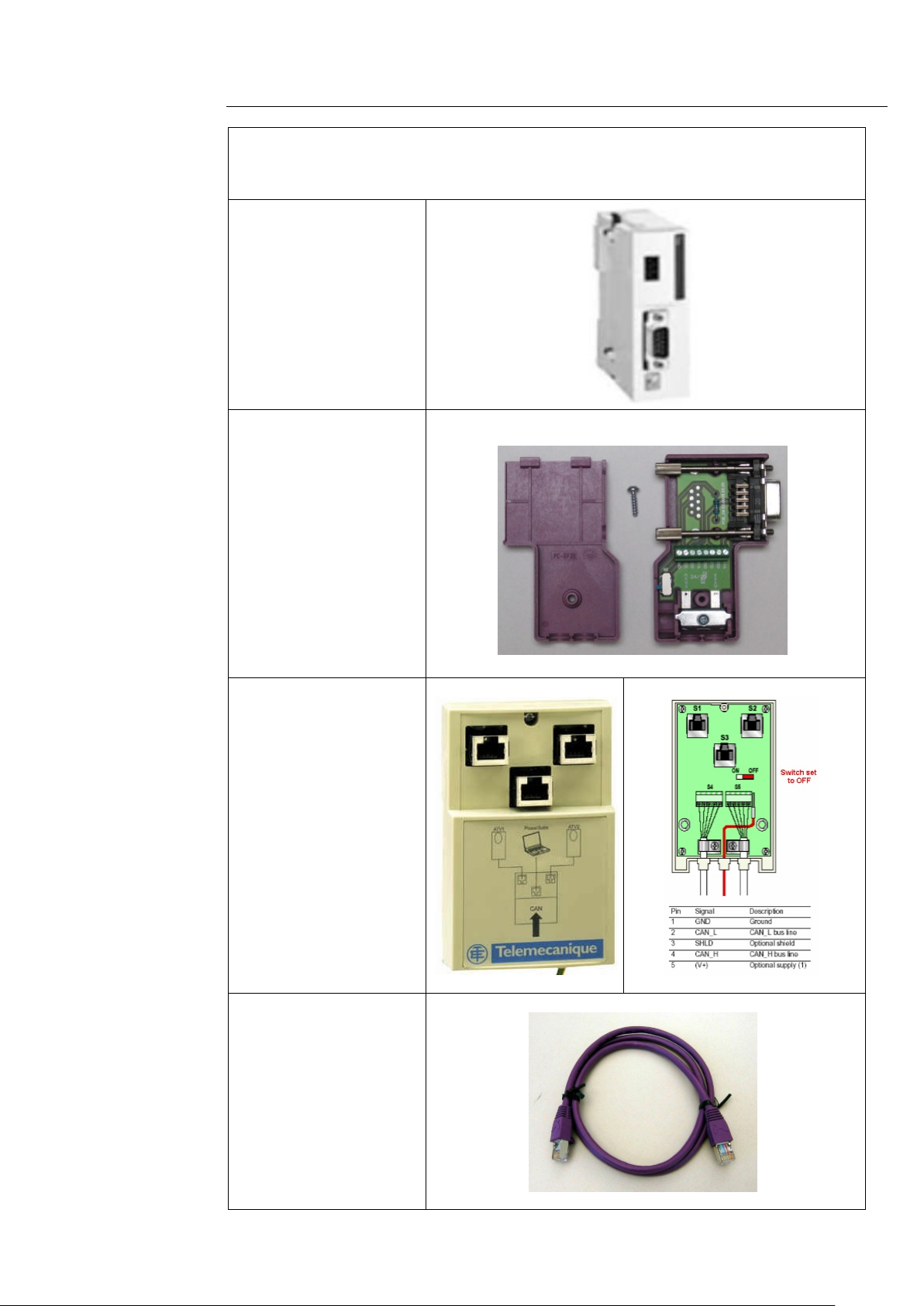

Twido PLC

modular power base

TWDLMDA20DRT

Twido PLC

interface module

CANopen master

TWDNCO1M

Twido DC IN module

8x DC IN

TWDDDI8DT

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

20

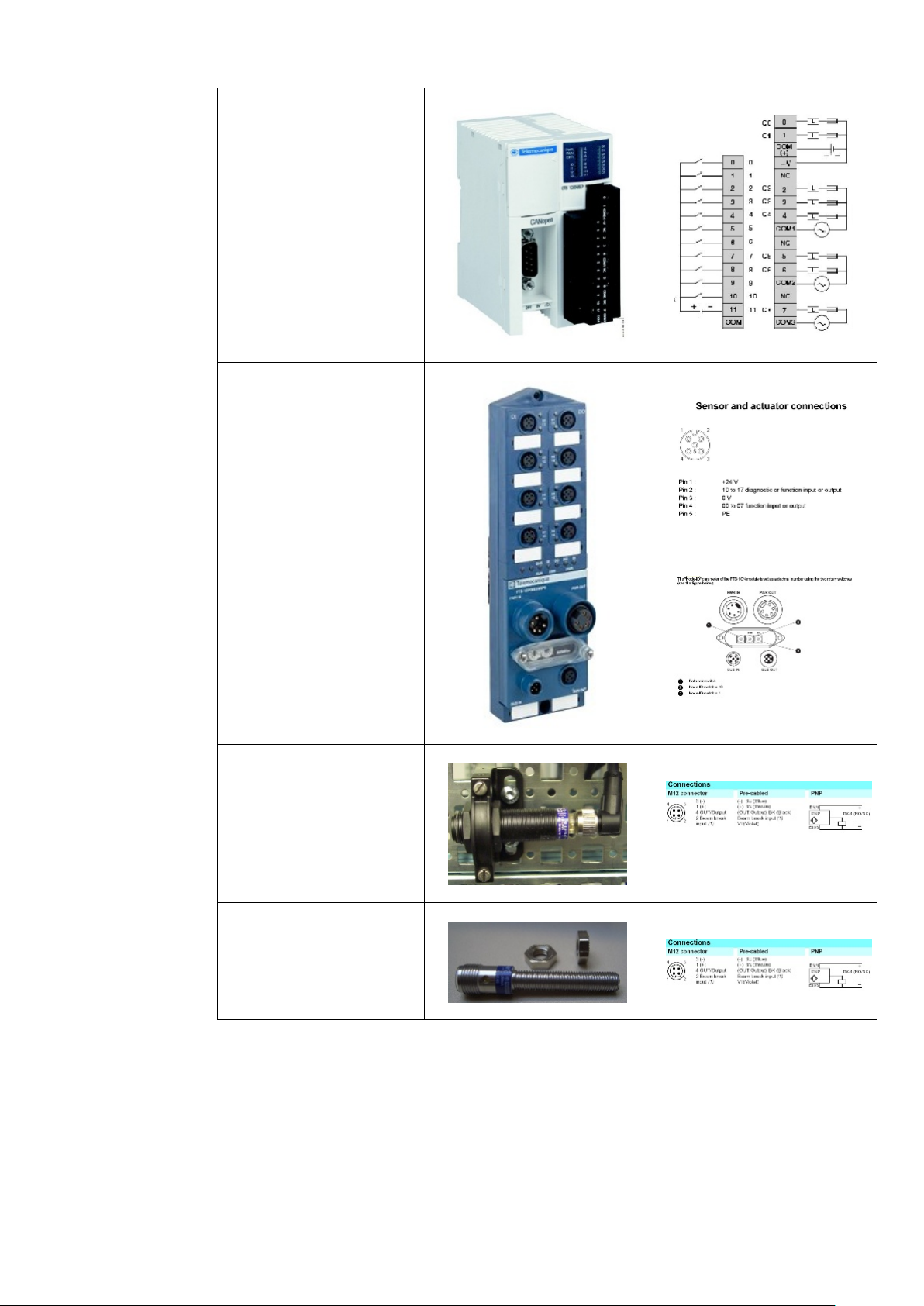

Twido OT B

OTB1C0DM9LP

CANopen module 12x DC

IN/6x DC O UT/2x AC

OUT

FTB module

8 IN/diagnostic 8 OUT

FTB1CN08E08S

Light Curtain

XUB1APANM12

Proximity sensor

XS608B1PAM12

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

21

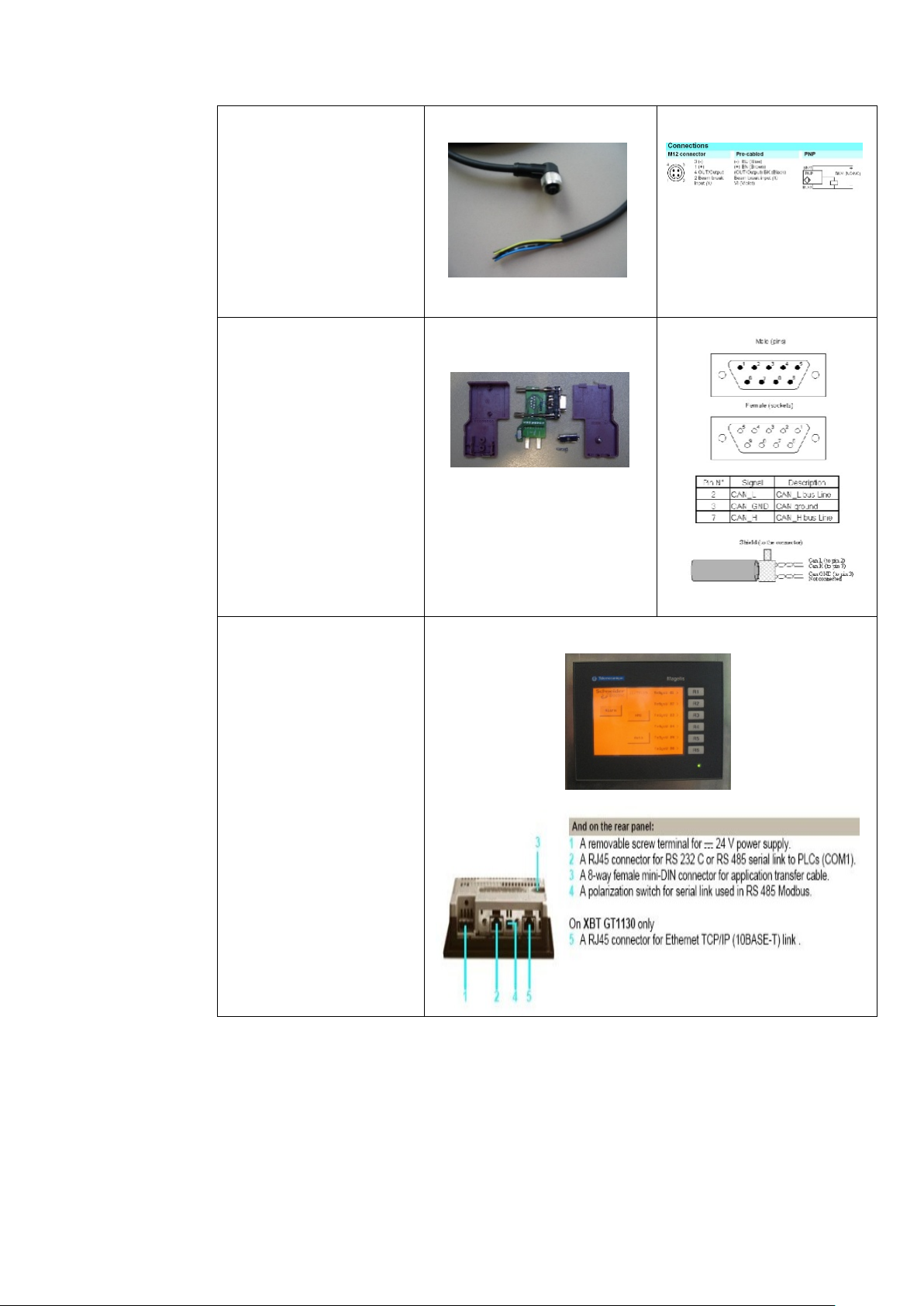

Cable for photo

barriers and proximity

sensor

XZCP1 264L2

Only 1x M12 connector for

sensor: other side must be

extended with connector

XZCC12FDM40B

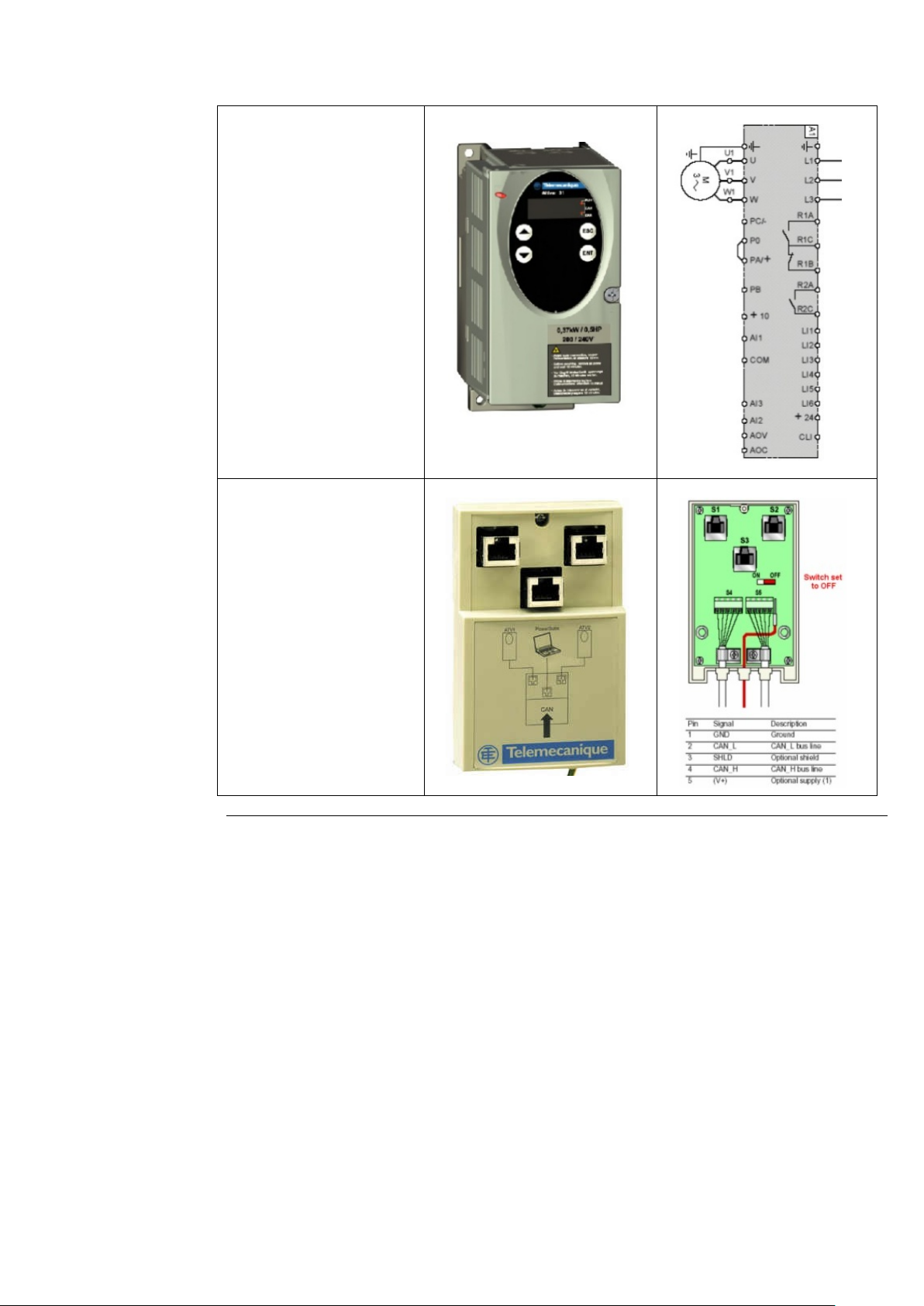

CANopen connector

TSX CANKCDF90TP

(additional contact for bus

analysis) or

TSX CANKCDF90T

Both incl. terminating

resistor for connection to

Twido CANopen Master

CANopen cable

TSXCANCA50

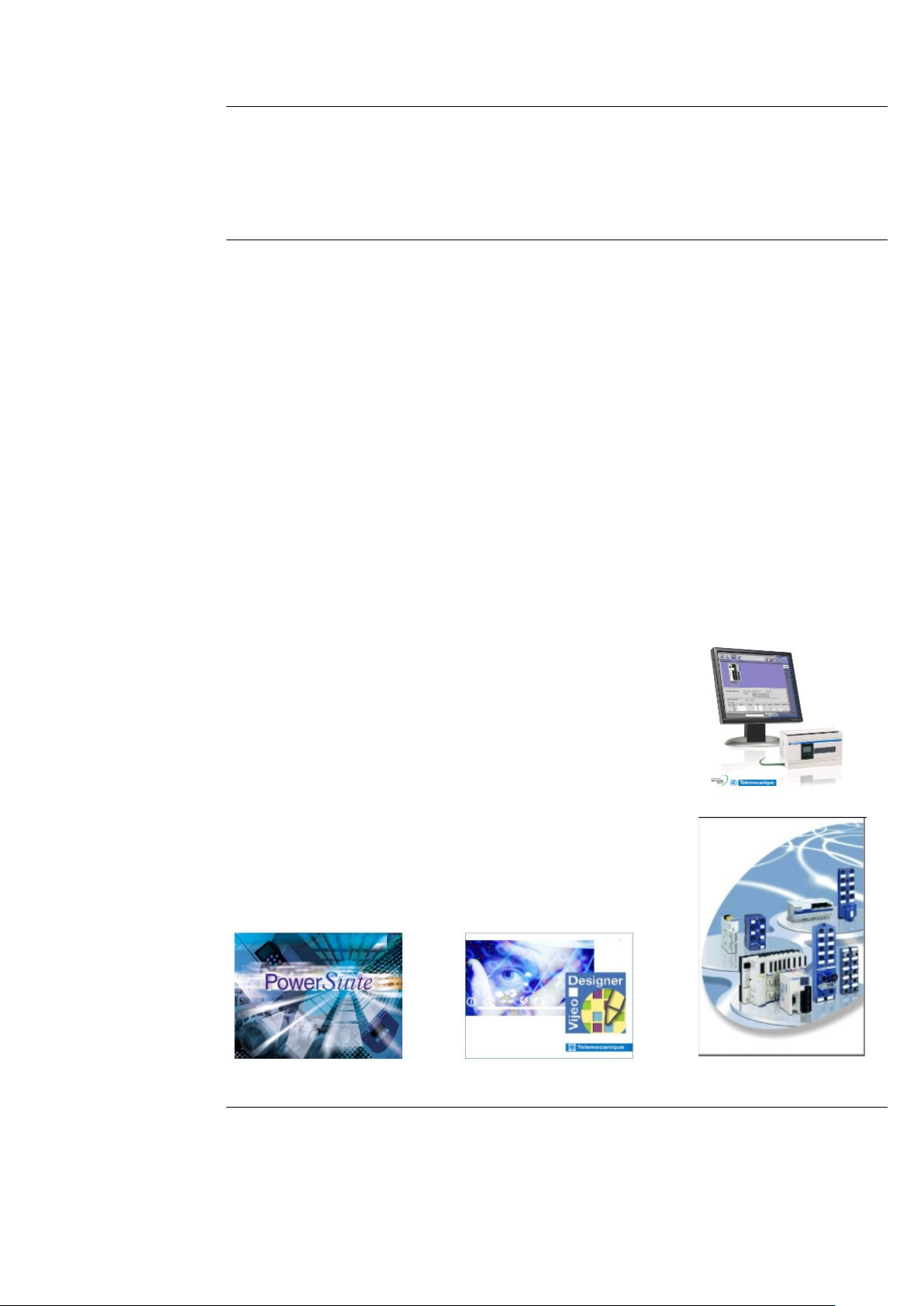

Magelis operator

terminal

XBTGT 1100

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

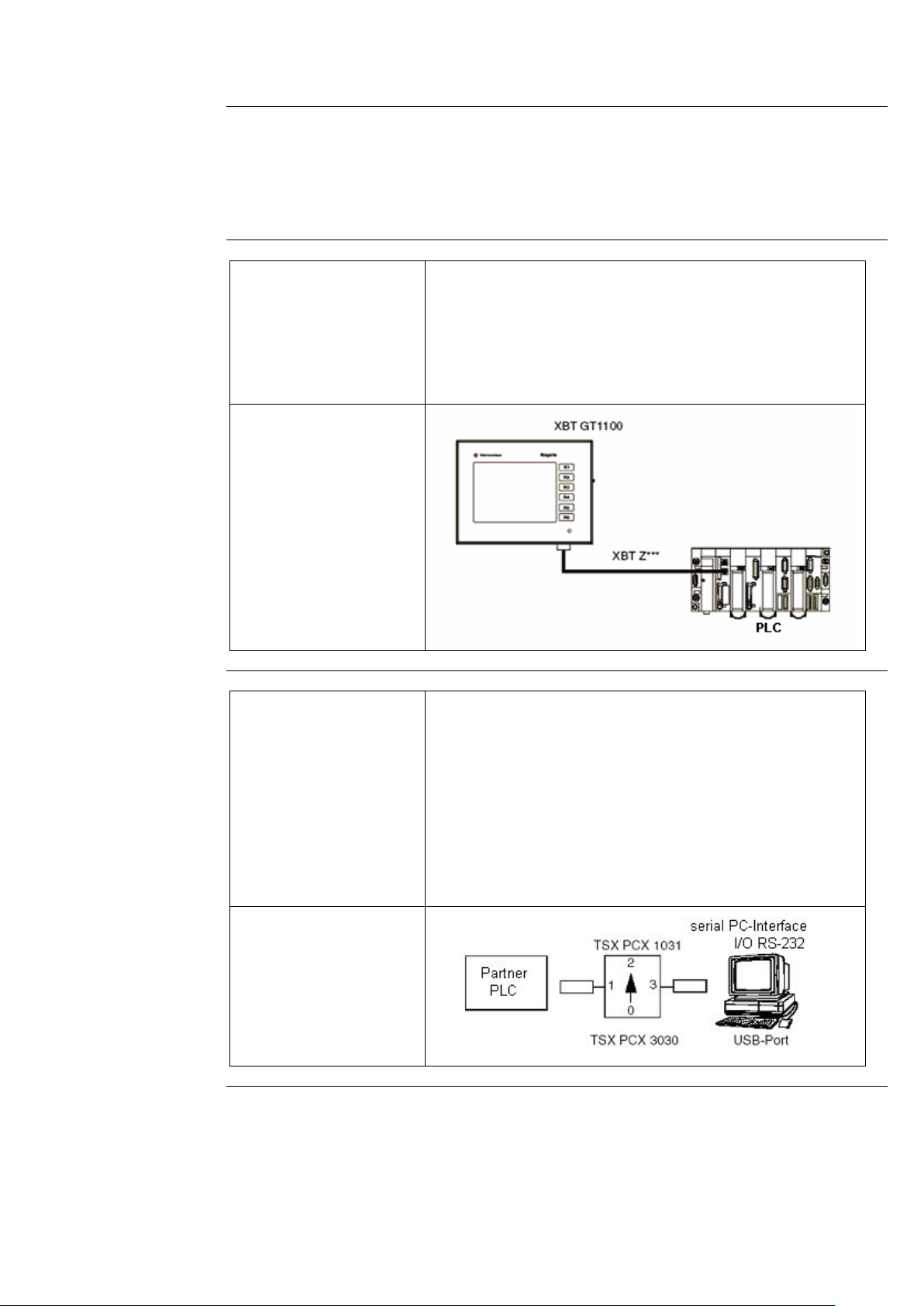

22

Variable speed drive

Altivar ATV31

ATV31H037N4

CANopen TAP

VW3CANTAP2

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

23

General

Software

The software is primarily used for programming the Twido PLC and configuring CANopen

communication, as well as for visualization.

The TwidoSuite programming tool is used for programming the PLC.

The HMI application on the XBT-GT 1100 Magelis display terminal is configured using

Vijeo Designer software.

Although Altivar 31 variable speed drives can be parameterized via the front panel, the

PowerSuite software is a more user-friendly option. As well as providing a convenient

means of setting drive parameters, this software also enables data to be saved and

archived. These functions are extremely useful as they mean that parameters can be

restored rapidly whenever service tasks need to be performed. The software can also help

you to optimize the parameters online. The software is supplied with the drive.

To use the software packages, your PC must have the appropriate Microsoft Windows

operating system installed:

Windows 2000 or

Windows XP

The software tools have the following default install paths:

TwidoSuite

C:\Program Files\Schneider Electric\TwidoSuite

Advantys

C:\Program Files\Schneider Electric\Advantys

Vijeo Designer

C:\Program Files\Schneider Electric\VijeoDesigner

PowerSuite ATV31

C:\Program Files\Schneider Electric\PowerSuite

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

24

Communication

HMI <> Twido

Magelis

communication cable

XBTZ9780

A Modbus connection is used to excha nge data between the

Magelis termina l and the Twido PLC. The XBTZ9780

communication cable shown below is needed to connect

these two devices. The software driver required for Modbus

communication is already contained in the software

packages for the Magelis panel and the Twido.

Twido <> PC

Twido programming

cable

TSXPCX1031 (serial)

or

TSXPCX3030 (USB)

A TSXPCX1031 (serial) or TSXPCX3030 (USB)

communication cable is used to exchange data between the

Twido PLC and the programming PC.

An extra driver must be installed for the USB cable. The

driver for the serial cable is integrated into the TwidoSoft

tool.

Ensure that switch position 2 is set on the cable. Port 1 must

be set/configured on the control system for poin t-to-point

communication.

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

25

HMI <> PC

An XBTGZ915 communications cable is used to exchange

data between the HMI XBTGT 1100 and the programming

PC.

This is contained in the Vijeo Designer software package.

XBTG programming

cable

XBTGZ915

ATV31 <> PC

Programming the Altivar is done using the cable VW3A8106

and the Powersuite cable RJ45<>SubD 9 (black).

ATV31-Programming

Cable

VW3A8106

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

26

CANopen

The data transfer between the individual bus clients can be implemented with either self

made or pre-confectioned cable. Below you will find a component description.

CANopen

Master Module

TWDNCO1M

The CAN open-Interface-

Module is plugged into

the Twido PLC and has

a Sub-D-9 CANopen

connection

CANopen Plug

TSXCANKCDF90T

Use this plug on the

TWDNCO1M. Plug

includes a terminal

resistor.

CANopen-Kabel

TSXCANCD50

Flexibles Kabel

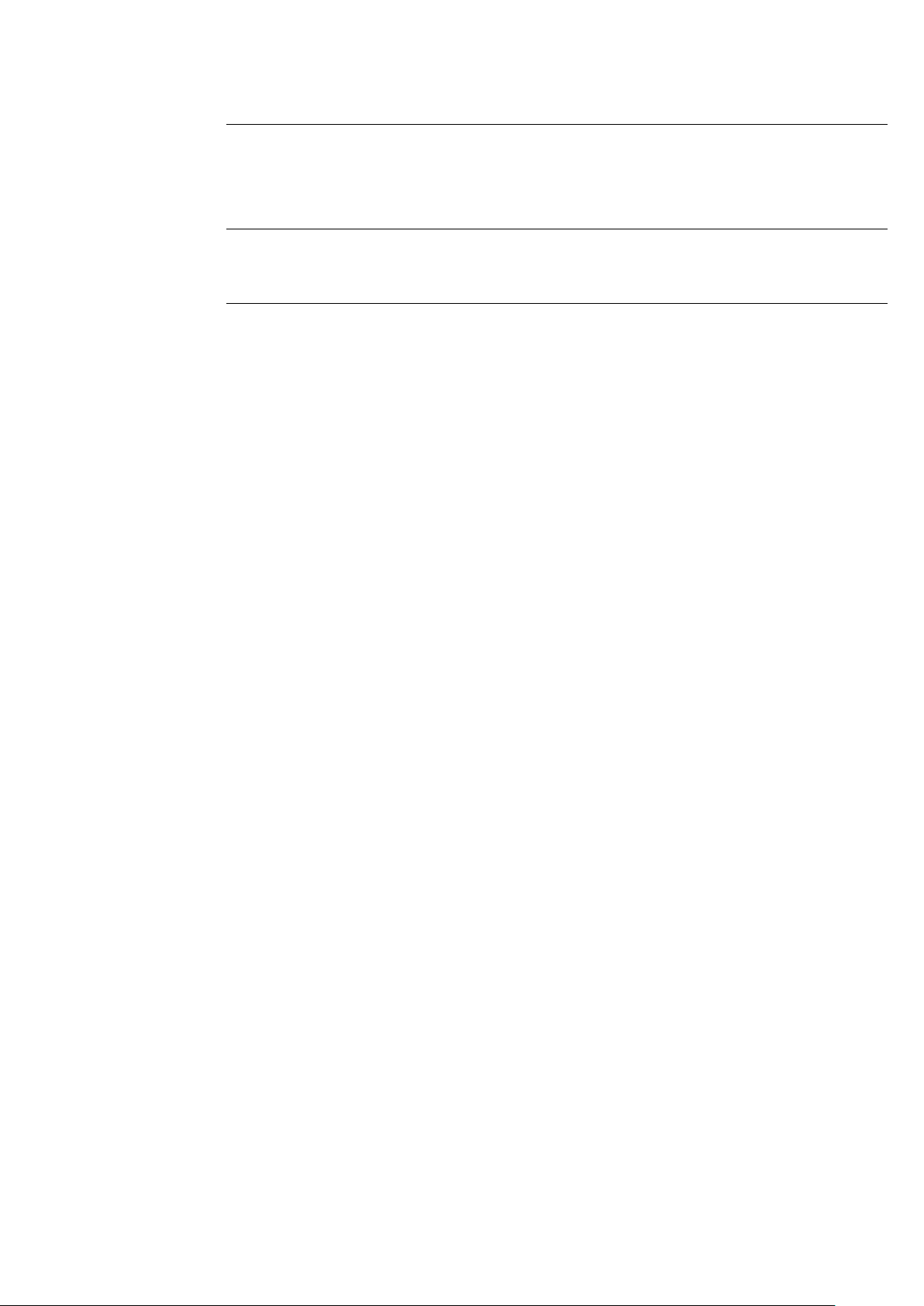

CANopen-TAP

VW3CANTAP2

Connection for 2 drives

of type Altivar 31.

Configuration port for

use with PowerSuite.

Terminal resisitor can be

selected using the

ON /OFF switch.

The image shows the

resistor set to OFF.

CanOpen

Branch Cable

VW3CANRR1

Connects the TAP to the

Altivar 31 with two RJ54

plugs.

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

27

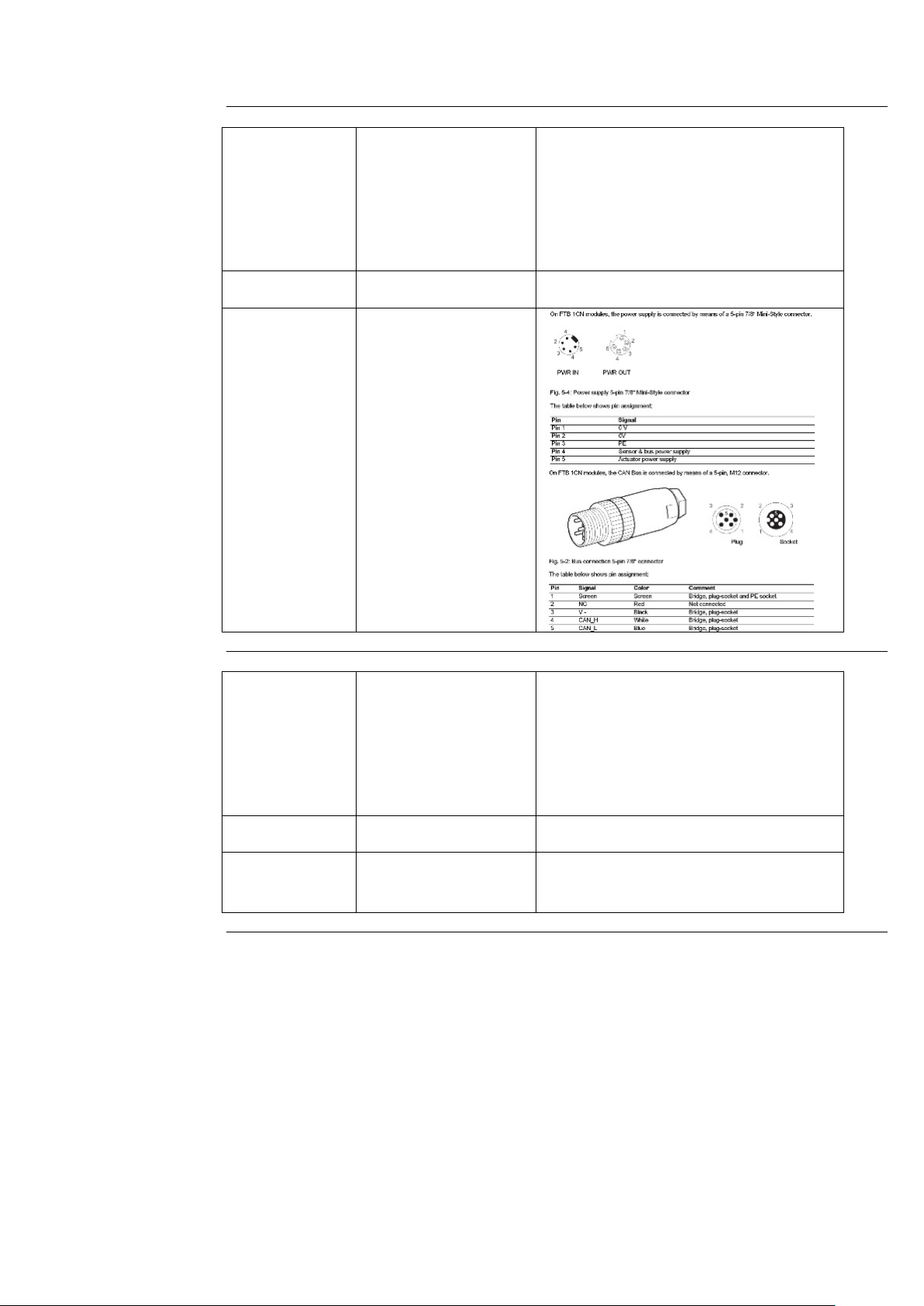

Bus Cable CANopen

FTXCN3210

Connect the FTB

modules in serie starting

with the

CANopen-Tap

VW3CANTDM4.

PIN Signal Colour

1 Shld -

2 V+ Red

3 GND Black

4 CAN_H White

5 CAN_L Blue

Power Supply Cable

FTXDP2210

the FTB power supply

cables are linked in serie

from one module to the

next.

Advantys FTB

Terminal Resistor

CANopen

FTXCNTL12

Connect to the last

FTBModule in the series

on the BU S OUTSocket.

PIN Signal Cable

1 0V 1

2 0V 2

3 PE Green/Yellow

4 +24V DI 3

5 +24V DO 4

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

28

Introduction

Function

General

Manual & Auto

Implementation

The implementation chapter describes all the steps necessary to initialise, to configure, to

program and start-up the system to achieve the application functions as listed below.

This is a simple function which has been selected to illustrate all of the components used in

a practical application and to demonstrate their functions.The function can of course be

modified to your own requirements.

The conveyor belt system consists of five belts. The packets are delivered via the chute onto

the first belt. The first three belts, operating at different speeds, increase the distance

between the packets and are controlled by the first three VSDs. The next stage is a short

belt on a turntable. The turntable alters the direction of transport by 90°. The packet is finally

conveyed via a fifth belt to the exit. Here the packet is passed onto the next section by a

robot.

Photo barriers are used to isolate the packets so that at any time there is only one packet in

a segment/belt. All three belts are controlled by variable speed drives (VSD) to permit

differing speeds.

Belt 4 only accepts packets from belt 3 in the “Receive” position, during which belt 4 is

driven then stopped as soon as the photo barrier is broken. The turntable then moves to the

next position, “Release”. As soon as the turntable reaches the “Release” position, the belt is

restarted and then runs for a certain time to ensure that the packet has left the belt . The

turntable then returns to the “Receive” position.

The turntable is controlled by a fourth VSD and monitored by four proximity sensors as

position indicators and two limit switches as impact protection devices..

Belt 5 receives the packet in the “Receive” position and conveys it until it has passed the

photo barrier. If the photo barrier is then opened, the belt is run as “Empty”.

Belts 4 and 5 are both controlled by a TeSys U. The belts are thus run at a constant speed.

There are 3 operation modes: Manual and Automatic and HMI. A pushbutton is provided to

change between manual and automatic. It reacts to a rising edge.

The individual buttons for motor control are only enabled in manual mode but the buttons in

the 4-button housing and the two individual acknowledge buttons are excluded from this precondition. The HMI mode can only be selected and de-selected on the Magelis XBTG

device.

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

29

Safety devices

Push

Buttons

Illuminated beacon

the Emergency-off buttons switch the power off for the complete plant. This excludes all

PLC components and sensors. This is registered and displayed as a fault on the illuminated

beacon. As long as the fault is present, the acknowledge button blinks, turning to permanent

when the emergency off buttons have been unlocked.

When activated, the light curtain isolates all four VSDs from the motors. This is signaled

and displayed as a fault on the illuminated beacon. Although an acknowledgement is

possible, the acknowledge button for the light curtain assum es that the fault is still active and

blinks permanently.

The door switch disconnects the two belt motors from the TeSys U units when the door is

opened. Although an acknowledgement is possible, the acknowledge button for the door

switch assumes that the fault is still active and blinks permanently.

All switch-off operations are performed on the hardware itself, only the relevant fault

signaling must be performed in the PLC.

The buttons as described here and in the assembly model, are housed in an external

housing. They could, however, be built into a cabinet door. If you decide on this option, the

buttons require a 22mm diameter hole and you do not need to order the separate button

housing.

The quadruple button housing is for the buttons Start, Stop, Man/Auto und Acknowledge.

Start CANopen Master Reset on Slave fault

Stop Error reset for ATV31 Devices after CANopen I nitialisation.

Man/Auto Automatic Mode (white LED off) / Manual Mode (white LED blinks)

Acknowledge1 E-OFF button 1 and E_OFF button 2

Acknowledge button 2 Light curtain

Acknowledge button 3 Door switch

All Preventa modules send Information to the PLC.

Manual mode provides 3 control buttons for all belts:

Button 1 reverse belt

Button 2 stop belt

Button 3 belt forwards

The illuminated beacon displays the various states. It consists of three indicator lamps.

The green lamp indicates Run. It is permanently lit when the pla nt is operating normally.

The red lamp indicates a Fault. The lamp flashes for emergency-off/safety violations; for

other faults caused by logic- or component-related problems, the light should burn

continuously.

The yellow lamp indicates Manual or HMI mode.

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

30

Plant

Example

Conveyor belt

system

CANopen

Layout

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

31

Communication

Introduction

Device Links

Datalink

Drive_1 <> PLC

Data direction ATV -> PLC

%IWC1.0.0 D_STATUS_DRIVE_1 6041 Drivecom status register

%IWC1.0.1 D_CONTROL_DRIVE_1 6044 Control effort

%IWC1.0.2 D_IERROR_DRIVE_1 603F Error Code

%QWC1.0.0 D_COMMAND_DRIVE_1 6040 Drivecom command

%QWC1.0.1 D_TARGET_DRIVE_1 6042 Target velocity

This lists the individual points between which data is exchanged via the bus

systems (e.g., CANopen, Modbus Plus or TCP/IP) that are not directly linked to

digital or analog hardware interfaces.

This list contains:

The devices concerned in each case

The direction of transfer

The symbolic name and

The direct bus address on the device concerned.

The Modbus and CANopen bus systems are used in this application.

The devices below are networked via CANopen:

- a Twido PLC, bus address 127 (fixed setting)

- four Altivar variable speed drives, bus addresses 1..4

- four FTBs, bus addresses 5..8

- four OTBs, bus addresses 9..12

Only two devices are interconnected via Modbus:

- Magelis-Panel XBT-G, bus address 1

- Twido PLC, bus address 2

Twido PLC

(CANopen ma ster, #127)

Address Name Index Designation

Data direction PLC -> ATV

Address Name Index Designation

Altivar 31, Drive_1

(CANopen slave #1)

register

Datalink

Drive_2 <> PLC

Data direction ATV -> PLC

%IWC1.1.0 D_STATUS_DRIVE_2 6041 Drivecom status register

%IWC1.1.1 D_CONTROL_DRIVE_2 6044 Control effort

%IWC1.1.2 D_IERROR_DRIVE_2 603F Error Code

%QWC1.1.0 D_COMMAND_DRIVE_2 6040 Drivecom command

%QWC1.1.1 D_TARGET_DRIVE_2 6042 Target velocity

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

Address Name Index Designation

Address Name Index Designation

(CANopen master, #127)

Twido PLC

Altivar 31, Drive_2

(CANopen slave #2)

Data direction PLC -> ATV

register

32

Datalink

Drive_3 <> PLC

(CANopen master, #127)

Twido PLC

Altivar 31, Drive_3

(CANopen sla ve #3)

Data direction ATV -> PLC

Address Name Index Designation

%IWC1.2.0 D_STATUS_DRIVE_3 6041 Drivecom status register

%IWC1.2.1 D_CONTROL_DRIVE_3 6044 Control effort

%IWC1.2.2 D_IERROR_DRIVE_3 603F Error Code

Address Name Index Designation

%QWC1.2.0

D_COMMAND_DRIVE_3

Data direction PLC -> ATV

6040 Drivecom command register

%QWC1.2.1 D_TARGET_DRIVE_3 6042 Target velocity

Datalink

Drive_4 <> PLC

(CANopen ma ster, #127)

Twido PLC

Altivar 31, Drive_1

(CANopen slave #4)

Data direction ATV -> PLC

Address Name Index Designation

%IWC1.3.0 D_STATUS_DRIVE_4 6041 Drivecom status register

%IWC1.3.1 D_CONTROL_DRIVE_4 6044 Control effort

%IWC1.3.2 D_IERROR_DRIVE_4 603F Error Code

Address Name Index Designation

%QWC1.3.0 D_COMMAND_DRIVE_

Data direction PLC -> ATV

6040 Drivecom command register

4

%QWC1.3.1 D_TARGET_DRIVE_4 6042 Target velocity

Datalink Twido PLC (CANopen master, #127) FTB1 (CANopen slave #5) FTB1 <> PLC Data direction FTB -> PLC Address Name Index Designation %IWC1.4.0 FTB_IN_1 6000 Digital Input 8 Bits

Address Name Index Designation

Data direction PLC -> FTB

%QWC1.4.0 Test_FTB1 6200 Write Outputs 1 to 8

Datalink Twido PLC (CANopen master, #127) FTB2 (CANopen slave #6) FTB2 <> PLC Data direction FTB -> PLC Address Name Index Designation %IWC1.5.0 FTB _IN_2 6000 Digital Input 8 Bits

Address Name Index Designation

Data direction PLC -> FTB

%QWC1.5.0 Test_FTB2 6200 Write Outputs 1 to 8

Datalink Twido PLC (CANopen master, #127) FTB3 (CANopen slave #7) FTB2 <> PLC Data direction FTB -> PLC Address Name Index Designation %IWC1.6.0 FTB _IN_3 6000 Digital Input 8 Bits

Address Name Index Designation

Data direction PLC -> FTB

%QWC1.6.0 Test_FTB3 6200 Write Outputs 1 to 8

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

33

Datalink Twido PLC (CANopen master, #127) FTB4 (CANopen slave #8) FTB4 <> PLC Data direction FTB -> PLC Address Name Index Designation %IWC1.7.0 FTB _IN_4 6000 Digital Input 8 Bits

Address Name Index Designation

Data direction PLC -> FTB

%QWC1.7.0 Test_FTB4 6200 Write Outputs 1 to 8

Datalink Twido PLC (CANopen master, #127) OTB1 (CANopen slave #9) OTB1 <> PLC Data direction OTB -> PLC Address Name Index Designation

%IWC1.8.0 OTB1 _IN_00_07 6000 Digital Input 0 to 7

%IWC1.8.1 OTB1 _IN_08_11 6000 Digital Input 8 to 11

Address Name Index Designation

Data direction PLC -> OTB

%QWC1.8.0 OTB1_OUT_00_07 6200 Write Outputs 0 to 7

Datalink Twido PLC (CANopen master, #127) OTB2 (CA Nopen slave #10) OTB2 <> PLC Data direction OTB -> PLC Address Name Index Designation

%IWC1.9.0 OTB2 _IN_00_07 6000 Digital Input 0 to 7

%IWC1.9.1 OTB2 _IN_08_11 6000 Digital Input 8 to 11

Address Name Index Designation

Data direction PLC -> OTB

%QWC1.9.0 OTB2_OUT_00_07 6200 Write Outputs 0 to 7

Datalink Twido PLC (CANopen master, #127) OTB3 (CA Nopen slave #11) OTB3 <> PLC Data direction OTB -> PLC Address Name Index Designation

%IWC1.10.0 OTB3 _IN_00_07 6000 Digital Input 0 to 7

%IWC1.10.1 OTB3 _IN_08_11 6000 Digital Input 8 to 11

Address Name Index Designation

Data direction PLC -> OTB

%QWC1.10.0 OTB3_OUT_00_07 6200 Write Outputs 0 t o 7

Datalink Twido PLC (CANopen master, #127) OTB4 (CA Nopen slave #12) OTB4 <> PLC Data direction OTB -> PLC Address Name Index Designation

%IWC1.11.0 OTB4 _IN_00_07 6000 Digital Input 0 to 7

%IWC1.11.1 OTB4 _IN_08_11 6000 Digital Input 8 to 11

Address Name Index Designation

Data direction PLC -> OTB

%QWC1.11.0 OTB4_OUT_00_07 6200 Write Outputs 0 to 7

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

34

Datalink Twido PLC (Modbus #2) HMI Magelis XBT-G (Modbus #1) HMI -> PLC Data direction HMI -> PLC Address Name Address Designation

%M101 M_AUTO %M102 Automatic mode

%M106 HMI_resetcanopen %M106 Reset CANopen Master

%M107 HMI_resetaltivar %M107 Reset Altivar31

%M121 M_HAND %M122 Manual mode

%M131 M_HMI %M131 HMI mode

%M200 Mhmi_D1_FWD %M200 Drive 1 Forward HMI

%M201 Mhmi_D1_REV %M201 Drive 1 Reverse HMI

%M202 Mhmi_D1_STOP %M202 Drive 1 Stop HMI

%M205 Mhmi_D2_FWD %M205 Drive 2 Forward HMI

%M206 Mhmi_D2_RE V %M206 Drive 2 Reverse HMI

%M207 Mhmi_D2_STOP %M207 Drive 2 Stop HMI

%M210 Mhmi_D3_FWD %M210 Drive 3 Forward HMI

%M211 Mhmi_D3_RE V %M211 Drive 3 Reverse HMI

%M212 Mhmi_D3_STOP %M212 Drive 3 Stop HMI

%M215 Mhmi_D4_FWD %M215 Drive 4 Forward HMI

%M216 Mhmi_D4_RE V %M216 Drive 4 Reverse HMI

%M217 Mhmi_D4_STOP %M217 Drive 4 Stop HMI

%M220 Mhmi_D5_FWD %M220 Drive 5 Forward HMI

%M221 Mhmi_D5_RE V %M221 Drive 5 Reverse HMI

%M222 Mhmi_D5_STOP %M222 Drive 5 Stop HMI

%M225 Mhmi_D6_FWD %M225 Drive 6 Forward HMI

%M226 Mhmi_D6_RE V %M226 Drive 6 Reverse HMI

%M227 Mhmi_D6_STOP %M227 Drive 6 Stop HMI

%MW15 Manu_Velo_1 %MW15 Drive 1 Target Value

%MW16 Manu_Velo_2 %MW16 Drive 2 Target Value

%MW17 Manu_Velo_3 %MW17 Drive 3 Target Value

%MW18 Manu_Velo_4 %MW18 Drive 4 Target Value

%MW230 CAN_Failure_Slaves %MW17 Failure bit for every Slave

%MW232 CAN_Failure_BUS %MW18 Failure bit for the BUS

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

35

Datalink Twido PLC (Modbus #2) HMI Magelis XBT-G (Modbus #1) PLC -> HMI Data direction PLC -> HMI Address Name Address Designation

%M101 M_auto %M101 Automatic Mode

%M102 HMI_estop1 %M102 E-off 1 pressed

%M103 HMI_lightcurrtain %M103 Light curtain active

%M104 HMI_door %M104 Door Protection Triggered

%M105 HMI_estop2 %M105 E-off 2 pressed

%M140 M_no_error_drive1 %M140 Drive1 o.k.

%M141 M_no_error_drive2 %M141 Drive2 o.k.

%M142 M_no_error_drive3 %M140 Drive3 o.k.

%M143 M_no_error_drive4 %M140 Drive4 o.k.

%M144 M_no_error_drive5 %M140 Drive5 o.k.

%M145 M_no_error_drive6 %M140 Drive6 o.k.

%MW15 Manu_Velo_1 %MW15 Drive 1 Target Value

%MW16 Manu_Velo_2 %MW16 Drive 2 Target Value

%MW17 Manu_Velo_3 %MW17 Drive 3 Target Value

%MW18 Manu_Velo_4 %MW18 Drive 4 Target Value

%MW204 B1Actual %MW204 Drive 1 Actual Value

%MW205 B2Actual %MW205 Drive 2 Actual Value

%MW206 B3Actual %MW206 Drive 3 Actual Value

%MW207 B4Actual %MW207 Drive 4 Actual Value

%MW230 CAN_Failure_Slaves %MW230 Failure bit for every Slave

%MW232 CAN_Failure_BUS %MW232 Failure bit for the BUS

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

36

General Addressing

Various hardware addresses, as well as flags and flag words, are used in the PLC

example program. To facilitate orientation, an overview of the addresses used appears

below in list format.

Type Address Comment

Digital inputs %Ir.m.x Digital inputs are specified on a hardware basis:

r indicates the rack numb er, m the slot and x the

input number.

Example: Emergency-off feedback %I0.3.0.

Digital outputs %Qr.m.x Digital outputs are specified on a hardware basis:

r indicates the rack numb er, m the slot and x the

output number.

Example: Indicator lamp for manual mode

%Q0.5.1.

Analog inputs %IWr.m.c Analog inputs are specified on a hardware basis:

r indicates the rack numb er, m the slot and c the

channel number.

Example: Emergency-off feedback %IW0.3.0.

Analog outputs %QWr.m.c Analog outputs are specified on a hardware basis:

r indicates the rack number, m the slot and c the

channel number.

Example: Emergency-off feedback %QW0.3.0.

CANopen inputs %MW0 to

%MW31

CANopen outputs %MW100

to

%MW131

Data for Viewer %MW200

to

%MW299

Data from Viewer %MW300

to

%MW399

CANopen status %CHr.m.c Status data for CANopen is read via data

CANopen inputs are written to flag words;

individ ual bits can be addressed via %MWi.x.

Example: 2. ATV status word %MW2

CANopen outputs are read by flag words;

individ ual bits can be addressed via %MWi.x.

Example: 3. ATV control word %MW104

Data for Viewer is written to flag words. Individual

bits are written v ia block BIT_TO_WORD.

Example: Motor velocity %MW220

Data from Viewer is read by flag words. Individual

bits are extracted via block WORD_TO_BIT.

Example: Motor velocity %MW220

structure T_COM_CPP110 (IODDT). Channel

address: r indicates the rack number, m the slot

and c the channel number.

Example: CANopen status %CH0.1.1

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

37

HMI

Introduction

Preconditions

This application features a Magelis XBT-GT1100 HMI device, which is connected to the

PLC via Modbus protocol.

Vijeo Designer software is used to program and configure the terminal. The following

pages describe how to create and upload a program.

Proceed as follows to integrate the HMI:

Create a New Project

Install the Correct Driver

Configure the Programming Connection

Configure the driver

Linking Variables

Create a Variable

Import Project

Creating Screens – examples

Build the Project

Download the Project

In order to work with Vijeo Designer you must first:

Install Vijeo-Designer V4.4 on your PC.

chaeck that the Magelis terminal is connected to a power supply and turned on

Connect the Magelis terminal to the PC using the data cable XBTZG925 (USB).

Vijeo Designer

Layout

1 The Vijeo Designer

environment consists of

the following elements:

1 - Navigator

2 - Info display

3 - Inspector

4 - Data list

5 - Feedback zone

6 - Toolbox

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

38

Create a new

Project

1 Start up Vijeo Designer and

select

Create new Project.

You will be automatically

guided through the

subsequent steps.

continue with Next>.

2 Now enter the project name

for the application, e.g.,

“DCO Example”.

A more detailed description

can be added in the

Description or Comment

box.

No accented characters or

umlauts (ö, ü, ä, etc.) are

permitted.

Continue with Next>.

3 Select the target device to

be used. Your target name

can be any name you wish.

Target Name:

Exampleproject

Target Type:

XBT–GT1000

Series

XBTG Model:

XBT-GT1100

Continue with Next>

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

39

4 The selected device has no

Ethernet port, so you can go

to the next screen using

Next>.

5 In order to be able to

exchange data with the PLC,

the Magelis terminal requires

a communication driver.

In the Create New Project

dialog, select:

Add

to go to the New Driver

dialog.

Install the

correct driver

In the New Driver dialog

6

select:

Schneider Electric

Industries SAS

in the manufacturer‘s list.

Now transfer the Modbus

(RTU) driver to the

Equipment list as Modbus

Equipment for

communication with the

Twido PLC.

Confirm the settings with

OK.

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

40

7 Once you have added the

driver, exit the driver

configuration process with

Finish.

Vijeo Designer now returns

8

you to its work top, with an

empty display and the

project navigator

A single mouseclick on

Target1 in the navigator

lists the properties of target1

in properties inspector

(or if the properties

inspector is closed, a right

mouseclick on Target1 and

selecting Properties in the

pop-up menu, opens up the

properties inspector)

Configure the

Programming

Connection

First check the setup for the

1

USB programming cable

XBTZG925.

Check the properties of the

project and in particular the

properties of the COM port.

As default it is set to serial

and COM1.

As we are using a USB

cable the connection must

be changed.

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

41

2 First check in the Windows

Device Manager which

COM port is used for the

USB connection.

Here COM4 is used.

3

Configure the

driver

In Vijeo Designer select the

COM to match the Windows

setup, in this case COM4,

and input it as the COM

port.

Leave the connection type

as it is, Serial.

For the communications to

1

work you must set up the

parameters in the Modbus

RTU-Driver.

For this, right mouseclick on

ModbusRTU01 in the

Navigator

and select

Configuration...

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

42

In the Driver Configuration

2

dialog,

input:

- 19200 Baud

- 8 Data bits

- 1 Stop bit

- No Parity

Note: The configuration

must match the port

definition on the Twido.

Exit the dialog with OK.

In the Navigator you can

3

rename the configuration to

PLC with a right mouseclick

on the name and selecting

Rename.

Rightmouse click on PLC to

4

go to the device configuration.

In this configuration the HMI

is slave, the PLC is master.

In the Equipment

5

Configuration dialog set the

Slave Equipment Address to

2. and set the checkbox for

IEC61131 Syntax

you can leave the other

inputs at their default values.

Exit with OK.

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

43

Linking

Variables

Acknowledge the confirm-

6

ation for the IEC61131

Syntax with YES.

As the variables have already

1

been input in TwidoSuite (or

some other Schneider

product) . Vijeo-Designer

offers an option to link up to

these variables.

Select the Variables tab in

the the Navigator.

Right mouse click on the

project name (here

TARGET1) and select

Link Variables…

in the pop-up menu

In the Link Variables window

2

give the path to the file, the

type of file and the

Equipment type (here as

named above PLC)

Select the file and click on

Open.

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

44

In this example the path was

3

set to the TwidoSoft directory,

the file type set to TwidoSoft

and the Equipment set to

PLC.

Then a Twido file (*.twd) was

selected and opened.

Once the file was successfully

4

opened you will be offered a

selection list of the available

variables

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

45

Mark the variables you wish to

5

link to and click on Add.

Linked variables are now de-

6

activated with grey text.

If you have finished linking the

variables you require, exit the

dialog with a click on Close.

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

46

All variables can now be

7

viewed in the navigator on

the Variables tab.

Creating a

variable

To create variables, click on

1

the Tab Variable in t he

navigator.

A right mouse click on

Target1 opens up the pop-up

menu

Click on :

New Variable -> New…

followed by the datatype

required to go to variable

definition dialog.

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

47

To create a variable you must

2

input a:

Variable name

Data type

Data Source (External)

Address in the PLC

In the variable properties

dialog you can enter the

name and a description for

the variable

Important here is what device

delivers the value if it comes

from an external system.

If this is the case you must

enter a ScanGroup and a

Device Address.

The device address is not the

hardware address. It is the

memory address in the device

that delivers the value.

To select a device address

click on the button at the right

end of the list box.

Device Address:

Here you can address bits

(%M..), memory words

(%MW..) in the PLC.

clicking on the Device

3

Address opens up a dialog

for the input of the address.

PLC internal formats such as

counters muss first be

transferred to memory words

before the Magelis can

display them.

Integers and Reals :

30001 + i and

40001 + I

Discretes:

00001 + i and

10001 + i and

30001 + i, j and

40001 + i, j

where „i“ represents the bit

number or word num ber i.e.

you address them with the

appropriate offset.

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

48

4

Examples:

PLC %M106

HMI 00001 + 106

=> 00107

PLC %MW207

HMI 40001 + 207

=> 40208

PLC %MW100 Bit5

HMI 40001 + 100, 5

40101,05

The image shows the variable

Test with its attributes listed

in the Property Inspector.

Import

Project

1

To import a project select the

Vijeo-Manager tab in the

Navigator. Right mouse click

on Vijeo-Manager in the tab

window opens a pop-up

menu.

select Import Project..

If the function is de-activated

(greyed) close any open

projects first and re-try.

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

49

2

3

4 In the Navigator you can now

Enter the path to search in,

the file type (*.VDZ) and select

a project file from the list

offered.

Import the project by clicking

on Open.

When the import is finished,

acknowledge with OK.

see the project listed. Double

click on it to open it.

Creating

Screens

Examples

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

Example: Insert Text

1

Select the text tool in the tool

bar.

The toolbar displays the

toolbox with tools for editing

the display.

50

Example: Create Text

2

With the text tool, position t he

text box on the display. You

can adjust its size by „pulling“

on the box or by givin g a

value in the text editor dialog.

Double click on the text box to

open up the text editor dialog

you can input the text to be

displayed and define its size,

font, etc.

After inputting the text you can

3

define/change the text

characteristics in the Property

Inspector

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

51

A right mouse click on the text

4

object in the display leads to

the animation.

This is the same animation as

seen in the property inspector

(see image above) but in

another format. Both formats

contain the same attributes.

Animation Properties:

5

Colour

Position

Value

Visibility

For the variable used to

animate this object, you can

either manually input the

variable or click on the

lightbulb icon to browse the

variable list and select a

variable.

If you input an unknown

variable it is shown in red –

the variable has yet to be

defined

Once activated variables can

be selected and their display

format defined.

If the value requires further

processing before use, such

as trigonomic functions, you

can select these via the

calculator icon.

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

52

Text and Graphics examples.

6

This picture shows one the

7

finished configuration screens

with some animations and

buttons

Build the

project

Before you download the

1

project to the Magelis you

must validate it .

With Validate All you can

analyse your project.

The Feedback Zone shows

you the results of the analysis.

You can invoke the project

analysis using Build All too.

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

53

Download

the Project

Before you can download the

1

project you must build the

project (see the section

above)

Downloading the project to the

Magelis (HMI):

Select the project in the

Navigator.

Use Build->Download All to

transfer the project to the HMI

device.

The transfer is done using the

configured protocol (modbus

in this case).

The download process is

indicated with a progress bar.

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

54

Introduction

Pre-conditions

Start ing

Twidosuite

PLC

The PLC chapter describes how to initialize, parameterize and load the program to the

PLC in order to implement the functional description described above.

The PLC program is created using TwidoSuite.

Before carrying out the steps described below, you must ensure the following:

The TwidoSuite programming tool is installed on your PC

The TwidoSuite example project is available

The Twido PLC is switched on and supplied with power

The PLC is connected to the PC with programming cable (TSXPCX1031)

1

To start work with

Twidosuite, click on:

Programming Mode

Use the language

selection buttons to set

the language for this

session.

2

The start up screen for

the main menu is

displayed.

With

Create a new project

you can start a new

project.

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

55

Create a new

Project

1 Once Create a new

Project is selected, enter

a Project name and

select the Directory path

to save it.

You can enter Project

Information if required

but it is not mandatory.

Confirm with Create.

Select the

1 Now go to Describe to

Hardware

2

configure the hardware.

In the configuration

Workspace you will see

a Twido PLC.

In the Catalog on the

RHS you can select the

hardware/modules you

wish to configure

The Workspace offers

you graphical documentation.

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

56

3 In the Catalog, first

select the correct type of

Twido

TWDLMDA20DRT.

4

Use Drag&Drop to drag

the selection to the

graphical image of the

Twido.

The grahical image will

change to green.

Drop the selected Twido

while the mouse icon is in

the green field.

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

57

5

6

As next module select the

CANopen Master

TWDNCO1M.

Use Drag&Drop to place

it to the right of the Twido

PLC in the graphical

image.

Now add the extra digital

inputs module

TWDDDI18DT

Again, using drag&drop

place it next to the

CANopen Master.

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

58

7 Now add the Magelis

Terminal

XBTGT1100

For this add the general

Magelis Modbus element

to the configuration.

8

9

The Workspace now

shows a graphic display

of the configured

modules/devices.

The connection HMI/PLC,

via the Modbus interface,

has still to be done.

To confgure the HMI

connection, move the

mouse icon over the HMI

until the mouse icon

changes to a

screwdriver. Now a

doubleclick opens up the

configuration dialog.

Give the device a Name

and check that the defaul t

Protocol Modbus at

Address 1 is offered.

Confirm with OK.

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

59

10

11

12

Name and Modbus

address now appear in

the graphic display next

to the HMI device.

Now do the same for the

PLC modbus interface.

Position the mouse icon

on the modbus interface

of the PLC. When the

mouse icon changes to a

screwdriver, doubleclick

to open up the configuration dialog.

Change the Protocol type

to Modbus and set the

Address to 2.

Confirm with OK.

Now connect the two

devices in the graphics

display by linking the

white crosses that

reperesent t he linking

points.

To do this click on the

white cross of one device

and then the next so that

the link is displayed.

13

After linking the devices

you can give the network

a name and set the baud

rate by double clicking on

the connecting line or the

network box.

In this case we use the

default values.

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

60

Hardware

Configuration

1

For the hardware

configuration select the

main menu Program.

2

Twido SPS

1

The screen shows the

PLC rack.

Note the menus on the

RHS and bottom of the

display area.

Menus on the RHS are

sub-menus to the main

menu along the top.

You can now configure

all the I/O variables for

the PLC.

To name the variables

click on the Symbol

column for a particular

I/O and input the new

name.

2

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

Spaces and special

characters are not

allowed in symbol

names.

If the variable is already

in use in the program,

the check box to the

LHS is activated.

61

3

4

5

All symbol names are

shown in uppercase.

Changes are only made

when the Apply button

is pressed.

If you try to exit the

dialog without pressing

Apply, you will be

reminded.

Symbols entered in the

configuration are

automatically inserted

into the variable list.

1

CANopen Master

The next step is to

configure the CANopen

Master.

Click on the CANopen

module in the graphics

image.

2 Click on Configure in the

module configuration.

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

62

3 The CANopen

Configuration Tool

appears.

4 If there is no entry in the

catalogue for Advantys

FTB or Advantys OTB,

the SPA files have not

been imported. The files

are installed with

Twidosuite.

To import the files, click

on the import/export

function (arrow icon,top

left) to go to the standard

Windows Open dialog

In the open dialog set the

5

path to the required SPA

(Schneider Product

Archive) files:

File type : *.SPA

Path: Twidosuite

6 Once the SPA files are

imported they appear in

the list under DS-401 .

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

63

7

8

9

Use the import function to

import the EDS Files

(Electronic Data She et)

for the components.

Here :

FTB_CN08E08SPO.eds

(See the example project)

The import displays a

progress bar.

do the same for

OTB_1CODM9LP.eds.

10

After a successful import

the components are listed

as DS-401 I/O Modules.

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

64

11

12

13

The configuration files for

the Alti var 31 drives are

already installed.

For our example the first

four slaves are used by

the Alti vars. To insert an

Altivar as slave, double

click on the Altivar entry

in the catalogue.

Use the arrow icons to

move the entries up/down

in the list.

Slaves 5-8 are the FTB

modules.

.

14

15

Ther OTB Modules are

Slaves 9-12.

Set the baudrate for the

CANopen bus to:

500Kbit/s

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

65

16 Double click on the

Supervision column for

each slave and set the

supervsion type to

heartbeat

(the default is normally

set to None)

17 In the Mapping tab you

can edit the Transmit

and Receive PDOs.

18 Note:

You do not need to

change the PDOs. If you

do however, bear in mind

that the SDO memory

requirement changes.

The maximum SDO

memory is fixed in the

PLC and cannot be

exceeded.

19 Use the tab Linking to

select the PDOs that are

to be transferred.

You must do this for both

the transmit and receive

direction.

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

66

20 Under receive AND

transmit, doubleclick on

the PDO to move it from

the slave to the master

PDO.

Note : all PDOs that are

used must be moved.

Normally you would move

all PDOs. Those not

moved are redundant

21 Us the Symbol tab give

your I/O variables names.

The Altivar 31 variables

have standard names but

can still be changed.

22

23

Variables without names

do not appear in the

variable list. For ease of

programming it is

preferable to give the

variables names.

To save the configuration

click on Apply then exit

the dialog with OK.

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

67

27

Digital

1

Input-Modul

TwidoSuite now displays

a table with all the

configured CANopen

slaves.

Click on the the digital

input module in the

graphic.

The list of Inputs appears

for the module.

Symbol names can be

input and applied.

The variables are

automatically inserted

into the variable list

Drive Macros

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

1

To use the TwidoSuite

macros for the Altivar

31,

they must first be

configured.

To do this select:

Program->

Configure->

Configure the Data->

Advanced object->

Macros drive

68

2

3

4

5

For legibility, the

macros are given the

same number as the

slave addresses, i.e. 1

– 4.

Select a macro to

configure it by activating

the check box.

Set:

Network: CANopen

Network Address : 1

Reserve the memory

words for the function in

the entry D_Manager.

In the example 30

words are reserved for

macro drive 1, from

MW30 to MW59, by

giving the start address

and the number of

words required

Setting the check box in

the Symbols column

allows the variables to

be included in the

variable list.

6

Click Apply to

implement the drive

configuration.

In the example drives 14 are set up with

MW30, MW60, MW90

and MW120

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

69

7

8

Change now to the

main menu Describe

and you will receive a

request to resize the

workspace.

Acknowledge the

message with OK.

TwidoSuite has

increased the

workspace and the

configured drives and

CANopen bus are now

shown in the graphics.

Resizing

1

Workspace

2

You can re-position

objects in the graphi c to

save space and for

better legibility.

Note: if you now print

the image for

documentation

purposes empty fields

are prin ted too.

To delete the empty

fields, change the

workspace format from

3x3 to 1x2.

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

70

Variable List

3 The re-sized

workspace.

1

In the variable list you

can add symbols, give

them a memory

address and input a

comment about them.

3

Create an

2

1 Use the Edit Program

application

Program

To add a symbol click

on the insert icon.

First enter the symbol

name.

Now you can add the

address and a

comment.

Use the different

column headers as sort

criteria to sort the table

in alphabetical order.

function to go to the

program editor.

Starting a new program

always begins with

LADDER as the

programming language.

You can only view the

program in LIST mode

once the first rung has

been completed and

analysed.

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

71

2

3

4

5

6

Starting with an empty

program, add a

section. This will create

a section with empty

rungs. The first rung is

marked in red on the

LHS to denote that it

has logical errors.

Click on the top of a

rung to rename it.

You can also rename

the section

Clicking on the rung

changes its colour to

green and indicates the

current rung being

edited. Clicking on an

icon in the toolbar

inserts the selected

object at the first

available place on the

rung.

So, you can add

contacts…

….and outputs, etc.

7

To make a logical

connection, simply mark

the source and pull it to

the destination. All

possible connecting

points are shown in

green

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

72

8

9

10

11 The Analysis is done for

Once a link has been

inserted you can add a

contact to form the

logical OR.

To assign an object to

an address or variable,

click on the upper half

of the object

The editor automatically

recognises whether a

rung is syntactically

complete and marks it

in yellow.

The rung, however,has

not yet been analysed.

The analyze program

button is in the bottom

right hand corner.

all contacts.

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

73

12

13

If the ana lysis is error

free, the yellow band

changes to green.

You can now change

the display mode to

LIST if you wish.

If erros are found, these

are listed at the bottom

of the edit field.

Click on the arrow icon

to enlarge the dis play.

14

15

A common error is

No Start In Run Was

Selected

To fix this, select:

Program->

Configure->

Configure the

behavior

In the Configure the

Behavior dialog select:

Automatic start in Run

This is an operation

mode that causes the

PLC to start up

automatically on return

of power after a power

failure.

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

74

16

After restarting the

analysis the error field

is empty.

Macro Drive

1

To use the macros for

the drives, a second

rung is added using the

add a rung icon.

2 Insert an operation

block for the macro.

3

4

To link the operation

block to the macro drive

input D_manager 1.

D_manager is the

macro function to

access the drive and

the 1 indicates Drive 1.

The space between

D_manager and the 1

is mandatory.

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

75

5

Save / export

1

the project

As the macro is already

configured, the address

field also contains the

symbolic macro name

D_MANAGER 1.

The SHORT seen here

must be exchanged for

a control variable.

You can now repeat this

for the other macros:

D_CLEAR_ERR

D_RUN_FWD

D_RUN_REV

D_STOP und

D_SELECT_SPEED .

To save the project

select Save current

project in the Project

menu.

In the Save current

project window you can

select the folder for the

save, input the file

name and designate the

file Format.

You can save the file as

a normal Project file or

as an Archive file. The

Archive file has the

advantage of being

portable and is a single

file.

Twido_Altivar_Magelis_OTB_FTB_EN.doc Schneider Electric

76

Open a Project

1

To open a project use

the Open an existing

project function in the

Project menu.

In the open an existing

project window select

the medium :

disk or Controller

Give the file type under

Format (for a project

file: Project), select the